Patents

Literature

64results about How to "Guaranteed stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synergistically degrading phenol wastewater through electrocatalytic oxidation and electric-Fenton technology

InactiveCN102424465AImprove degradation efficiencyApplicable to a wide range of pHWater/sewage treatment by oxidationElectrolysisOxygen

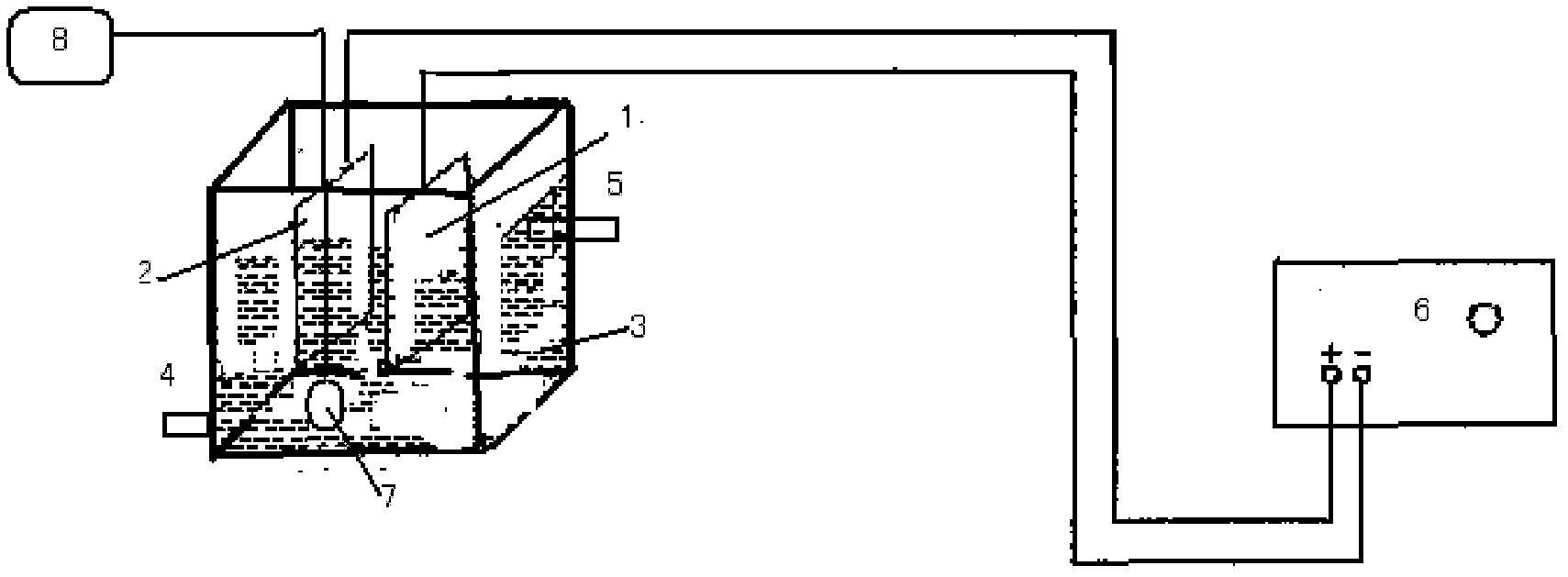

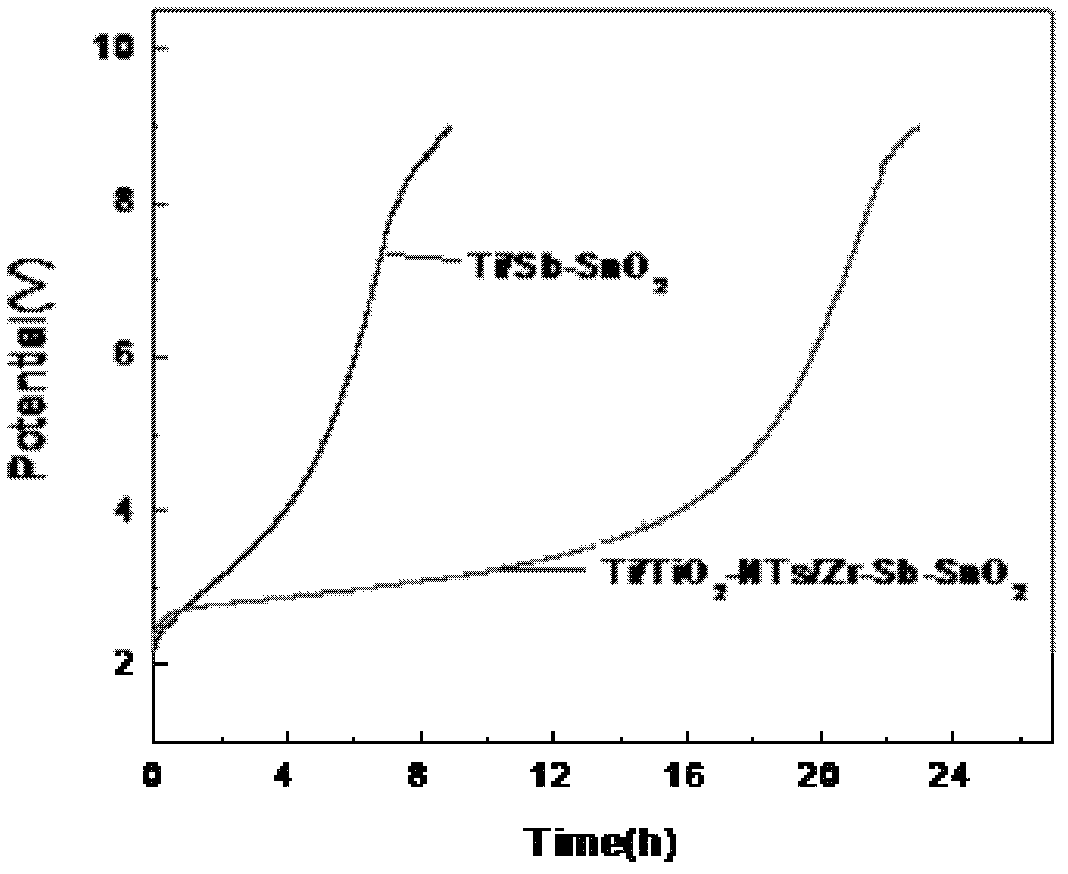

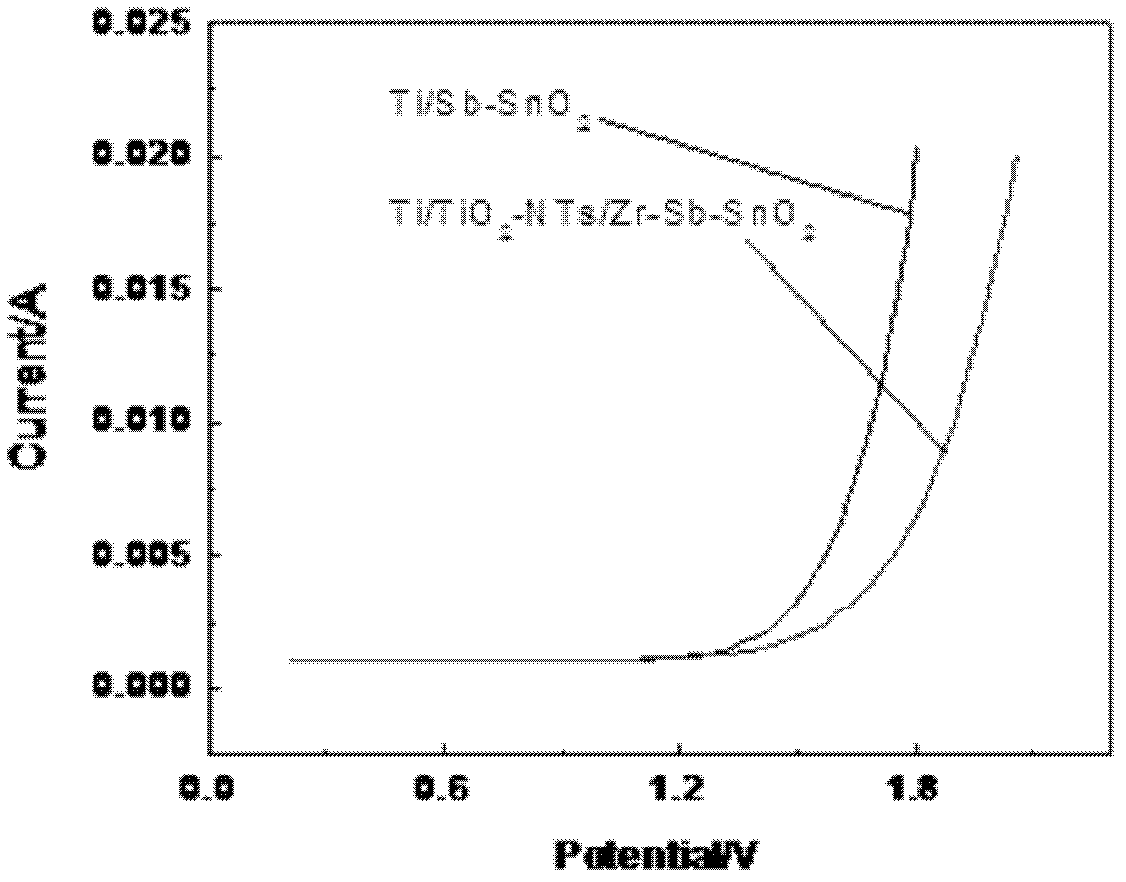

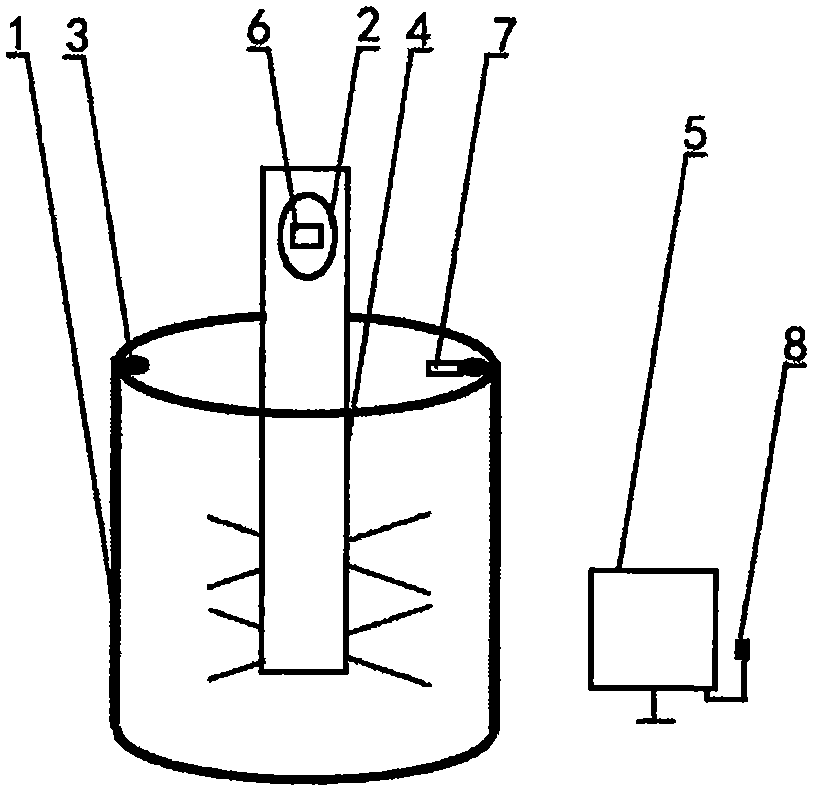

The invention provides a method for synergistically degrading phenol wastewater through electrocatalytic oxidation and an electric-Fenton technology. The wastewater is introduced into an electrolyzer of which two sides are provided with a water inlet pipe and a water outlet pipe, Ti / TiO2-NTs / Zr-Sb-SnO2 is taken as an anode, foamed nickel coated FeOOH+active carbon powder+polytetrafluoroethylene (PTFE) is taken as a cathode, the anode and the cathode are connected with a voltage-stabilized source, air is provided through aeration or stirring, OH is generated on the surface of the anode, organic matters are degraded through electrocatalytic oxidation action of the anode, oxygen in the solution generates H2O2 on the surface of the cathode, and the H2O2 and the cathode-loaded FeOOH are subjected to heterogeneous Fenton reaction. The method has the advantages of high degradation efficiency, no addition of chemical reagents, no generation of iron mud, and a wide pH value application range, is suitable for treating the phenol wastewater, can be used for treating multiple kinds of organic wastewater and has a wide application prospect in actual application.

Owner:HARBIN ENG UNIV

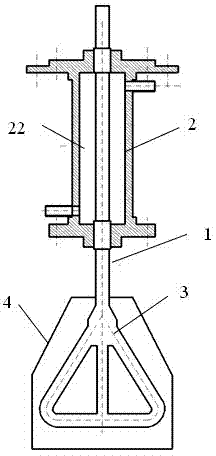

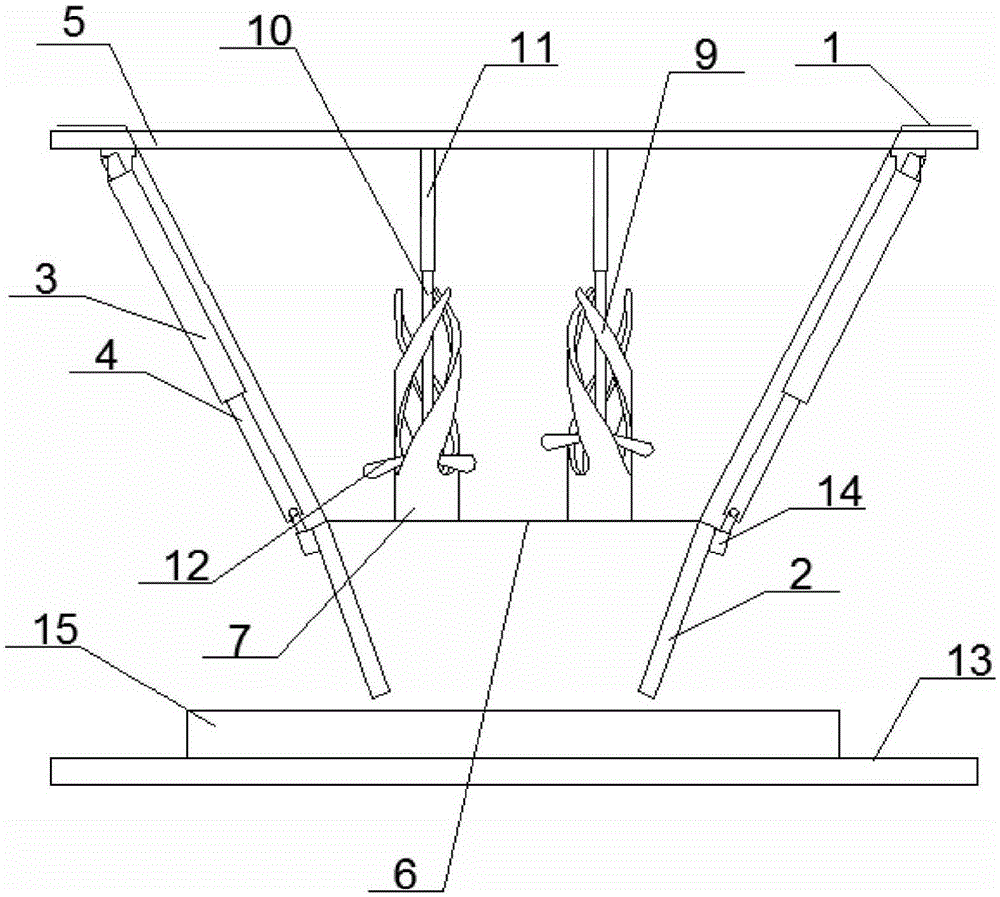

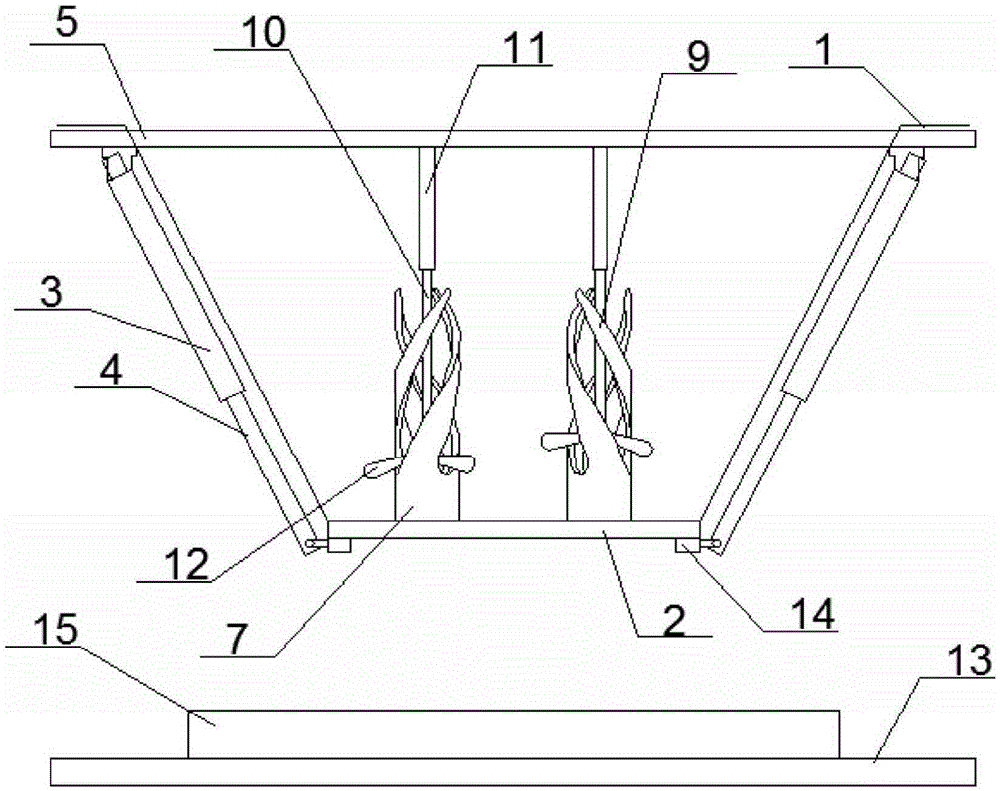

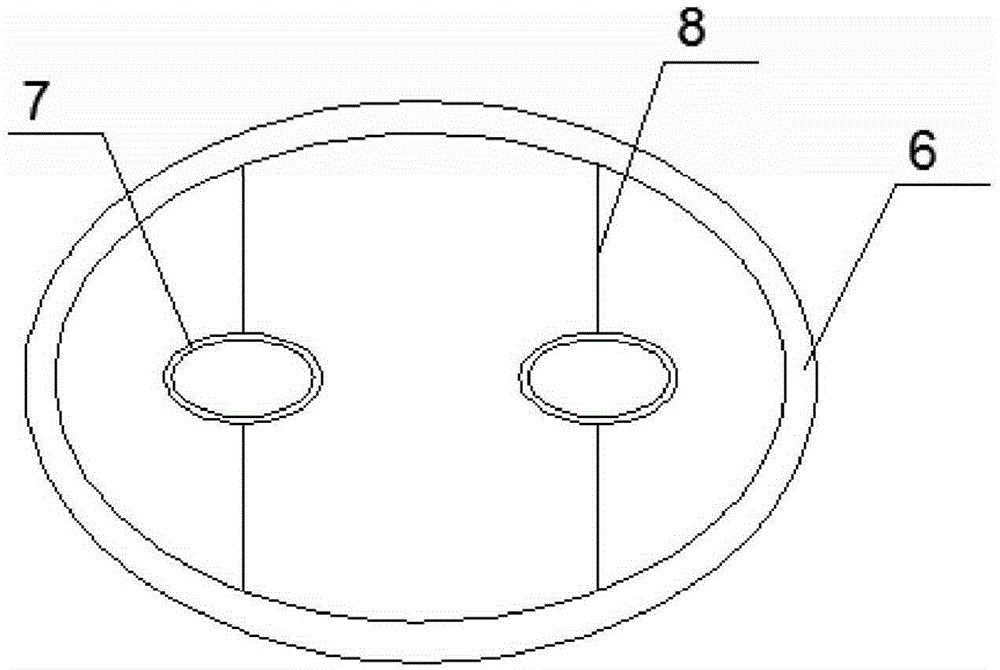

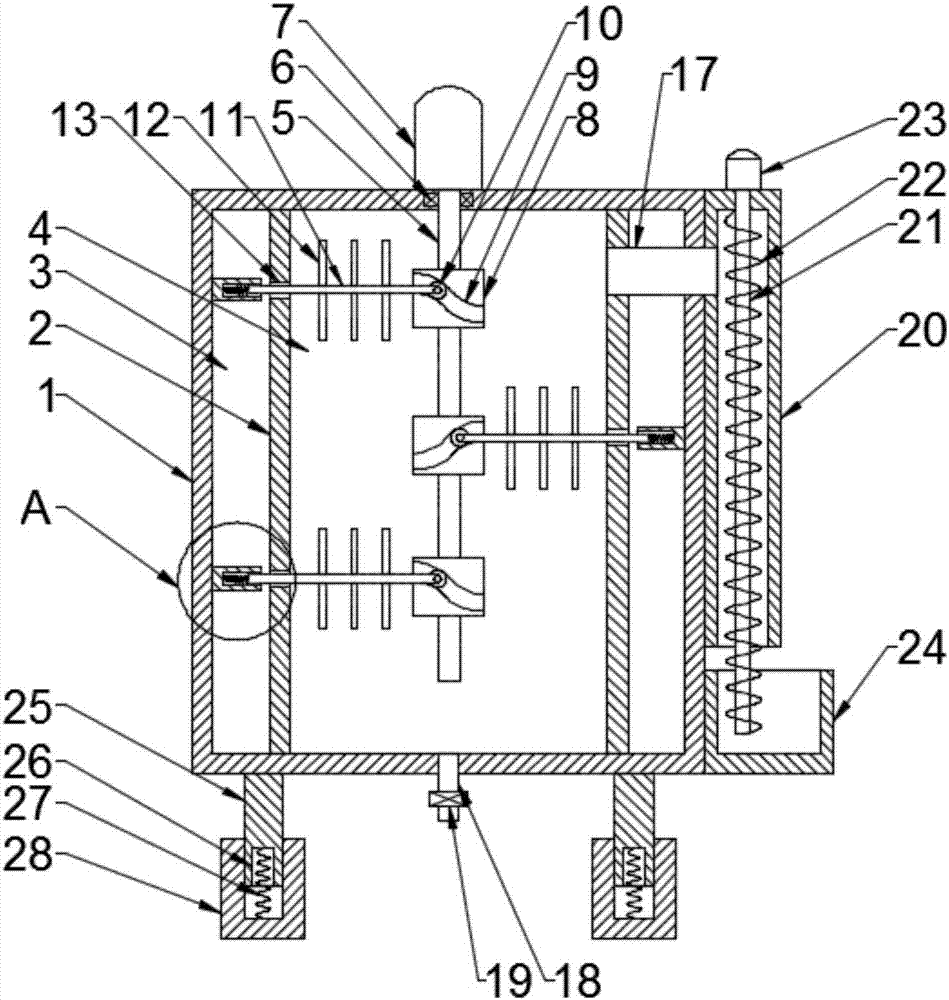

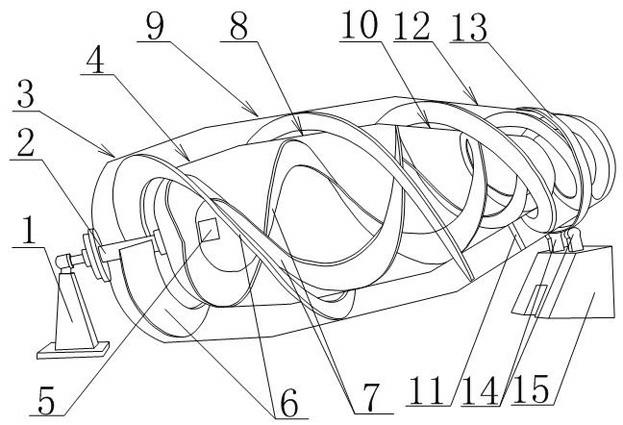

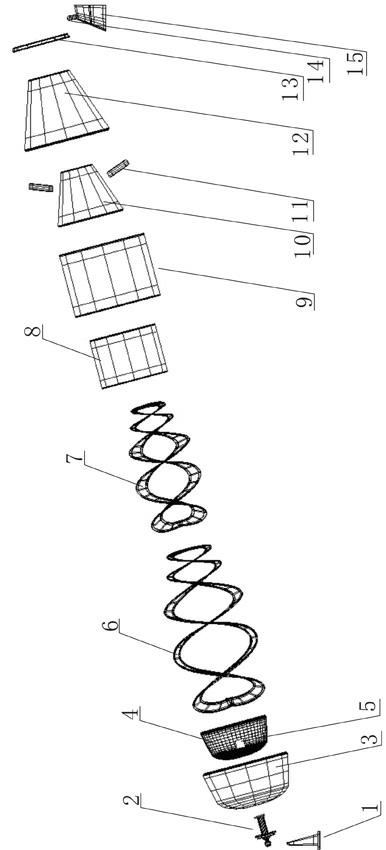

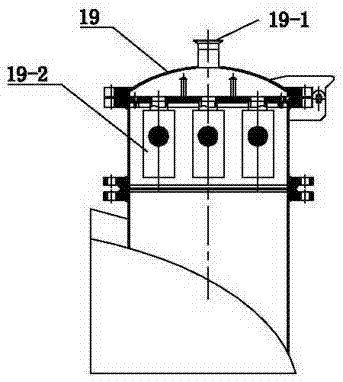

Irregularly-shaped rotary heat pipe applicable to various rotation speeds

InactiveCN104266516AGuaranteed reflowGuaranteed stirringIndirect heat exchangersEngineeringHeat pipe

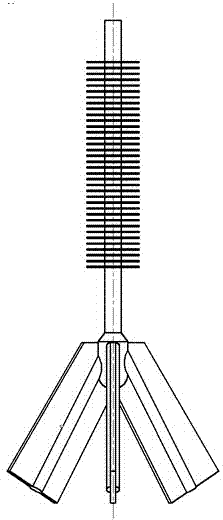

The invention discloses an irregularly-shaped rotary heat pipe applicable to various rotation speeds. The heat pipe comprises a heat pipe main body, wherein the lower section of the heat pipe main body is a heat pipe evaporation section; the upper section of the heat pipe main body is a heat pipe cooling section; a condensate reflow structure is machined on the inner wall of the heat pipe; the lower end of the heat pipe evaporation section is provided with at least one branch layer; each branch layer is provided with at least two dendritic heat absorbing pipes; the heat absorbing pipes are uniformly distributed by taking the heat pipe main body as the center and extend towards the side lower part; the outer surfaces of the heat absorbing pipes are provided with ribs to form blades. Under the condition that the evaporation section of the heat pipe type stirring paddle is at a lower rotation speed, the gravity is used as main power for reflow of a working medium. Under the condition of higher rotation speed, centrifugal force produced by rotation is used as main power for reflow, so that the heat pipe type stirring paddle has excellent adaptability at various rotation speeds.

Owner:NANJING UNIV OF TECH

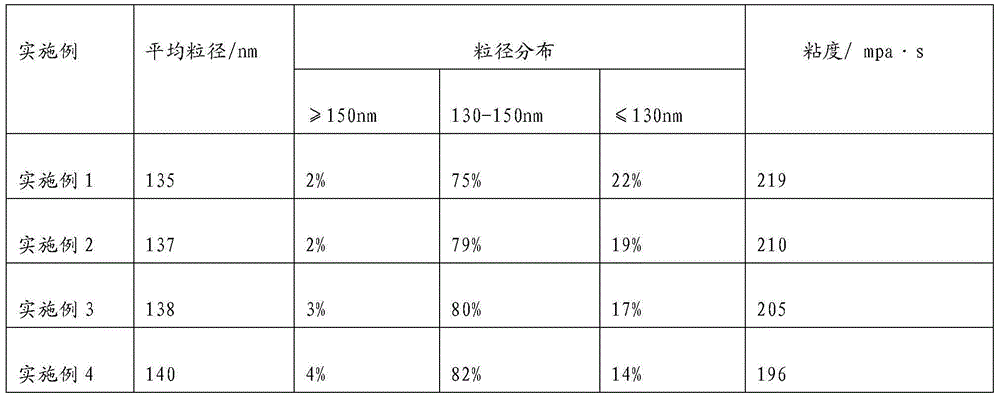

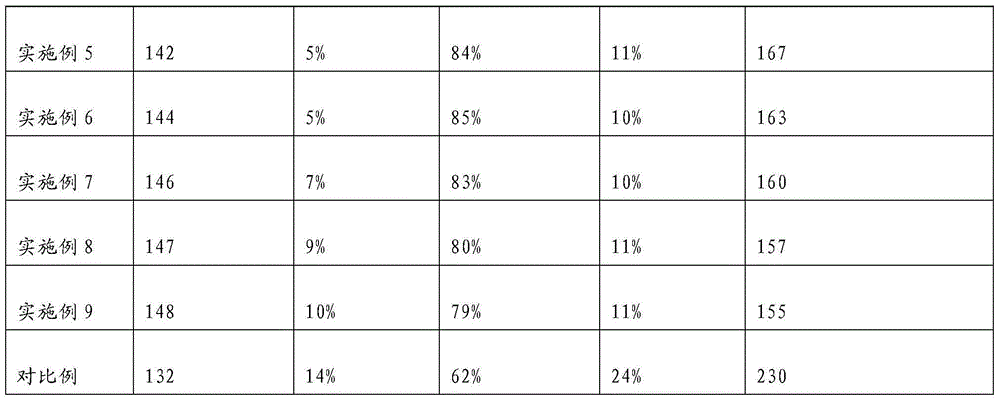

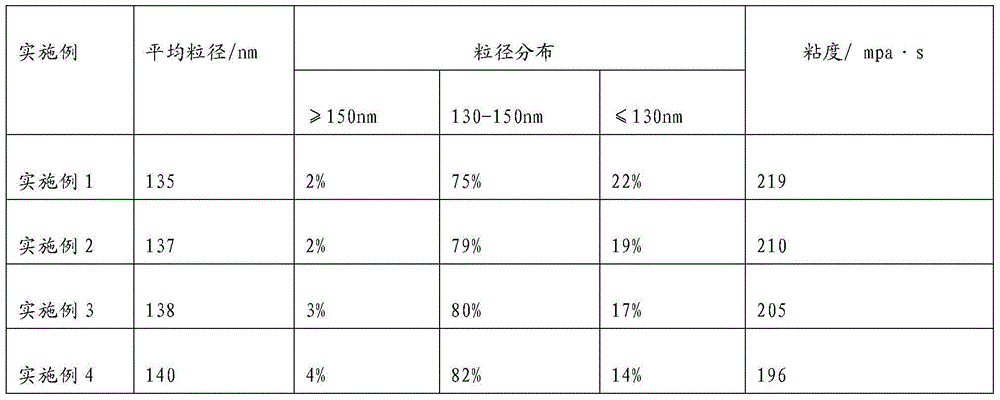

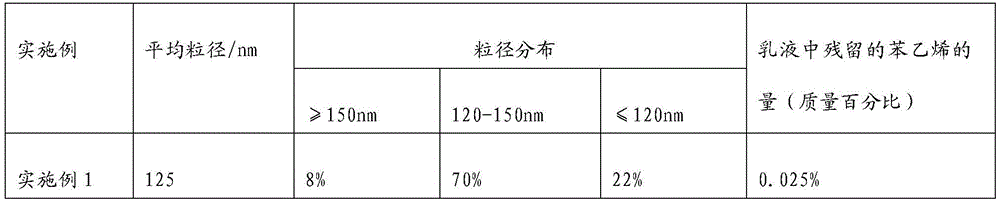

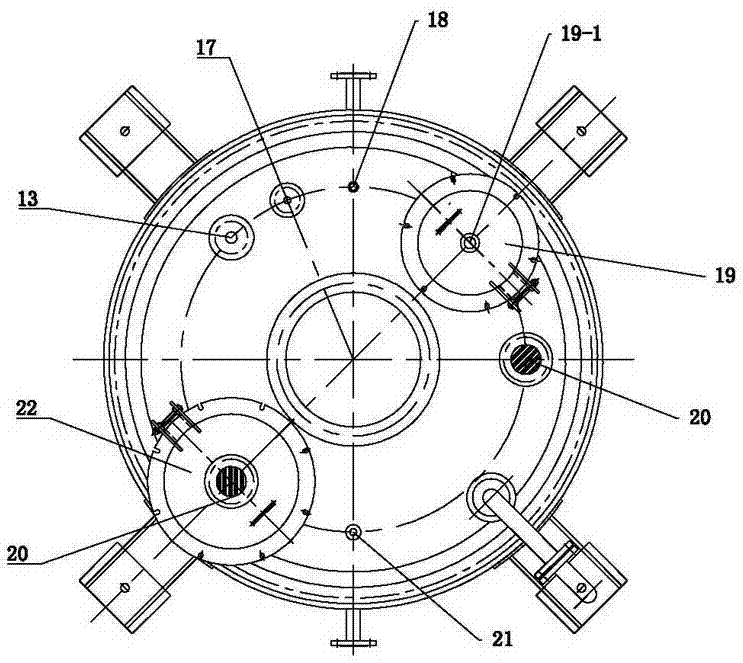

Carboxylated styrene-butadiene latex

ActiveCN104628953AStable molecular structureMolecular weight controllableButadiene-styrene rubberMechanical property

The invention relates to a carboxylated styrene-butadiene latex. High-speed steam is utilized to provide reaction heat energy for the reaction of the carboxylated styrene-butadiene latex, and the cooled steam is converted into high-temperature deionized water; the high-speed steam also drives the liquid in the reaction vessel to rotate, and the liquid in the reaction vessel is dispersed by the steam flow to form abundant micro steam-water combinations so as to push the material in the reaction vessel to quickly flow; and the substances and temperature in the reaction vessel are uniformly distributed, the polymerization reaction is uniform, and thus, the carboxylated styrene-butadiene latex has the advantages of stable molecular structure, controllable molecular weight and more centralized size distribution, has balanced and excellent mechanical properties, and enhances the qualification rate and quality of the product.

Owner:宁波卫山多宝建材有限公司

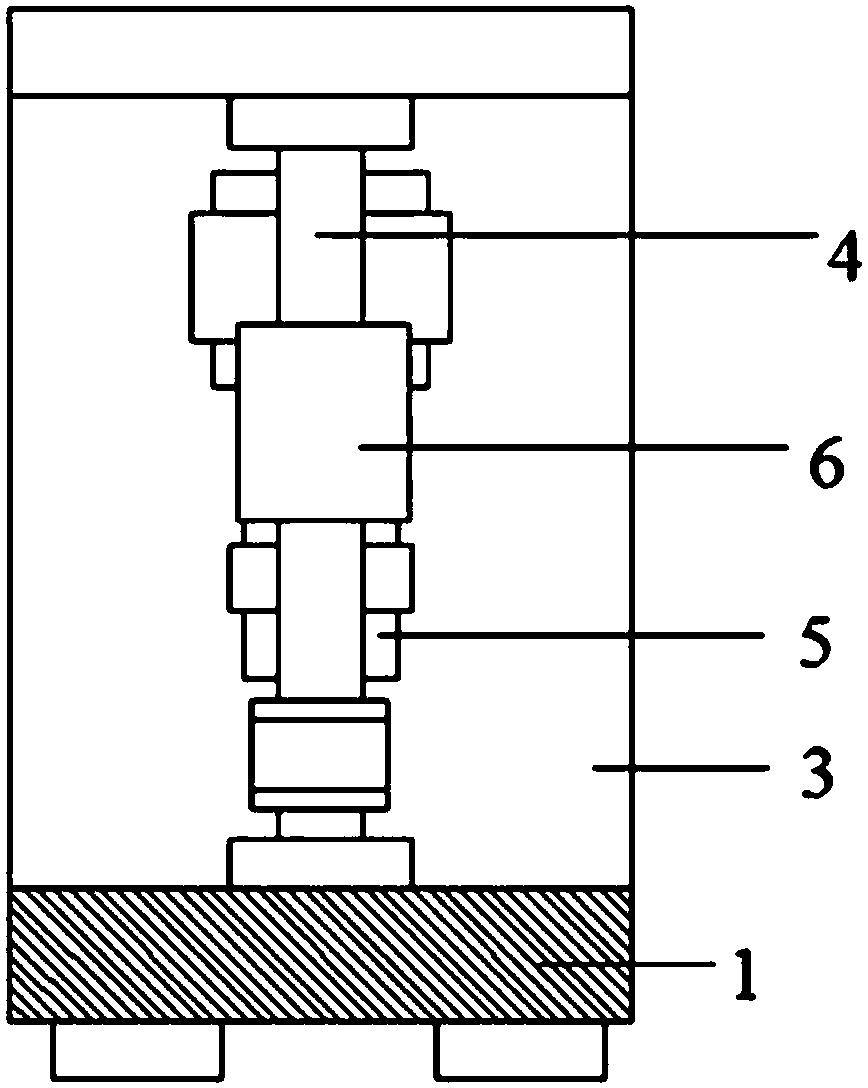

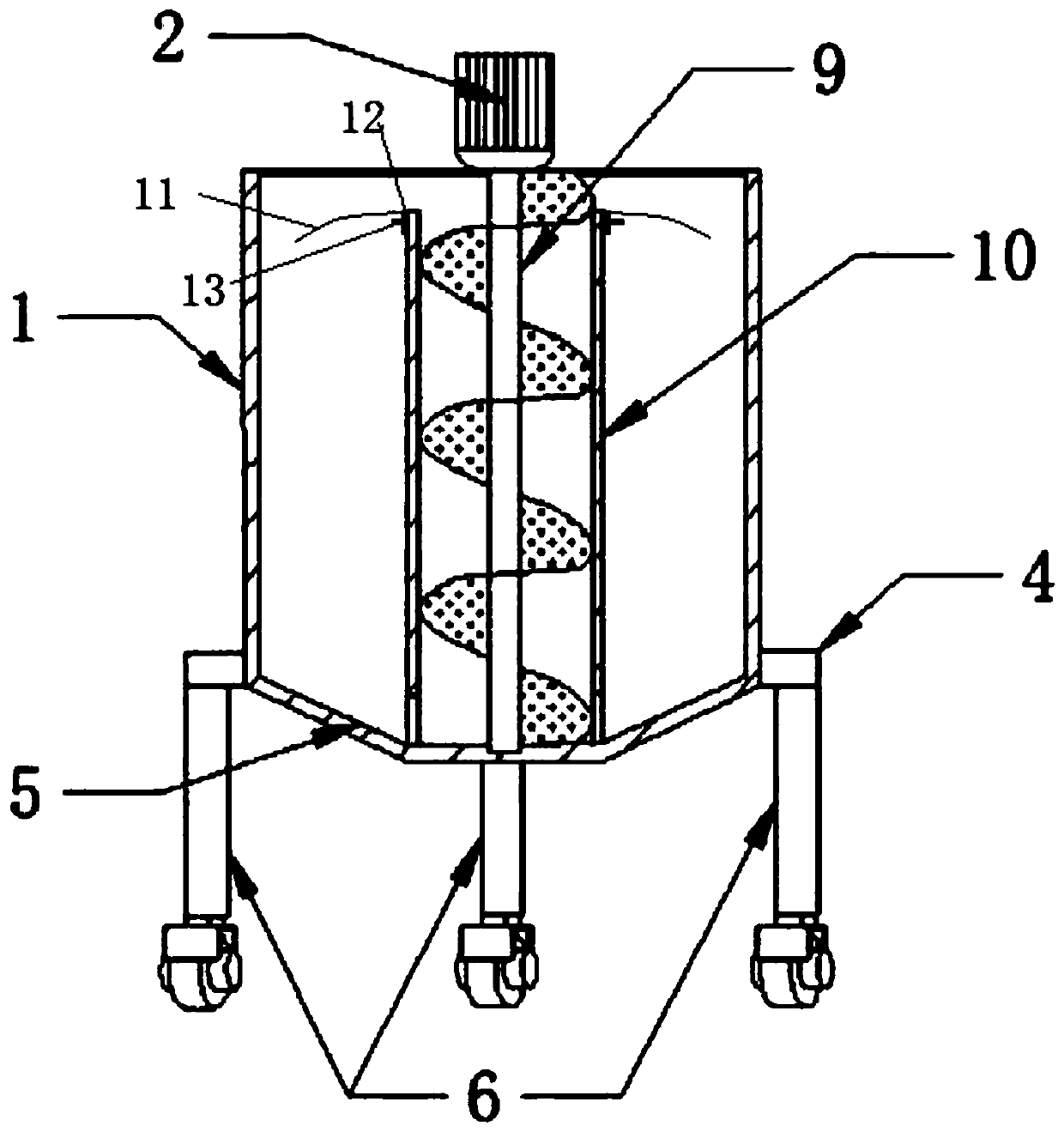

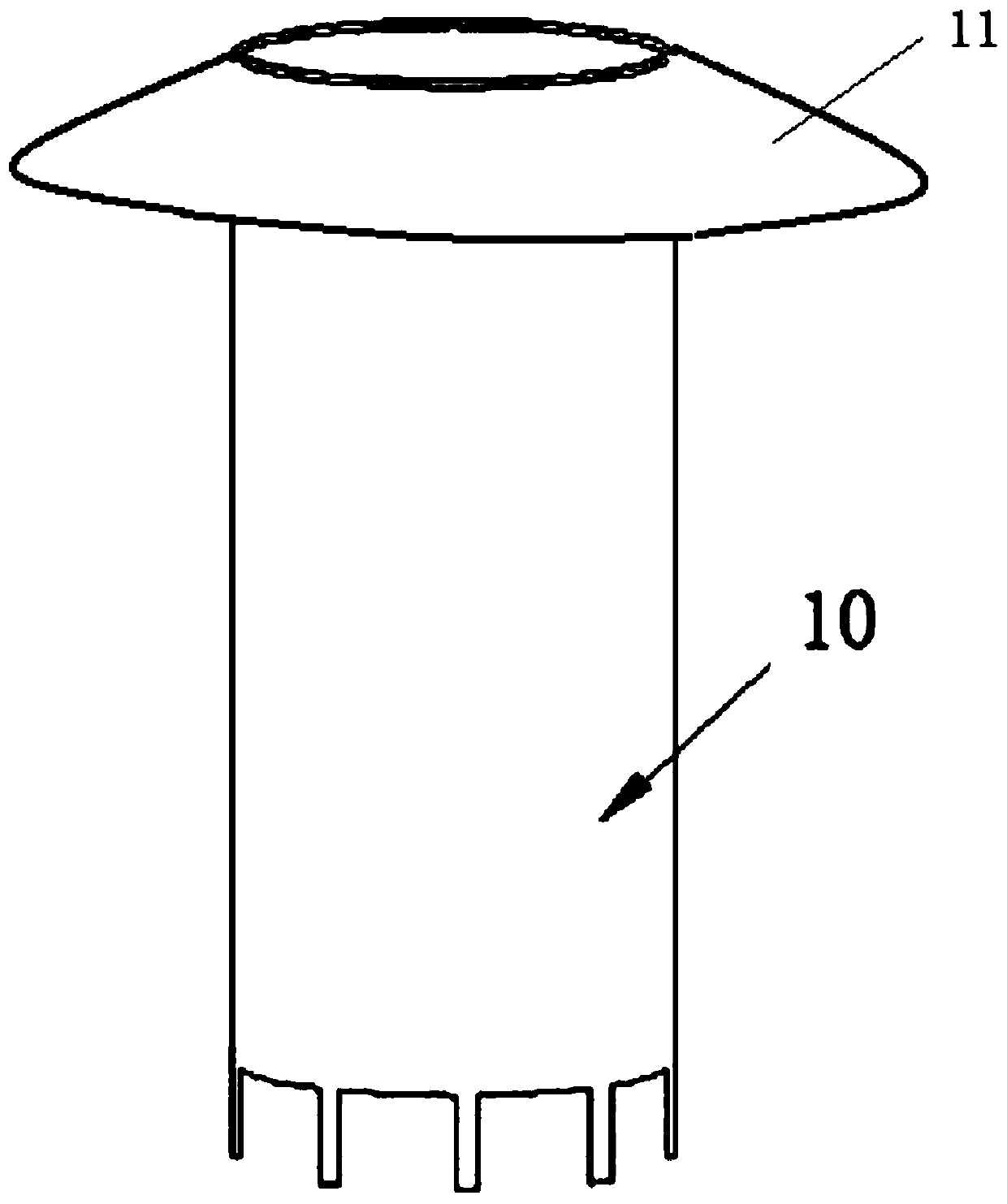

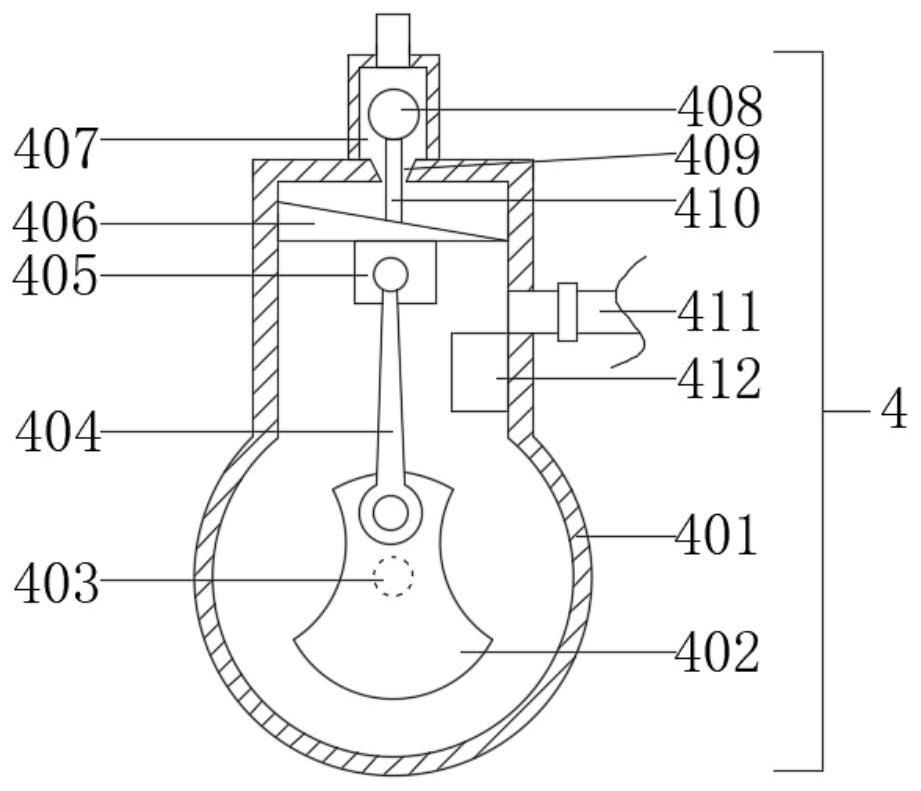

Anti-blocking switch gear of discharge bin

ActiveCN105346876AAvoid blocking problems such as archingIncrease the output speedLarge containersEngineeringMechanical engineering

The invention discloses an anti-blocking switch gear of a discharge bin, the anti-blocking switch gear is arranged above a discharge hole in the bottom of the discharge bin, and the cross section of the discharge hole is circular. The anti-blocking switch gear comprises a discharge mechanism, an arch breaking mechanism and a rotary mechanism, wherein the discharge mechanism comprises a baffle plate, an air cylinder and a circular ring; the circular ring is connected with a motor, so that the motor drives the circular ring to rotate for driving the air cylinder and the baffle plate to rotate; the arch breaking mechanism comprises a circular-ring-shaped base and a cylindrical supporting base; the base is hinged with the baffle plate to realize linkage; the side edge of the upper surface of the supporting base is provided with a plurality of spiral pawls which are in upward right-handed rotation, so that a plurality of spiral openings are formed; the rotary mechanism comprises an outer rod, an inner rod extending into a space formed by the pawls, and a plurality of blades, wherein one blade is blocked into one opening, so that the corresponding blade is driven to rotate in a rotary process of the supporting base. The anti-blocking switch gear has the advantages of being capable of effectively preventing the discharge hole from arching, uniform in discharge of the discharge bin, simple in structure, high in working efficiency and the like.

Owner:GUANGXI SHENTA MACHINERY EQUIP CO LTD

Preparation method of carboxylic butadiene-styrene latex

ActiveCN104592447AStable molecular structureConcentrated particle size distributionThermal energyMechanical property

The invention relates to a preparation method of a carboxylic butadiene-styrene latex; reaction thermal energy is provided for reaction of the carboxylic butadiene-styrene latex through high-speed water vapour; after being cooled, the water vapour is converted into high-temperature deionized water; furthermore, the high-speed water vapour is also used for driving liquid in a reaction container to rotate; the liquid in the reaction container is dispersed by a water vapour flow to form a lot of tiny steam and water mixtures; a material in the reaction container is driven to flow rapidly; substances and temperature in the reaction container are uniform to distribute; the polymerization reaction is also uniform; therefore, the final product, namely the carboxylic butadiene-styrene latex, is steady in molecular structure, easy in molecular weight control and more centralized in particle diameter distribution; the balanced and good mechanical property can be obtained; and the yield and quality of the product are increased.

Owner:NANTONG TENGLONG CHEM TECH CO LTD

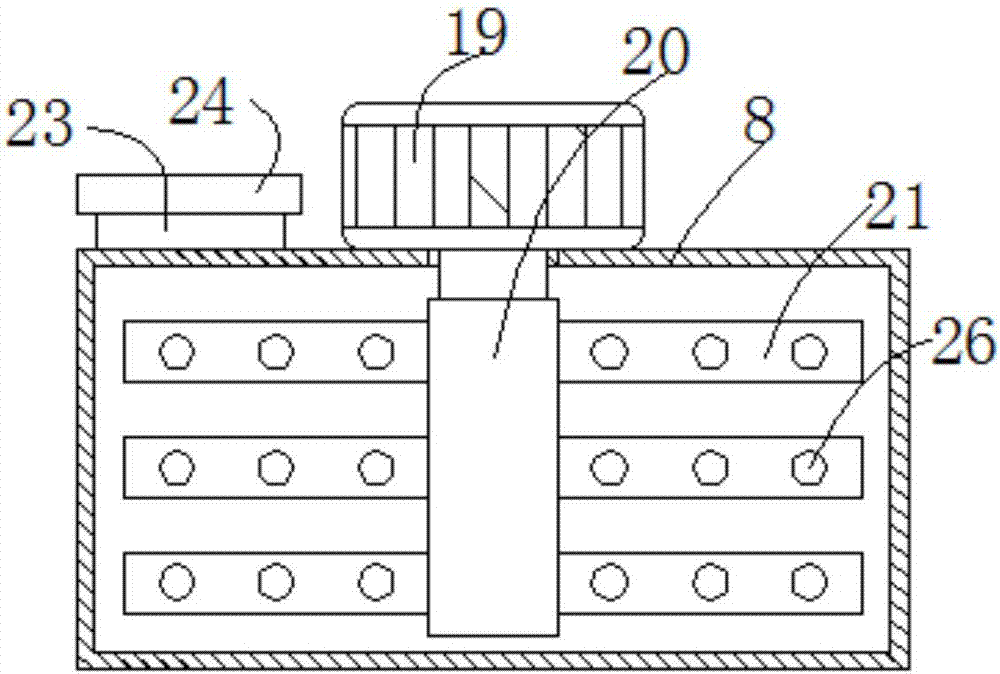

Concrete stirring device for construction site

InactiveCN107310032AImprove stirring efficiencyGuaranteed stirringMixing operation control apparatusCement mixing apparatusArchitectural engineeringMotor shaft

The invention discloses a concrete stirring device for a construction site, which comprises a case. The inner cavity of the case is symmetrically provided with baffles left and right, a plurality of through holes are arranged in the baffles, the baffles divide the inner cavity of the case into a stirring cavity and two clamping cavities, the inner wall on one side of each clamping cavity is provided with a plurality of pushing covers corresponding to the through holes, pushing holes are arranged in the pushing covers, a main stirring rod is arranged in the stirring cavity, the top end of the main stirring rod penetrates through the case and is fixedly connected to the motor shaft of a main motor, the main stirring rod is uniformly provided with a plurality of rollers, track grooves are arranged in the rollers, idler wheels are arranged in the track grooves, the idler wheels are fixedly connected to secondary stirring rods, the secondary stirring rods are uniformly provided with a plurality of stirring blades, and the bottom end of the case is uniformly provided with a plurality of support legs. The main motor of the concrete stirring device drives the main stirring rod to rotate and further drives the rollers to rotate, the rollers drive the secondary stirring rods to move and stir, such that the stirring blades stir materials irregularly, the stirring efficiency of the materials is improved, and sand, stones, and the like are enabled to be totally stirred.

Owner:童贤波

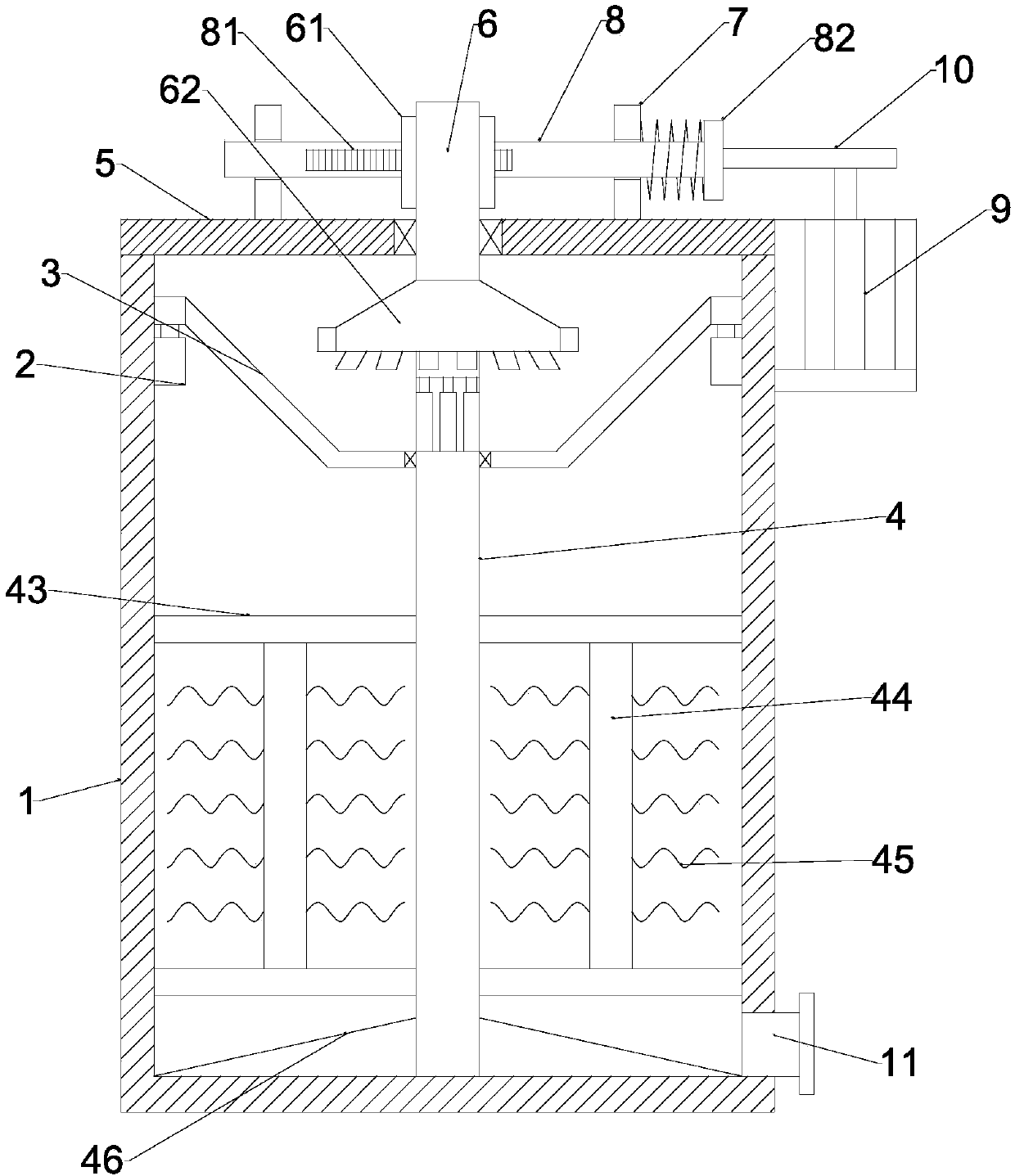

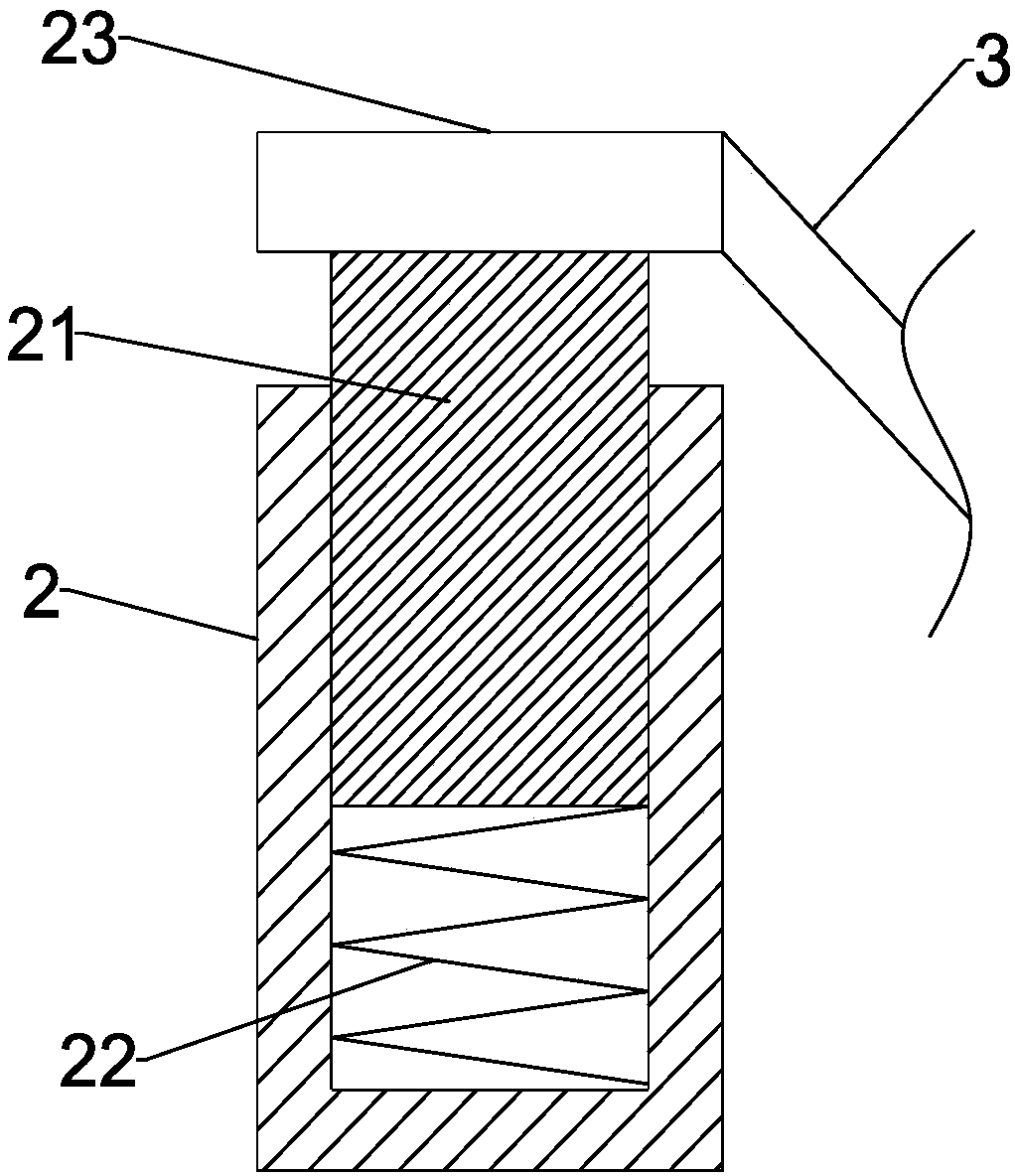

Sieving and mixing device for poultry breeding feed

InactiveCN107712979AImprove sieving efficiencyHigh speed impact effectSievingFeeding-stuffEngineeringCam

The invention discloses a sieving and mixing device for a poultry breeding feed. The sieving and mixing device comprises a housing, wherein clamping sleeves are arranged on two sides of the housing; asliding connecting rod and a compression spring are arranged in each clamping sleeve; a metal ring and a filter screen bag are arranged between the sliding connecting rods; a stirring shaft is arranged at the middle part of the filter screen bag; elastic rods and a base plate are arranged at the upper end of the stirring shaft; the stirring shaft is provided with stirring brackets, vertical connecting rods, ripple stirring blades and stirring bottom plates; upper covers are arranged at the upper end of the housing; a feeding pipe, a gear sleeve, a discharging hopper, a supporting plate, a sliding rod, a rack and a limiting baffle are arranged on the upper covers; a motor and a discharging pipeline are arranged on the right wall of the housing; and a cam is arranged at the output end of the motor. According to the sieving and mixing device disclosed by the invention, the feed can be uniformly and quickly sieved, the mixed feed can be stirred, the sieving efficiency of materials is improved in a swinging manner, and the mixing of the materials is promoted, so that the processing efficiency is effectively improved.

Owner:怀化市神通农牧科技有限公司

Smelting furnace for uniform full feeding

ActiveCN106766885AAvoid accumulationInvest evenlyFurnace componentsCrucible furnacesEngineeringIngot

The invention discloses a smelting furnace for uniform full feeding. A slide rail for passing through the center of a furnace cover is arranged on the inner surface of the furnace cover; a stirring paddle includes a hydraulic rod and a blade connected to one end of the hydraulic rod; a pulley is mounted at the other end of the hydraulic rod, and is slidingly matched with the slide rail; the pulley is connected with a slide motor; the hydraulic rod is an extension rod, and is connected with an extension motor; the inner wall of a furnace body is connected with a cache frame through a spring; the cache frame includes a leakage ring, and a cross bar connected with the inner wall of the leakage ring; and a discharge port of a material channel is positioned above the intersection of the cross bar. The extension motor shortens the stirring paddle, and slides the stirring paddle to one side, so that an aluminum ingot is fully fed in the smelting furnace; the inner wall of the furnace body is connected with the cache frame through the spring; the cache frame includes the leakage ring and the cross bar; and the discharge port of the material channel is positioned above the intersection of the cross bar, so that the fed aluminum ingot is stopped in the intersection of the cross bar, and is rebounded to fall in the smelting furnace by a hole formed by the cross bar so as to prevent nonuniform smelting.

Owner:湖南振升恒佳新材料科技有限公司

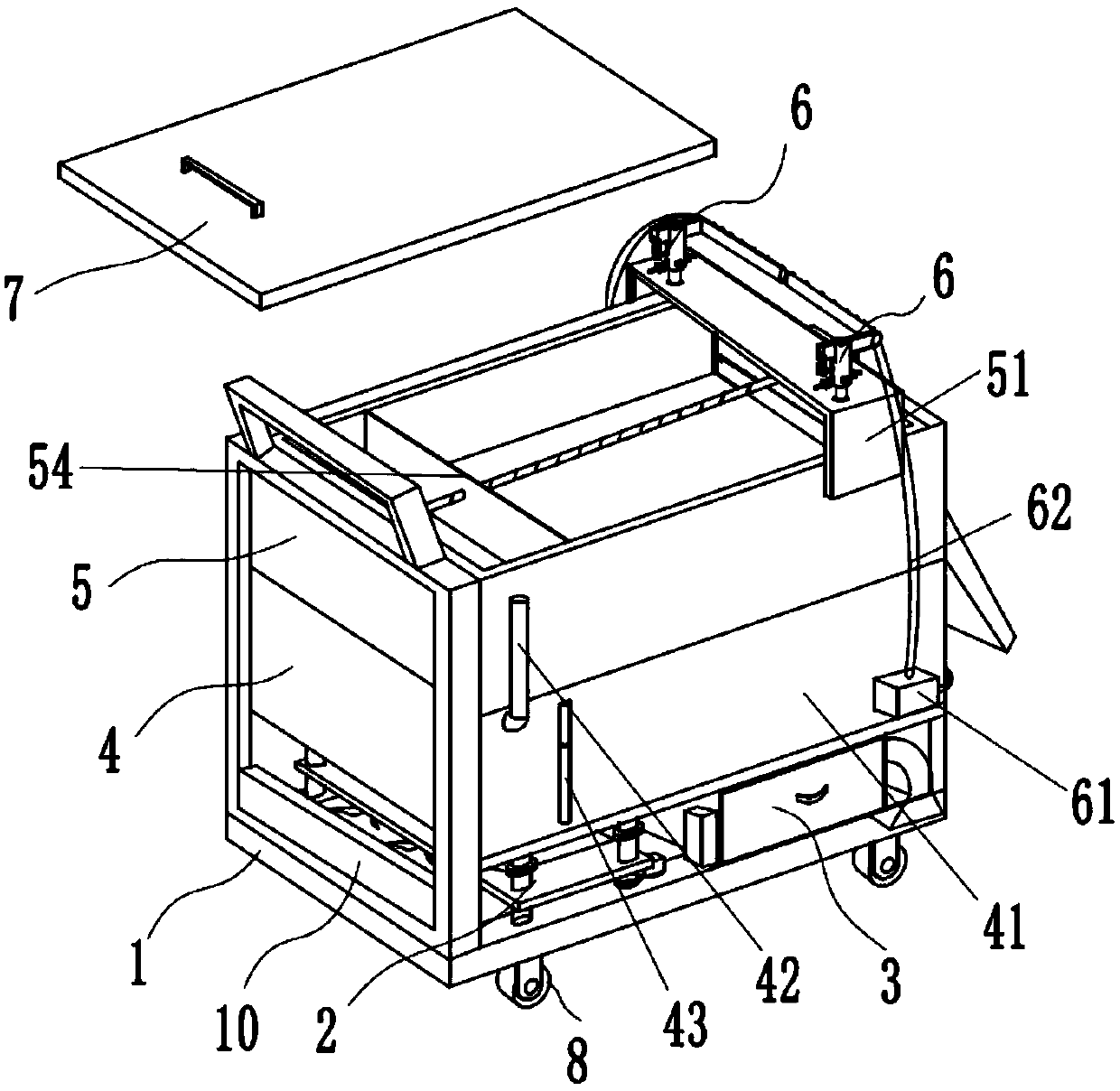

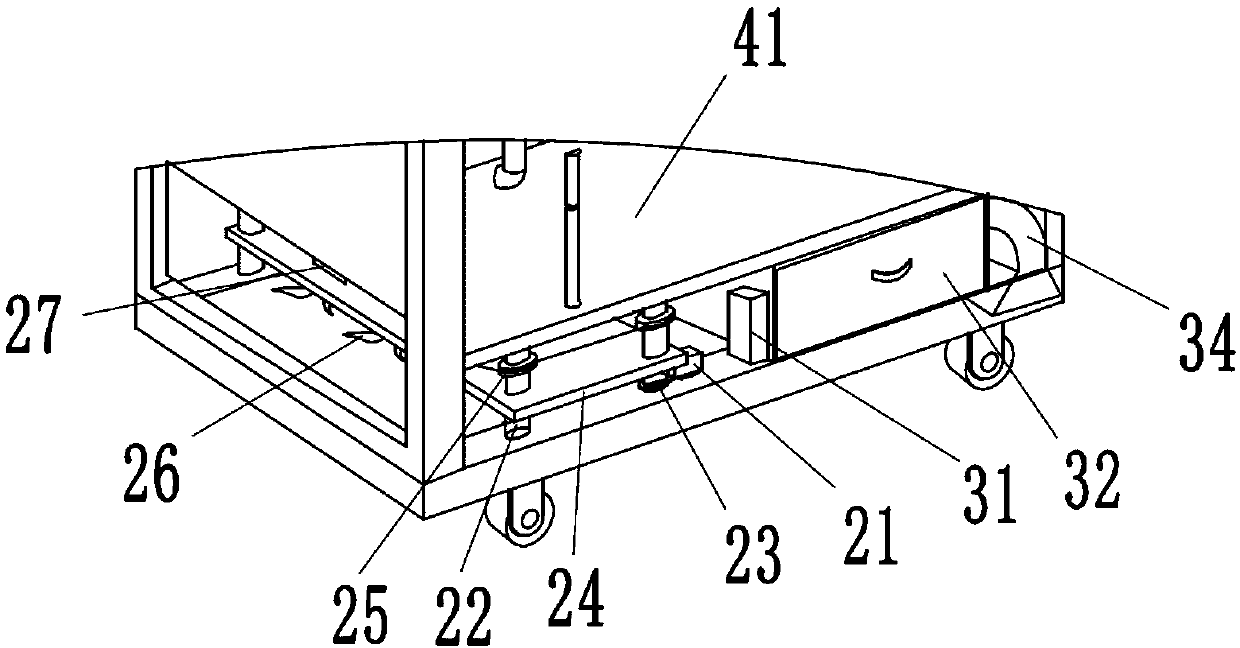

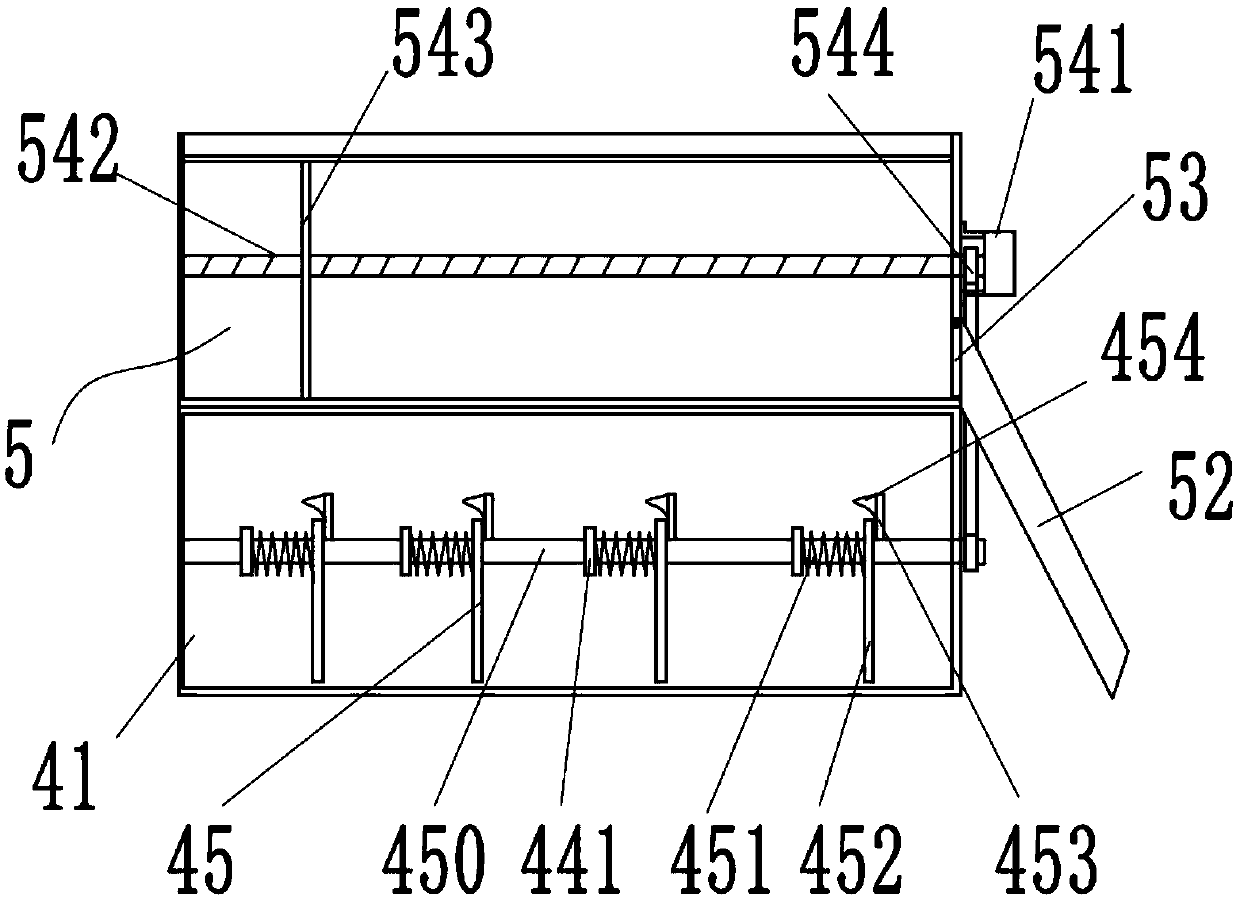

Maintenance equipment for garden

ActiveCN109618625AEasy to useImprove applicabilityShaking/oscillating/vibrating mixersTransportation and packagingLocking mechanismAgricultural engineering

The invention provides maintenance equipment for a garden. The equipment comprises a moving trolley frame, a grass cutting device arranged on the moving trolley frame, a grass collecting device, a pesticide liquid box, a fertilizer box and a pesticide spraying device arranged on the fertilizer box, and the grass cutting device comprises a lifting mechanism, a lifting plate arranged on the liftingmechanism and several cutters arranged on the lifting plate; the grass collecting device comprises a vacuum generator, a storage box and a negative pressure pipe, and the storage box is separately communicated with the vacuum generator and the negative pressure pipe; a stirring mechanism is arranged in the pesticide liquid box; a material pushing device is arranged in the fertilizer box and is inlinkage with the stirring mechanism; the pesticide spraying device comprises a pesticide pump and a pair of spraying mechanisms, the pesticide pump is communicated with the pesticide liquid box, and each spraying mechanism comprises a rotary shaft, a pair of locking mechanisms used for locking the rotary shaft, a height adjusting mechanism and a mist spraying rod; the rotary shaft is movably arranged on the fertilizer box, the mist spraying rod is arranged on the rotary shaft through the height adjusting mechanism in a swing mode, and one end of the mist spraying rod is communicated with the pesticide pump through a liquid supplying pipe. The equipment is convenient to use and saves time and labor.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH

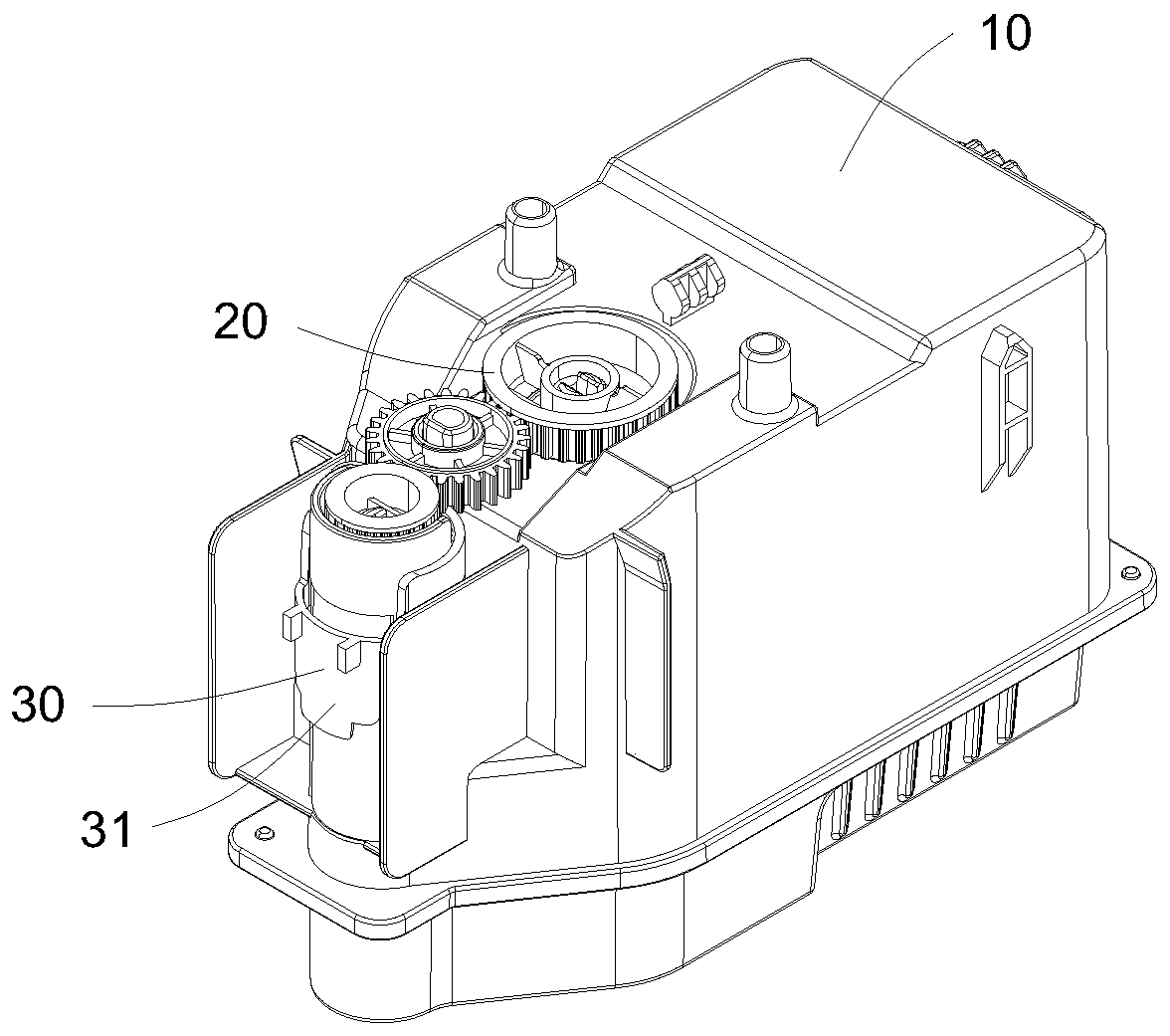

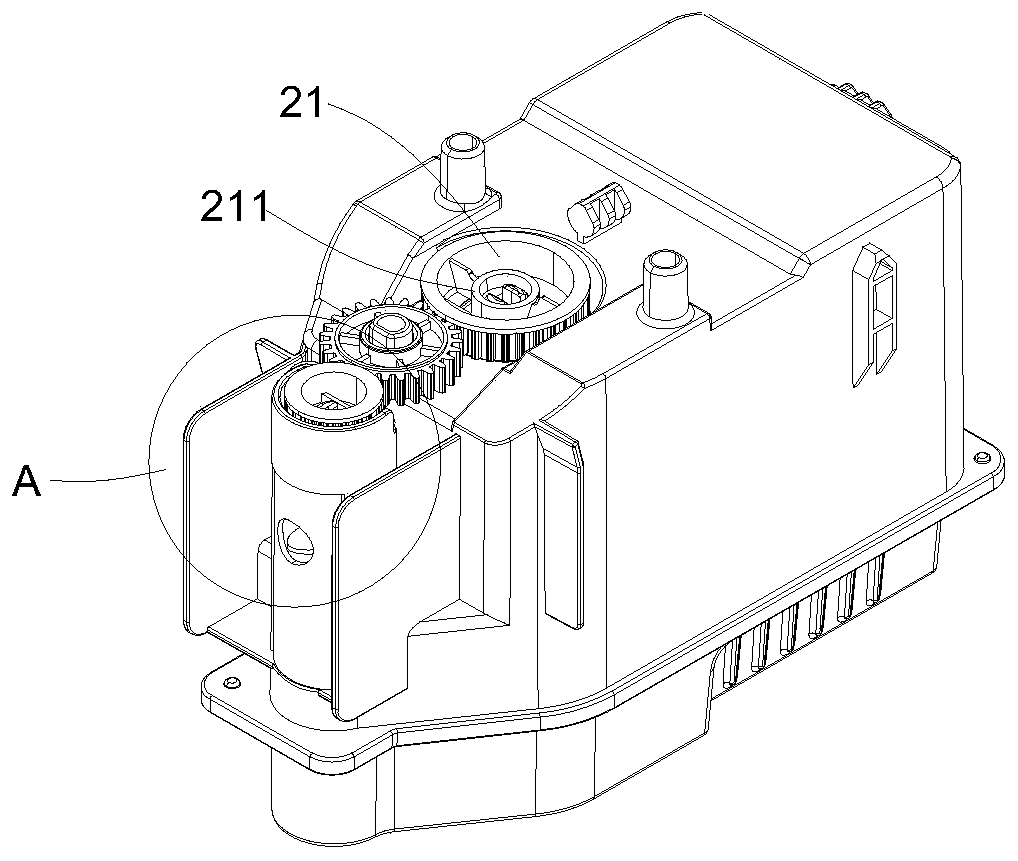

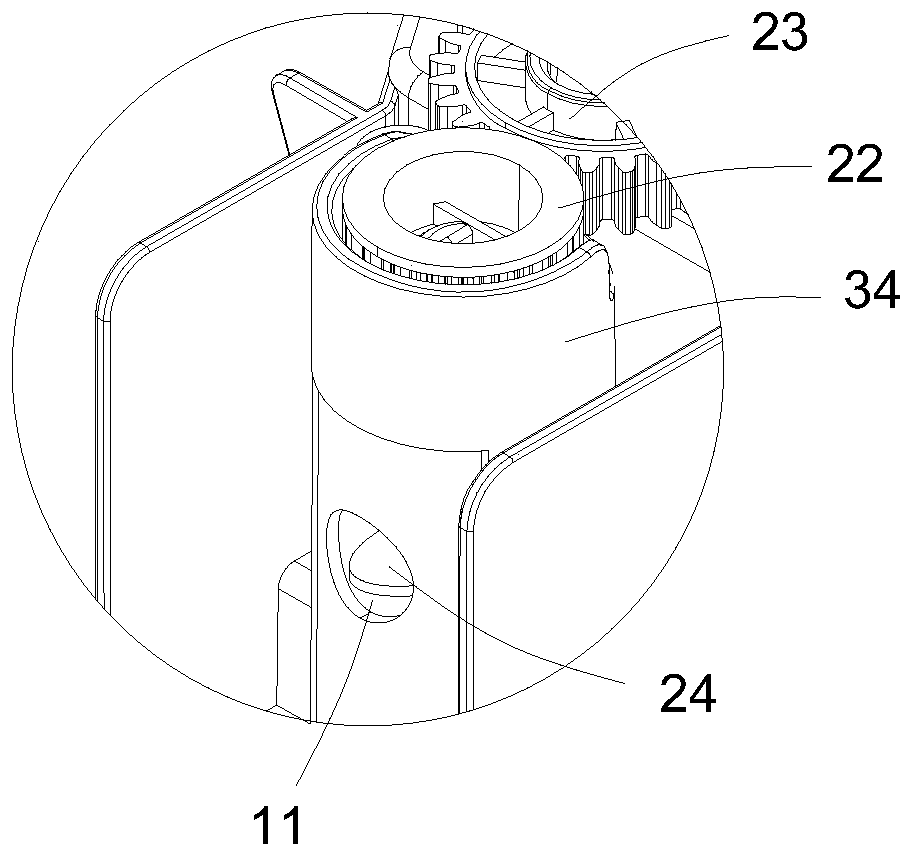

Developer supply device

InactiveCN111562731AGuaranteed stirringImprove the way of powderElectrographic process apparatusGear wheelEngineering

A developer supply device includes a shell, a cavity for storing a developer is formed in the shell; a powder outlet communicated with an inner cavity of the shell is formed in the shell; the developer in the shell flows out of a supply container and enters imaging equipment; the developer supply device further includes a driving gear train arranged on the shell and a sealing assembly connected with the driving gear train. The driving gear train is connected with a driving part in the image forming device after a developer supply container is installed in the imaging equipment, and when the driving gear train is driven by a driving device to rotate, the sealing assembly acts along with the action of the driving gear train to control opening and closing of the powder outlet. The driving gear train and the sealing assembly are arranged, the powder discharging mode is improved, and adverse faults such as jamming after installation are avoided in any step and any occasion.

Owner:JIANGXI KAILIDE TECH CO LTD

Novel rotary evaporator

InactiveCN108079604AEvenly heatedEffective rotationEvaporator accessoriesDistillation in rotating vesselsWater bathsRotary evaporator

The invention discloses a novel rotary evaporator. The novel rotary evaporator comprises a base, a water bath kettle is arranged on the upper side of a base plate, an electric control box is arrangedon the right side of the water bath kettle, an L-shaped connecting plate is arranged at the outer end of the upper side of the base, a screw rod is connected with the L-shaped connecting plate, a first motor is arranged outside the screw rod, a sliding block is arranged on the screw rod, an L-shaped connecting rod is arranged on the inner side of the sliding block, a third motor is arranged on theupper side of the L-shaped connecting rod, an upper side of the L-shaped connecting rod is provided with a bearing seat, connecting pipes are arranged inside the bearing seat, a rotary evaporation bottle is arranged between the connecting pipes, a feeding port is arranged on the right side of the upper side of the rotary evaporation bottle, a stirring rod shaft is arranged inside the rotary evaporation bottle, a second motor is arranged on the right side of the stirring shaft, stirring rods are arranged on the upper and lower sides of the stirring shaft, and a connecting hose is arranged on the left side of the connecting pipe on the left end, and a first condensing tube, a second condensing tube, and a liquid storage tube are arranged on the left side of the connecting hose. The novel rotary evaporator can effectively facilitate stirring and moving up and down in a process of rotary evaporation of the evaporator, and can effectively facilitate rotary evaporation of the evaporator.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

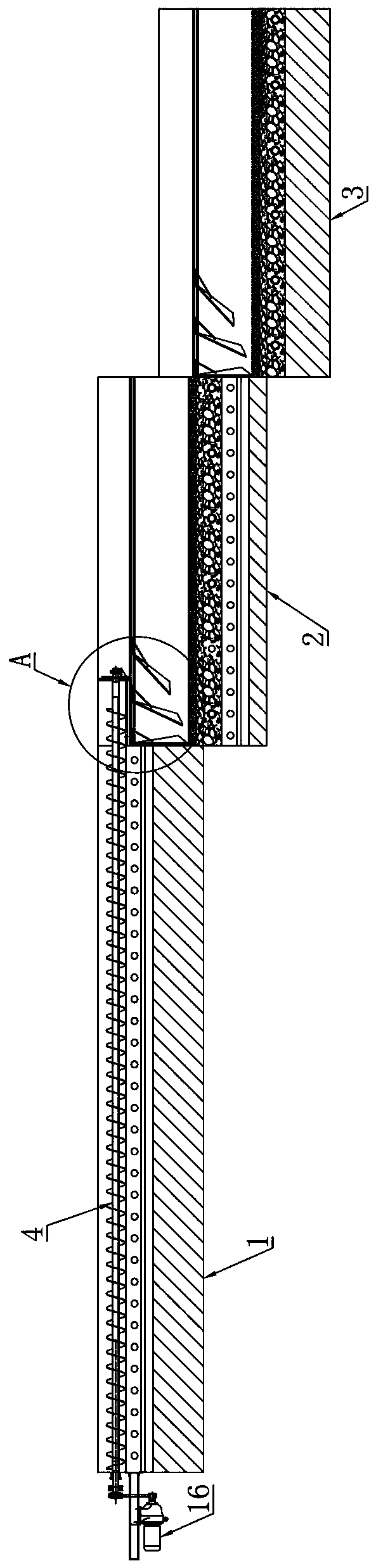

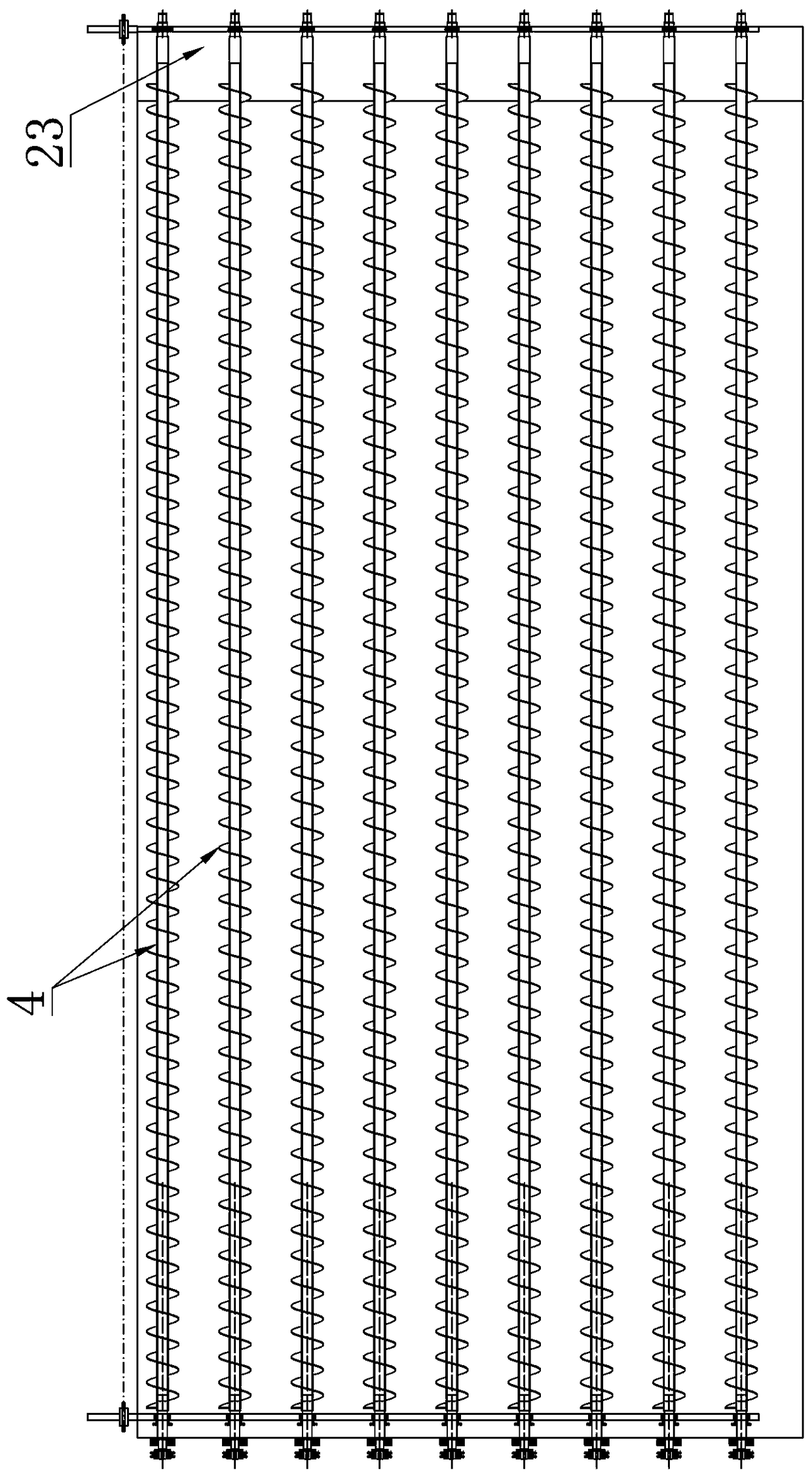

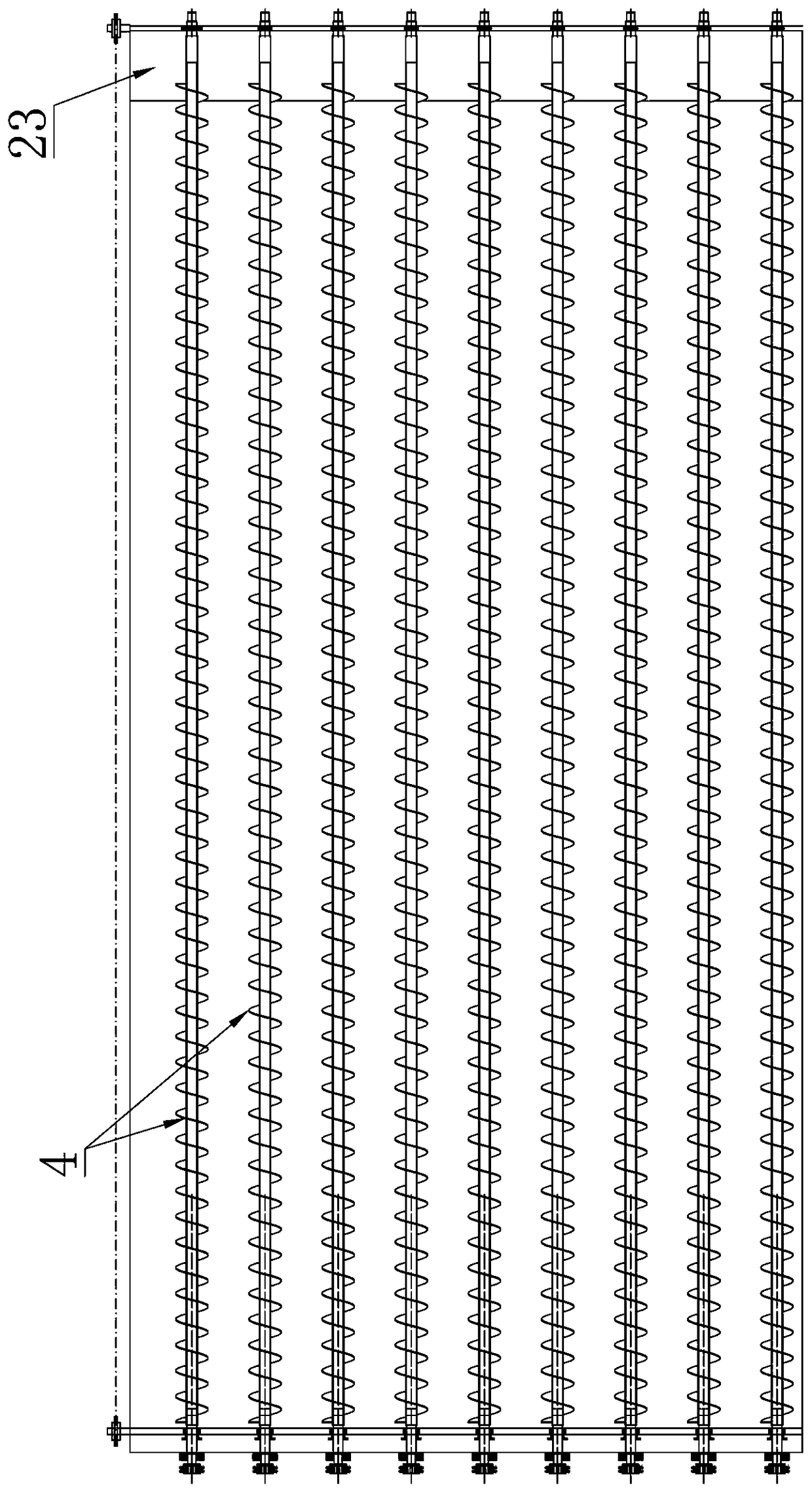

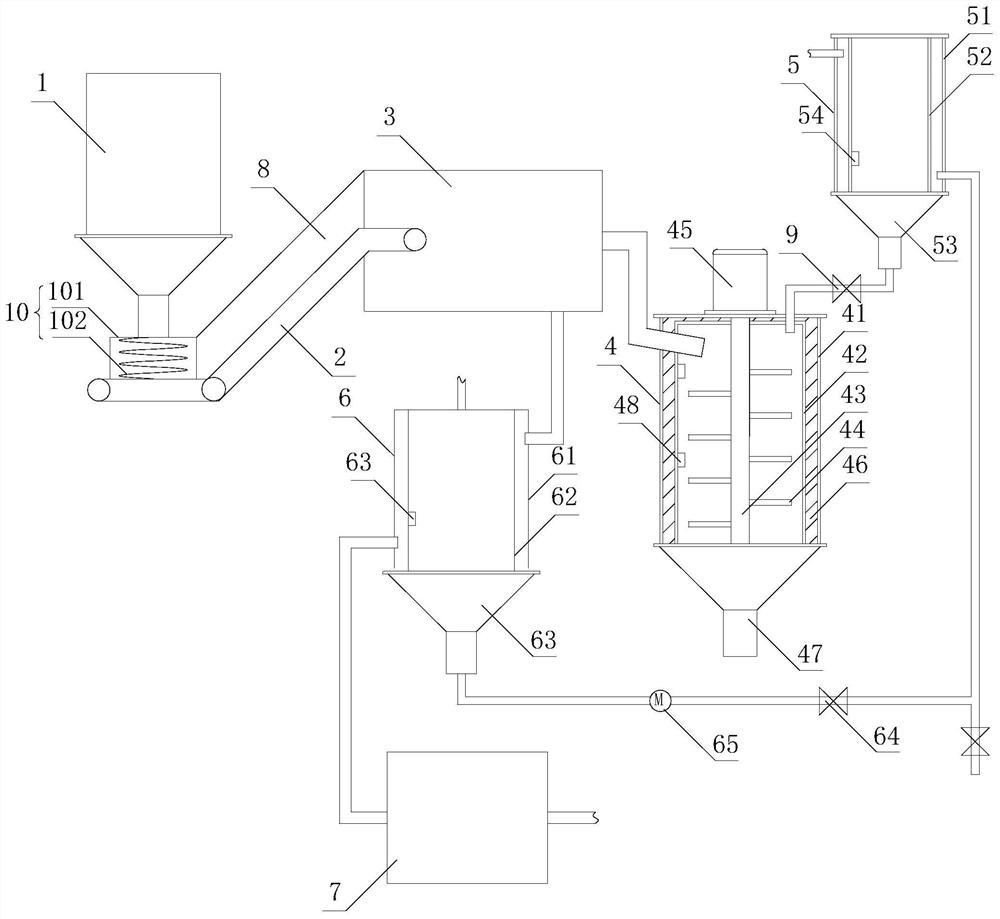

Dry fermentation bed system for municipal sludge

ActiveCN108558159AEasy transferBreak the knotSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgeEngineering

The invention relates to a dry fermentation bed system for municipal sludge. The dry fermentation bed system comprises a dry fermentation bed, wherein the dry fermentation bed comprises a dry pretreatment zone, a fermenting degradation zone and an aging stabilization zone which are sequentially arranged and are arranged in a stepped manner from high to low; a plurality of screw conveying devices which are uniformly arranged in parallel are arranged in the dry pretreatment zone; distributing mechanisms are respectively arranged in the fermenting degradation zone and the aging stabilization zone. According to the dry fermentation bed system disclosed by the invention, the dry pretreatment zone, the fermenting degradation zone and the aging stabilization zone in the whole dry fermentation bedare arranged in a continuous and sequentially-reduced stepped form, and transfer of materials is facilitated; pavement and pushing transfer of the materials can be smoothly realized by the screw conveying devices and the distributing mechanisms.

Owner:江西省兆龙环保科技有限公司

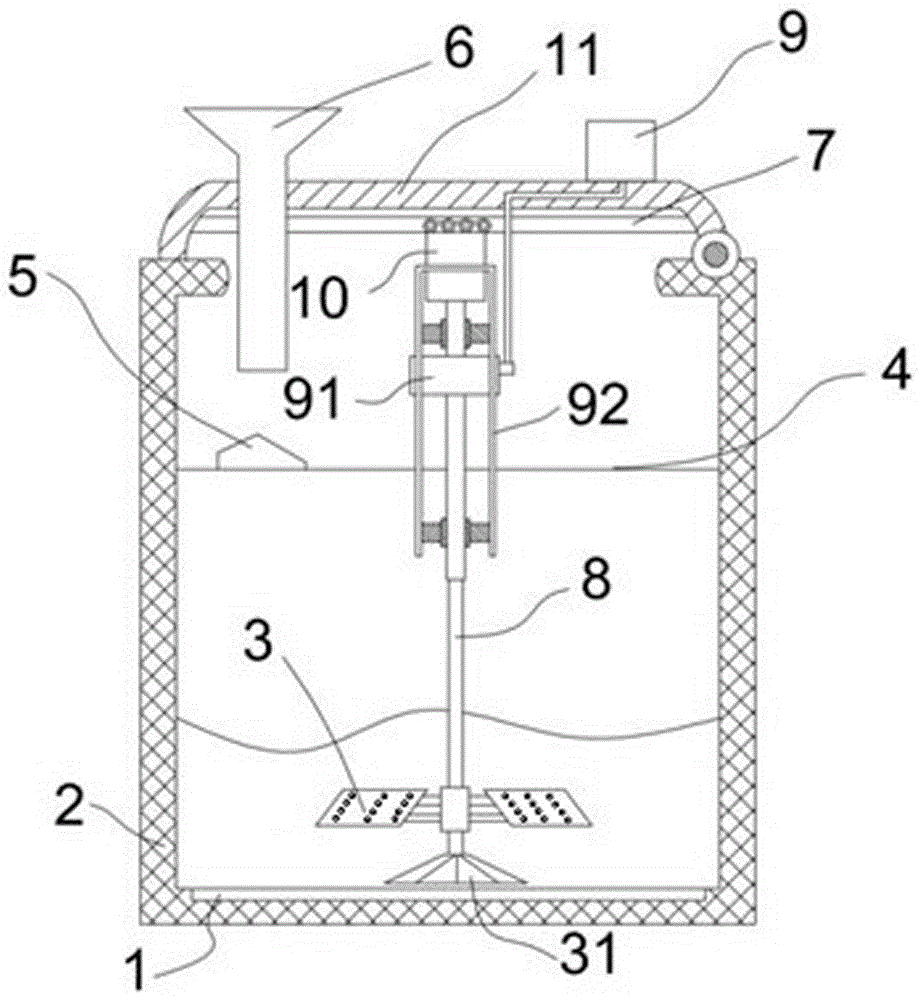

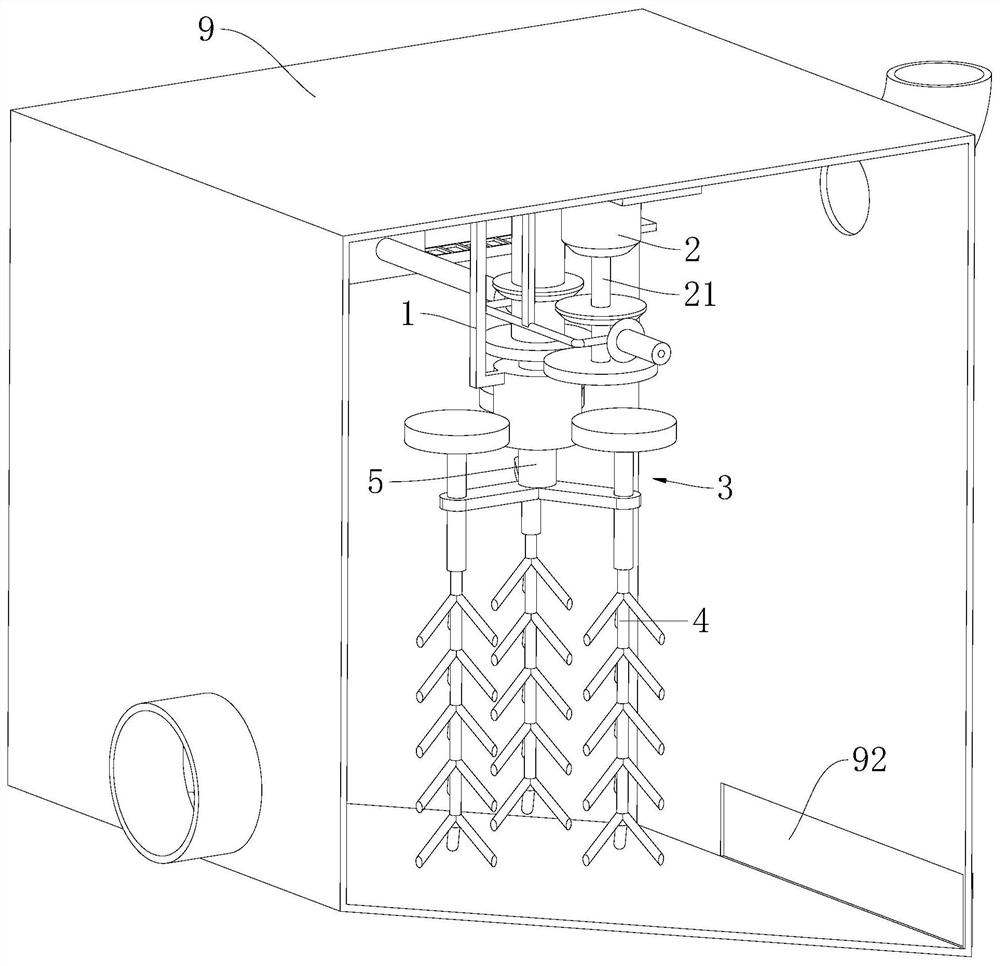

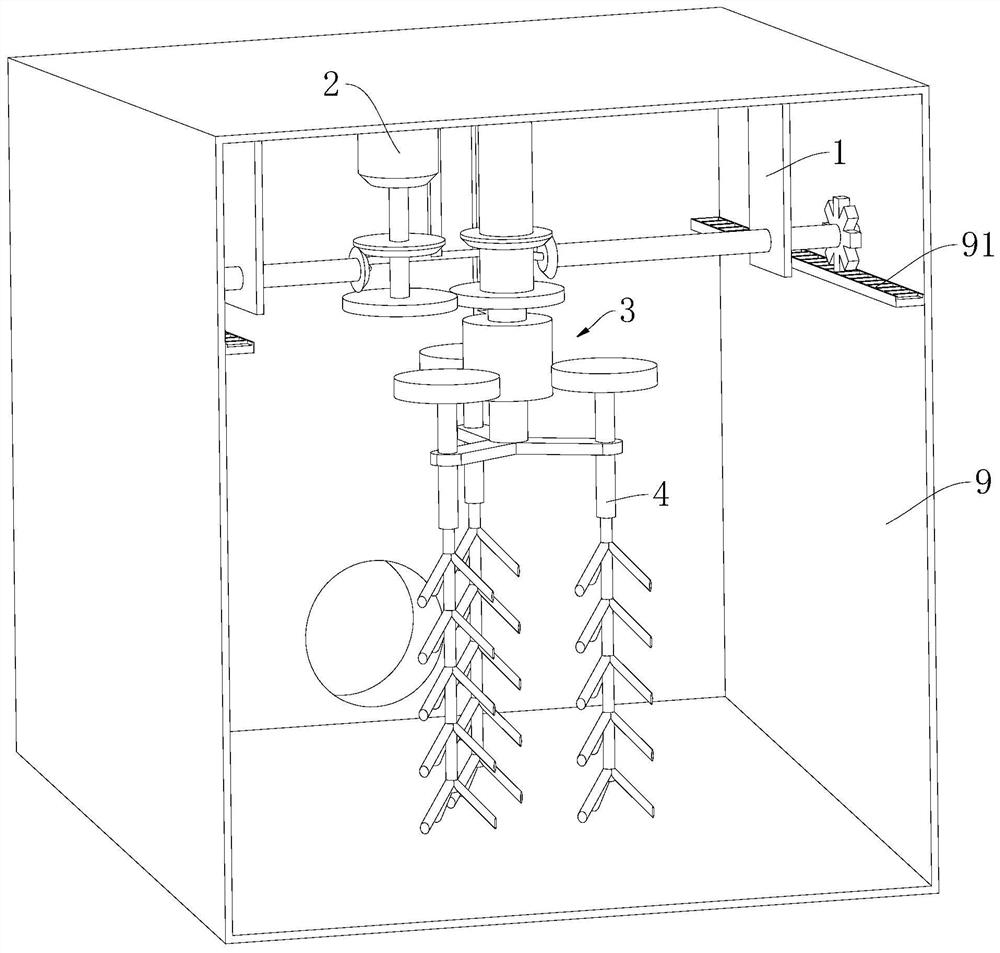

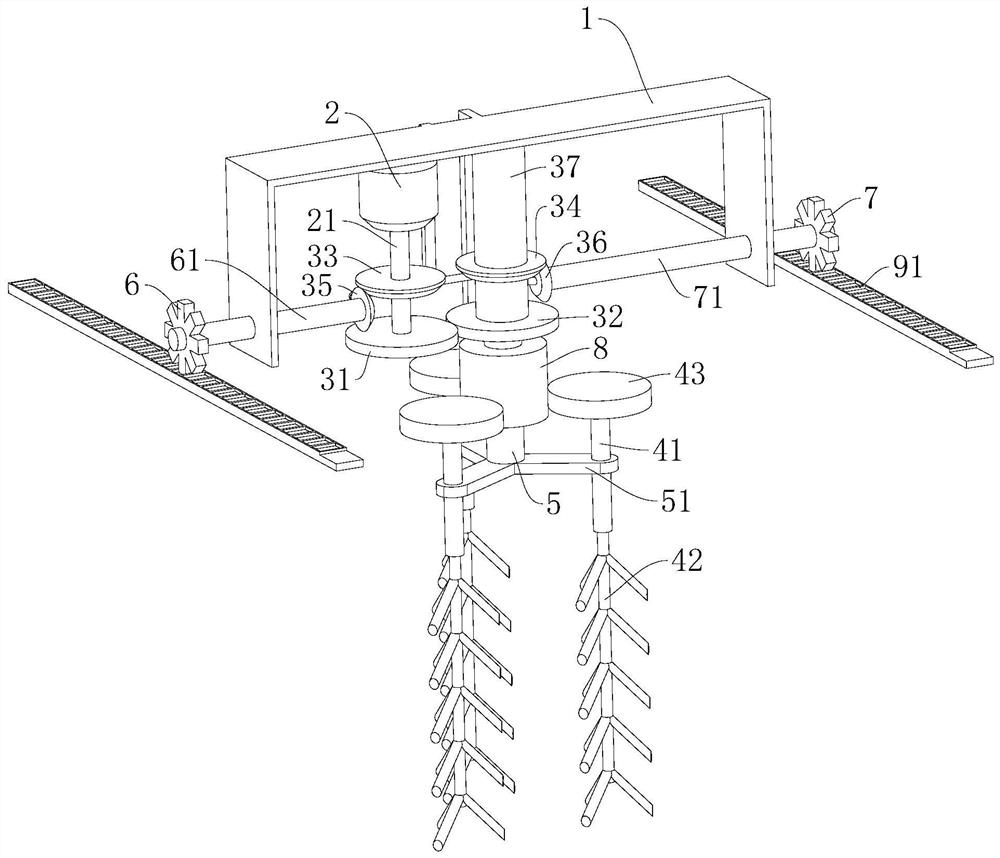

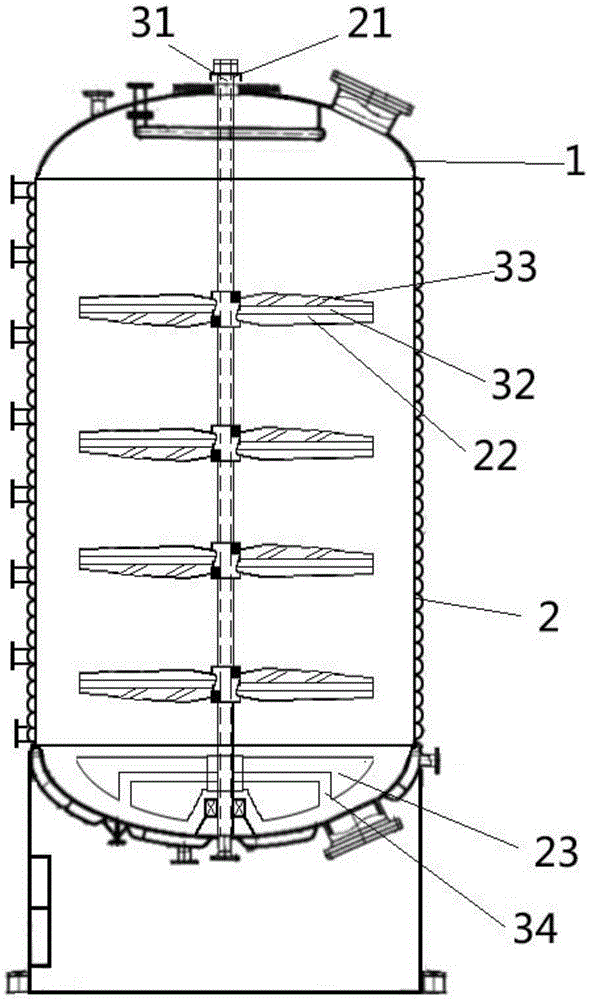

Stirrer and smelting furnace with stirrer

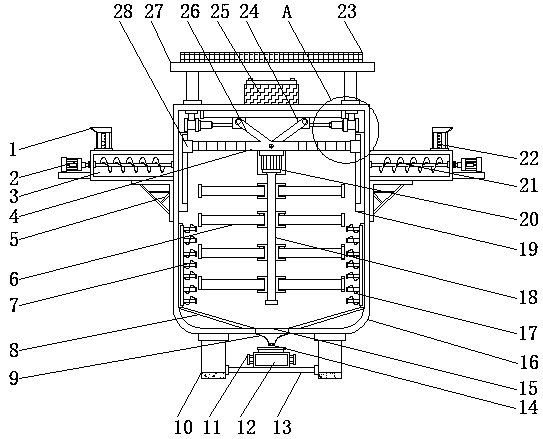

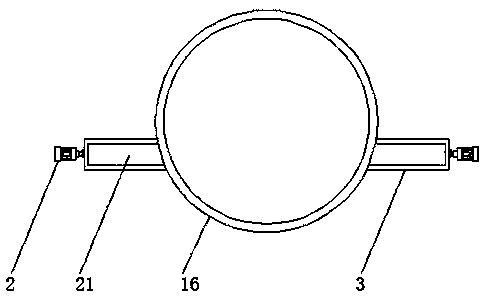

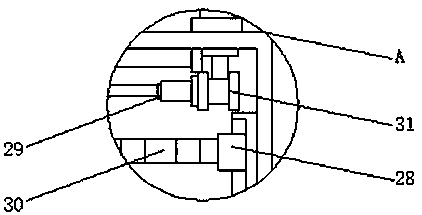

ActiveCN111678353AStir evenly and thoroughlyImprove mixing uniformityStirring devicesCharge treatment typeElectric machineryDrive motor

The invention discloses a stirrer and a smelting furnace with the stirrer. The stirrer comprises a traveling support, a driving motor, a transmission structure and stirring paddles, wherein the driving motor is arranged on the traveling support, an output shaft of the driving motor is connected with the stirring paddles through the transmission structure and drives the stirring paddles to rotate,and a first traveling wheel and a second traveling wheel are respectively arranged on two sides of the traveling support; and the output shaft of the driving motor is respectively connected with the first traveling wheel and the second traveling wheel through the transmission structure, drives the first traveling wheel and the second traveling wheel to synchronously rotate, and drives the traveling support and the stirring paddles arranged on the traveling support to horizontally move. The driving motor is arranged to control the two traveling wheels to rotate on guide rails, so that the traveling support is driven to travel in the smelting furnace, the smelting furnace can be stirred, and the stirring is more uniform and thorough.

Owner:湖南森科有色金属有限公司

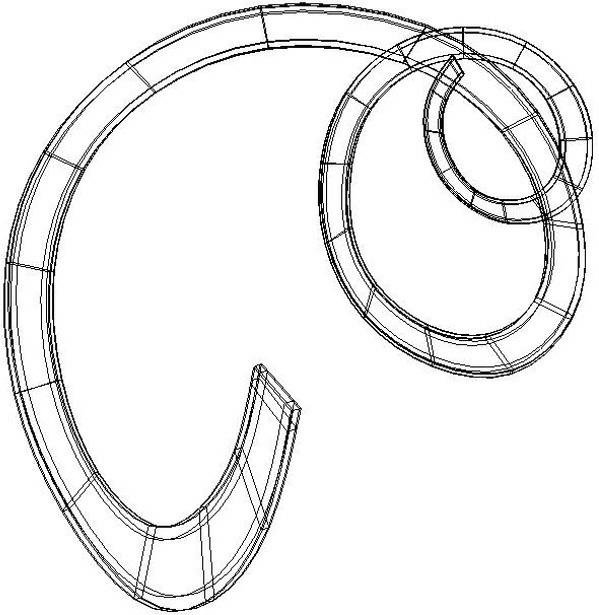

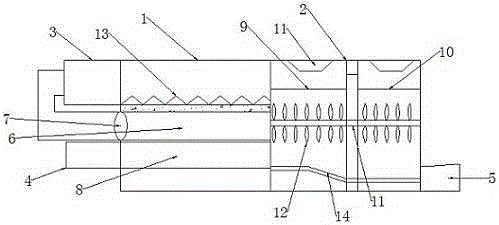

Double-layer mixing device

InactiveCN102600748AGuaranteed stirringAvoid cloggingRotary stirring mixersMechanical engineeringMechanics

The invention discloses a double-layer mixing device, which comprises a front bracket, a rear bracket and a large mixing tank. The inner wall of the large mixing tank is provided with a pair of large helical mixing blades, a small mixing tank is fixedly arranged in the large mixing tank and is coaxial with the large mixing tank, the inner wall of the small mixing tank is provided with a pair of small helical mixing blades, the small mixing tank is at least provided with a communication hole, the rotational direction of the large helical mixing blades is opposite to the rotational direction of the small helical mixing blades, and a clearance is arranged between the large helical mixing blades and the outer surface of the small mixing tank. Materials are pushed into different directions respectively in the large mixing tank and the small mixing tank and respectively move in a circulating way in the large mixing tank and the small mixing tank, thereby effectively ensuring that the materials can be fully mixed. Due to mixing in the circulating way, the problem of non-uniformity of mixing can be solved completely. Since a clearance is arranged between the outer surface of the small mixing tank and the large helical mixing blades, the blockage and stoppage of materials can be avoided effectively.

Owner:李文强

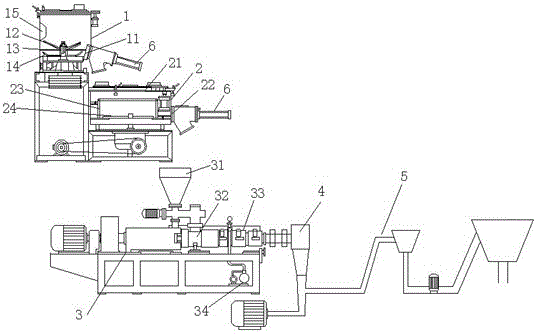

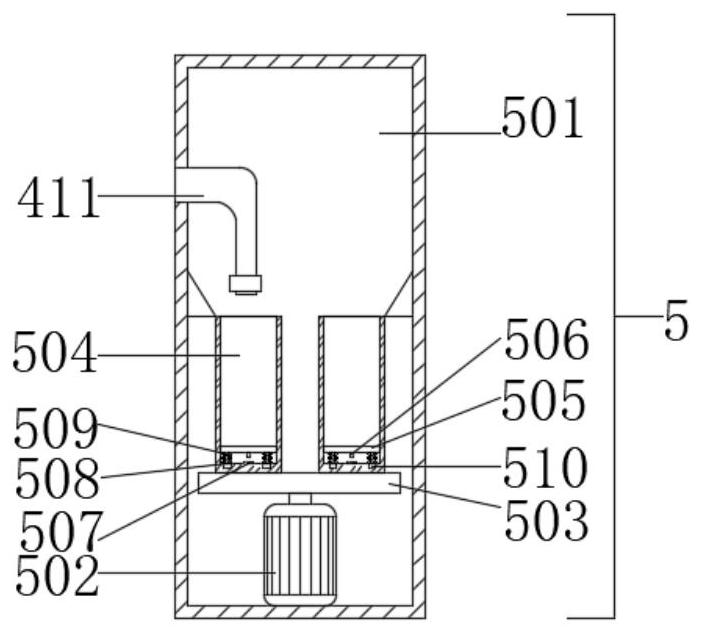

Medical PVC particle production system

The invention relates to a medical PVC particle production system. The system comprises a hot mixing machine, a cold mixing machine, an extruding machine, a granulating machine and an air supply system; the hot mixing machine is arranged at the upper part of the cold mixing machine; the extruding machine is arranged at the lower part of the cold mixing machine, and is connected with the granulating machine and the air supply system in sequence; a discharge port of the hot mixing machine is vertically formed in the upper part of a feed port of the cold mixing machine; a discharge port of the cold mixing machine is vertically formed in the upper part of a hopper of the extruding machine; a stirring device is arranged in the hot mixing machine; a cooling device is arranged in the cold mixing machine; a screw rod conveying module is arranged in the extruding machine; and a heating device is arranged out of the screw rod conveying module. The medical PVC particle production system is high in automation degree, is provided with time and temperature controllers on the hot mixing machine and the cold mixing machine for guaranteeing material stirring and cooling effects to lay foundation for subsequent PVC particle production, and is provided with a vacuum purifying device on one side of the extruding machine for effectively reducing molecular groups and impurities in materials to guarantee subsequent production quality.

Owner:ZHENJIANG KANGYUAN NEW MATERIAL TECH CO LTD

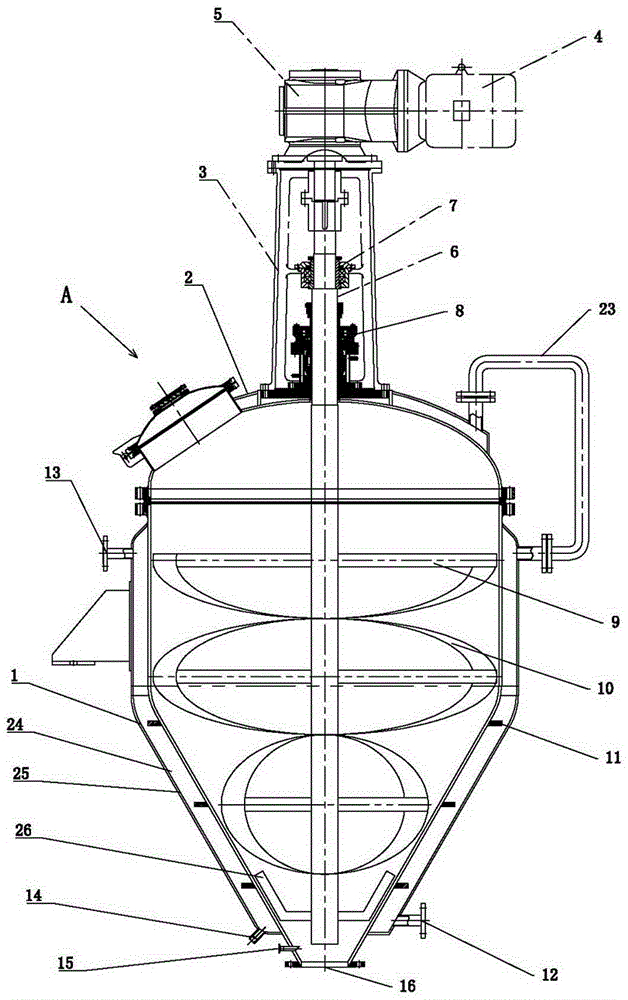

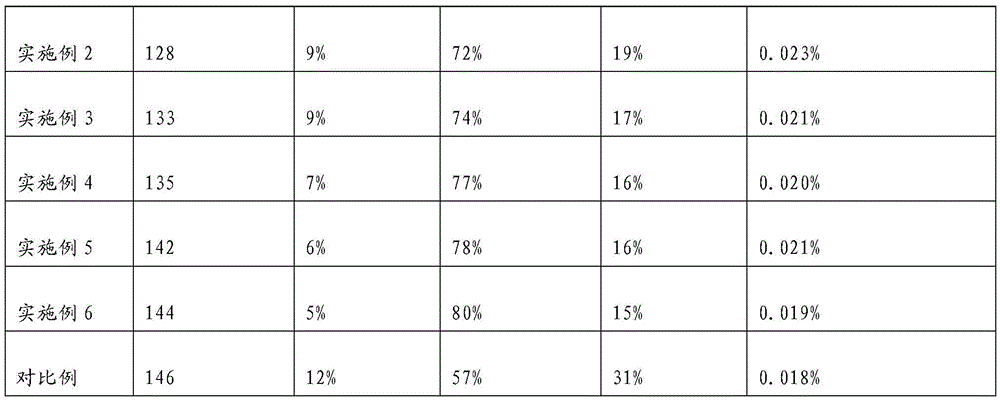

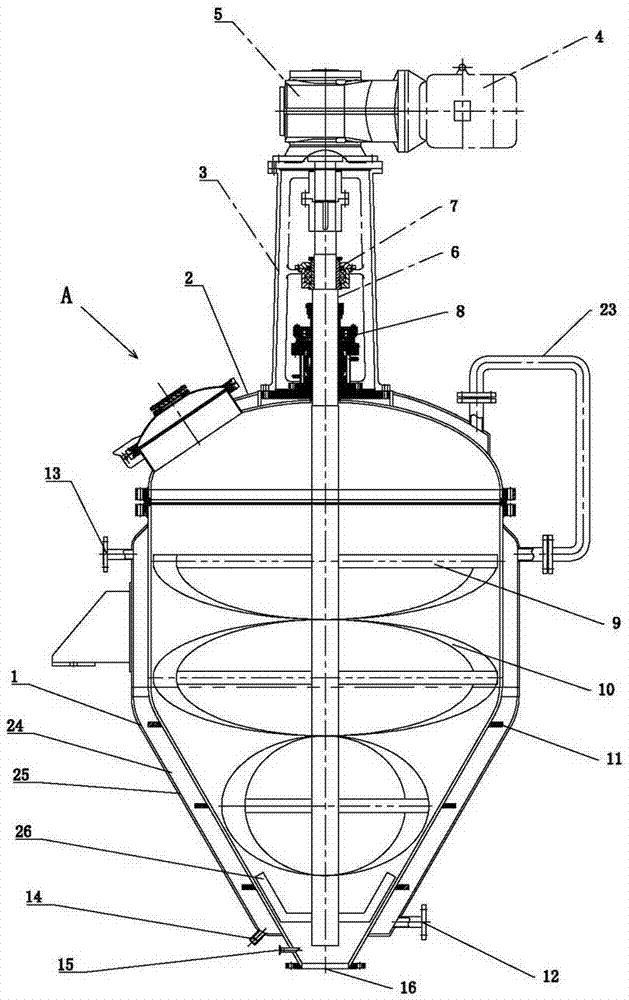

Helical ribbon vacuum dryer and working method thereof

InactiveCN105716400AAvoid cakingGuaranteed stirringDrying using combination processesDrying machines with non-progressive movementsEngineeringApplication areas

The invention relates to a helical ribbon vacuum dryer and a working method thereof. The helical ribbon vacuum dryer comprises a barrel body, wherein the upper part of the barrel body is provided with a barrel cover, a hollow support is arranged at the upper part of the barrel cover, the upper part of a stirring shaft is in vertical and rotary fit to the inside of the support, and the middle-lower part of the stirring shaft is located in the barrel body; double helical ribbons are distributed in the middle lower part of the stirring shaft, the outer edges of the double helical ribbons are distributed close to the inner wall of the barrel body; a concave scraper matched with the inner wall of the bottom of the barrel body is arranged at the lower end of the stirring shaft; and the top of the concave scraper does not exceed the bottom of the double helical ribbons. According to the invention, the top of the concave scraper does not exceed the bottom of the double helical ribbons, namely the scraper and the double helical ribbons are distributed up and down, and force application area of the scraper and the double helical ribbons acting on the material is relatively small, thus preventing overall movement in movement of the material in a whole container and avoiding material caking.

Owner:陆文光

Method for controlling rotating speed of stirring motor of ice cream machine based on temperature and forming degree

PendingCN114732078AMaster the real working status in real timeReduce energy consumptionFrozen sweetsFrequency changerMotor speed

The invention discloses a method for controlling the rotating speed of a stirring motor of an ice cream machine based on temperature and forming degree, the ice cream machine further comprises a control system, the control system comprises a main controller, a temperature monitoring module and a frequency converter, and the frequency converter is connected with the stirring motor and used for adjusting the input frequency of the stirring motor. The temperature monitoring module is used for monitoring the temperature of ice cream materials in the evaporation cylinder or the air return temperature value of the evaporation cylinder and transmitting the temperature monitoring value to the main controller, and the main controller obtains the real-time forming degree proportion value of ice cream in the evaporation cylinder according to the working torque value of the stirring motor or the rotating speed value of the motor. The main controller is used for adjusting the output power supply frequency of the frequency converter according to any one or the combination of two of a temperature monitoring value and a real-time forming degree proportion value, so as to adjust the rotating speed of the stirring motor. The energy consumption and noise of the ice cream machine can be reduced.

Owner:ZHONGSHEN TECH (GUANGDONG) CO LTD

Method for controlling rotating speed of stirring motor of ice cream machine based on temperature and forming degree

InactiveCN113068760AAccurate speed controlReduce energy consumptionFrozen sweetsFrequency changerMotor speed

The invention discloses a method for controlling the rotating speed of a stirring motor of an ice cream machine based on temperature and forming degree, the ice cream machine further comprises a control system, the control system comprises a main controller, a temperature monitoring module and a frequency converter, and the frequency converter is connected with the stirring motor and used for adjusting the input frequency of the stirring motor. The temperature monitoring module is used for monitoring the temperature of the ice cream material in the evaporation cylinder or the air return temperature value of the evaporation cylinder and transmitting the temperature monitoring value to the main controller, and the frequency converter obtains the real-time working torque value of the stirring motor and transmitts the monitored working torque value to the main controller so as to obtain the real-time forming degree proportion value of the ice cream in the evaporation cylinder, and the main controller adjusts the output power frequency of the frequency converter according to any one or the combination of the temperature monitoring value and the real-time forming degree proportion value and the rotating speed of the stirring motor is further adjusted. The energy consumption and noise of the ice cream machine can be reduced.

Owner:ZHONGSHEN TECH (GUANGDONG) CO LTD

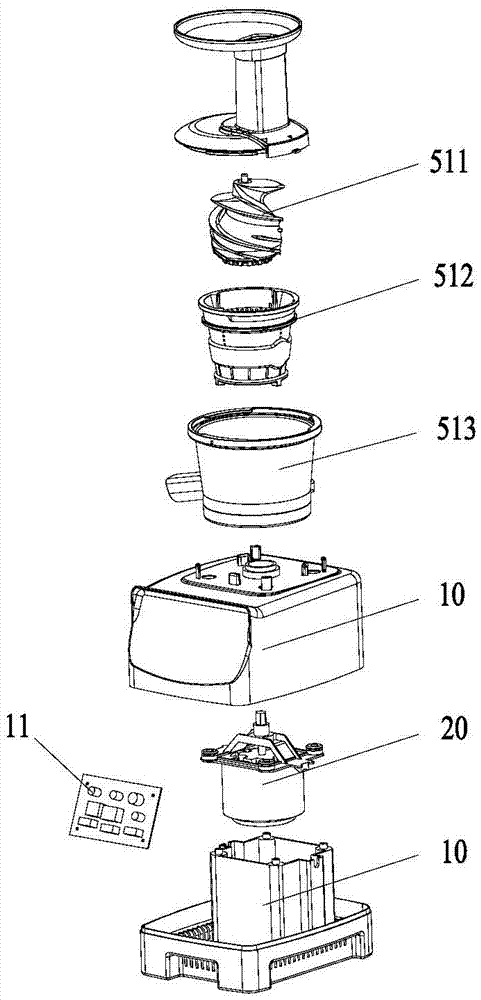

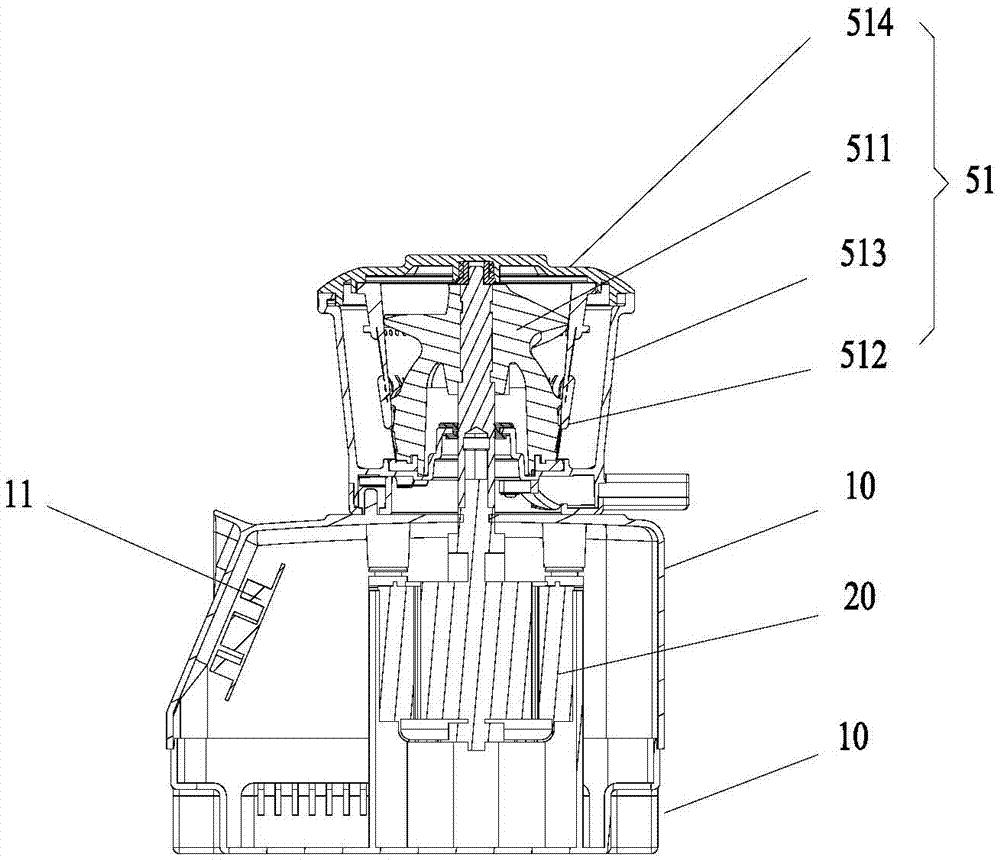

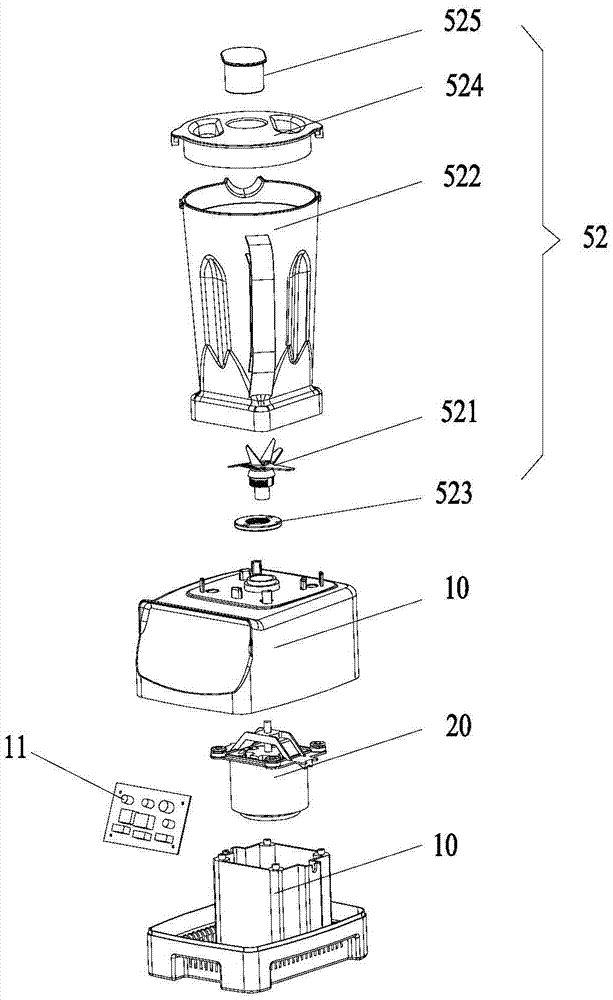

Food processor

PendingCN107080473ACompact structureBeautify the appearanceStrainersControl signalControl engineering

The invention provides a food processor which comprises a base, a motor, at least two functional components, a control module, a controller and a motor control circuit, wherein the functional components can be detachably matched with the base, and process to-be-processed food in different manners at different rotating speeds of the motor; different switching signals are generated when the different functional components are matched with the base; the control module comprises a plurality of control parts, and is arranged on the base or an external remote controller; the controller can be communicated with the control module, receives the different switching signals, and then selectively activates at least partial control parts in the control module; the motor control circuit controls the motor; the controller can receive input signals of the activated partial control parts, and further transmits corresponding control signals to the motor control circuit to control operation of the motor. With the adoption of the technical scheme, the problem of larger base in the prior art can be effectively solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Cement mixing device and operation method thereof

InactiveCN109291248AMeet the requirement of stirringMeet the requirements of discharging and storingTransportation and packagingMixing operation control apparatusMaterials scienceCement

The invention discloses a cement mixing device and an operation method thereof. The cement mixing device comprises a mixer, a cement feeding device and a cement mixing device body, wherein the cementfeeding device and the cement mixing device body are arranged in the mixer; the mixer is internally provided with a waste cavity; the mixer is internally provided with a cement placement cavity; the mixer is provided with a guillotine cavity located on the lower side of the cement placement cavity; the mixer is provided with a second return spring cavity located in the upper side of the guillotinecavity; the mixer is internally provided with a cement mixing cavity located in the lower right side of the guillotine cavity; and a cement mixing driving column is fixedly arranged on the bottom wall of the cement mixing cavity.

Owner:象山知航机电科技有限公司

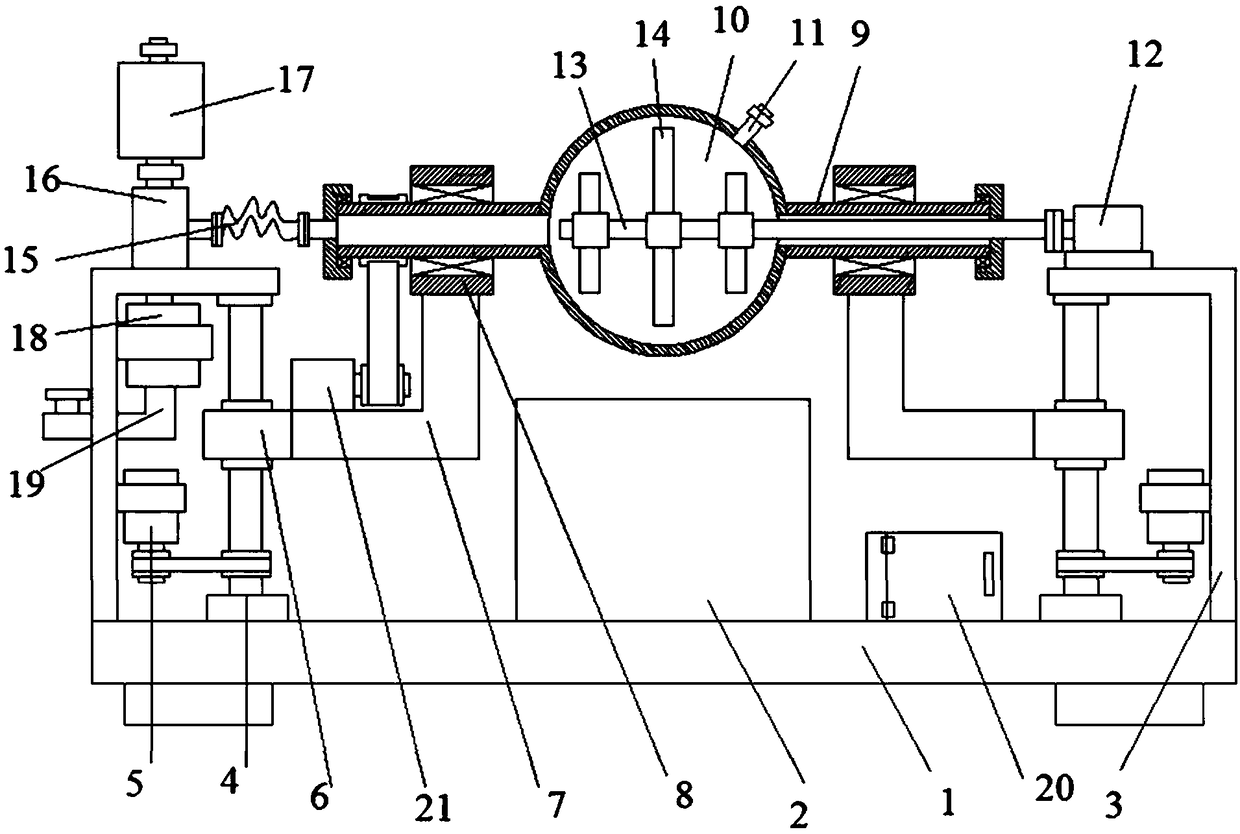

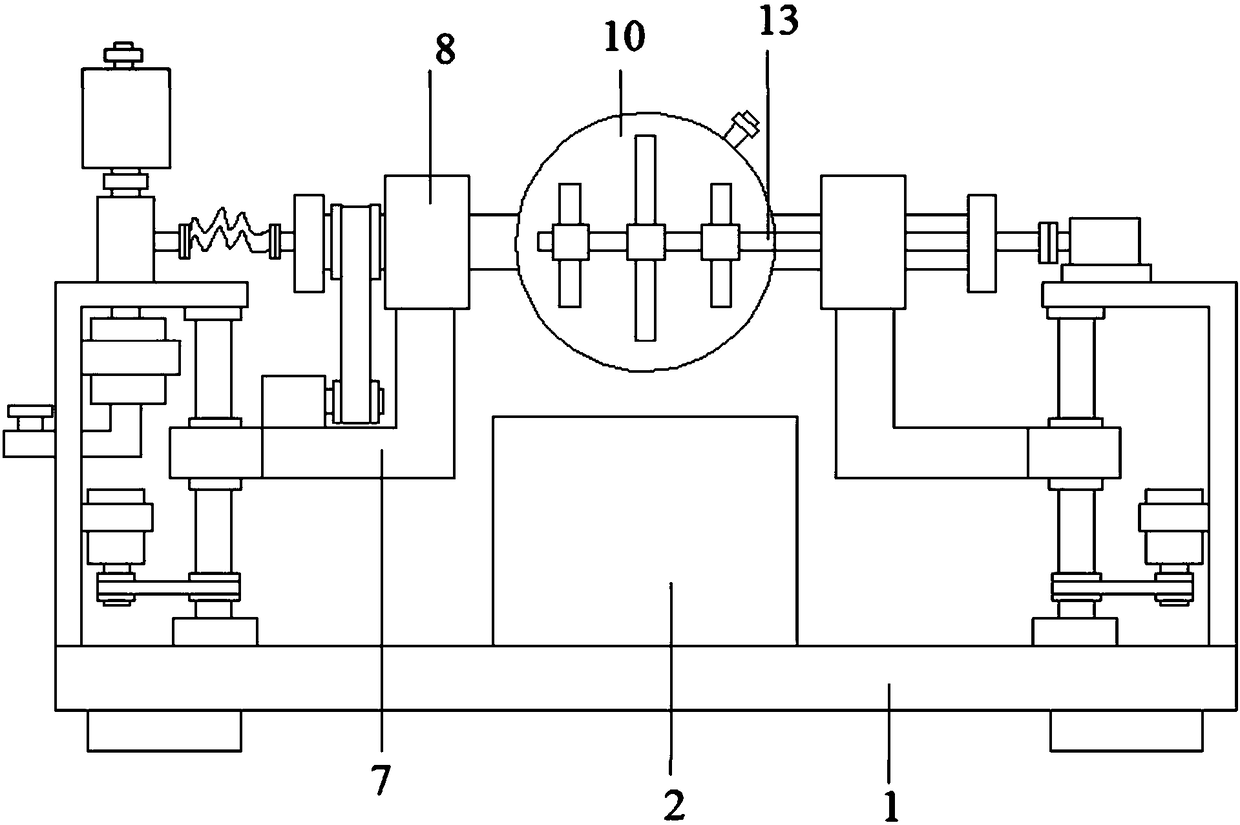

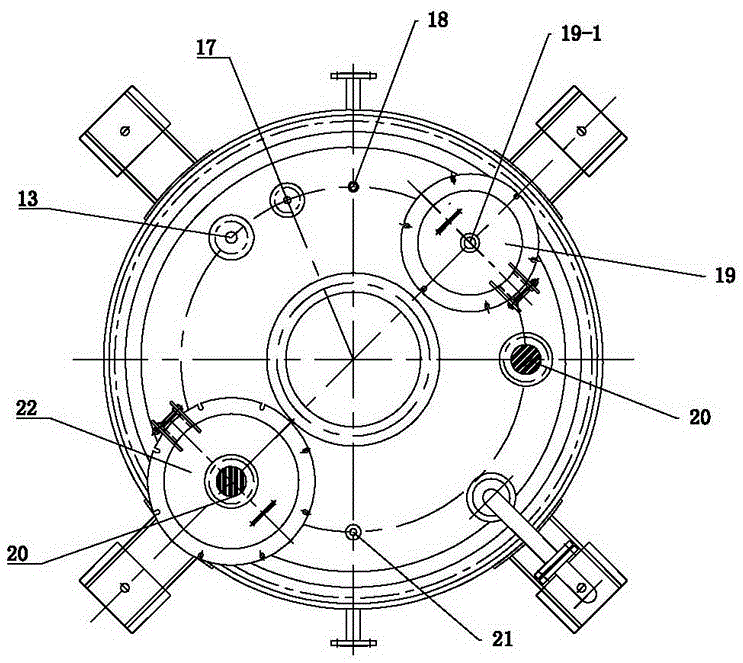

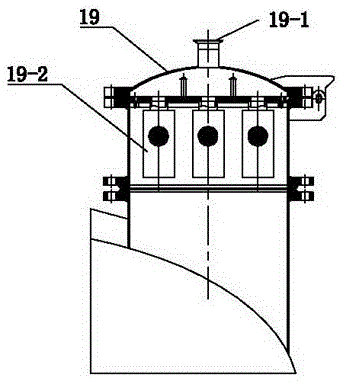

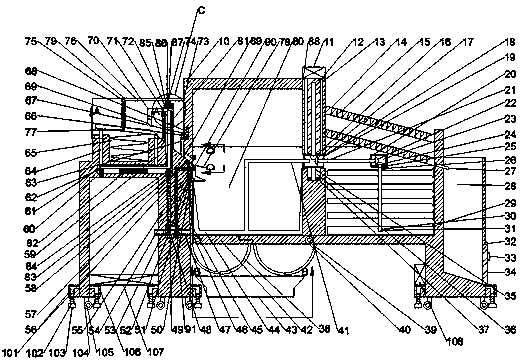

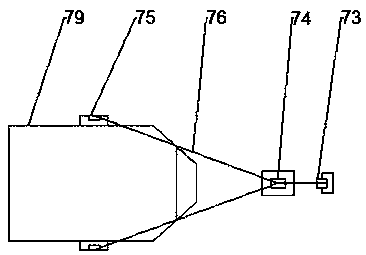

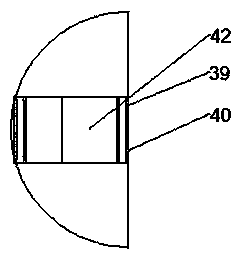

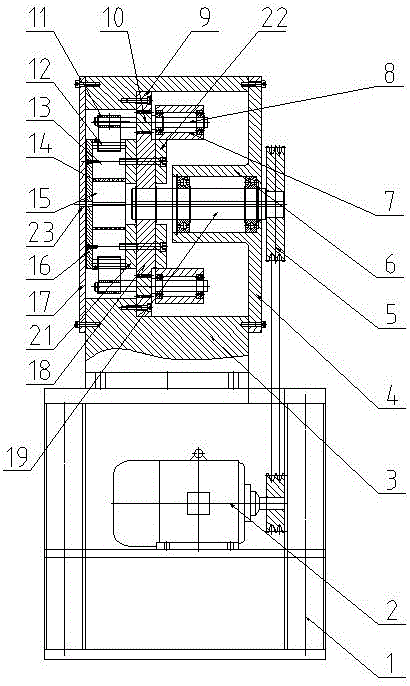

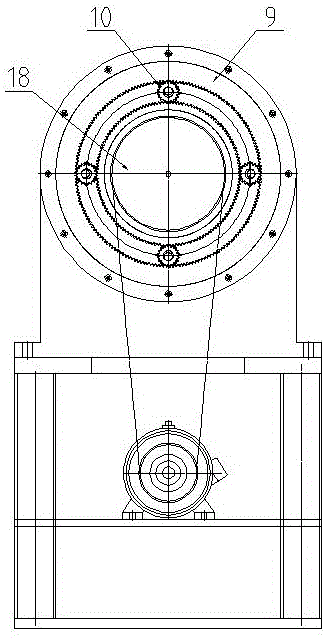

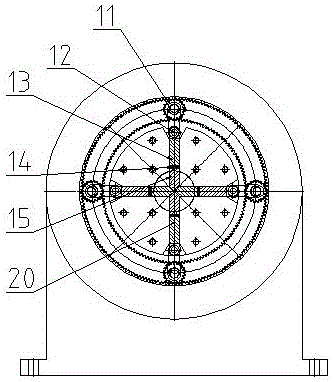

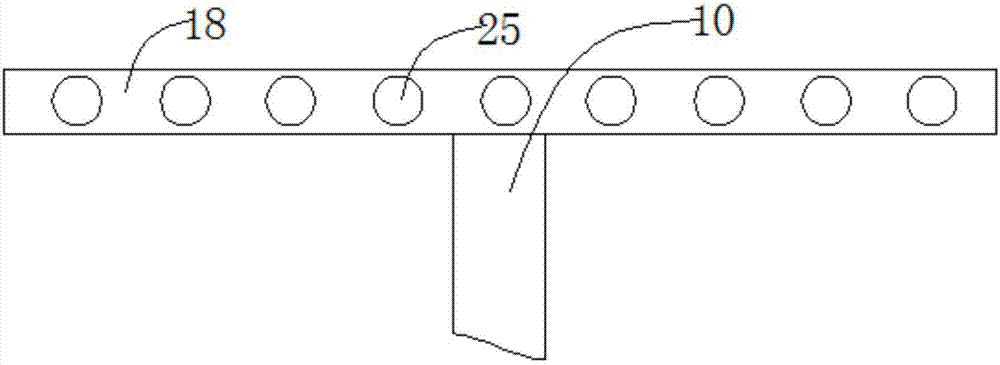

Stranded welding wire hammering machine

The invention relates to a stranded welding wire hammering machine. The stranded welding wire hammering machine comprises a hammering machine base (3), wherein a mandrel (19) is installed in the center of the hammering machine base (3) in a penetrating manner, a big gear wheel (18) is arranged at the left end of the mandrel (19), a gear ring (9) is arranged on the periphery of the big gear wheel (18), a plurality of second bearing pedestal (7) are arranged on the periphery of the right side of the big gear wheel (18), one eccentric shaft (8) is installed on each second bearing pedestal (7) in a penetrating manner, one pinion (10) is arranged on each eccentric shaft (8), a plurality of limiting sliding grooves (20) are evenly formed in a left fixing plate (21) outwards along the center of the left fixing plate (21), one hammer forging die (15) and one transmission block (13) are arranged in each limiting sliding groove (20), one crank (11) is arranged at the left end of each eccentric shaft (8), and one end of each crank (11) is connected with the corresponding transmission block (13). The working efficiency of the stranded welding wire hammering machine is high, the phenomena that stranded welding wires are slub and have internal stress can be eliminated, and the ideal surface state of the stranded welding wires can be achieved.

Owner:河北联之捷焊业科技有限公司

Improved material mixing device

PendingCN110681290AImprove stirring efficiencyQuality assuranceRotary stirring mixersTransportation and packagingElectric machineryStructural engineering

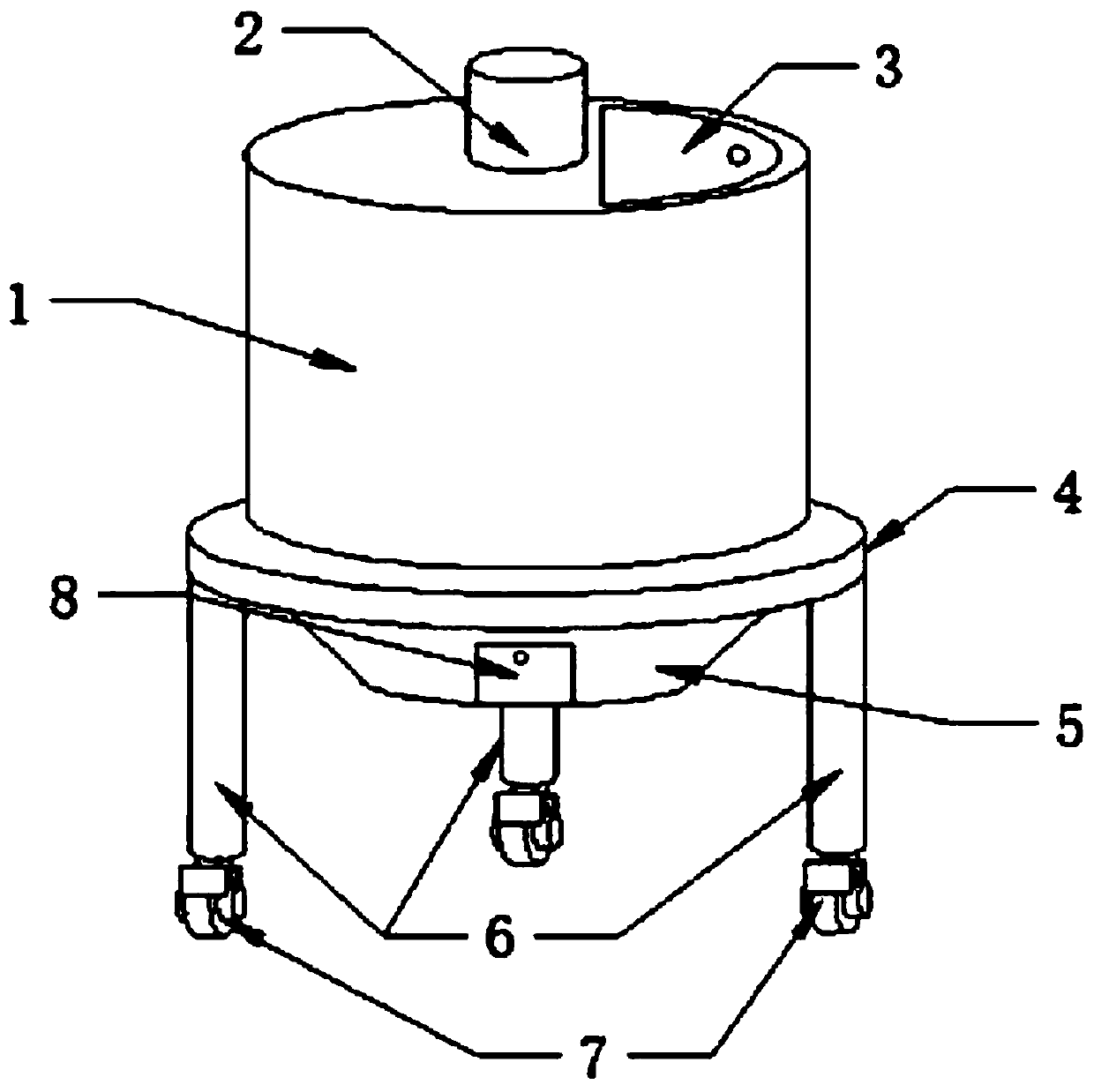

The invention discloses an improved material mixing device, which comprises a body, wherein the body is cylindrical, a funnel is fixedly installed at the lower end of the body and is in an inverted frustum shape, a material outlet is formed in the side edge of the funnel, a fixing ring is installed on the periphery of the bottom of the outer wall of the body, three supporting legs are evenly and fixedly installed below the fixing ring, universal wheels are installed below the supporting legs and are provided with self-locking structures, a door is embedded in the upper end surface of the bodyand is in a semicircular plate shape, a stirring shaft is installed in the center of the interior of the body, protective plates are installed on the periphery of the stirring shaft, the protective plates are barrel-shaped, openings are formed in the lower ends of the protective plates, gaps are reserved between the upper ends of the protective plates and the upper end surface of the body, a motoris correspondingly connected to the upper portion of the stirring shaft, the lower portion of the stirring shaft is embedded into the bottom end of the funnel, and a flow guide edge is arranged at the top of the protective plate, so that seeds coming out of the top of the protective plate can be guided to fall to the edge of the funnel.

Owner:HUNAN FEIYING NEW ENERGY TECH

Steel slag concrete stirring device

The invention discloses a steel slag concrete stirring device, wherein a stirring drum is connected with a mixing drum, a steel slag feeding hole and a concrete feeding hole are respectively connected with the mixing drum; a discharging hole is connected with the stirring drum; a sawtooth-shaped filtering layer is arranged at the upper part in the mixing drum; a buffering layer is arranged on the lower side of the filtering layer; a recycling pump is arranged on one side of the buffering layer; a mixing layer is arranged at the lower part of the buffering layer; the concrete feeding hole is formed in one side of the mixing layer; the other side of the mixing layer is connected with the stirring drum; a rough machining and stirring drum is connected with a fine machining and stirring drum through a stirring shaft; a dust removing device is arranged at the top of the stirring drum. According to the steel slag concrete stirring device, the steel slag is screened and is mixed with the concrete, thereby ensuring that the steel slag and the concrete are uniformly stirred; different machining processes are used for stirring the concrete; the quality of the concrete can be improved; the influence of the dust on the environmental pollution in the machining process can be effectively removed; the concrete stirring process can be completed in an energy-saving and environment-friendly manner; the operation is convenient; the stirring efficiency is high; the blockage is not liable to generate.

Owner:南京汪海混凝土有限公司

Preparing method of styrene-acrylate latex and styrene-acrylate latex

InactiveCN105461841AHomogeneous substanceUniform temperatureParticle-size distributionEnvironmentally friendly

The invention relates to a preparing method of styrene-acrylate latex. Reaction heat energy is provided for a reaction of styrene-acrylate latex through high-speed steam which is transformed into high-temperature deionized water after being cooled; in addition, the high-speed steam drives liquid in a reaction vessel to rotate, the liquid in the reaction vessel is dispersed by the steam flow to form a large number of tiny steam and water combined bodies, and materials in the reaction vessel are pushed to flow rapidly; furthermore, mechanical stirring is conducted for cooperation, the materials and the temperature in the reaction vessel are uniformly distributed, and a polymerization reaction is also very uniform, so that the end product styrene-acrylate latex is stable in molecular structure, molecular weight is easy to control, particle size distribution is more concentrated, the conversion rate of monomers can reach 99% or above, the content of unreacted polymerization monomers in latex is very small, and prepared styrene-acrylate latex is more environmentally friendly.

Owner:ZHEJIANG TIANCHEN PLASTIC IND

Ribbon vacuum dryer

ActiveCN104075550BAvoid cakingGuaranteed stirringDrying machines with non-progressive movementsDrying solid materialsPulp and paper industryCaking

The invention relates to a vacuum drying machine with spiral strips. The vacuum drying machine comprises a barrel. A barrel cover is arranged on the upper portion of the barrel, a hollow support is arranged on the upper portion of the barrel cover, the upper portion of a stirring shaft is arranged in the support in a perpendicular running fit manner, and the middle lower portion of the stirring shaft is arranged in the barrel; the double spiral strips are distributed on the middle lower portion of the stirring shaft, and the outer edges of the double spiral strips are adjacent to the inner wall of the barrel; a concave scraper which is matched with the inner wall of the bottom of the barrel is arranged at the lower end of the stirring shaft; the top of the concave scraper is not higher than the bottoms of the double spiral strips. The vacuum drying machine has the advantages that the top of the scraper is not higher than the bottoms of the double spiral strips, in other words, the scraper and the double spiral strips are vertically distributed, the areas of force which is applied to materials by the scraper and the double spiral strips are small, accordingly, integral movement can be prevented when the materials in an integral container move, and caking of the materials can be prevented.

Owner:CHANGZHOU YUTONG DRYING EQUIP

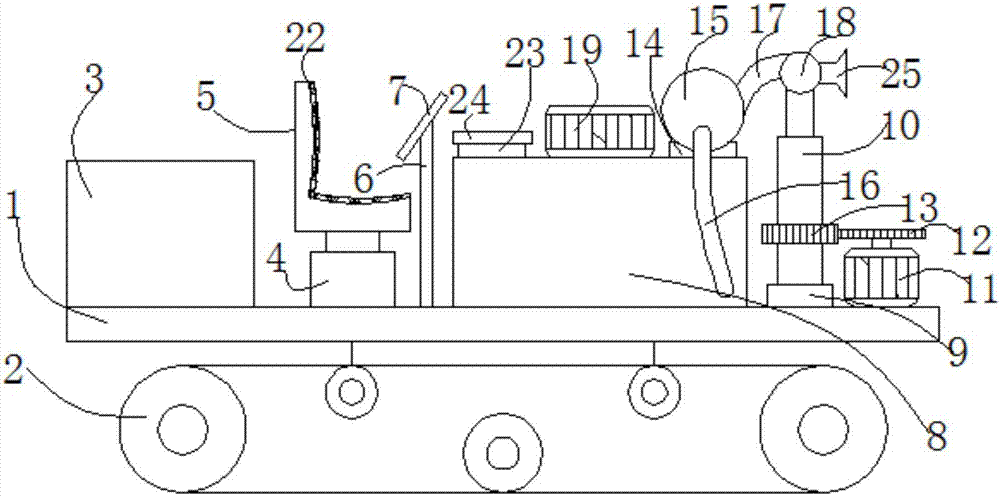

Crawler-type efficient medicine spraying cart

InactiveCN107410266AImprove spraying efficiencyGuaranteed spraying effectEndless track vehiclesInsect catchers and killersIntermediate bulk containerVehicle frame

The invention discloses a crawler-type high-efficiency spraying vehicle, which includes a vehicle frame, the bottom of the vehicle frame is movably connected with a walking crawler, the left side of the top of the vehicle frame is fixedly connected with an engine, and the top of the vehicle frame is located at The right side of the engine is fixedly connected with a hydraulic rod, the top of the hydraulic rod is fixedly connected with a seat, the top of the vehicle frame is fixedly connected with a strut on the right side of the seat, and the top of the strut is fixedly connected with a control panel. The present invention uses a control panel, a ton bucket, a bearing, an electric telescopic rod, a first motor, a driving gear, a driven gear, a base, a water pump, a first hose, a second hose, a spray pipe, a second motor, and a transmission rod. Used in conjunction with the stirring blade, it can not only adjust the angle of spraying, but also can stir the liquid medicine inside the ton bucket while spraying the medicine, so that the medicine will not settle, which improves the efficiency of spraying medicine and ensures the spraying effect. Effect.

Owner:浙江聚彩精密设备有限公司

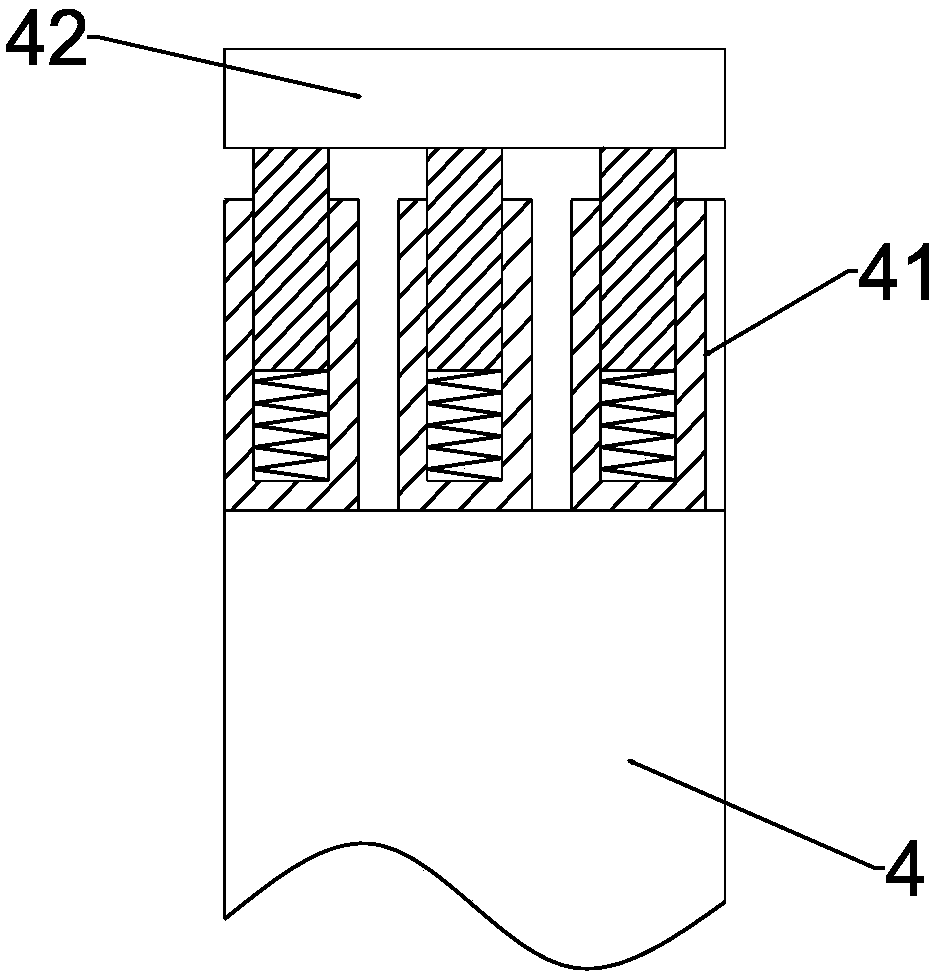

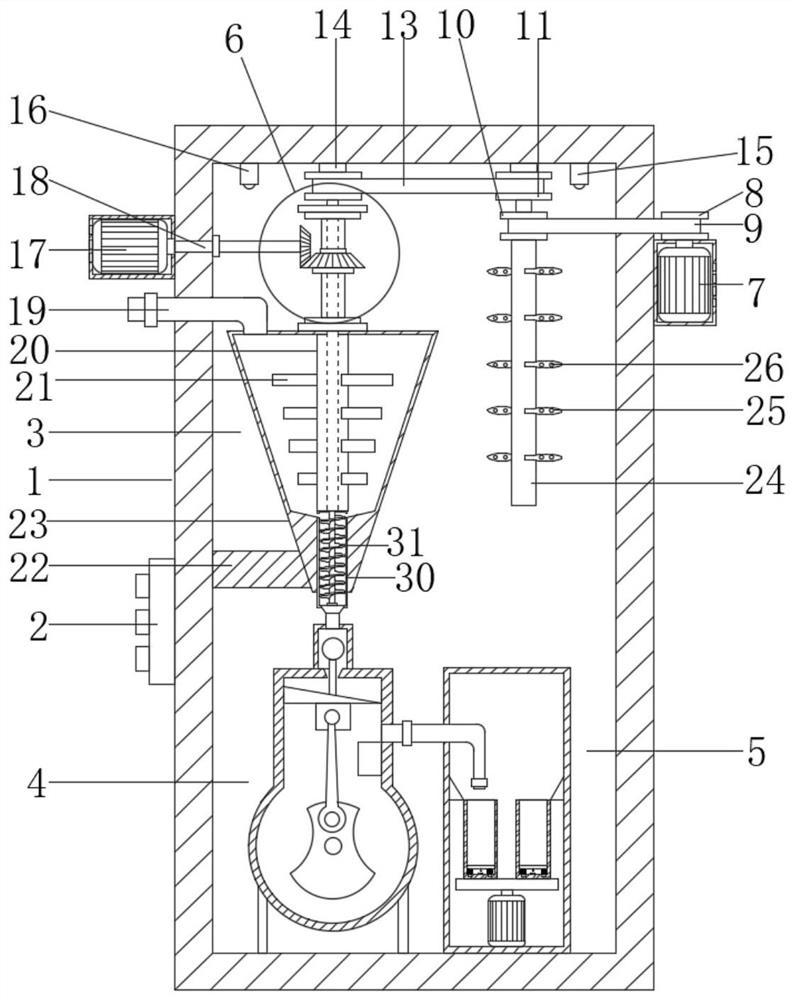

Concentric operation control module for industrial electric stirrer

InactiveCN107213817AGuaranteed stirringAvoid affecting the performance of the operationRotary stirring mixersTransportation and packagingMarine engineeringVibration sense

The invention provides a concentric operation control module for an industrial electric stirrer. The concentric operation control module comprises a machine body (1), wherein a vibration sensing module (2), a concentric reference module (3), a stirring module (4) and a management module (5) are arranged on the machine body (1); when the concentric operation control module is in operation, the vibration sensing module (2) is arranged on the stirring module (4) and senses the condition of stirring during operation; the concentric reference module (3) senses and contrasts the position of the stirring module (4), and the sensed information is processed by the management module (5); a setting module (6) is arranged on the vibration sensing module (2) and sets the condition of allowable emitted vibration during normal stirring operation; a position labeling module (7) is arranged on the concentric reference module (3) and labels the position condition of the stirring module (4) in real time; a prompt module (8) is arranged on the management module (5); and through real-time sensing of the operation condition of a stirring bar, concentric stirring is guaranteed, and influence on operation effects is avoided.

Owner:XINCHANG COUNTY JINGLING TOWN KANGLIU ELECTRONICS COMPONENT FACTORY

Mixing device for raw materials for processing ceramic insulator

InactiveCN110270254AQuality impactGuaranteed stirringShaking/oscillating/vibrating mixersTransportation and packagingSolenoid valveElectromagnet

The invention discloses a mixing device for raw materials for processing a ceramic insulator. The device comprises a material inlet box, a horizontal plate, a stirring box and an installation frame; supporting columns are installed at four corners of the bottom end of the stirring box, and a bottom plate is transversely installed among the bottom ends of the inner sides of the supporting columns; a material holding box is installed at the central position of the top end of the bottom plate, and handles are installed at the middle position of two sides of the material holding box; a reserved groove is arranged in the central position of the bottom end of the stirring box, and a material outlet pipe is installed at the bottom end, located below the reserved groove, of the stirring box; and the bottom end of the material outlet pipe is provided with a solenoid valve, material smoothly-falling plates are obliquely installed at the inner bottom end of the part, located at two sides of the reserved groove, of the stirring box, and electromagnets are uniformly installed at the lower part of the inner side of the part, located at the top ends of the material smoothly-falling plates, of the stirring box. According to the device provided by the invention, a material inlet and scale bars are installed, and material measurement is observed through the scale bars, so that the materials are prevented from being poured too much or too little into the device to affect quality of the insulator prepared in the later period.

Owner:醴陵市浦口电瓷制造有限公司

Modified asphalt mixing equipment and mixing method thereof

InactiveCN112709110AReduce generationReduce shockRoads maintainenceProcess engineeringHeat conservation

The invention relates to modified asphalt mixing equipment which comprises an aggregate bin, a lifting mechanism, a drying bin, a mixing bin, an asphalt bin, a heat exchange bin and a dust removal mechanism, aggregate in the aggregate bin is conveyed to the drying bin through the lifting mechanism, and a discharging port of the drying bin is communicated with a feeding port of the mixing bin; a discharging port of the asphalt bin is communicated with the other feeding port of the mixing bin, a liquid inlet of a heat preservation cavity of the asphalt bin is communicated with a liquid outlet of the heat exchange bin, the heat preservation cavity of the asphalt bin is communicated with the heat exchange bin, a transduction cavity of the heat exchange bin is communicated with the drying bin, and the transduction cavity of the heat exchange bin is communicated with the dust removal mechanism. Targeted heating and stirring are conducted through the mixing bin, meanwhile, high-temperature flue gas in the drying bin enters the heat exchange bin to heat heat exchange liquid, the heat exchange liquid is conveyed into the asphalt bin to heat and preserve heat of asphalt, repeated utilization of heat energy is achieved, energy is saved, the cost is reduced, and the flue gas is exhausted after being treated by the dust removal mechanism. and environmental pollution is avoided.

Owner:襄阳路桥建设集团有限公司

Efficient stirring device for steelmaking continuous casting tail end and using method of efficient stirring device

InactiveCN113059132AImprove labor enthusiasmGuaranteed stirringElectric machineryProcess engineering

The invention discloses an efficient stirring device for a steelmaking continuous casting tail end and a using method of the efficient stirring device, and relates to the technical field of steelmaking stirring equipment. The efficient stirring device comprises a stirring box and a control panel, wherein a stirring assembly is installed in the stirring box and comprises a rotating sleeve and a stirring bin, and the stirring bin is installed in the stirring box. The device has the beneficial effects that the rotating assembly, a third motor and a fourth motor are arranged, the labor enthusiasm of workers is improved, normal stirring operation is implemented through operation of the fourth motor, and it is guaranteed that stirring, controlled discharging and peculiar smell purification are conducted at the same time; quantitative control over discharging is implemented through a quantitative assembly, blockage happens less, and the overall service life is prolonged; as a conveying assembly is arranged, conveying treatment, it is convenient for conveying treatment to be carried out, the labor intensity of workers is reduced, and the overall stirring work efficiency is improved.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com