System and method for measuring vision of variable optical axis

A visual measurement and boresight technology, applied in the field of visual measurement, can solve problems such as limiting the measurement range of the system, the limited number of boresight points, and reducing image resolution, so as to reduce the search range, expand the imaging field of view and measurement range, and ensure The effect of integration and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

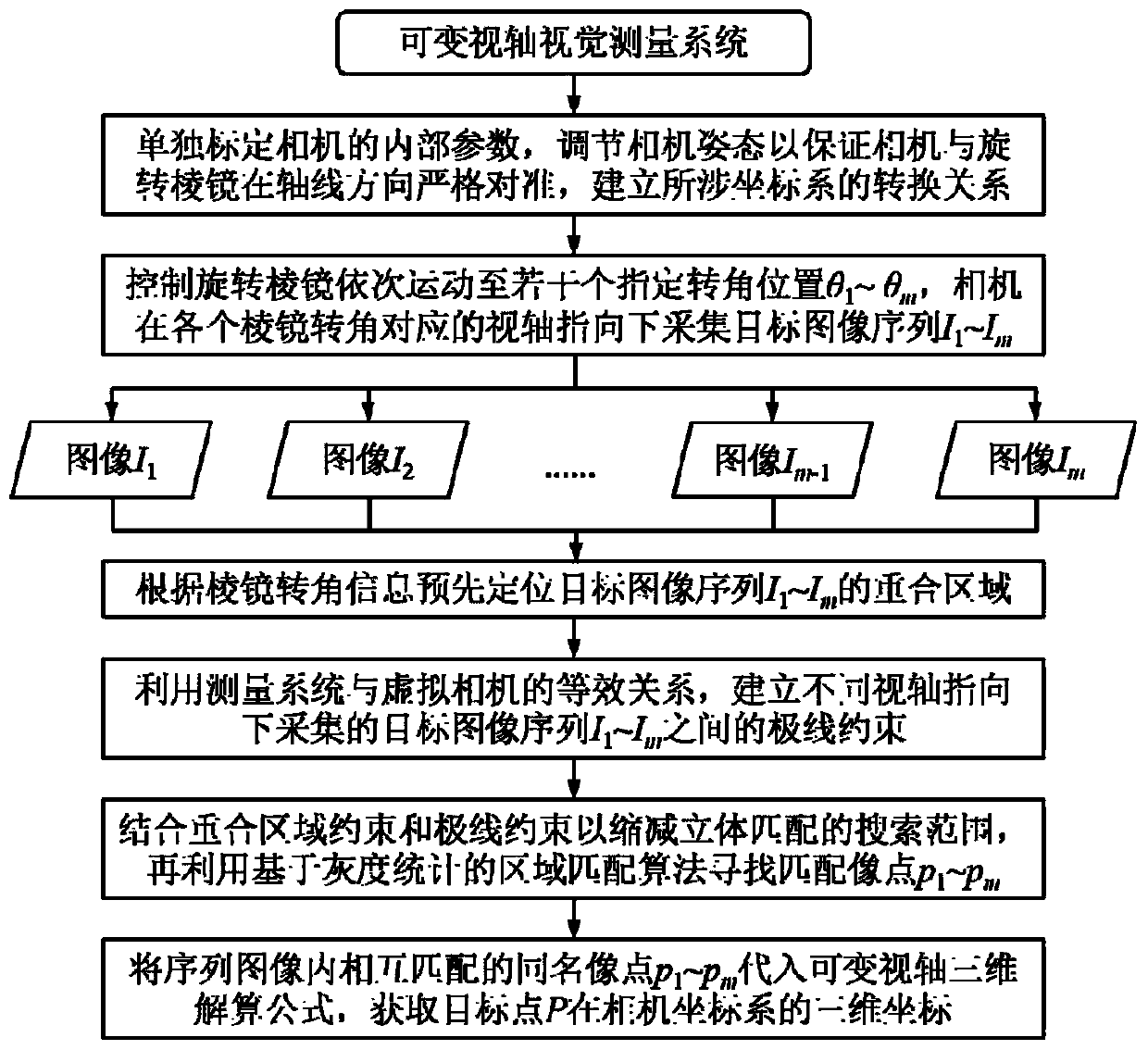

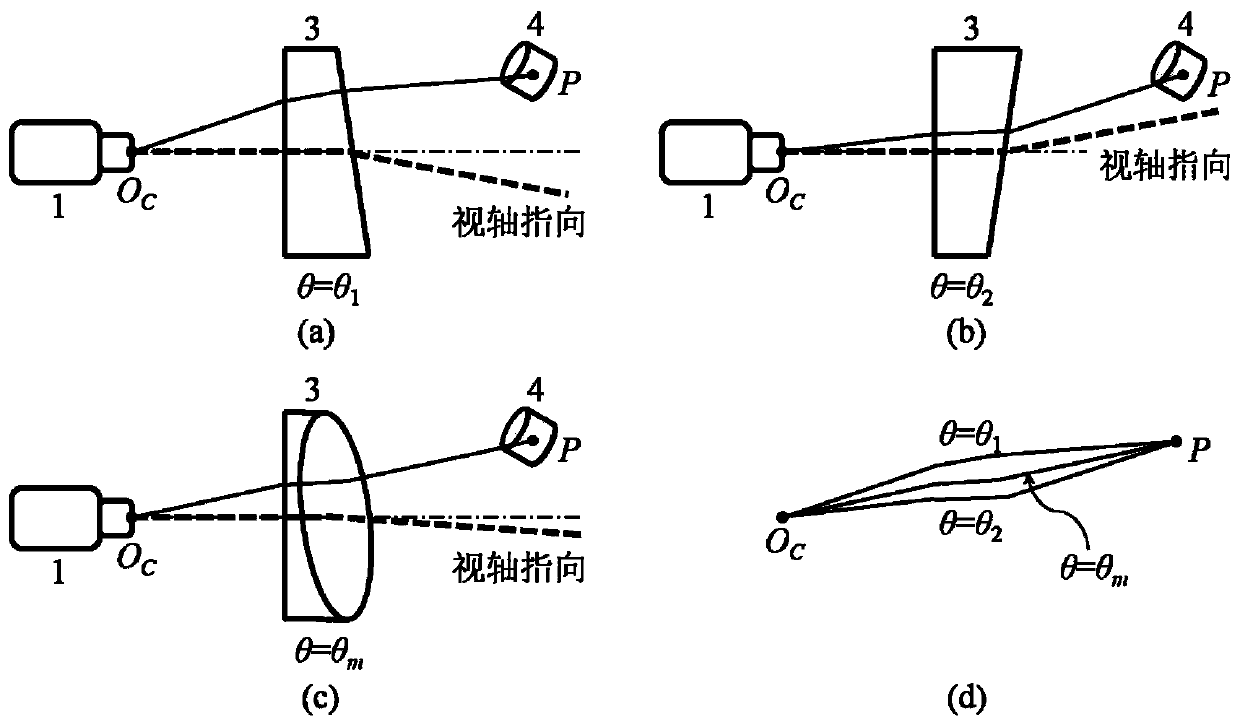

[0123] In this embodiment, the detailed steps of obtaining the three-dimensional contour information of the target by using the variable boresight visual measurement method are as follows:

[0124] S1. Key parameters of the calibration measurement system

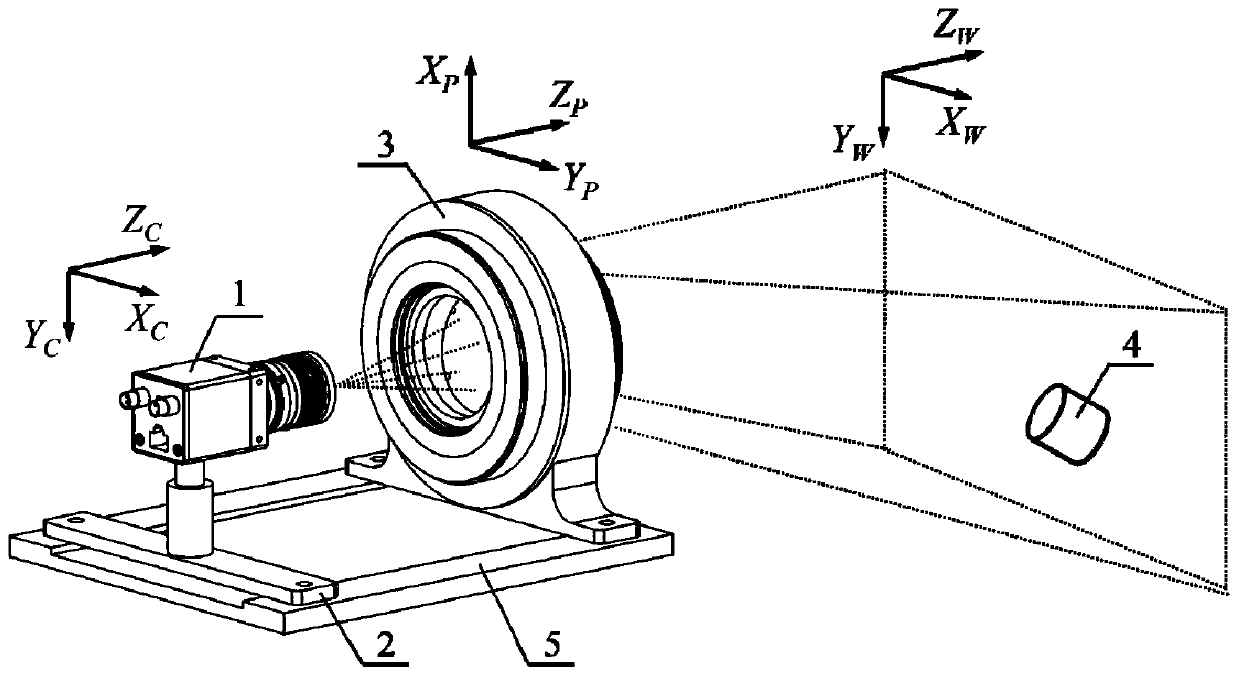

[0125] S11. Establishing the camera coordinate system O C -X C Y C Z C , Prism coordinate system O P -X P Y P Z P and the world coordinate system O W -X W Y W Z W ;

[0126] S12. Separately calibrate the internal parameter matrix A of the industrial camera 1 using Zhang's plane calibration method int and distortion coefficient k 1 、k 2 ;

[0127] S13, install the adjustment mechanism 2 and the rotating prism device 3 carrying the industrial camera 1 on the base 5, and change the height and posture of the camera 1 through the camera adjustment mechanism 2, in order to ensure the axial alignment of the camera and the rotating prism Determine the relative rotation matrix R of the two based on PC and the relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com