Double-layer mixing device

A stirring device and double-layer technology, which is applied in the field of double-layer stirring devices, can solve problems such as uneven mixing of materials, and achieve the effects of saving labor, saving electricity, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

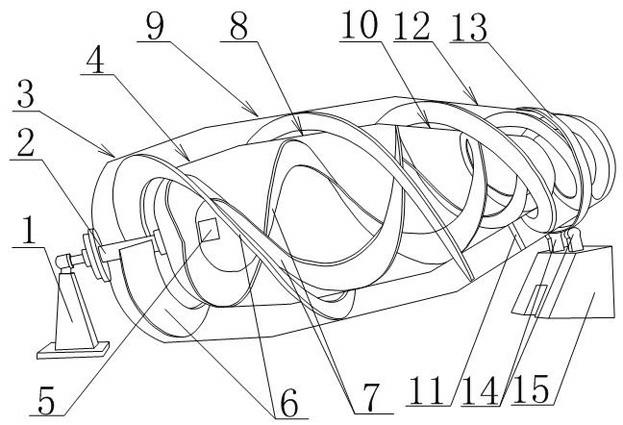

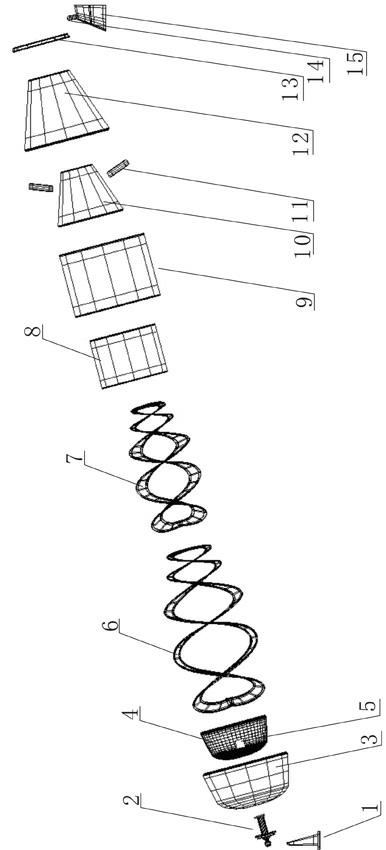

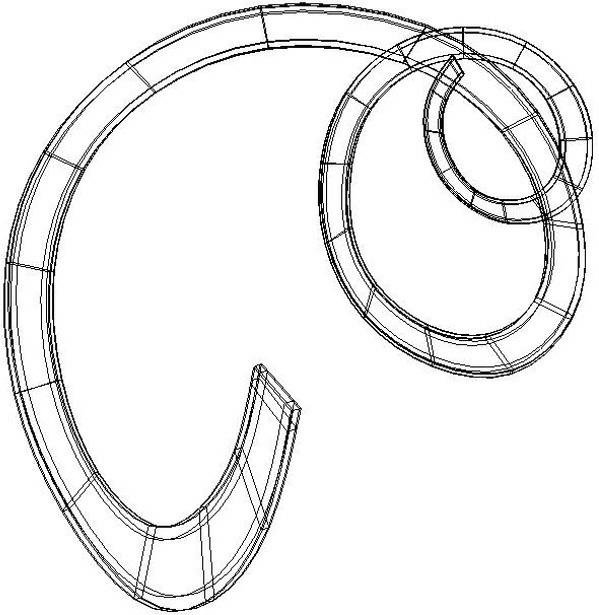

[0025] Such as Figures 1 to 4As shown, a double-layer mixing device of the present invention includes a front bracket 1, a rear bracket 15, and a large mixing tank installed on the front bracket 1 and the rear bracket 15. The large mixing tank includes a connecting shaft 2 installed on the front bracket 1 The front cone 3 of the large tank on the top, the middle circle 9 of the large tank connected to the front cone 3 of the large tank, and the rear cone 12 of the large tank connected to the middle circle 9 of the large tank, the connecting shaft 2 is installed on the front bracket 1 On the rear cone 12 of the large tank, there is an annular track 13 installed, two tugs 14 matching the annular track 13 are installed on the rear support 15, and a pair of large spiral stirring blades 6 are installed on the inner wall of the large mixing tank. The two large spiral stirring blades 6 are all logarithmic spiral stirring blades, and are respectively symmetrical to the axis of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com