Electric imaging calibration well group

An electrical imaging and calibration technology, which is applied in the direction of boreholes/well components, earthwork drilling, etc., can solve the problems of weak backflow on the inner wall of the rock module, low imaging accuracy of electrical imaging logging tools, etc., and achieve the effect of improving imaging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings, which cannot be used to limit the protection scope of the present invention.

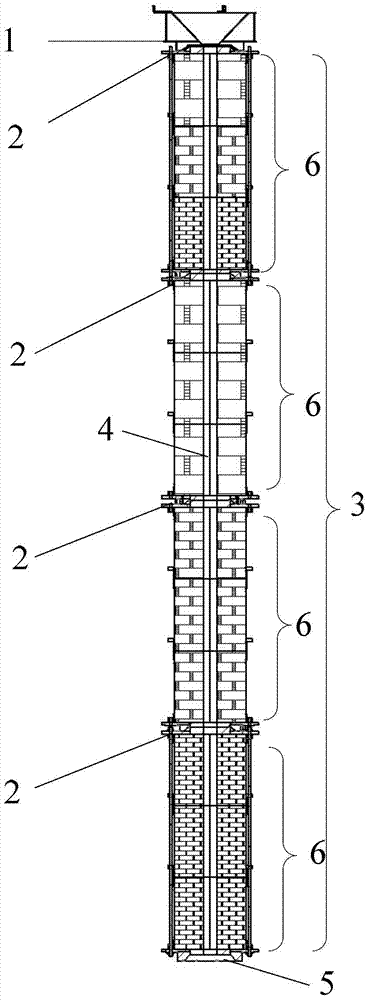

[0027] see figure 1 , the present invention proposes electrical imaging calibration well group, at least including:

[0028] One or more calibration wells used for inspection and calibration of electrical imaging logging tools.

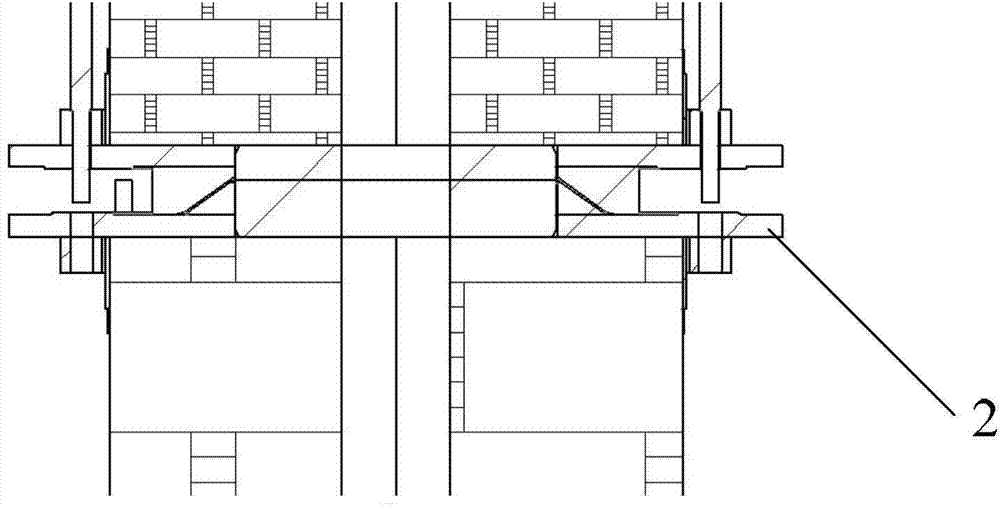

[0029] Wherein, the calibration well at least includes: a rock module 3 , an instrument through hole 4 arranged in the middle of the rock module 3 , and radial gaps are included behind the image of the inner wall of the rock module 3 .

[0030] Wherein, the radial slit can be realized by openwork technology, and the specific realization belongs to the common knowledge of those skilled in the art, and is not used to limit the scope of protection of the present invention, and will not be repeated her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com