Method of preparing ceramsite by utilizing municipal sewage plant sludge and waste glass

A technology for urban domestic sewage and waste glass, which is applied in the field of solid waste treatment and recycling, can solve the problems of inability to achieve large-scale treatment and disposal of sludge, failure to reach building materials, and low usage, so as to improve environmental stability and The effect of safety, high added value and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

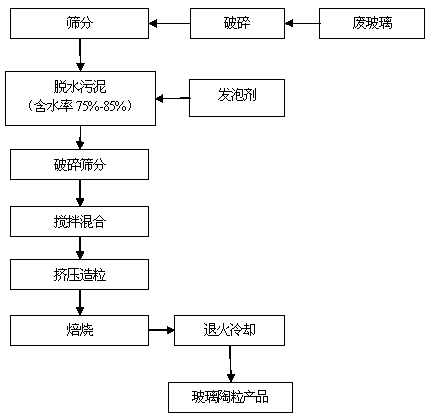

Method used

Image

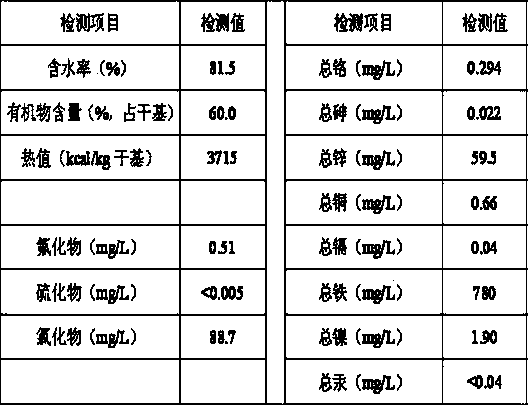

Examples

Embodiment 1

[0031] A. Crumble and grind the waste glass (container glass) powder with 80 parts by mass, pass through a 200-mesh sieve, add 100 parts by mass of sludge while stirring at a speed of 20 r / min at room temperature, and add Foaming agent limestone 5 parts, continuously stirred and mixed to form a uniform sludge + glass powder batch.

[0032] B. Put the batch material formed in A into the granulator to extrude and granulate to make 1cm particle size pellets and put them into the rotary kiln.

[0033] C. Control the roasting heating rate to 5°C / min, raise the temperature to 350°C, preheat at 350°C for 20 minutes, then raise the temperature to 1100°C at a heating rate of 5°C / min, and roast at this temperature for 30 minutes.

[0034] D. Use natural cooling to lower the furnace temperature to room temperature naturally to obtain glass ceramsite.

Embodiment 2

[0036] A. The waste glass (plate cullet) powder with a mass component number of 70 is crushed, ground, passed through a 200 mesh sieve, and 100 parts of sludge with a mass component number is added while stirring at a speed of 30 r / min at room temperature, and added 3 parts of foaming agent limestone, continuously stirred and mixed to form a uniform sludge + glass powder batch.

[0037] B. Extrude and granulate the batch formed in A to make pellets with a particle size of 0.5 cm, and put them into a rotary kiln.

[0038] C. Control the roasting heating rate to 3°C / min, raise the temperature to 355°C, preheat at 355°C for 23 minutes, then raise the temperature to 1000°C at a heating rate of 5°C / min, and roast at this temperature for 30 minutes.

[0039] D. Use natural cooling to lower the furnace temperature to room temperature naturally to obtain glass ceramsite.

Embodiment 3

[0041] A. The waste glass (flat cullet and container glass) powder with a mass component number of 100 is crushed, ground, passed through a 200 mesh sieve, and 100 parts of mass component sludge is added while stirring at a speed of 25 r / min at room temperature. And add 5 parts of foaming agent limestone, stir and mix continuously to form a uniform sludge + glass powder batch material.

[0042] B. Extrude and granulate the batch formed in A to make 1cm pellets and put them into the rotary kiln.

[0043] C. Control the roasting heating rate to 5°C / min, raise the temperature to 350°C, preheat at 350°C for 20 minutes, then raise the temperature to 1050°C at a heating rate of 5°C / min, and roast at 1050°C for 30 minutes.

[0044] D. Use natural cooling to lower the furnace temperature to room temperature naturally to obtain glass ceramsite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com