Synergic treatment method of heavy metals in hazardous waste incineration plant wastewater and fly ash

A hazardous waste and co-processing technology, applied in chemical instruments and methods, solid waste removal, water/sewage multi-stage treatment, etc. Significant energy-saving effect, reduced leaching toxicity, and reduced leachate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

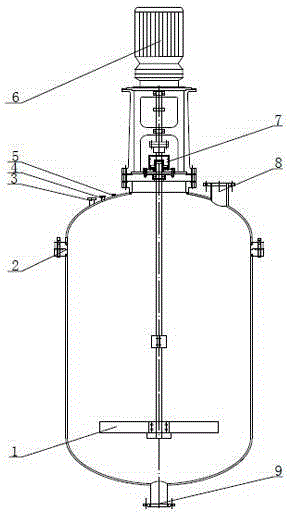

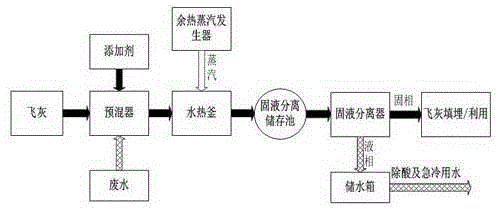

[0022] With reference to the accompanying drawings,

[0023] Step 1: Mix 20kg of fly ash from a hazardous waste incineration plant, 4kg of fly ash from a coal-fired power plant, and 200L of waste water from a hazardous waste incineration plant; add 0.8kg of NaOH to the mixture to adjust the pH value of the mixture, and test to ensure that the solution is alkaline (PH >12); check that the discharge port of the reactor is closed, and inject the mixed solution into a 500L hydrothermal reactor;

[0024] Step 2: Close the mixed liquid injection port of the hydrothermal reactor, turn on the automatic agitator (100r / min), connect the flue waste heat steam generator, slowly open the steam inlet valve, and use the waste heat steam to gradually increase the temperature and pressure inside the reactor; Observe the temperature and pressure gauges of the reactor to ensure safe operation;

[0025] Step 3: After the temperature reaches 250°C (about 4.0MPa), adjust the steam flow to keep the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com