Sludge ozonization dehydration treatment method and device

A treatment method and technology of treatment device, which are applied in dewatering/drying/concentrating sludge treatment, oxidation treatment of sludge, etc., can solve the problems of unstable dewatering effect of filter press, inability to obtain dewatering effect, and easy failure, and achieve saving The effect of chemical stirring device, saving equipment investment and reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

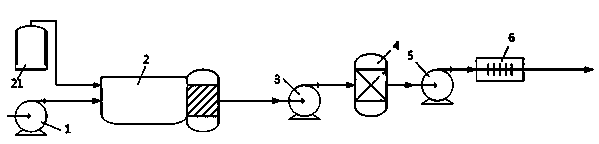

[0035] A sludge ozonation dehydration treatment method, comprising the following steps in sequence:

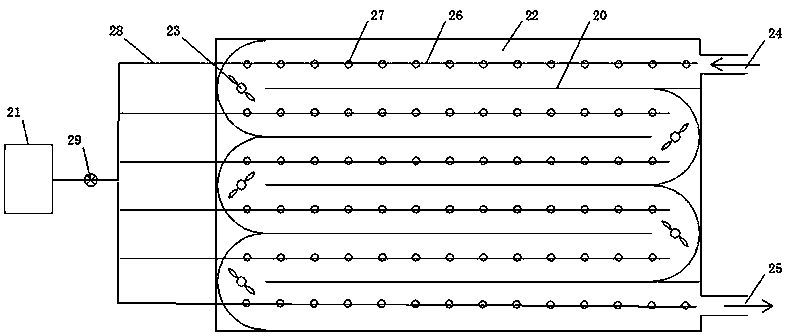

[0036] A. The raw sludge with a water content of 99% is pumped into the sludge ozonation reaction tank, and the raw sludge flows through a tortuous channel in the sludge ozonation reaction tank, where it is fully contacted with ozone for ozonation, The interstitial water and cell water in the original sludge are released, and the ozone intake concentration and intake flow rate are as shown in Table 1;

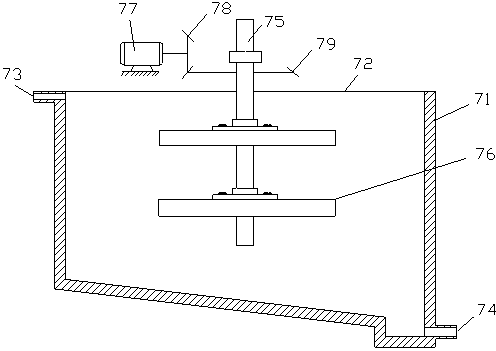

[0037] B. Mechanically thicken the sludge after ozonation;

[0038] C. Pump the mechanically concentrated sludge to the chamber diaphragm filter press, and add polymer flocculant at the outlet of the pump. The polymer flocculant is mixed evenly with the sludge by means of the rapid rotation of the sludge pump. , so that the sludge is adsorbed and aggregated, and then coagulated and precipitated;

[0039] D. The sludge after flocculation is pumped into the compartment memb...

Embodiment 2

[0048] A sludge ozonation dehydration treatment method, comprising the following steps in sequence:

[0049] A. The raw sludge with a water content of 99% is pumped into the sludge ozonation reaction tank, where it is stirred and fully contacted with ozone for ozonation, so that the interstitial water and cell water in the raw sludge Released, the ozone intake concentration and intake flow are shown in Table 2;

[0050] B. Mechanically thicken the sludge after ozonation;

[0051] C. Pump the mechanically concentrated sludge to the chamber diaphragm filter press, and add polymer flocculant at the outlet of the pump. The polymer flocculant is mixed evenly with the sludge by means of the rapid rotation of the sludge pump. , so that the sludge is adsorbed and aggregated, and then coagulated and precipitated;

[0052] D. The sludge after flocculation is pumped into the compartment membrane filter press for pressure filtration;

[0053] E. After pressing the filter, the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com