Lubricating oil emulsification scale control module for operation of air compressor

A technology for controlling modules and lubricating oils, which is applied in mechanical equipment, machines/engines, and liquid variable-capacity machinery, etc., and can solve the problems of abnormality, influence, and poor operation effect when adding or replacing lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

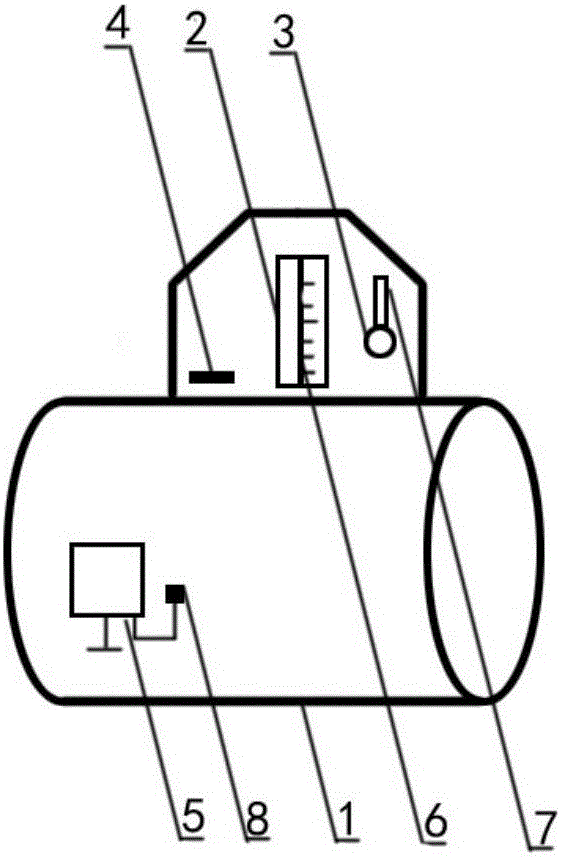

[0012] Example: as shown in the drawings. The air compressor operating lubricant emulsification scale control module includes a body (1). The body (1) is provided with an oil volume sensor module (2), a replacement indicator module (3), a moisture sensor module (4), and a management module ( 5) During operation, the oil quantity sensor module (2) senses the specific situation of the oil quantity, the replacement indicator module (3) indicates the time to replace the lubricating oil, the moisture sensor module (4) senses the moisture content in the lubricating oil, and the management module (5) Process comprehensive information.

[0013] The lubricating oil emulsification scale control module of the air compressor is provided with a scale display module (6) on the oil quantity sensor module (2) to display the sensed oil quantity capacity scale in real time.

[0014] The air compressor operation lubricating oil emulsification scale control module is equipped with a gas acid-base sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com