Operation face plate maintenance module of automatic screw driving machine

A technology for automatic locking screw machines and maintenance modules, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as affecting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

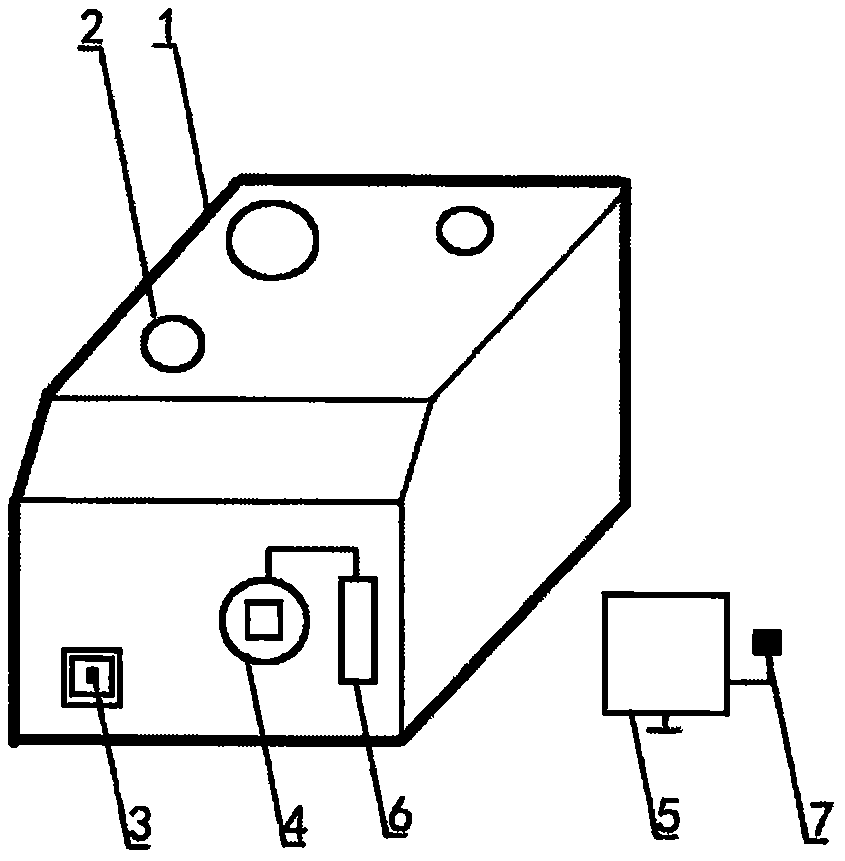

[0012] Embodiment: as shown in the accompanying drawing. The maintenance module of the operation panel of the automatic locking screw machine includes a body (1), on which a contact sensing module (2), a running sensing module (3), a cleaning indication module (4), and a management module (5) are arranged. , during operation, the operation sensing module (3) senses the operating state of the body (1), and when it is in a closed state, the contact sensing module (2) senses whether there is an extra object on the body (1), and the sensed information is given by The management module (5) processes.

[0013] The maintenance module of the operation panel of the automatic locking screw machine is provided with a timing module (6) on the cleaning indication module (4), and the time period for cleaning the operation panel of the body (1) is set according to the operation requirements.

[0014] The operation panel maintenance module of the automatic locking screw machine is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com