Water washing pretreatment method for making fly-ash from incineration harmless

A harmless technology for incineration of fly ash, applied in the field of environmental engineering, can solve problems such as clogging of cement kilns and hindrance of cement hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

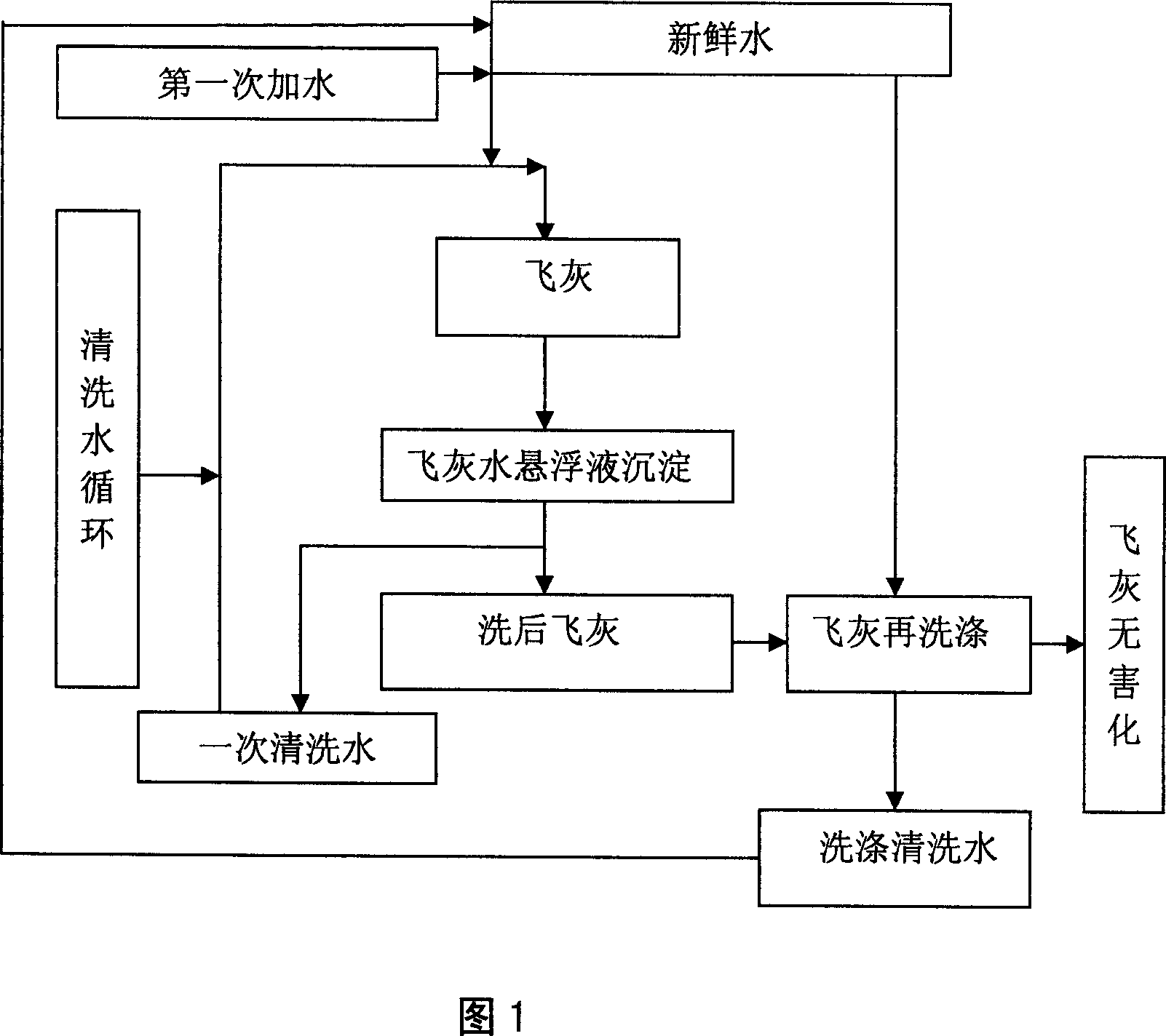

[0012] After the fly ash is washed twice with water at a solid-to-liquid ratio of 1:8 at room temperature, chloride ions in the fly ash are removed to reduce the mass percent concentration to below 1%, and part of the heavy metals are washed out. The water for the second wash is reused as the wash water for the next batch of fly ash, reducing the water demand for the washing process.

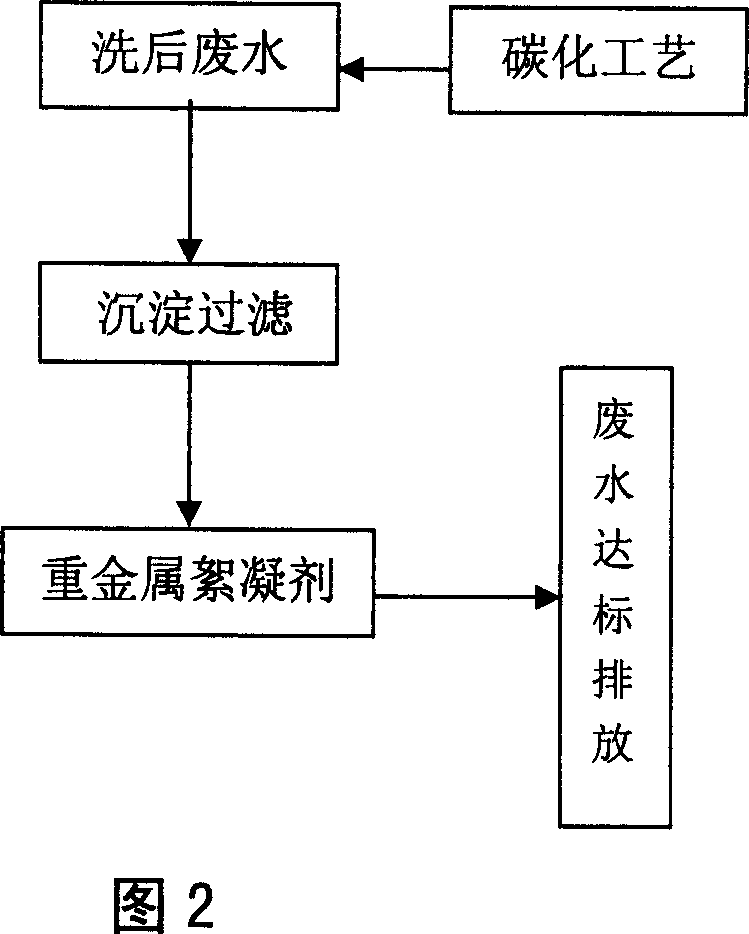

[0013] The washing wastewater generated in the washing process is fed into CO at normal temperature and pressure. 2 , settling for half an hour to reduce the concentration of heavy metals in wastewater, then add a small amount of mixed organic flocculant, stir at room temperature, after precipitation, the concentration of ss and heavy metals in wastewater can be reduced to below the national wastewater discharge standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com