Method for preparing ceramsite by using waste incineration fly ash and waste glass

A waste incineration fly ash and waste glass technology, applied in the direction of solid waste removal, application, household appliances, etc., can solve the problems of large land occupation, environmental pollution, toxic substances seepage, etc., achieve high added value, simple process, The effect of improving environmental stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

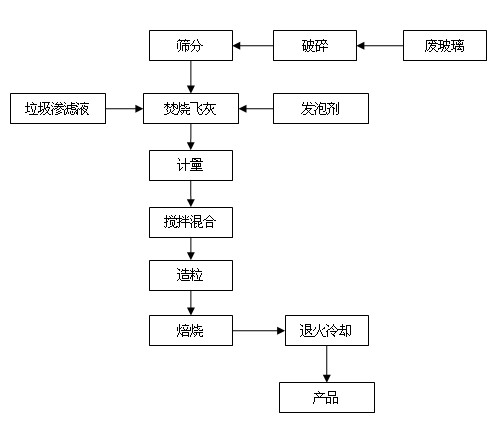

Method used

Image

Examples

Embodiment 1

[0032] A, crush and grind 90 parts of waste glass with a mass component number, pass through a 200-mesh sieve, add waste incineration fly ash with a mass component number of 60 while stirring at room temperature at a speed of 20-30 r / min, and add Foaming agent CaCO 3 0.5 parts, continuously stirred and mixed to form a uniform mixture of fly ash + glass powder.

[0033] B. Add 40 parts of domestic waste leachate to the powdery mixture obtained in step A at room temperature while stirring at a speed of 20-30 r / min, and continuously stir and mix to form a uniform mortar mixture.

[0034] C. Granulate the mortar mixture formed in B to make 0.5~1cm pellets. Then put the formed pellets into the muffle furnace for roasting. Control the temperature rise rate of the muffle furnace to 5°C / min, and the temperature rises to 130°C, so that the balls are fully dried and preheated before firing. Raise the temperature at 5°C / min to the calcination temperature of 900°C, and keep the temper...

Embodiment 2

[0039] A. Break and grind 40 parts of waste glass with a mass component number, pass through a 200-mesh sieve, and add waste incineration fly ash with a mass component number of 60 while stirring at room temperature at a speed of 20-30 r / min, and add foaming Agent Na 2 CO 3 5 parts, mixed with continuous stirring to form a uniform fly ash + glass powder mixture.

[0040] B. Add 40 parts of domestic waste leachate to the powdery mixture obtained in step A at room temperature while stirring at a speed of 20-30 r / min, and continuously stir and mix to form a uniform mortar mixture.

[0041] C. Granulate the mortar mixture formed in B to make 0.5~1cm pellets. Then put the formed pellets into the muffle furnace for roasting. Control the temperature rise rate of the muffle furnace to 5°C / min, and the temperature rises to 120°C, so that the balls are fully dried and preheated before roasting. Raise the temperature at 8°C / min to the calcination temperature of 1000°C, and keep the ...

Embodiment 3

[0046] A. Break and grind 80 parts of waste glass with a mass component number, pass through a 200-mesh sieve, and add waste incineration fly ash with a mass component number of 20 while stirring at room temperature at a speed of 20-30 r / min, and add foaming CaCO 3 0.5 parts, continuously stirred and mixed to form a uniform mixture of fly ash + glass powder.

[0047] B. Add 60 parts of domestic waste leachate to the powdery mixture obtained in step A at room temperature while stirring at a speed of 20-30 r / min, and continuously stir and mix to form a uniform mortar mixture.

[0048] C. Granulate the mortar mixture formed in B to make 0.5~1cm pellets. Then put the formed pellets into the muffle furnace for roasting. Control the temperature rise rate of the muffle furnace to 3°C / min, and the temperature rises to 125°C, so that the balls are fully dried and preheated before firing. Raise the temperature at 10°C / min to the calcination temperature of 1200°C, and keep it for 1h....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com