Furnace slag water-stable base material and preparation method thereof

A water-stabilized base material and slag technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as insignificant economic value, reduce pavement cracks and diseases, save mineral resources, and save stacking The effect of the venue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

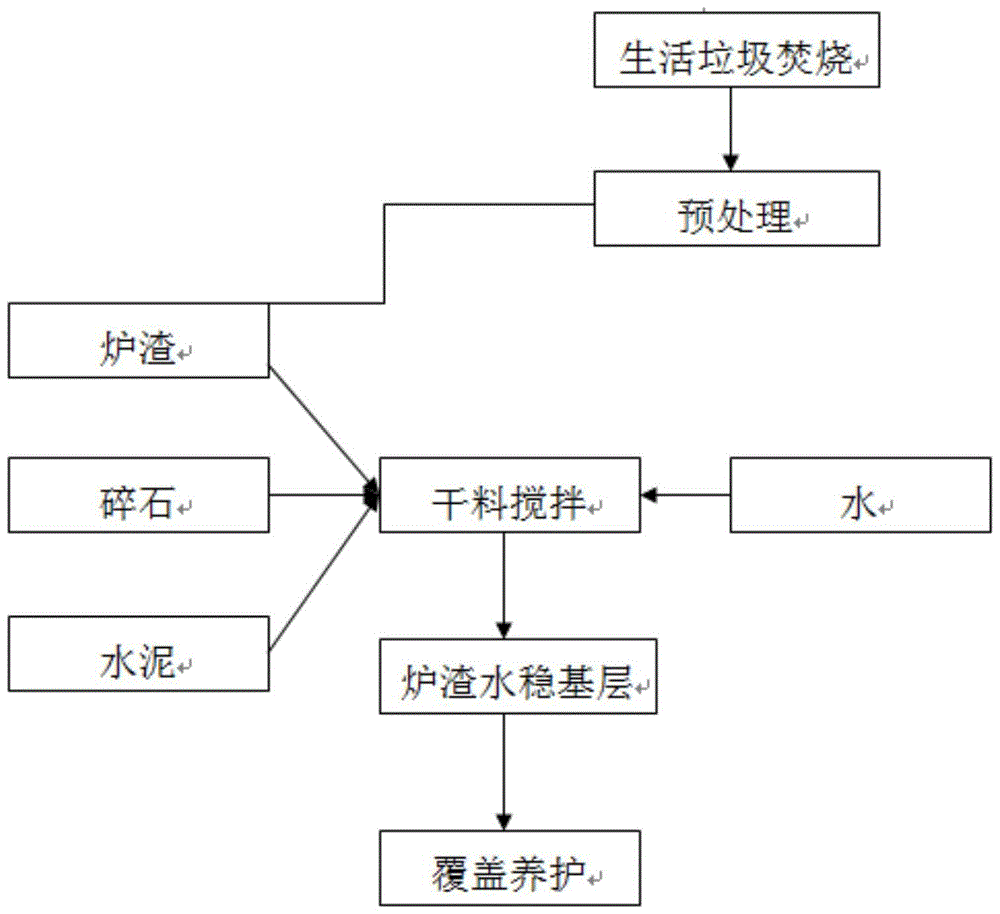

Method used

Image

Examples

Embodiment 1

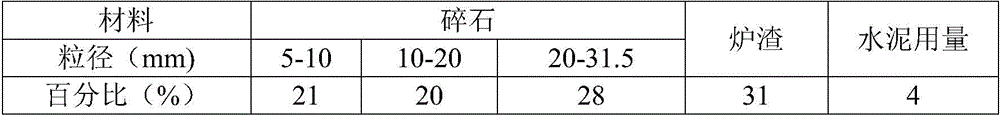

[0024] The slag is pretreated to remove metal substances. The slag is mechanically screened and the dissolved salt content is detected. The particle size of 0-5mm is used, and the particle size above 5mm is not used; the gradation composition of the slag aggregate after pretreatment is shown in Table 1. The gravel is divided into three particle sizes, namely 5-10mm, 10-20mm and 20-31.5mm. After mixing, the weight percentages of cement, slag and gravel are shown in Table 2.

[0025] Table 1 Gradation composition of slag aggregates after pretreatment

[0026] Sieve hole(mm)

19

9.5

4.75

2.36

0.6

0.075

Passing rate(%)

100

90.2

75.0

54.8

30.1

1.8

[0027] Table 2 weight percentage of each material

[0028]

[0029] The preparation method of slag water stabilized base material comprises the following steps:

[0030] 1) Put the pretreated slag, crushed stone, cement and water into the water stabilization soil ...

Embodiment 2

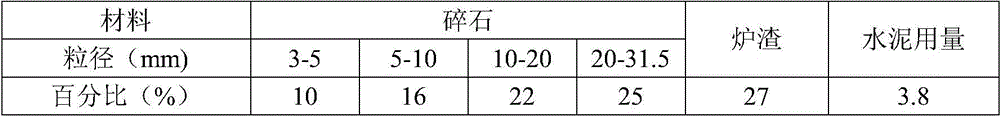

[0033] The slag is pretreated to remove metal substances, the slag is mechanically screened, and the dissolved salt content is detected. The particle size of 0-5mm is used, and the particle size above 5mm is not used; the gradation composition of the slag aggregate after pretreatment is shown in Table 3 The gravel is divided into four particle sizes, namely 3-5mm, 5-10mm, 10-20mm, and 20-31.5mm. After mixing, the weight percentage of each material is shown in Table 4.

[0034] Table 3 Gradation composition of slag aggregate after pretreatment

[0035] Sieve hole(mm)

19

9.5

4.75

2.36

0.6

0.075

Passing rate(%)

100

98.7

77.9

58.7

23.1

2.0

[0036] Table 4 weight percentage of each specification material

[0037]

[0038] The preparation method of slag water stabilized base material comprises the following steps:

[0039] 1) Put the pretreated slag, gravel, cement and water into the water stabilization soil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com