Ink scraping plate structure of printer

A squeegee and printing press technology, applied in printing presses, general parts of printing machinery, printing, etc., can solve the problems of long distance, uneven distribution, and flow between the squeegee and the ink roller and the printing plate cylinder, and achieve Effective scraping and uniform ink effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

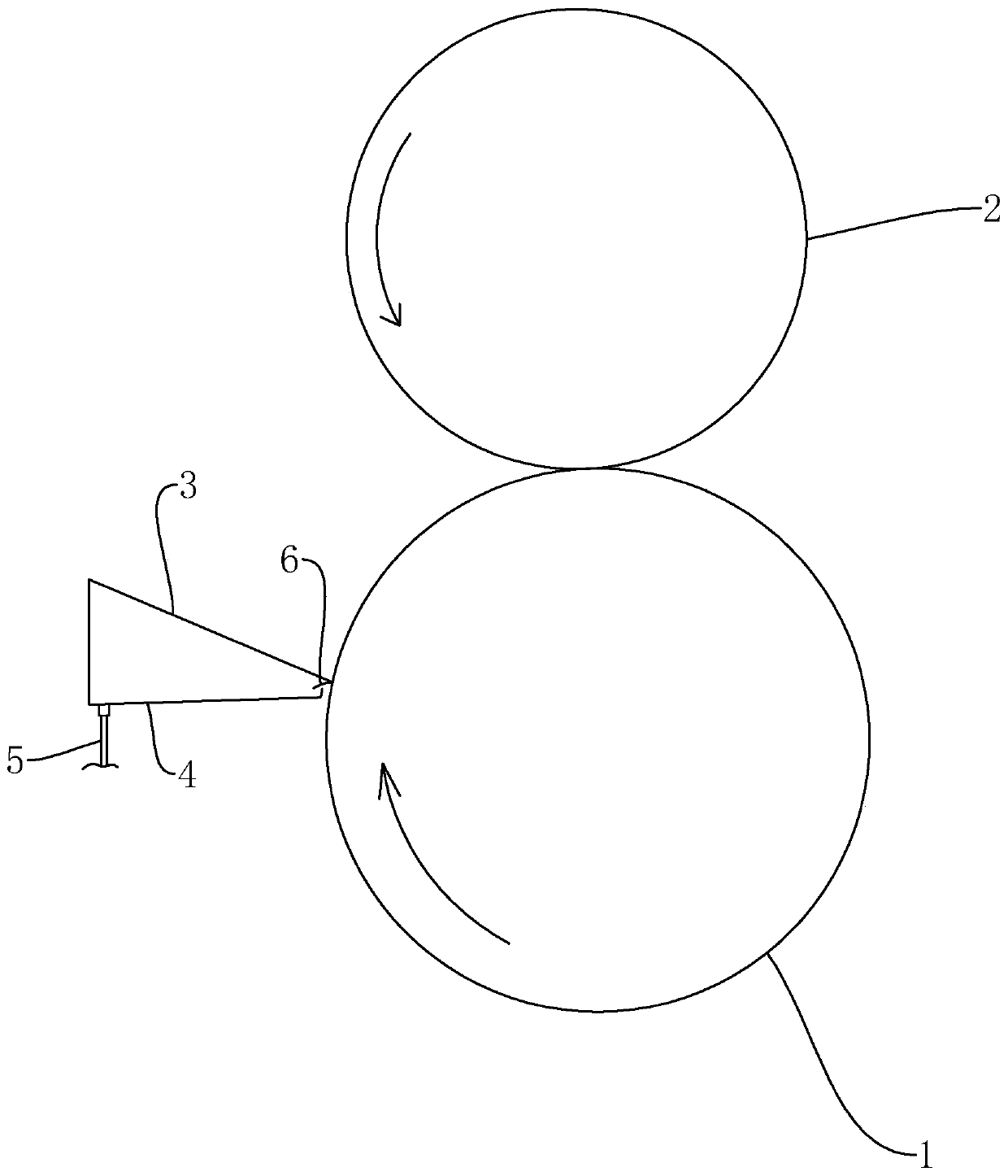

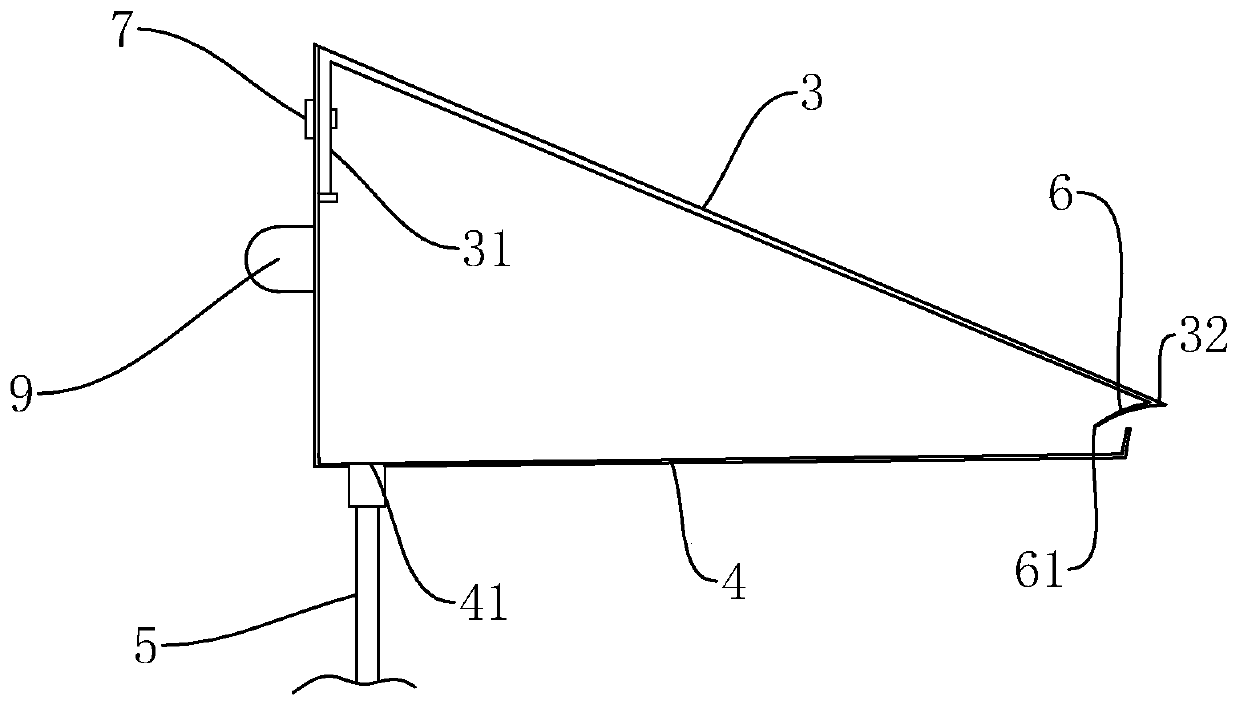

[0017] combine Figure 1 to Figure 2 The structure of the squeegee of the printing machine of the present invention will be further described.

[0018] A squeegee structure of a printing machine, characterized in that it includes a squeegee 3, an ink receiving groove 4 and a deflector 6;

[0019] There is an ink outlet 41 on the groove bottom of the ink receiving tank 4, and a conduit 5 is connected to the ink outlet 41, and a connecting block 9 is arranged on the outer wall of the ink receiving tank, through which the present invention can be installed. on a printing press;

[0020] The scraper 3 is located on the notch of the ink tank 4, and one end of the scraper 3 is a fixed end 31 and is fixed on the inner sidewall of the ink tank 4, and the end facing away from the fixed end 31 is a scraper end 32 And extend to the outside of the ink tank 4;

[0021] The first end of the deflector 6 is connected to the scraping end 32, the second end 61 of the deflector 6 extends into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com