Stable solidification method of arsenic-containing waste residues

A solidification method and waste residue technology, which is applied in the field of hazardous solid waste treatment and disposal, can solve the problems of complex process operation and reduced toxicity of arsenic-containing waste slag leaching, and achieve the effects of simple process operation, shortened curing time, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

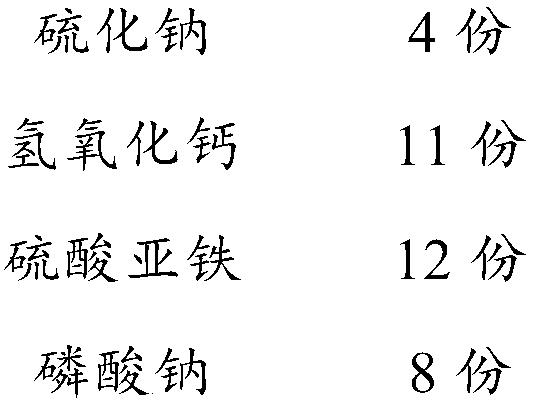

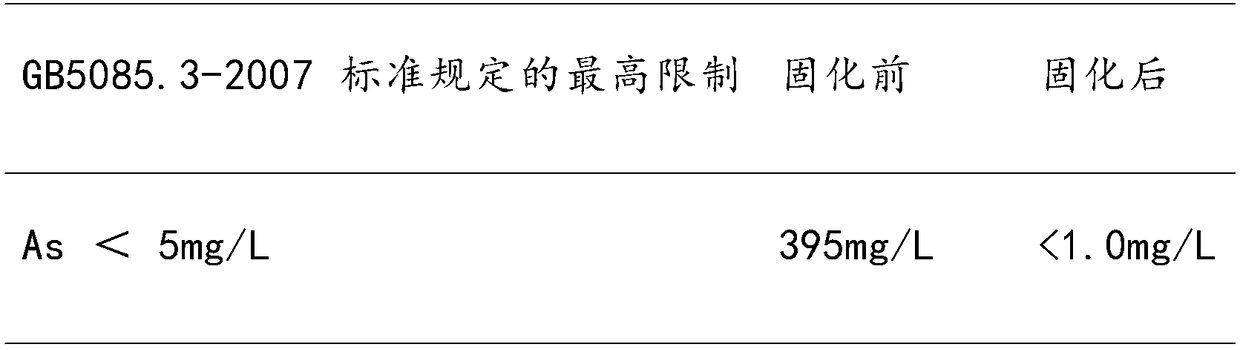

[0038] A soil stabilizer, each component in parts by weight, comprises:

[0039]

[0040] In this embodiment, a method for stabilizing arsenic-containing waste residues, combining arsenic-containing waste residues with a soil stabilizer, includes the following steps:

[0041] S1, configuring a soil curing agent, adding water to the components in the above parts by weight and stirring them evenly;

[0042] S2, adding the arsenic-containing waste residue into the mixer;

[0043] The arsenic-containing waste residue mainly contains arsenic sulfide, and also contains a small amount of other free arsenates. The arsenic-containing waste residue has a high water content and is in the form of sludge. It can be directly added to the mixer without crushing.

[0044] S3. Add the aqueous solution of each component configured in step S1 to the mixer in turn, and stir for 3-5 minutes;

[0045] The stirring process is carried out at normal temperature (15-25°C). During the stirring proc...

Embodiment 2

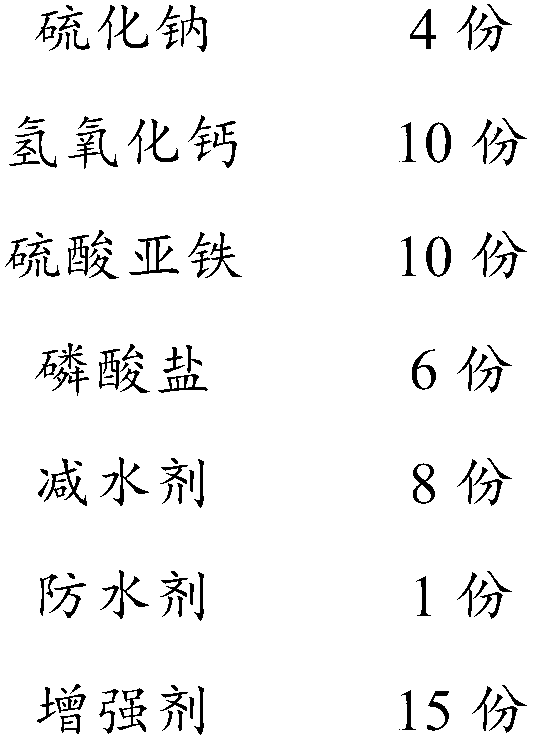

[0060] A soil stabilizer, each component in parts by weight, comprises:

[0061]

[0062] Among them, the phosphate is preferably sodium phosphate, the water reducer is preferably sulfamate and sodium lignosulfonate, the waterproofing agent is preferably sodium silicate, and the reinforcing agent is preferably sodium carboxymethyl cellulose and hydroxyethyl cellulose.

[0063] In this embodiment, a method for stabilizing arsenic-containing waste residues, combining arsenic-containing waste residues with a soil stabilizer, includes the following steps:

[0064] S1, configuring a soil curing agent, adding water to the components in the above parts by weight and stirring them evenly;

[0065] S2, adding the arsenic-containing waste residue into the mixer;

[0066] S3. Add the aqueous solution of each component configured in step S1 to the mixer in turn, and stir for 3-5 minutes;

[0067] S4. Add auxiliary binder, stir for 10-20 minutes, then add appropriate amount of water, ...

Embodiment 3

[0077] A soil stabilizer, each component in parts by weight, comprises:

[0078]

[0079] Among them, the phosphate is preferably sodium phosphate and potassium dihydrogen phosphate, the water reducing agent is preferably sodium lignosulfonate, calcium lignosulfonate and sodium naphthalenesulfonate condensate, the waterproofing agent is preferably sodium silicate, and the reinforcing agent is preferably Sodium carboxymethylcellulose and hydroxyethylcellulose.

[0080] In this embodiment, a method for stabilizing arsenic-containing waste residues, combining arsenic-containing waste residues with a soil stabilizer, includes the following steps:

[0081] S1, configuring a soil curing agent, adding water to the components in the above parts by weight and stirring them evenly;

[0082] S2, adding the arsenic-containing waste residue into the mixer;

[0083] S3. Add the aqueous solution of each component configured in step S1 to the mixer in turn, and stir for 5-10 minutes;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com