Solidification/stabilization treatment method for papermaking sludge

A technology for stabilizing and treating papermaking sludge, which is applied in the field of environmental engineering, can solve problems such as potential safety hazards in landfills, increased loads on garbage dams, troublesome landfill operations, etc., to increase strength, reduce leaching rate, and reduce cement The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

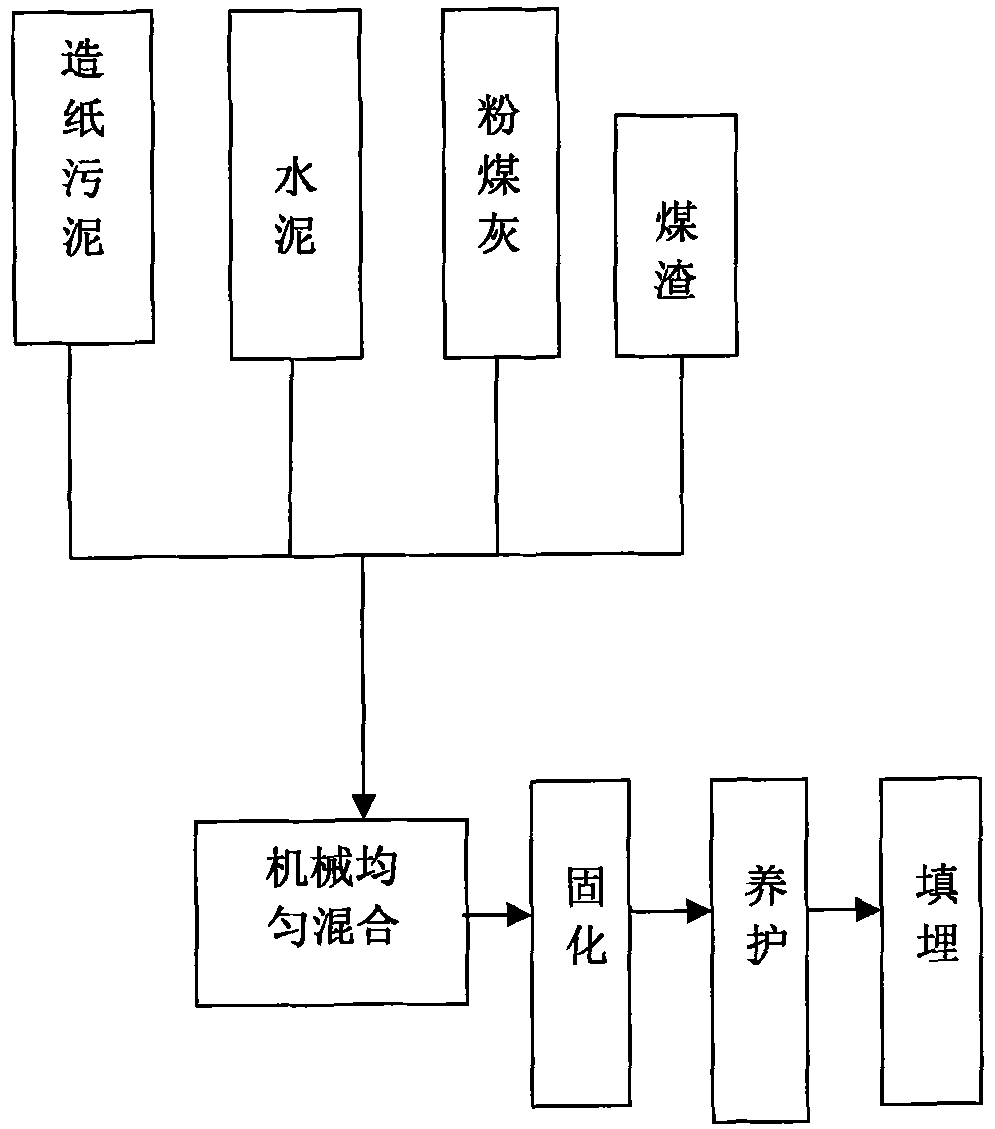

Method used

Image

Examples

Embodiment 1

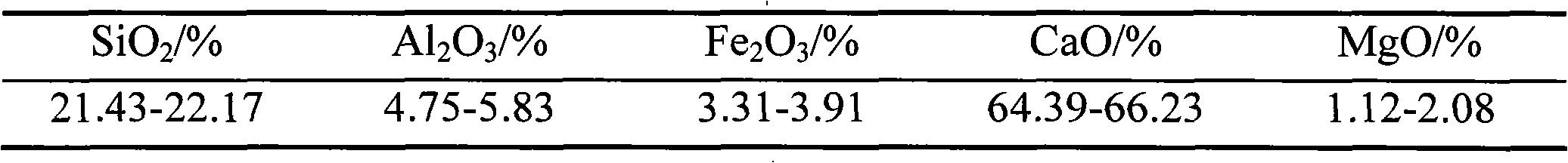

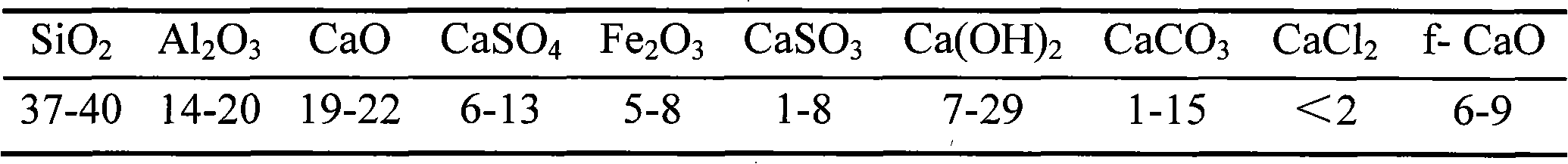

[0041] Add 70kg of Portland cement, 25kg of fly ash, and 45kg of coal cinder to 1 ton of papermaking sludge, stir it mechanically for 10 minutes, lay it flat in the landfill, and add a waterproof membrane for maintenance. Lay the stirred solidified sludge mixture to a thickness of 5cm, and place it in a cool place for 2 days of maintenance. The compressive strength of the sludge solidified quickly reaches 160kPa, and the moisture content is 38%. The mass concentration of heavy metals leached from the solidified block meets the national standard (GB 5085.3- 2007).

Embodiment 2

[0043] Add 80kg of Portland cement, 30kg of fly ash, and 50kg of cinder to 1 ton of papermaking sludge, mix them with mechanical stirring for 12 minutes, lay them flat in the landfill, and add a waterproof membrane for maintenance. Lay the stirred solidified sludge mixture to a thickness of 30cm, and place it in a cool place for 5 days of maintenance. The compressive strength of the sludge solidified quickly reaches 210kPa, and the water content is 37.5%. The mass concentration of heavy metals leached from the solidified block meets the national standard (GB 5085.3- 2007).

Embodiment 3

[0045]Add 90kg of Portland cement, 30kg of fly ash, and 80kg of cinder to 1 ton of papermaking sludge, stir it mechanically for 15 minutes, lay it flat in the landfill, and add a waterproof membrane for maintenance. Lay the stirred solidified sludge mixture to a thickness of 50 cm, and place it in a cool place for curing for 8 days. The compressive strength of the sludge solidified quickly reaches 240kPa, and the moisture content is 35.4%. The mass concentration of heavy metals leached from the solidified block meets the national standard (GB 5085.3- 2007).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com