Irregularly-shaped rotary heat pipe applicable to various rotation speeds

A rotary heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large material consumption, non-reflux of liquid, and low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

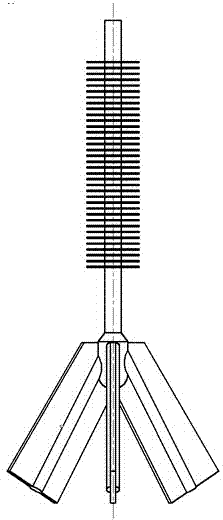

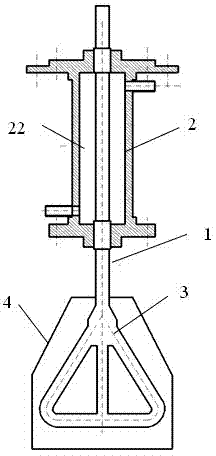

[0024] Such as Figure 1A and 1B As shown, a special-shaped rotating heat pipe suitable for various rotation speeds includes a heat pipe main body 1, the upper section of the heat pipe main body is a heat pipe cooling section 2, the lower section of the heat pipe main body is a heat pipe evaporation section 3, and the outer surface of the heat pipe cooling section 2 is provided with Fin21. The outer side of the heat pipe evaporation section 3 may be provided with a paddle layer 4 (abbreviated as heat absorbing pipe hereinafter).

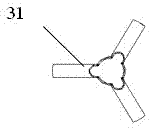

[0025] Such as Figure 2A As shown, the heat pipe evaporating section 3 is provided with three heat absorbing pipes 31. The heat absorbing pipes 31 are evenly distributed around the heat pipe main body 1 and extend sideways and downwards. The outer surface of the heat absorbing pipes 31 is provided with ribs 4 to form blades.

[0026] Such as Figure 2B As shown, the heat pipe evaporating section 3 is provided with four heat absorbing pipes 31. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com