Patents

Literature

33results about How to "Avoid affecting the performance of the operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

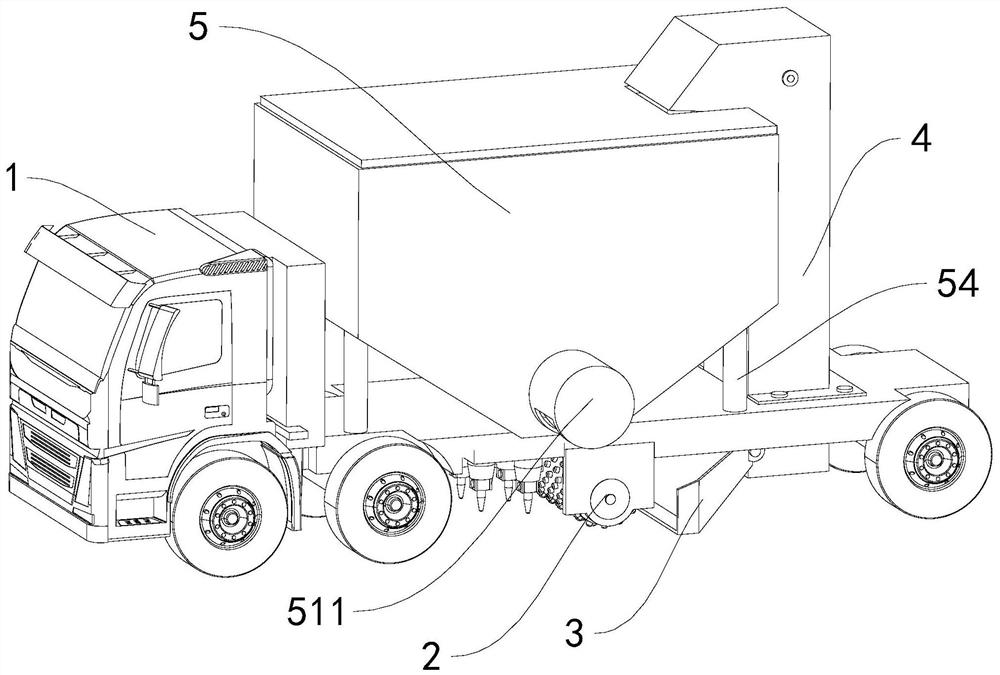

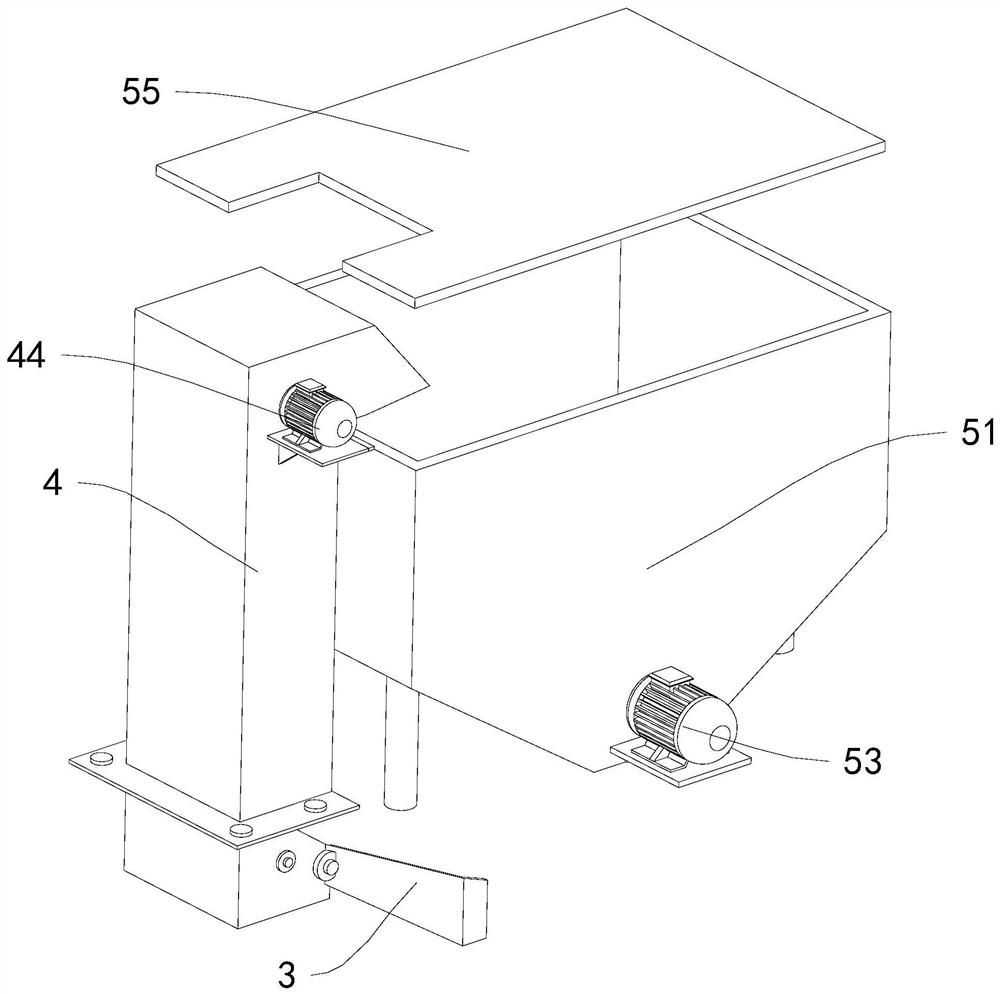

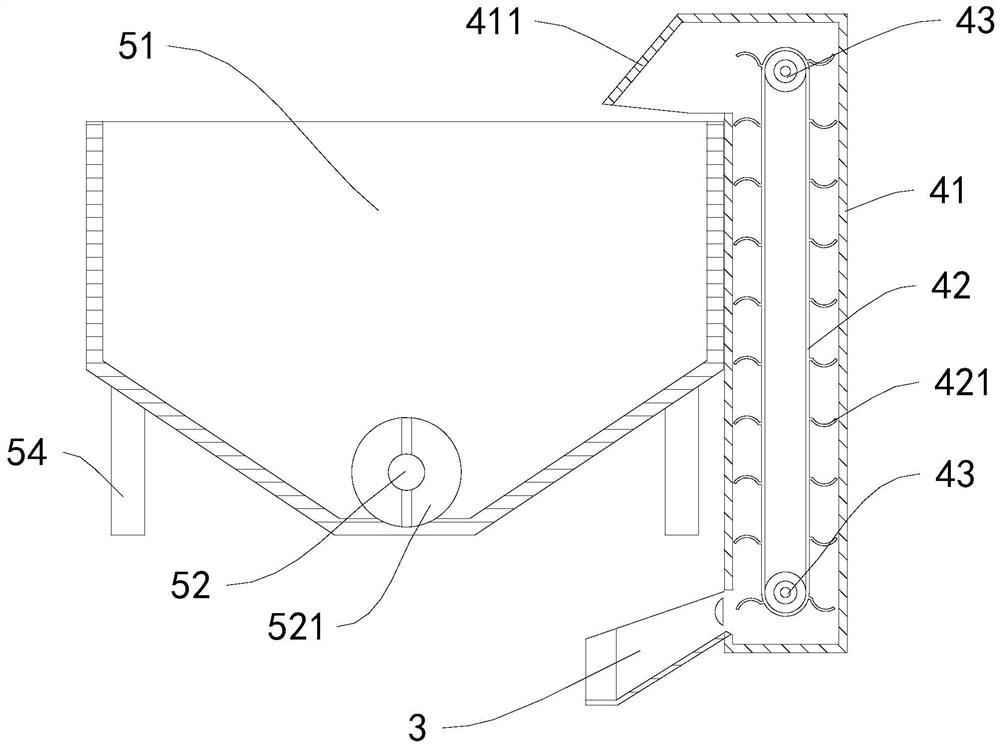

Concrete recovery device for building energy conservation and environmental protection

InactiveCN111809495ACrushing efficiency Reduced crushing efficiencySolve the technical problem of recycling inefficiencyRoads maintainenceStructural engineeringBuilding energy

The invention discloses a concrete recovery device for building energy conservation and environmental protection, which relates to the technical field of concrete recovery devices. The device comprises a tractor, a concrete crushing mechanism, a concrete shoveling bucket, a concrete lifting mechanism and a concrete storage mechanism, wherein the concrete crushing mechanism is mounted at the bottomof the tractor; the concrete lifting mechanism is vertically arranged at the tail end of the tractor; the concrete shoveling bucket is connected to the concrete lifting mechanism and located at the rear end of the concrete crushing mechanism, the tail end of the concrete shoveling bucket communicates with the bottom of the concrete lifting mechanism, the concrete storage mechanism is arranged onthe tractor, and the top of the concrete lifting mechanism communicates with the concrete storage mechanism. Concrete is crushed through the concrete crushing mechanism, the crushed concrete is liftedthrough the concrete lifting mechanism and conveyed into the concrete storage mechanism to be stored, and therefore integration of the concrete recovery device is achieved, and the recovery efficiency of the concrete is improved.

Owner:航仟源科技(杭州)有限公司

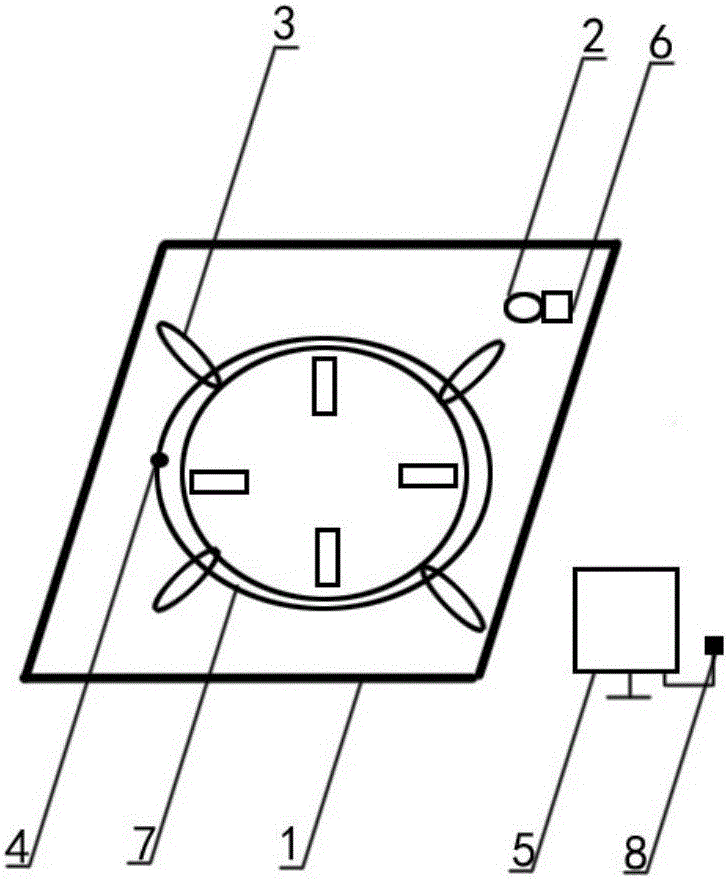

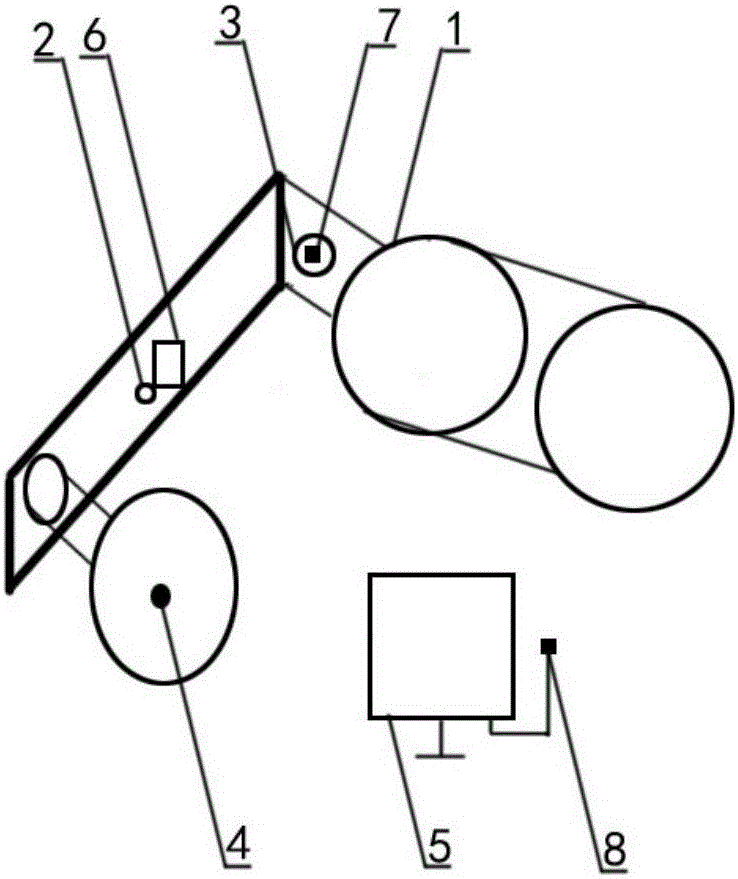

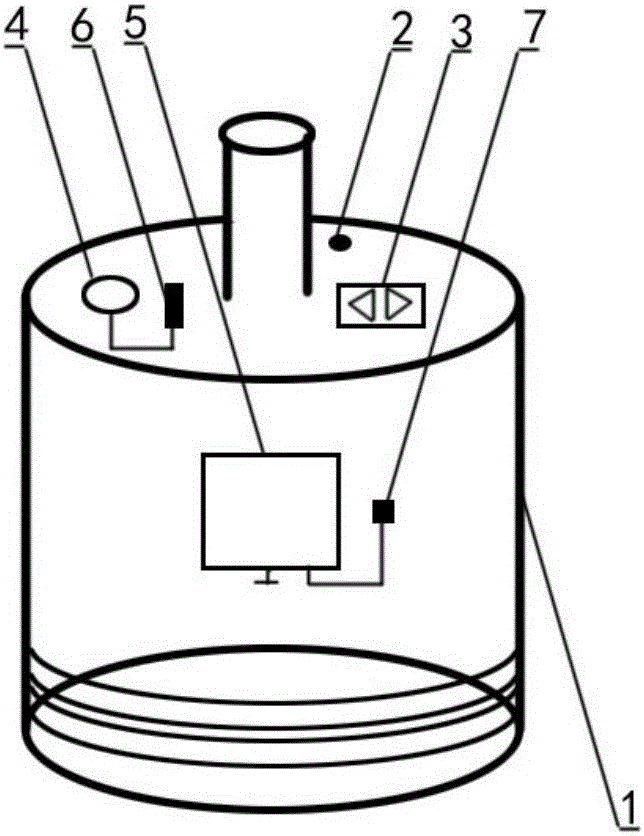

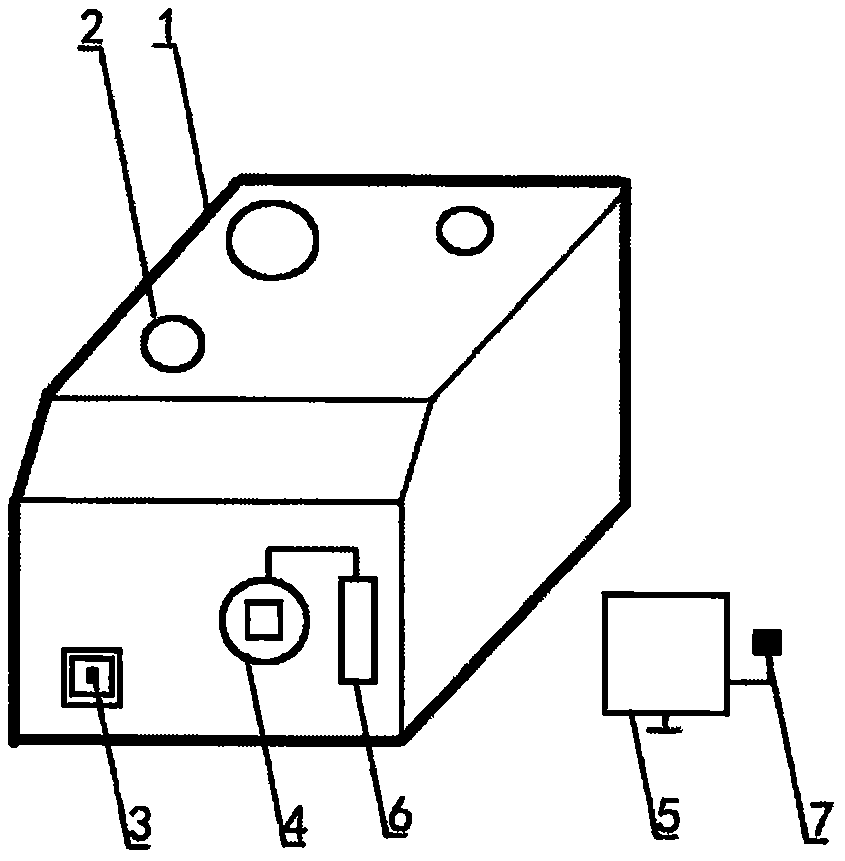

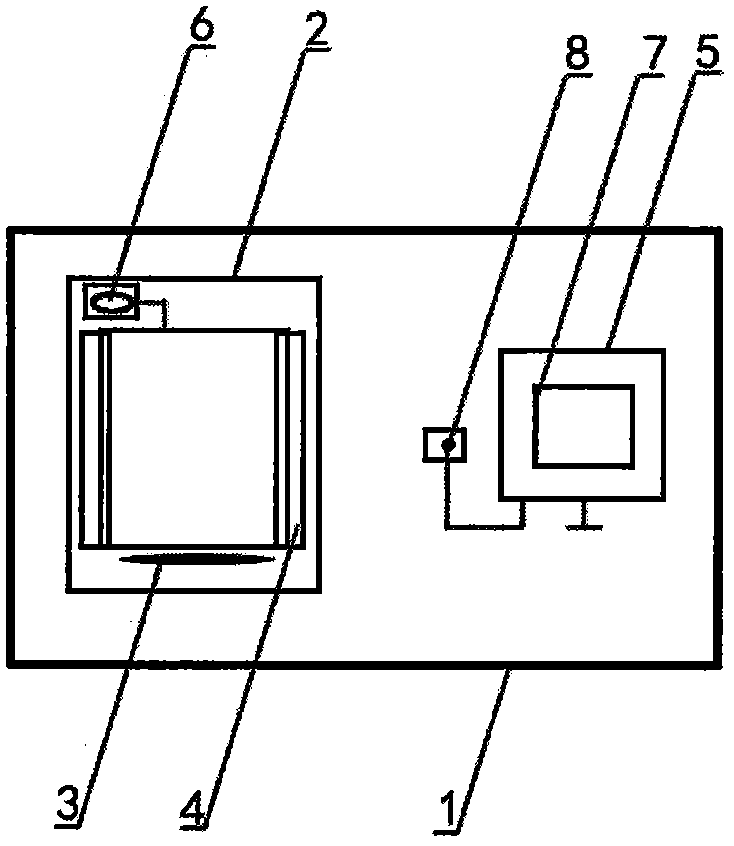

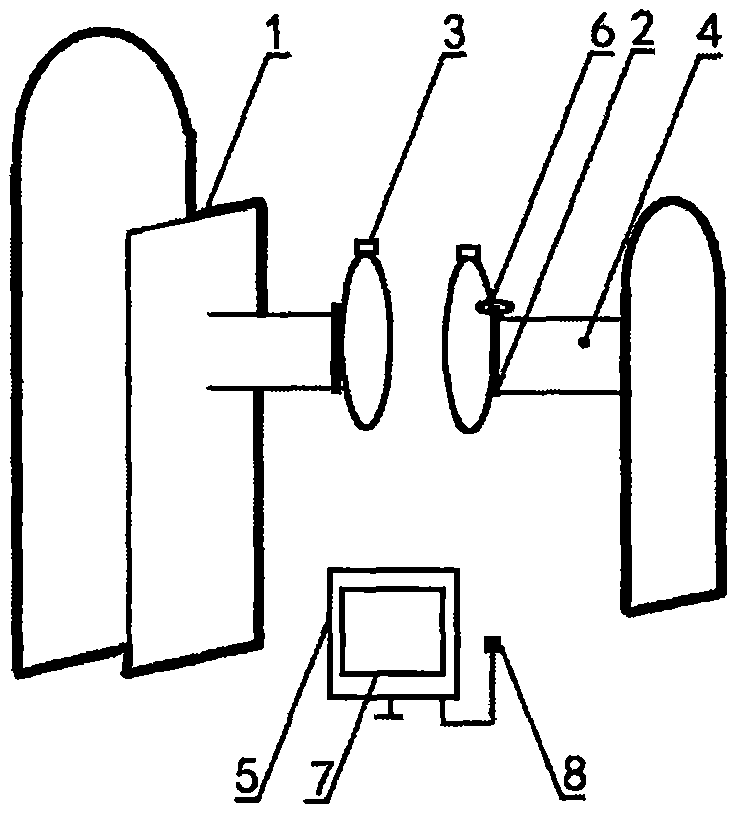

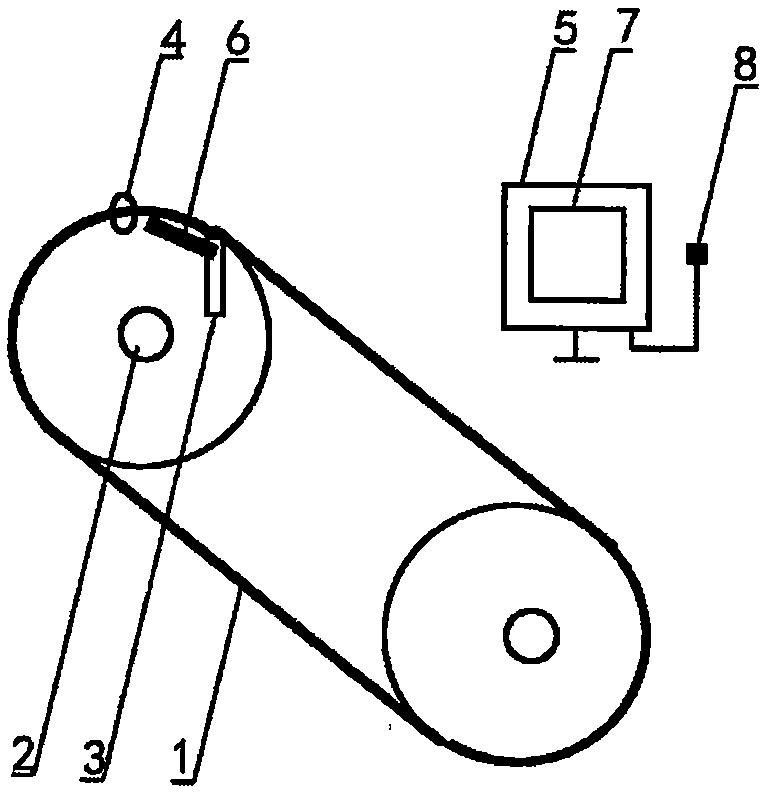

Defoaming machine transmission part tension adjustment module

InactiveCN105797437AAvoid affecting the performance of the operationFoam dispersion/preventionRemote communicationExtrusion

A defoaming machine transmission part tension adjustment module comprises a machine body (1).An operation induction module (2), an extrusion module (3), a remote communication module (4) and a management module (5) are arranged on the machine body (1).During operation, the operation induction module (2) inducts the operating state of the machine body (1), the extrusion module (3) is arranged above a transmission part and conducts extrusion detection on the transmission part, and inducted information is transmitted to the management module (5) through the remote communication module (4) for processing; a timing module (6) is arranged on the operation induction module (2), and it is set that the extrusion module (3) operates after the machine body stops operating for a period of time; a pressure adjustment module (7) is arranged on the extrusion module (3), and extrusion operating pressure is set according to operation of the transmission part; a prompt module (8) is arranged on the management module (5); by detecting tension of the transmission part regularly or irregularly, it is avoided that the operating effect is affected.

Owner:安徽科信伟德机电产品设计有限公司

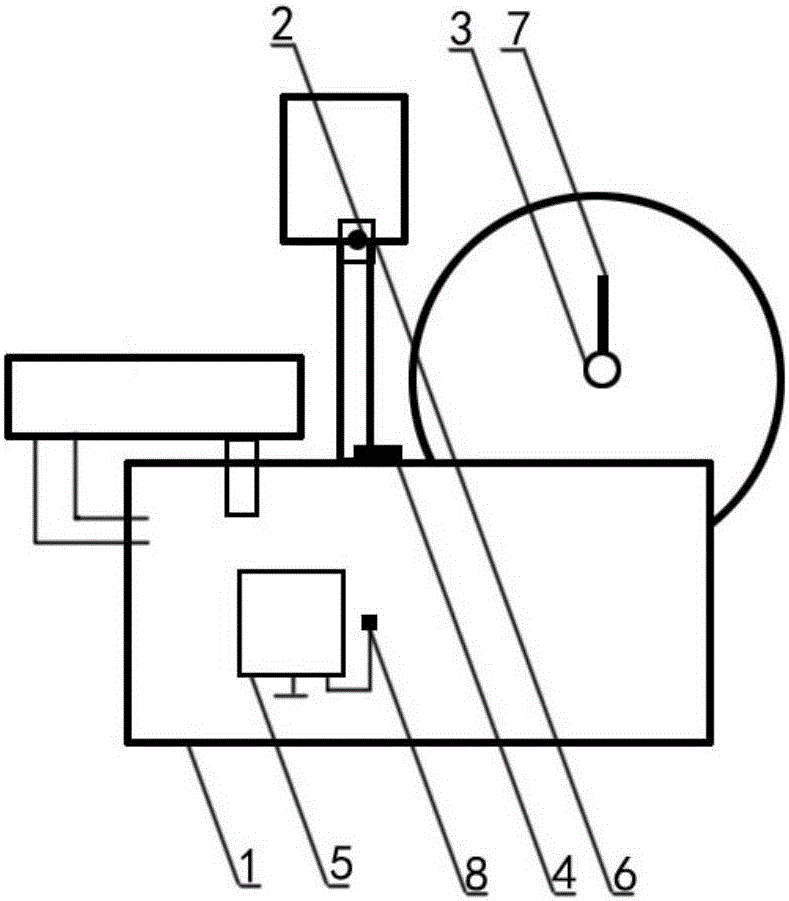

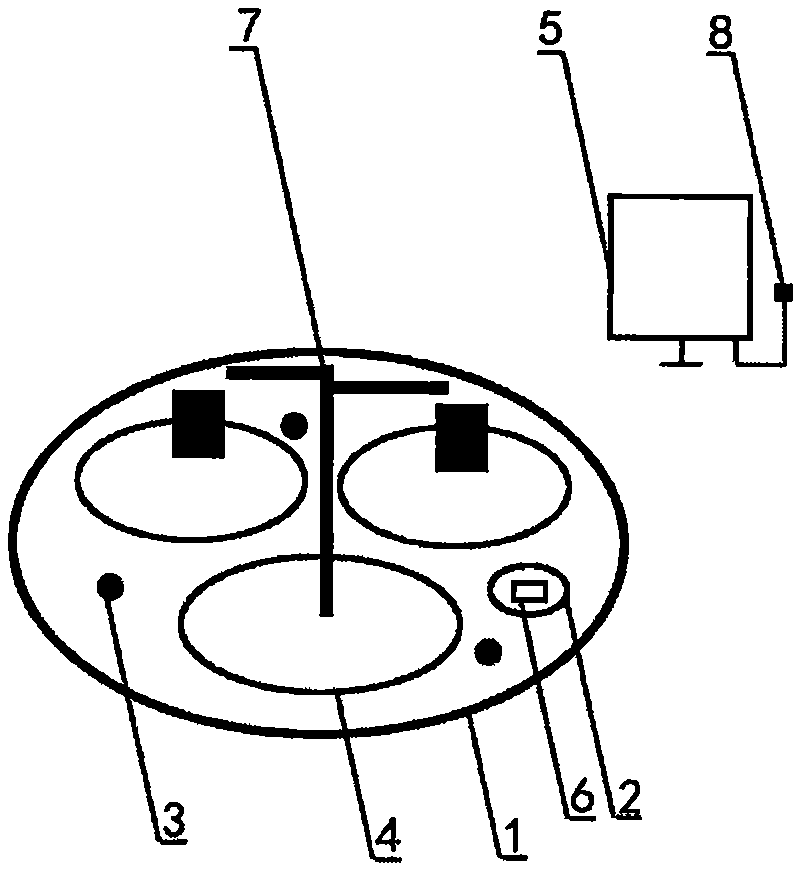

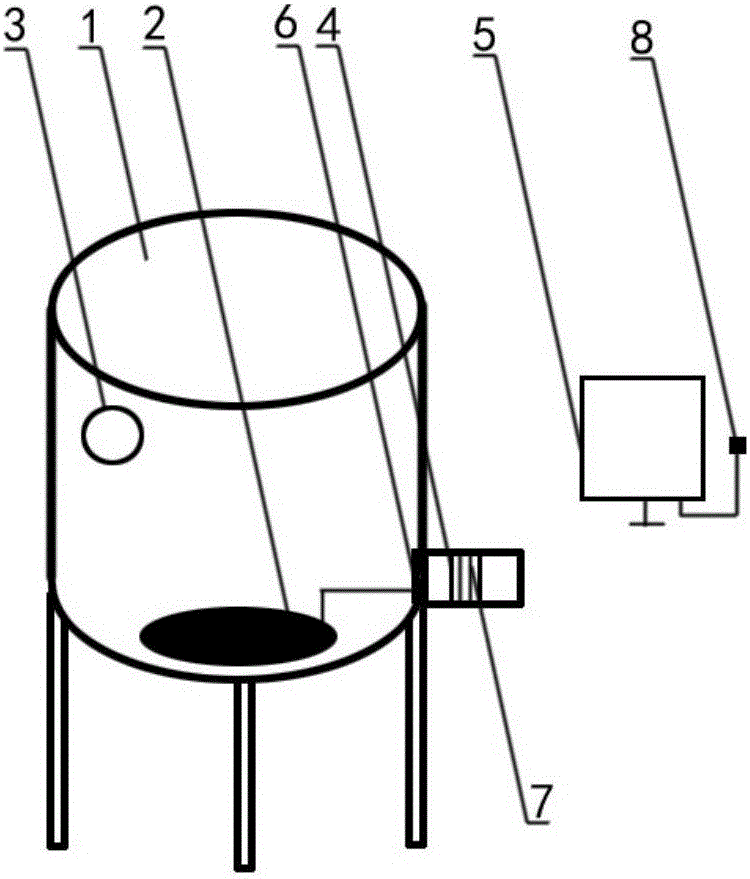

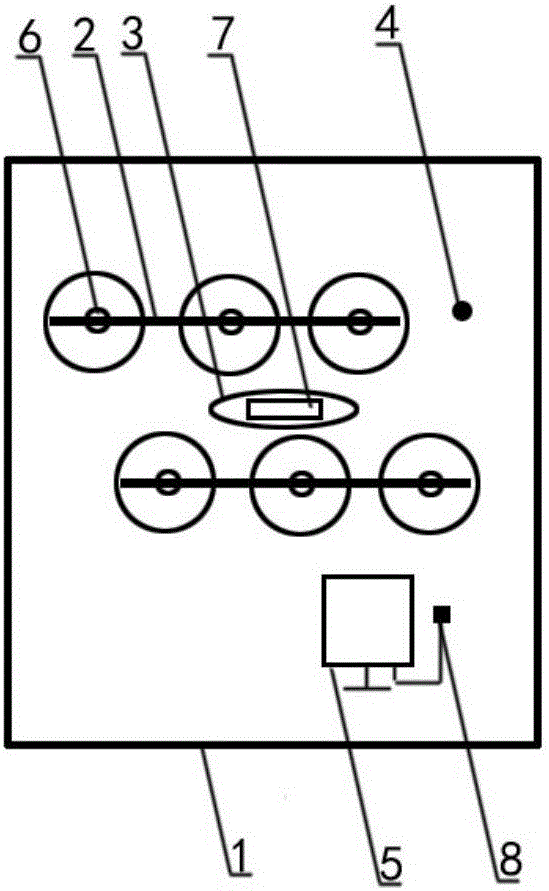

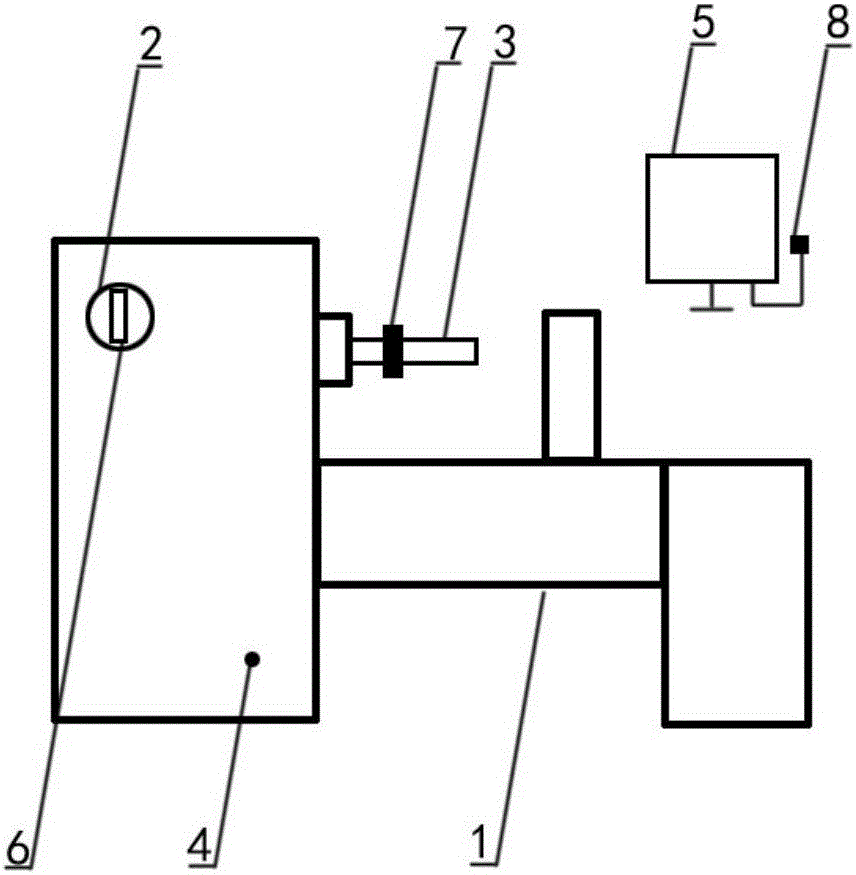

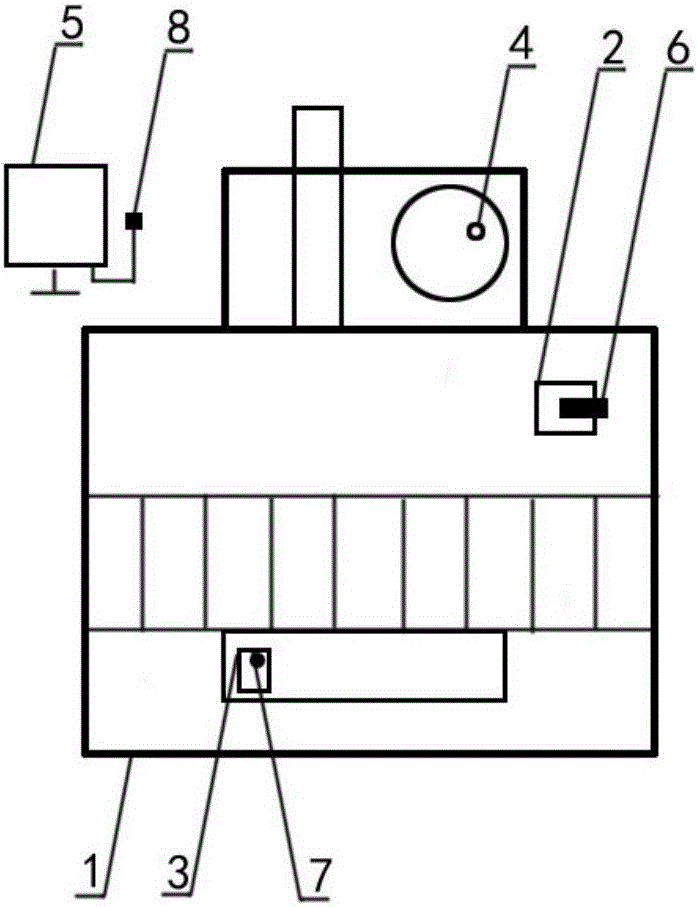

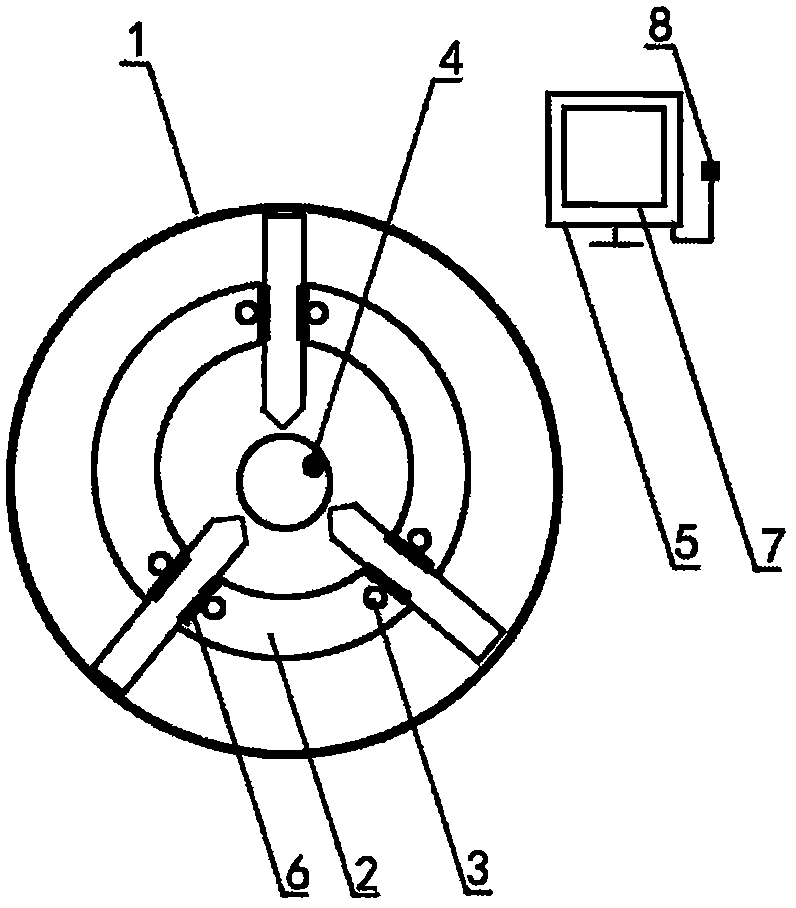

Automatic adjustment module for grinding wheel angle of circular saw blade tooth-grinding machine

InactiveCN105689801AAvoid affecting the performance of the operationSawing tools dressing arrangementsComputer moduleCircular saw

The automatic adjustment module of the grinding wheel angle of the circular saw blade gear grinding machine includes a body (1), on which a grinding wheel rotation module (2), a contact sensing module (3), a positioning module (4), and a management module (5 ), during operation, the grinding wheel rotation module (2) rotates the grinding wheel frame, the contact sensing module (3) senses the contact between the sawtooth and the material, the positioning module (4) sets the operation orientation, and the management module (5) processes comprehensive information; A rotation limit module (6) is set on the module (2) to limit the maximum position of the rotating grinding wheel frame; a length setting module (7) is set on the contact sensing module (3) to set a reasonable length range of the sawtooth contact area; A prompt module (8) is provided on the management module (5), and when an abnormality is sensed in the rotation angle or the contact area, a prompt is issued; and the operation effect is avoided by adjusting the angle of the grinding wheel and the contact condition of the sawtooth.

Owner:ANQING HONGYU IND PROD DESIGN

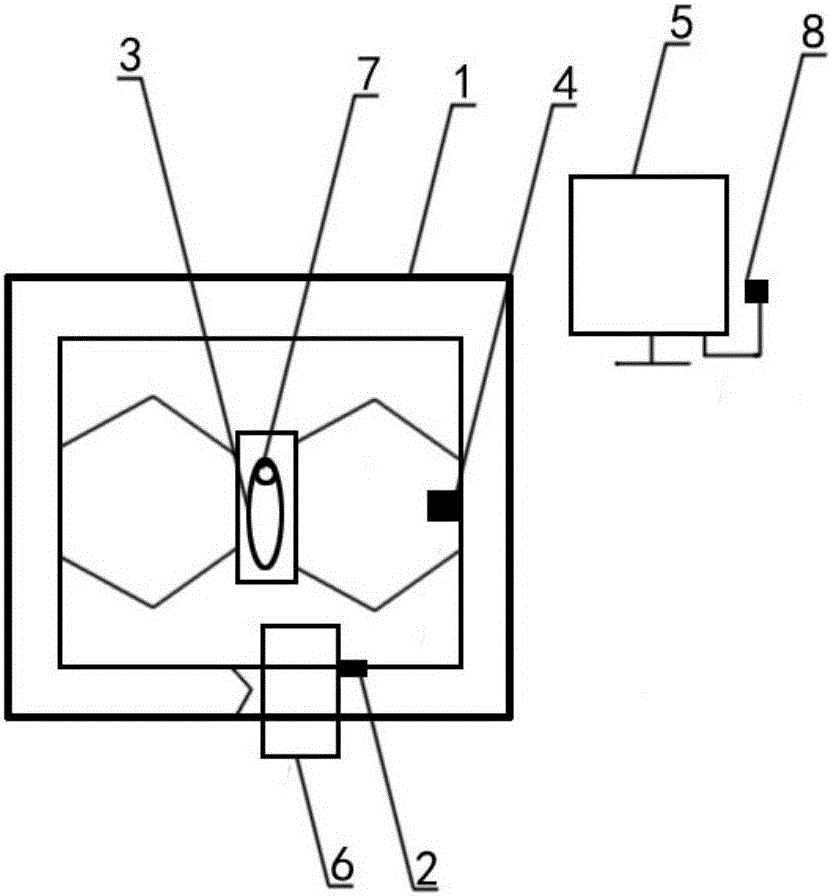

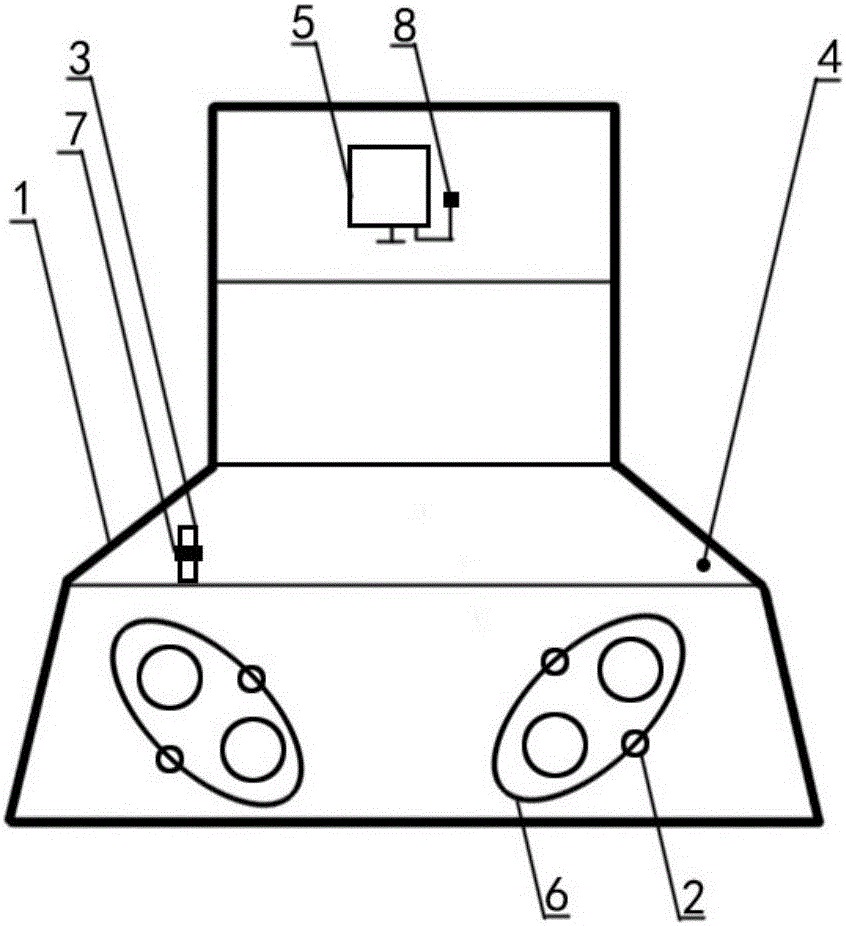

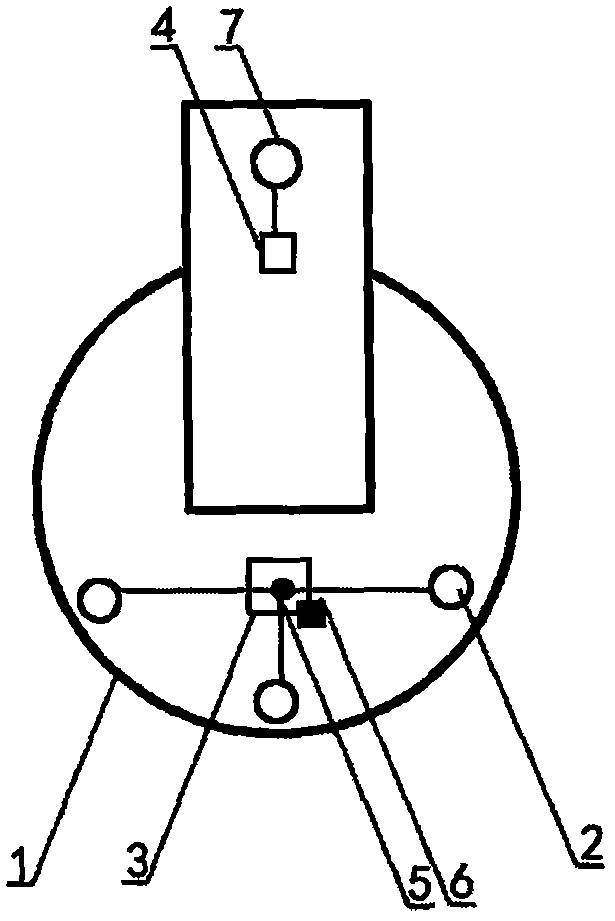

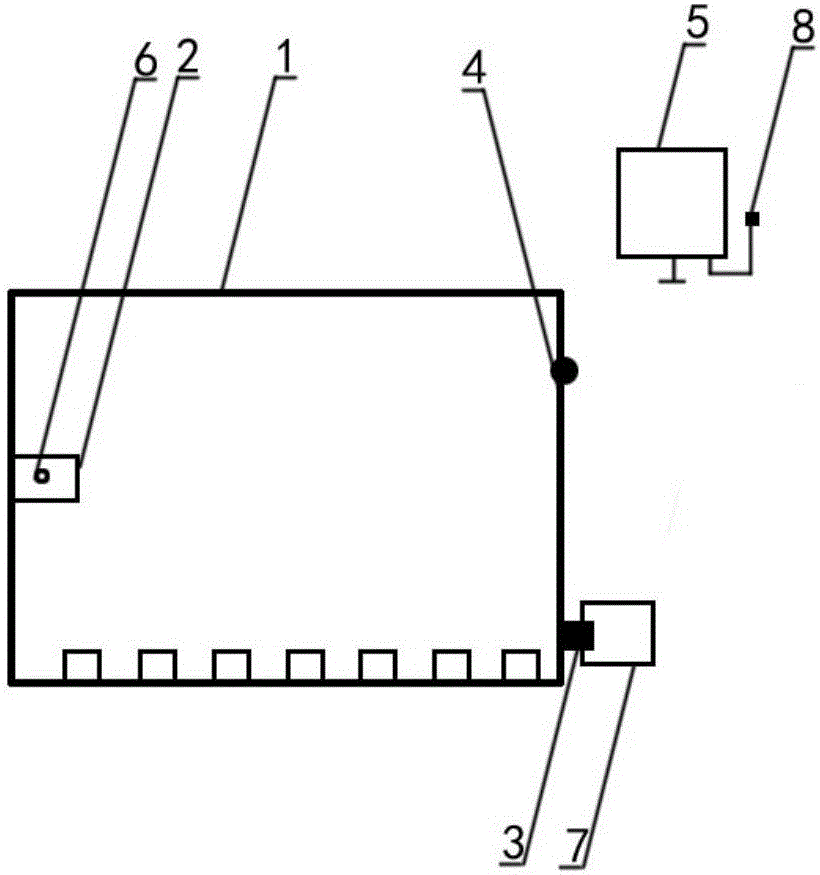

Overload and idling prevention assembly for electric oil well pump

InactiveCN105927528AAvoid affecting the performance of the operationPump controlPositive-displacement liquid enginesLoad sensingComputer module

An overload and idling prevention assembly for an electric oil well pump comprises a machine body (1) which is provided with an operation sensing module (2), a load sensing module (3), an information sensing module (4) and a management module (5). During operation, the operation sensing module (2) senses the operation state of a pump body, the load sensing module (3) senses the load condition of the pump body, and the information sensing module (4) transmits sensed information to the management module (5) for processing; a rotating speed sensing module (6) is arranged on the operation sensing module (2) and used for sensing the rotating speed change condition when the pump body operates; a setting module (7) is arranged on the load sensing module (3) and used for setting a proper numerical value range of the pump body load; and a prompt module (8) is arranged on the management module (5) and used for giving out a prompt when the rotating speed or the load of the pump body is abnormal. By controlling the load of the pump body, the situation that the operation effect is affected by idling or overload is avoided.

Owner:HUAINAN YILIU MACHINERY TECH CO LTD

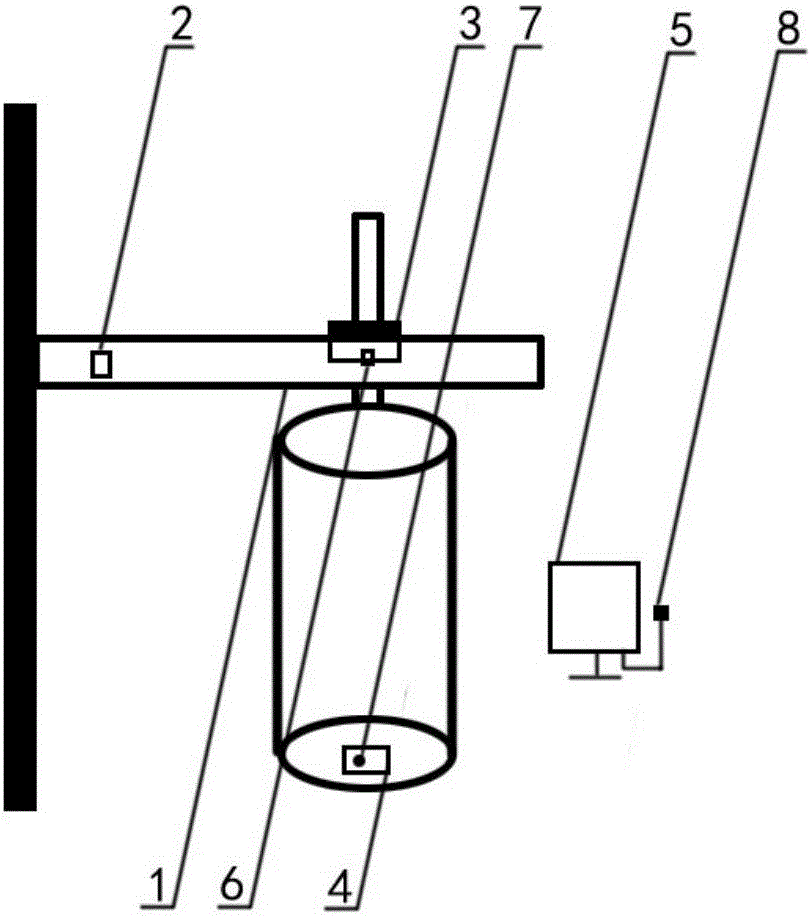

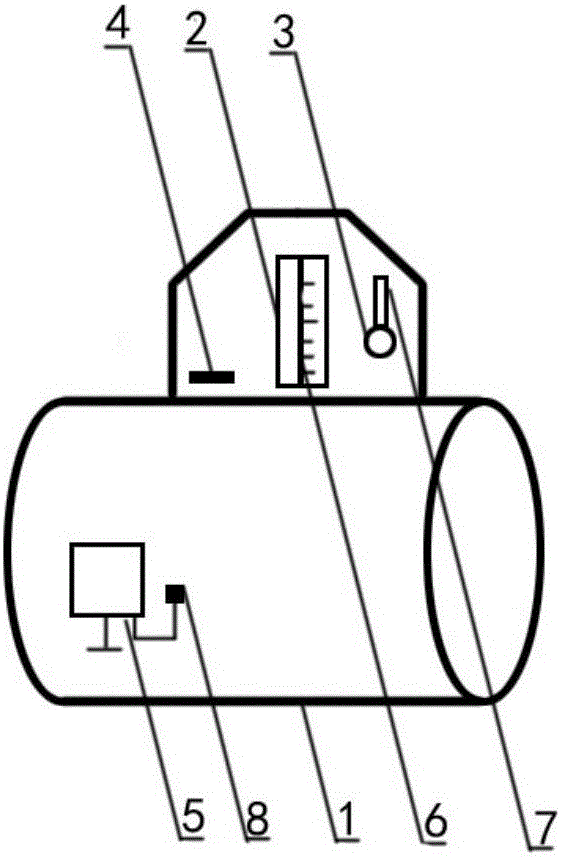

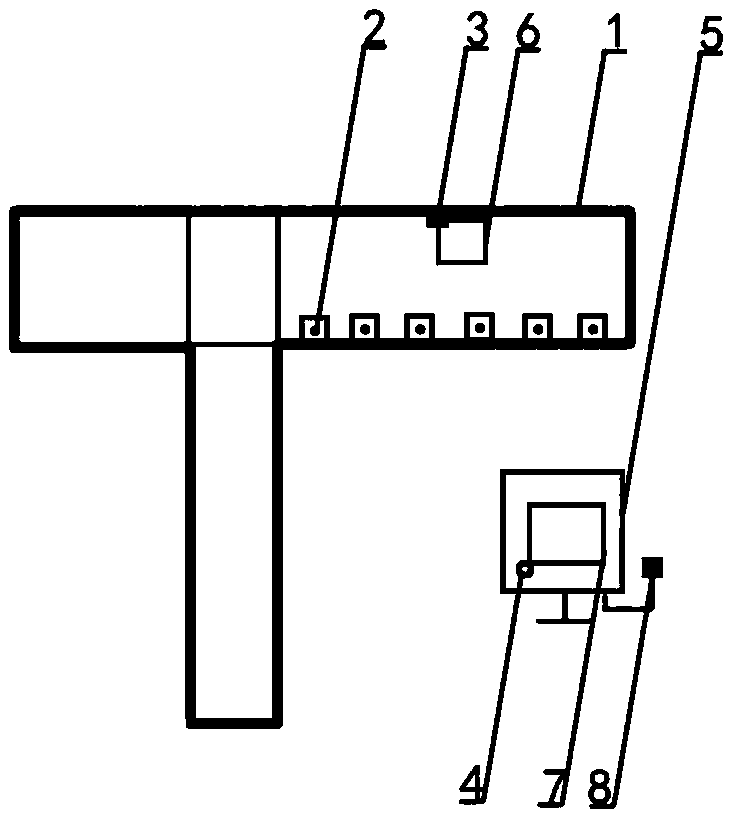

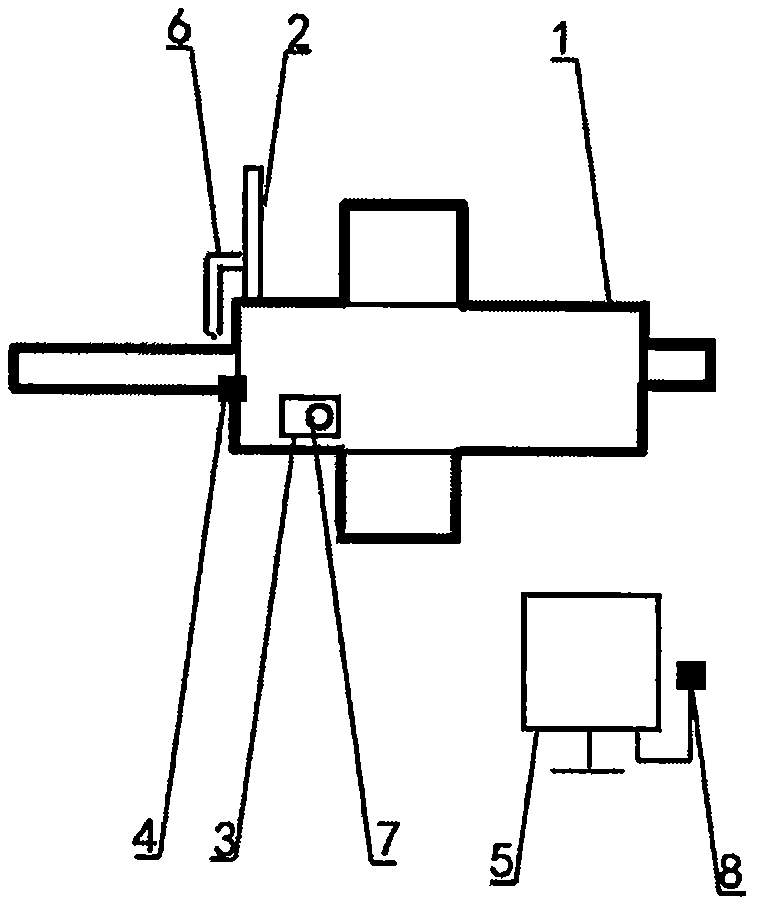

Drill hoisting speed and direction control assembly for core-drilling machine

InactiveCN106053128AAvoid affecting the performance of the operationWithdrawing sample devicesEngineeringDrill bit

A drill hoisting speed and direction control assembly for a core-drilling machine comprises a machine body (1). The machine body (1) is provided with an operation induction module (2), a hoisting control module (3), a pressure induction module (4) and a management module (5). During running, the operation induction module (2) inducts the operation state of a machine frame, the hoisting control module (3) controls the drill hoisting situation, the pressure induction module (4) inducts the stress situation of a drill, and the management module (5) processes general information. The hoisting control module (3) is provided with a speed regulating module (6) and controls the hoisting speed of the drill according to the operation state of the machine frame; the pressure induction module (4) is provided with a direction induction module (7). The management module (5) is provided with a prompting module (8), and the promoting module gives a prompt when inducting an abnormal hoisting speed and an abnormal pressure situation. The hoisting speed is properly adjusted according to the operation state of the machine frame, and the operation effect is prevented from being affected.

Owner:HUAINAN YILIU MACHINERY TECH CO LTD

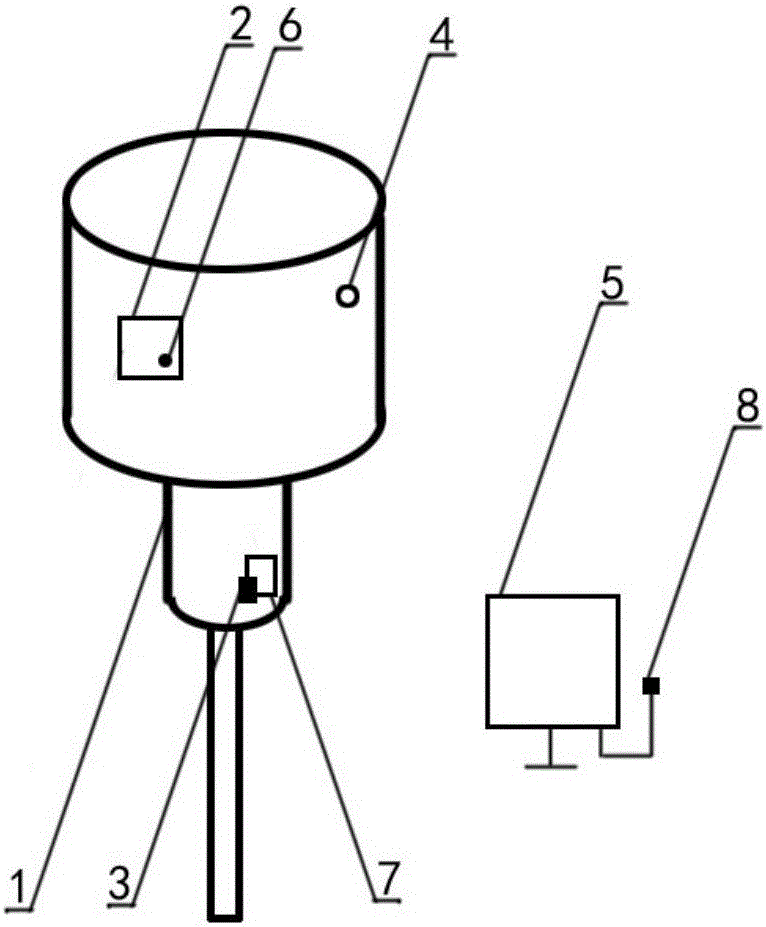

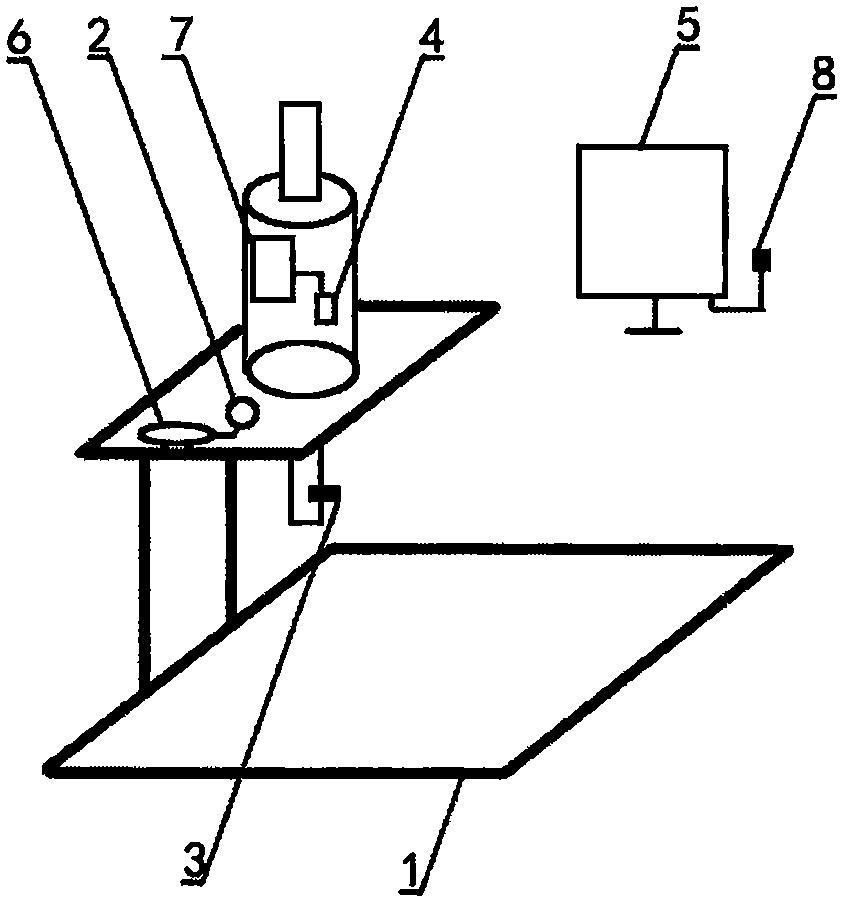

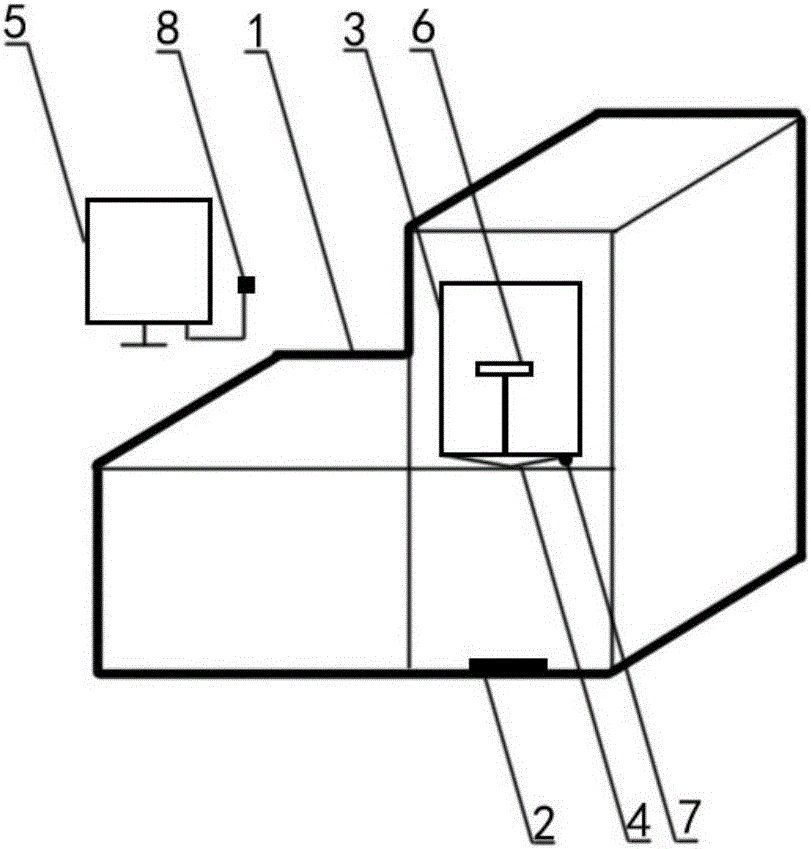

Concentric operation control module for industrial electric stirrer

InactiveCN107213817AGuaranteed stirringAvoid affecting the performance of the operationRotary stirring mixersTransportation and packagingMarine engineeringVibration sense

The invention provides a concentric operation control module for an industrial electric stirrer. The concentric operation control module comprises a machine body (1), wherein a vibration sensing module (2), a concentric reference module (3), a stirring module (4) and a management module (5) are arranged on the machine body (1); when the concentric operation control module is in operation, the vibration sensing module (2) is arranged on the stirring module (4) and senses the condition of stirring during operation; the concentric reference module (3) senses and contrasts the position of the stirring module (4), and the sensed information is processed by the management module (5); a setting module (6) is arranged on the vibration sensing module (2) and sets the condition of allowable emitted vibration during normal stirring operation; a position labeling module (7) is arranged on the concentric reference module (3) and labels the position condition of the stirring module (4) in real time; a prompt module (8) is arranged on the management module (5); and through real-time sensing of the operation condition of a stirring bar, concentric stirring is guaranteed, and influence on operation effects is avoided.

Owner:XINCHANG COUNTY JINGLING TOWN KANGLIU ELECTRONICS COMPONENT FACTORY

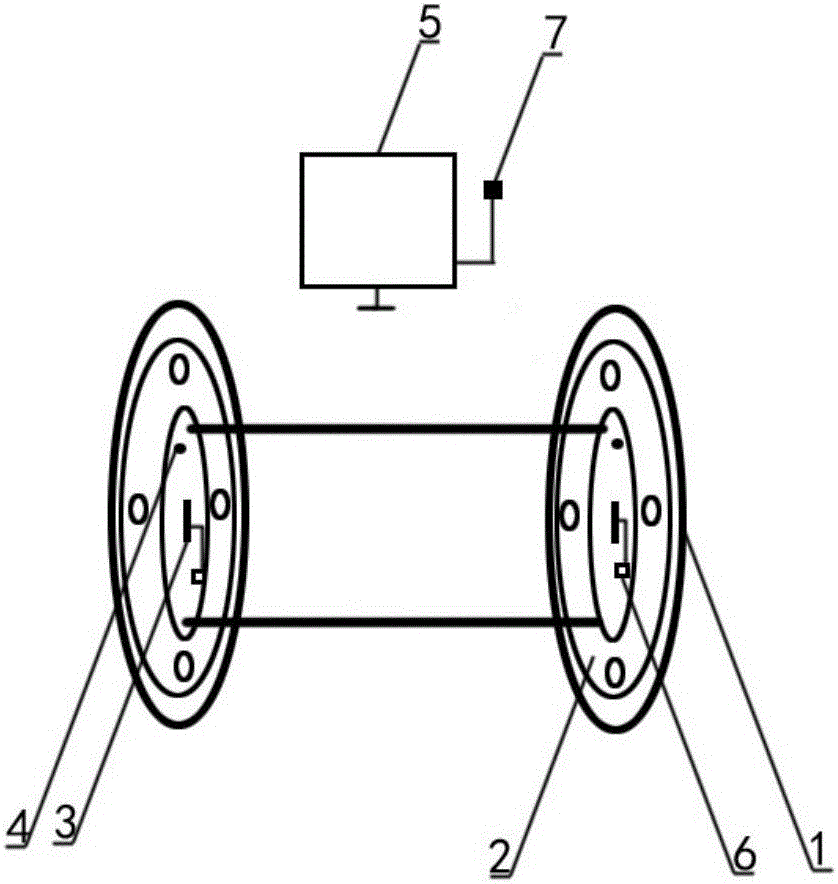

Calibration adjustment device for center of two shafts of coupling of industrial induced draft fan

InactiveCN105927577AAvoid affecting the performance of the operationPump componentsPump controlCouplingComputer module

The invention discloses a calibration adjustment device for a center of two shafts of a coupling of an industrial induced draft fan. The calibration adjustment device comprises a machine body (1), wherein a fixed point reference module (2), an infrared horizontal detection module (3), an information receiving module (4) and a management module (5) are arranged on the machine body (1); during operation, the fixed point reference module (2) is arranged in the center of the two shafts; the infrared horizontal detection module (3) detects the horizontal position situation between the two shafts; the information receiving module (4) receives corresponding information; the management module (5) processes the received information; a position adjustment module (6) is arranged on the fixed point reference module (2), and a reference position is set according to machine body operation and coupling mounting situations; a direction setting module (7) is arranged on the infrared horizontal detection module (3) to measure the horizontal alignment situation in a certain direction; and a prompt module (8) is arranged on the management module (5). According to the calibration adjustment device, through calibrating and controlling the central position of the two shafts, the operation effect is prevented from being influenced.

Owner:ANQING FENGBANG IND PROD DESIGN

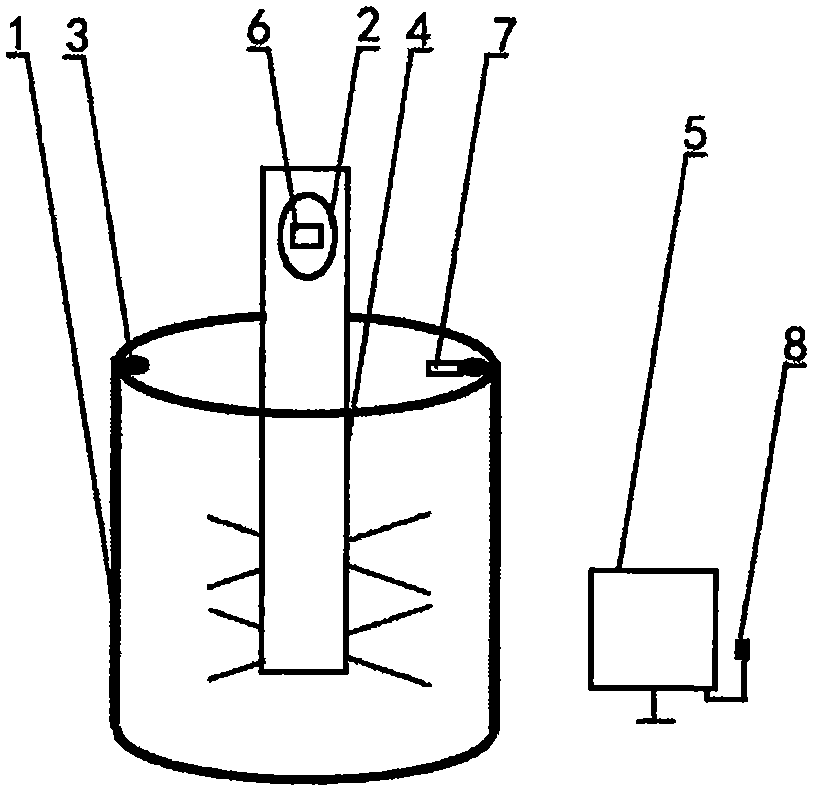

Smashing operation material drying assembly of vibration sample grinding machine

InactiveCN107305094AMaintain humidityAvoid affecting the performance of the operationDrying solid materialsVibration amplitudeInformation processing

Vibration mill crushing operation material drying components, including a body (1), on the body (1) is equipped with a humidity sensing module (2), a drying module (3), a vibration module (4), a management module (5), run , the humidity sensing module (2) senses the humidity of the material, and when the humidity is too high, the drying module (3) is started to dry the material, the vibration module (4) stirs the material, and the drying is accelerated, and the management module (5) processes the comprehensive information; A setting module (6) is set on the humidity sensing module (2) to set the suitable humidity range for the material to operate and its humidity limit; a strength adjustment module (7) is set on the vibration module (4) to adjust the humidity of the auxiliary drying material. Slight vibration amplitude; a prompt module (8) is set on the management module (5), and when the humidity of the material is sensed to be too high for operation; by controlling the humidity of the material, ensure that the humidity is within a reasonable range to avoid affecting the operation effect.

Owner:董幼兰

Operation rotating speed and flow rate control module of pneumatic diaphragm pump

InactiveCN105889047AAvoid affecting the performance of the operationPump controlPositive-displacement liquid enginesDiaphragm pumpPressure sense

An operation rotating speed and flow rate control module of a pneumatic diaphragm pump comprises a machine body (1), wherein a flow rate sensing module (2), a rotating speed sensing module (3) and a pressure sensing module (4) are arranged on the machine body; the flow rate sensing module (2) can be used for sensing the flow rate condition in the machine body; the rotating speed sensing module (3) is used for sensing the operation speed of a pump body; the pressure sensing module (4) is used for sensing the applied operation pressure number; the sensed information is processed by a managing module (5); a particle buffering module (6) is arranged on the flow rate sensing module (2) and used for buffering excessive material particles in case of excess flow rate; a setting module (7) is arranged on the rotating speed sensing module (3) and used for setting the rotating speed of the pump body within a reasonable number range; a prompting module (8) is arranged on the managing module (5) and used for prompting in case that an abnormal number is sensed. With the adoption of the operation rotating speed and flow rate control module, the flow rate, the rotating speed and the pressure are detected on real time, so that abnormal conditions which influence the operation effect can be avoided.

Owner:ANQING JINHAI IND PROD DESIGN

Connection tightness detection apparatus for flexible rubber joint

InactiveCN105699065AAvoid affecting the performance of the operationMachine part testingPressure senseEngineering

The flexible rubber joint connection tightness detection device includes a body (1), and a contact induction ring (2), a balance calibration module (3), a remote communication module (4), and a management module (5) are arranged on the body (1). ), during operation, the contact induction ring (2) is arranged on the contact surface between the body (1) and the bolt, and the balance calibration module (3) senses whether the pressure on the contact surface is balanced, and the sensed information is transmitted through the remote communication module (4) to the management module (5) for processing; a pressure sensing module (6) is set on the contact sensing ring (2) to sense the pressure difference when the pressure on the contact surface is unbalanced; a prompt module is set on the management module (5) (7), when the pressure and the pressure difference are too large, it will be prompted in time; the contact induction ring (2) is made of metal sheet memory material; through real-time detection of the connection between the rubber joint and the flange, if there is any abnormality, it will be prompted in time to avoid the impact Operational effect.

Owner:ANQING XINGBOTE ELECTRONICS TECH

Injection test prompt module of foam generator

InactiveCN105664412AAvoid affecting the performance of the operationFire rescueComputer moduleEngineering

A foam generator spray test prompt module, comprising a frame (1), on which a closure sensing module (2), an end confirmation module (3), a test indication module (4), and a management module (5) are arranged , during operation, the closed sensing module (2) senses the operating state of the foam generator, and when it is sensed that it stops operating, it is confirmed whether the task is terminated through the end confirmation module (3), if so, the test indication module (4) is started, and other The information is processed by the management module (5); a feedback module (6) is set on the test instruction module (4), and after the injection instruction is issued, it is fed back whether to carry out the injection test operation; a prompt module (7) is set on the management module (5) ; The prompting module (7) sends out prompts in the form of sound or LED display; after installation or operation, prompt the injection test in time to avoid affecting the next operation effect.

Owner:ANQING XINGBOTE ELECTRONICS TECH

Filter sieve for preventing blocking of feed valve in operating process of whirlcone

InactiveCN105964426AAvoid affecting the performance of the operationSievingScreeningImpurityGravitation

A filter sieve for preventing blocking of a feed valve in the operating process of a whirlcone comprises a sieve body (1). A gravity induction module (2), an operation induction module (3), a filtering screening module (4) and a management module (5) are arranged on the sieve body (1). In the operating process, the gravity induction module (2) is arranged in a feed pool to induce the load condition of the feed pool; the operation induction module (3) induces the operation condition of the sieve body (1); the filtering screening module (4) is arranged on a port of the feed pool; and the management module (5) is used for handling comprehensive information. An inductive switch module (6) is arranged on the gravity induction module (2) and used for controlling the opening and closing of the feed pool according to the operation condition and the sieve body load condition. A sieve pore adjusting module (7) is arranged on the filtering screening module (4) and used for adjusting the sizes of sieve pores according to the material operation condition. A reminding module (8) is arranged on the management module (5); and through screening impurities in materials, the operation effect is prevented from being affected by valve blocking.

Owner:ANHUI YILIU ELECTRONICS SCI & TECH

Auxiliary assembly for disassembling and assembling riveting head of riveting machine

A riveting machine riveting head removal and installation auxiliary component, including a body (1), on which a length measurement module (2), a rotation sensing module (3), a pressure sensing module (4), and a management module (5 ), during operation, the length measurement module (2) monitors the length of the riveting head in real time, the rotation sensing module (3) senses the rotation of the riveting head, the pressure sensing module (4) senses the force of the body (1), and the sensed The information is processed by the management module (5); a limit module (6) is set on the length measurement module (2) to set the appropriate length and limit value of the riveting head; a timing module (7) is set on the pressure sensing module (4) , the machine body (1) records its continuous running time under the high-pressure operation state; a prompt module (8) is set on the management module (5); the length of the rivet head and the pressure of the machine body are monitored in real time to avoid affecting the operation effect.

Owner:XINCHANG COUNTY YULIN STREET YUQUAN MACHINERY FACTORY

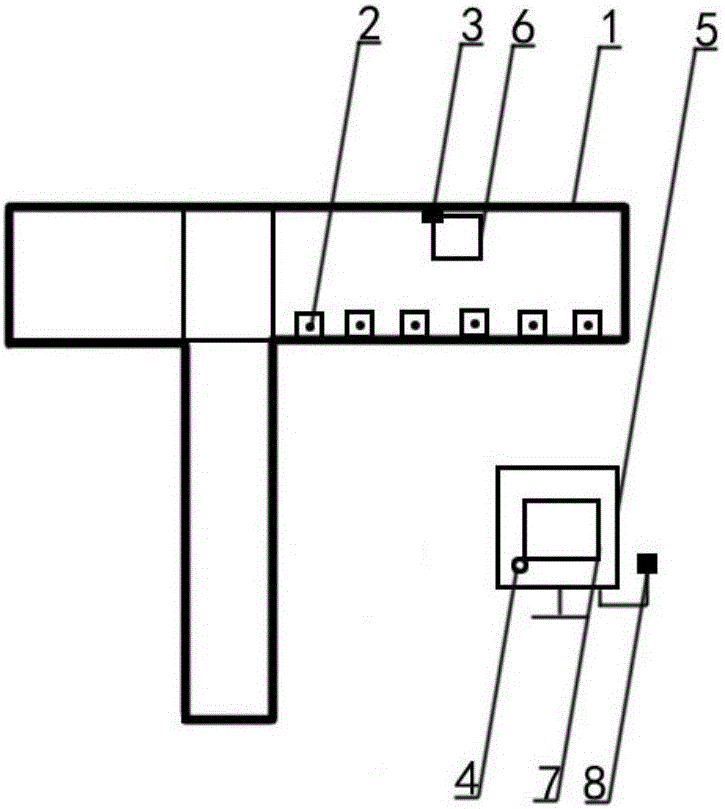

Fulcrum spacing regulation control device for horizontal rail window cleaning machine

ActiveCN105877627AAvoid affecting the performance of the operationCarpet cleanersFloor cleanersComputer moduleReal time display

The invention relates to a fulcrum spacing regulation control device for a horizontal rail window cleaning machine. The fulcrum spacing regulation control device for the horizontal rail window cleaning machine comprises a machine body (1); information sensing modules (2), an infrared measurement module (3), an information receiving module (4) and a management module (5) are arranged on the machine body (1); in the operating process, each information sensing module (2) is arranged on each fulcrum, the infrared measurement module (3) measures an interval distance of the fulcrums, the information receiving module (4) receives a position condition of each fulcrum, and the management module (5) processes sensed information; a setting module (6) is arranged on the infrared measurement module (3), and is used for setting a suitable range of the spacing between the fulcrums and a minimum spacing value; a display module (7) is arranged on the information receiving module (4), and is used for displaying the receiving position condition of each fulcrum in real time; a prompting module (8) is arranged on the management module (5); by controlling the distance between the fulcrums and the number of the fulcrums, influence on an operation effect is avoided.

Owner:南京潥航仿生产业研究院有限公司

Operation face plate maintenance module of automatic screw driving machine

InactiveCN107225388AAvoid affecting the performance of the operationMetal working apparatusTemperature controlMaterial Design

An operation face plate maintenance module of an automatic screw driving machine comprises a machine body (1). Contact sensing modules (2), an operation sensing module (3), a cleaning indication module (4) and a management module (5) are arranged on the machine body (1). During operation, the operation sensing module (3) senses the operation state of the machine body (1), when the machine body is in the switched-off state, the contact sensing modules (2) sense whether extra objects exist on the machine body (1), the sensed information is processed by the management module (5), and a timing module (6) is arranged on the cleaning indication module (4) and sets the time period for clean the operation face plate of the machine body (1) according to operation requirements. A prompt module (7) is arranged on the management module (5). When it is sensed that impurities exist on the operation face plate or the operation face plate is not cleaned in time, the prompt module (7) gives out a prompt. The contact sensing modules (2) are made of a temperature control material. Through timely cleaning of the operation face plate, the situation that the impurities are placed on the machine body, so that the operation effect is influenced is avoided.

Owner:XINCHANG CHENGTAN TOWN KANGCHENG MACHINERY FITTINGS FACTORY

Fixed-point instruction control device for man-machine operation direction of straightening machine

InactiveCN105834252AAvoid affecting the performance of the operationShaping safety devicesMan machineComputer science

The human-machine operation orientation fixed-point instruction control device of the straightening machine includes a body (1), and an information sensing module (2), a corresponding reference module (3), an information receiving module (4), and a management module ( 5), during operation, the information sensing module (2) is arranged on each operating part, the corresponding reference module (3) corresponds to the man-machine situation on each operating part, the information receiving module (4) receives corresponding information, and the management module (5) Process comprehensive information; set a label indicator module (6) on the information sensing module (2) to indicate the situation of different components and corresponding personnel; set a correction setting module (7) on the corresponding reference module (3), when man-machine When there is a change in the correspondence, it is corrected in time; a prompt module (8) is set on the management module (5); and by controlling the one-to-one correspondence of man-machine operations, it avoids affecting the operation effect.

Owner:淮南市鸿裕工业产品设计有限公司

Sensitive testing instrument for contact performance of sensor of laminating machine

InactiveCN105711233AAvoid affecting the performance of the operationControlling laminationLaminationContact pressureBiochemical engineering

A contact performance sensitive tester for a laminating machine sensing device, comprising a body (1), on which a contact sensing module (2), a pressure sensing module (3), a remote communication module (4), and a management module (5 ), during operation, the contact sensing module (2) is arranged on the sensor to sense its contact with the fuselage, the pressure sensing module (3) senses the contact pressure value, and the sensed information is transmitted to the The management module (5) processes; the coincidence setting module (6) is set on the contact sensing module (2), and the reasonable position of its contact is set according to the requirements; the positioning lifting module (7) is set on the pressure sensing module (3) , set the lifting condition of the contact position; set the prompt module (8) on the management module (5); and avoid affecting the operation effect by testing the contact condition between the sensor and the fuselage components.

Owner:ANQING DECHUANG ELECTROMECHANICAL PROD DESIGN

Lubricating oil emulsification scale control module for operation of air compressor

InactiveCN105971854AAvoid affecting the performance of the operationPositive displacement pump componentsPositive-displacement liquid enginesGas compressorProcess engineering

A lubricating oil emulsification scale control module for operation of an air compressor comprises a machine body (1). An oil quantity induction module (2), a replacement indicating module (3), a moisture induction module (4) and a management module (5) are arranged on the machine body (1). When the air compressor operates, the oil quantity induction module (2) induces the specific oil quantity condition, the replacement indicating module (3) indicates the time for replacing lubricating oil, the moisture induction module (4) induces the moisture content in the lubricating oil, and the management module (5) processes comprehensive information. A scale display module (6) is arranged on the oil quantity induction module (2) and used for displaying the oil volume scale condition in real time. A gas acid-alkaline induction module (7) is arranged on the replacement indicating module (3), and when it is inducted that acid or alkaline substances exist in the gas, the time for replacing the lubricating oil is changed. A prompt module (8) is arranged on the management module (5). The lubricating oil content and replacement time are controlled according to the machine body storage environment and operation condition, and the operation effect is prevented from being affected.

Owner:ANHUI YILIU ELECTRONICS SCI & TECH

Screw fixing assisting device for bench screw

InactiveCN107283331AAvoid affecting the performance of the operationVicesLED displayVibration sensor

A bench vise screw fixing auxiliary device, comprising a body (1), on which a screw fastening module (2), a sealing module (3), a vibration sensing module (4), and a fastening connection module ( 5), during operation, the screw fastening module (2) fastens the screws respectively, the fastening connection module (5) connects the three fastening points, seals through the sealing module (3), and the vibration sensing module (4) senses the tightness Check the tightness of the vibration of the fixed point; install a balance sensor module (6) on the sealing module (3) to sense the pressure on the three connection points, and compare whether the difference is large; in the vibration sensor module (4) A reminder module (7) is set on the sheet, and when it senses that the vibration of the fastening point is serious, a reminder is issued; the method of the reminder module (7) is sound or LED display; the influence is avoided by detecting and controlling the firmness of the clamping screw Operational effect.

Owner:XINCHANG COUNTY DASHIJU TOWN HONGJU MACHINERY PLANT

Horizontal track window cleaning machine fulcrum spacing control device

ActiveCN105877627BAvoid affecting the performance of the operationCarpet cleanersFloor cleanersEmbedded systemEngineering

Owner:南京潥航仿生产业研究院有限公司

Forced and moderate cutting removing assisting device for deep hole drilling machine

InactiveCN105798697AAvoid affecting the performance of the operationMeasurement/indication equipmentsMaintainance and safety accessoriesLED displayMarine engineering

The invention relates to a forced and moderate cutting removing assisting device for a deep hole drilling machine. The forced and moderate cutting removing assisting device comprises a device body (1), and a running sensing module (2), an adsorption module (3), a remote communication module (4) and a management module (5) are arranged on the device body (1); during running, the running sensing module (2) senses the running state of the device body, and the adsorption module (3) absorbs and contains cuttings; sensed information is transmitted to the management module (5) through the remote communication module (4) to be processed; a timing module (6) is arranged on the running sensing module (2), and the cutting absorbing time is set according to the running condition; a storage and containing module (7) is arranged on the adsorption module (3) and used for containing and storing the cuttings absorbed in a timing and forced manner; and a prompting module (8) is arranged on the management module (5), and the prompting manner of the prompting module (8) is sounds or LED display. The cuttings are removed in a timing and forced manner, so that influences of too-many cuttings on the running effect are avoided.

Owner:ANQING FENGBANG IND PROD DESIGN

Bed charge supplementing instrument for glue adding work of hot melt glue machine

InactiveCN106000792AAvoid affecting the performance of the operationLiquid surface applicatorsCoatingsComputer moduleHot melt

A bed charge supplementing instrument for glue adding work of a hot melt glue machine comprises a machine body (1), and a gravity induction module (2), a bed charge supplementing module (3), an induction switch module (4) and a management module (5) are arranged on the machine body (1); during running, the gravity induction module (2) is arranged on a glue pot, and induces the condition of glue in the pot, the bed charge supplementing module (3) supplements the glue according to the condition of the glue in the glue pot, and the induction switch module (4) controls the operating state of the bed charge supplementing module (3); the management module (5) processes comprehensive information; a flow control module (6) is arranged on the bed charge supplementing module (3) and controls the amount of supplemented glue; an information induction module (7) is arranged on the induction switch module (4) and induces the condition of numerical value changes of the glue in the glue pot; and a prompt module (8) is arranged on the management module (5). Through control over the time and the amount of glue supplementing, the phenomenon that the amount of base gel is abnormal, and consequently the operating effect is affected is avoided.

Owner:ANHUI YILIU ELECTRONICS SCI & TECH

Concentration and volume detection device for medium-speed wire working solution

InactiveCN107297551AAvoid affecting the performance of the operationElectrical-based auxillary apparatusWorking fluidEngineering

The medium-feeding working fluid concentration and capacity detection device includes a frame (1), on which a working fluid storage module (2), a gravity sensing module (3), a flow sensing module (4), and a management module ( 5), during operation, the gravity sensing module (3) senses the weight change in the working fluid storage module (2) before and after operation, the flow sensing module (4) senses the capacity change, and the sensed value is determined by the management module (5 ) processing; set the time setting module (6) on the working fluid storage module (2), set the single and total duration of the working fluid operation added in the same time period; set the display module (7) on the management module (5) ), display the outflow speed of the working fluid according to the operation time and flow change; set a prompt module (8) on the management module (5); detect its flow speed through real-time sensing to avoid being too fast or too slow, which will affect the operation effect.

Owner:XINCHANG CHENGTAN CHENGSHE MACHINERY FACTORY

Operating component gap and relative movement regulation and control device of hollow brick machine

InactiveCN106003409AAvoid affecting the performance of the operationAuxillary shaping apparatusBrickComputer module

The invention provides an operating component gap and relative movement regulation and control device of a hollow brick machine. The operating component gap and relative movement regulation and control device of the hollow brick machine comprises a machine body (1). A gap measurement module (2), a speed induction module (3), an information induction module (4) and a management module (5) are arranged on the machine body (1). During operation, the gap measurement module (2) measures a gap numerical value, the speed induction module (3) induces the movement speed condition of relevant components, and induced information is transmitted to the management module (5) through the information induction module (4) to be processed. A setting module (6) is arranged on the gap measurement module (2) and used for setting the gap condition of the relevant components within the proper range. A direction induction module (7) is arranged on the speed induction module (3) and used for inducing the direction condition of movement components. A prompt module (8) is arranged on the management module (5) and used for giving out a prompt message when abnormal gaps and movement condition of the relevant components are induced. By controlling the gaps and movement directions of the components of the machine body, the operating effect is prevented from being affected.

Owner:ANHUI HAICHENG DECHANG ELECTRONICS TECH

Fetching and conveying tool based on workpiece dimensions for stamping piece

InactiveCN105817547AAvoid affecting the performance of the operationMetal-working feeding devicesMetal working apparatusElectricityComputer module

The invention provides a fetching and conveying tool based on workpiece dimensions for a stamping piece. The fetching and conveying tool based on the workpiece dimensions for the stamping piece comprises a machine body (1). A workpiece induction module (2), a pyroelectric infrared sensing module (3), an information receiving module (4) and a management module (5) are arranged on the machine body (1). During operation, the workpiece induction module (2) induces the dimension numerical value of a workpiece, the pyroelectric infrared sensing module (3) induces the distance condition between a worker and the workpiece, and received information is transmitted to the management module (5) by the information receiving module (4) to be processed; a dimension adjustment module (6) is arranged on the workpiece induction module (2), and it is set that workpieces within a certain dimension range cannot be directly fetched or conveyed; a distance setting module (7) is arranged on the pyroelectric infrared sensing module (3), and a reasonable range of the distance numerical values between workers and workpieces is set; and a promoting module (8) is arranged on the management module (5). The effect that workpieces with excessively small sizes or special workpieces are not directly fetched or conveyed with hands is guaranteed, and accordingly the operating effect is prevented from being affected.

Owner:安徽科信伟德机电产品设计有限公司

Buffer operation auxiliary module for fixture of nozzle device of chip mounter

InactiveCN107306490AAvoid affecting the performance of the operationElectrical componentsPressure senseRunning time

The auxiliary module for clamp buffer operation of the suction nozzle device of the placement machine includes a body (1), on which a moving module (2), a speed sensing module (3), a pressure detection module (4), and a management module (5 ), during operation, the mobile module (2) drives the fixture to move on the nozzle part, the speed sensing module (3) senses the moving speed, and the pressure detection module (4) detects its pressure situation, and the sensed information is sent by the management module (5 ) processing; on the mobile module (2), a lubrication adding module (6) is set, and when the moving speed is too slow, lubricating oil is added appropriately; on the speed sensing module (3), a timing module (7) is set to record different speeds The time point; the prompt module (8) is set on the management module (5), and when the pressure or speed value is abnormal, a prompt is issued; by checking whether the clamping operation is smooth, the actual operation effect is avoided.

Owner:董幼兰

Torsion testing machine two-way chuck rotation limit module

InactiveCN107192603AAvoid affecting the performance of the operationStrength propertiesTorsion testMarine engineering

The rotation limiting module of the two-way chuck of the torsion testing machine includes a body (1), and a limit module (2), a length measurement module (3), a remote communication module (4), and a management module (5) are set on the body (1) , during operation, the limit module (2) limits the movement of the chuck in the fixed direction, the length measurement module (3) measures the distance between the two-way chucks, and the sensed information is transmitted to the management module (5) by the remote communication module (4) ) processing; a rotation sensing module (6) is set on the limit module (2) to sense the movement and direction of rotation of the chuck; a display module (7) is set on the management module (5) to display the distance between the two-way chucks in real time and movement and rotation; a prompt module (8) is set on the management module (5), and when the distance or movement is detected to be abnormal, a prompt is issued; by real-time sensing of the distance and movement position, the operation effect is avoided.

Owner:XINCHANG HONGYU IND PROD DESIGN

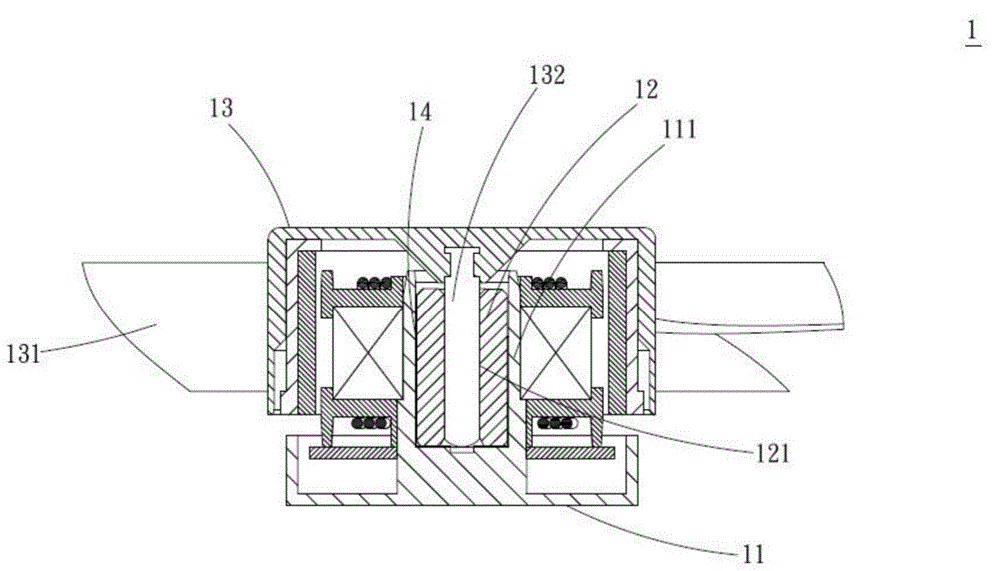

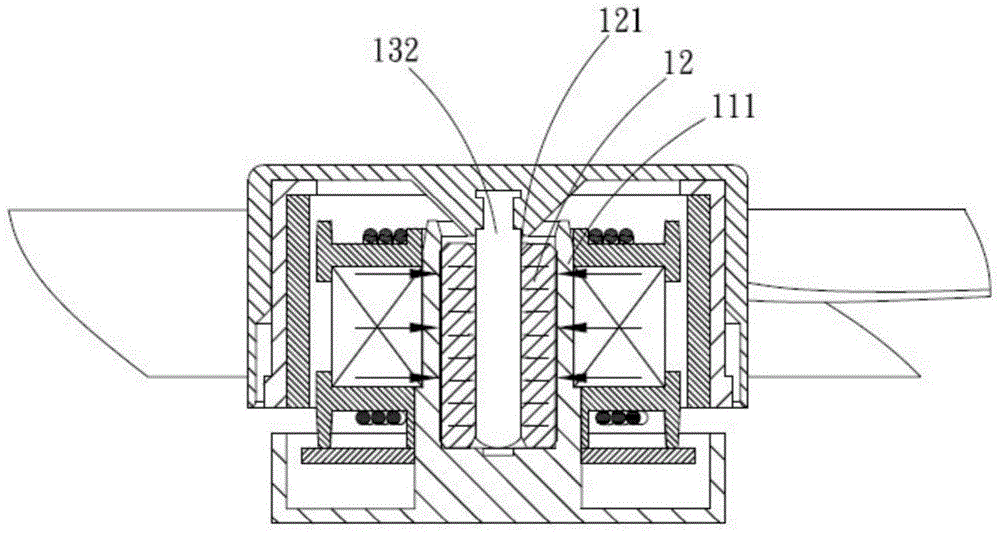

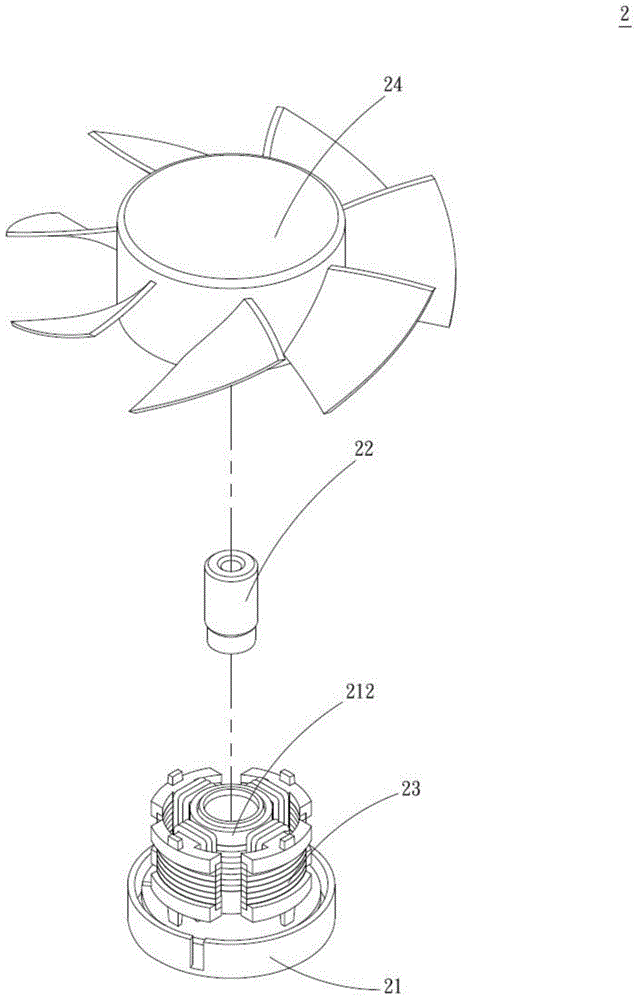

Fan device with oil bearing

ActiveCN105443430AAvoid affecting the performance of the operationEffectively fixedPump componentsPumpsButt jointEngineering

The invention provides a fan device with an oil bearing. The fan device comprises a base and the oil bearing, wherein the base is provided with a middle pipe and a shaft barrel extending from the middle pipe to one side; a bearing hole is formed in the shaft barrel; at least one butt joint portion is arranged in the position, opposite to the bearing hole, of the middle pipe; the oil bearing is provided with at least one assembling-connecting portion assembled on the butt joint portion. Therefore, the oil bearing is fixedly arranged in the bearing hole through mutual assembly of the assembling-connecting portions and the butt joint portions, and the situation that operation is affected by close-fitting interference and difficult control over dispensing can be avoided.

Owner:ASIA VITAL COMPONENTS CHENGDU

Clearance regulation module of machine tool workpiece clamping device

InactiveCN107283176AAvoid affecting the performance of the operationMeasurement/indication equipmentsPositioning apparatusComputer moduleReal time display

The gap control module of the workpiece clamping device of the machine tool includes a body (1), on which a workpiece positioning module (2), a gap measurement module (3), a remote communication module (4), and a management module (5) are arranged, During operation, the workpiece positioning module (2) fixes its position according to the workpiece installation, the gap measurement module (3) detects the gap value between the workpiece and the body (1), and the detected value is transmitted to the management module (5) through the remote communication module (4) ) processing; a direction sensing module (6) is set on the workpiece positioning module (2) to sense whether the direction of the workpiece is consistent with the auxiliary parts of the body (1); a display module (7) is set on the management module (5) for real-time display The sensed gap value and the position of the workpiece; the prompt module (8) is set on the management module (5); and the position and gap between the workpiece and the fuselage parts are monitored in real time to avoid affecting the operation effect.

Owner:XINCHANG COUNTY DASHIJU TOWN HONGJU MACHINERY PLANT

Wire fracture limitation and prevention module used during operation of wire straightening machine

InactiveCN107186126AAvoid affecting the performance of the operationMetal working apparatusContact pressureEngineering

The invention provides a wire fracture limitation and prevention module used during operation of a wire straightening machine. The wire fracture limitation and prevention module comprises a machine body (1). A pressure sensing module (2), an information generation module (3), an information receiving module (4) and a management module (5) are arranged on the machine body (1). During operation, the information generation module (3) is arranged in the fixed position of the machine body (1); the information receiving module (4) is arranged on a compression spring; the pressure sensing module (2) senses the conditions of contact pressure of the information generation module (3) and the information receiving module (4), and sensed information is processed by the management module (5); a contact sensing module (6) is arranged on the information generation module (3) and is used for sensing the condition of the region, bearing pressure of the compression spring, of the machine body (1); a display module (7) is arranged on the management module (5) and is used for displaying the value of the pressure borne by the machine body (1) and the condition of the region bearing pressure; a prompt module (8) is arranged on the management module (5) and is used for guaranteeing no broken wires by detecting and controlling the pressure of the compression spring and the condition of the position of the compression spring. The operating effect cannot be affected.

Owner:XINCHANG DASHIJU TOWN HAIFANG MACHINERY PLANT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com