Novel technique for harmless treatment of medical refuse burning flyash

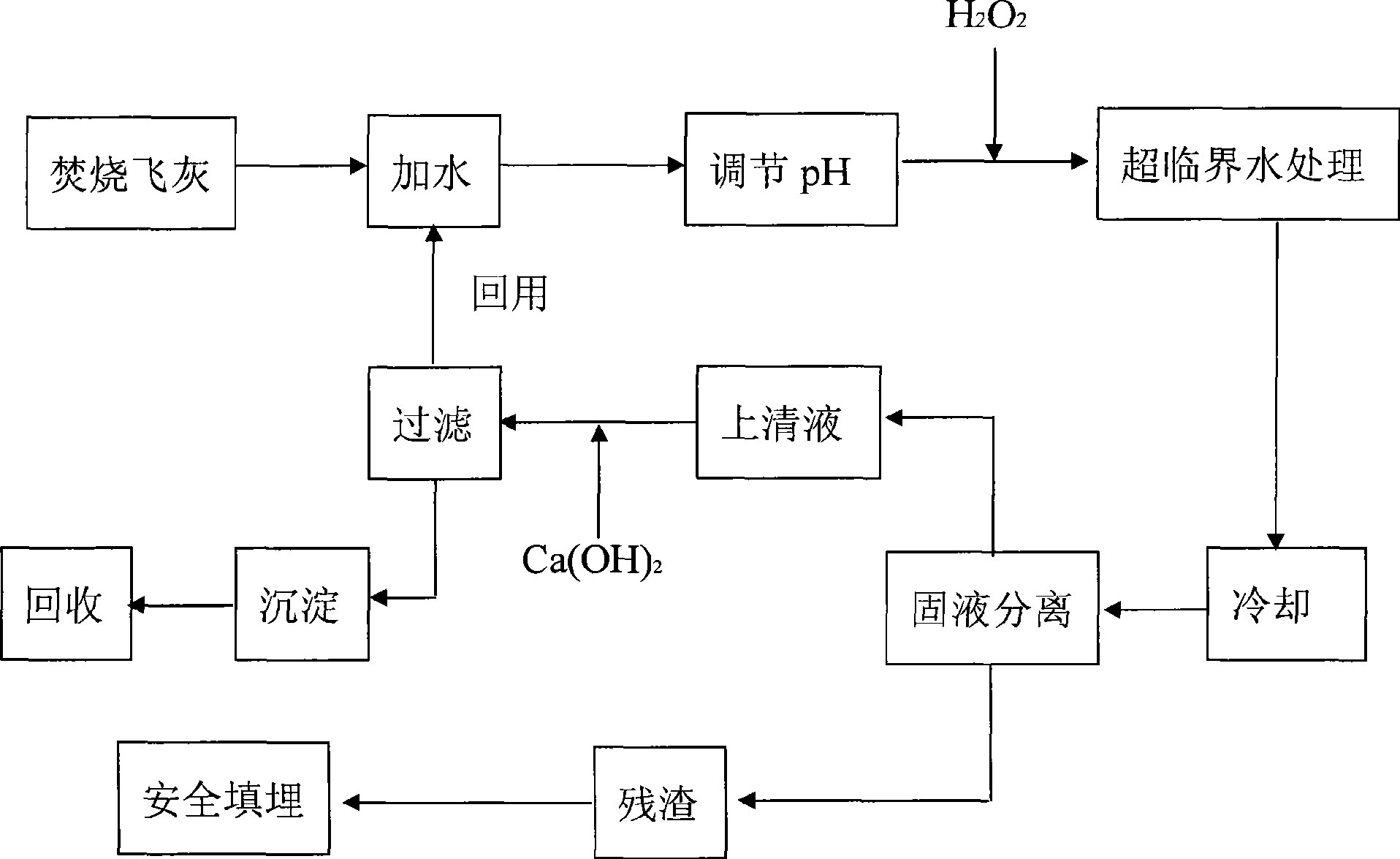

A technology of harmless treatment and incineration of fly ash, which is applied in the direction of waste treatment and solid waste removal, and can solve the problems of secondary pollution of the environment and the inability to completely harmless treatment of incineration fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] In this example, the fly ash produced by the rotary kiln is used for the incineration fly ash of medical waste. The pH of the fly ash is 3.22, and the heavy metal content is 81.5 mg / kg As, 1002 mg / kg Ba, 60.7 mg / kg Cd, and 234 mg / kg Cr , Cu 13g / kg, Pb 11.8g / kg, Zn 37.1g / kg, loss on ignition was 31%. Take 3g of fly ash and mix it with water at a solid-to-liquid ratio of 1:30, add 10ml of H 2 o 2 . Adjust the pH value of the mixed solution to 7.2, then transfer it into a high-pressure reaction kettle, seal it and heat it. When the temperature reaches 450°C and the pressure is stable between 30MPa and 40MPa, start timing, keep it for 1h, and then cool to room temperature. After solid-liquid separation, the reaction residue was measured. The quality of the residue is 35% of the original fly ash addition, and the loss on ignition of the residue is reduced to 0.4%. The heavy metal leaching concentration in the product is measured by the toxicity leaching test (GB5085.3-19...

Embodiment 2

[0010] In this example, the fly ash produced by the pyrolysis gasification furnace was used as the fly ash for medical waste incineration. kg, Cu 2.73g / kg, Pb 4.34g / kg, Zn 48.8g / kg, loss on ignition is 12%. The pH of the fly ash after adding water was 6.84, no need to adjust the pH value, and it was directly treated with supercritical water according to the same treatment method as in Example 1. The quality of the treated residue is 33% of the former fly ash addition, and the loss on ignition of the residue is reduced to 1.53%. The heavy metal leaching concentration in the product is measured by the toxicity leaching test (GB5085.3-1996), and the results show that the heavy metal ( As, Ba, Cd, Cr, Cu, Pb, Zn) leaching amounts are all below the standard value stipulated by the national standard. Treatment of aqueous solution for recycling is the same as case 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com