Buffer operation auxiliary module for fixture of nozzle device of chip mounter

An auxiliary module and chip mounter technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as impact, poor operation effect, and uneven clamp buffer operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

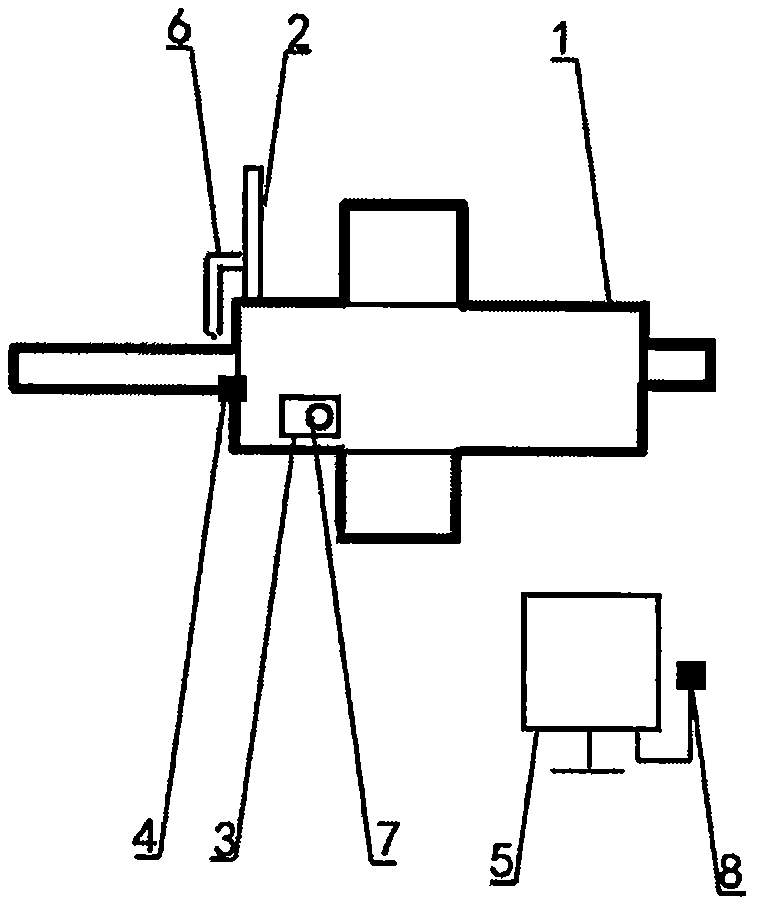

[0012] Embodiment: as shown in the accompanying drawing. The auxiliary module for clamp buffer operation of the suction nozzle device of the placement machine includes a body (1), on which a moving module (2), a speed sensing module (3), a pressure detection module (4), and a management module (5 ), during operation, the mobile module (2) drives the fixture to move on the nozzle part, the speed sensing module (3) senses the moving speed, and the pressure detection module (4) detects its pressure situation, and the sensed information is sent by the management module (5 )deal with.

[0013] The mounting machine suction nozzle device clamp buffer operation auxiliary module is provided with a lubrication adding module (6) on the moving module (2), and when the moving speed is too slow, lubricating oil is properly added.

[0014] The mounting machine suction nozzle device clamp buffer operation auxiliary module is provided with a timing module (7) on the speed sensing module (3) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com