Patents

Literature

65results about How to "Guaranteed reflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

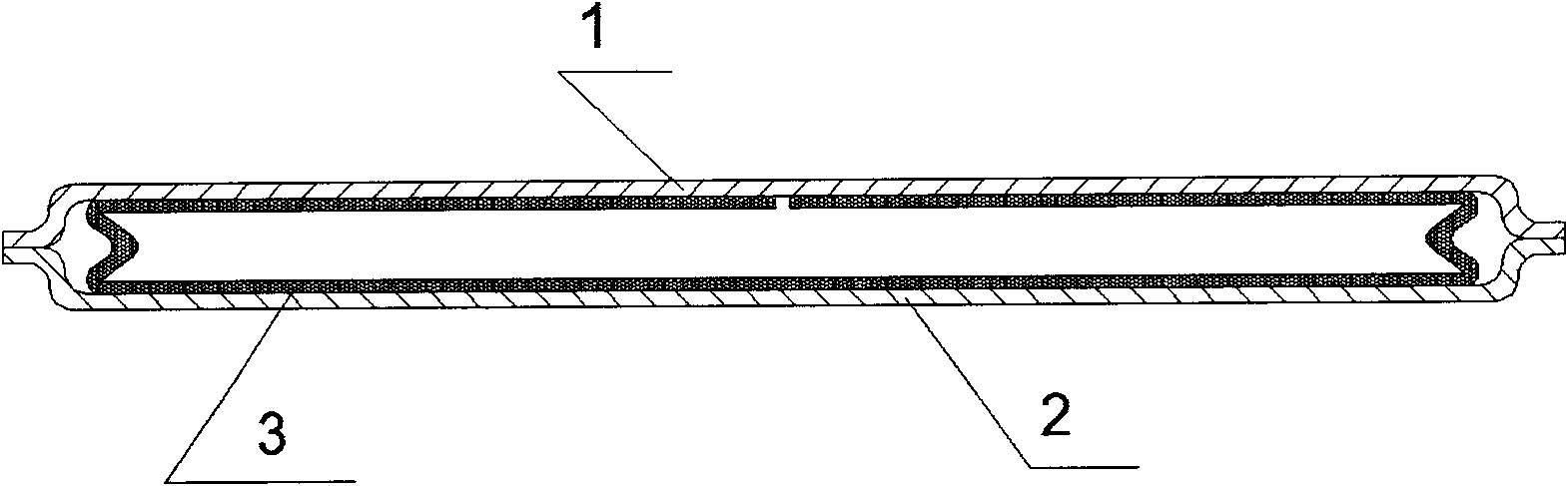

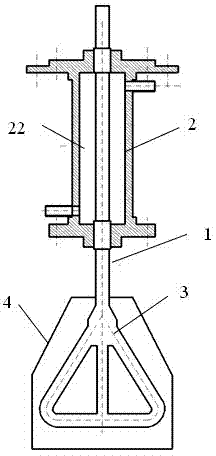

Soaking plate of foam metal and copper powder compounded capillary structure

InactiveCN101848629AReduce penetration resistanceReduce return lossIndirect heat exchangersCooling/ventilation/heating modificationsCopperThermal contact

The invention discloses a soaking plate of a foam metal and copper powder compounded capillary structure. In the technical scheme, a main body is a vacuum chamber which consists of an upper cover and a lower cover, a compounded capillary structure formed by foam metal and copper powder is arranged in the chamber, the chamber is also filled with a certain quantity of working medium which can boil and transfer heat at a low temperature, the upper cover and the lower cover are both made of deoxidized plate, and the compounded capillary structure is formed through sintering a foam metal plate and copper powder of a certain size. Compared with the traditional capillary structure, the compounded capillary structure has the significant advantages of large lower capillary force, small upper osmotic resistance, accurate control of the capillary force, small thermal contact resistance and the like; and the capillary structures of the upper cover plate and the lower cover plate can be designed as a whole, thereby improving the backflow capacity. Compared with the traditional product, the soaking plate of the foam metal and copper powder compounded capillary structure has the significant advantages of low cost, high irradiating efficiency, long service life and the like when achieving the identical irradiating effect.

Owner:SOUTH CHINA UNIV OF TECH

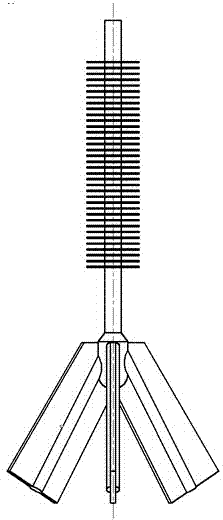

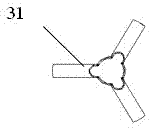

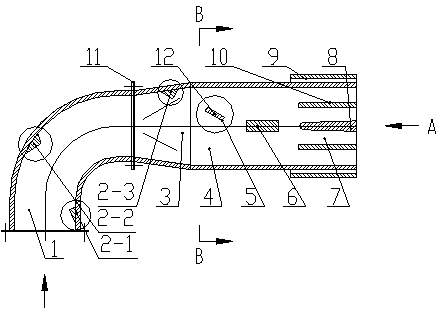

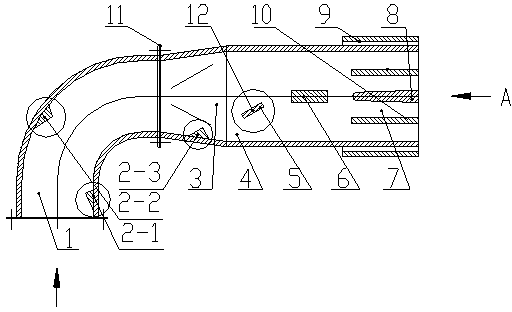

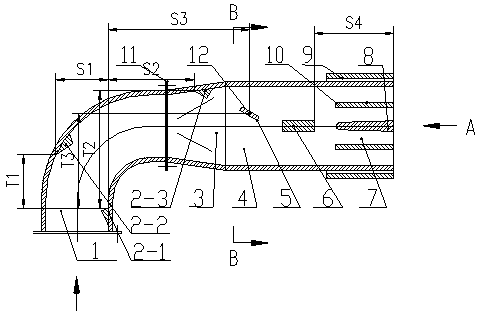

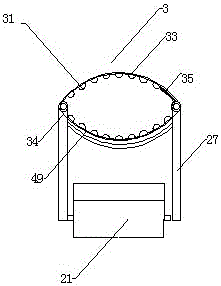

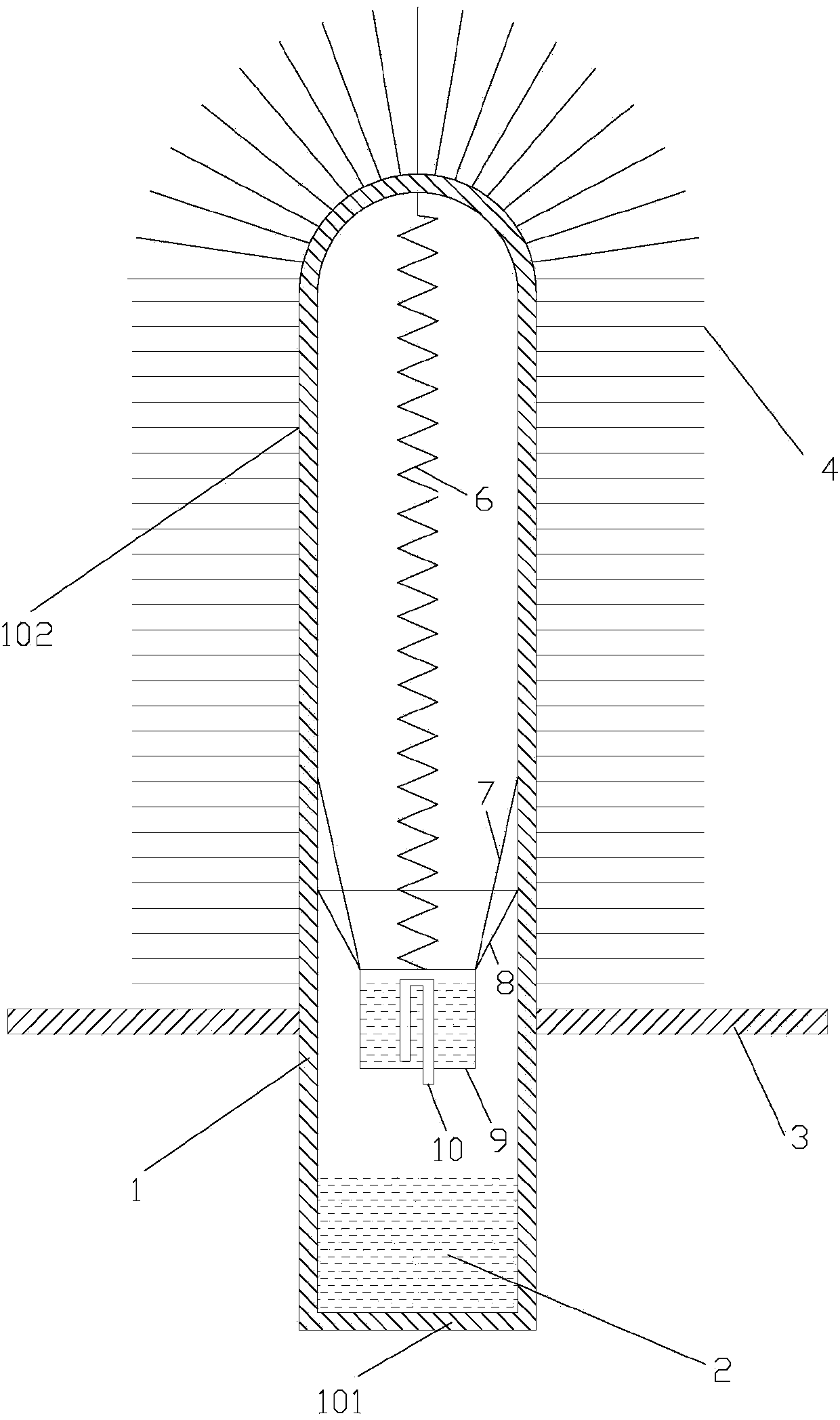

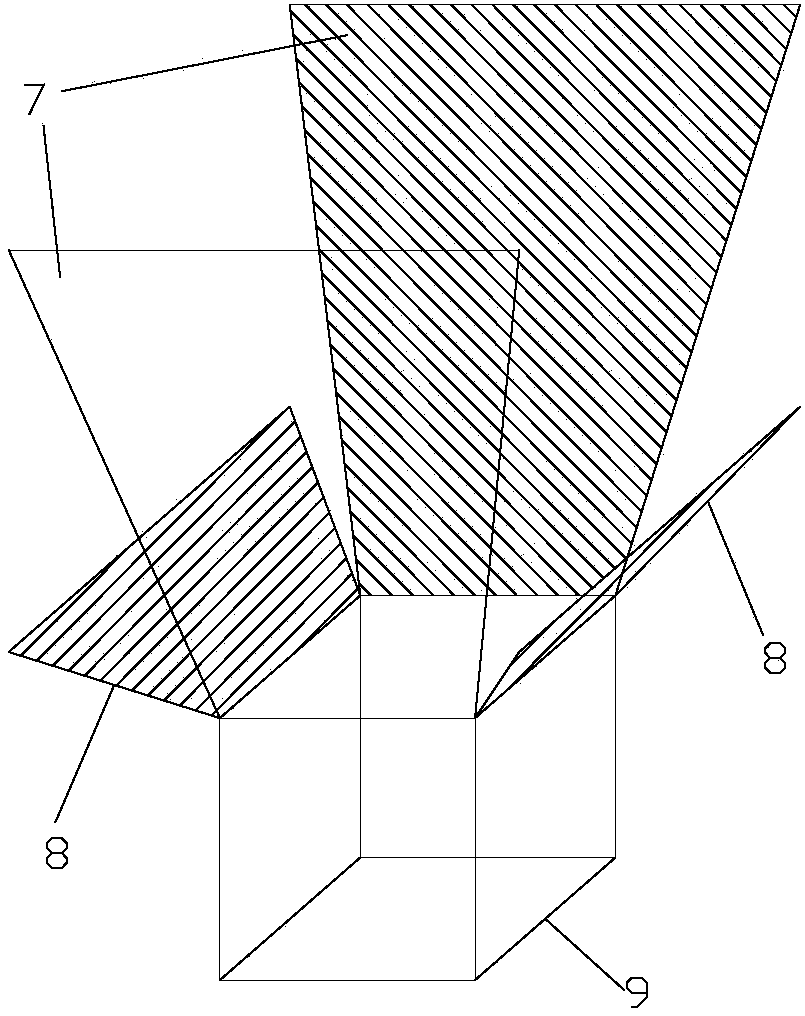

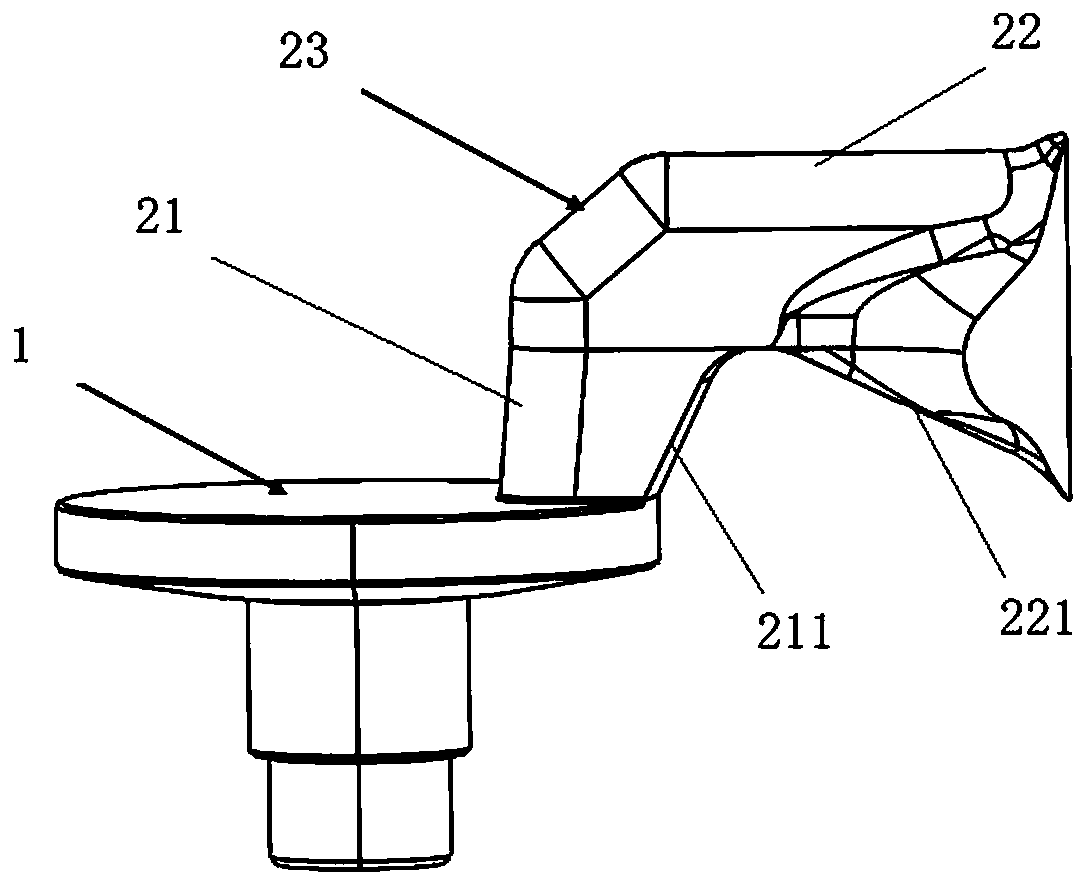

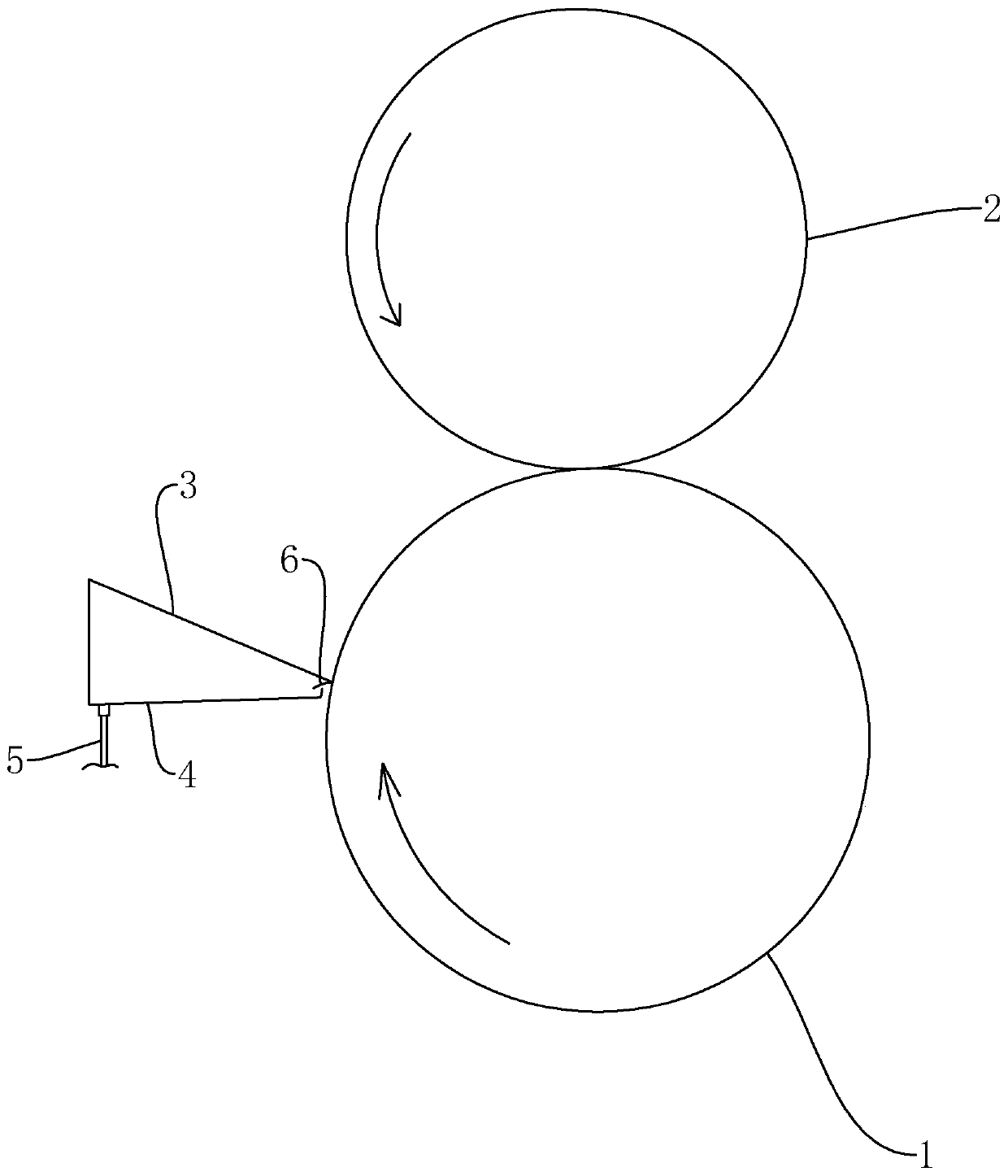

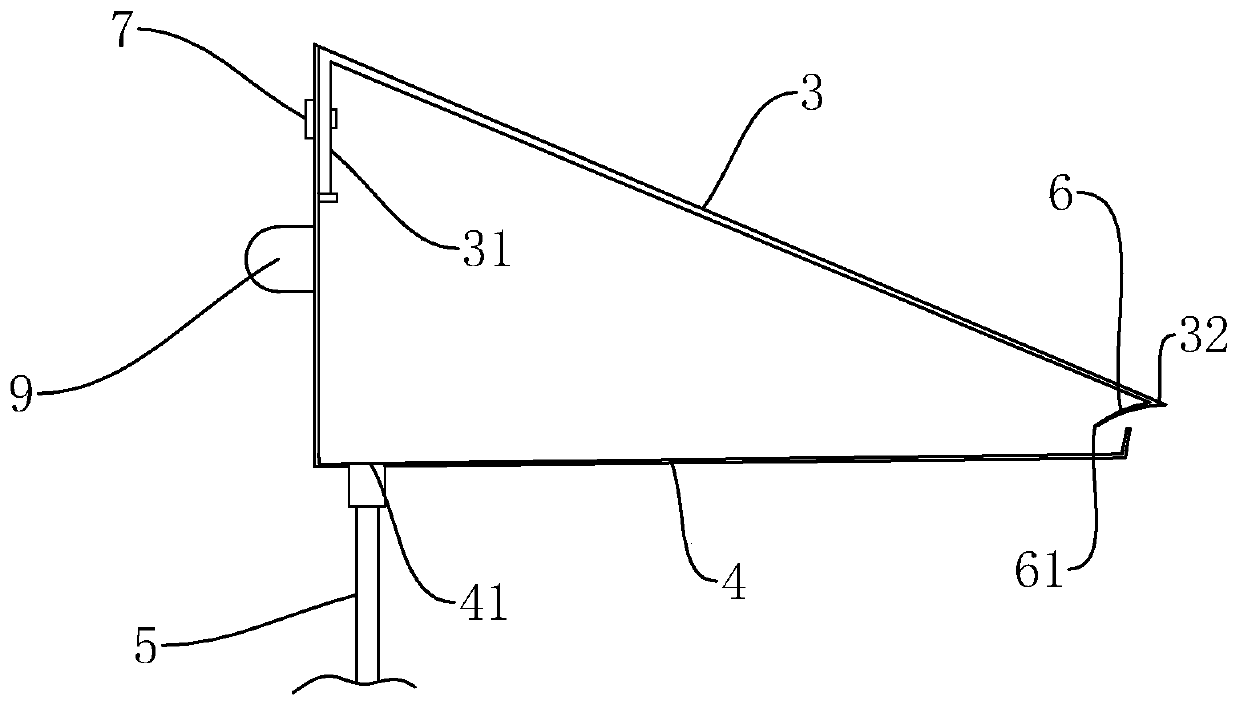

Irregularly-shaped rotary heat pipe applicable to various rotation speeds

InactiveCN104266516AGuaranteed reflowGuaranteed stirringIndirect heat exchangersEngineeringHeat pipe

The invention discloses an irregularly-shaped rotary heat pipe applicable to various rotation speeds. The heat pipe comprises a heat pipe main body, wherein the lower section of the heat pipe main body is a heat pipe evaporation section; the upper section of the heat pipe main body is a heat pipe cooling section; a condensate reflow structure is machined on the inner wall of the heat pipe; the lower end of the heat pipe evaporation section is provided with at least one branch layer; each branch layer is provided with at least two dendritic heat absorbing pipes; the heat absorbing pipes are uniformly distributed by taking the heat pipe main body as the center and extend towards the side lower part; the outer surfaces of the heat absorbing pipes are provided with ribs to form blades. Under the condition that the evaporation section of the heat pipe type stirring paddle is at a lower rotation speed, the gravity is used as main power for reflow of a working medium. Under the condition of higher rotation speed, centrifugal force produced by rotation is used as main power for reflow, so that the heat pipe type stirring paddle has excellent adaptability at various rotation speeds.

Owner:NANJING UNIV OF TECH

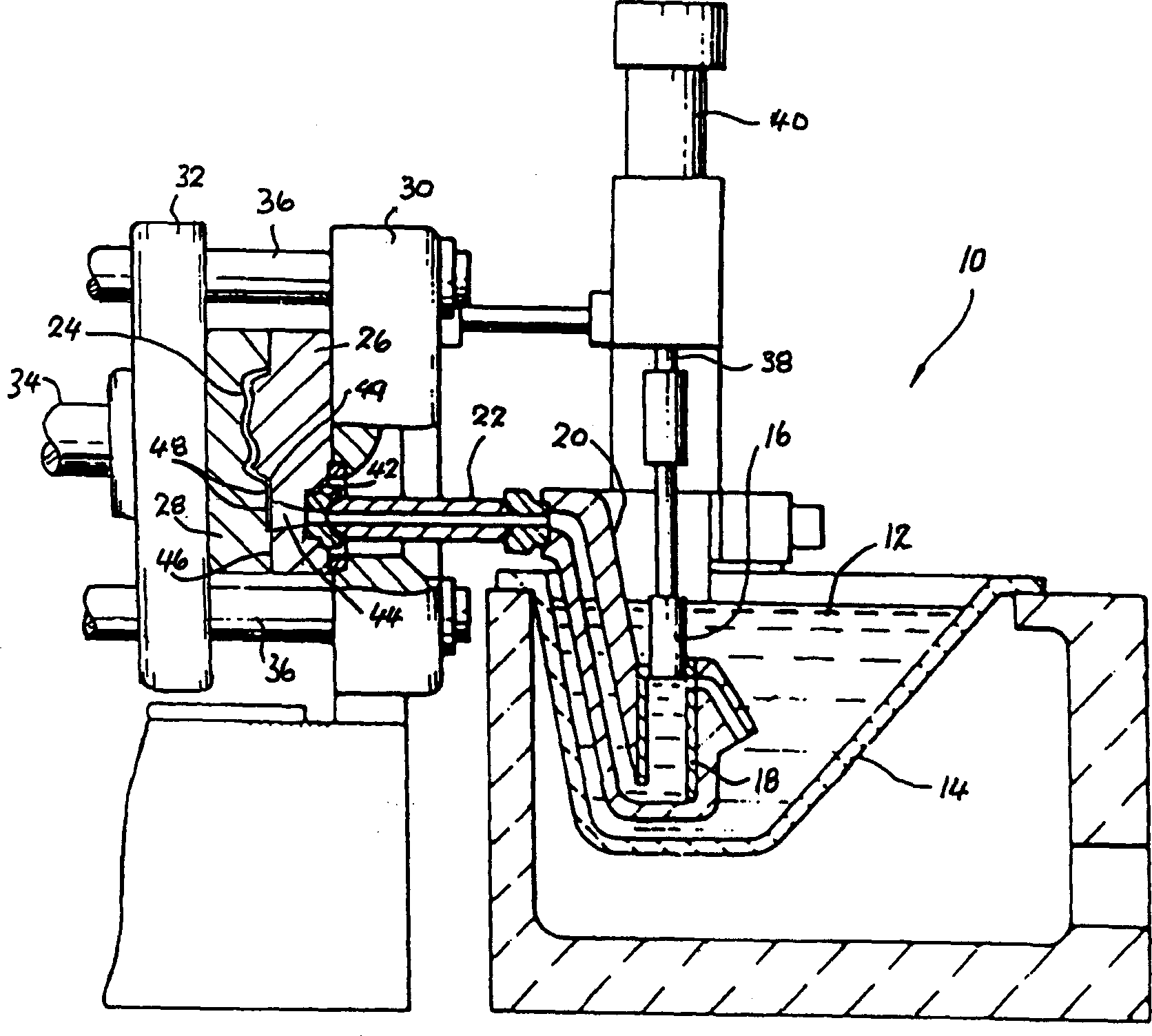

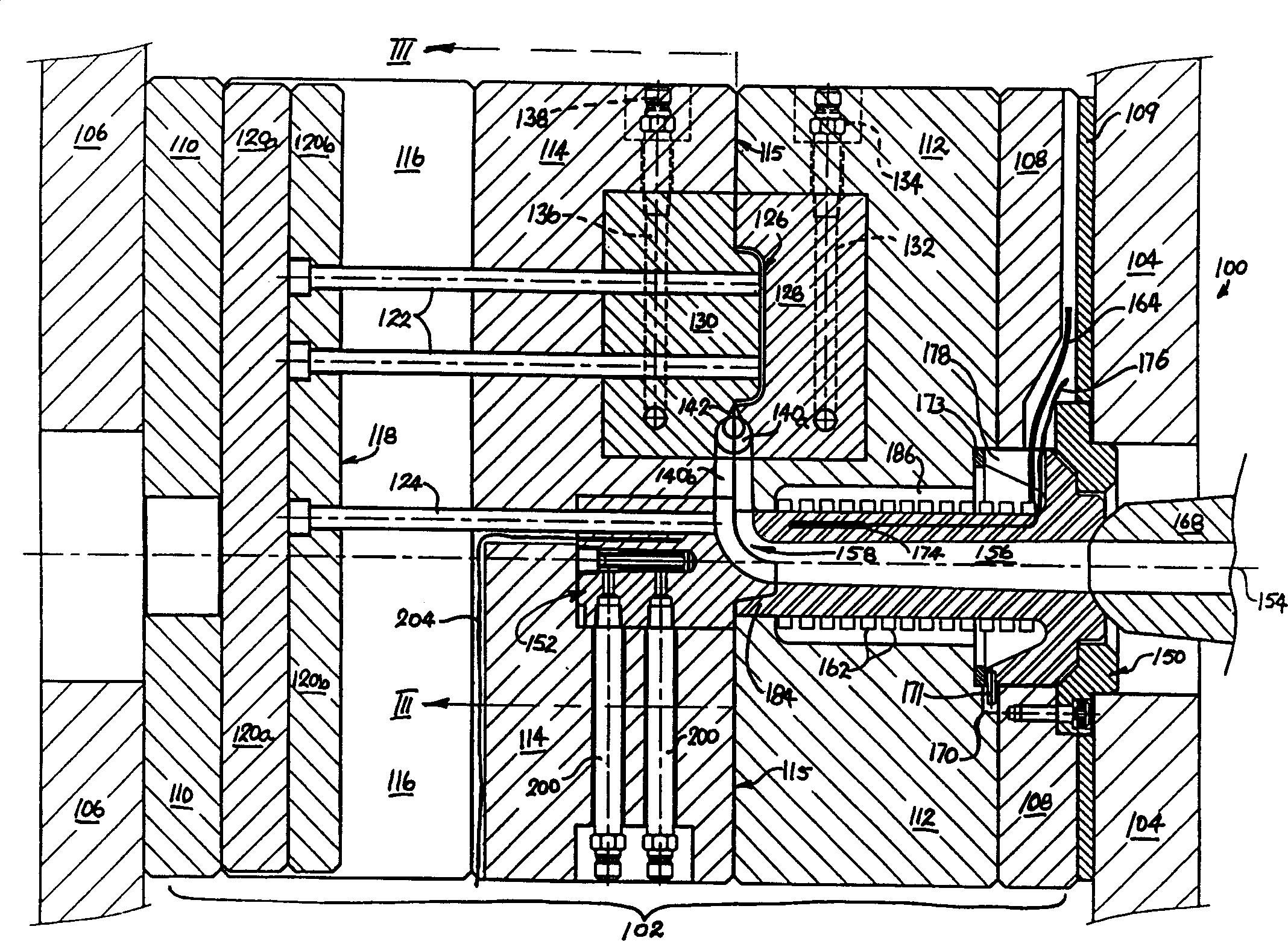

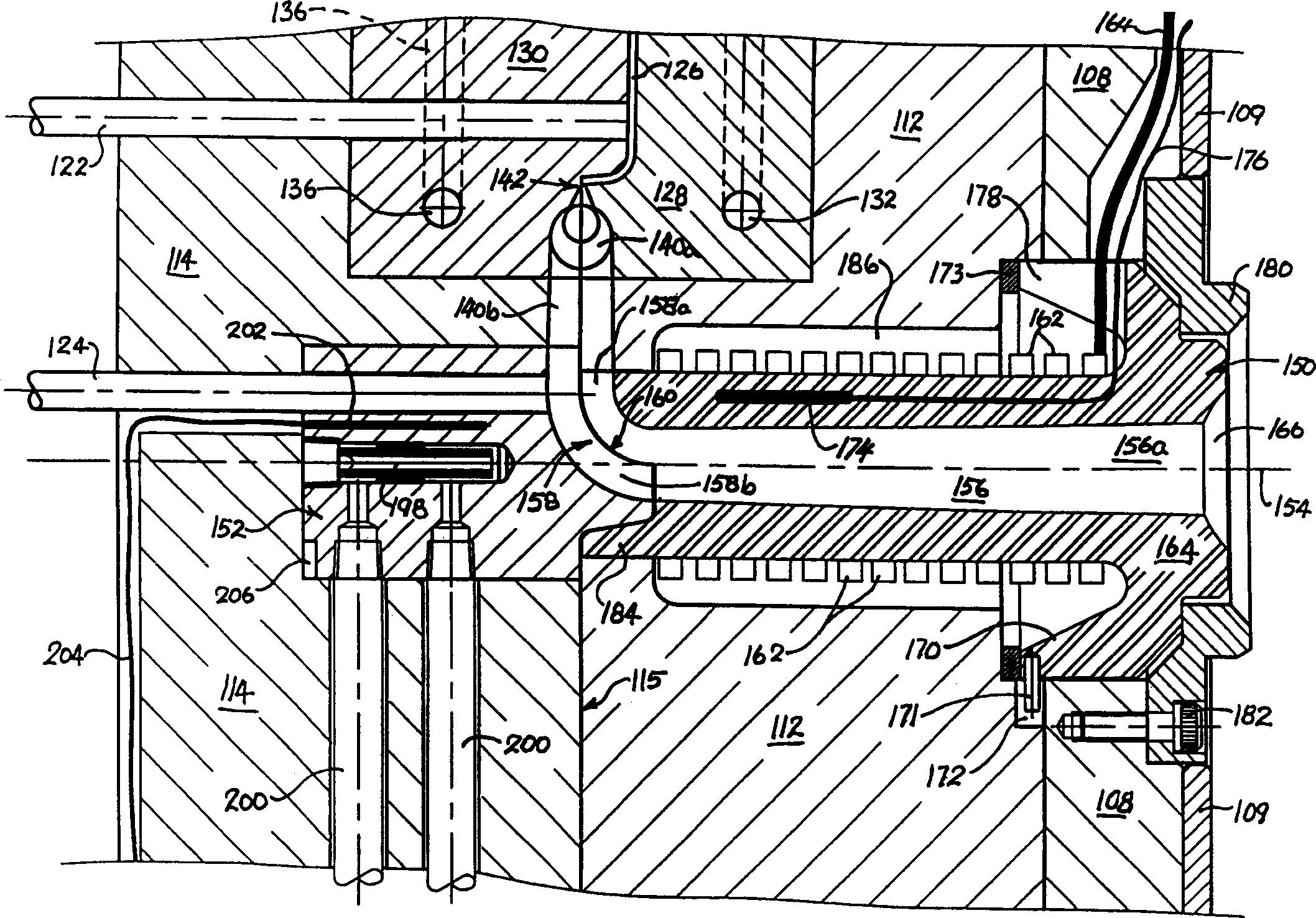

Hot sprue system for diecasting

InactiveCN1373695ANo need to change the general layoutTemperature controlFoundry mouldsFoundry coresHigh pressureMetal mold

The invention discloses a mold insert and a process method for high-pressure hot-chamber metal mold casting, which basically eliminates the sprue casting body and greatly improves the flow conditions of molten metal. The mold insert includes: (1) a heated sprue body insert (130, 258) positioned within a stationary block (112) in the mold assembly and including a sprue channel (136, 260); (2) a sprue channel (136, 260); Cooled sprue head inserts (132, 266) are installed in the moving module (114) of the mold assembly. The sprue channel body inserts and head inserts are mounted coaxially so that their inner ends fit well with each other in the area of the parting surface (155) of the mold and at least form a curved transition channel ( 138,262,264) which connects the sprue channel (136,260) with at least one sprue channel (140,254,256) formed along the parting surface. The temperature of the sprue body inserts and head inserts is controlled, so that the solidification point of the molten metal can occur just in the transition channel, and after each injection, the sprue channel can be ensured. Residual molten metal is returned to the nozzle of the casting machine, so that the sprue body is never formed again.

Owner:HOTFLO DIECASTING

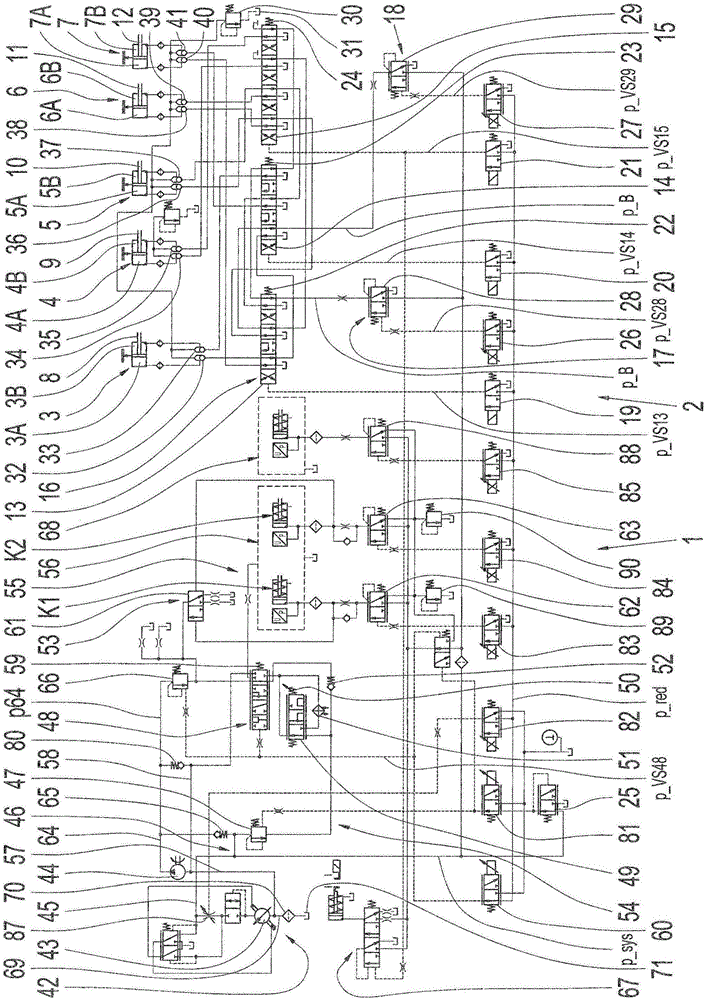

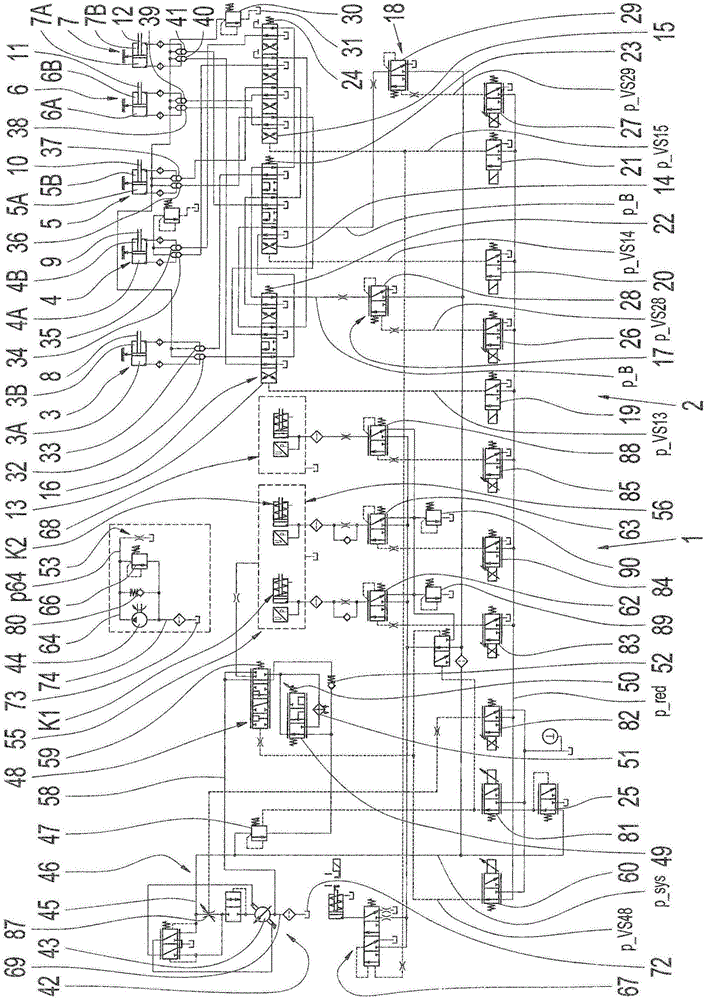

Transmission device having a hydraulic system

ActiveCN106233044AReduce hydraulic power consumptionAvoid reducing spontaneityToothed gearingsGearing controlSystem pressureHydraulic pump

A hydraulic system (1) of a transmission device (2) is connected to a hydraulic pump (43) which can be driven via a transmission input shaft and to a further hydraulic pump (44) which can be driven via a transmission shaft, and conducts hydraulic fluid volumes, which are delivered by the hydraulic pumps (43, 44), to transmission components. Hydraulic fluid can be applied to transmission components via a primary pressure circuit (46) and via a secondary pressure circuit (54). A pressure side (45) of the hydraulic pump (43) is coupled directly to the primary pressure circuit (46) and can be connected to the secondary pressure circuit (54) via the system pressure valve (47). A pressure side (64) of the further hydraulic pump (44) is connected directly to the secondary pressure circuit (54). The pressure side (45) of the hydraulic pump (44) can be connected in the region of the secondary pressure circuit (54) via a valve device (48) to a transmission component configured as a wheelset and to a transmission component configured as a dual clutch system (56) and also to an intake region (69) of the hydraulic pumps (43, 44). The pressure side (64) of the further hydraulic pump (44) is connected to the wheelset and can be coupled to the dual clutch system (56) via the valve device (48).

Owner:ZF FRIEDRICHSHAFEN AG

Rich-lean separated pulverized coal burner

ActiveCN103267282AGuaranteed reflowStable combustionPulverulent fuel combustion burnersEngineeringHigh-temperature corrosion

Owner:HARBIN BOSHEN TECH DEV CO LTD

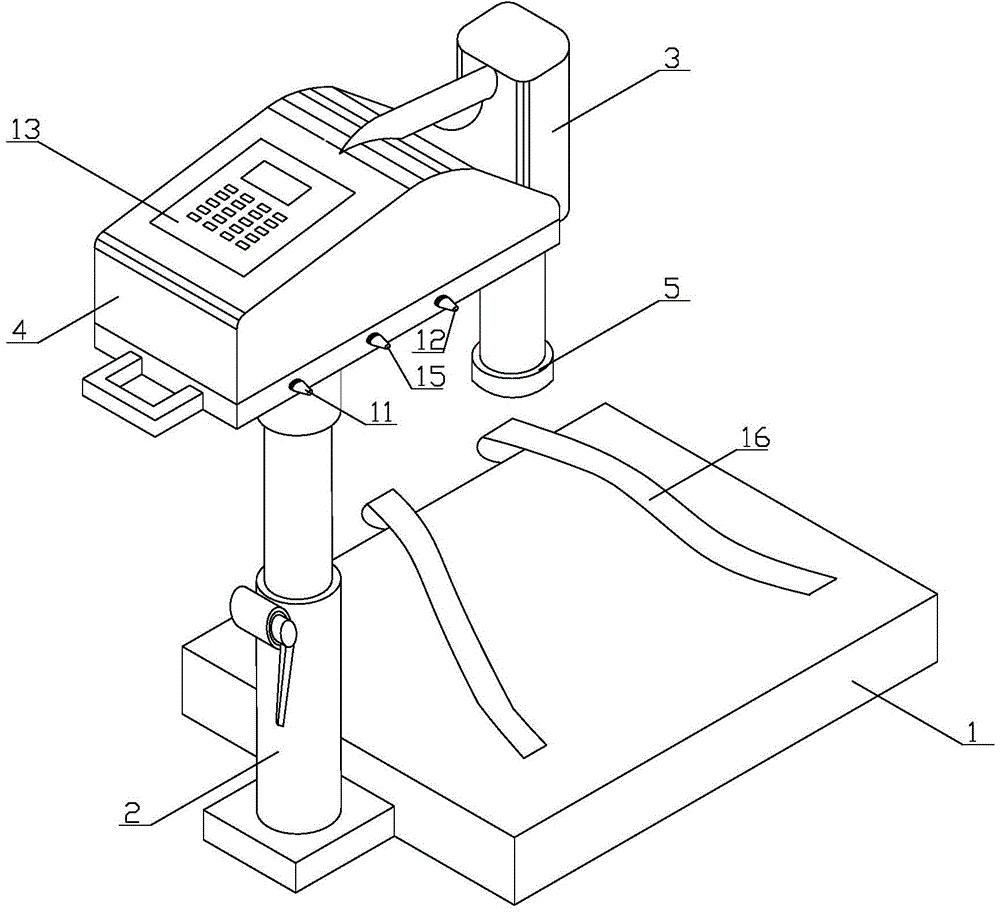

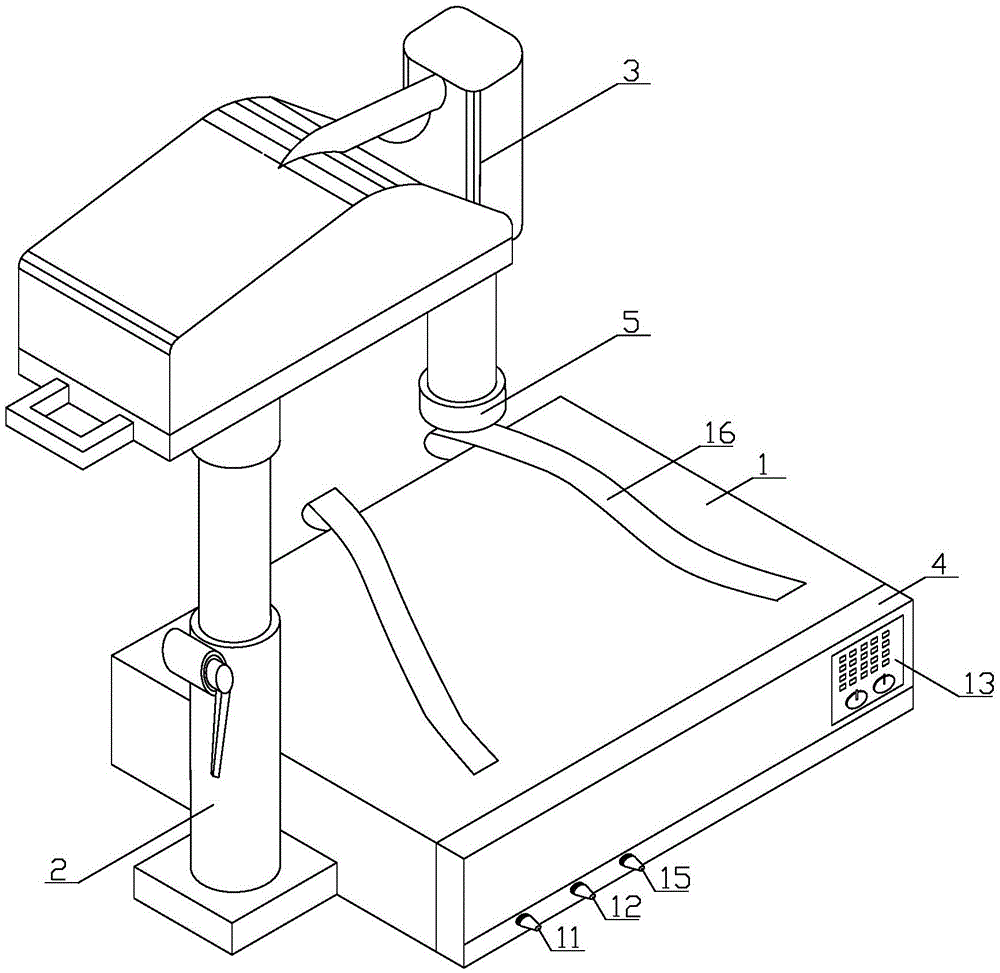

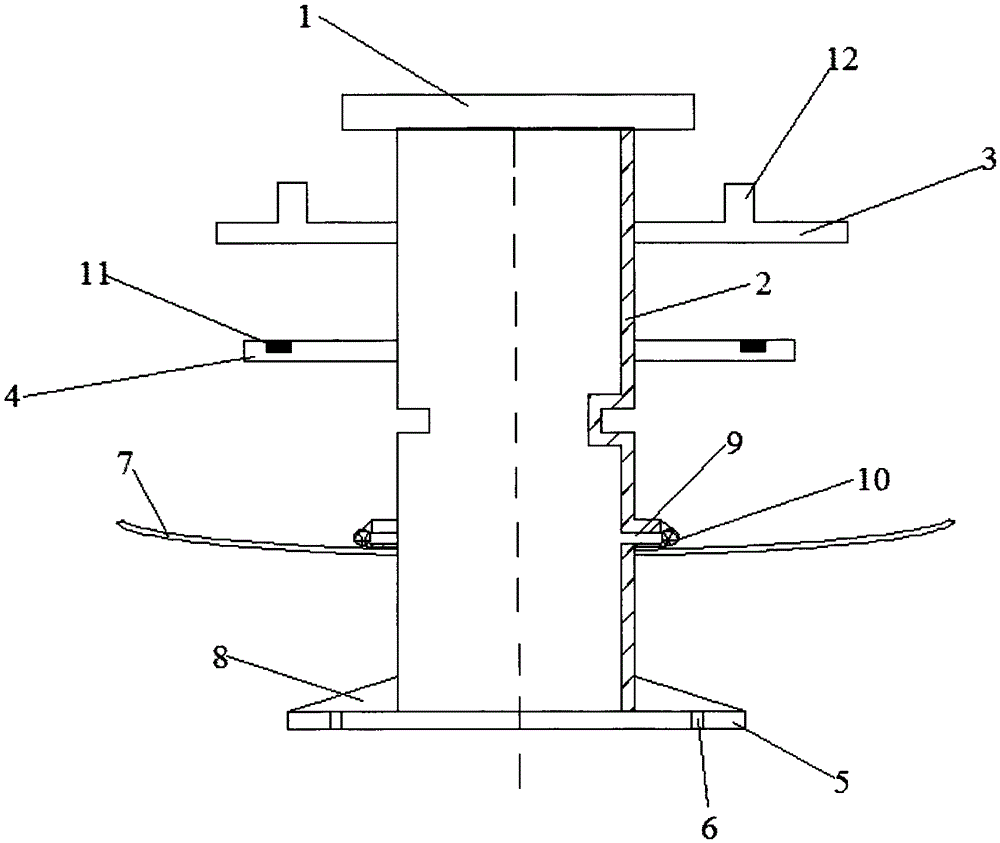

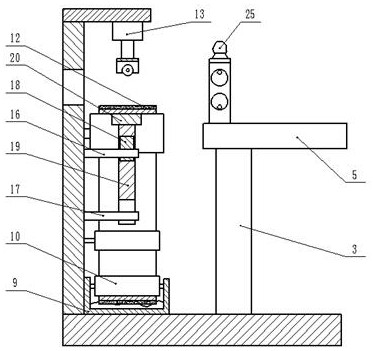

Cardio-pulmonary resuscitation machine with high-frequency ventilation function

ActiveCN104146856ANo damageGuaranteed reflowIron-lungsEngineeringIntermittent positive pressure ventilation

The invention discloses a cardio-pulmonary resuscitation machine with a high-frequency ventilation function. The cardio-pulmonary resuscitation machine comprises a bottom plate, an upright, an external chest compressor, a controller shell, a high-frequency ventilation electromagnetic valve and a high-frequency ventilation air source connector, wherein the upright is arranged on the side of the bottom plate, the external chest compressor is arranged on the upright, the controller shell is mounted at the top end of the upright or on the bottom plate, the high-frequency ventilation electromagnetic valve is mounted in the controller shell, and the high-frequency ventilation air source connector is arranged on the controller shell. An air outlet of the high-frequency ventilation electromagnetic valve is connected with the high-frequency ventilation air source connector through a pipeline, and the high-frequency ventilation electromagnetic valve is electrically connected with a compression ventilation controller in the controller shell. The cardio-pulmonary resuscitation machine has the advantages that on the basis of a conventional cardio-pulmonary resuscitation machine, the open type high-frequency ventilation function is added, so that the cardio-pulmonary resuscitation machine can be switched to use between an intermittent positive-pressure ventilation function and the open type high-frequency ventilation function, application range is broadened, and the cardio-pulmonary resuscitation machine is applicable to emergency treatment of various critical patients with respiratory failure and asphyxia.

Owner:乌日娜

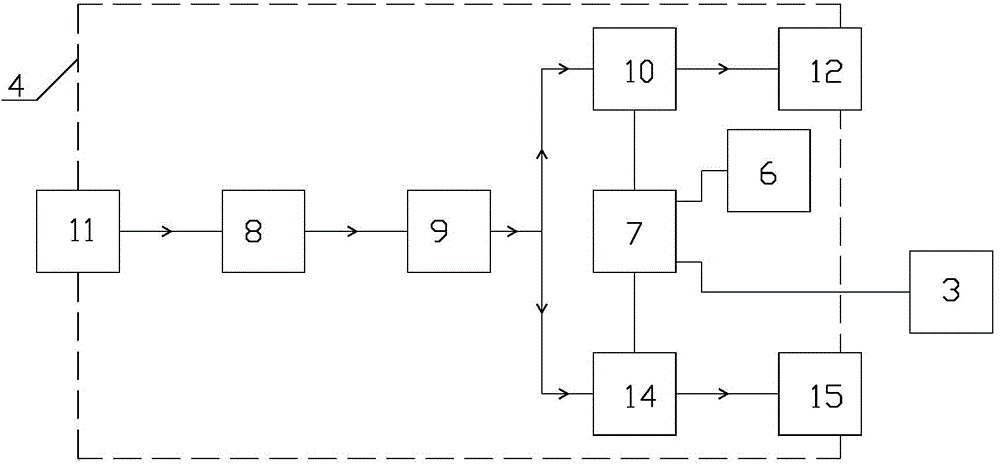

Compound rehabilitation system

ActiveCN106137504AHigh activitySave human effortPneumatic massageChiropractic devicesMotor speedThree vessels

The invention relates to a compound rehabilitation system. The rehabilitation system comprises a rehabilitation training bed, a lower-limb pulling muscle joint training module in the accommodating cavity and a control system, wherein the rear half part of the rehabilitation training bed is provided with an accommodating cavity; a lower limb blood circulation rehabilitation module is fixed on the lower-limb pulling muscle joint training module; and the control system comprises a microprocessor, a memory, an input module, an output module, a rotary coder, a pulling motor speed-regulation controller, an overload torque sensor, an air pressure sensor, a temperature sensor and a communication module. The compound rehabilitation system integrates joint motion, muscle extension, blood vessel function and blood circulation into a whole, is used for controlling motion of the rehabilitation system by means of the control system, and is intelligent since spontaneous determination can be carried out according to the rehabilitation training condition of a patient; and rehabilitation training condition of a patient can be carries safety and efficiency.

Owner:杨如山

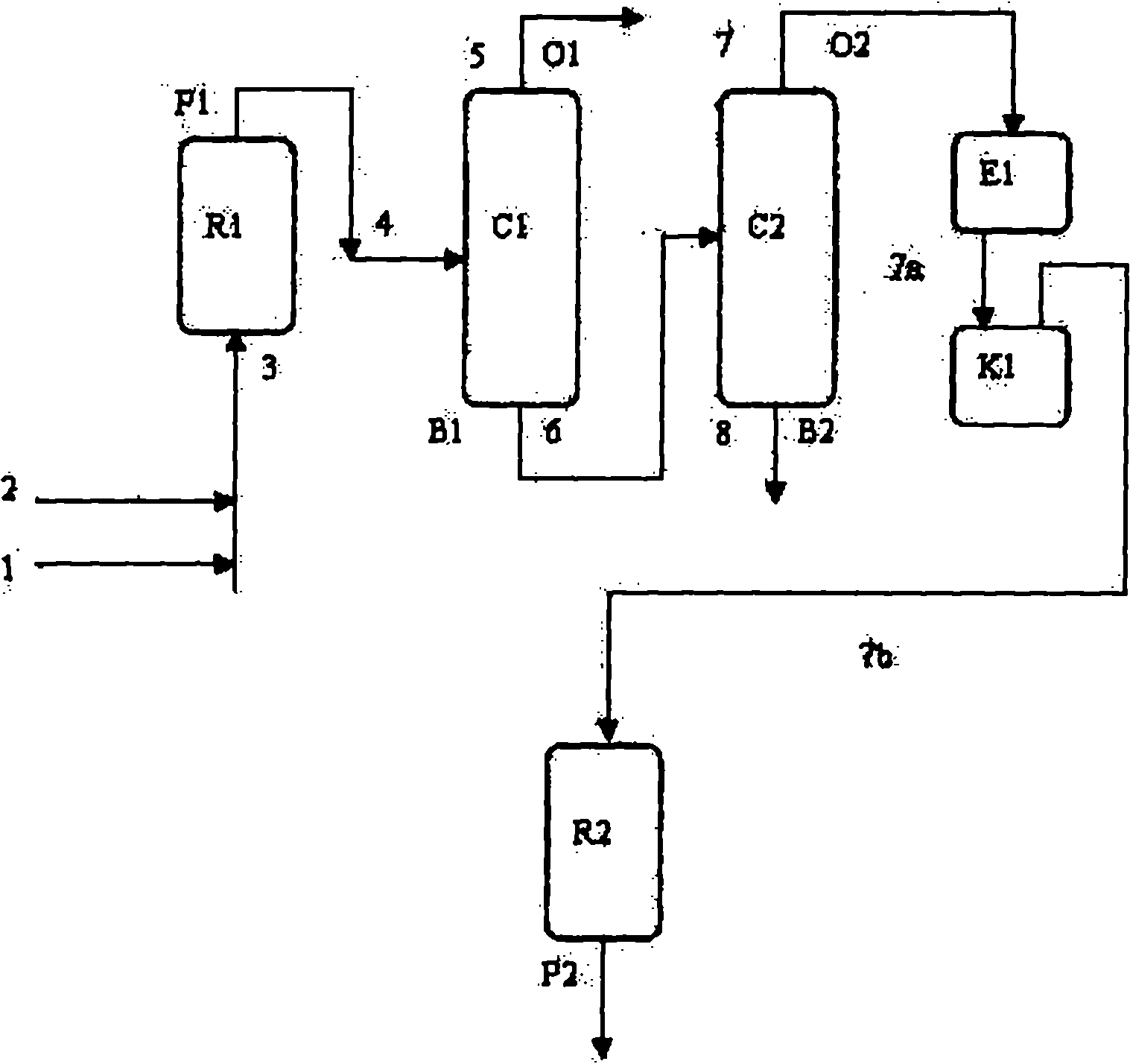

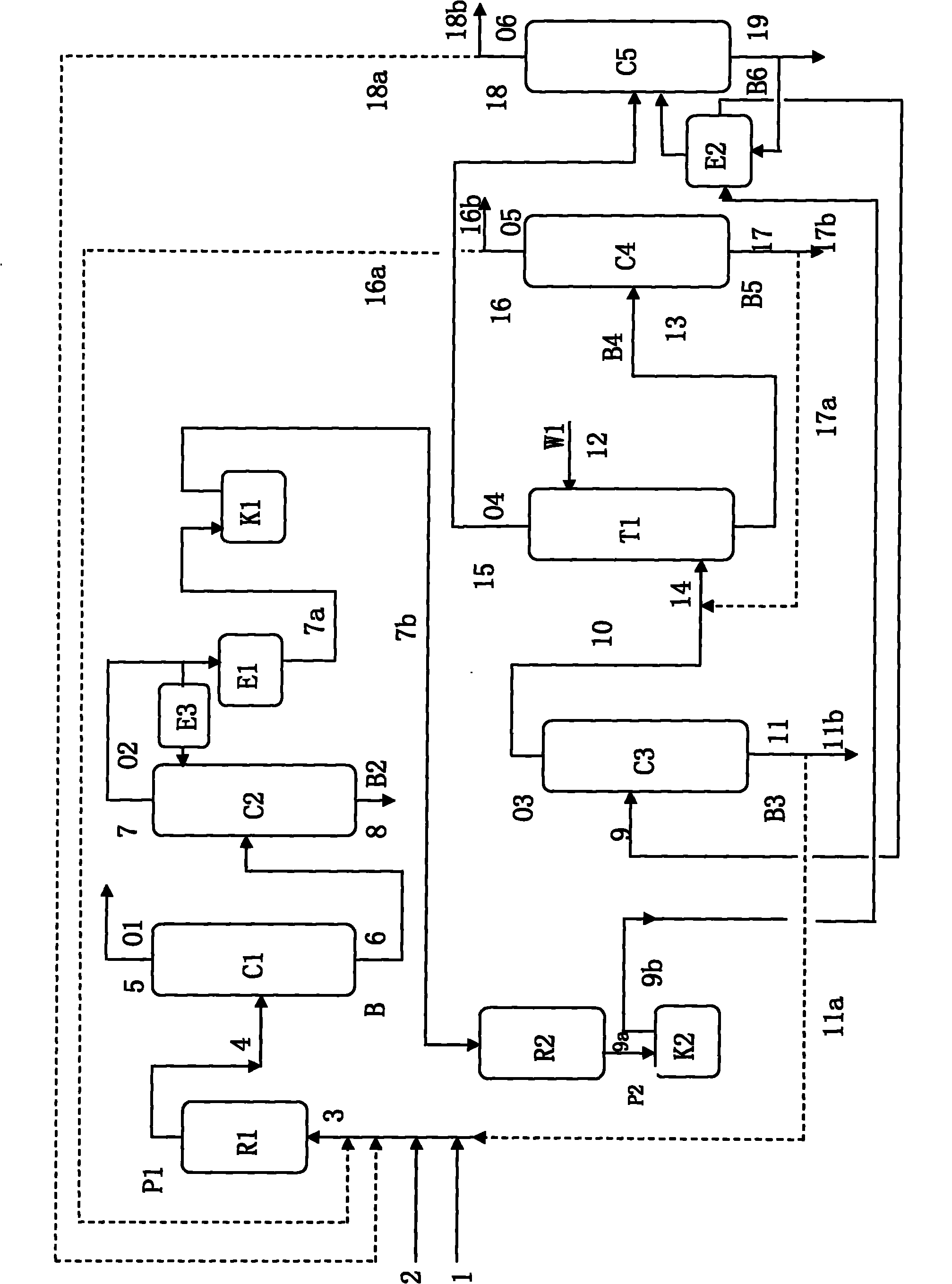

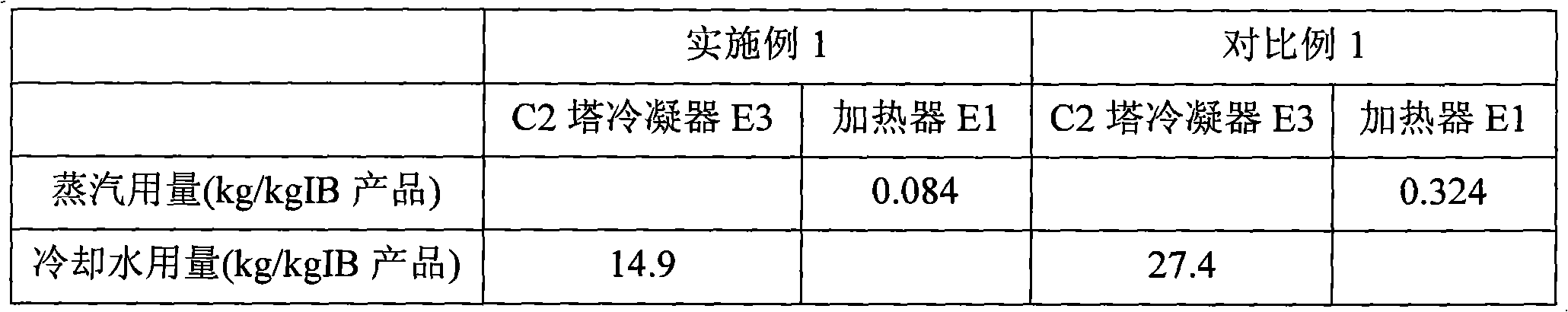

Isoolefine production method

ActiveCN102050690ALow operating pressureEasy to separateHydrocarbon from oxygen organic compoundsReboilerGas phase

The invention discloses an isoolefine production method comprising the following procedures: the tower top product of a second fraction column is obtained in gas phase; and the gas is heated to an ether cracking reaction temperature and enters into an ether cracking reaction vessel after compression. Therefore, gas phase condensation and repeated heating are avoided, required recirculated water and steam are less, the equipment energy consumption is lower, the operating pressure of the second fraction column is lower, the separation effect of the fraction column is improved, and the operation is facilitated. In the isoolefine production method, the gas phase reaction product at the outlet of the ether cracking reaction vessel is compressed to serve as the heat source for a fifth fraction column reboiler, and is sent to a third fraction column after condensation, so that the total steam amount and the recirculated water amount are reduced, and the equipment energy consumption is further lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

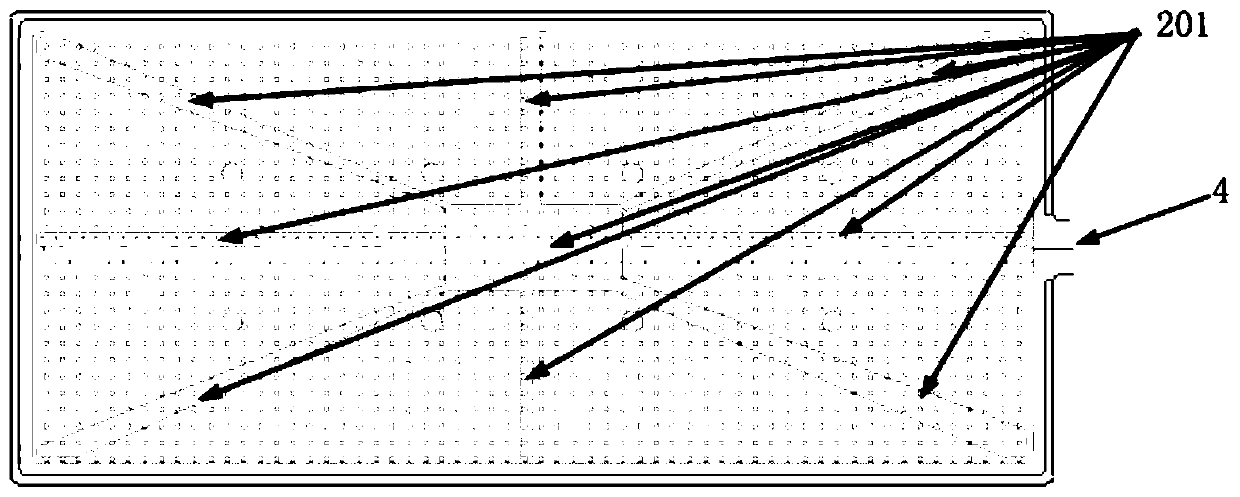

Electric imaging calibration well group

InactiveCN104763415AImproving Imaging AccuracyGuaranteed reflowBorehole/well accessoriesPhysicsElectricity

The invention discloses an electric imaging calibration well group which at least comprises one or more than one calibration well for verifying and scaling an electric imaging logging instrument, wherein the calibration well at least comprises a rock module (3), and an instrument through hole (4) formed in middle of the rock module (3); a radial gap is included behind the inner wall image of the rock module (3). The radial gap behind the inner wall image of the rock module is used for ensuring backflow of a measurement signal. Thus the imaging precision to the image of the electric imaging logging instrument is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Disposable embedded water stop joint for constructional engineering drainage and construction method thereof

InactiveCN105650357AGuaranteed installation accuracyGuaranteed reflowPipesDomestic plumbingBackflowWaterstop

The invention discloses a disposable embedded water stop joint for constructional engineering drainage and a construction method thereof. The water stop joint comprises a connecting pipe, a positioning ring, a water stop step, a base, a connecting hole, an arc-shaped lower water stop step ring, reinforcing ribs, a water stop hole, a spherical screen mesh and an upper water stop ring and can be applicable to pipeline penetration and installation of cast-in-place floors of rest rooms, kitchens, balconies, terraces and the like of residential building houses, and the installing accuracy of the water stop joint can be well ensured and the installation quality problem of the water stop joint can be prevented by arranging the positioning ring. In addition, the disposable embedded water stop joint can effectively prevent seeped water produced in surrounding gaps of the water stop ring in the construction process from causing leakage by being provided with the arc-shaped lower water stop step ring and the water stop hole, and ensures backflow of the seeped water. The disposable embedded water stop joint also prevents the blockage effect on the water stop hole of concrete sand in the construction process by being provided with the spherical steel wire mesh, can ensure the effect playing of the water stop hole and improves a water stop effect.

Owner:南京汇协建筑材料有限公司

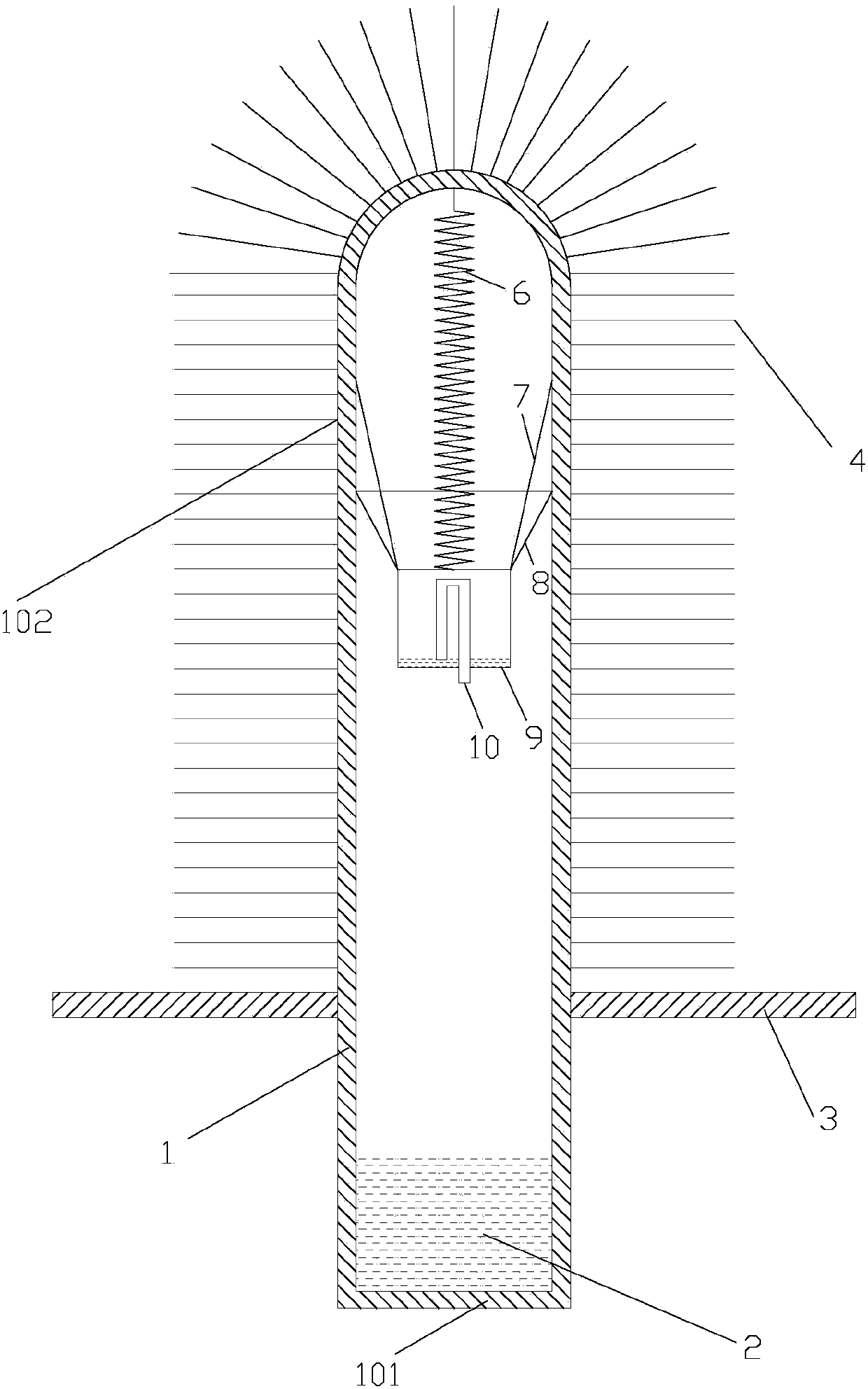

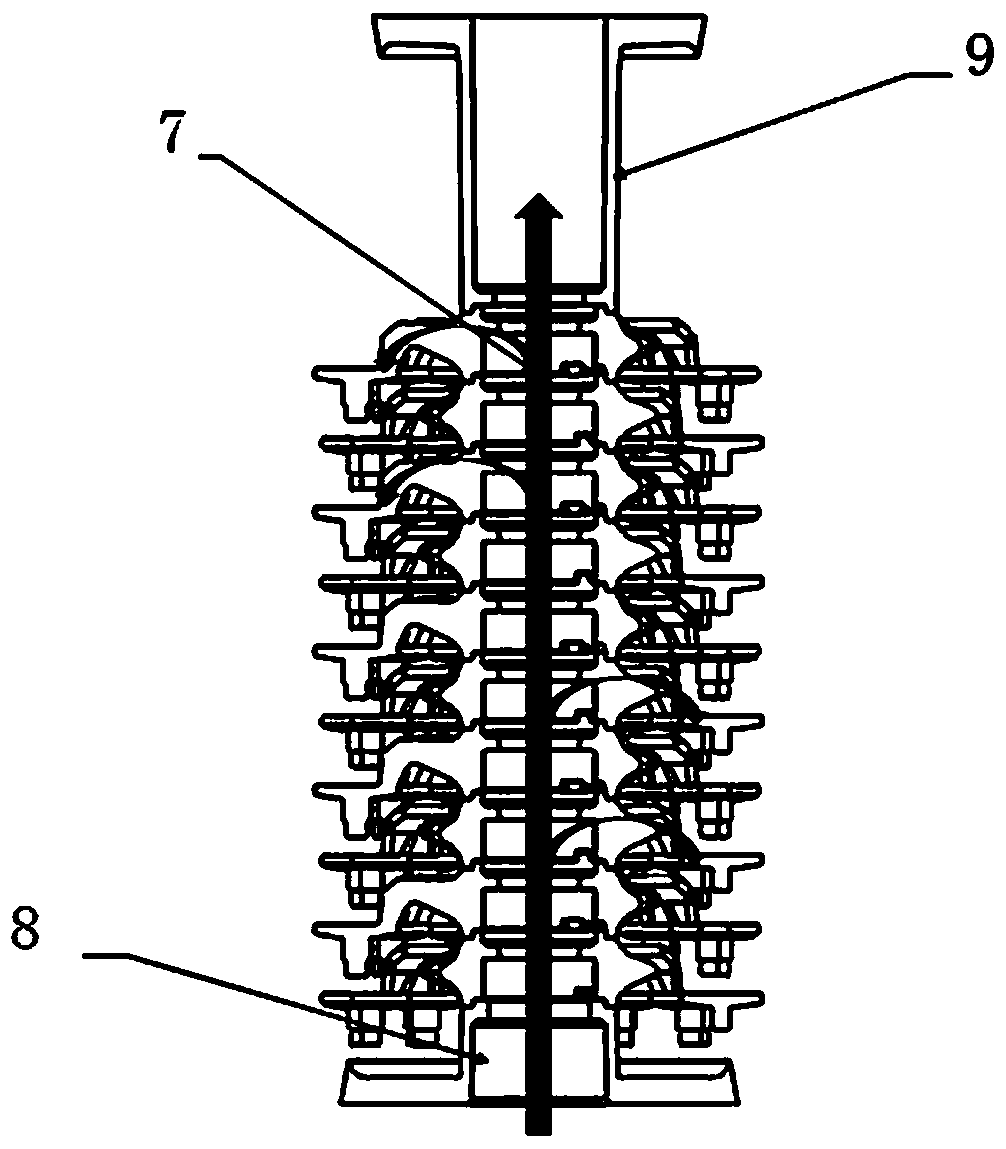

Strengthened heat transfer gravity assisted heat pipe

ActiveCN104197761AImprove condensation efficiencyReduce heat transfer resistanceIndirect heat exchangersSiphonWorking fluid

The invention discloses a strengthened heat transfer gravity assisted heat pipe comprising a pipe body, a working fluid, partitions, radiating fins and a fluid scraping device. The partitions are fixedly connected on the outer wall surface of the pipe body; the radiating fins are fixedly connected on the outer wall of a condensation section, and the working fluid is located inside an evaporation section; the fluid scraping device comprises a spring, two first backflow plates, two second backflow plates, a lifting tank and a siphon pipe, one end of the spring is fixedly connected on the inner wall surface of the top of the pipe body while the other end is fixed to the bottom of the lifting tank, the siphon pipe is fixedly connected on the bottom surface of the lifting tank, and the bottom ends of the first backflow plates and the second backflow plates are fixedly connected on the periphery of the top end of the lifting tank; flow guide bosses are arranged at two side edges of each of the first backflow plates and the second backflow plates, and a rubber scraping strip is mounted at the top end of each of the first and second backflow plates. Gas and fluid in the heat pipe can circulate effectively, heat transfer efficiency can be improved effectively, and the strengthened heat transfer gravity assisted heat pipe can be well applied to occasions of cooling of computer chips, instrument and equipment.

Owner:SOUTHEAST UNIV

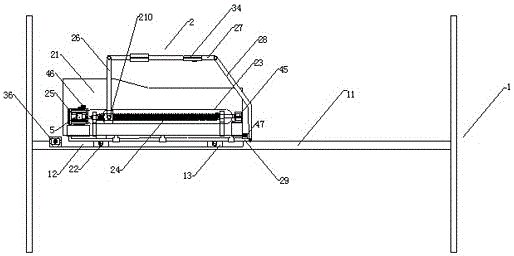

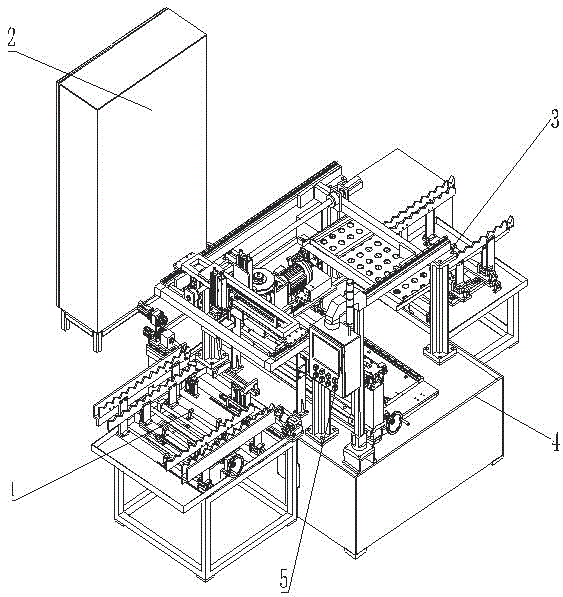

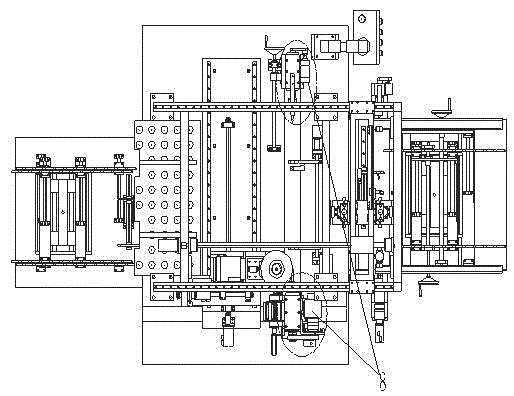

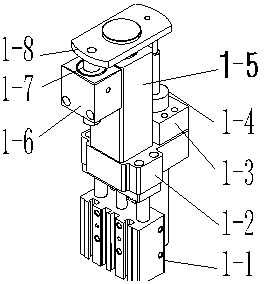

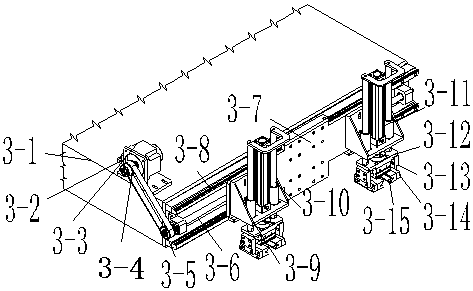

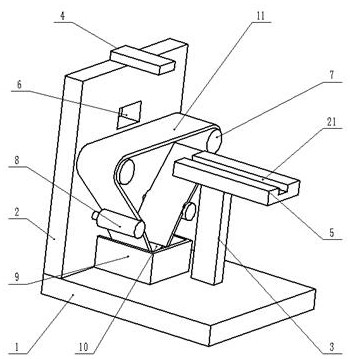

Longitudinal rack polishing machine

ActiveCN105983896AMeet polishing requirementsGuaranteed reflowPolishing machinesGrinding drivesMotor driveProgrammable logic controller

The invention belongs to the field of ultra-precision machining equipment and relates to a longitudinal rack polishing machine. The longitudinal rack polishing machine comprises an automatic discharging mechanism, a PLC (programmable logic controller) electrical control box, an automatic feeding mechanism, a frame, a touch screen control board, an automatic shape modifying mechanism, a polishing mechanism and a centre driving mechanism. A nylon resin polishing wheel is adopted for longitudinal polishing of a tooth back portion and a shaft portion of a rack. The polishing wheel in high-speed rotation has a certain floating quantity and can completely fit the rack, and the polishing wheel has a certain precompression force on the rack by the aid of a servo motor and a pressure sensor. Angular rotation of the rack is also realized under action of the servo motor, and full coverage of the tooth back portion can be realized. The servo motor drives the polishing wheel to move longitudinally to meet requirements of workpieces in different lengths. In electrical control, A PLC and a touch screen are adopted for controlling, and the servo motor and an air cylinder serve as power sources to be responsible for all operation instructions of equipment and implementation.

Owner:吉林瑞铭机电设备有限公司

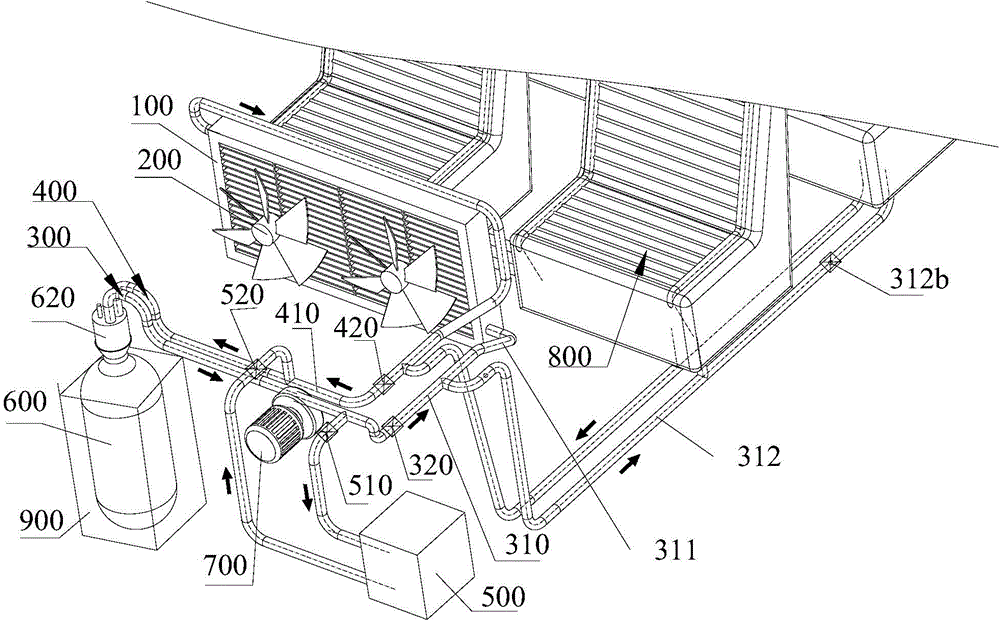

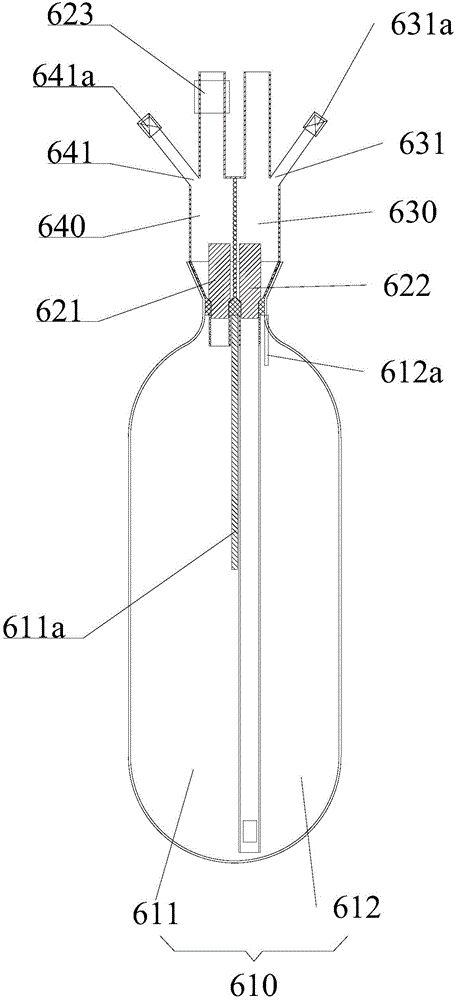

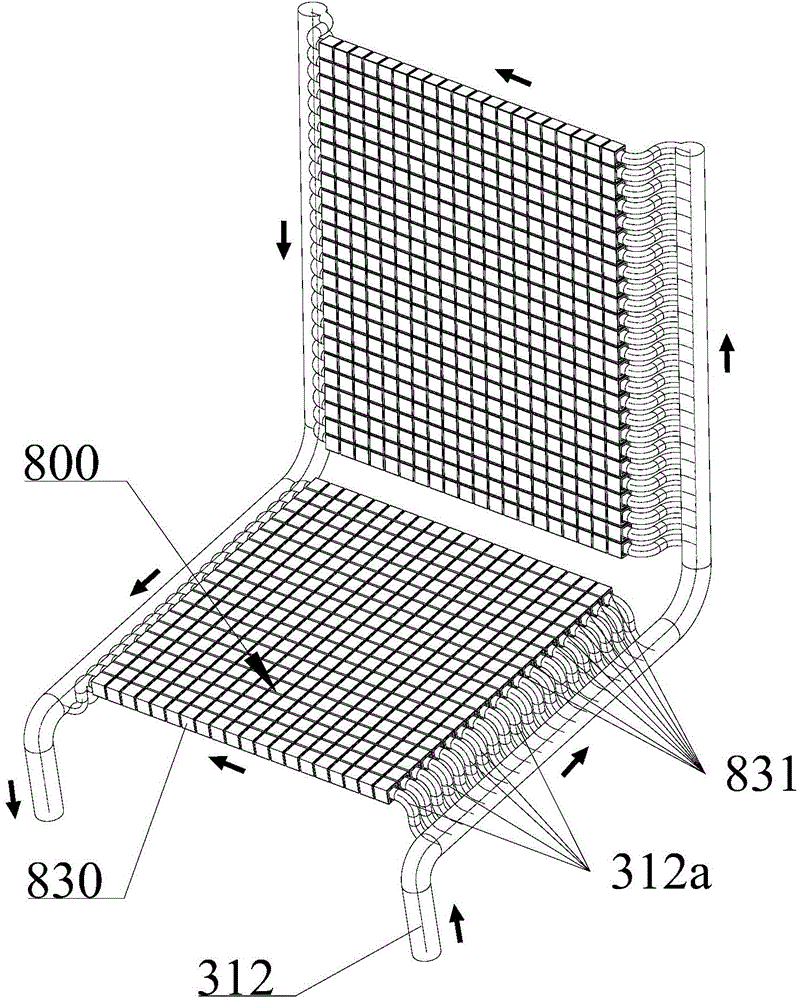

Indoor vehicle temperature regulating device and temperature regulating method thereof

InactiveCN104943508AMeeting comfort needsRapid coolingAir-treating devicesVehicle heating/cooling devicesUser needsEngineering

The invention belongs to the technical field of temperature regulating, and aims at providing an indoor vehicle temperature regulating device and a temperature regulating method thereof. The indoor vehicle temperature regulating device comprises a fluid output circulating assembly, a fluid input circulating assembly, a thermal insulating storage filled with thermal insulating fluid and seat temperature regulating devices arranged on seats. Under the condition that an existing air conditioning device is arranged in an indoor vehicle, under the control of a control device, before a user enter the indoor vehicle, the thermal insulating fluid flows into a temperature dissipation device and the seat temperature regulating devices through the fluid output circulating assembly, and flows back to the thermal insulting storage from the temperature dissipation device and the seat temperature regulating devices. In addition, due to the fact that a refrigerator is arranged in a pipeline, under the control of the control device, the thermal insulating fluid inside the thermal insulating storage can be circulated and cooled so that rapid cooling can be achieved on the indoor vehicle air and the seats continuously at any time by the temperature regulating device during user needs, and the comfort requirement for the indoor vehicle by the user can be met.

Owner:封时广

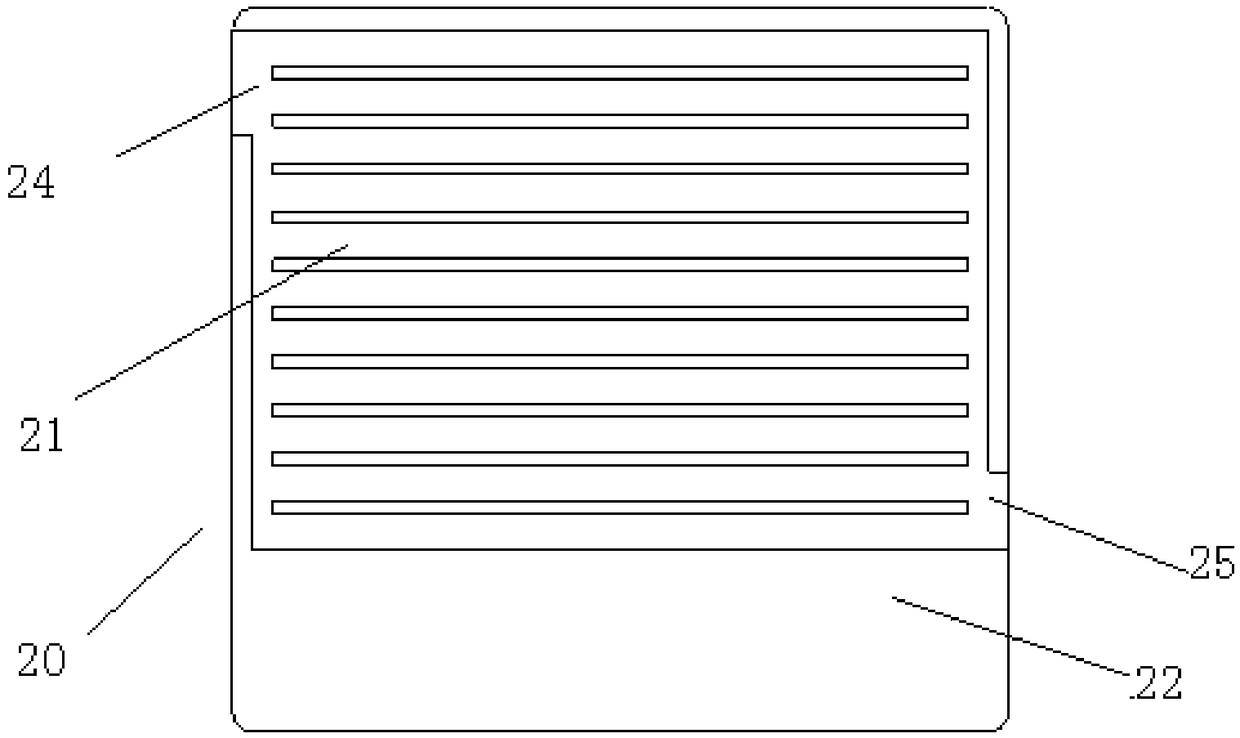

Heat radiation bipolar plate for fuel battery

ActiveCN108110276ARealize self-circulation coolingAvoid complex structuresFuel cellsFuel cellsHydrogen

The invention provides a heat radiation bipolar plate for a fuel battery and belongs to the field of heat control. The heat radiation bipolar plate comprises an oxygen plate and a hydrogen plate, wherein the oxygen plate and the hydrogen plate are buckled to form a hollow structure and are used for storing phase change mediums and radiating heat through phase changes; both the oxygen plate and thehydrogen plate comprise working parts and cooling parts; oxygen distribution runners are arranged on outer surfaces of the working parts of the oxygen plates; hydrogen distribution runners are arranged on outer surfaces of the working parts of the hydrogen plates; insulating coatings are arranged on outer surfaces of the cooling parts and are used for radiating heat outside; phase change medium runners are arranged in the hollow structure. Due to self-circulation cooling of a phase-change medium, the problems that the structure is complex, poor in reliability, and the like because of circulation water cooling, are avoided, and the system reliability is improved.

Owner:BEIJING SATELLITE MFG FACTORY

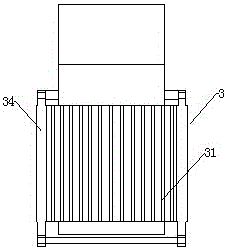

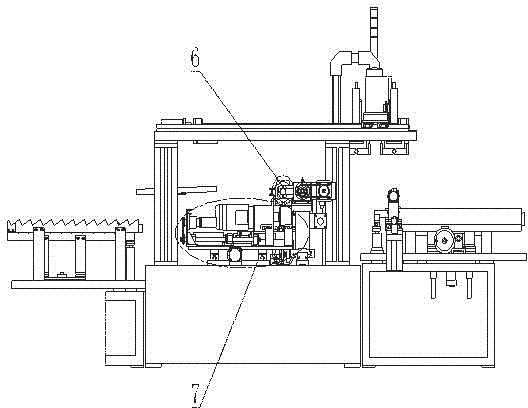

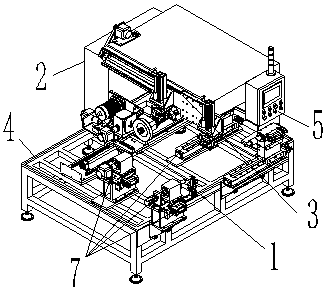

Full automatic toothed rack tooth brushing machine

PendingCN110064798AReduce human interventionLabor savingMeasurement/indication equipmentsFeeding apparatusElectrical controlElectric machinery

The invention discloses a full automatic toothed rack tooth brushing machine, and belongs to the field of precision machining equipment. The full automatic toothed rack tooth brushing machine comprises a tooth surface detection mechanism, a PLC electrical control box, an automatic pouring mechanism, a rack, a touch screen control panel, a toothed rack clamping mechanism and an automatic tooth brushing mechanism. According to the full automatic toothed rack tooth brushing machine, tooth surface automatic recognition and automatic pouring are adopted, linear production requirements are met, andmanpower is saved; automatic pressure compensation can be carried out on abrasion of a steel brush, takt is saved, and manual work amount is reduced; a touch screen is adopted as an artificial interface, setting of operation data is more flexible while operation is simplified, and processing requirements of different workpieces can be met; the tooth surface position is confirmed through a displacement sensor, and full automation is achieved; a servo motor is adopted as a power source of toothed rack rotation, and the tooth surface can be rotated to an optimal tooth brushing angle; a pressure sensor is adopted, pressure applied by the steel brush to a toothed rack is consistent during tooth brushing, and automatic compensation can be achieved after the steel brush is abraded; and a PLC andthe touch screen are adopted for electronic control, and the servo motor and a cylinder are adopted as a power source responsible for all-operation instruction implementation of equipment.

Owner:吉林瑞铭机电设备有限公司

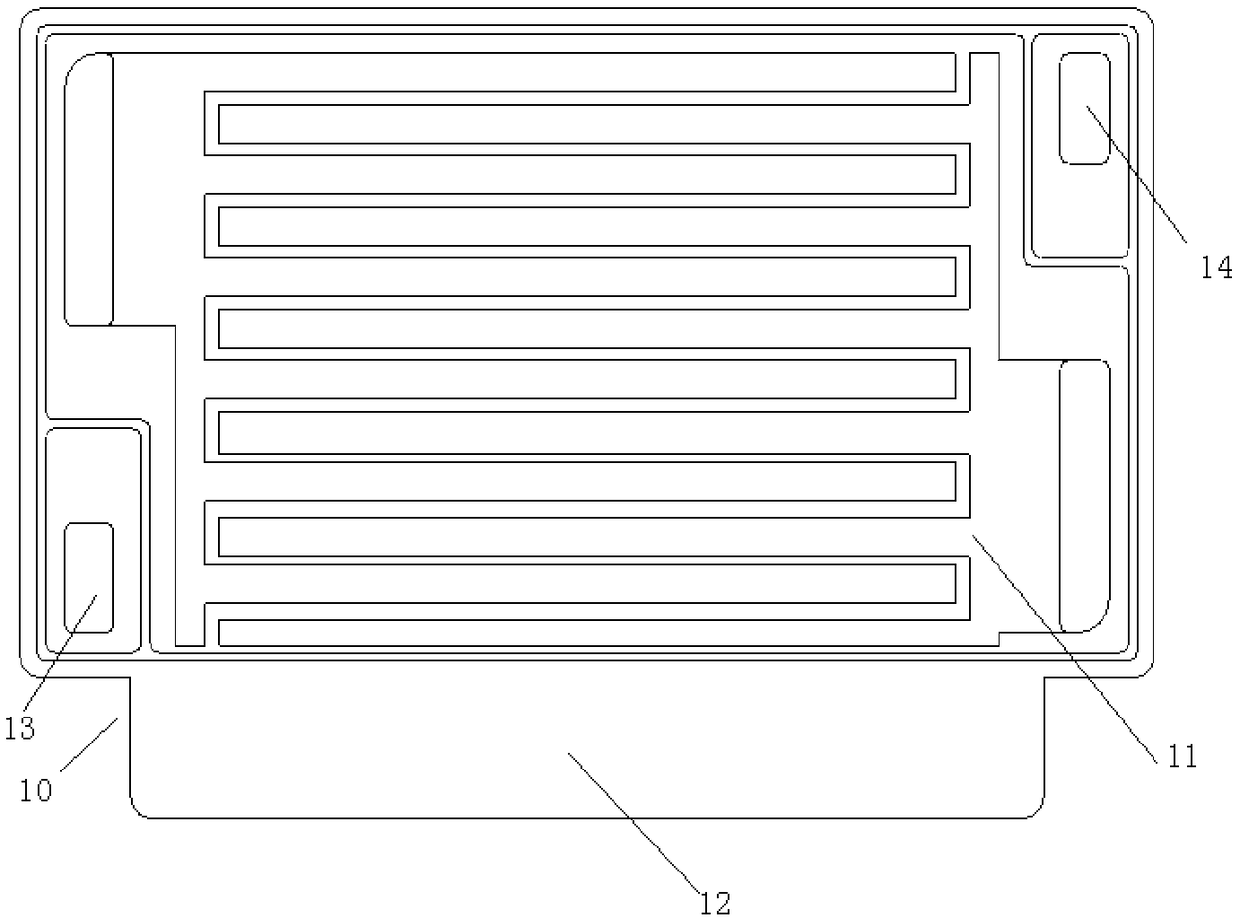

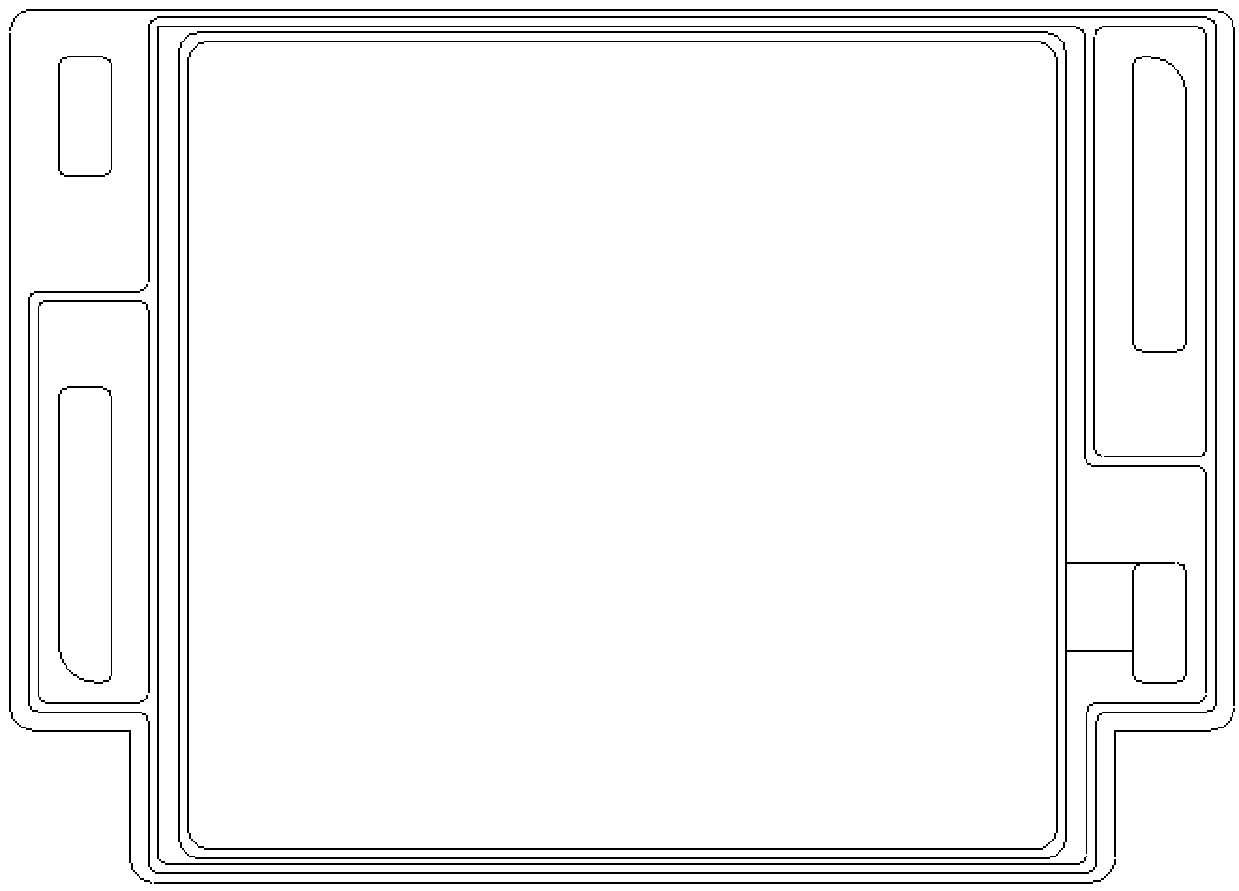

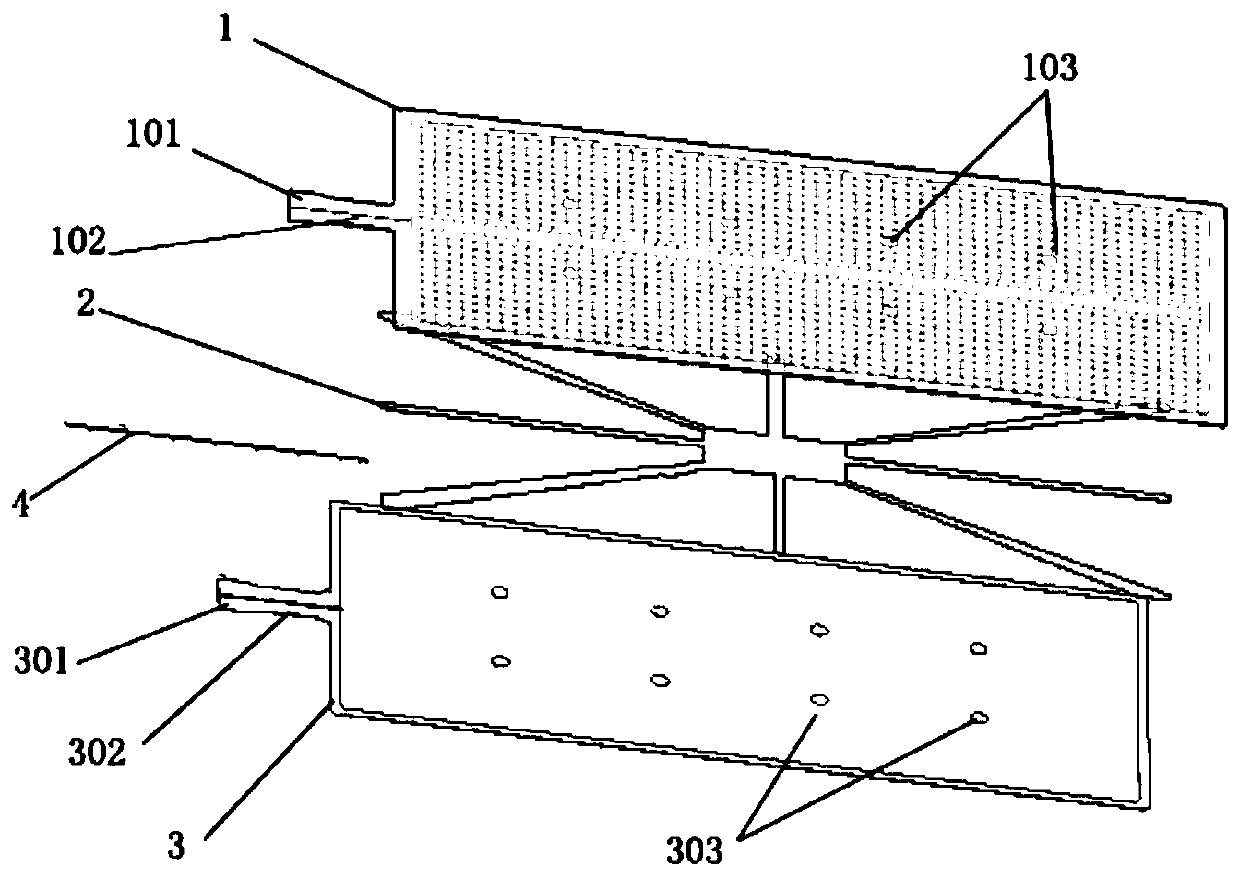

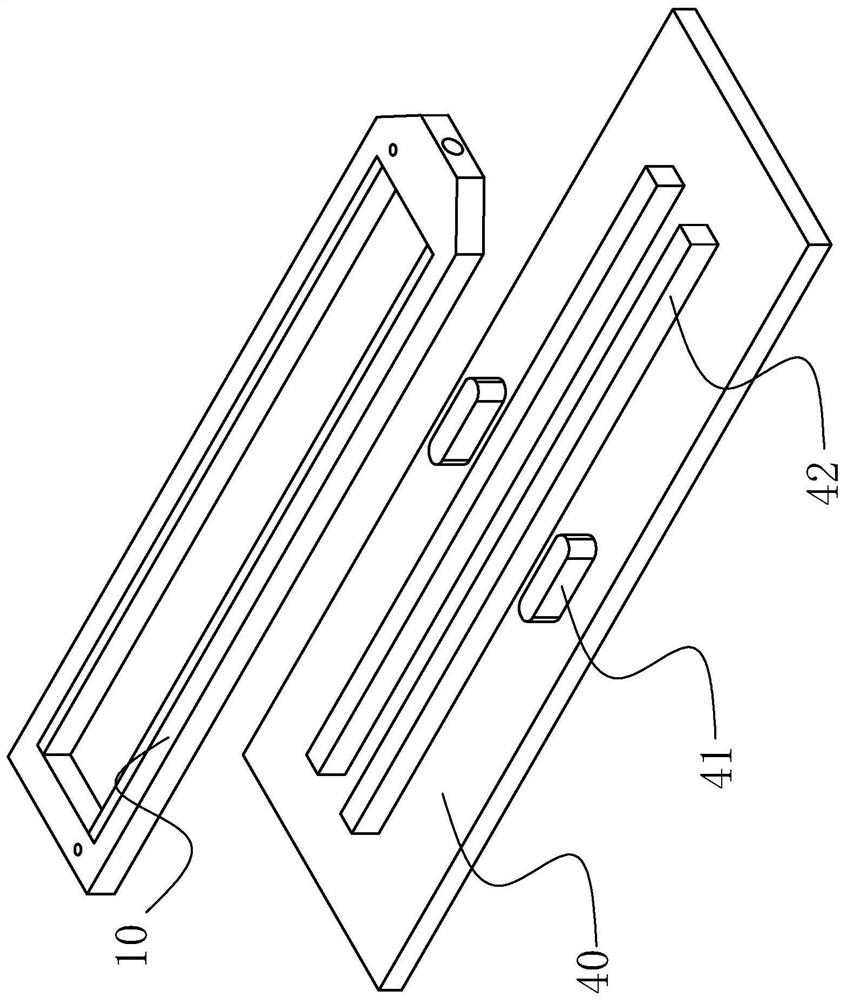

Ultra-thin vapor chamber and manufacturing process thereof

PendingCN111220013AGuaranteed reflowIncrease the flow space of saturated steamIndirect heat exchangersEngineeringPipe

The invention discloses an ultra-thin vapor chamber and a manufacturing process thereof. The vapor chamber comprises a cover plate, a bottom plate and a porous capillary structure arranged between thecover plate and the bottom plate; a plurality of supporting columns are fixedly connected to the inner side wall of the cover plate, and a plurality of buckling parts corresponding to the supportingcolumns are arranged on the inner side wall of the bottom plate; a first protruding part is fixedly arranged at the end of one side of the cover plate, and a first groove is formed in the inner wall of the first protruding part; a second protruding part is fixedly arranged at the end of one side of the bottom plate, a second groove is formed in the inner wall of the second protruding part, and a vacuumizing pipe / liquid injecting pipe is welded between the first groove and the second groove in a penetrating mode; and the porous capillary structure is a special-shaped porous capillary structure, and the porous capillary structure is in an asterisk shape or other shapes. According to the ultra-thin vapor chamber which is large and thin, when the total thickness of products is smaller than 0.4 mm, it is guaranteed that the saturated steam flowing space is increased by 30 %-50 %, and the overall heat dissipation performance can be improved by 30% or above.

Owner:深圳威铂驰热技术有限公司

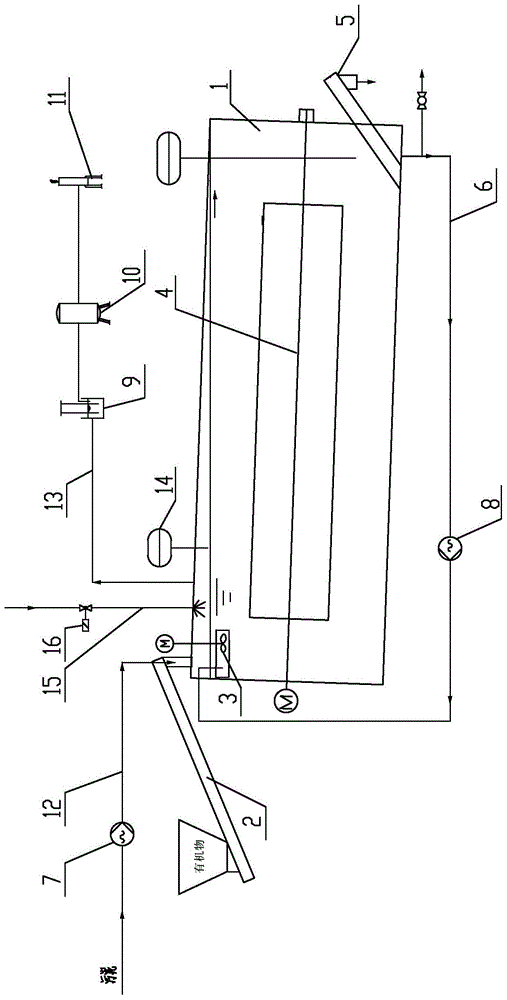

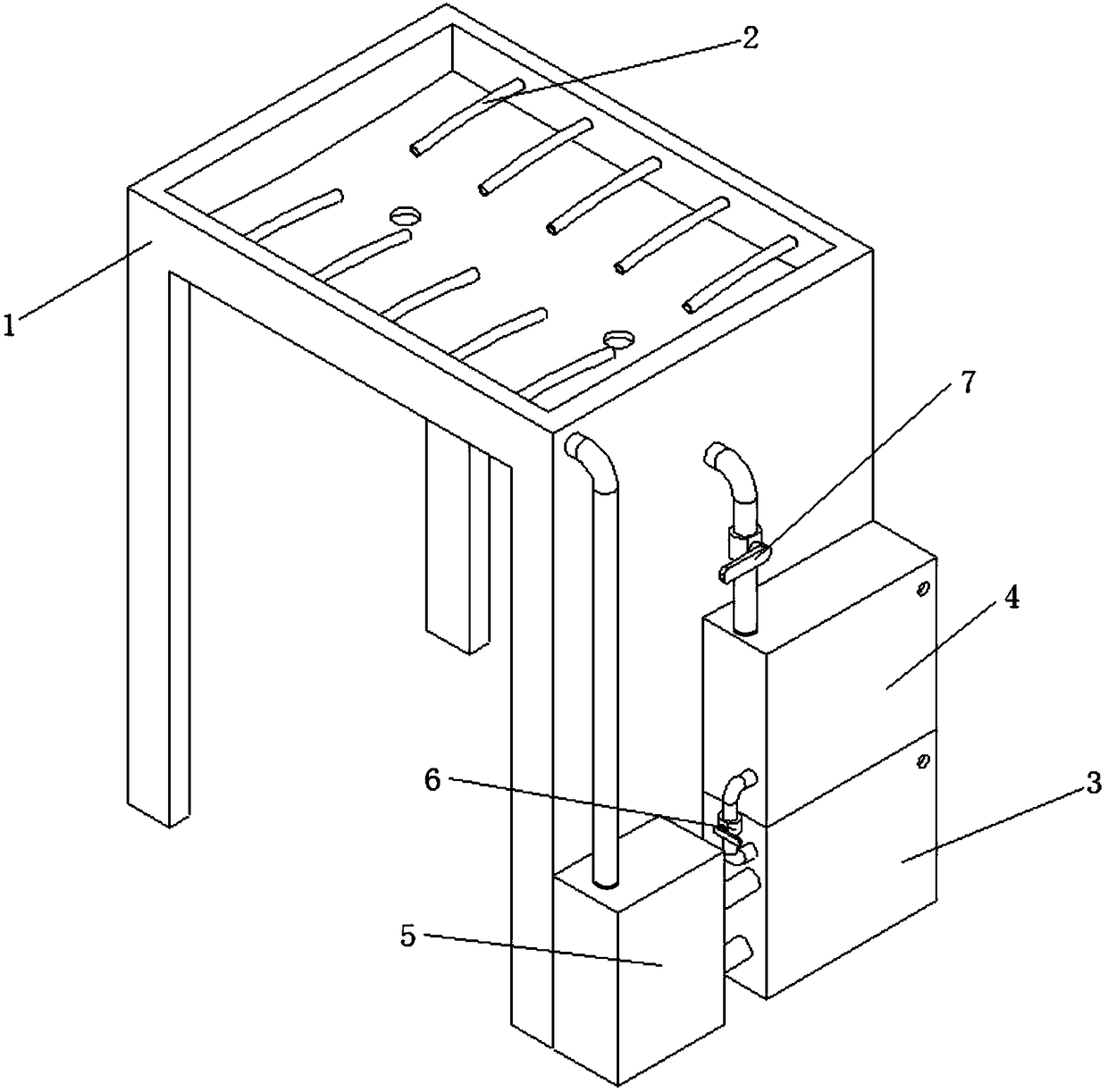

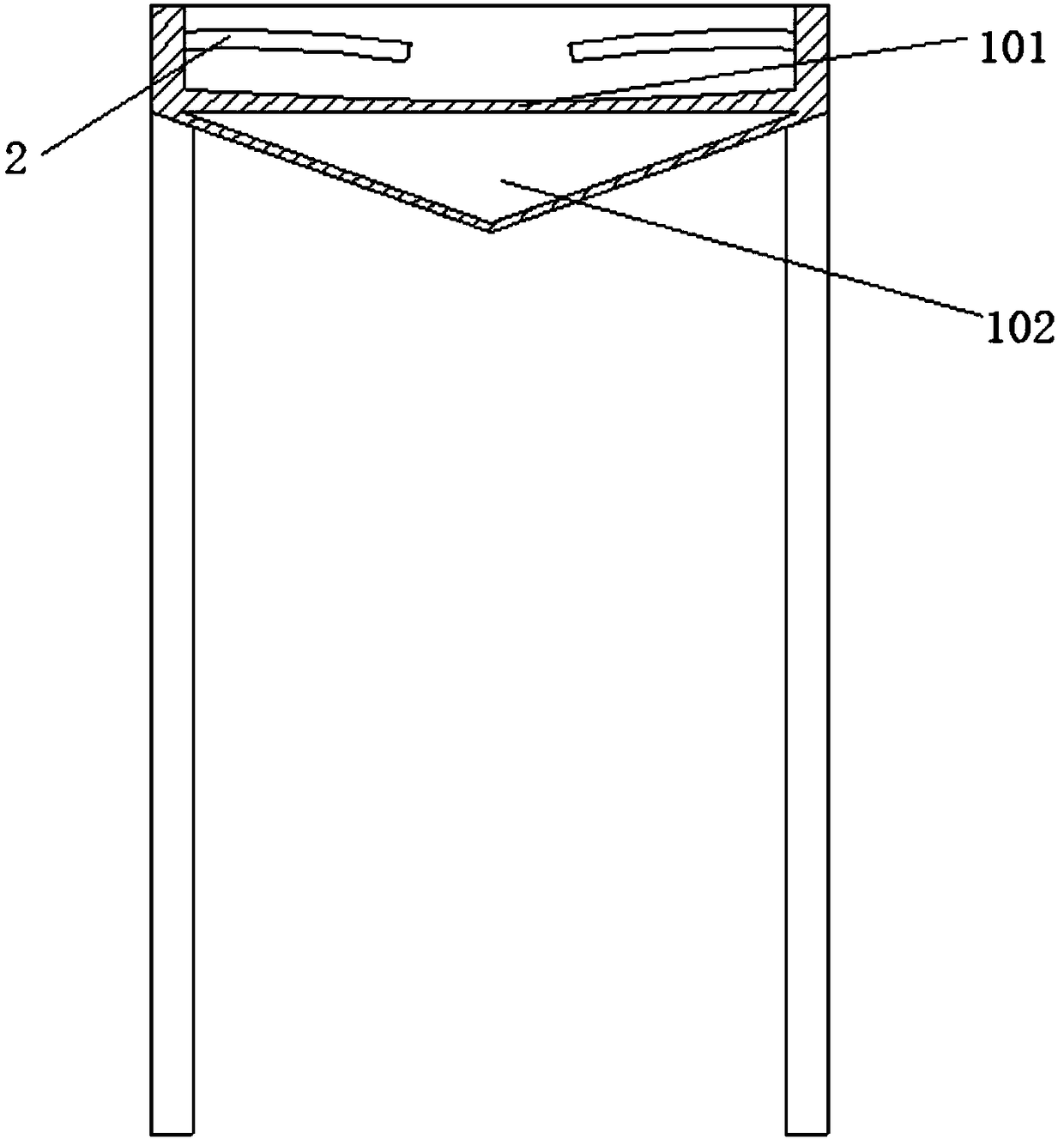

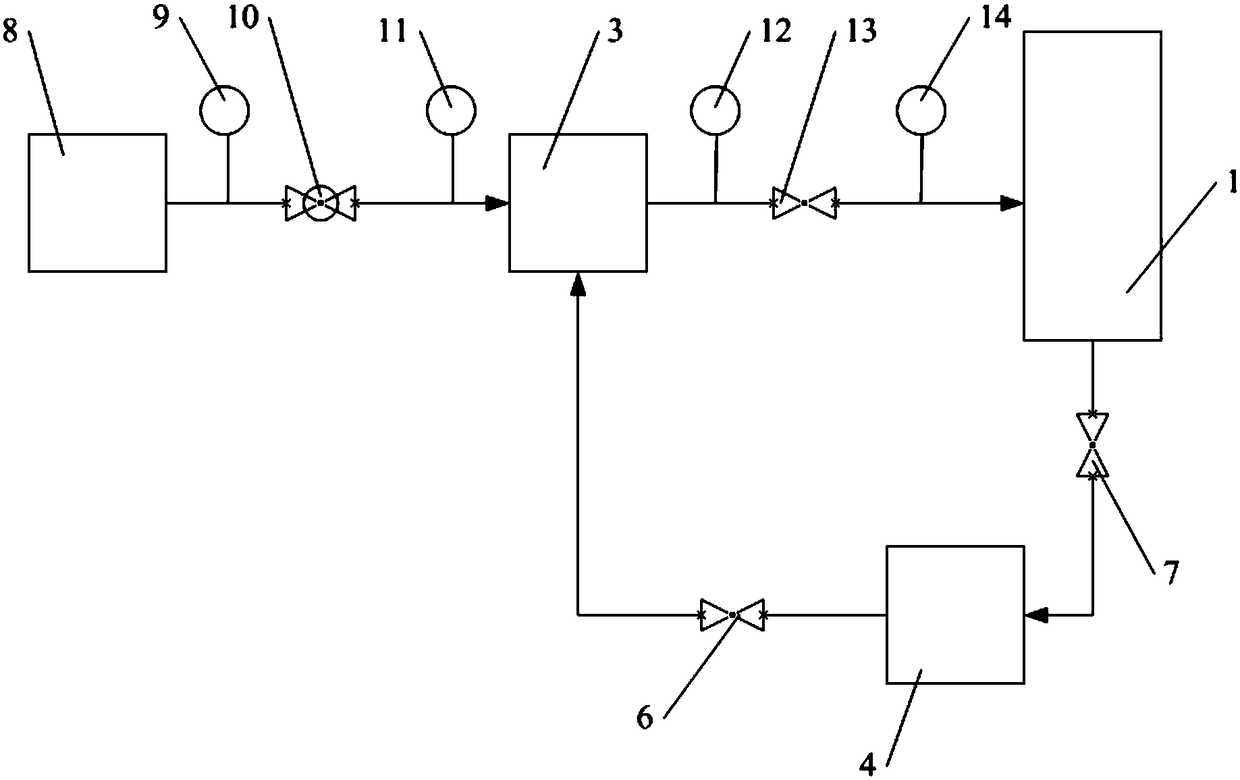

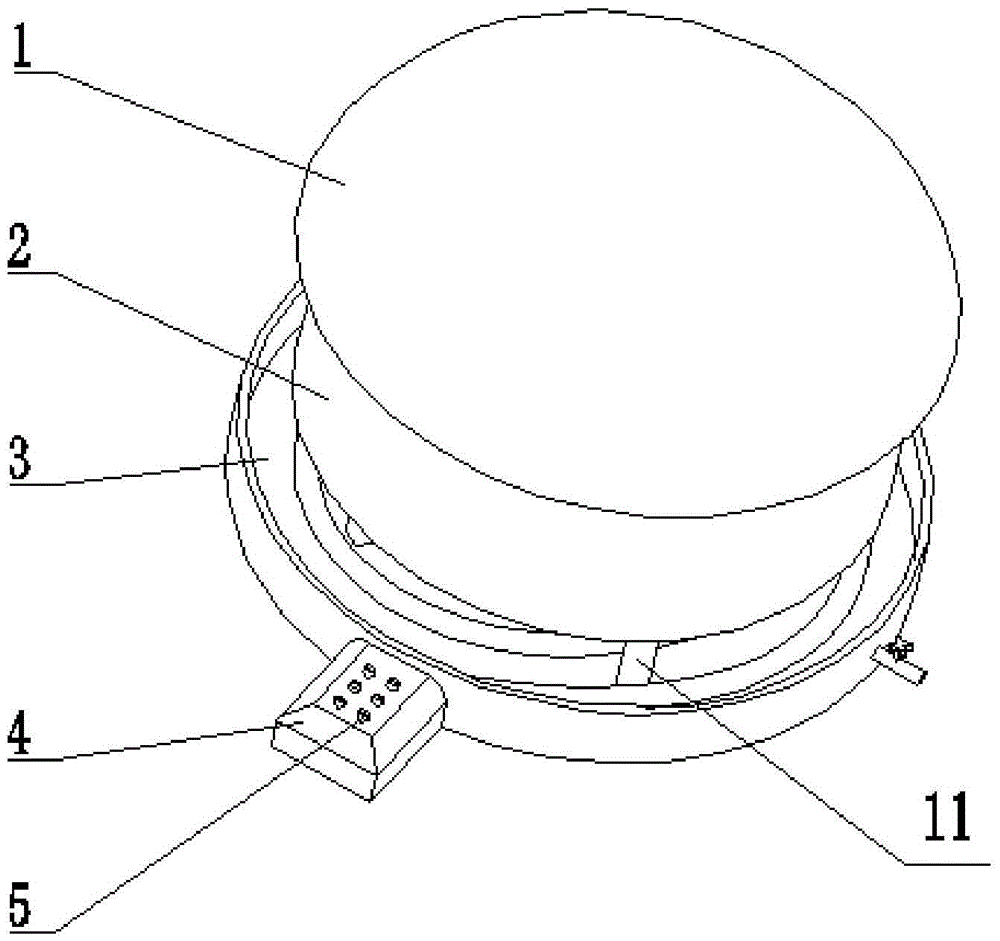

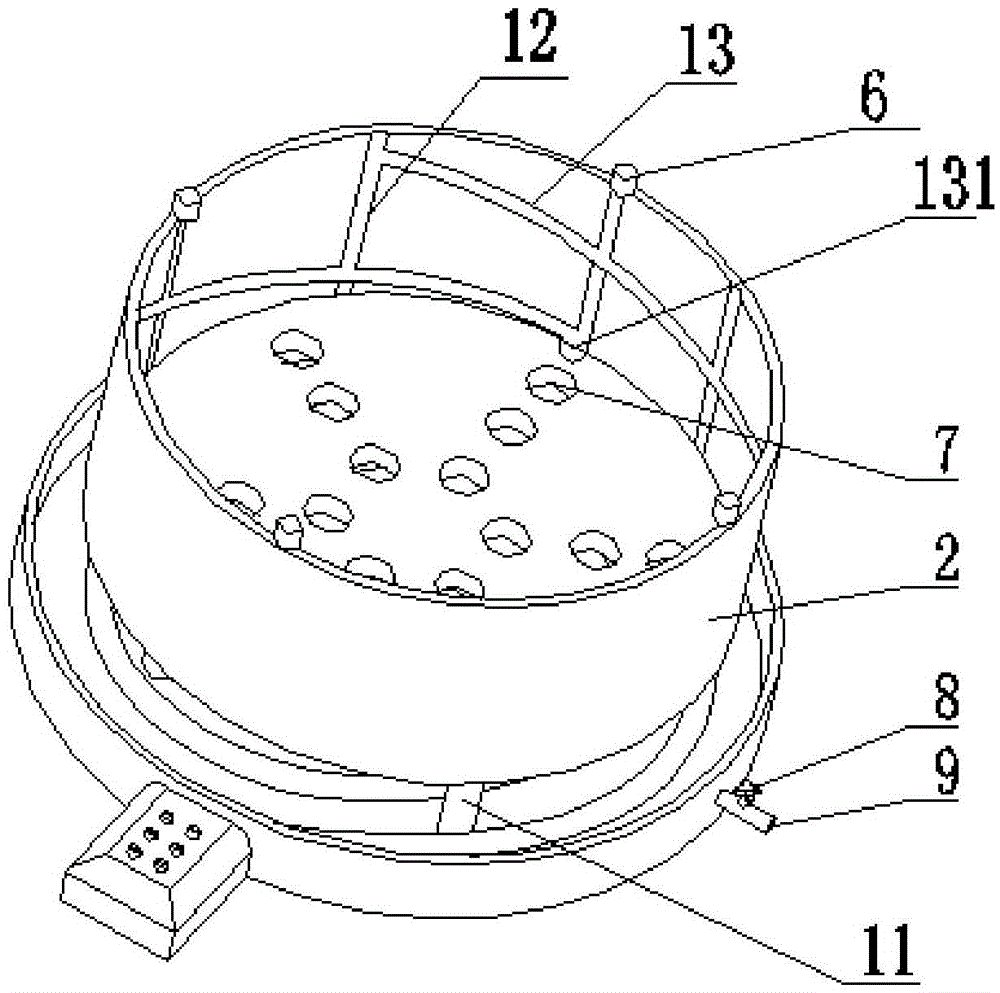

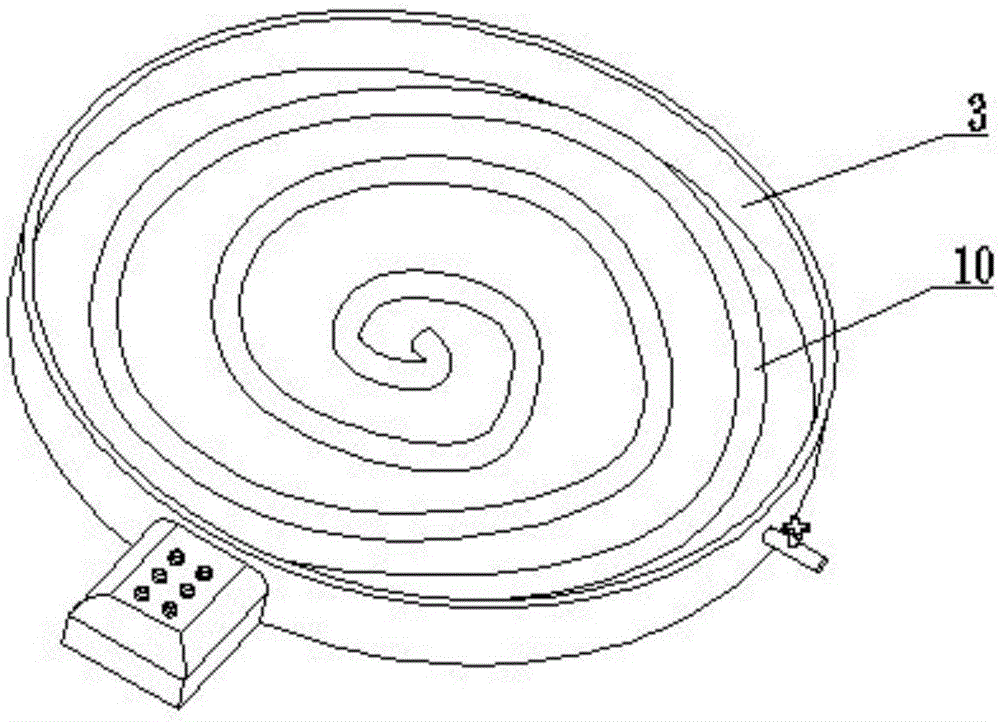

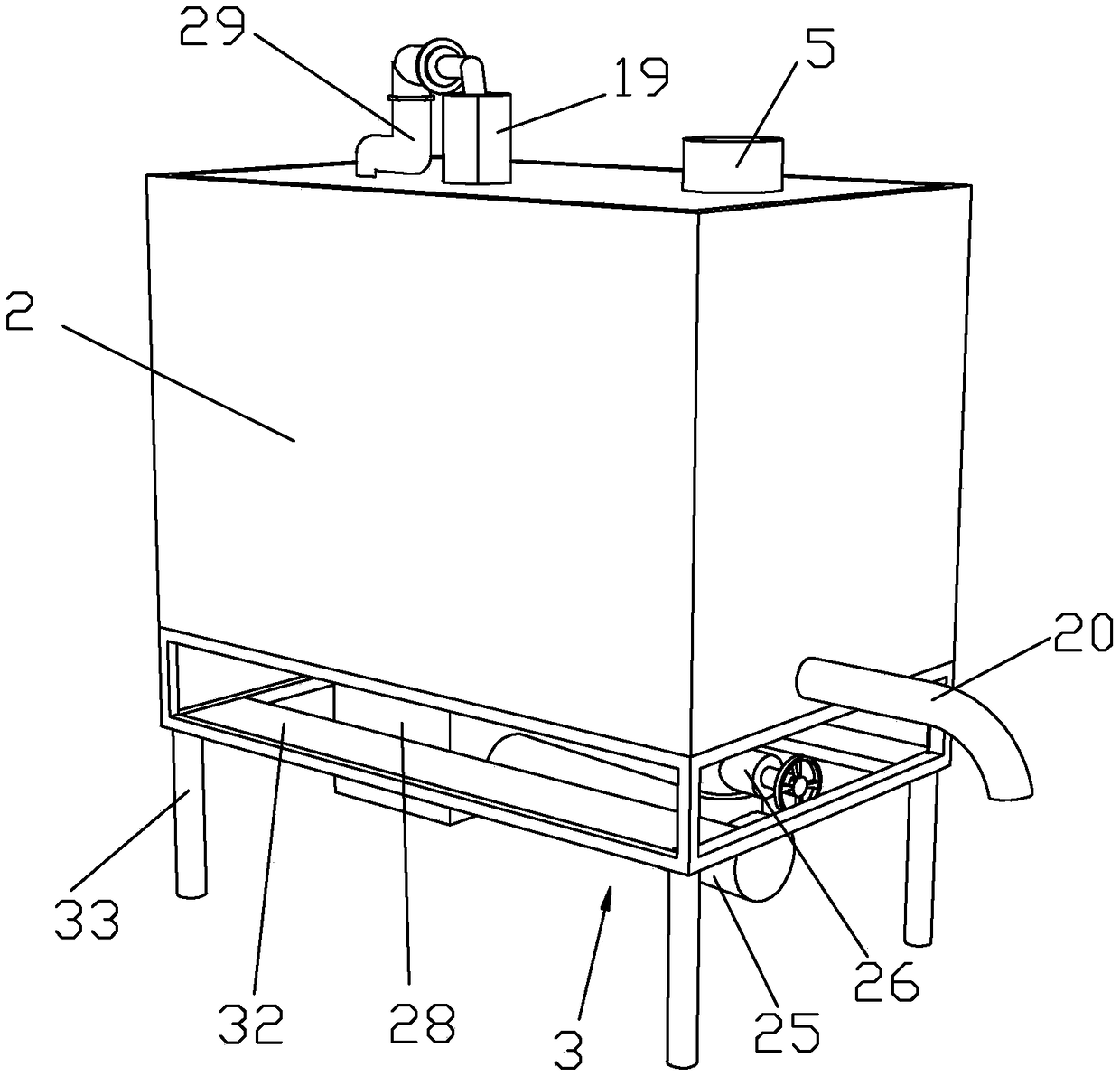

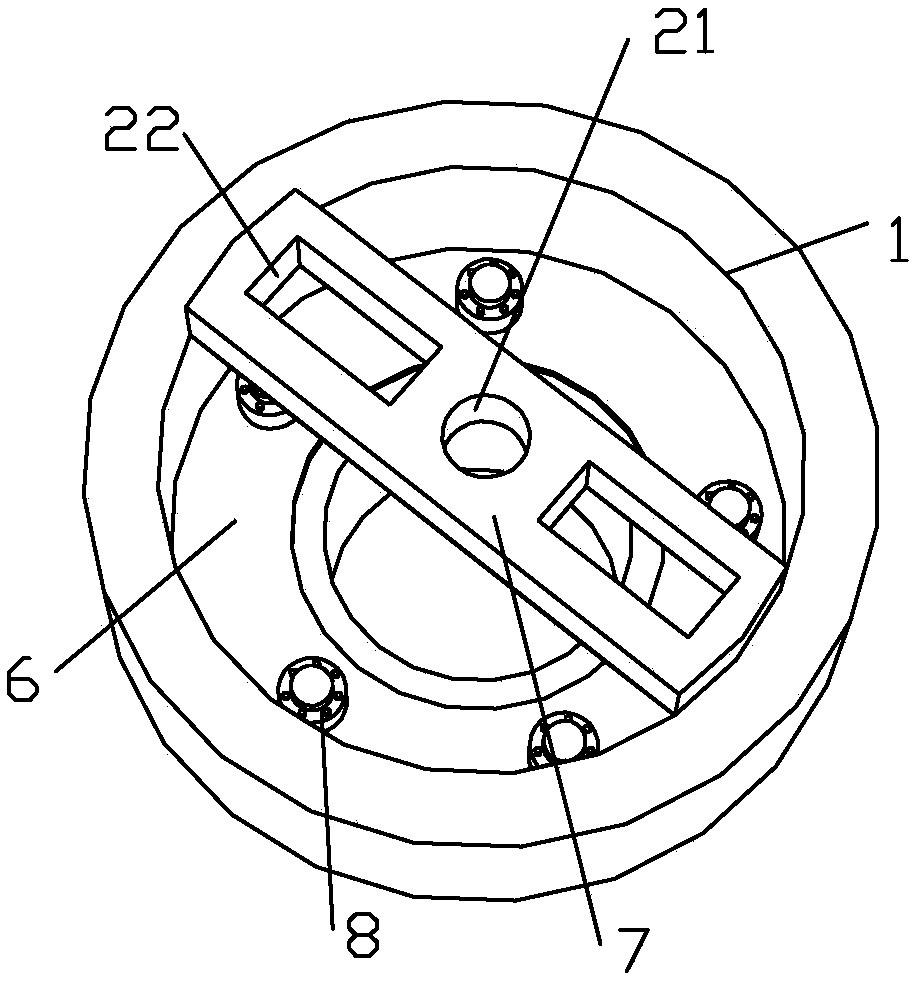

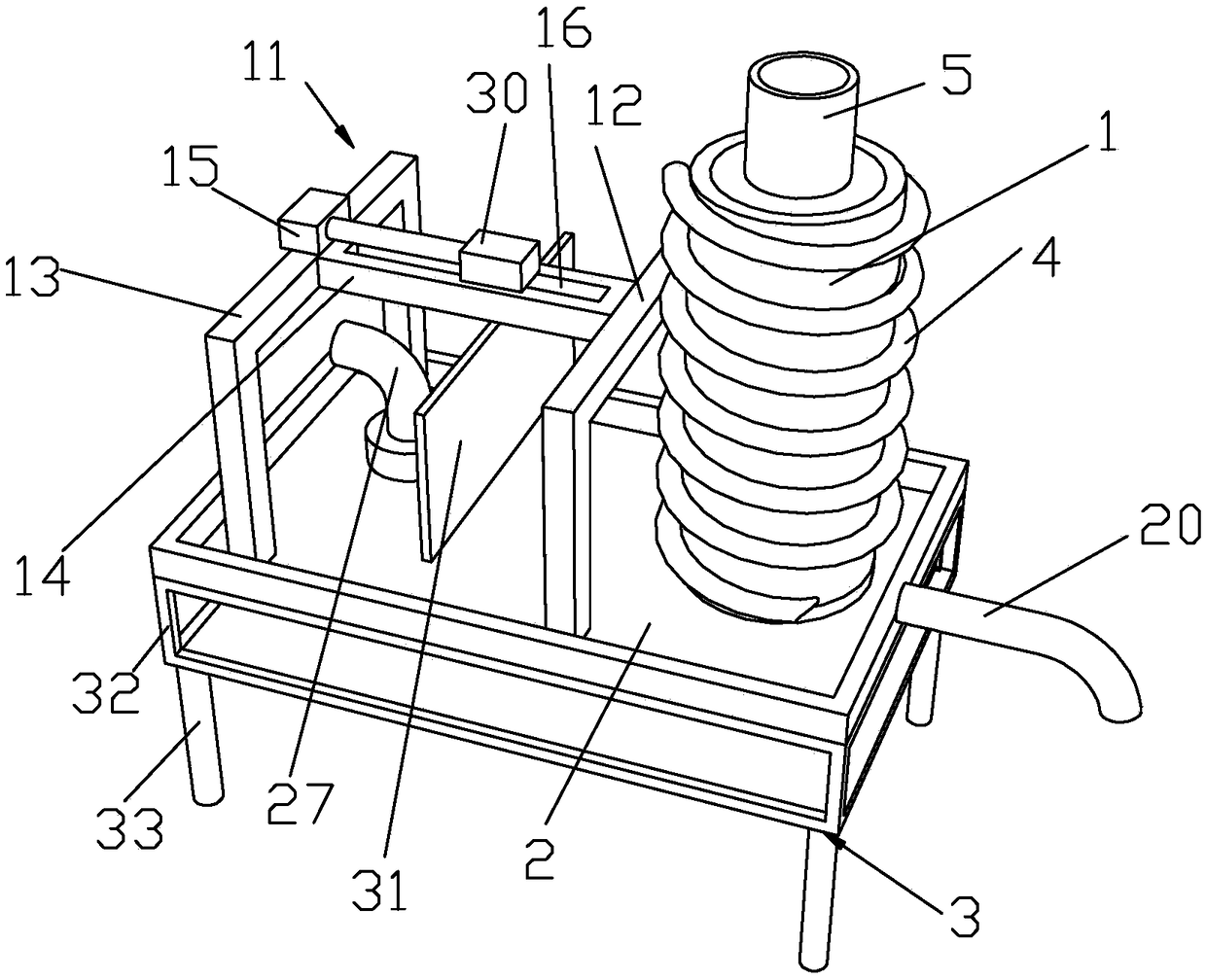

Anaerobic fermentation system and method for producing biogas by carrying out sludge digestion reaction through anaerobic fermentation system

ActiveCN104673629AGuaranteed long stayGuaranteed reflowBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeDigestion

The invention relates to the technical field of waste treatment and in particular relates to an anaerobic fermentation system and a method for producing biogas by carrying out a sludge digestion reaction through the anaerobic fermentation system. The anaerobic fermentation system comprises a fermentation tank, wherein the fermentation tank is of a sealed structure, and a horizontal stirring device is arranged inside the fermentation tank; a feeding end and a discharging end are respectively arranged at two ends of the fermentation tank in the horizontal direction; a biogas pipe is arranged on the top of the fermentation tank; a feeding hole is formed in the top, which is close to the feeding end, of the fermentation tank; the feeding hole is respectively connected with a feeding screw conveying device and a sludge conveying pipeline; a device for stirring and mixing the materials is arranged below the feeding hole and inside the fermentation tank; a discharge opening is formed in the discharging end and is connected with the screw conveying device; a return pipeline is arranged on one side of the discharging end; and the other end of the return pipeline is connected with the feeding end. The system has the advantages of small size, reasonable design, continuous operation and the like.

Owner:AQSEPTENCE GRP HANGZHOU CO LTD

Teaching device used for simulating ligation of artery blood vessel of human body

The invention discloses a teaching device used for simulating ligation of an artery blood vessel of a human body, and belongs to the technical field of medical simulation teaching devices. The teaching device comprises a test bed, simulated blood vessels, a simulated blood storage tank and a pressurization device, wherein a cofferdam is arranged on the test bed; a plurality of simulated blood vessels are arranged in the cofferdam; the simulated blood vessels are connected with the simulated blood storage tank; and the pressurization device is connected with the simulated blood storage tank. The pressurization device is used for supplying stable pressure of a simulated human body to the simulated blood storage tank, so that the problem of a gravitational flow type device in the prior art that the bleeding pressure and the flow velocity change due to the increase of the amount of bleeding as the blood pressure and the blood flow velocity change with the height of a blood bag is solved, so that the simulation test teaching is closer to an actual situation, and an effect of simulation teaching is improved.

Owner:SECOND AFFILIATED HOSPITAL OF XIAN MEDICAL UNIV

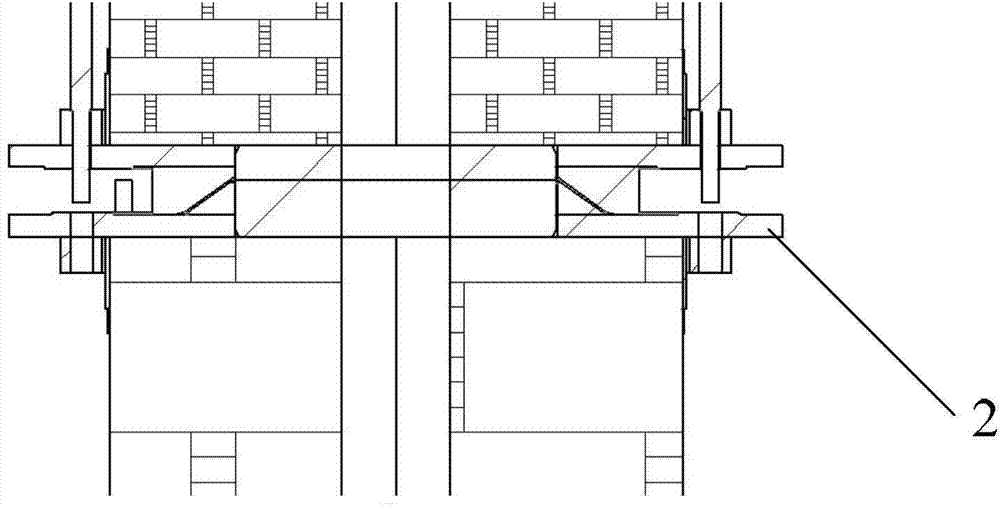

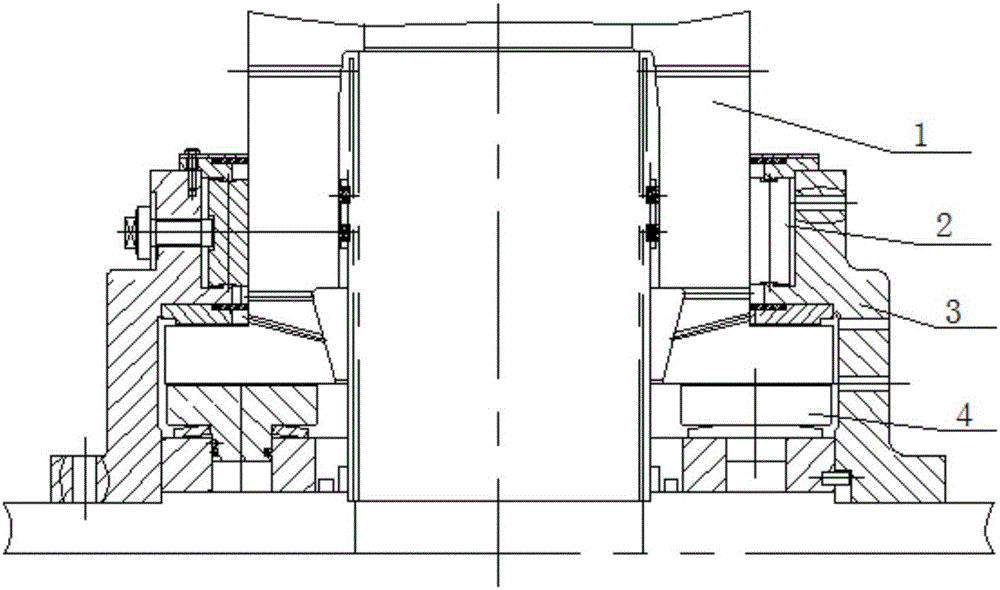

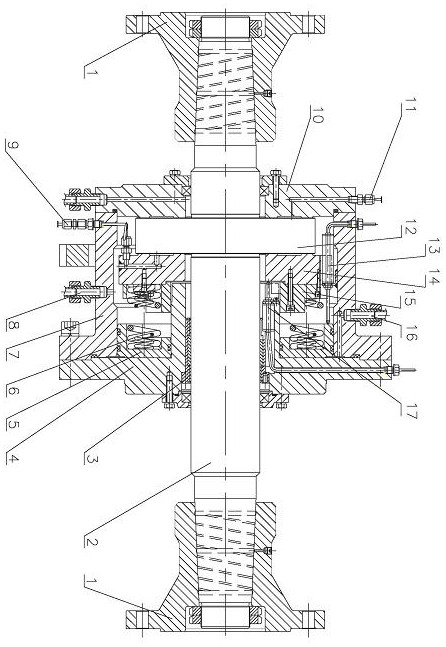

Vertical type thrust sliding bearing

InactiveCN106640968ABearings are compactApplicable to a wide range of working conditionsBearingsHigh pressureOil distribution

The invention discloses a vertical type thrust sliding bearing. The vertical type thrust sliding bearing comprises a thrust head, a guide tile, a guide bearing seat, a thrust tile, a thrust disc and a high-pressure oil system, wherein the guide tile sleeves the outer part of the lower section of the thrust head; the guide tile is mounted in the guide bearing seat; the thrust tile and the thrust disc are mounted in the guide bearing seat and are located at the lower end of the thrust head; the high-pressure oil system comprises a thrust tile oil injection device, a high-pressure oil inlet pipe, a high-pressure oil ring pipe and splitters; one end of the high-pressure oil inlet pipe is communicated with the high-pressure oil ring pipe; the plurality of splitters are arranged and are mounted at the top of the guide bearing seat at intervals; the high-pressure oil ring pipe is communicated with the splitters; the thrust tile oil injection device comprises a plurality of high-pressure oil distribution pipes and a high-pressure oil integrated receiving pipe; one end of each high-pressure oil distribution pipe is communicated with the corresponding splitter and the other ends of the high-pressure oil distribution pipes are communicated with the high-pressure oil integrated receiving pipe; the high-pressure oil integrated receiving pipe is inserted into an oil hole of the thrust tile. The vertical type thrust sliding bearing disclosed by the invention is compact in structure, wide in applicable working condition range and high in economical efficiency.

Owner:HUNAN CHONGDE IND TECH

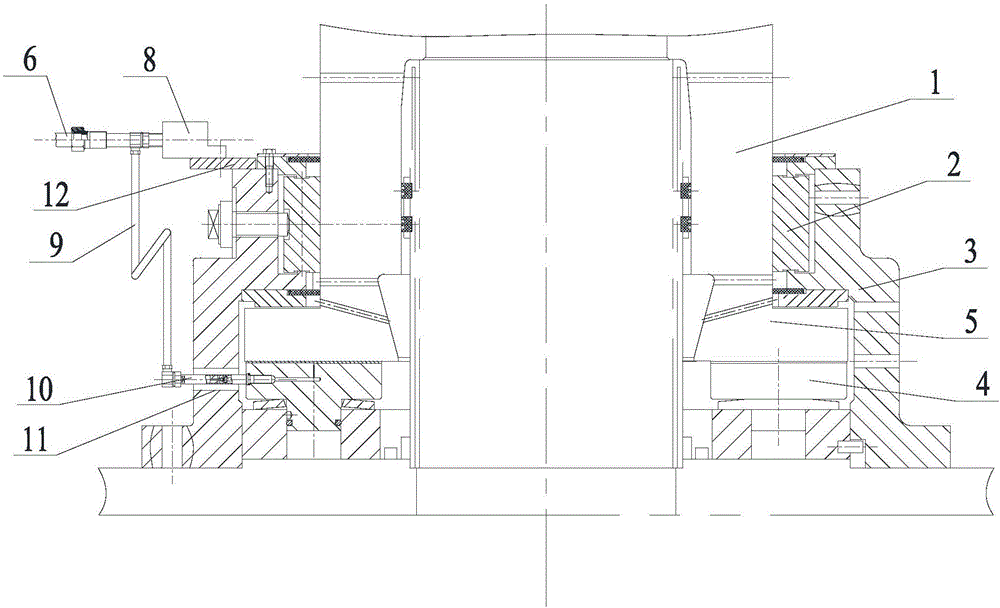

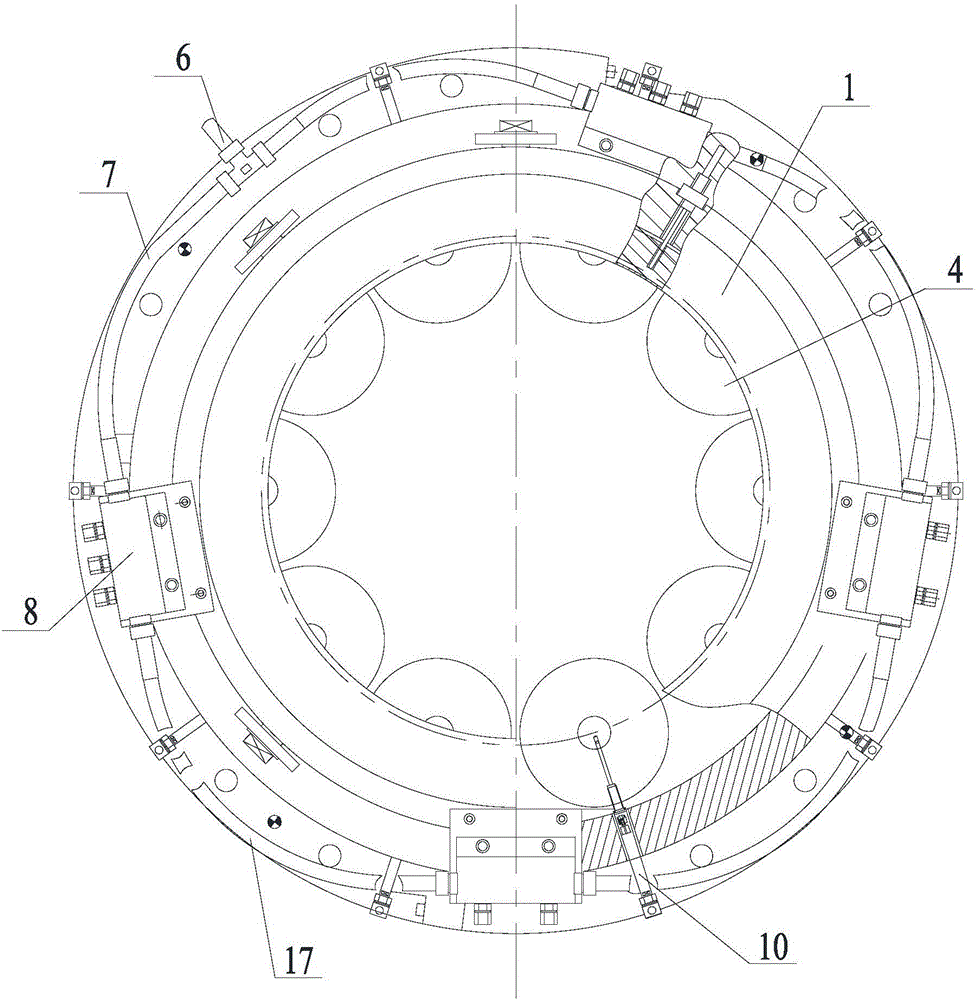

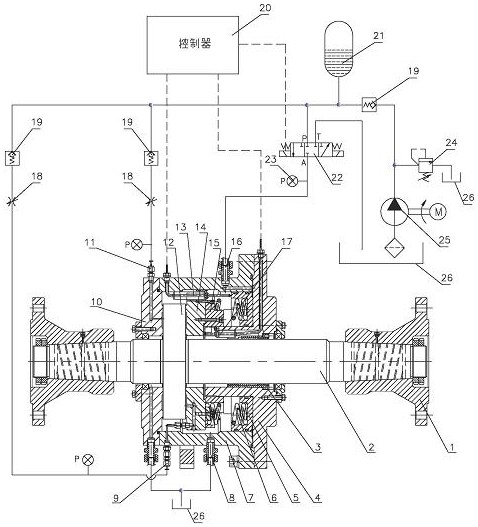

Automatic displacement compensation thrust bearing

PendingCN112046721AHigh displacement accuracyHigh compensation accuracyPropulsive elementsPropulsive transmissionAxial displacementHydraulic pump

The invention discloses an automatic displacement compensation thrust bearing which comprises a thrust shaft and a thrust disc. One side of the thrust disc is supported on the inner side face of a left end plate in a sliding mode, a thrust block is supported on the other side face of the thrust disc in a sliding mode, and a displacement compensation piston is arranged in a bearing shell in a sliding mode. A compensation damping spring is supported between the thrust block and the inner end of the displacement compensation piston. A thrust block displacement sensor is arranged on the thrust block, and a piston displacement sensor is arranged on the displacement compensation piston. An oil outlet of a hydraulic pump communicates to a pressure oil port P of a hydraulic reversing valve, a portA of the hydraulic reversing valve leads to a hydraulic oil cavity between the displacement compensation piston and a right end plate, and an oil return port T of the hydraulic reversing valve is connected to an oil tank. The piston displacement sensor and the thrust block displacement sensor are electrically connected with an automatic controller, and the automatic controller is electrically connected with the hydraulic reversing valve. The automatic displacement compensation thrust bearing not only can automatically compensate axial displacement of the thrust shaft, but also can effectivelyreduce structural vibration of the bearing.

Owner:DONGTAI VESSEL FITTINGS

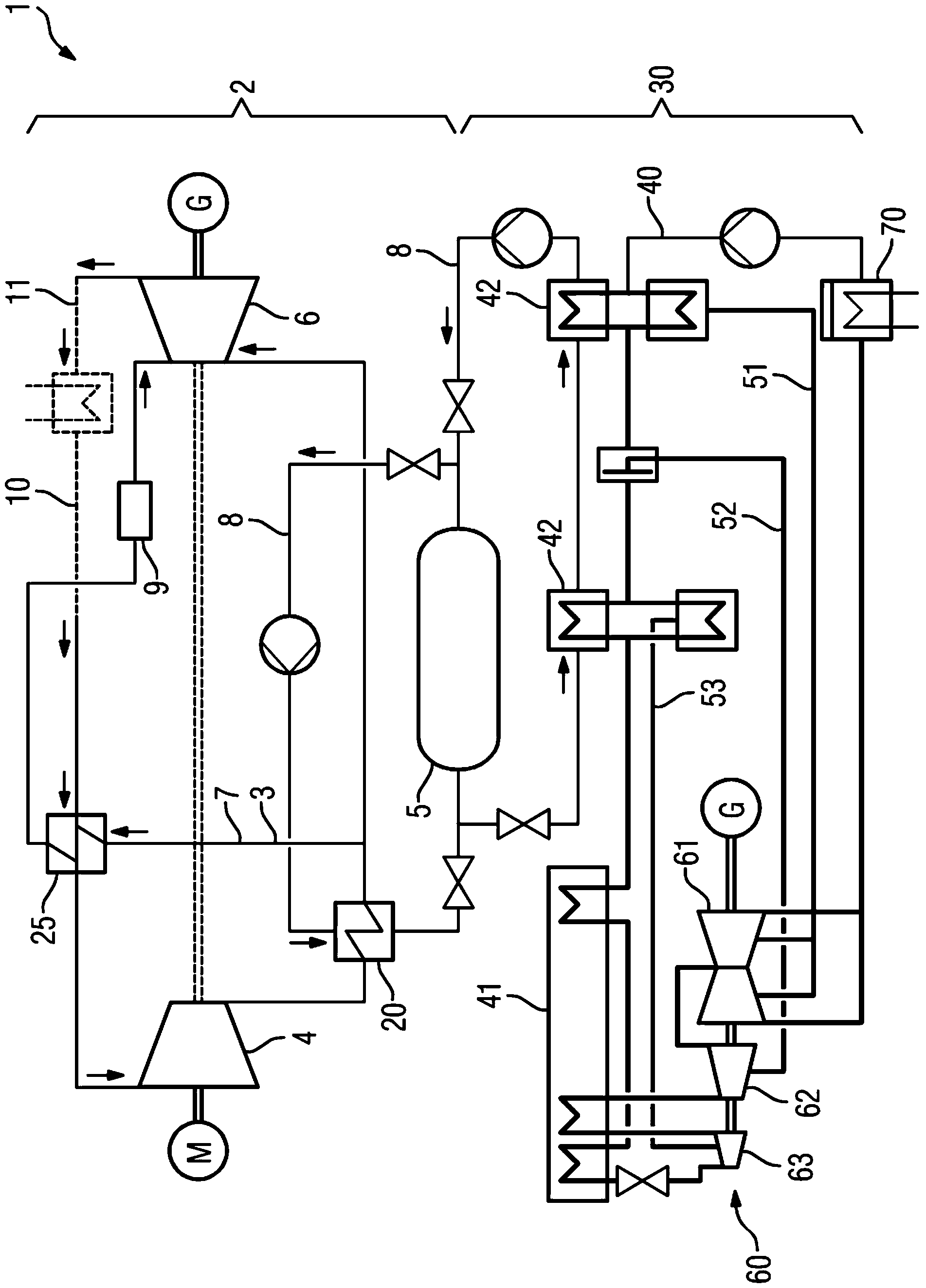

Energy storage apparatus for the preheating of feed water

InactiveCN104234761ATemperature level changesGuaranteed reflowSafety/regulatory devicesSteam engine plantsThermal energyEngineering

The invention relates to an energy storage apparatus for the storage of thermal energy. The energy storage apparatus is equipped with a charging circuit, having a compressor, a heat store and an expansion turbine, the compressor connected on the outlet side to the inlet of the expansion turbine via a first pipe for a first working gas, and the heat store inserted into a second pipe, and the first pipe connected to a first heat exchanger, by means of which the first pipe and the second pipe are coupled in thermal thechnology, and, furthermore, having a discharge circuit which has a water / steam circuit equipped with a steam generator and which has at least one feed water preheater preceding the steam generator with respect to the direction of flow of the water in this water / steam circuit, and thermal coupling between the charging circuit and discharge circuit achieved by the feed water preheater, in particular achieved solely by the feed water preheater.

Owner:SIEMENS AG

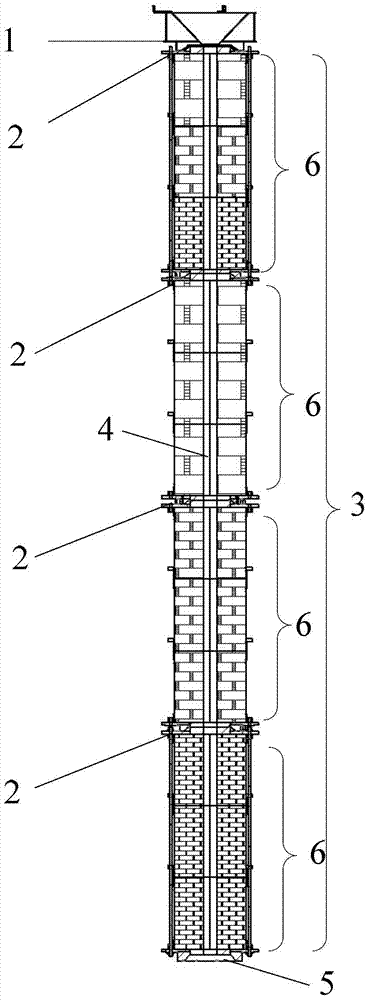

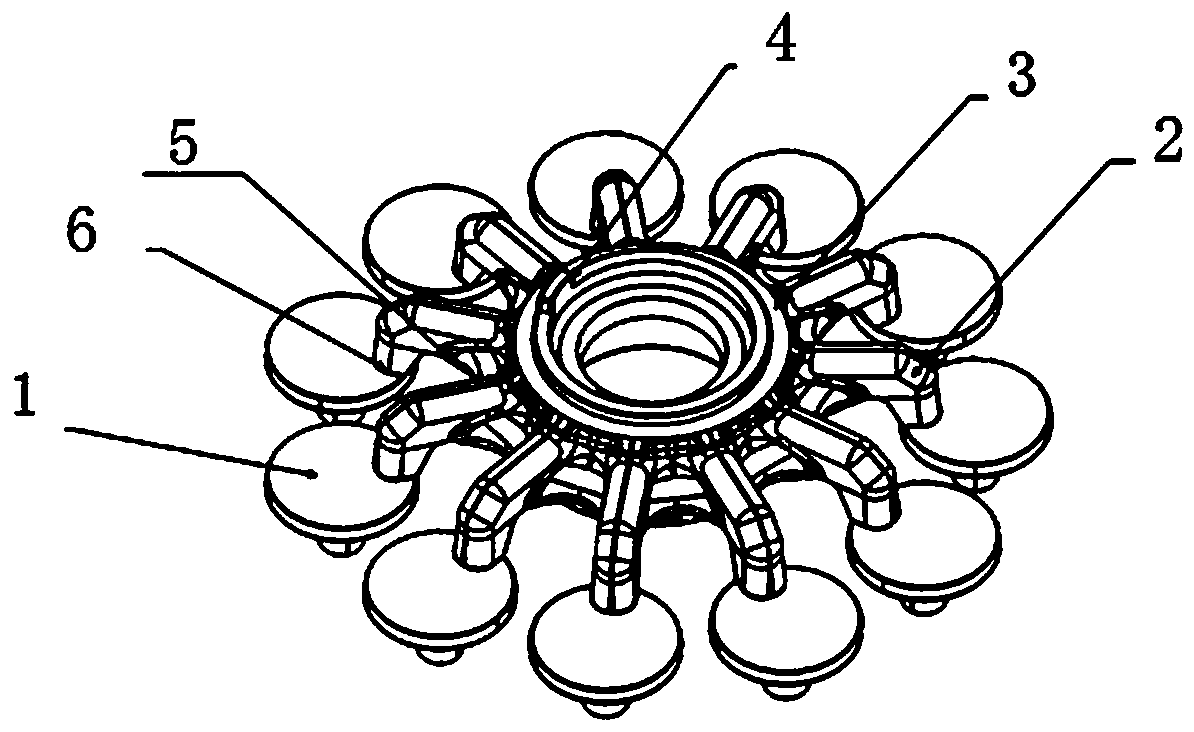

Wax mold structure for vacuum suction casting

The invention relates to a wax mold structure for vacuum suction casting. The wax mold structure comprises a main pouring gate and casting wax molds dispersed around the main pouring gate. Each of themultiple casting wax molds surrounds the main pouring gate to form a layer of casting wax mold assembly, and the casting wax mold assemblies are overlapped through inlaid structures. The multiple casting wax mold assemblies are overlapped to form the cylindrical wax mold structure, an upper cover is arranged at the top of the wax mold structure, and a base is arranged at the bottom of the wax mold structure. The casting wax molds and the main pouring gate are connected through inner pouring gates. According to the wax mold structure, the mold precision is greatly improved, liquid backflow isavoided, the casting quality can be improved easily, meanwhile, the casting wax mold assemblies can be overlapped, the manufacturing speed of a wax tree is fast increased, sticky wax connection is notneeded, and operation is simple and fast.

Owner:SHANGHAI SINOTEC

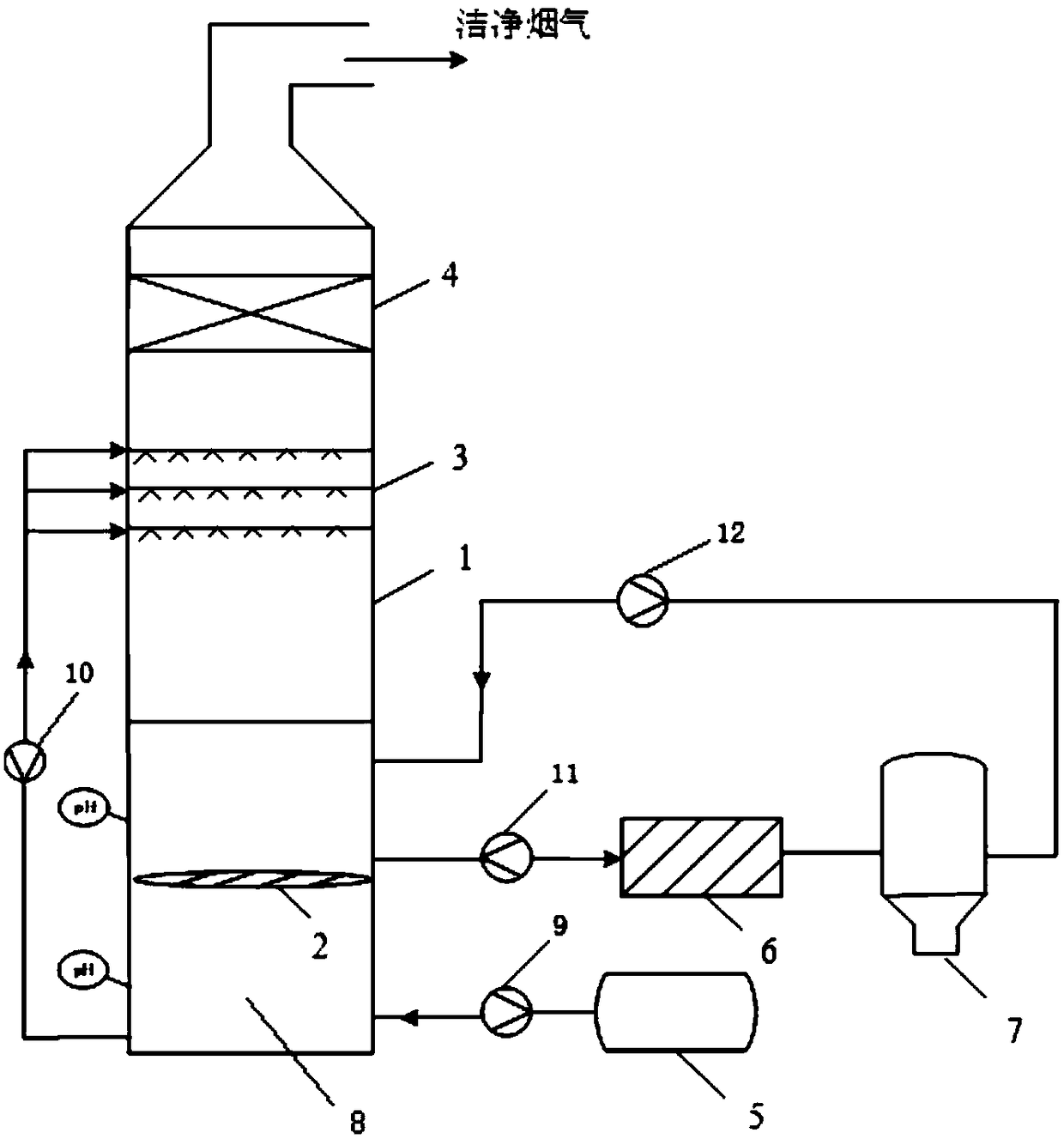

Treatment system and method for nitrite and nitrate absorption liquid after wet flue gas denitration

ActiveCN109173642ARealize resource utilizationAchieve recyclingAmmonium nitratesUsing liquid separation agentResource utilizationEvaporation

The invention relates to a treatment system and method for a nitrite and nitrate absorption liquid after wet flue gas denitration. The system comprises a desulfurization tower, an absorption liquid supply system and a by-product separation and recovery system. The top in the desulfurization tower is provided with a direct discharge chimney, the bottom in the desulfurization tower is provided witha slurry tank, a spray layer is arranged between the direct discharge chimney and the slurry tank, a slurry double-zone division sieve plate is arranged in the slurry tank and divides the slurry tankinto a lower absorption zone and an upper self-decomposition reaction zone, the absorption zone is communicated with the absorption liquid supply system and is communicated with a spray pipe of the spray layer, and the by-product separation and recovery system comprises a nitrate evaporation crystallizer and a nitrate solid-liquid separator which are sequentially communicated to the self-decomposition reaction zone. The treatment method comprises wet denitration and absorption liquid denitrification. The treatment process is free of other reactants and treatment devices. The method is simple,does not cause secondary pollution and realizes the resource utilization of the product and the recycling of the additive.

Owner:HUANENG POWER INT INC +1

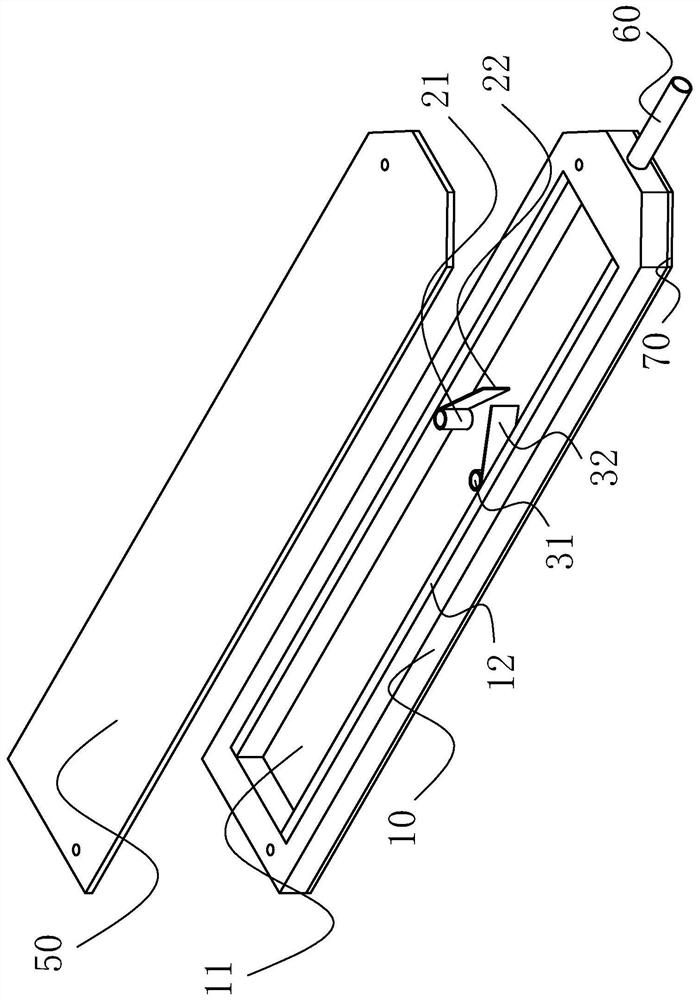

Middle core wire oiling device for wire and cable production

ActiveCN112435803AGuaranteed reflowReduce wasteClimate change adaptationCable/conductor manufactureDrive shaftStructural engineering

The invention discloses a middle core wire oiling device for wire and cable production, and relates to the technical field of wire and cable production equipment, the middle core wire oiling device comprises a bottom plate, a vertical plate and a support plate, the vertical plate is fixedly connected to the left end of the bottom plate, and the upper end of the vertical plate is fixedly welded with a transverse plate and fixedly connected to the bottom plate; a guide plate is fixedly connected to the upper end of the support plate; and the vertical plate is provided with a wire inlet, the right side of the vertical plate is rotationally connected with main belt rollers which are symmetrical front and back, and auxiliary belt rollers are arranged below the main belt rollers. Compared with the prior art, the oiling device has the beneficial effects that through rotation of the driving shaft of the lead mechanism, the driving lever intermittently keeps the conveying belt at different positions under the action of the eccentric wheel to oil a central core wire, the oil immersion roller enables the conveying belt and the oil cloth to be stained with oil in the opening box, and meanwhile, the auxiliary belt rollers on the two sides play a role in extrusion; and by means of the mode, oiling is even, waste of oil is effectively reduced, and production cost is saved.

Owner:SHANDONG QUANXING YINQIAO OPTICAL & ELECTRIC CABLE SCI & TECH DEV

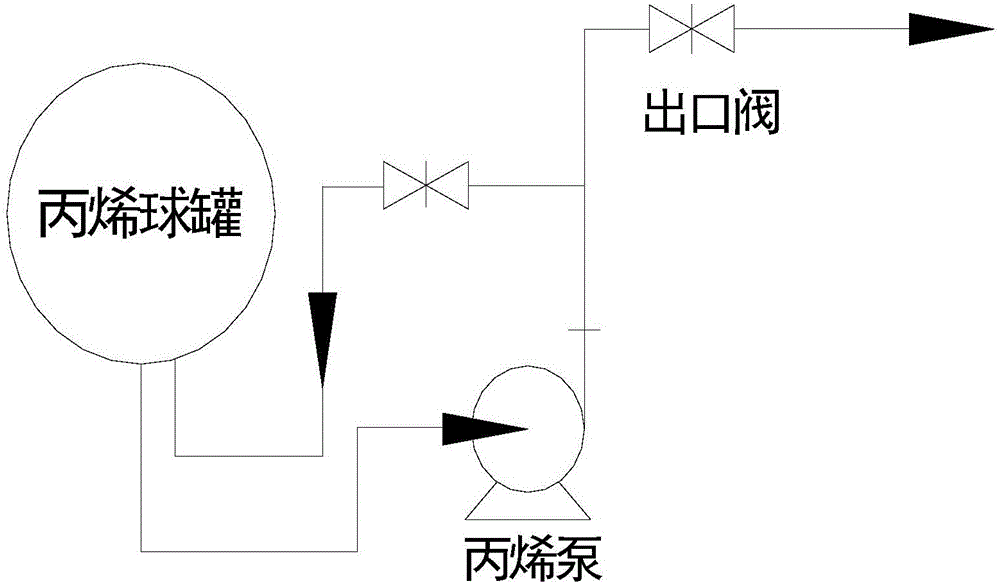

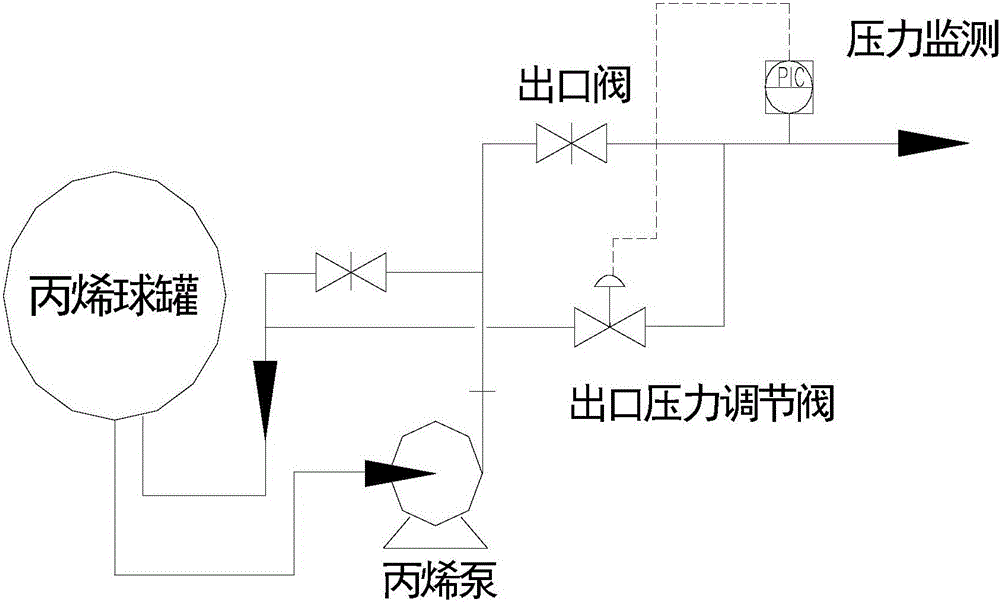

Propylene pump delivery constant pressure regulating method

InactiveCN105781954AConstant pressureGuaranteed reflowPump controlPositive-displacement liquid enginesRefluxEngineering

The present invention provides a propylene pump delivery constant pressure regulating method. The outlet pressure of a pump can be detected, the outlet pressure of the pump is effectively guaranteed to be constant, and a return pipeline is additionally arranged, so that the pump reflux is guaranteed.

Owner:ZHANGJIAGANG HUACHANG NEW MATERIAL TECH CO LTD

Thermal diode and processing method thereof

ActiveCN111895827ALow costGood effectIndirect heat exchangersModifications using liquid coolingEngineeringMechanical engineering

The invention discloses a thermal diode. The thermal diode comprises a holder, a steam channel, liquid channels and an one-way conduction assembly; one end of the holder is an evaporation section, andthe other end of the holder is a condensation section; the steam channel is arranged in the retainer, one end of the steam channel extends to the evaporation section, and the other end of the steam channel extends to the condensation section; the liquid channels are arranged on the two sides of the steam channel, one end of each liquid channel extends to the evaporation section, and the other endof each liquid channel extends to the condensation section; the one-way conduction assembly is arranged in the steam channel and controls the steam channel to be in one-way conduction in the direction from the evaporation section to the condensation section. According to the thermal diode, the evaporation section is arranged to be in butt joint with the fever element, the condensation section isarranged to be in butt joint with the heat dissipation element to achieve the basic function of a heat pipe, and the steam channel and the liquid channel are arranged to achieve the circulating heat transfer effect; therefore, internal steam can only flow along one direction on the premise that the thermal diode works in any direction, and the effect of protecting important elements is achieved.

Owner:GUANGZHOU UNIVERSITY

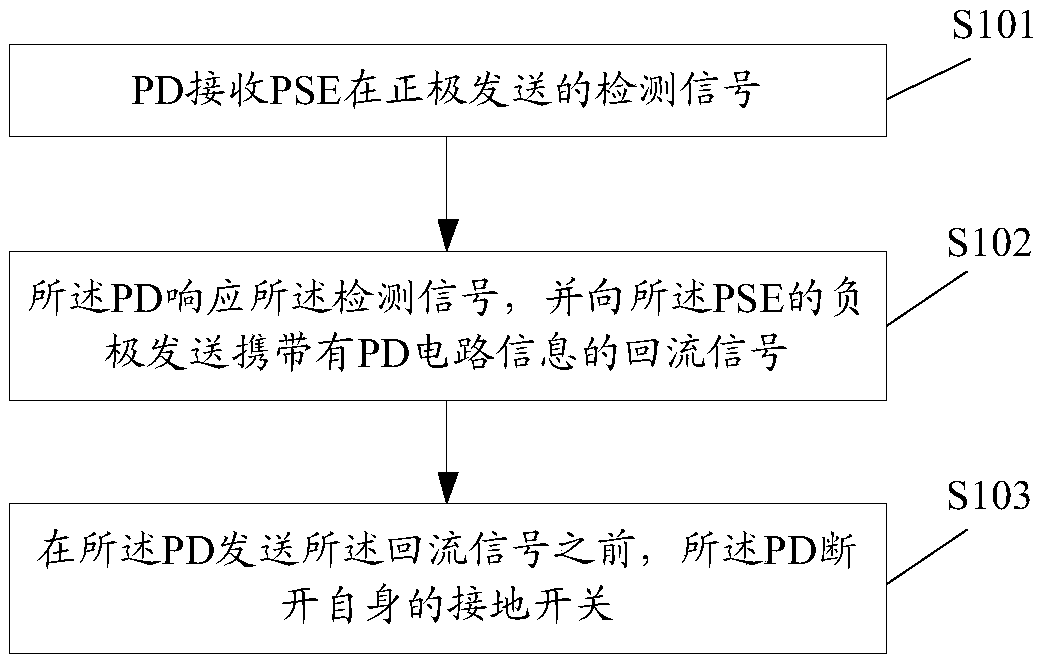

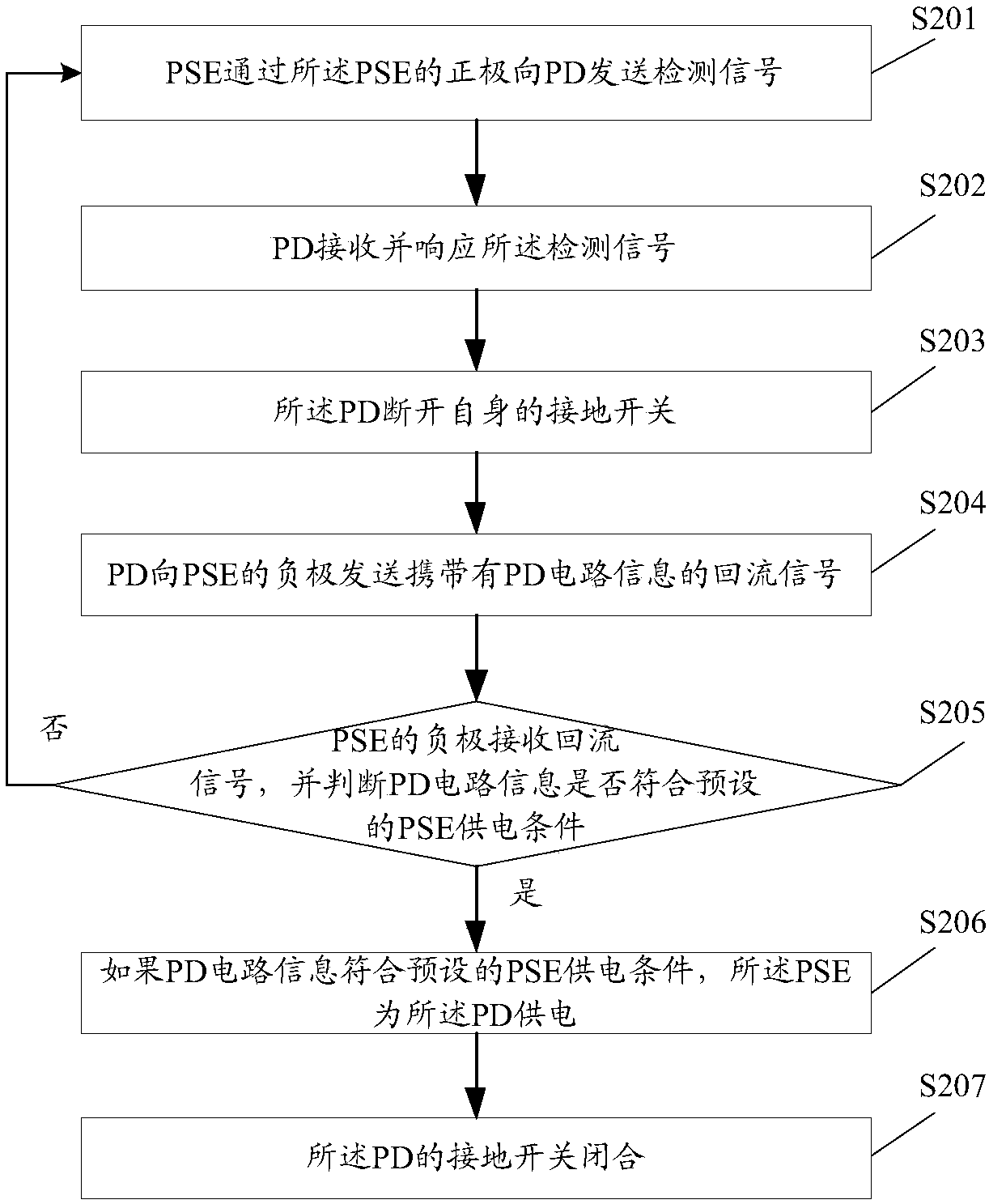

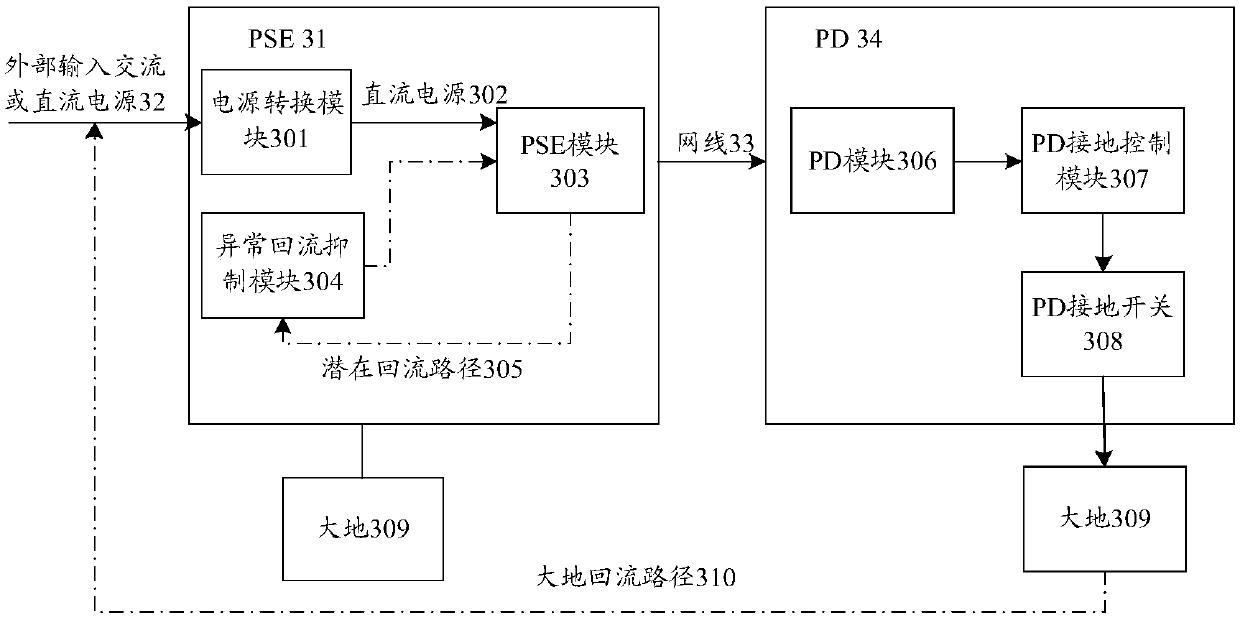

POE power supply method and device and storage medium

ActiveCN110048859AEfficient identificationGuaranteed reflowData switching current supplyElectricityEngineering

The embodiment of the invention provides a POE power supply method and device and a storage medium, and the method comprises the steps that a powered device PD receives a detection signal sent by a power supply device PSE at a positive electrode; the PD responds to the detection signal and sends a backflow signal carrying PD circuit information to the negative electrode of the PSE; and before thePD sends the backflow signal, the PD turns off the grounding switch of the PD.

Owner:ZTE CORP

Ink scraping plate structure of printer

The invention discloses an ink scraping plate structure of a printer. The ink scraping plate structure is characterized by comprising a scraping plate, an ink receiving slot and a flow deflector, wherein an ink outlet is formed in the slot bottom of the ink receiving slot; the ink outlet is connected with a guide tube; the scraping plate is positioned on aslot openingof the ink receiving slot; one end of the scraping plate is a fixed end, and is fixed on the inner side wall of the ink receiving slot; theend back to the fixed end is an ink scraping end and extends to the outer side of the ink receiving slot; the first end of the flow deflector is connected onto the ink scraping end, and the second end of the flow deflector extends into the ink receiving slot; and the first end is higher than the second end. The ink scraping plate structure can scrape ink at the position close to a contact point of an ink roller and a printing plate roller, and also effectively enables scraped-off printing ink to flow back into an ink box.

Owner:海盐县鑫达印刷有限公司

Semi-opened self water collecting steam box

InactiveCN105605544AGuaranteed reflowSteam generation heating methodsSemi openProgrammable logic controller

The invention discloses a semi-opened self water collecting steam box, which comprises a ball-shaped cover, a steam box, a steam pool, a control body, support rods, a heating body, a first water collecting groove and a second water collecting groove, wherein a plurality of support rods are fixedly connected on the steam box, and are uniformly distributed along the upper part of the steam box; the steam box is arranged above the steam pool; the bottom of the steam box is fixedly connected with a plurality of cylinder rods; the cylinder rods are arranged in the steam pool; the ball-shaped cover is arranged on the support rods; the steam pool is put on a work platform; the heating body is arranged inside the steam pool; the control body is arranged outside the steam pool; a plurality of press buttons are arranged on the control body; a plurality of through holes are formed in the bottom surface of the steam box; the through holes are distributed along the bottom surface center circumference of the steam box. The semi-opened self water collecting steam box has the advantages that the steam box is designed into a semi-opened type, so that the air pressure in the steam box maintains consistency with the atmospheric pressure, meanwhile, the ball-shaped end cover and the water collecting grooves formed in the inner side surface of the steam box are used; condensed water is enabled to flow back into the steam pool; the heating process is controlled by a PLC (programmable logic controller) module.

Owner:潘玲玉

Pulp bleaching device for packaging paper

ActiveCN109183486AGuaranteed vertical installationGuaranteed circulationPulp bleachingBleachPulp and paper industry

The invention discloses a pulp bleaching device for packaging paper. The device comprises a reaction kettle and a reaction tank. The reaction kettle is installed in the reaction tank; the reaction tank is installed on a base; the reaction kettle is a cylindrical structure, and the outer side of the reaction kettle is surrounded by a heating pipe; a mounting ring plate and a mounting strip plate are arranged in the reaction kettle; the mounting ring plate is provided with a high-pressure nozzle hole; a pushing device is arranged in the reaction tank; and the upper inner side wall of the reaction tank is provided with an air inlet hole, which is communicated with a steam generator through an intake pipe. The device has a high-efficiency bleaching effect. By the device, paper pulp can be fully contacted with a bleaching agent; the bleaching time can be saved and the bleaching process can be simplified; the damage to the fiber structure of paper pulp by multiple operation steps is reduced,and the original quality of paper pulp can be guaranteed; the bleaching efficiency can be improved; equipment investment and floor space are reduced; and the production cost is reduced.

Owner:嵊州市东浦天地彩印包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com