Forced and moderate cutting removing assisting device for deep hole drilling machine

A technology for deep hole drilling machines and auxiliary devices, which is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., and can solve the problems of not removing chips in time and affecting the operation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

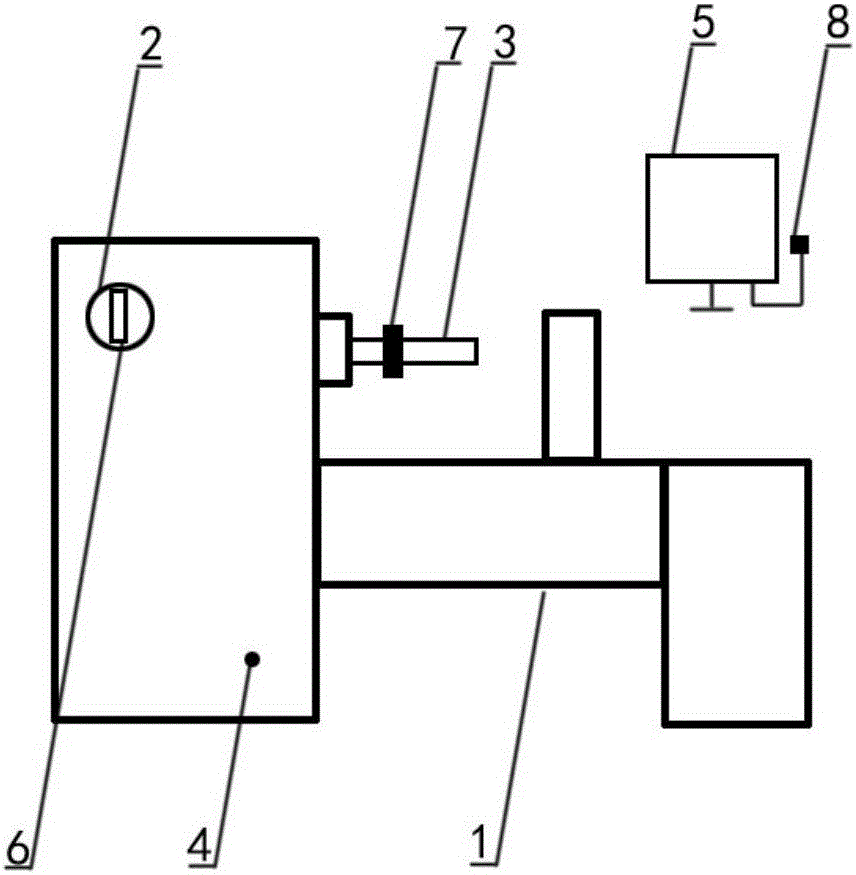

[0012] Embodiment: as shown in the accompanying drawing. The auxiliary device for forced and moderate removal of chips for a deep hole drilling machine includes a body (1), on which an operation sensing module (2), an adsorption module (3), a remote communication module (4), and a management module (5) are arranged, During operation, the operation sensing module (2) senses the operating state of the fuselage, the adsorption module (3) absorbs and stores chips, and the sensed information is transmitted to the management module (5) for processing through the remote communication module (4).

[0013] Auxiliary device for forced and moderate chip removal of deep hole drilling machine. A timing module (6) is set on the operation sensing module (2) to set the time for absorbing chips according to the operation situation.

[0014] The auxiliary device for forced and moderate removal of chips of the deep hole drilling machine is provided with a storage and storage module (7) on the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com