Semi-opened self water collecting steam box

A semi-open, self-collecting water technology, which is applied in the field of industrial heat preservation and moisturizing containers and large steam boxes, and can solve the problems of free flow of liquid water and complicated recovery of condensed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

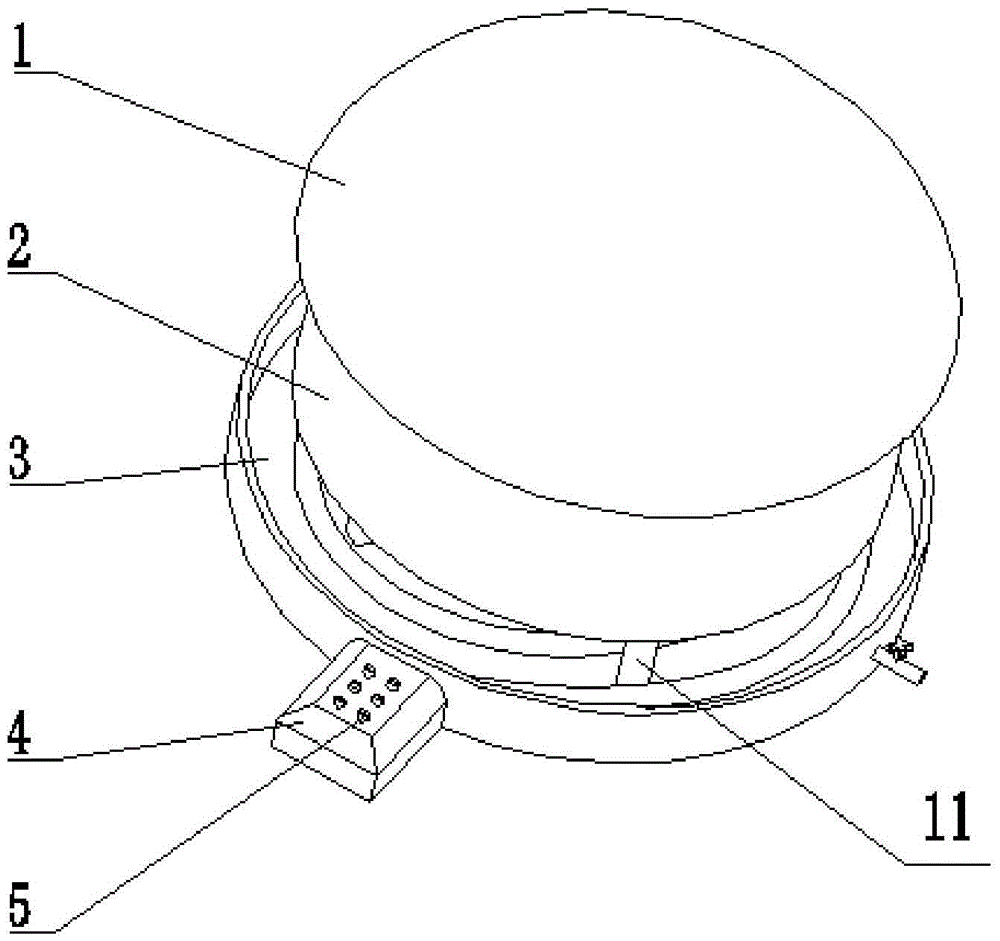

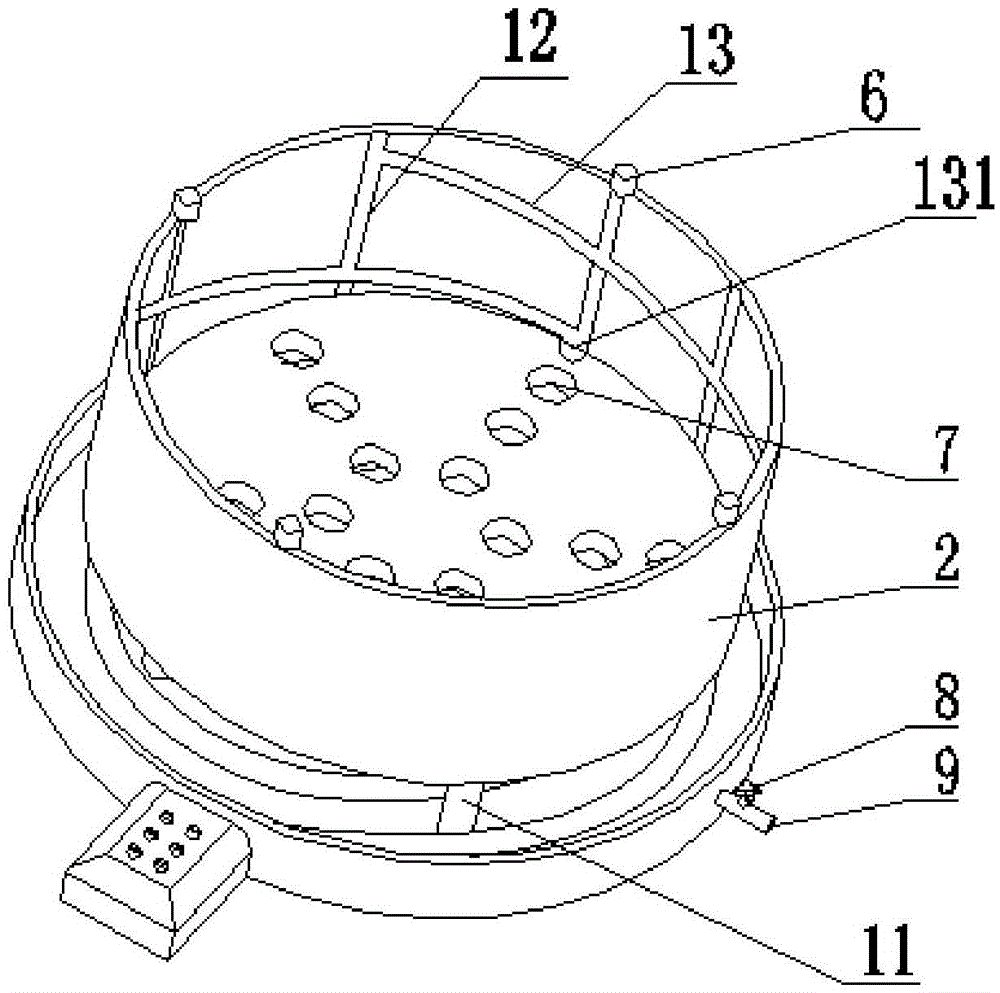

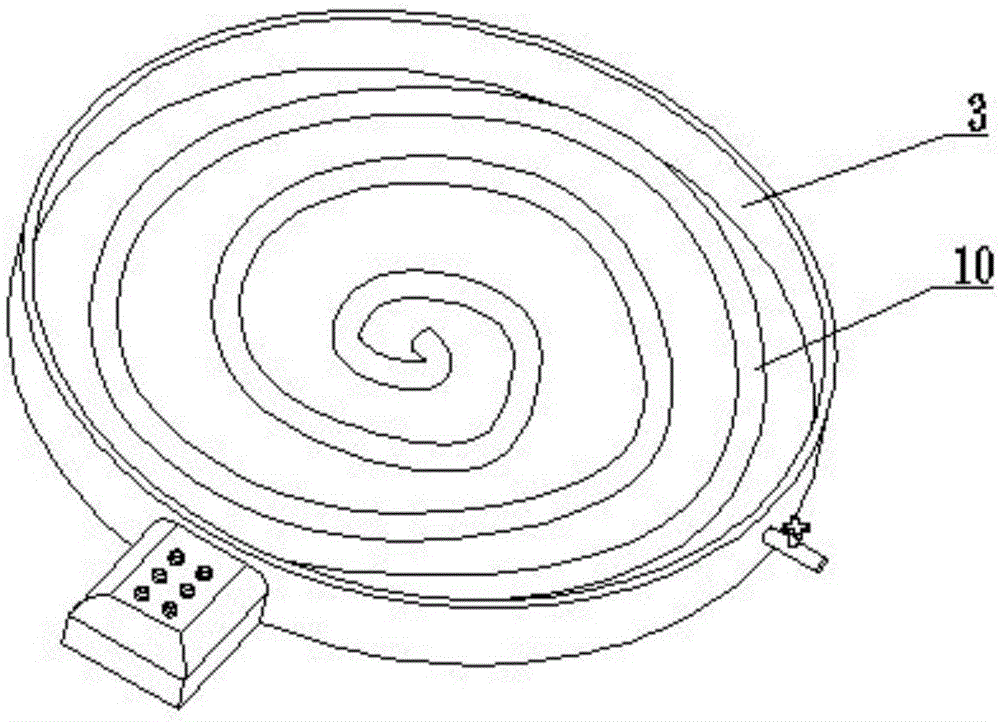

[0018] refer to figure 1 , figure 2 and image 3 , a semi-open self-collecting steam box of the present invention, comprising a spherical cover 1, a steam box 2, a steam pool 3, a control body 4, a support rod 6, a heating body 10, a first water collection tank 12 and a second water collection tank 13 , the steam box 2 is fixedly connected with several support rods 6, and the support rods 6 are evenly distributed along the upper part of the steam box 2; the steam box 2 is arranged above the steam pool 3, and the bottom of the steam box 2 is fixedly connected with several cylindrical rods 11. The cylindrical rod 11 is placed in the steam pool 3; the spherical cover 1 is installed on the support rod 6; the steam pool 3 is placed on the working platform, and the heating body 10 is installed inside the steam pool 3; the steam pool 3 A control body 4 is installed on the outside, and several buttons 5 are arranged on the control body 4; several through holes 7 are opened on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com