Bed charge supplementing instrument for glue adding work of hot melt glue machine

A technology of hot melt adhesive machine and base material, which is applied in the direction of coating, device for coating liquid on the surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

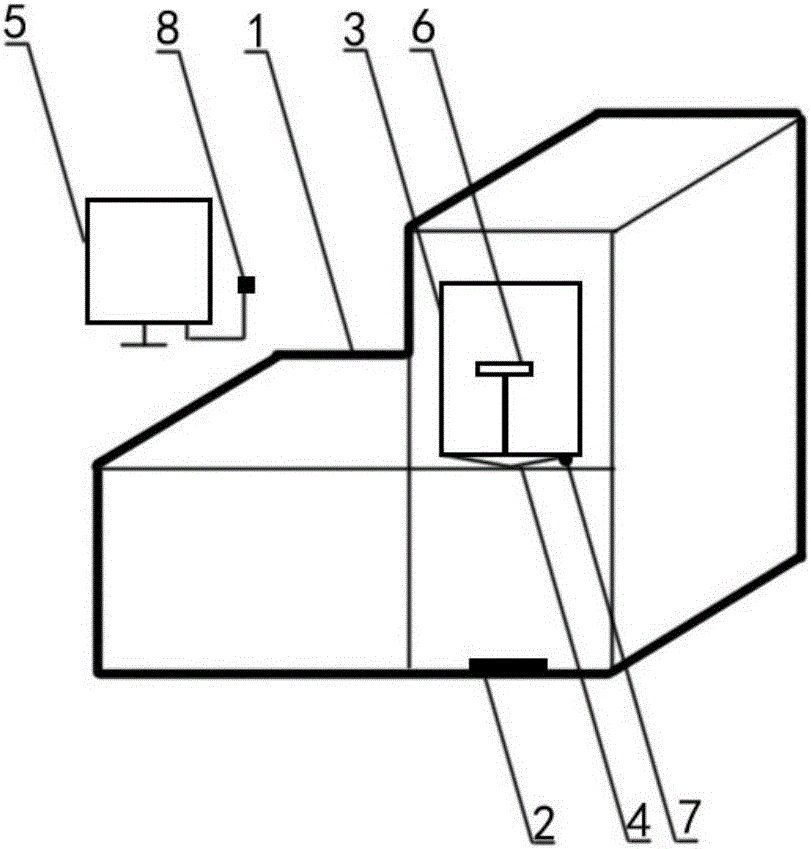

[0012] Embodiment: as shown in the accompanying drawing. A bottom material replenisher for hot melt glue machine, comprising a body (1), on which a gravity sensing module (2), a bottom material replenishment module (3), an induction switch module (4), The management module (5), during operation, the gravity sensing module (2) is set on the glue melting pot to sense the rubber material therein, the bottom material supplement module (3) replenishes the glue material according to the glue material situation of the melting glue pot, and the sensor switch module ( 4) Control the operation status of the bottom material replenishment module (3), and the management module (5) processes the comprehensive information.

[0013] A base material replenisher for hot-melt adhesive machine for continuous glue operation, in which a flow control module (6) is arranged on the base material replenishment module (3) to control the amount of added glue according to the sensed value of the glue.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com