Auxiliary assembly for disassembling and assembling riveting head of riveting machine

A technology for installation assistance and riveting machine, which is applied in the field of riveting machine parts, and can solve problems such as too long riveting head and rough installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

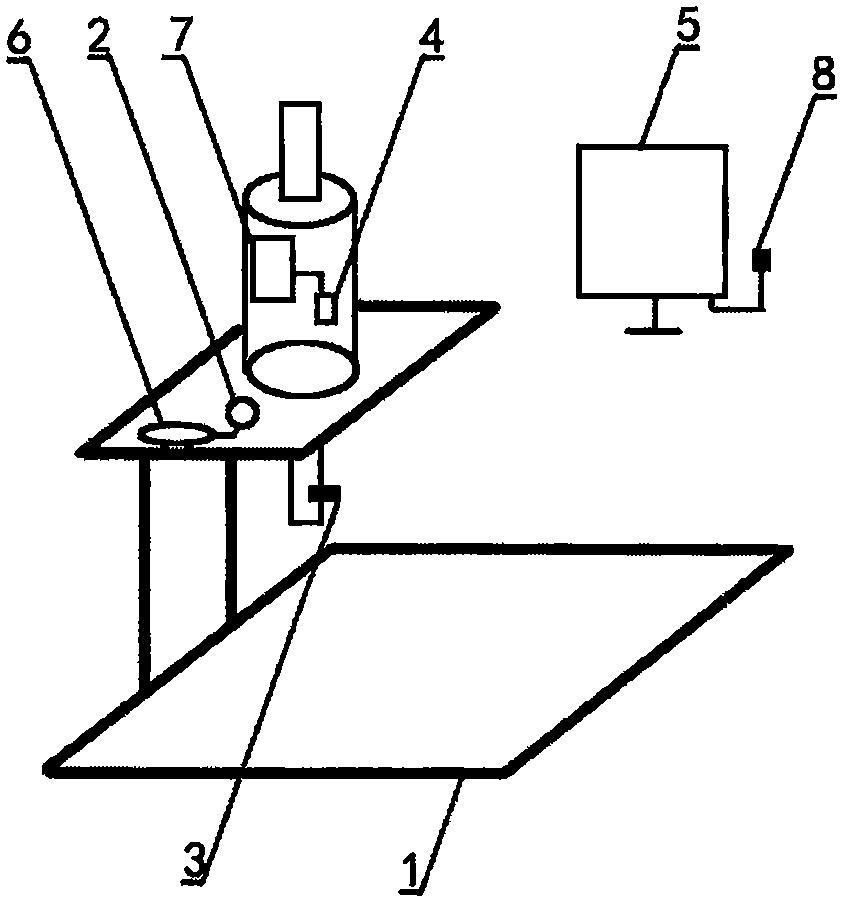

[0012] Embodiment: as shown in the accompanying drawing. A riveting machine riveting head removal and installation auxiliary component, including a body (1), on which a length measurement module (2), a rotation sensing module (3), a pressure sensing module (4), and a management module (5 ), during operation, the length measurement module (2) monitors the length of the riveting head in real time, the rotation sensing module (3) senses the rotation of the riveting head, the pressure sensing module (4) senses the force of the body (1), and the sensed The information is processed by the management module (5).

[0013] The rivet head of the riveting machine is disassembled and installed with an auxiliary component, and a limiting module (6) is set on the length measuring module (2) to set a suitable length and a limit value of the rivet head.

[0014] The riveting head of the riveting machine is dismantled and installed with auxiliary components, and a timing module (7) is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com