Blast electroslag furnace dedicated for treating electronic waste

A technology of electronic waste and electroslag furnace, which is applied in the field of incinerators, can solve problems such as the influence of recovery rate, incineration and separation are not thorough enough, and achieve the effect of high metal recovery rate and thorough incineration and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

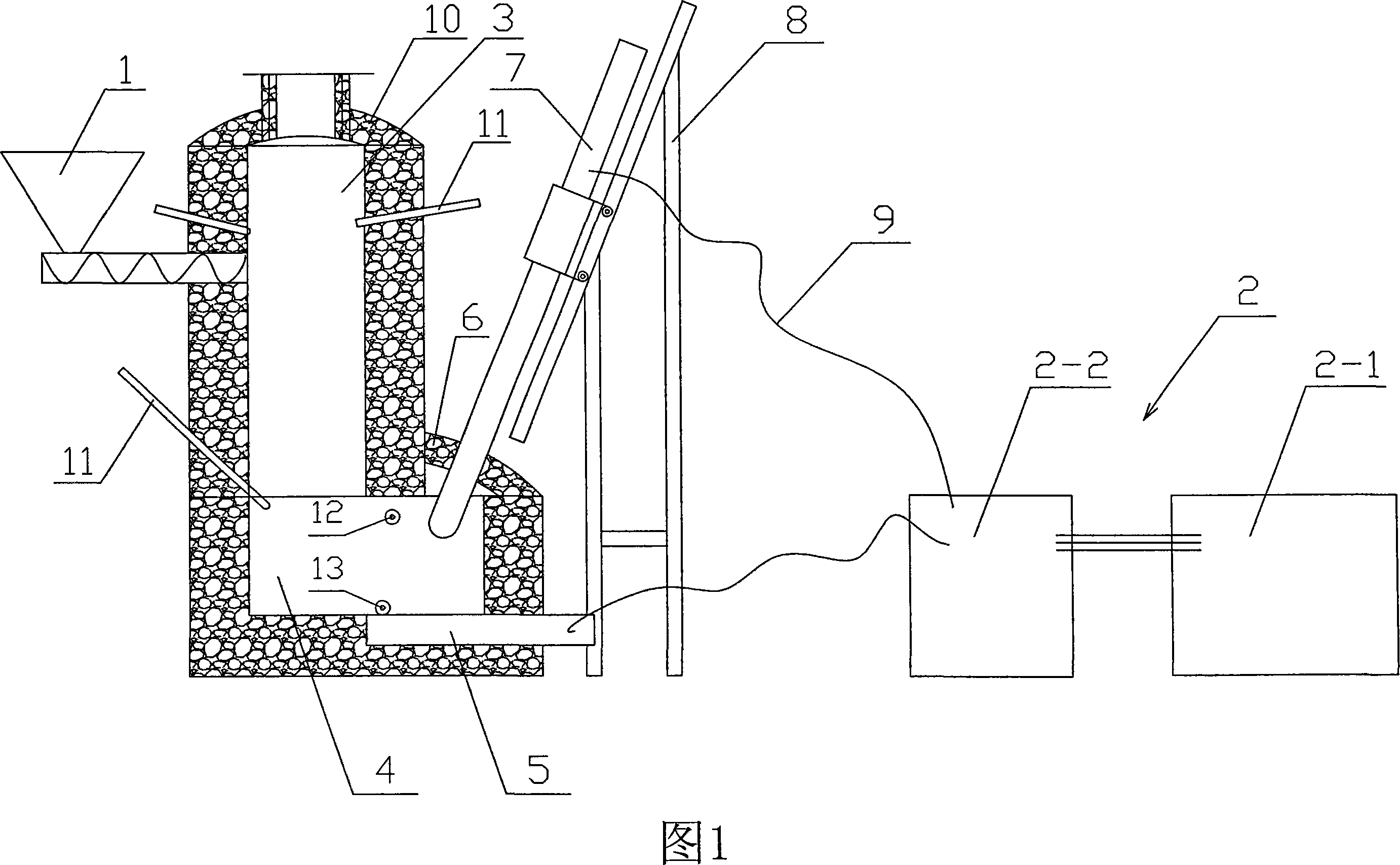

[0009] As shown in Figure 1, this embodiment is mainly composed of a screw feeder 1, a blast melting furnace 3, a slag body separation furnace 4, an electrode lifting mechanism 8 and a power supply device 2. In this example, the power supply device 2 consists of an electric furnace transformer 2- 1 and rectifier 2-2. The output end of the screw feeder 1 communicates with the blast melting furnace 3, and the blast melting furnace 3 is directly installed on the upper part of the slag body separation furnace 4 and communicates with it; the bottom of the slag body separation furnace 4 is provided with a The graphite plate 5 outside the body is equipped with a semicircular lower furnace cover 6 with an electrode insertion port on the top side, and is sealed and connected with the furnace body. One end of the graphite electrode 7 is obliquely inserted into the slag body separation furnace 4 through the electrode insertion port. The electrodes are fixed on the electrode lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com