Concentration and volume detection device for medium-speed wire working solution

A technology of capacity detection and working fluid, which is applied in the direction of accessory devices, manufacturing tools, electric processing equipment, etc., can solve the problems of unfavorable operation effect and the speed of working fluid flowing out too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

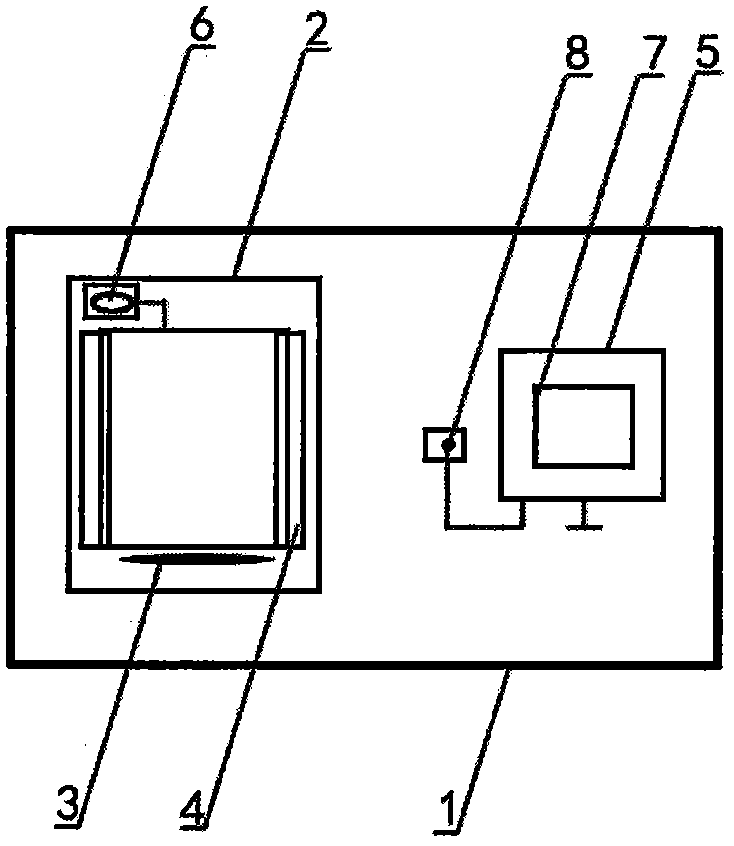

[0012] Embodiment: as shown in the accompanying drawing. The medium-feeding working fluid concentration and capacity detection device includes a frame (1), on which a working fluid storage module (2), a gravity sensing module (3), a flow sensing module (4), and a management module ( 5), during operation, the gravity sensing module (3) senses the weight change in the working fluid storage module (2) before and after operation, the flow sensing module (4) senses the capacity change, and the sensed value is determined by the management module (5 )deal with.

[0013] The medium-feeding working fluid concentration and capacity detection device is provided with a time setting module (6) on the working fluid storage module (2) to set the single operation and total duration of the working fluid added in the same time period.

[0014] In the medium-feeding working fluid concentration and capacity detection device, a display module (7) is provided on the management module (5) to displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com