Patents

Literature

49results about How to "Invest evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sectionalized construction method of deep and large foundation pit

InactiveCN103510520AIncrease stiffnessOptimizing the supporting structure systemExcavationsEngineeringBuilding construction

The invention provides a sectionalized construction method of a deep and large foundation pit, and relates to the technical field of engineering construction of deep and large foundation pits. According to an existing construction method of the deep and large foundation pit, due to the negative factors that the excavation area of the foundation pit is overlarge, and the flat shape is irregular, or a lot of important buildings exist in the influence range of excavation of the foundation pit, the problems that influence of construction of the deep and large foundation pit on the surroundings is excessively high, and the construction period is long are caused. The sectionalized construction method of the deep and large foundation pit comprises the steps of (1) selecting the sectionalized construction method according to the engineering geological conditions of a construction field of the deep and large foundation pit, the nature of the foundation pit and the surroundings of the foundation pit; (2) dividing the deep and large foundation pit into a first foundation pit body, a second foundation pit body and a third foundation pit body, wherein the first foundation pit body, the second foundation pit body and the third foundation pit body are arranged in sequence, and the first foundation pit body and the third foundation pit body are arranged on the two sides of the deep and large foundation pit, and are not adjacent to each other.

Owner:上海市建工设计研究总院有限公司

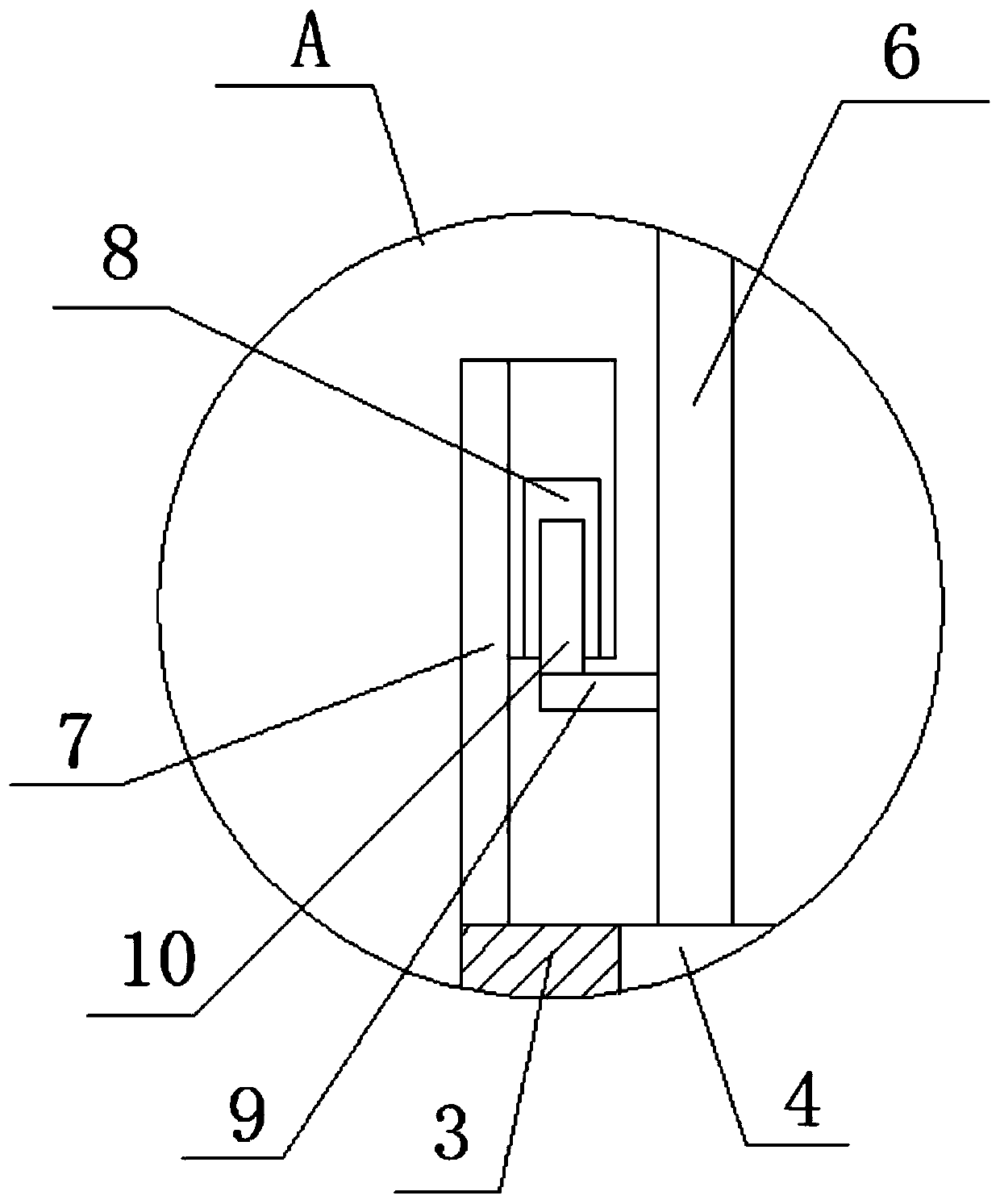

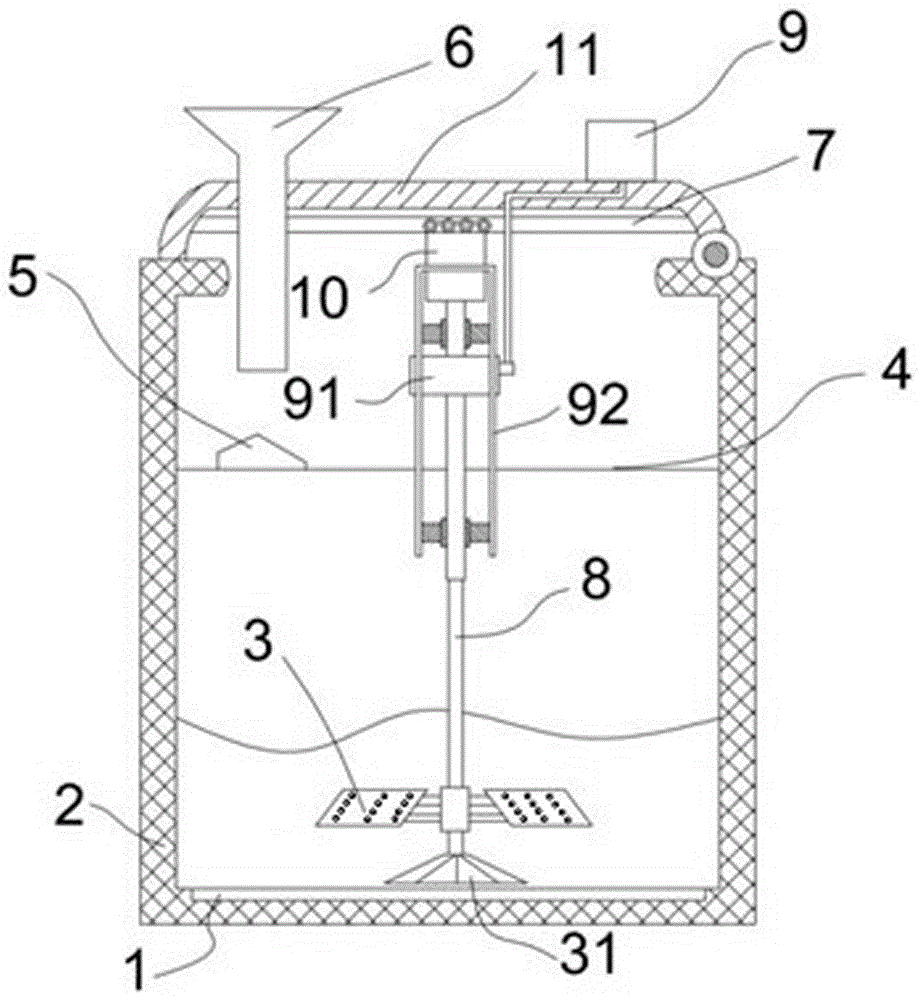

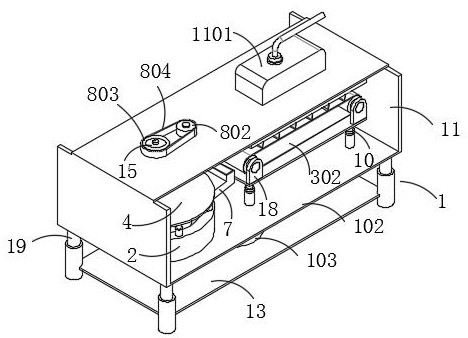

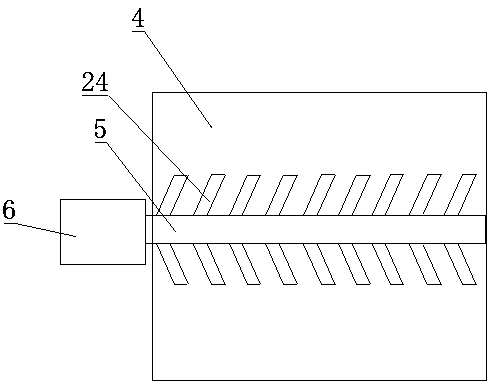

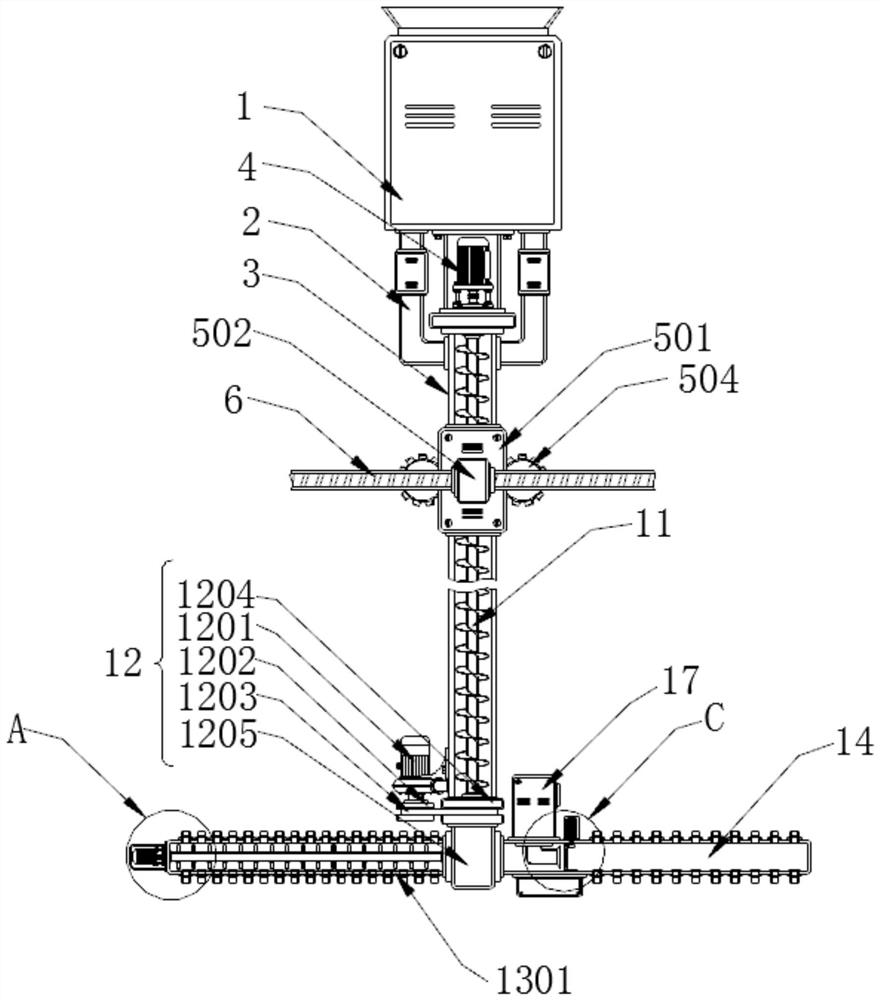

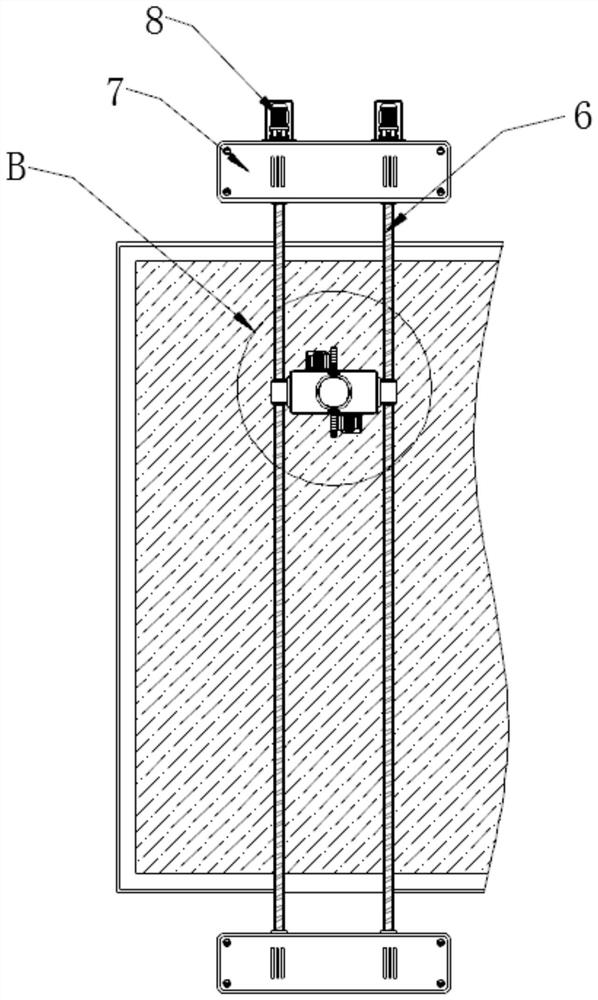

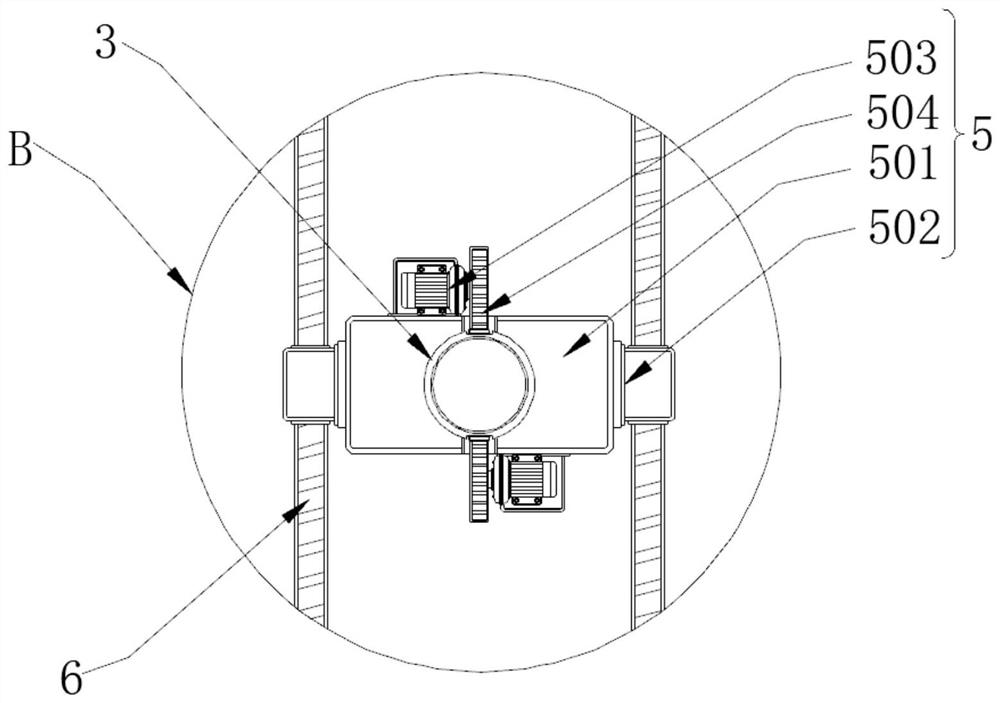

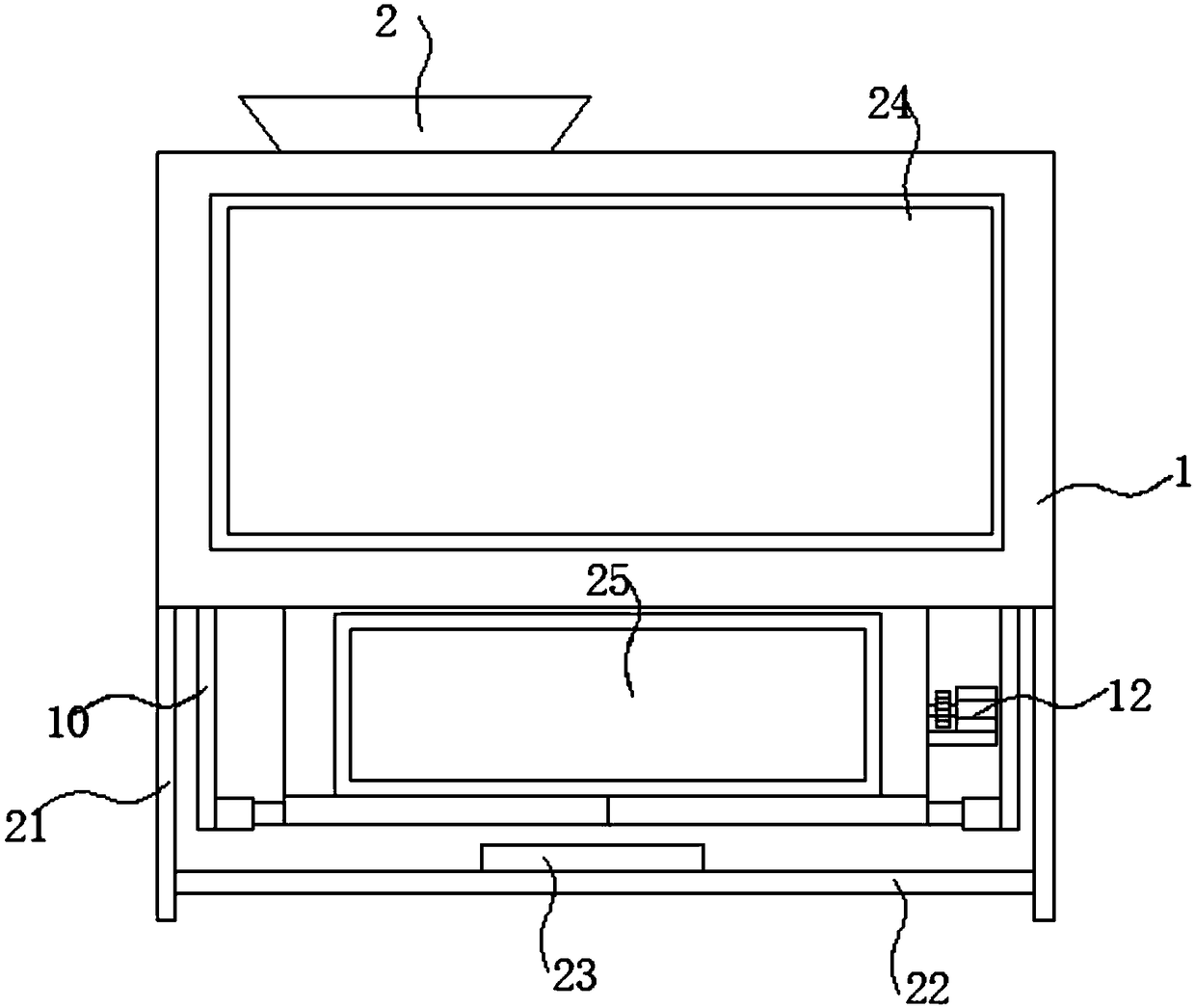

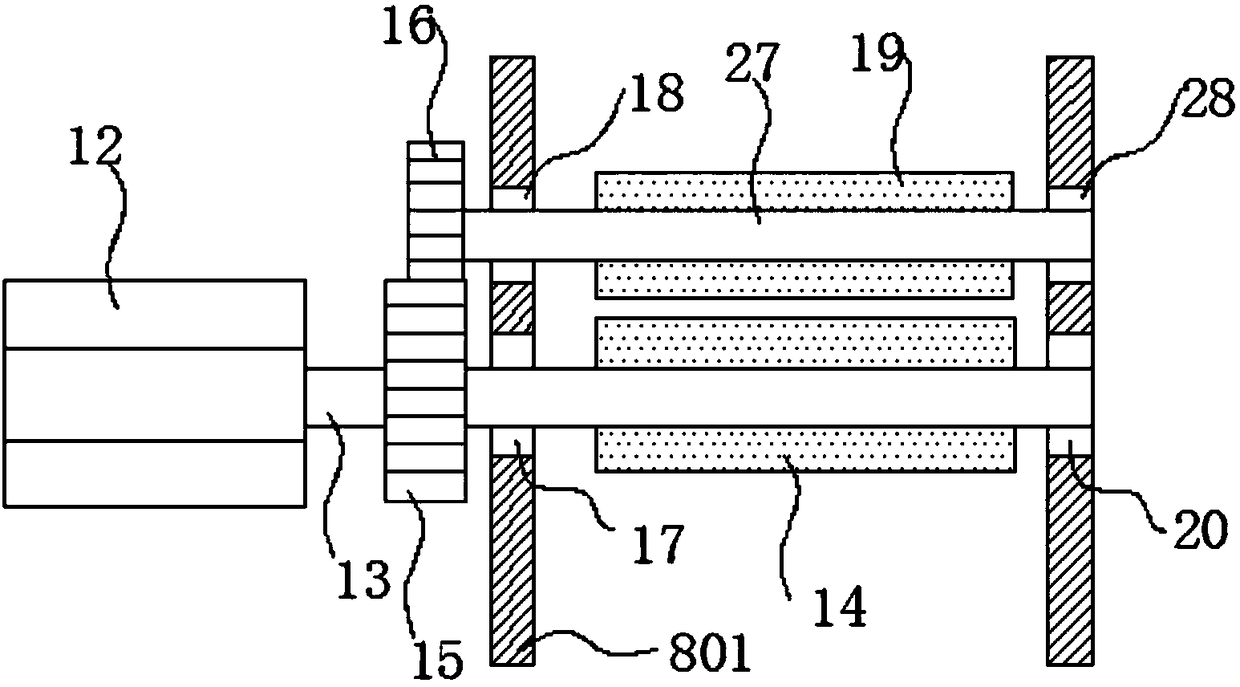

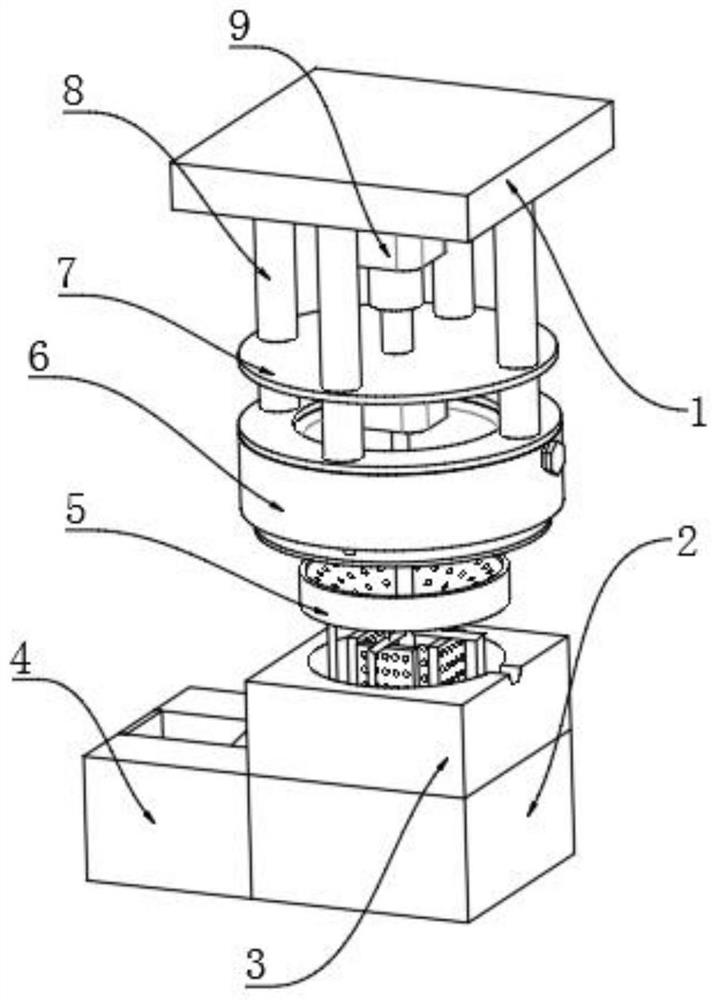

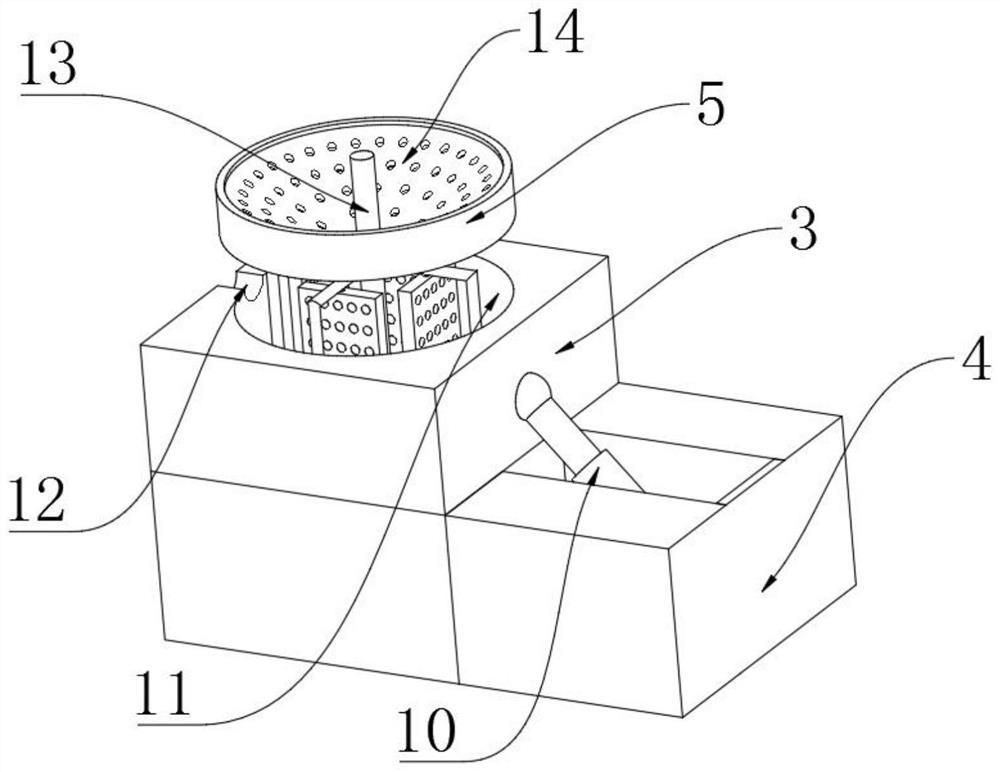

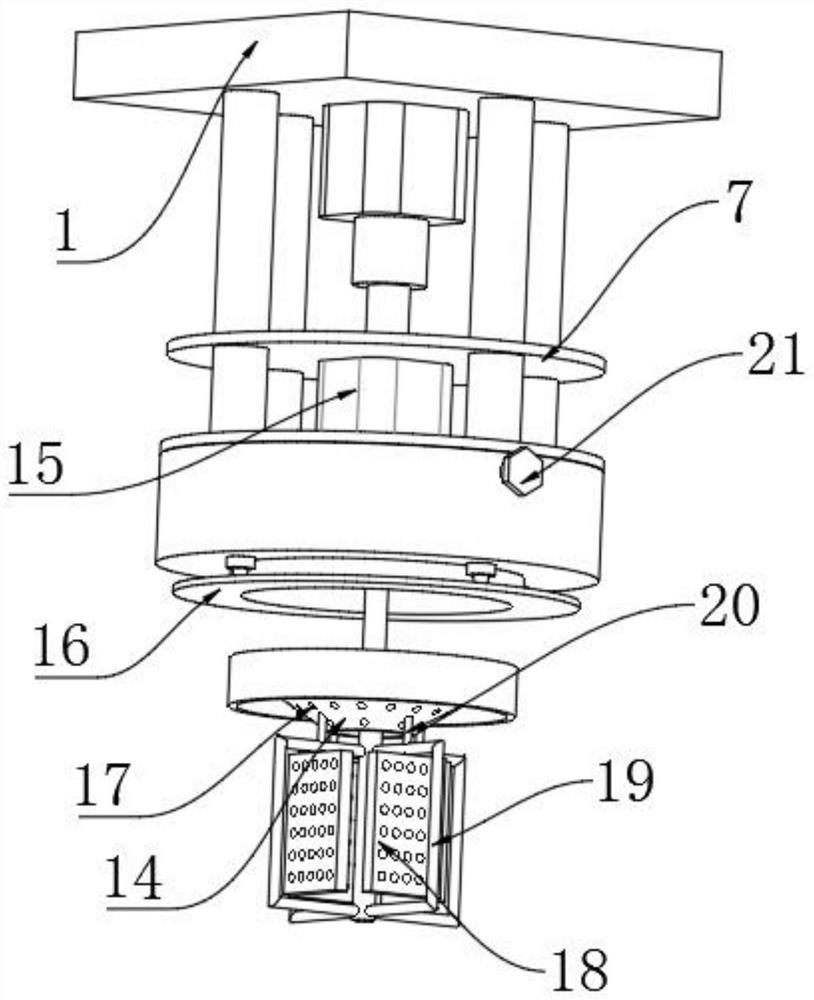

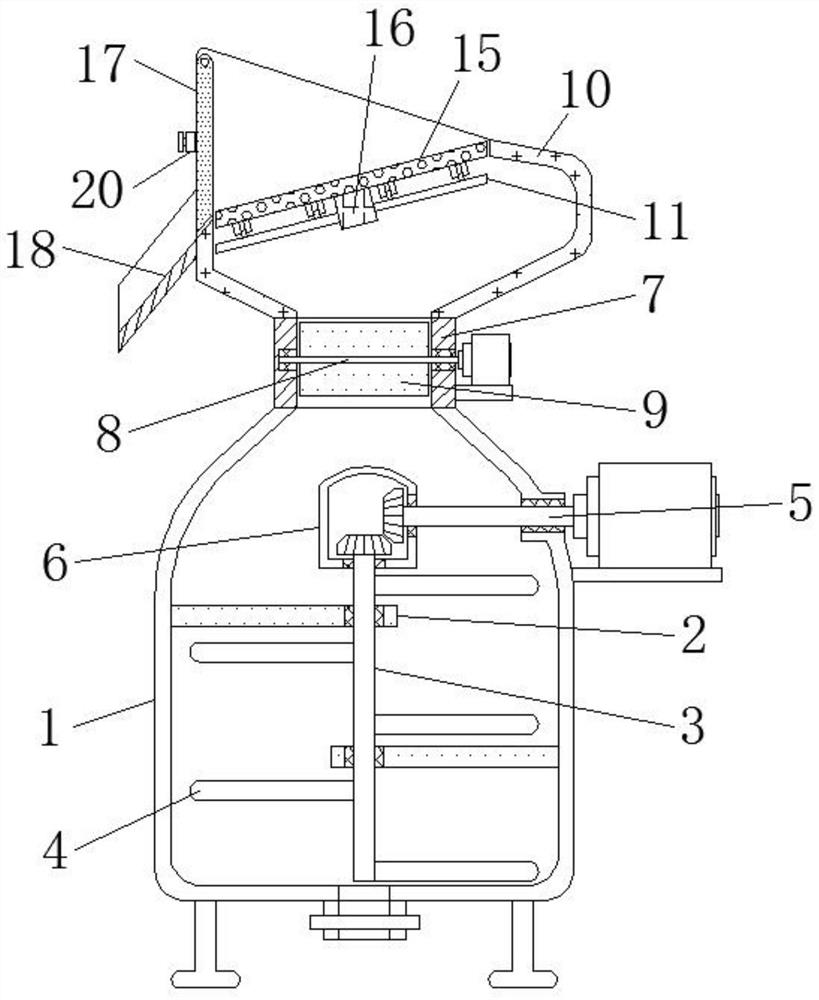

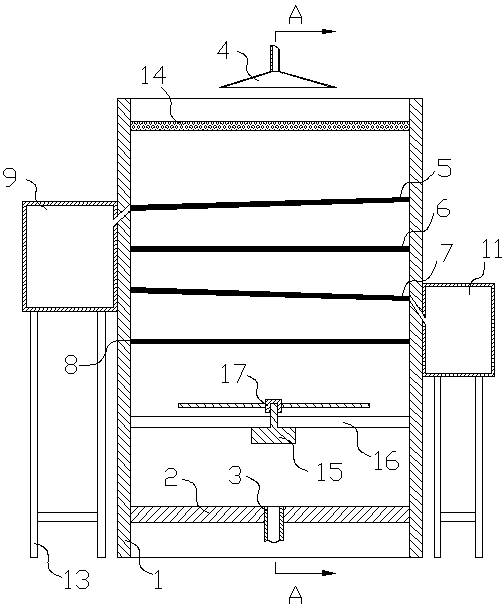

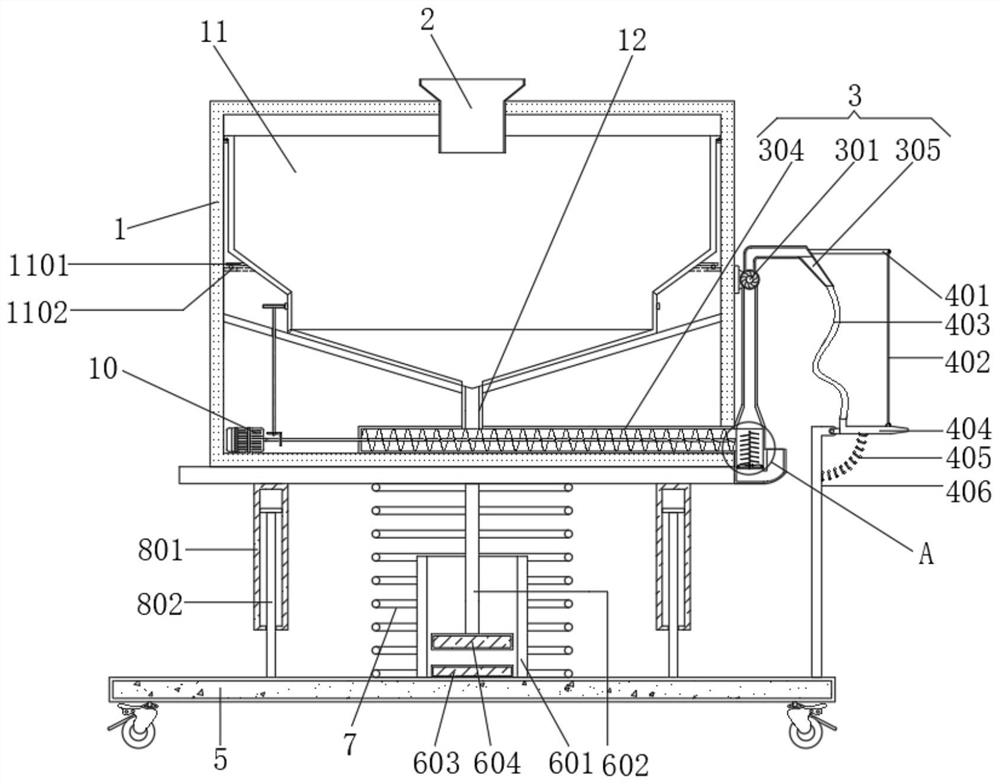

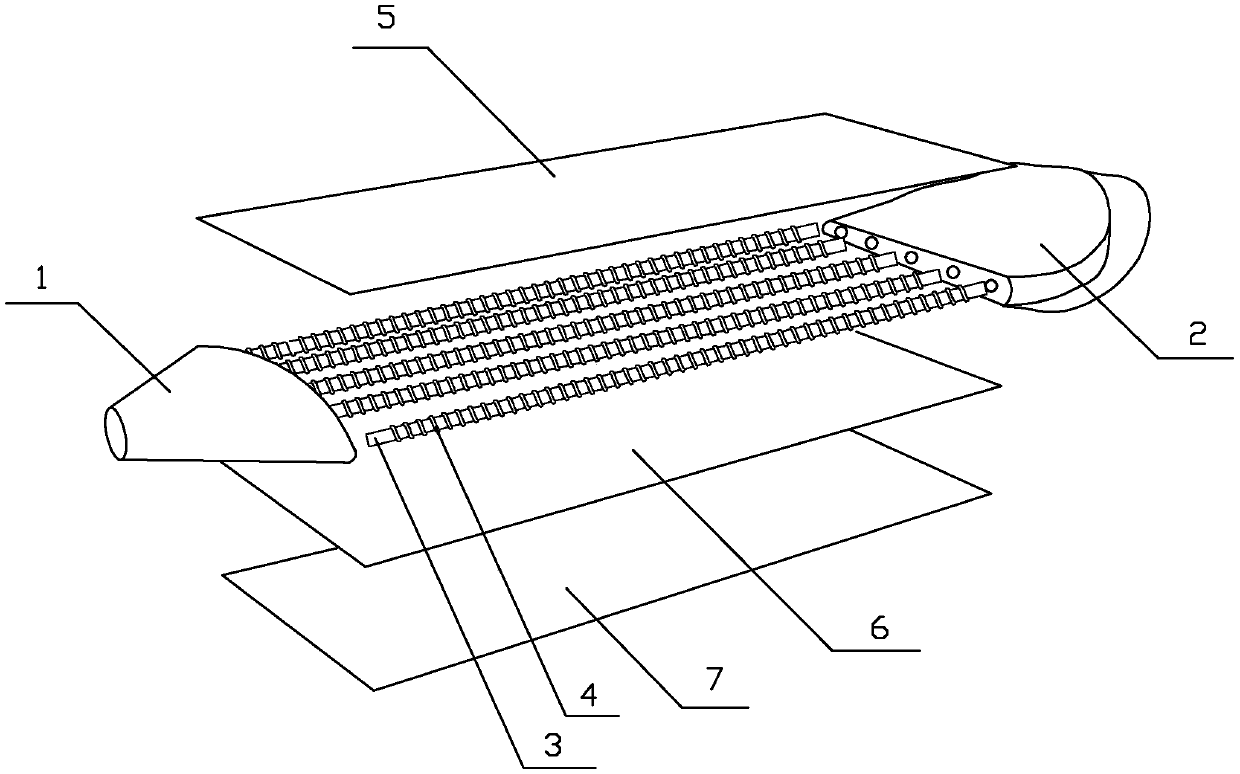

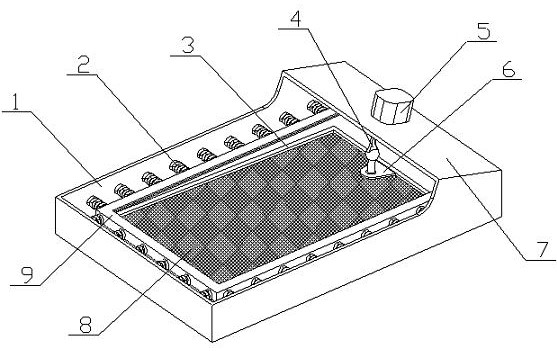

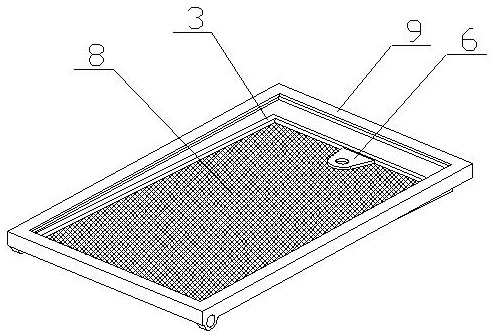

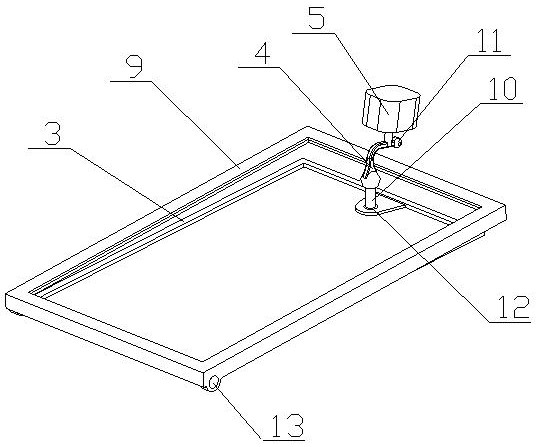

Automatic feeding device for breeding in animal husbandry, and method thereof

InactiveCN111466303AInvest evenlyReduce labor intensityAnimal feeding devicesAvicultureAnimal scienceZoology

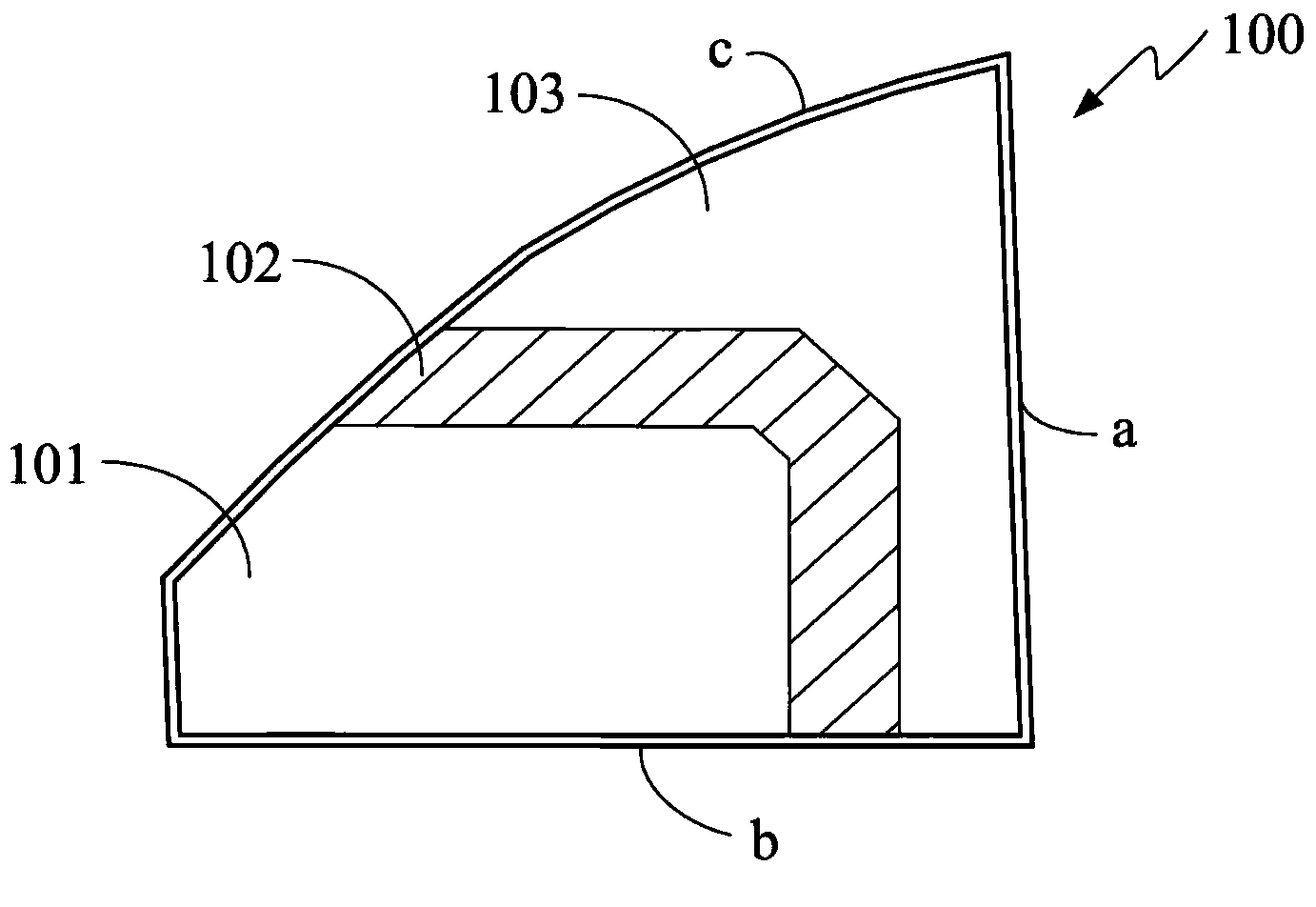

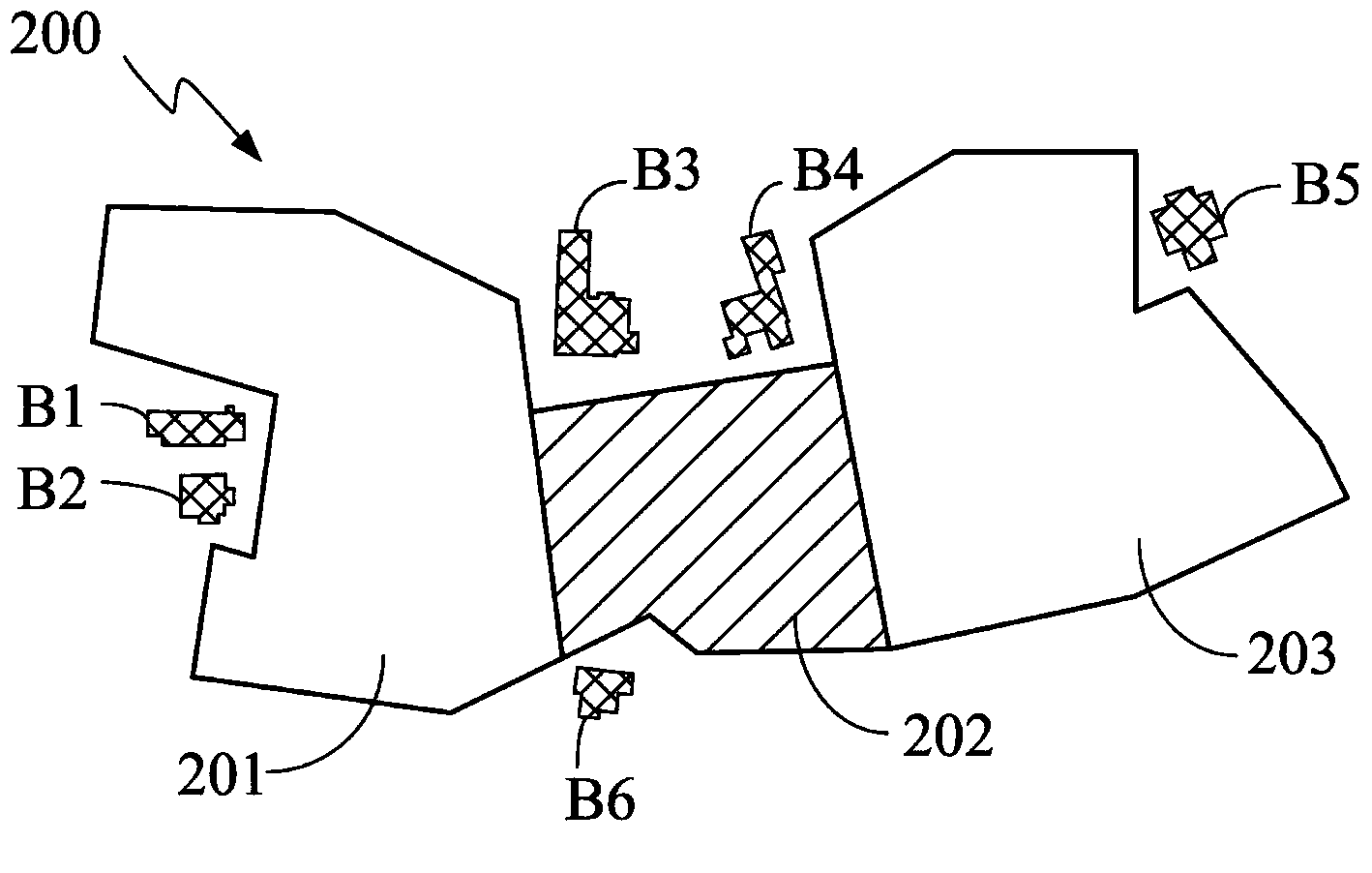

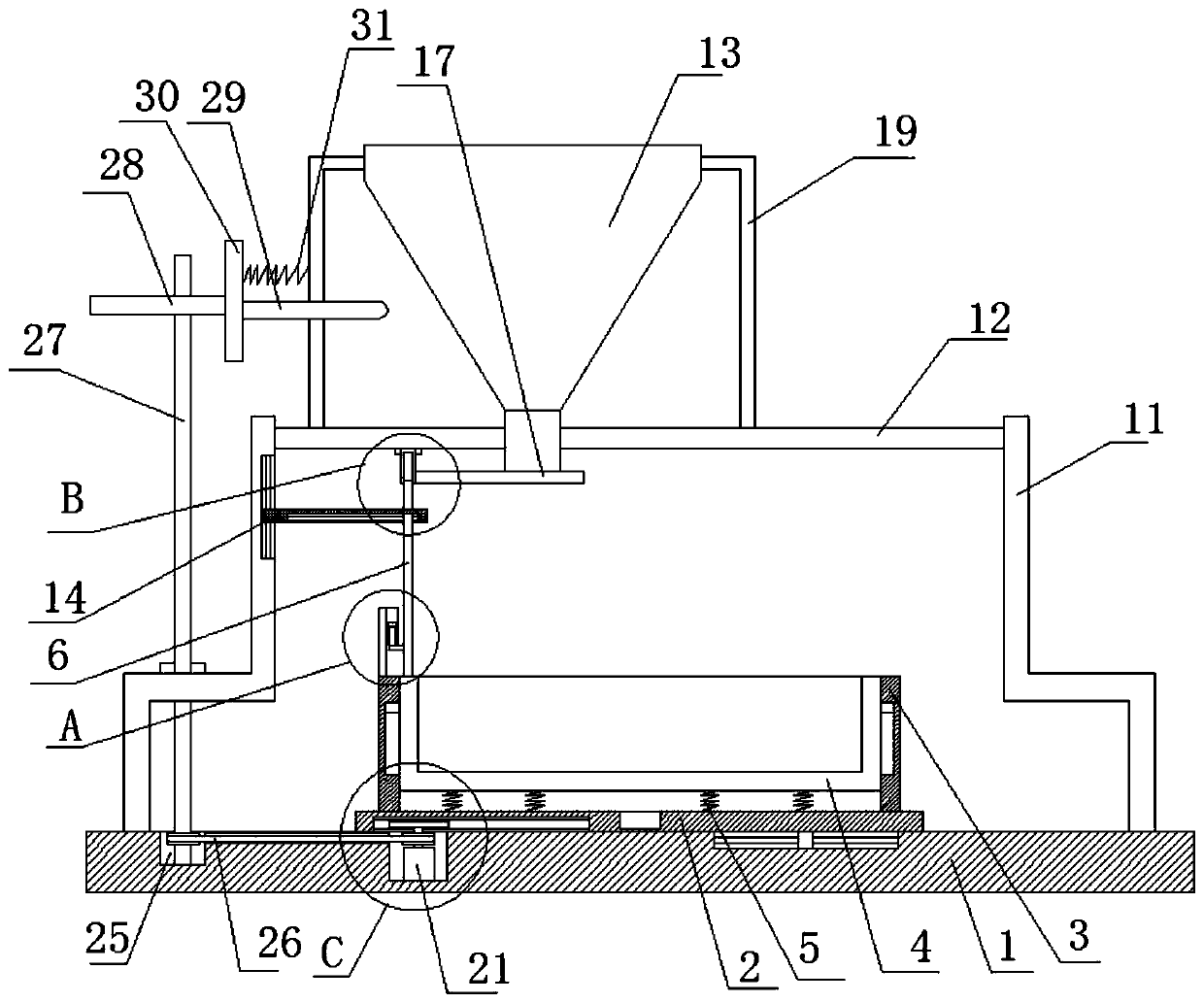

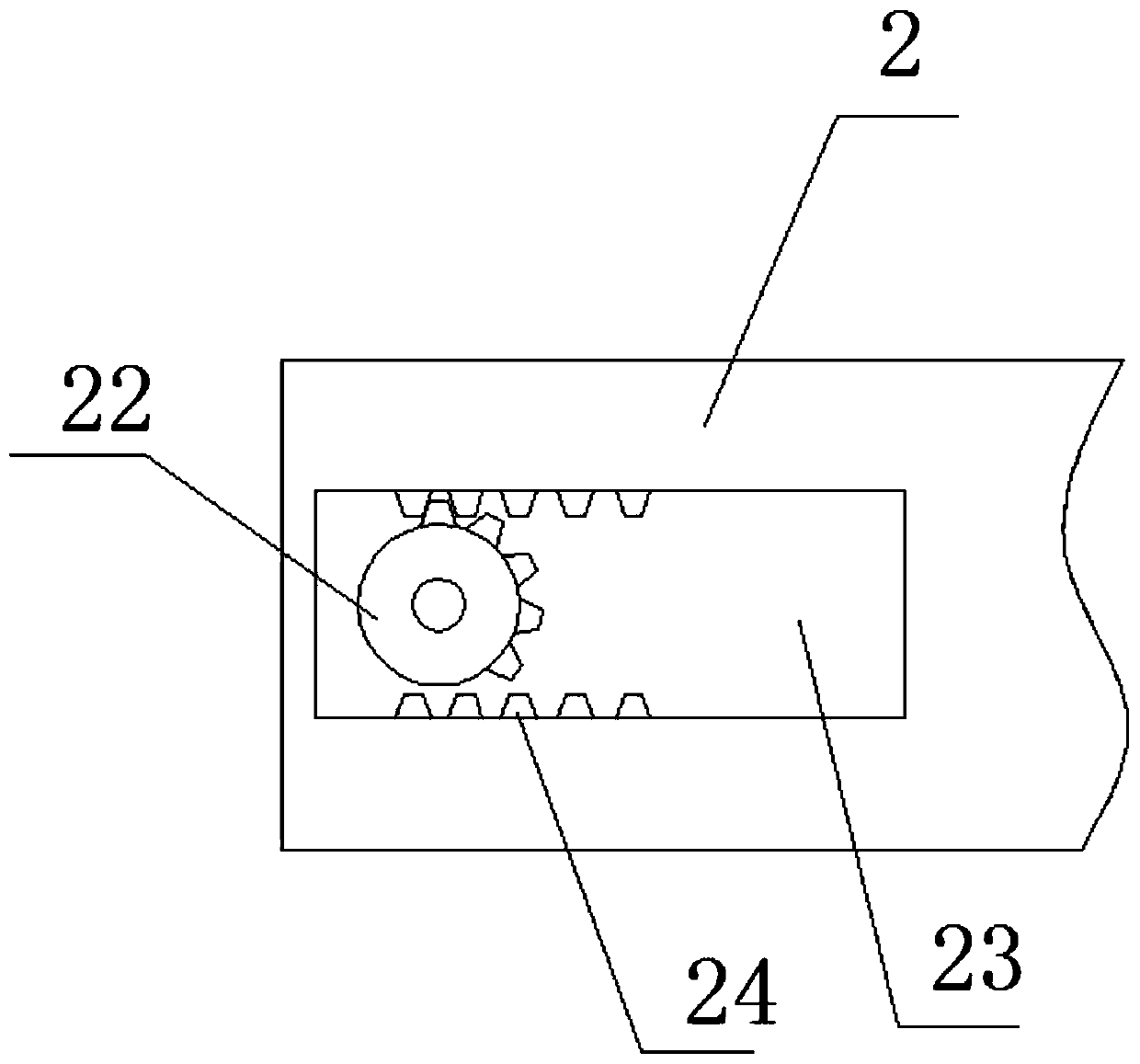

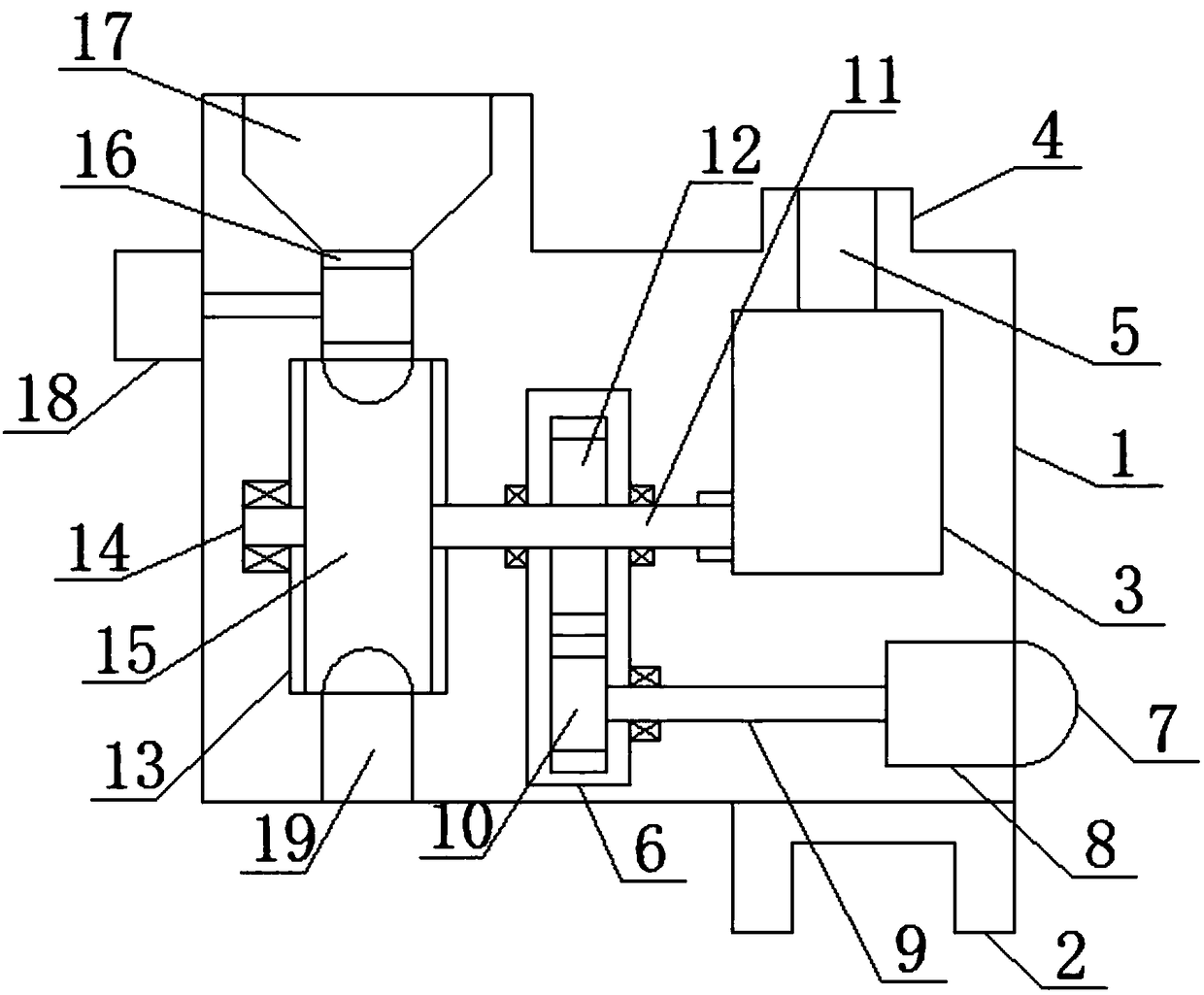

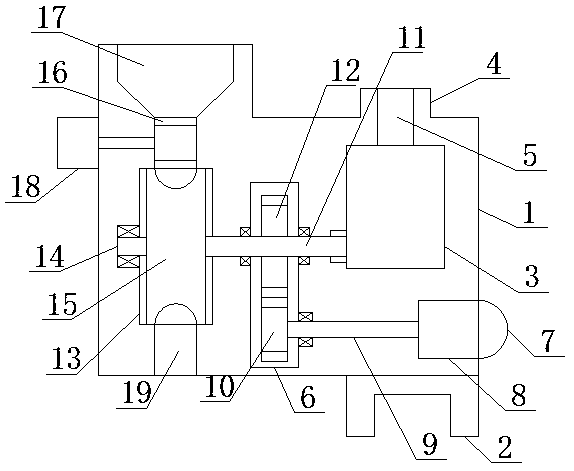

The invention belongs to the technical field of automatic feeding devices, and in particular relates to an automatic feeding device for breeding in the animal husbandry, and a method thereof. For thetime-wasting and labour-wasting problem that feeds mostly need to be artificially delivered into feeding grooves currently, the following scheme is provided: the automatic feeding device comprises a base; a sliding base is glidingly installed on the top of the base; two fixed plates are fixedly installed on the top of the sliding base; the same feeding groove is glidingly installed at the mutuallyclose sides of the two fixed plates; one ends of multiple springs are fixedly installed at the bottom of the feeding groove; the other ends of the multiple springs are fixedly connected with the topof the sliding base; two brackets are fixedly installed on the top of the base; the same installation plate is fixedly installed on the two brackets; two support plates are fixedly installed on the top of the installation plate; and the same hopper is fixedly installed on the two support plates. According to the automatic feeding device for breeding in the animal husbandry, and the method thereofin the invention, automatic feeding can be carried out; furthermore, feeding is uniform; the time and the labour are saved; and thus, the labour intensity of workers is reduced.

Owner:TANGSHAN HARBIN SHIP TECH CO LTD +1

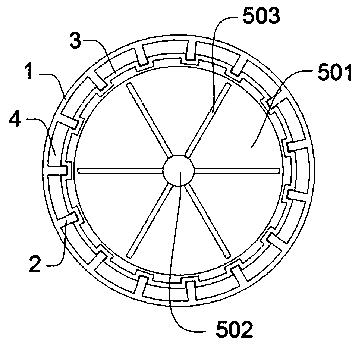

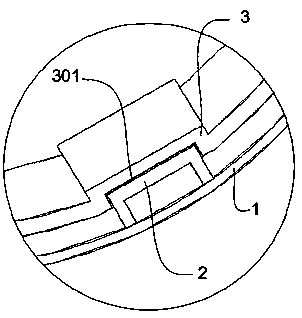

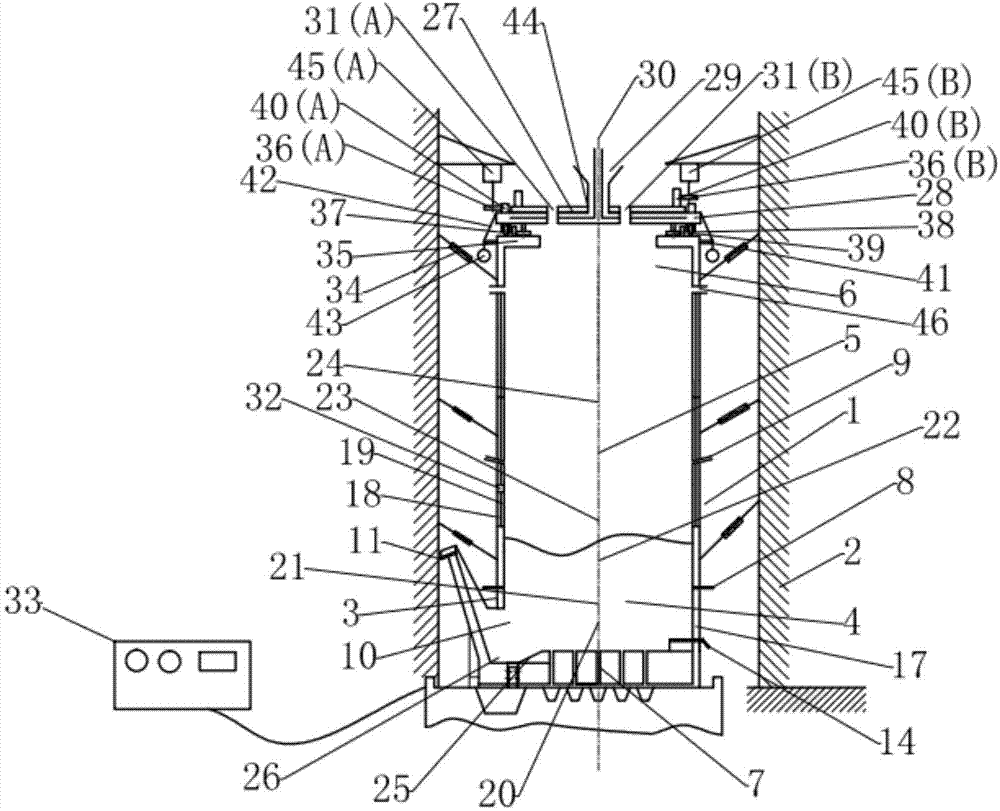

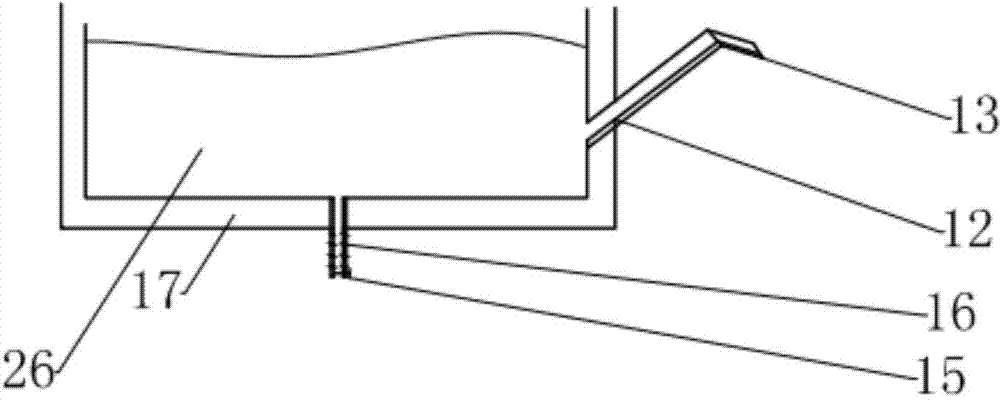

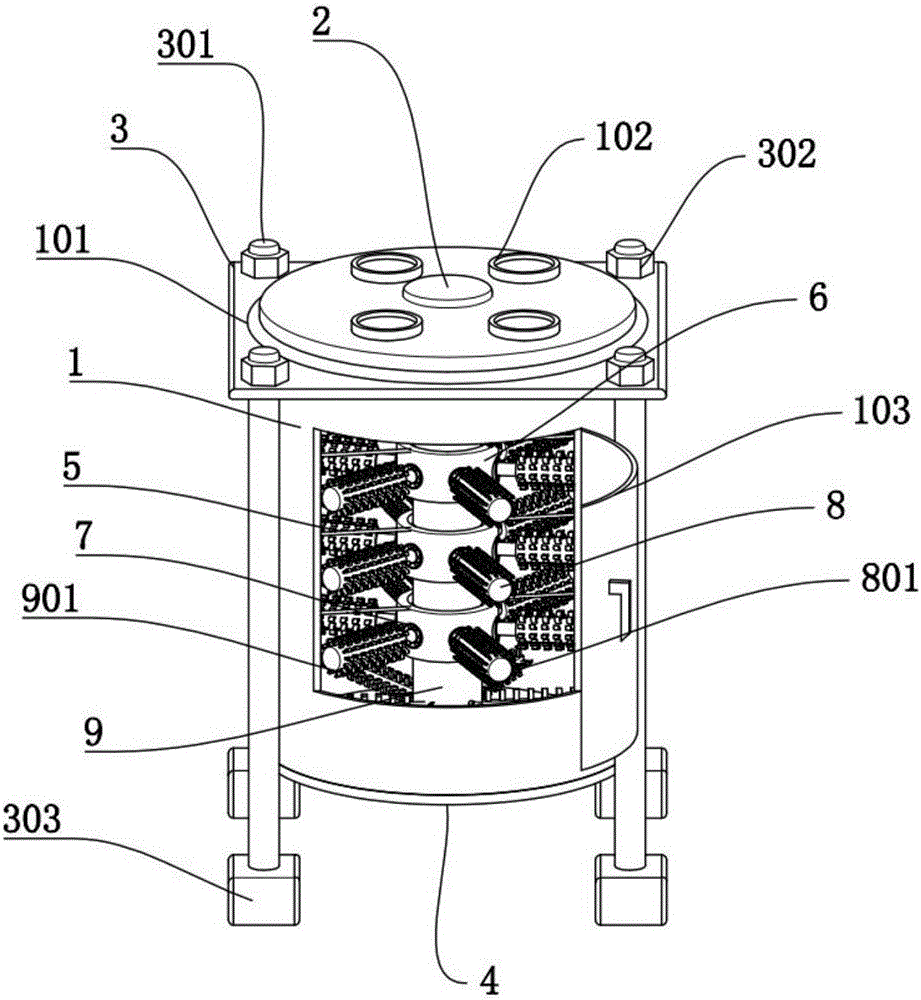

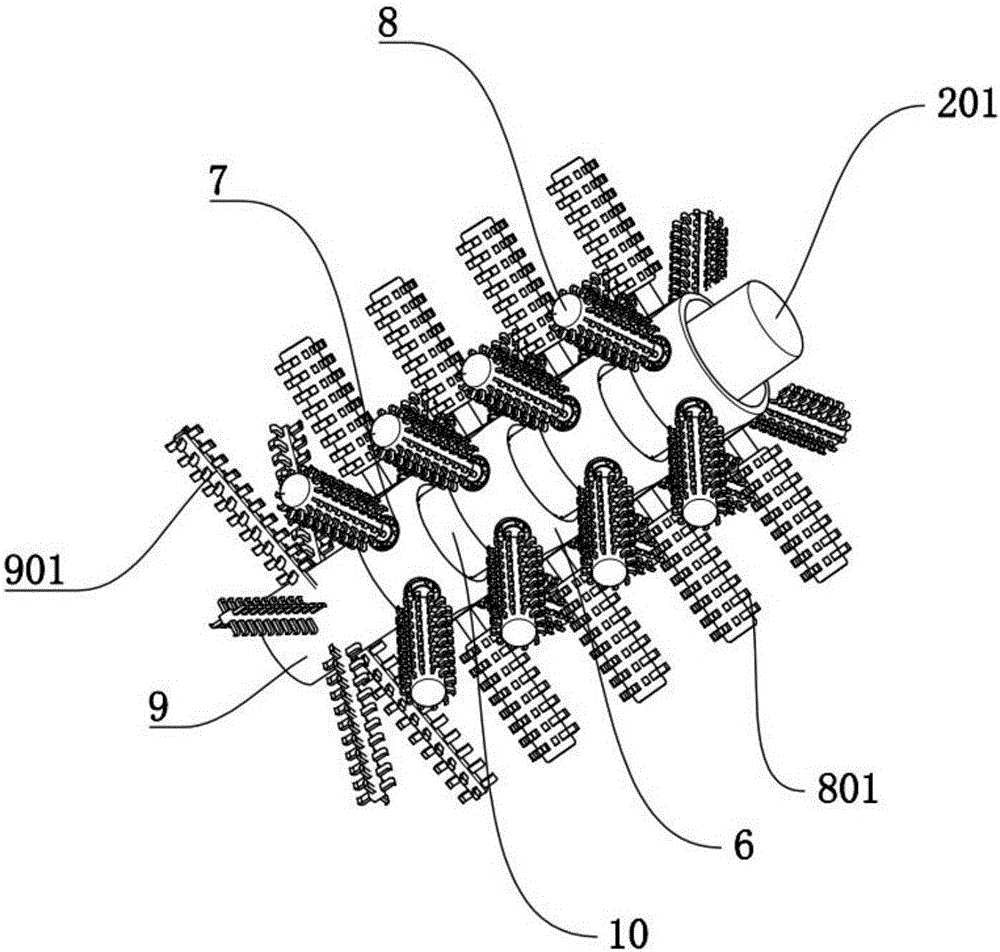

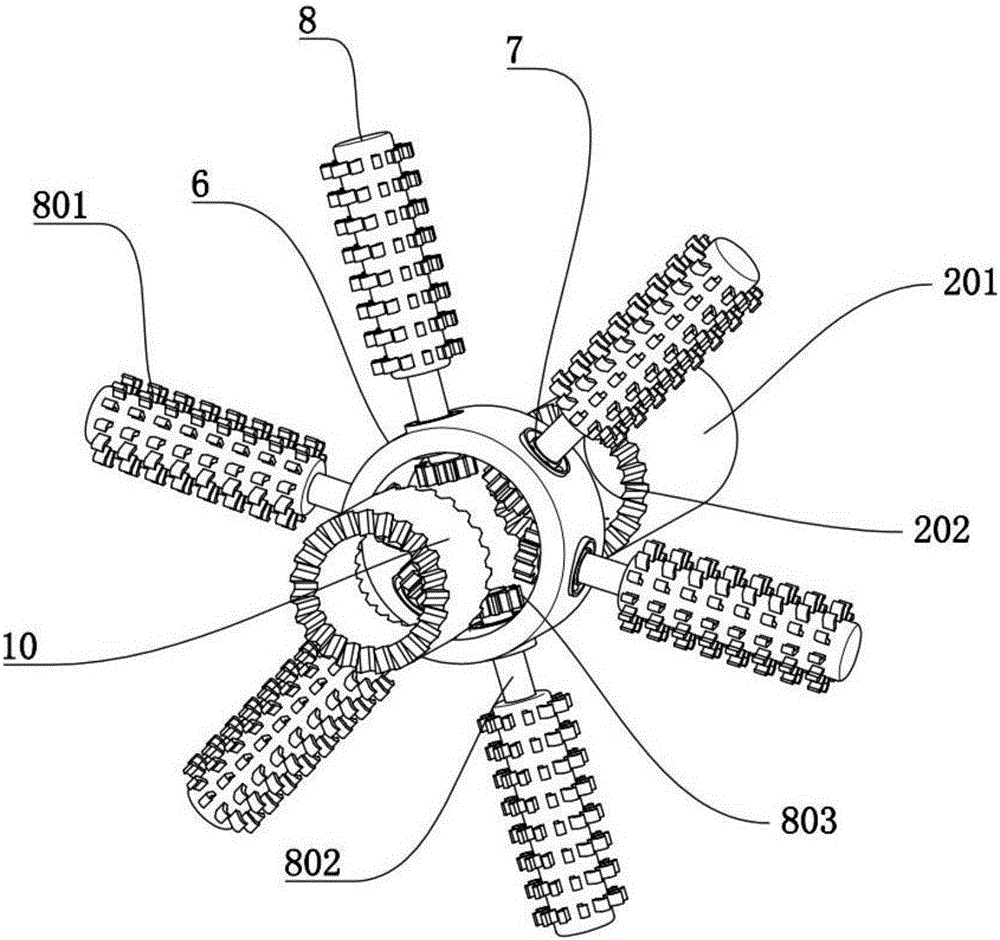

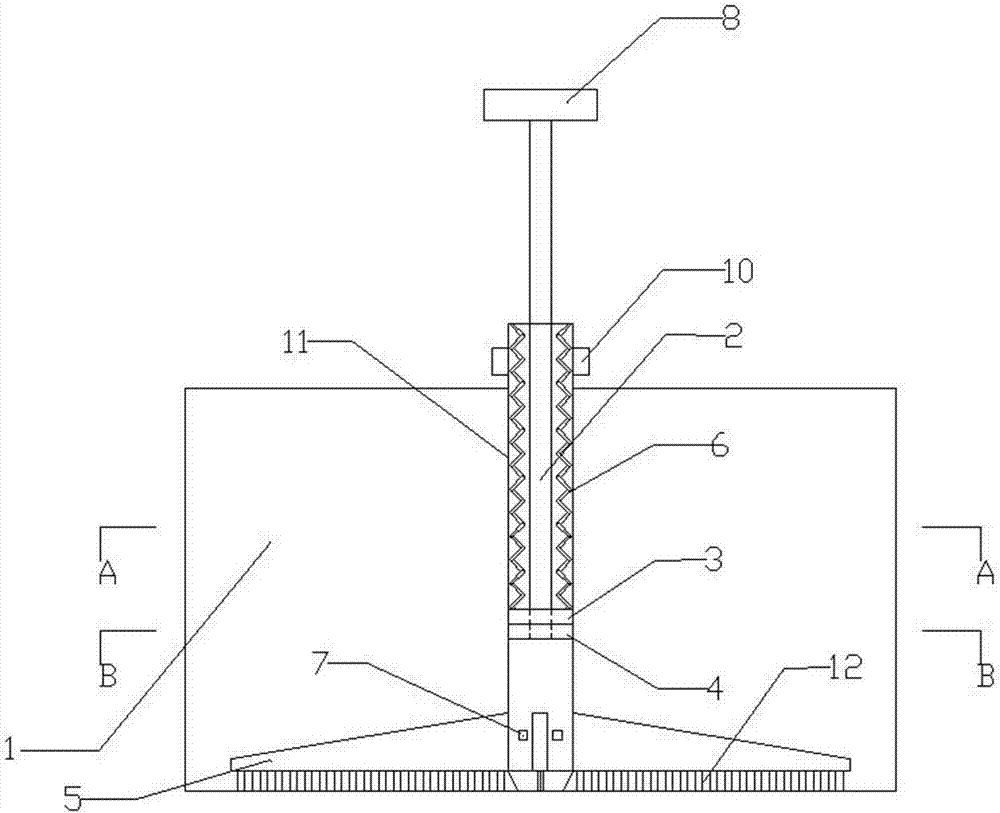

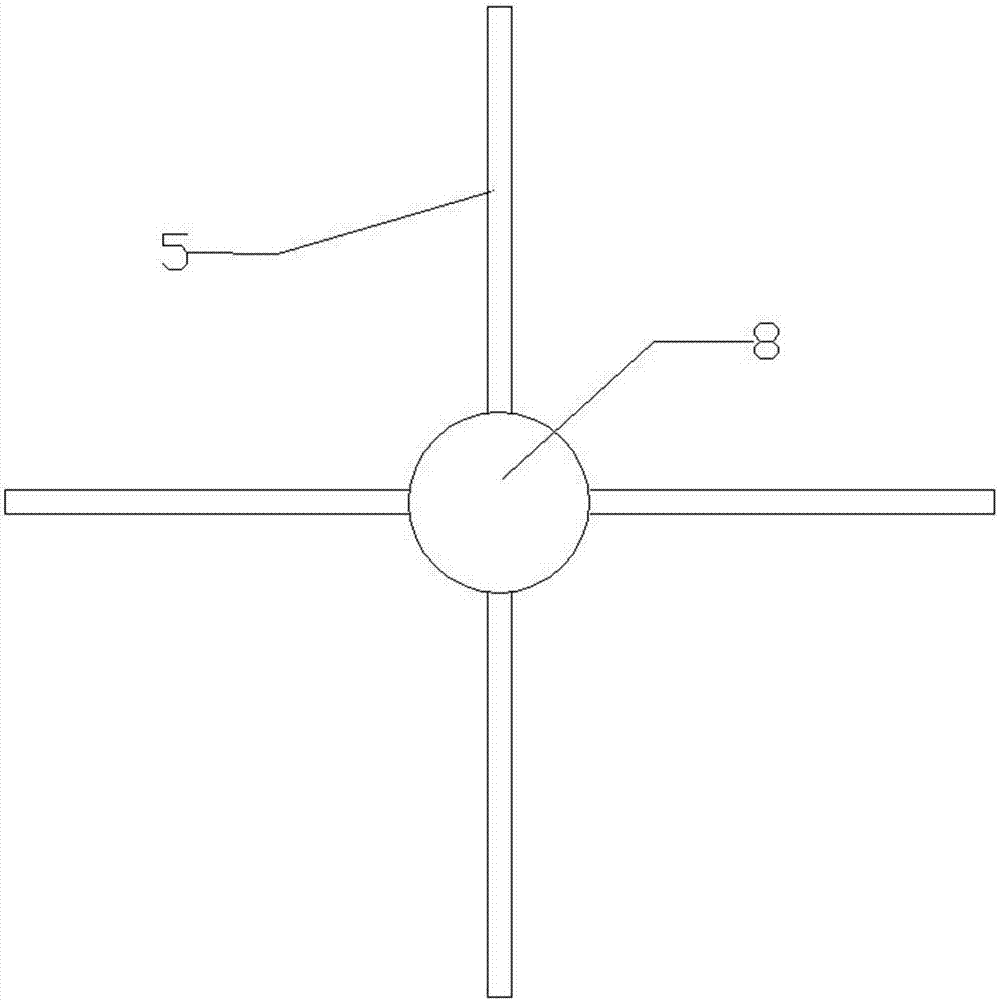

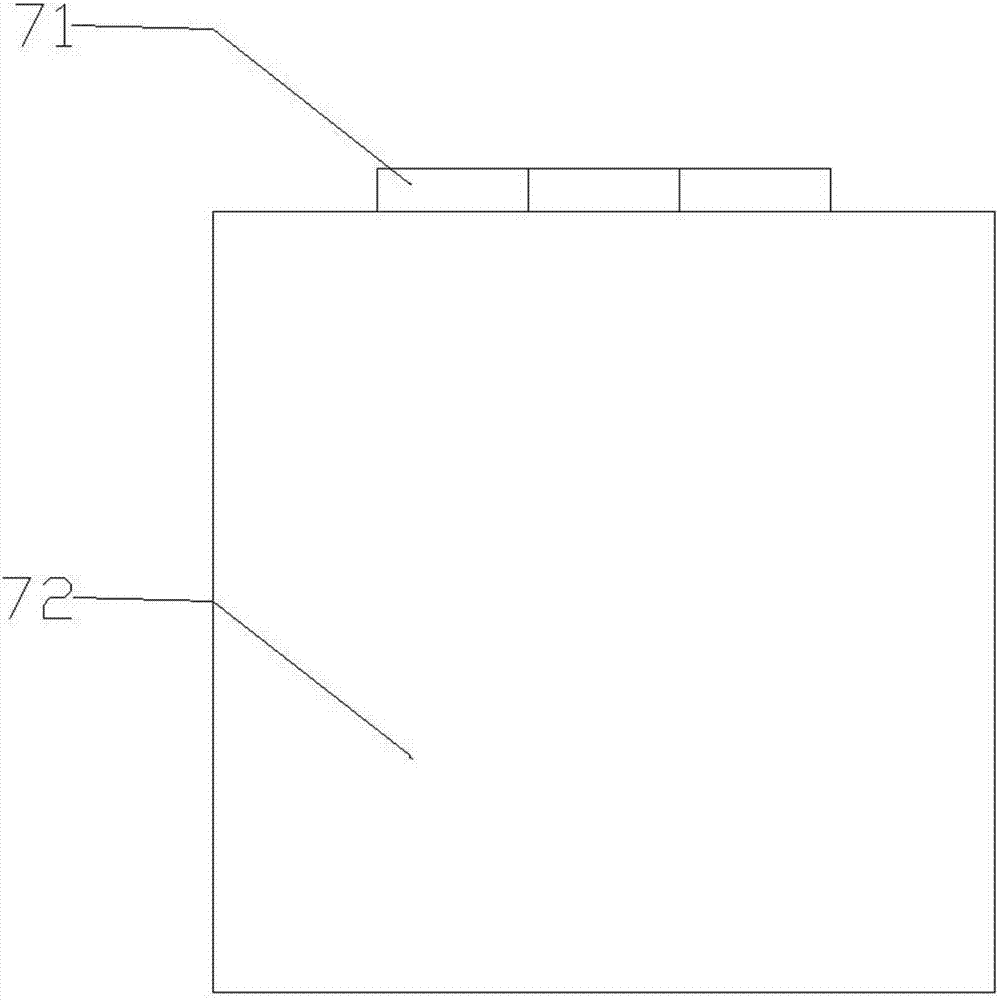

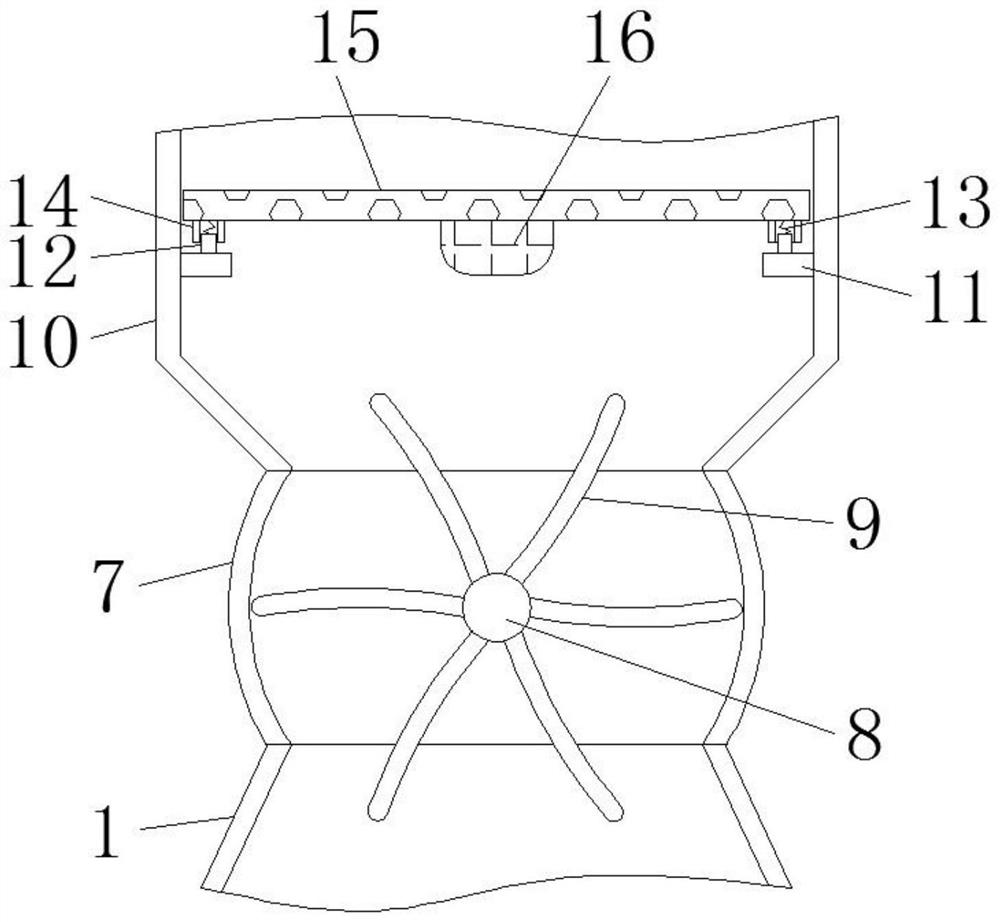

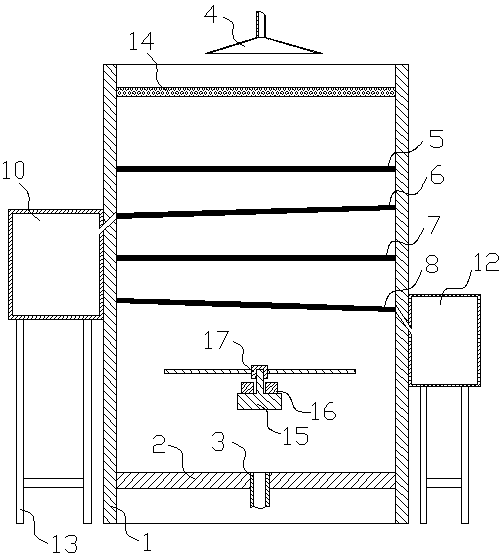

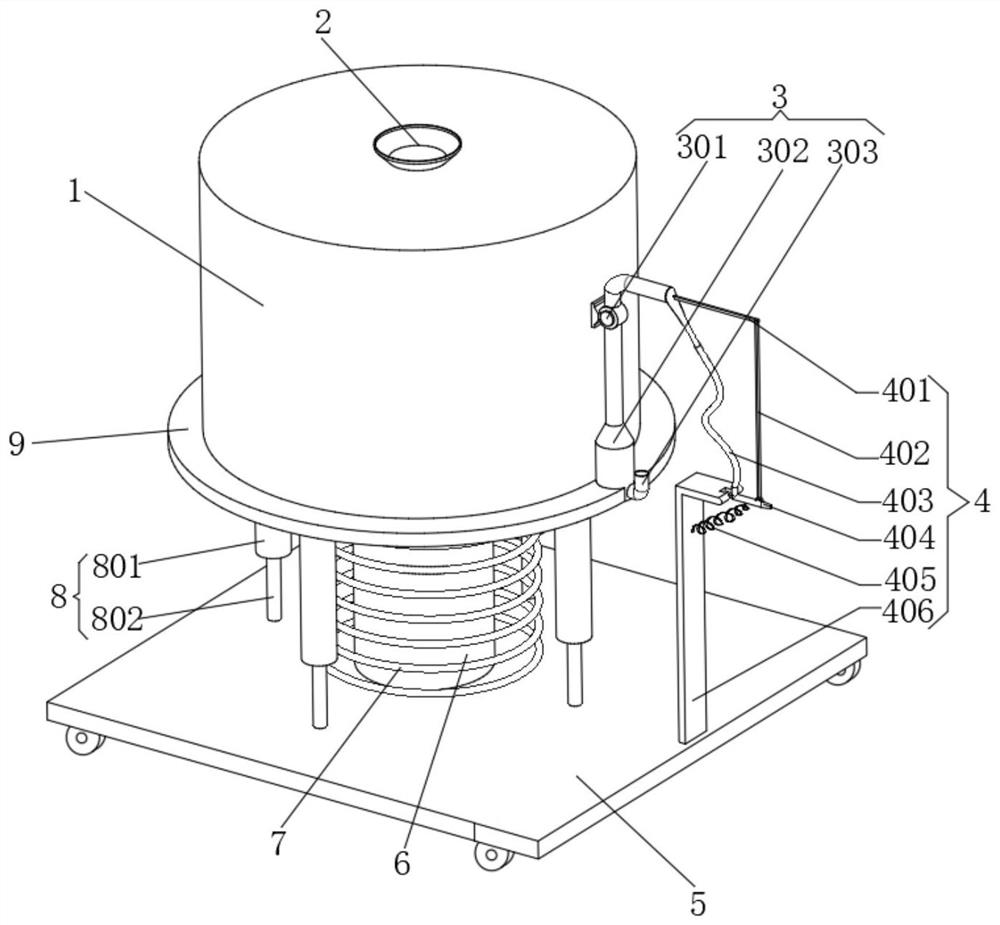

Smelting furnace for uniform full feeding

ActiveCN106766885AAvoid accumulationInvest evenlyFurnace componentsCrucible furnacesEngineeringIngot

The invention discloses a smelting furnace for uniform full feeding. A slide rail for passing through the center of a furnace cover is arranged on the inner surface of the furnace cover; a stirring paddle includes a hydraulic rod and a blade connected to one end of the hydraulic rod; a pulley is mounted at the other end of the hydraulic rod, and is slidingly matched with the slide rail; the pulley is connected with a slide motor; the hydraulic rod is an extension rod, and is connected with an extension motor; the inner wall of a furnace body is connected with a cache frame through a spring; the cache frame includes a leakage ring, and a cross bar connected with the inner wall of the leakage ring; and a discharge port of a material channel is positioned above the intersection of the cross bar. The extension motor shortens the stirring paddle, and slides the stirring paddle to one side, so that an aluminum ingot is fully fed in the smelting furnace; the inner wall of the furnace body is connected with the cache frame through the spring; the cache frame includes the leakage ring and the cross bar; and the discharge port of the material channel is positioned above the intersection of the cross bar, so that the fed aluminum ingot is stopped in the intersection of the cross bar, and is rebounded to fall in the smelting furnace by a hole formed by the cross bar so as to prevent nonuniform smelting.

Owner:湖南振升恒佳新材料科技有限公司

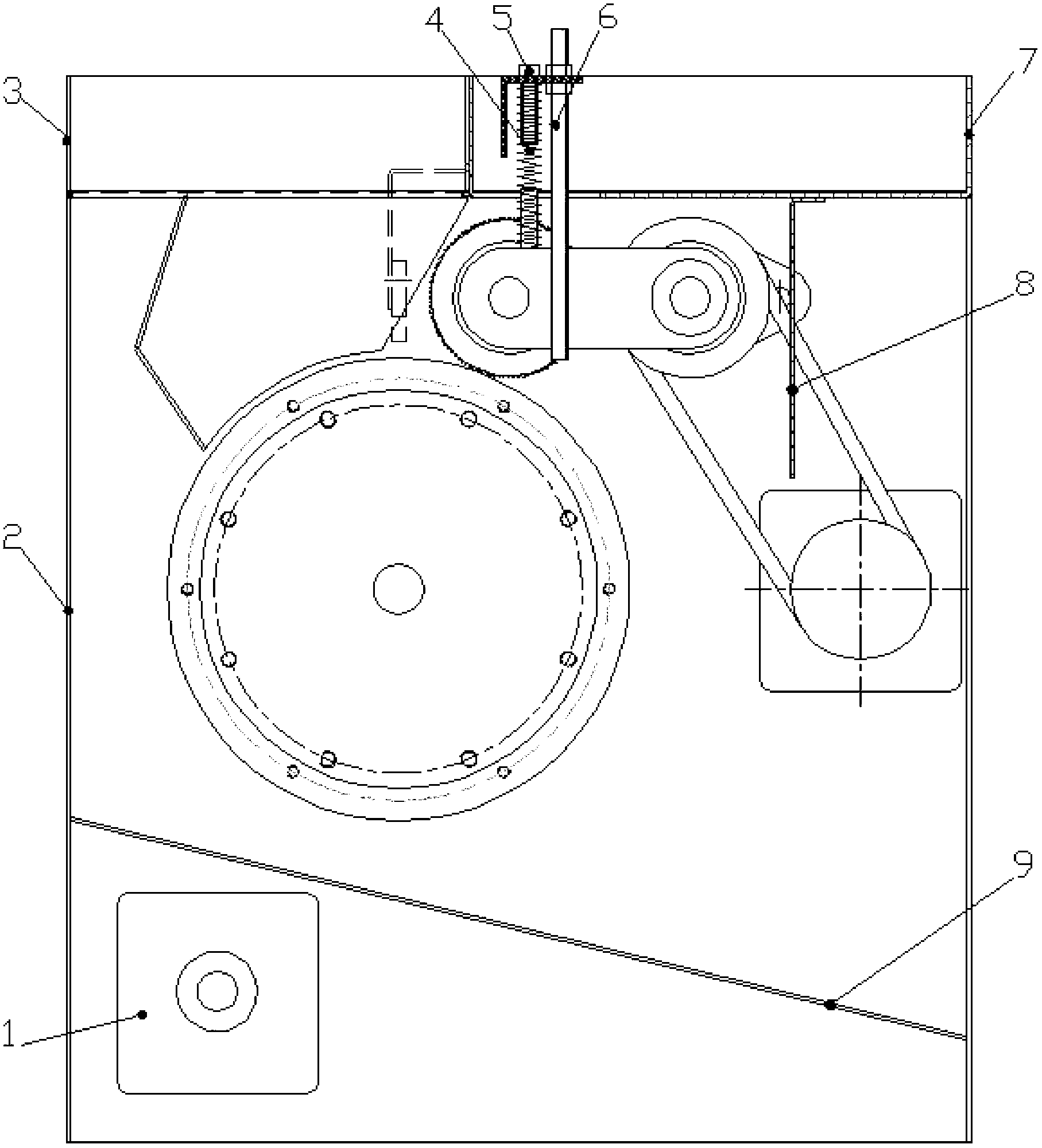

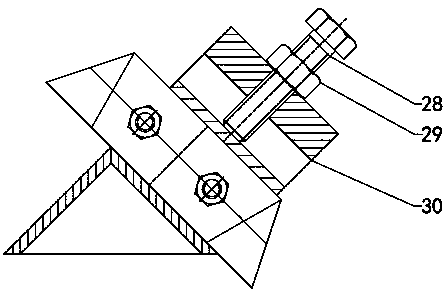

Rolling tube type Chinese chestnut opening machine

The invention discloses a rolling tube type Chinese chestnut opening machine, which belongs to the technical field of a Chinese chestnut opening machine and comprises a casing, a rolling tube, a cutter blade, a first motor, a second motor, a belt wheel A, a belt wheel B, a first belt wheel, a second belt wheel, a third belt wheel and a fourth belt wheel, wherein a hole is formed in a position on the casing corresponding to the rolling tube, the rolling tube is fixedly arranged in the casing through a rolling tube flange, a rolling tube shaft and a bearing seat, one end of the rolling tube shaft extends out of the casing, in addition, the belt wheel B is arranged on the end part and is connected with the belt wheel A arranged on the second motor through a belt, the cutter blade is fixedly connected with the fourth belt wheel through a cutter blade press plate and is fixedly arranged in the casing through a connecting plate, the third belt wheel, a baffle sleeve, a connecting plate shaft and a bearing seat, in addition, a cutter nose is right aligned with the center position of a rolling tube groove, the second belt wheel and the third belt wheel are arranged on the connecting plate shaft, and the second belt wheel is connected with the first belt wheel arranged on the first motor through a belt. The rolling tube type Chinese chestnut opening machine has the beneficial effects that the Chinese chestnut opening speed can be accelerated, the Chinese chestnut opening efficiency can be improved, and the work intensity can be reduced.

Owner:铜山县恒佳机械制造厂

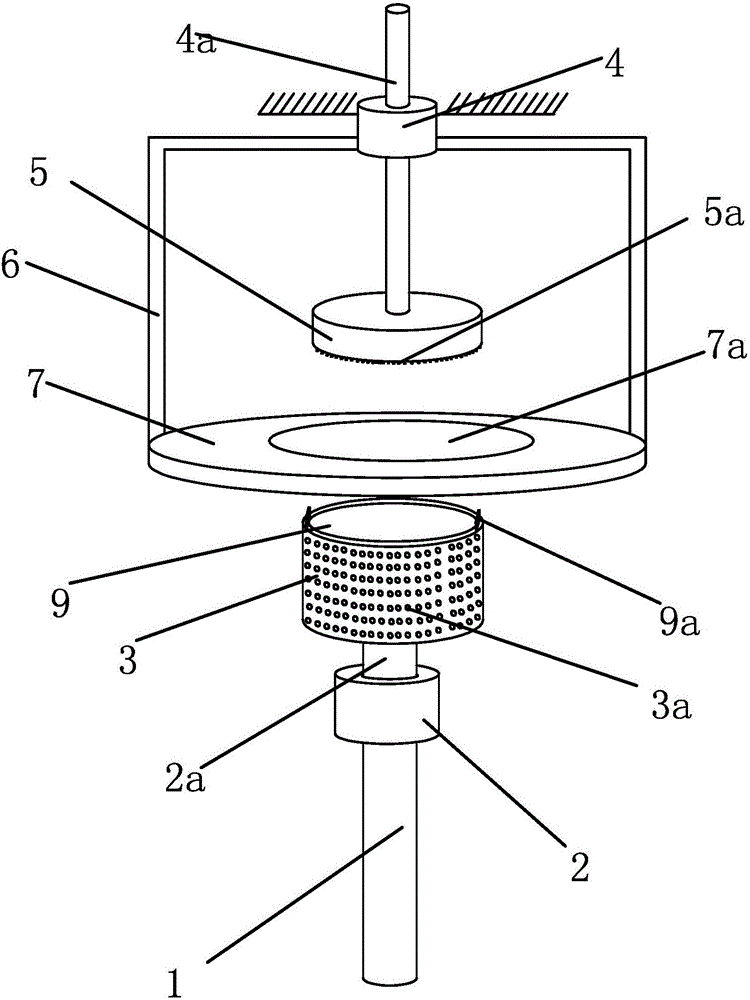

Fish domestication device

InactiveCN106719228AIngenious structural designImprove domestication effectClimate change adaptationPisciculture and aquariaFixed frameEngineering

The invention provides a fish domestication device, and belongs to the field of cultivation. The fish domestication device comprises an installing rod, wherein the lower end of the installing rod is fixedly connected with the bottom of a pond; the upper end of the installing rod is fixedly connected with a rotating motor; a cylindrical processing tube is fixedly connected onto a motor rotating shaft of the rotating motor; a plurality of material throwing holes are formed in the outer wall of the processing tube; the domestication device also comprises a linear motor arranged above the pond; a motor shaft of the linear motor is in vertical arrangement; the end part of the lower end of the linear motor is fixedly connected with a grinding block; the grinding block can enter the processing tube; a material blocking device is fixedly connected onto the linear motor; the material blocking device comprises fixing frames which are in a 7 shape and are respectively fixed at two sides of the linear motor; one end of each fixing frame is fixedly connected onto the linear motor; the other ends of the two fixing frames are in downward arrangement; a blocking block is fixedly connected between the end parts of the other ends of the two fixing frames; the middle part of the blocking block is provided with an extending-in hole; a flaring-shaped blocking plate is fixedly connected onto the outer wall of the blocking block, and covers the processing tube. The fish domestication device has the advantages that the structure design is ingenious; the material spreading is uniform; the domestication effect is good.

Owner:吴永凤

Integrated adhering device and method for broken sheets

ActiveCN110068254AEasy to arrange directlyImprove bonding efficiencyAmmunition projectilesProjectilesArchitectural engineering

Owner:SICHUAN UNIV

Mixing station host system, mixing station comprising host system, and mixing equipment comprising host system

The invention provides a mixing station host system, a mixing station comprising the host system, and mixing equipment comprising the host system. The mixing station host system comprises a mixing host, an intermediate aggregate cabin, a powder scale, and a transition hopper, wherein the intermediate aggregate cabin comprises a cabin body dust removal port and a cabin body discharging port which is connected to the mixing host; the powder scale comprises a powder scale dust removal port and a powder scale discharging port which is connected to the mixing host; the transition hopper comprises a first dust removal communication port, a transition charging port and a transition discharging port, wherein the transition discharging port is communicated to the mixing host; the powder scale dust removal port of the powder scale is communicated to the first dust removal communication port of the transition hopper through a powder scale airway; the powder scale discharging port of the powder scale is communicated to the transition charging port of the transition hopper; a first switching valve is arranged on a channel between the powder scale discharging port and the transition hopper. According to the mixing station host system disclosed by the invention, the problem that the air pressure in the mixing station host system and the air pressure in the powder scale are unbalanced can be prevented effectively, and the phenomena of scale dragging and scale pulling are avoided.

Owner:ZOOMLION HEAVY IND CO LTD

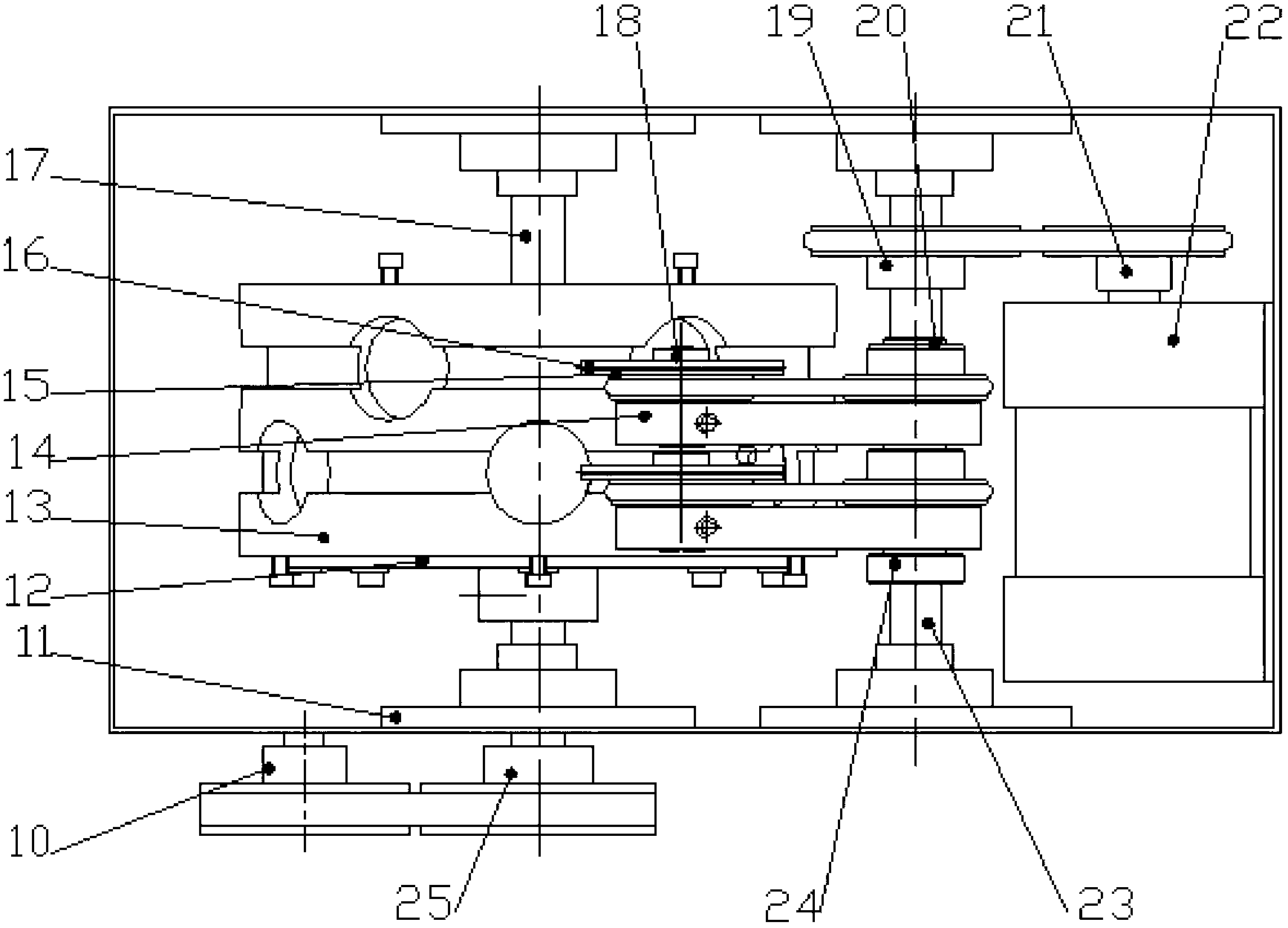

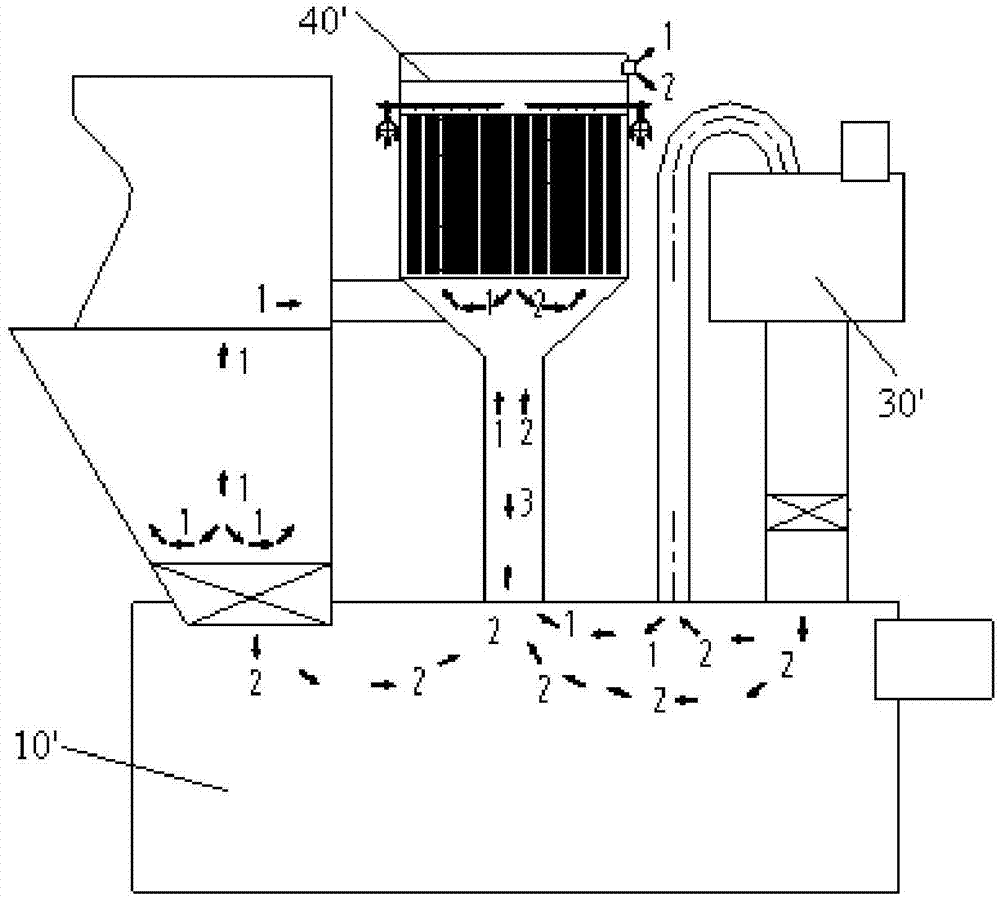

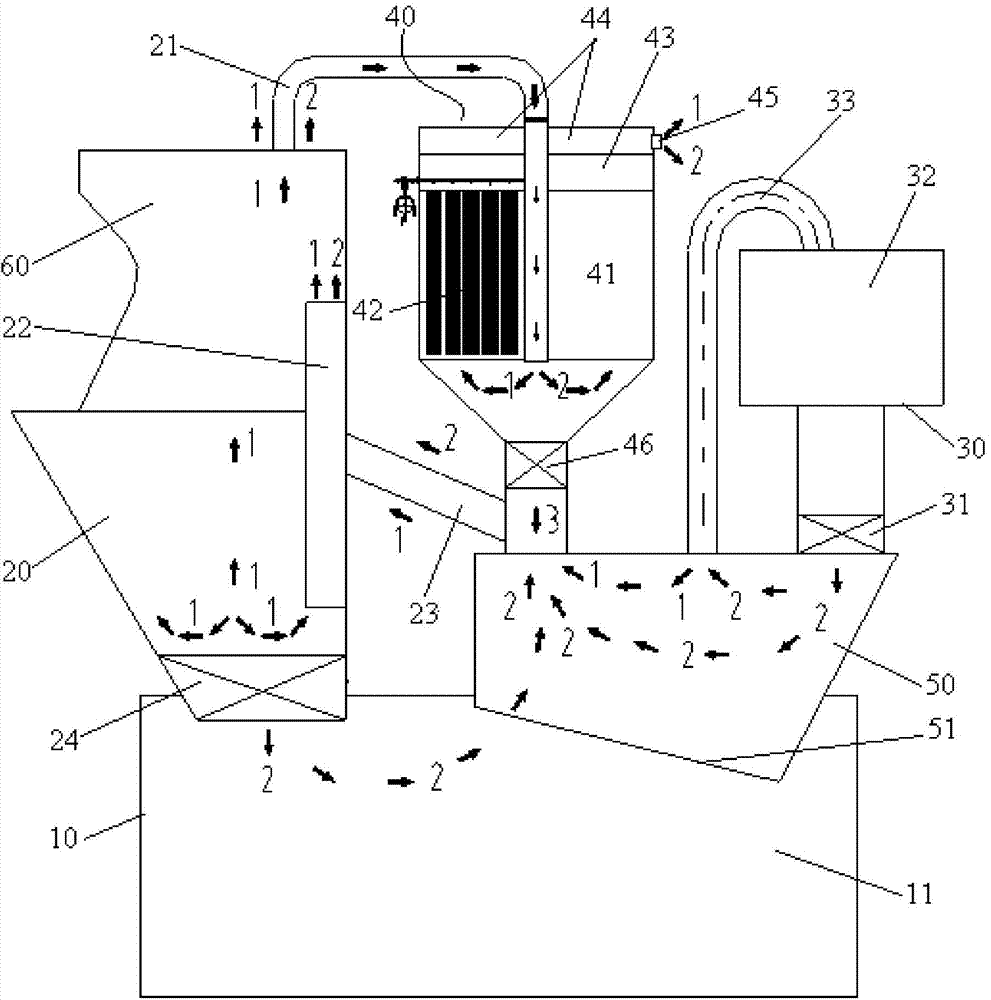

Combined regenerated lead oxygen-enriched three-blowing energy-saving smelting furnace

InactiveCN103834817AIncrease heightGuaranteed contactIncreasing energy efficiencyGas emission reductionSlagWater jacket

The invention discloses a combined regenerated lead oxygen-enriched three-blowing energy-saving smelting furnace. A furnace body 1 is arranged vertically, the whole furnace body 1 is divided into a lower section, a middle section and an upper section, the lower section is a smelting area 4 and comprises a stationary area 20, a bubbling area 21, and a reduction area 22 from bottom to top, the middle section is a waste heat utilization area 5, the lower half part of the waste heat utilization area is a secondary combustion area 23, the upper half part of the waste heat utilization area is a raw material preheating area 24, the upper section is a smoke discharging and feeding area 6. The vertical furnace body is more convenient to fully use the waste heat of the offgas for preheating the raw material, so that the energy-saving effect is remarkably improved, the dosage of the reducing agent is reduced, and the content of lead in the slag is lowered. The novel furnace body adopts a metal water jacket component and is combined by segmental hoisting, thus being convenient to maintain, and greatly lowering the maintenance cost.

Owner:ANHUI HUAXIN LEAD IND GROUP +1

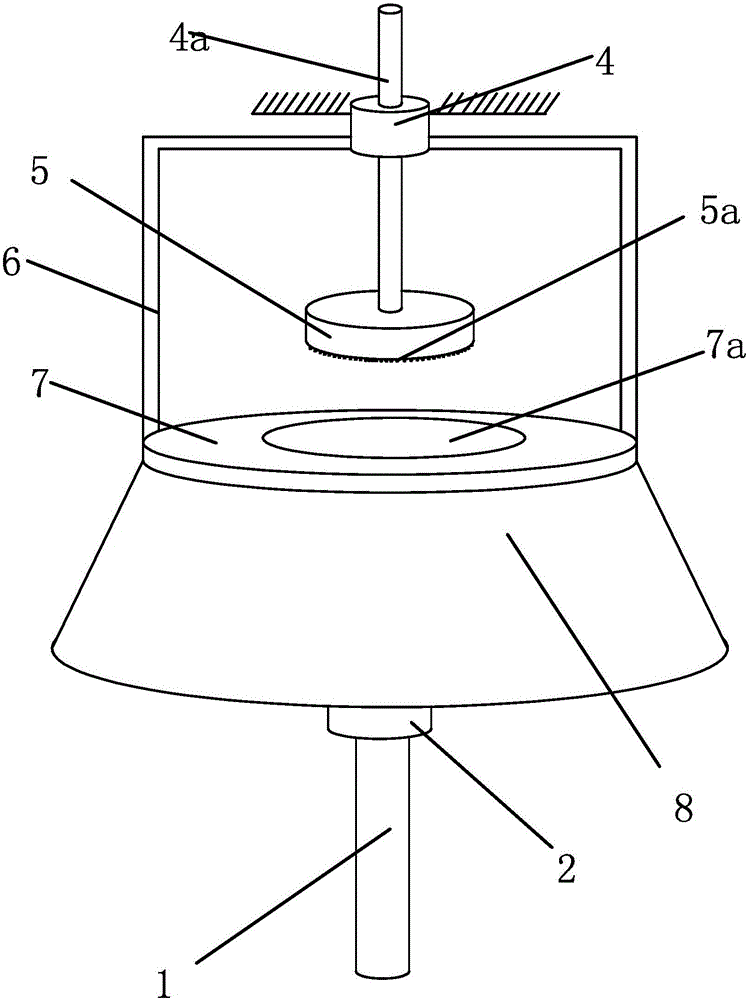

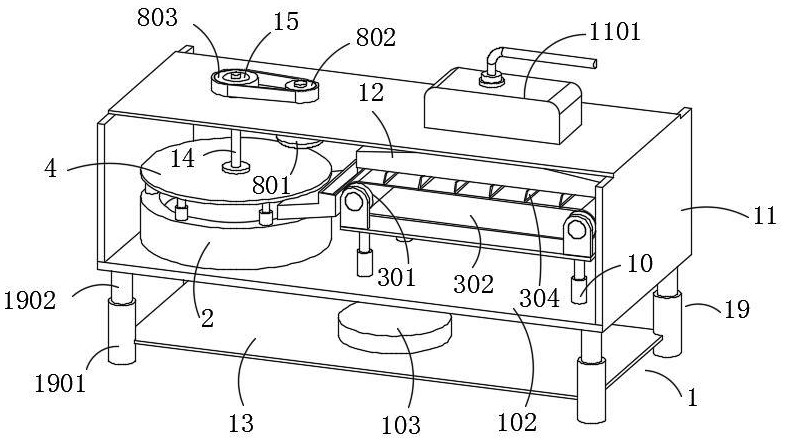

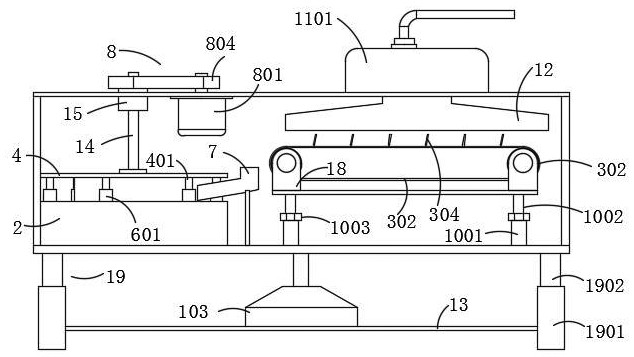

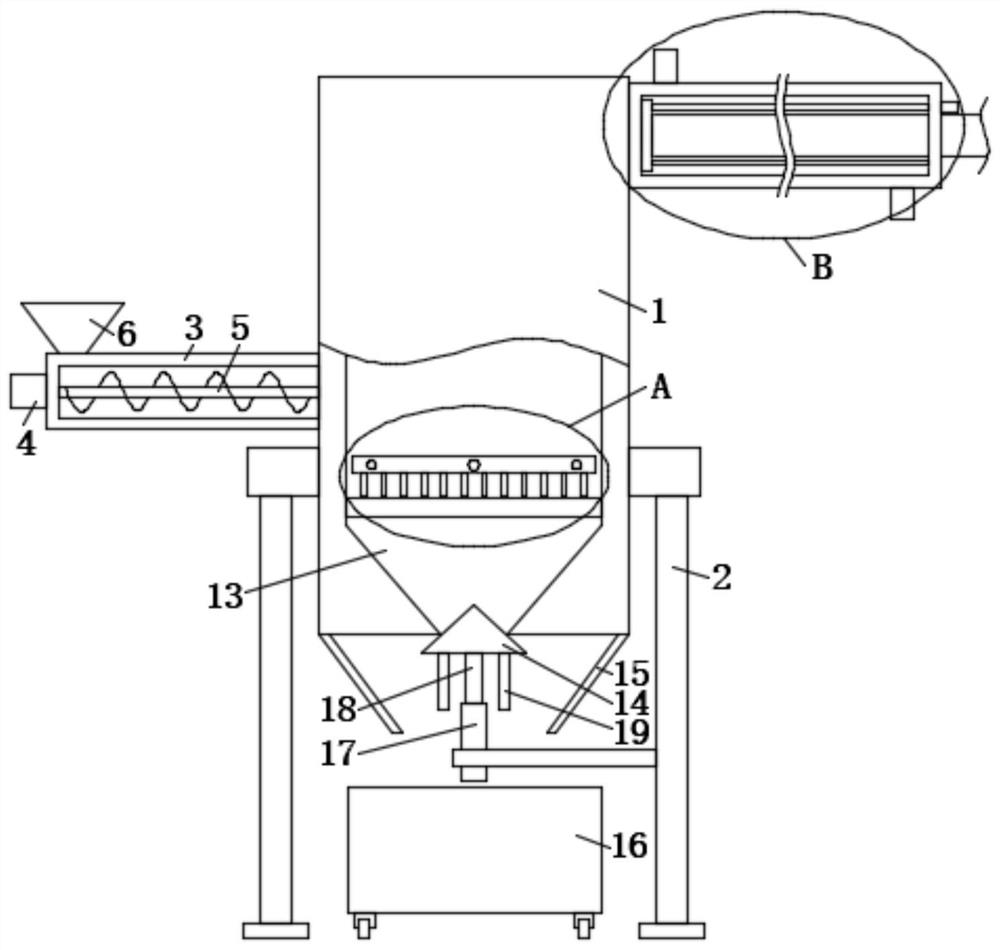

Granulating device for chicken feed production

PendingCN112956717AImprove work efficiencyIncrease the areaFeeding-stuffFood processingBiotechnologyElectric machinery

The invention discloses a granulating device for chicken feed production. The granulating device comprises a granulating platform, a granulating disc and a material conveying assembly, the granulating platform comprises four groups of telescopic rods, a bottom plate and a lifting motor, the granulating disc is fixedly mounted on the upper surface of the bottom plate, a grinding disc is rotatably mounted in the granulating disc, a conical grinding head is arranged at the bottom of the grinding disc, a conical grinding groove is formed in the granulating disc, the conical grinding head and the conical grinding groove are arranged in a matched mode, a feeding groove is fixedly formed in the position, located on one side of the grinding disc, of the upper surface of the bottom plate, the material conveying assembly is arranged on one side of the feeding groove, the top of the grinding disc is in transmission connection with a first driving assembly, screw sleeves are annularly arrayed on the position, located on the outer ring of the conical grinding groove, of the upper surface of the granulating disc at equal intervals, screws are annularly arrayed on the position, located on the outer ring of the conical grinding head, of the bottom surface of the grinding disc at equal intervals, and one ends of the screws are in threaded connection with the interiors of the screw sleeves. Automatic feeding is achieved, the working efficiency is improved, the grinding area is increased, and the grinding time is prolonged.

Owner:庞淑红

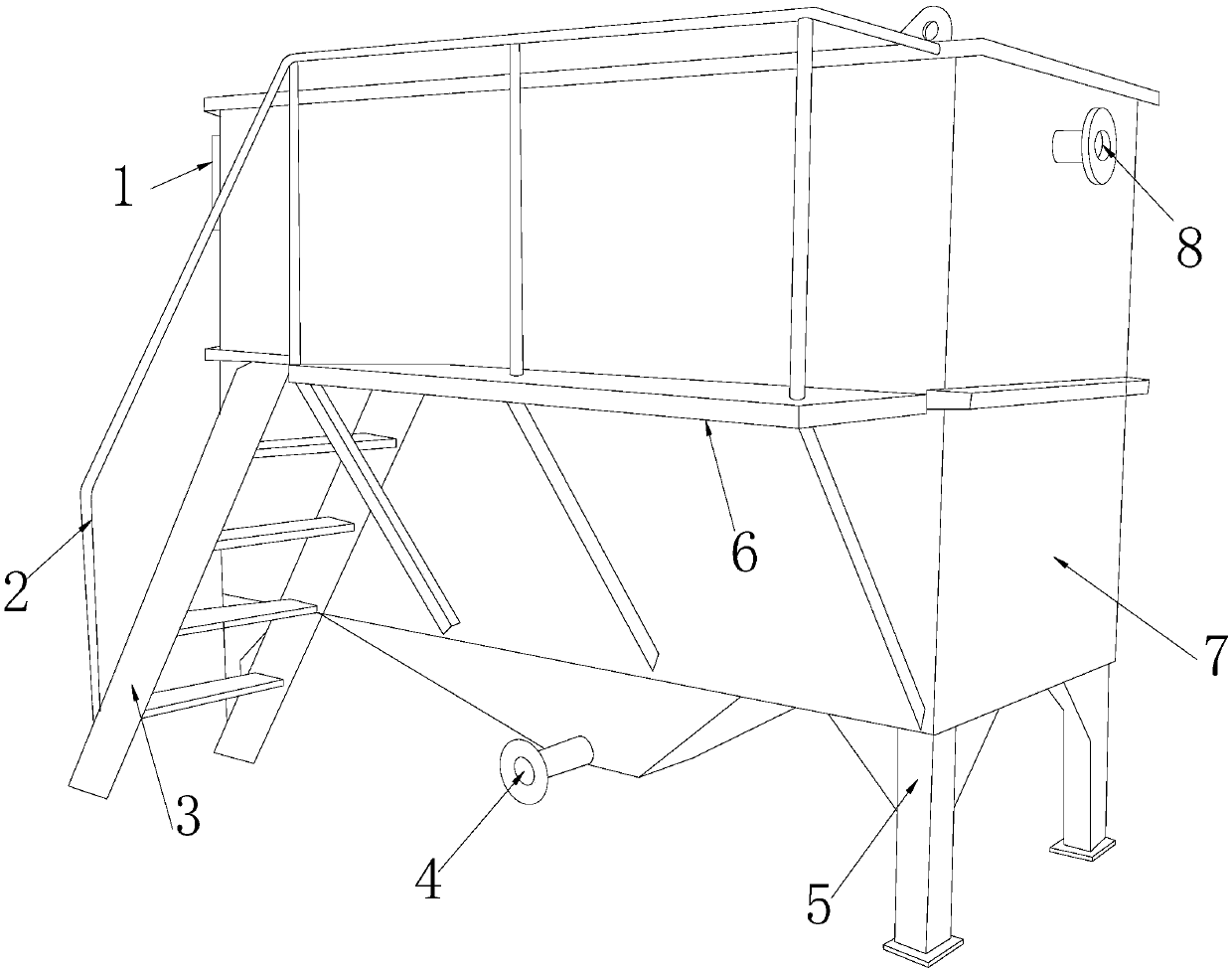

Acid pickling wastewater treater

InactiveCN108675428AEasy to moveInvest evenlyWaste water treatment from metallurgical processWater/sewage treatment by neutralisationDraining tubeReciprocating motion

The invention discloses an acid pickling wastewater treater. The structure of the treater comprises an automatic reagent feeding device, a guardrail, a ladder, a blow off pipe, supporting legs, a platform, a body and a drain pipe, wherein the supporting legs are vertically welded with four corners of the bottom of the body. The treater has the beneficial effects that the treater is provided with the automatic reagent feeding device, has an automatic reagent feeding function, does not need manual operation, automatically starts the automatic reagent feeding device to perform automatic reagent feeding through the matching of a PH probe when a detected value is smaller than a set value, automatically stops the automatic reagent feeding device to stop reagent feeding when the detected value isgreater than the set value, can uniformly stir reagents before automatic reagent feeding through the setting that a worm and gear rotating mechanism rotates to drive components, such as a reciprocating motion mechanism and a stirring mechanism, is more beneficial to the neutralization reaction between the reagents and water, reduces workload, improves the work efficiency, is accurate in blending,and is beneficial to the improvement of the wastewater treatment effect.

Owner:彭雄英

Opener

InactiveCN106676680ALess impuritiesReduce the impactFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineeringMechanical engineering

Owner:NINGBO EASTSUN TEXTILES

Rapid forming sand mold casting machine

PendingCN109290527AIncrease success rateQuality improvementMould handling/dressing devicesMoulding machinesConveyor beltRapid prototyping

The invention relates to a rapid forming sand mold casting machine. The rapid forming sand mold casting machine comprises a machine body, a liquid feeding opening and a solid feeding opening are formed above the machine body, a mixing bin is jointly connected to the lower parts of the liquid feeding opening and the solid feeding opening, a sand box is arranged below the mixing bin, a third air cylinder is arranged on the left side of the sand box, a conveyor belt is arranged on the right side of the sand box, and a second air cylinder is arranged on the right side of the conveyor belt. Telescopic rods are connected to the inner sides of the second air cylinder and the third air cylinder, fixing devices are connected to the inner sides of the telescopic rods, and left and right lateral plates of the sand box are fixedly connected to the fixing devices correspondingly. A supporting column is arranged on the rear portion of the machine body, a fixed rod is arranged on the supporting column, a first air cylinder is connected to the front portion of the fixed rod in a clamping mode, a piston rod is connected to the lower portion of the first air cylinder, a jolt-squeeze device is connected to the lower portion of the piston rod, the jolt-squeeze device is fixedly connected to a pressing plate, and a control panel is arranged on the left side of the machine body. The rapid forming sand mold casting machine has the advantages of scientific ratio, high automation degree and good forming effect.

Owner:禹州市毛吕铸造有限公司

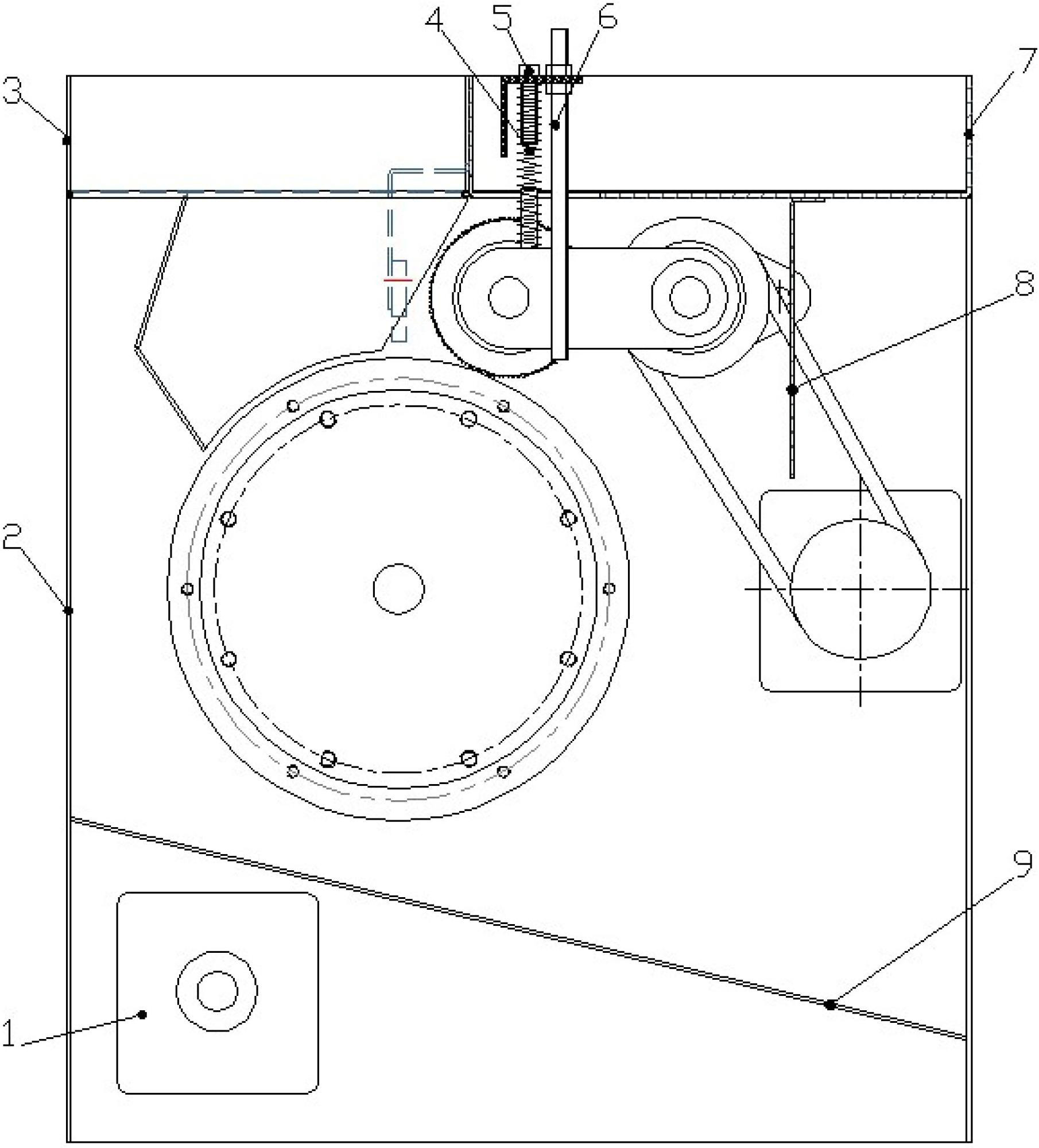

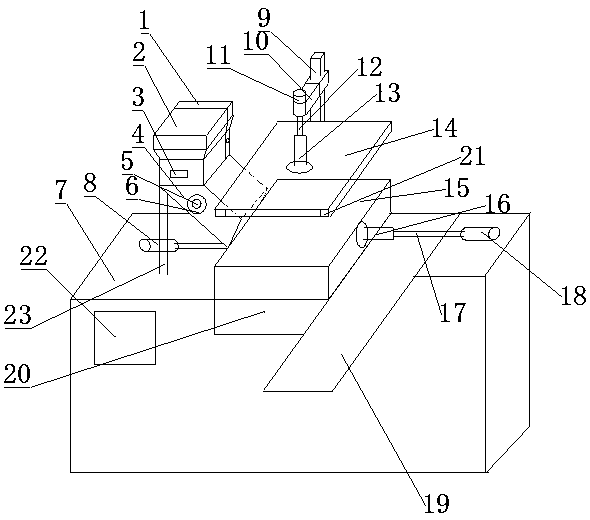

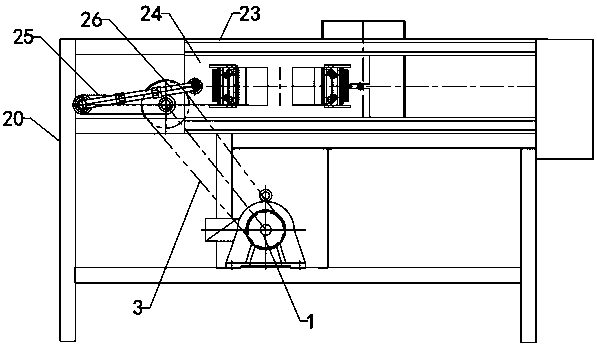

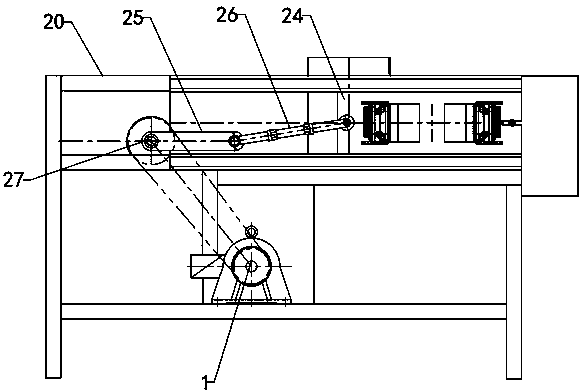

Fruit and vegetable shredding machine

PendingCN110722630AAvoid problems such as overloading, damage, etc.Simple structureMetal working apparatusAgricultural engineeringElectric machinery

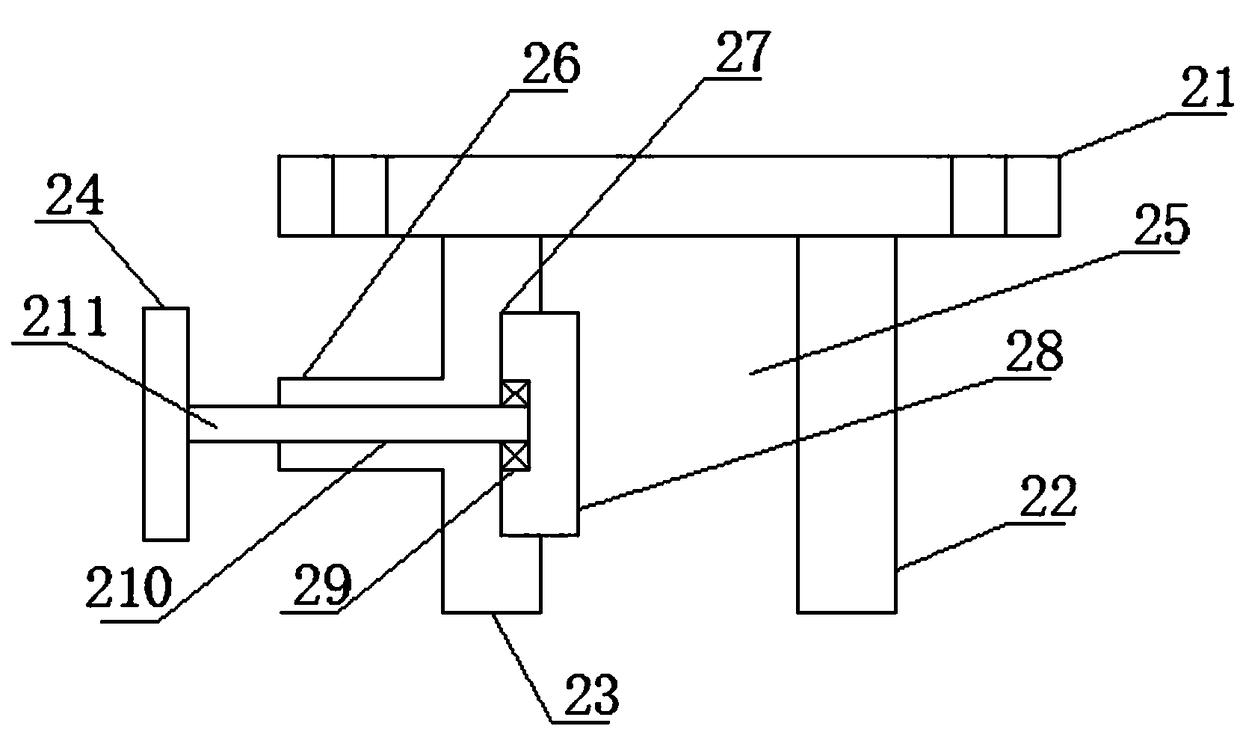

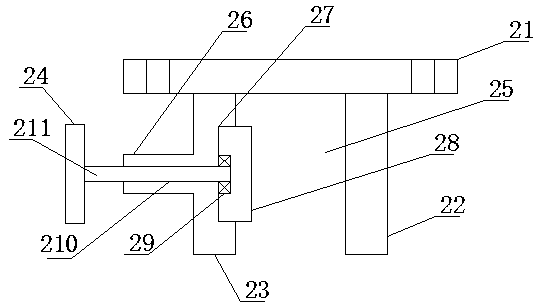

The invention discloses a fruit and vegetable shredding machine, and belongs to the technical field of fruit and vegetable machining devices. The fruit and vegetable shredding machine is characterizedby comprising a rack (20), a power mechanism, a transmission mechanism and shredding mechanisms, wherein the power mechanism, the transmission mechanism and the shredding mechanisms are arranged on the rack (20). The power mechanism comprises a speed reduction motor (1), the speed reduction motor (1) is connected with the shredding mechanisms through the transmission mechanism, the two shreddingmechanisms are arranged in a bilateral symmetry manner, the shredding mechanisms are arranged on the two sides of the material outlet end of a feeding box (21) in a sliding manner through mounting plates (24), the feeding box (21) is horizontally arranged on the upper portion of the rack (20), and a material conveying mechanism is arranged on the horizontal side of the feeding box (21). A speed reducer is directly adopted for achieving first-stage deceleration, the structure is greatly simplified, through the material conveying mechanism, automatic discharging is achieved, the problems that due to manual material conveying in, material input is not uniform, production rate is low, labor intensity is large, the overload is prone to generating, and the machine is easily damaged are solved, production rate is improved, labor intensity is reduced, and machine overload, damage and other problems are solved.

Owner:淄博市农业机械研究所

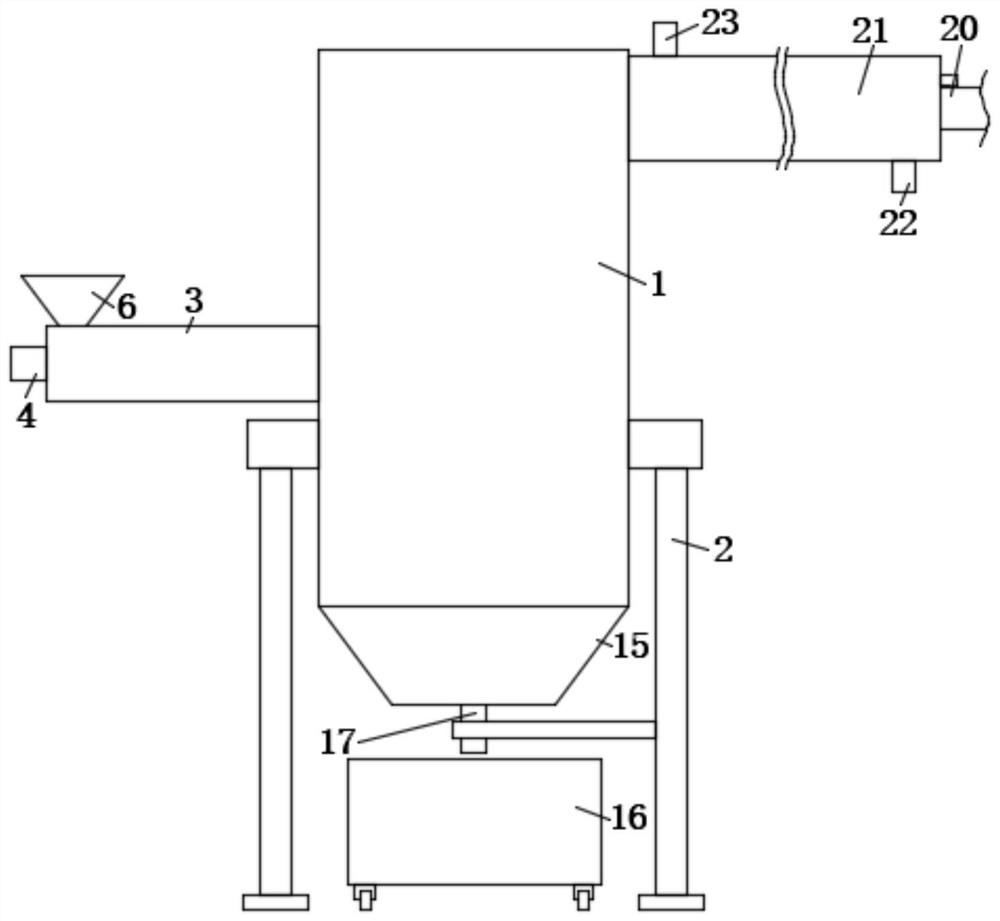

Seaweed feed for river crabs and automatic feeding equipment thereof

InactiveCN114711343AImprove the immunityReduce deathFood processingAnimal feeding stuffFisheryElectric machinery

The invention discloses seaweed feed for river crabs and automatic feeding equipment of the seaweed feed, and relates to the technical field of river crab breeding, the seaweed feed comprises a feeding box, a feed conveying pipe and a feeding assembly, feeding pipes are connected to the two sides of the outer portion of the feeding box, the feed conveying pipe is connected to the tail ends of the bottoms of the feeding pipes, and a first motor is arranged on the outer side of the top of each feeding pipe; a displacement assembly is arranged at the outer end of the conveying pipe, and lead screws are arranged on the two sides of the outer portion of the displacement assembly. A third motor works, a rotating gear can be driven to rotate, the rotating gear is meshed with butt joint tooth grooves in the two ends of the outer portion of a material conveying pipe, and therefore in the rotating process of the rotating gear, the material conveying pipe can be driven to ascend and descend on the inner side of a connecting box; the feed conveying pipe can drive the feeding pipe to move to the bottommost part of the crab pond, and due to the fact that the growth environment of river crabs is located at the pond bottom, the situation that feed is grabbed by fish in a lake due to the fact that the feed is directly fed on the lake surface can be effectively avoided by feeding the river crabs at the lake bottom.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Mechanical-type crushing mechanism facilitating feeding and discharging

InactiveCN108371978AReasonable designNovel structureGrain treatmentsEngineeringMechanical engineering

The invention discloses a mechanical-type crushing mechanism facilitating feeding and discharging. The mechanical-type crushing mechanism comprises a shell, one side of the upper end of the shell communicates with a feeding port, the shell is internally provided with a conveyor belt, and material separating plates are arranged on the conveyor belt at equal intervals; and one side of the inner wallof the shell is connected with a first electric cylinder, a material receiving plate is hinged to the tail end of the conveyor belt, and a second electric cylinder is hinged to the middle of the bottom of the material receiving plate. Materials are put into the shell through the feeding port, the shell is internally provided with the conveyor belt located at the bottom of the feeding port, the material separating plates are arranged on the conveyor belt at equal intervals so that the materials can be evenly put onto the conveyor belt, then the material receiving plate is made to be in an inclined state through arrangement of the second electric cylinder hinged to the bottom of the material receiving plate, so that the materials can intermittently and evenly fall into a crushing chamber, and meanwhile, the materials can smoothly fall into the crushing chamber better through arrangement of a material guiding plate.

Owner:浙江斯菲诺电气有限公司

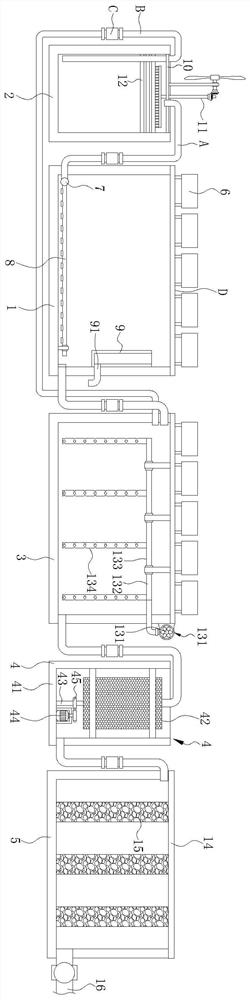

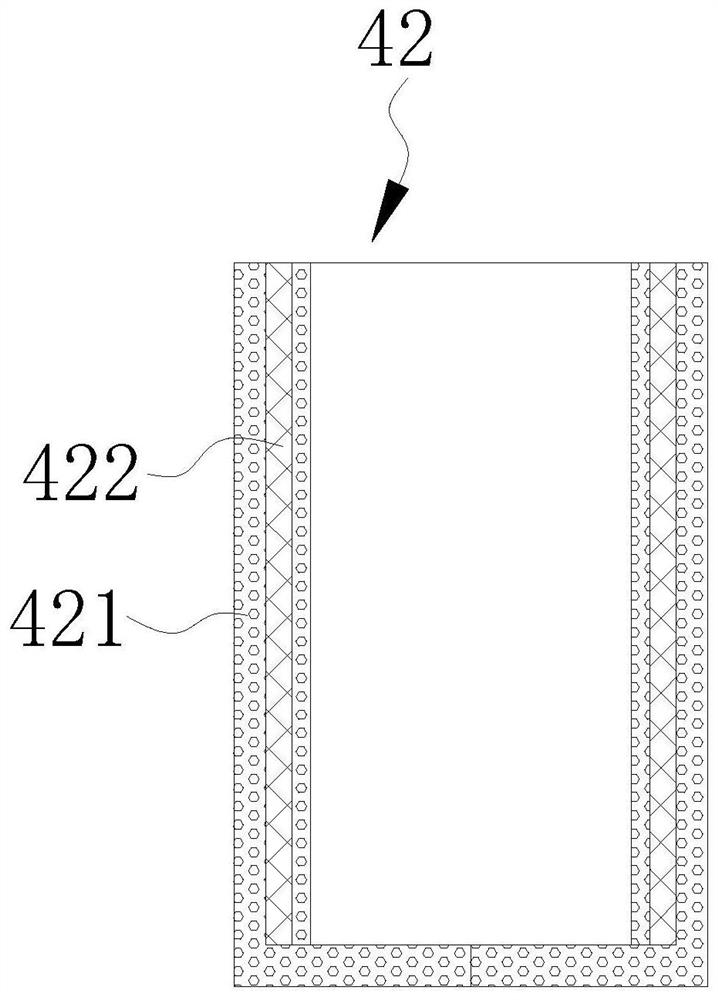

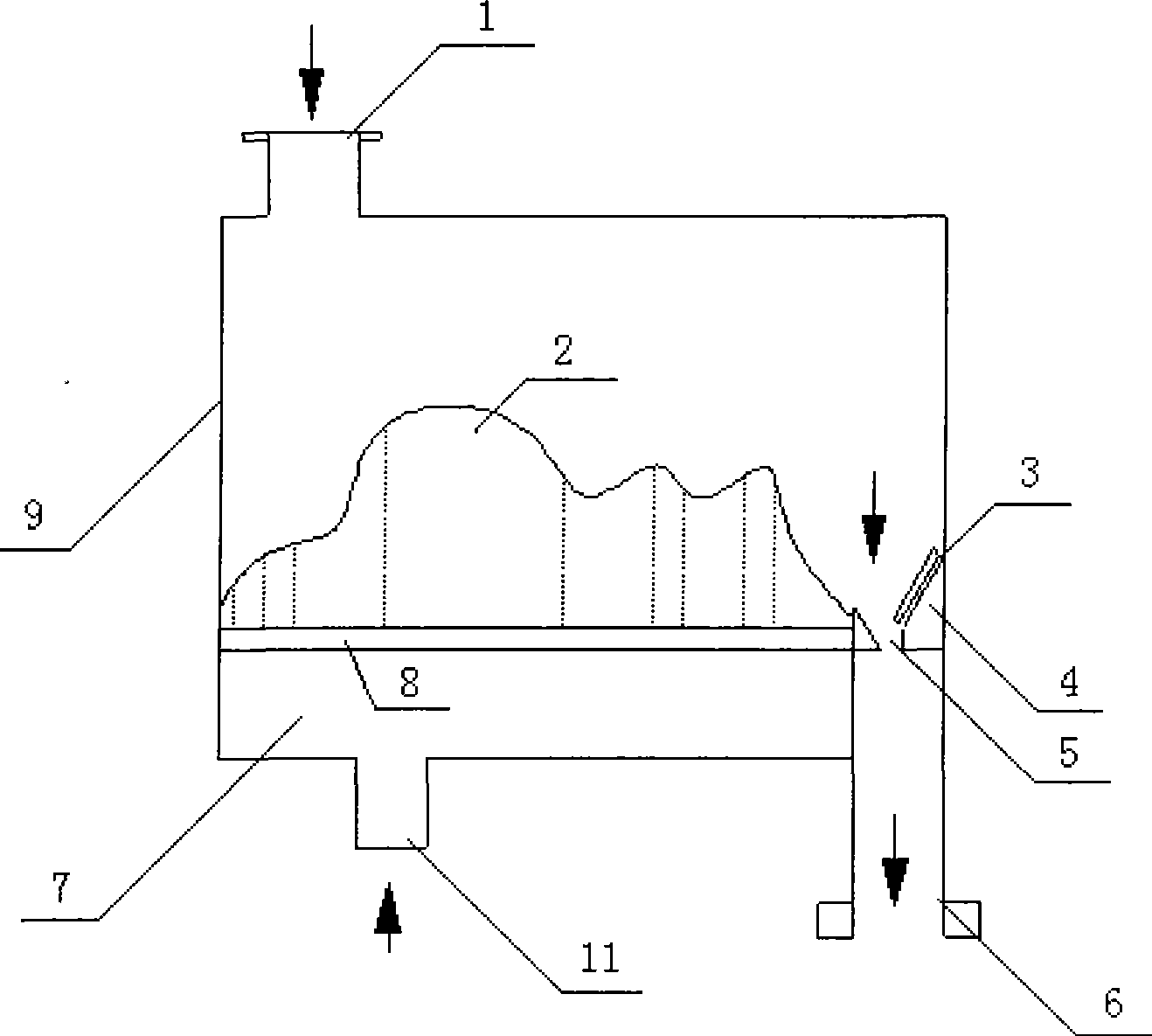

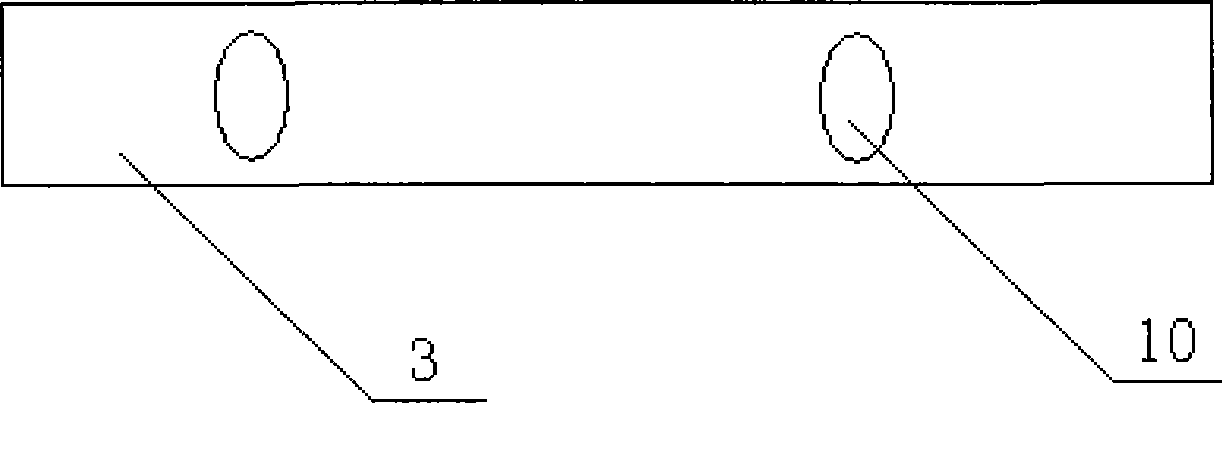

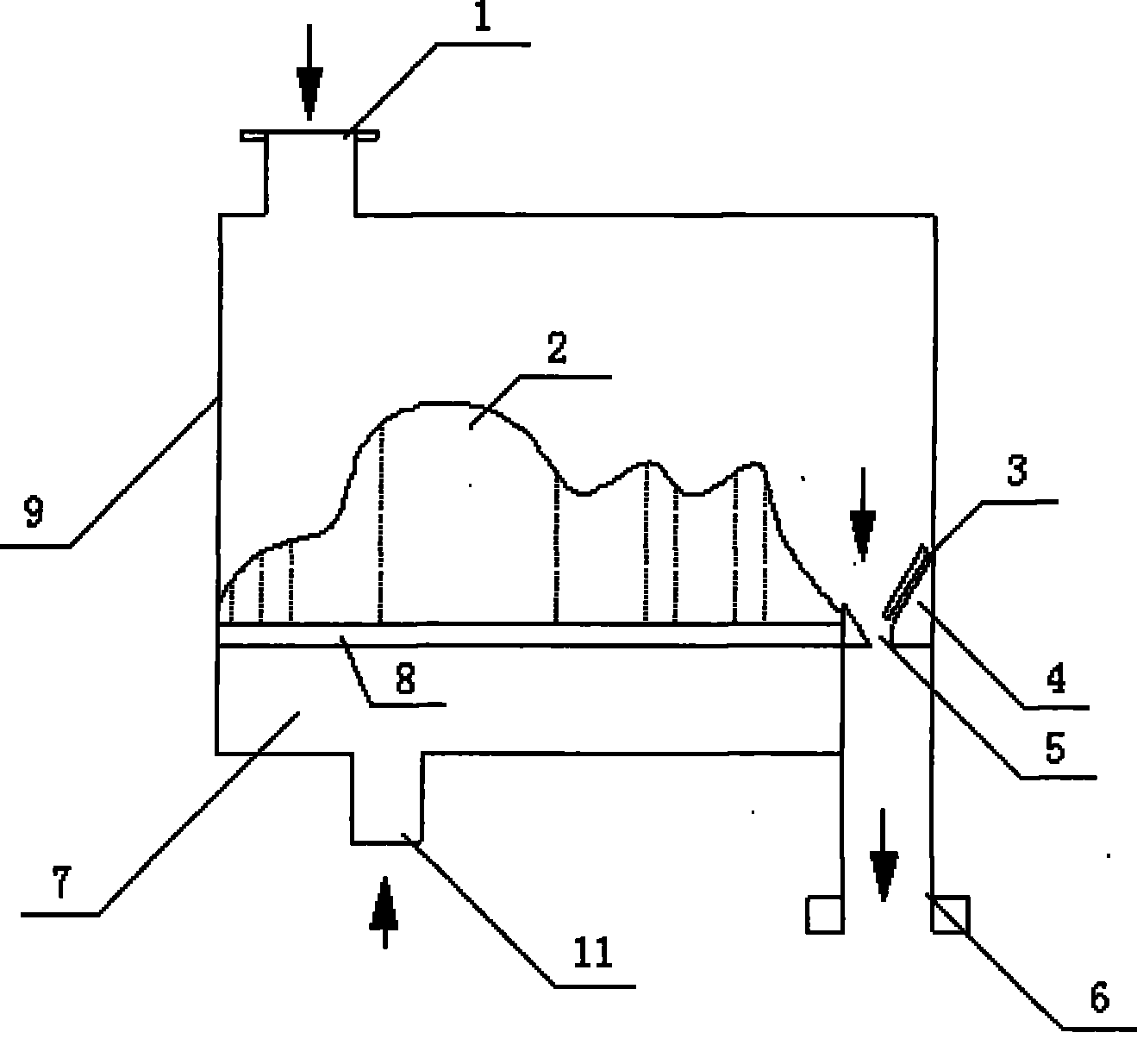

Solar micro-power sewage treatment system

InactiveCN113461217AConvenience to workInvest evenlyWater/sewage treatment by centrifugal separationGas treatmentActivated carbonWater treatment system

The invention relates to the technical field of sewage treatment, and discloses a solar micro-power sewage treatment system. The system comprises a sedimentation tank, a sediment separation tank, a chemical reaction separation tank, a separated dirt throwing and separating device and an activated carbon treatment tank; water pumping pipes are communicated between every two adjacent tanks, and a branch guide pipe is communicated between the sediment separation tank and the chemical reaction separation tank. Water suction pumps are arranged on the water suction pipe and the branch guide pipes; solar photovoltaic sets are arranged above the sedimentation tank and the chemical reaction separation tank through welded supporting frames, the water inlet end of a water pumping pipe communicated between the sedimentation tank and the sediment separation tank is communicated with a longitudinally-distributed transverse pipe, and the side face of the outer circle face of the transverse pipe is communicated with a plurality of sewage suction branch pipes; and a receiving cavity for containing floating objects is formed in the middle of the side wall of the sedimentation tank. The problems that traditional domestic wastewater treatment cannot meet the self-sufficiency power supply requirement, in addition, wastewater treatment time is too long, and self-cleaning is tedious are solved.

Owner:安徽百帮环境工程有限公司

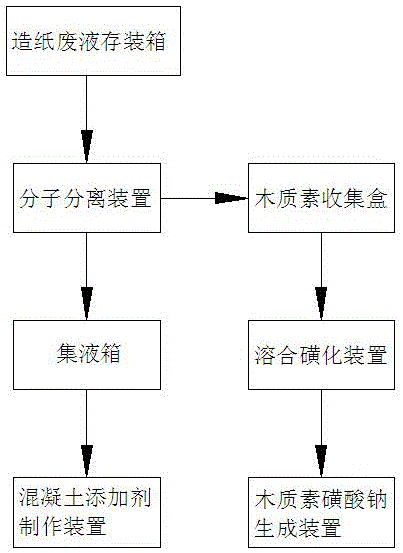

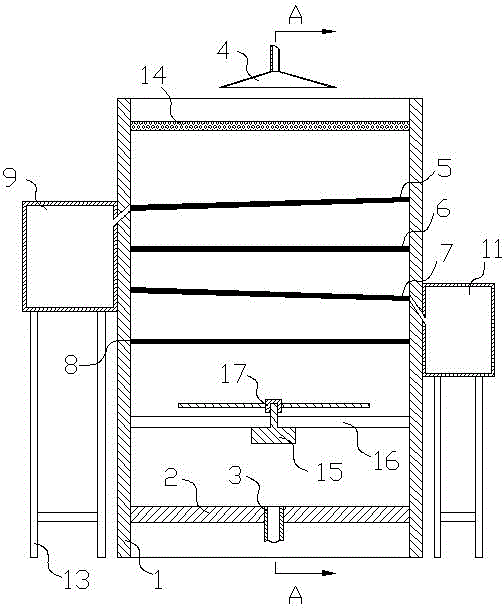

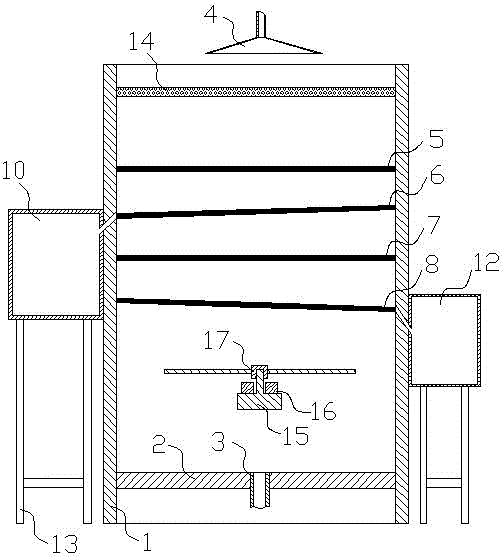

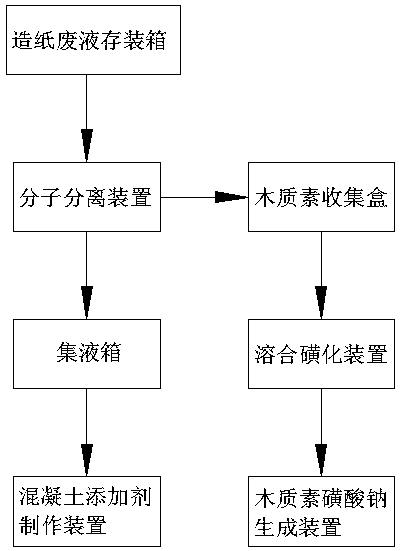

Equipment and production process for producing sodium lignin sulfonate from paper-making sewage

The invention relates to equipment for producing sodium lignin sulfonate from paper-making sewage. The equipment comprises a paper-making waste liquid storage tank, wherein the paper-making waste liquid storage tank is connected to a molecular separation device; the macromolecule solute outlet of the molecular separation device is connected to a lignin collecting box; the micromolecule solute outlet of the molecular separation device is connected to a catch box; the lignin collecting box is connected to a dissolution and sulfonation device; the dissolution and sulfonation device is connected to a sodium lignin sulfonate generation device; the catch box is connected to a concrete additive preparation device. The invention further relates to a production process for producing sodium lignin sulfonate from paper-making sewage. The production process comprises the following steps: collecting waste water, separating and retaining, dissolving and sulfonating, generating, and preparing a concrete additive. The invention aims to provide equipment and the production process for producing sodium lignin sulfonate from paper-making sewage, pollution caused by separated paper-making waste water can be avoided, and meanwhile the separated paper-making waste water can be adopted to prepare the concrete additive for further use.

Owner:通道神华林化有限公司

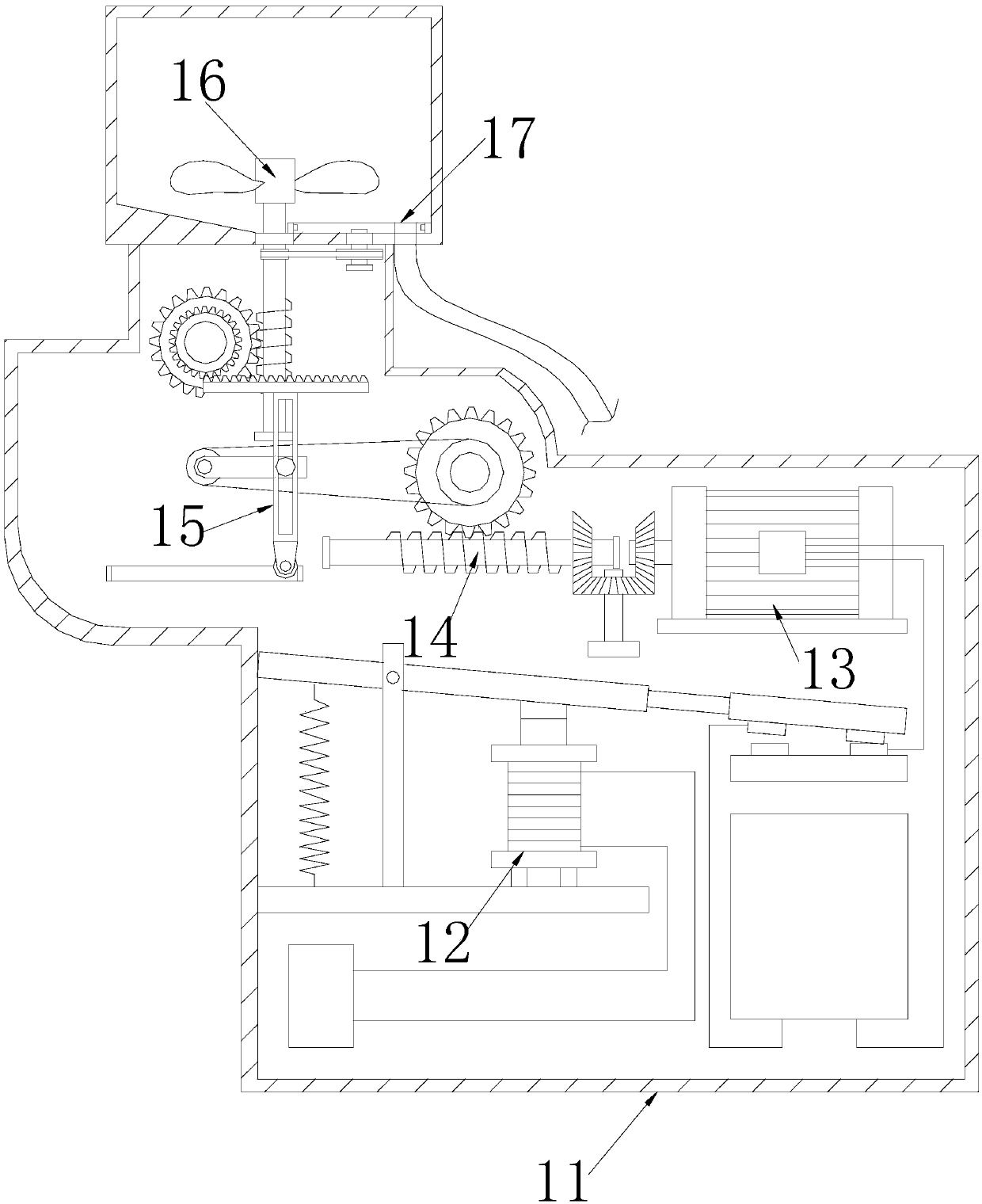

Synchronous adding device for liquid additive and solid additive

InactiveCN108607377ARealize the injectionRealize inputTransportation and packagingMixer accessoriesPulp and paper industryAutomation

The invention discloses a synchronous adding device for a liquid additive and a solid additive. The device comprises a main hollow casing, wherein a bottom clamping positioning mechanism is mounted onone side of the bottom of the main hollow casing. The solid additive and the liquid additive can be added synchronously by use of a motor, so that the added additives have the characteristics of automation and addition uniformity. Besides, the device can be clamped at an adding hole part of a raw material storage casing through the bottom clamping positioning mechanism, so that the following workcan be realized. In addition, the device is provided with a liquid injection rotating connecting mechanism, so that the injection of the liquid additive can be realized while connection drive is realized. Moreover, the device is provided with a solid and liquid additive rotating adding mechanism, so that injection of the solid additive can be realized on the premise of rotation. Besides, the device is provided with a solid additive conveying control mechanism, so that the conveying effect and speed of the solid additive can be controlled.

Owner:董洁 +3

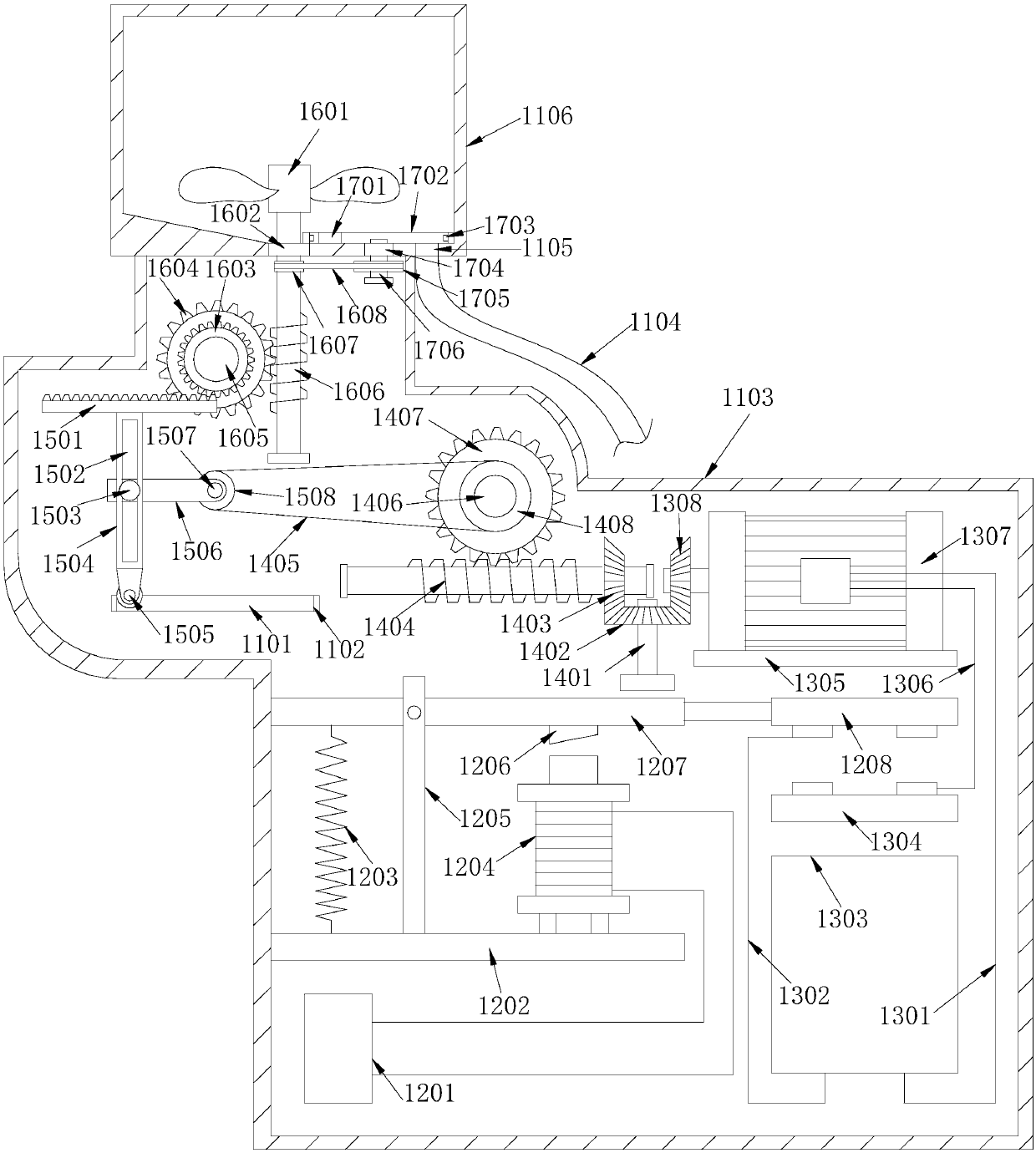

Device for synchronously feeding liquid additives and solid additives

InactiveCN108745191ARealize the injectionRealize inputTransportation and packagingMixer accessoriesEngineeringLiquid injection

The invention discloses a device for synchronously feeding liquid additives and solid additives. The device comprises a main hollow shell, wherein a bottom clamping and positioning mechanism is mounted on one side of the bottom of the main hollow shell. The device is capable of feeding the liquid additives and the solid additives in synchronization status by using an electromotor, so that the fedadditives are automatically and uniformly fed; meanwhile, the bottom clamping and positioning mechanism is arranged in the device and is capable of clamping the device in a material feeding hole partof a raw materials storage shell, so that the subsequent operations can be achieved; in addition, a liquid injecting, rotating and connecting mechanism is arranged in the device and is capable of achieving the effect of injecting the liquid additives while achieving connection driving; furthermore, a solid-liquid additive rotating and feeding mechanism is arranged in the device and is capable of achieving the effect of feeding the solid additives under the precondition of rotating; and a solid additive conveying control mechanism is arranged in the device and is capable of controlling the conveying speed and the conveying effect of the solid additives.

Owner:JINHUA ZHICHAN MAOYUAN INFORMATION TECH CO LTD

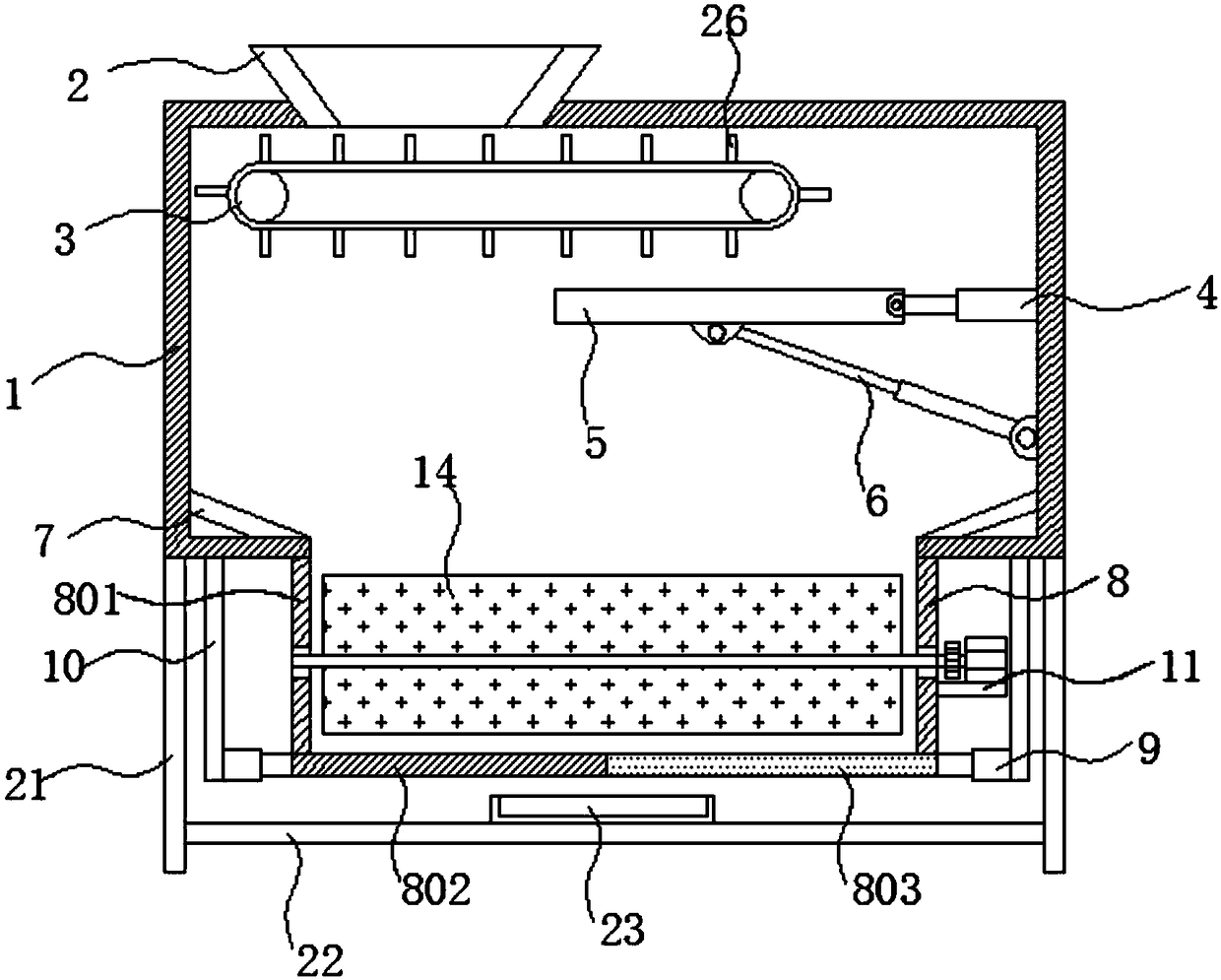

Incineration equipment for small-scale garbage disposal

PendingCN112113219ASimple structureEasy to useIncinerator apparatusEnvironmental engineeringRefuse Disposals

The invention discloses incineration equipment for small-scale garbage disposal. The incineration equipment comprises an incinerator; fixing supports are installed on the outer side wall of the bottomend of the incinerator; one side of the incinerator is connected with a feeding device; a partition plate is fixedly installed on the inner side wall of the bottom end of the incinerator; the partition plate is located at the bottom end of the feeding device; a plurality of strip-shaped through holes are evenly formed in the partition plate; an impurity turning device is arranged at the top end of the partition plate and comprises a movable plate movably installed in the incinerator; a plurality of rake teeth are evenly and fixedly installed on the bottom wall of the movable plate and evenlyarranged at the top end of the partition plate; a driving device matched with the movable plate is arranged in the incinerator; a discharging port is formed in the bottom end of the incinerator; the inner side wall of the discharging port is obliquely arranged; and the bottom end of the discharging port extends to the lower side of the incinerator. The incineration equipment for small-scale garbage disposal is simple in structure, convenient to use, low in manufacturing and using cost, wide in application range and good in practical effect, and is also suitable for small-budget and small-scalegarbage disposal.

Owner:李玉成

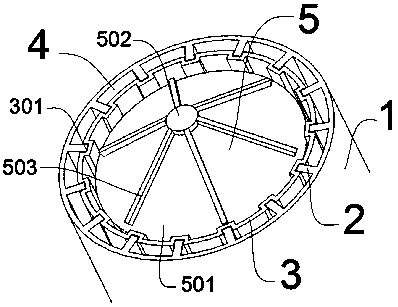

Building aggregate regeneration device and use method thereof

InactiveCN113043458AHigh strengthImprove qualitySolid waste managementFeeding arrangmentsPortland cementArchitectural engineering

The invention discloses a building aggregate regeneration device and a use method thereof, and relates to the technical field of concrete recycled aggregates. The problem that recycled concrete aggregates are poor in strength is solved. The building aggregate regeneration device comprises a top plate and a supporting base, wherein the outer wall of the bottom end of the top plate is connected with an electric push rod through a bolt. A working method of the building aggregate regeneration device comprises the following steps: guiding Portland cement, silica fume, quartz powder, fine aggregates and smashed concrete into a blending hole; and introducing water containing a water reducing agent into a water storage chamber, and putting steel fibers into a fiber storage ring. By arranging an electric push rod, a stirring plate and a circular hole, a rotating rod rotates to drive a stirring connecting rod to rotate, the stirring plate rotationally connected with the stirring connecting rod also starts to rotate around the rotating rod, and meanwhile, the stirring plate also starts to rotate in a material, so that the blended material and the crushed waste concrete are fully stirred, and the quality of the recycled concrete aggregates after production is improved.

Owner:詹玉琼

Septic tank treatment device

ActiveCN107032577AStir wellEvenly mixedTreatment with anaerobic digestion processesBiological sludge treatmentBiochemical engineeringDecomposition

The invention discloses a septic tank treatment device. The septic tank treatment device comprises a liquid adding device and a stirring device, wherein the stirring device comprises a driving disc and a stirring paddle, and the stirring paddle is fixed on the outer wall of a piston barrel; the liquid adding device comprises the piston barrel, a hinge piece, a piston and a rebounding piece; the piston comprises a piston handle, a piston rod and a piston head; the piston head comprises a base and a rubber head; the hinge piece is fixed on the outer wall of the piston barrel by virtue of a spring hinge, and a liquid outlet hole is formed in the lower part of the piston barrel; a through hole is formed in the center of the top of the piston barrel, and the piston handle is fixed at the top of the piston rod; the piston head is fixed at the lower part of the piston rod by virtue of a screw thread; the upper end of the rebounding piece is fixed at the top of the piston barrel, and the lower end of the rebounding piece is fixed on the upper part of the base; and a sliding chute is formed in each of the base and the rubber head, and a sliding bar is arranged on the inner wall of the piston barrel. The septic tank treatment device disclosed by the invention has the advantages that a biological decomposing agent can be uniformly put into a septic tank, decomposition of sewage and sediments of the septic tank is rapidly realized, cleaning is reduced and eliminated, pollution is reduced, and a hazardous gas accident is avoided.

Owner:赣州众顺环保容器设备有限公司

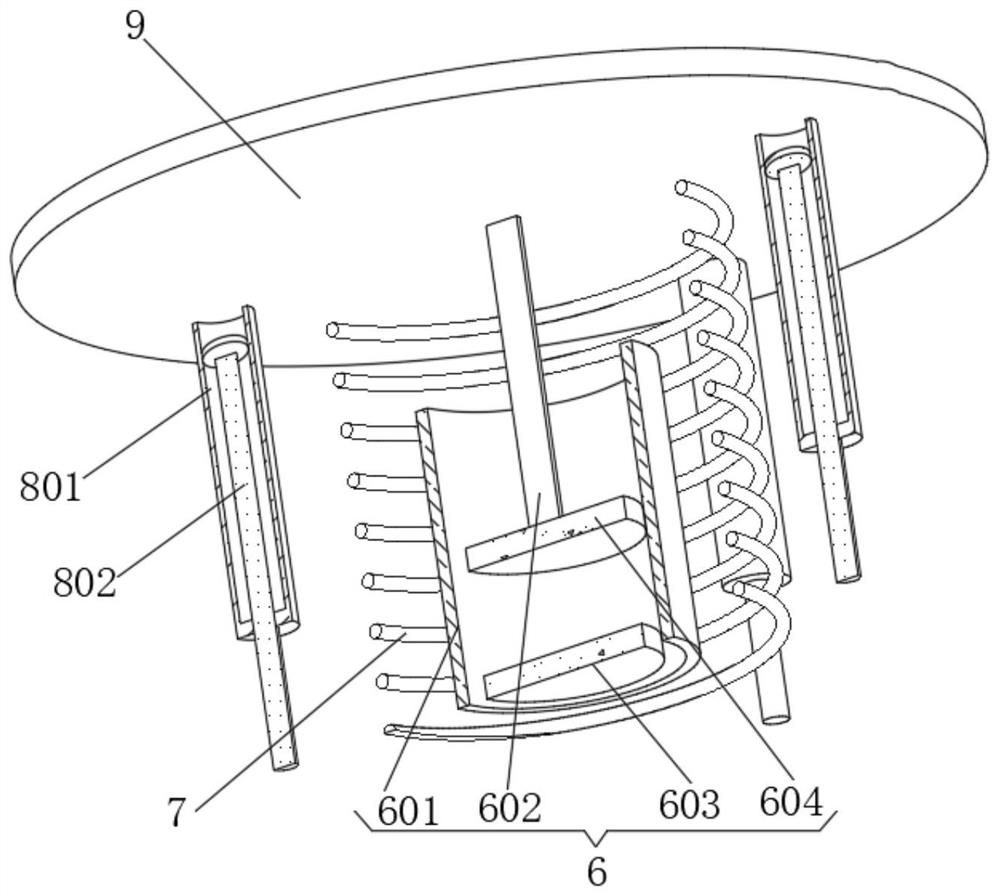

Reaction kettle convenient for uniform feeding

InactiveCN112452253AServe evenlyReduce deliveryChemical/physical/physico-chemical stationary reactorsFeed devicesStructural engineeringVibration exciter

The invention relates to a reaction kettle convenient for uniform feeding, which comprises a kettle body, a storage hopper and a vibration exciter, a mounting frame is fixedly welded to the inner wallof the kettle body, a mounting shaft is rotatably mounted in the middle of the mounting frame, stirring blades are fixedly welded to the outer surface of the mounting shaft, the storage hopper is fixed to the upper end of a conveying box in a welded mode, the lower ends of springs are welded to the upper ends of the supporting columns, a screening plate is fixedly connected to the upper ends of the springs, the vibration exciter is located in the middle of the lower surface of the screening plate, fixing bolts are welded to the front end and the rear end of the left side of the storage hopper, and shielding strips are embedded into the exteriors of the fixing bolts, and a guide plate welded and fixed with the storage hopper is arranged below a baffle plate. According to the reaction kettle convenient for uniform feeding, materials can be conveniently and uniformly fed, the feeding amount of the materials can be conveniently controlled, the fed materials can be effectively screened andfiltered, the product quality is guaranteed, and operation is convenient.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

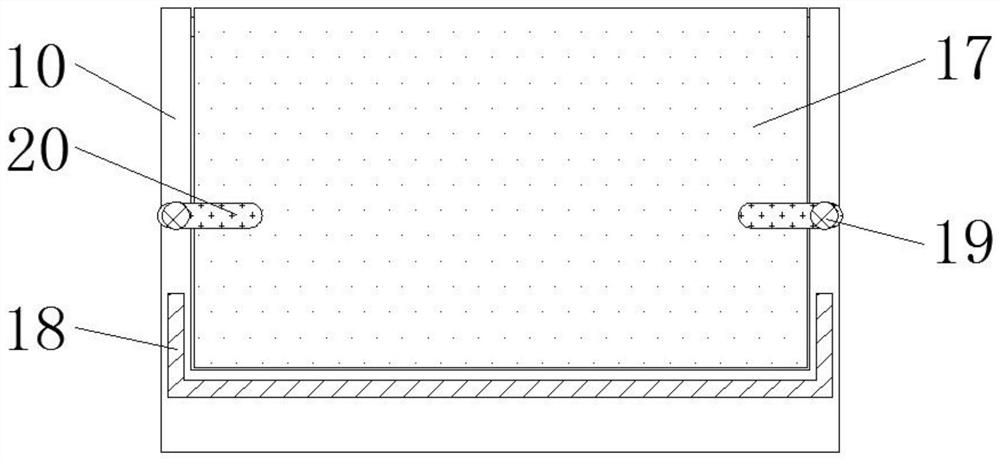

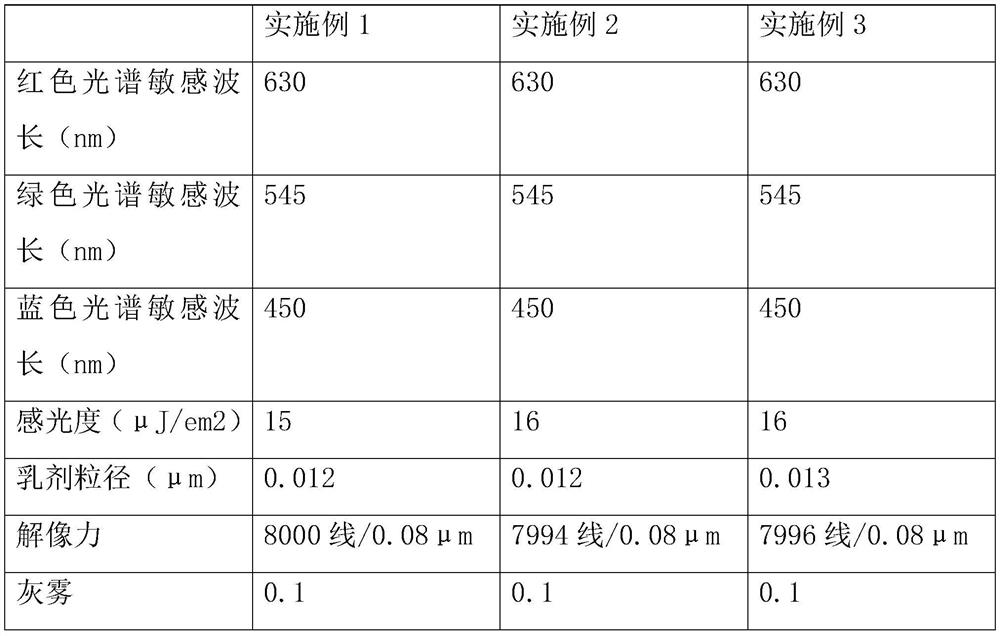

Laser holographic ultramicron silver salt photosensitive material and preparation method thereof

The invention discloses a laser holographic ultramicron silver salt photosensitive material and a preparation method thereof, and relates to the technical field of silver salt photosensitive materials. The material is prepared from distilled water, gelatin, benzotriazole, potassium chromium sulfate dodecahydrate, metronidazole, silver nitrate, citric acid, p-tert-butylphenol, sodium benzenesulfinate, potassium bromide, magnesium chloride, disodium ethylene diamine tetraacetate, nitrophenylhydrazine, sodium sulfonate, phenol, formamide, thymol, methanol and ethanol. The laser holographic ultramicron silver salt photosensitive material provided by the invention has excellent performances of low noise, high resolution, high sensitivity and high transparency, is sensitive to red light spectral line wavelength of 630 nm, green light spectral line wavelength of 545 nm and blue light spectral line wavelength of 450 nm, and has the sensitivity of 10-20 [mu]J / em<2>.

Owner:北京镭思顿科技开发公司

Equipment and production process for producing sodium lignosulfonate from papermaking wastewater

The invention relates to equipment for producing sodium lignin sulfonate from paper-making sewage. The equipment comprises a paper-making waste liquid storage tank, wherein the paper-making waste liquid storage tank is connected to a molecular separation device; the macromolecule solute outlet of the molecular separation device is connected to a lignin collecting box; the micromolecule solute outlet of the molecular separation device is connected to a catch box; the lignin collecting box is connected to a dissolution and sulfonation device; the dissolution and sulfonation device is connected to a sodium lignin sulfonate generation device; the catch box is connected to a concrete additive preparation device. The invention further relates to a production process for producing sodium lignin sulfonate from paper-making sewage. The production process comprises the following steps: collecting waste water, separating and retaining, dissolving and sulfonating, generating, and preparing a concrete additive. The invention aims to provide equipment and the production process for producing sodium lignin sulfonate from paper-making sewage, pollution caused by separated paper-making waste water can be avoided, and meanwhile the separated paper-making waste water can be adopted to prepare the concrete additive for further use.

Owner:通道神华林化有限公司

Biological agent quantitative feeding device for water environment treatment and use method of biological agent quantitative feeding device

InactiveCN113149235AEffective fragmentationGuaranteed granularitySpecific water treatment objectivesBiological water/sewage treatmentEnvironmental engineeringMechanical engineering

The invention discloses a biological agent quantitative feeding device for water environment governance and a using method thereof. The biological agent quantitative feeding device comprises a top tank and a base plate with brake wheels installed at the four corners of the outer wall of the bottom, a top plate is fixedly installed on the outer wall of the bottom of the top tank, and positioning assemblies are installed at the four corners of the opposite sides of the top plate and the base plate; an adsorption mechanism is installed on the side, opposite to the base plate, of the circle center of the outer wall of the bottom of the top plate, an inner end cylinder is arranged in the top tank, a discharging conical disc is fixedly installed on the circumferential inner wall of the end, close to the bottom, of the top tank, a conveying connecting pipe is fixedly installed at the bottom end of the discharging conical disc, a driving mechanism is fixedly installed at the inner bottom of the top tank, a material pumping mechanism is installed on one side of the top tank, and an adjustable discharging mechanism connected with the material pumping mechanism is installed at one end of the base plate. The height and the angle of a bulging point of the medicament can be increased, so that the drop point of the medicament is changed in real time, and the medicament can be fed more uniformly relative to the whole water area.

Owner:NANYANG NORMAL UNIV

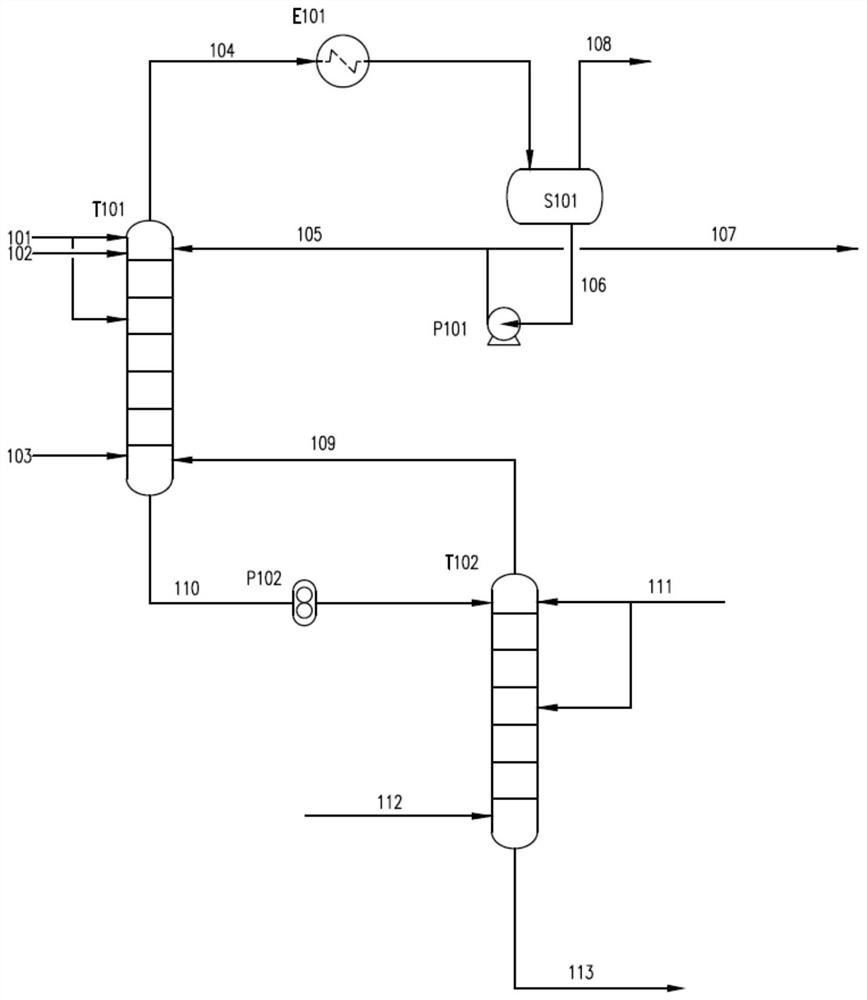

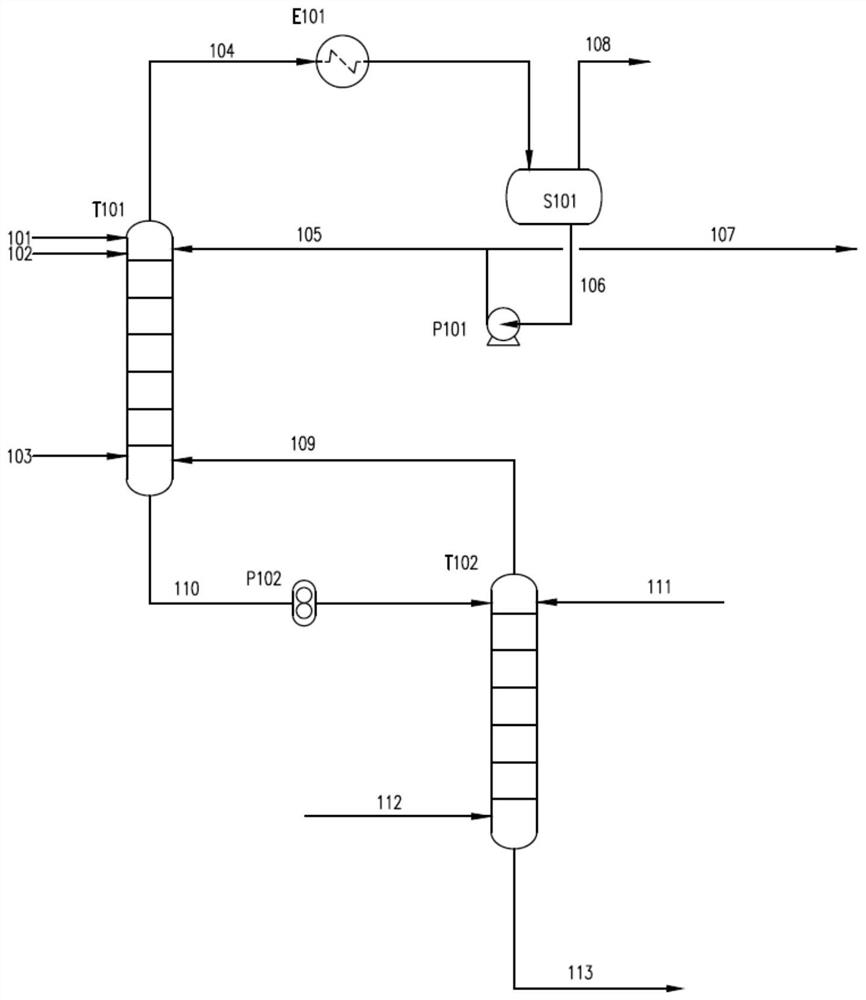

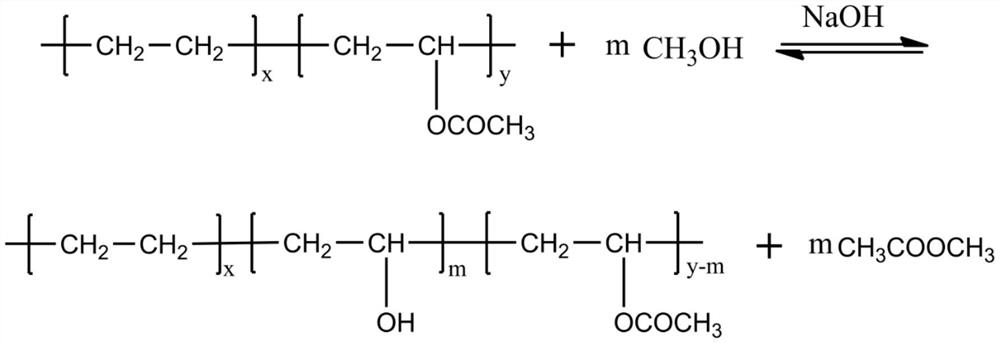

Method and device for preparing ethylene-vinyl acetate-vinyl alcohol copolymer

The invention discloses a method and a device for preparing an ethylene-vinyl acetate-vinyl alcohol copolymer. The method comprises the following steps: feeding a polymerization liquid containing the ethylene-vinyl acetate copolymer into the upper part of an alcoholysis tower I, feeding a basic catalyst material flow into the alcoholysis tower I, or mixing a basic catalyst and the polymerization liquid containing the ethylene-vinyl acetate copolymer, feeding the mixture into the upper part of the alcoholysis tower I, blowing methanol steam into the bottom of the alcoholysis tower I, and reacting; feeding tower bottoms of the alcoholysis tower I into the upper part of an alcoholysis tower II, feeding a basic catalyst material flow into the alcoholysis tower II, and blowing excessive fresh methanol steam into the bottom of the alcoholysis tower II for reaction; a gas-phase material flow obtained by the reaction is discharged from the tower top as tower top gas of the alcoholysis tower II and is completely introduced into the bottom of the alcoholysis tower I to serve as a main source of methanol steam, and the ethylene-vinyl acetate-vinyl alcohol copolymer is obtained after tower bottom liquid of the alcoholysis tower II is discharged. The method has the advantages of low process energy consumption, small molecular weight distribution index of the resin product, low equipment investment cost and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Linear feeding method for aluminum electrolysis flue gas purification system

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

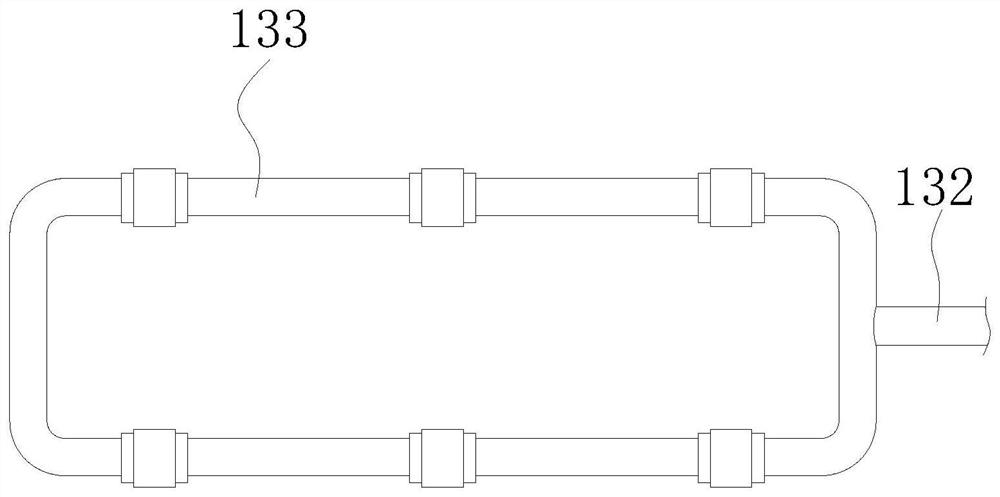

A water purifier rapid heating structure

The invention relates to a quick heating structure of a water purifier. The water purifier comprises multiple parallelly arrayed capillary water pipes arranged between a water inlet tank and a water outlet tank of the water purifier. All the capillary water pipes are located in a same plane to form a heating layer, at the outer circle of the pipe wall of each capillary water pipe, and carbon fiber infrared quartz electrical heating pipes are coiled from the capillary water pipe inlet to the capillary water pipe outlet in a spiraling mode. The inlet water tank and the outlet water tank are all in the structure that one end is big and the other end is small like the shape of a horn. The capillary pipe is a food level silica gel pipe. The inlet water cavity and the outlet water cavity are all food level silica gel cavities which are processed by a one-time forming method. The quick heating structure of the water purifier has the advantages of being fast in heating, short in heating time, and obvious in energy saving. Through the arrangement of a pressure release structure, the water steam impact is reduced, it is guaranteed that no water spray or splash occurs when the water temperature is too high, thus preventing users from being burned, and enhancing the use safety.

Owner:ZHEJIANG WATERHOR ENVIRONMENTAL PROTECTION TECH CO LTD

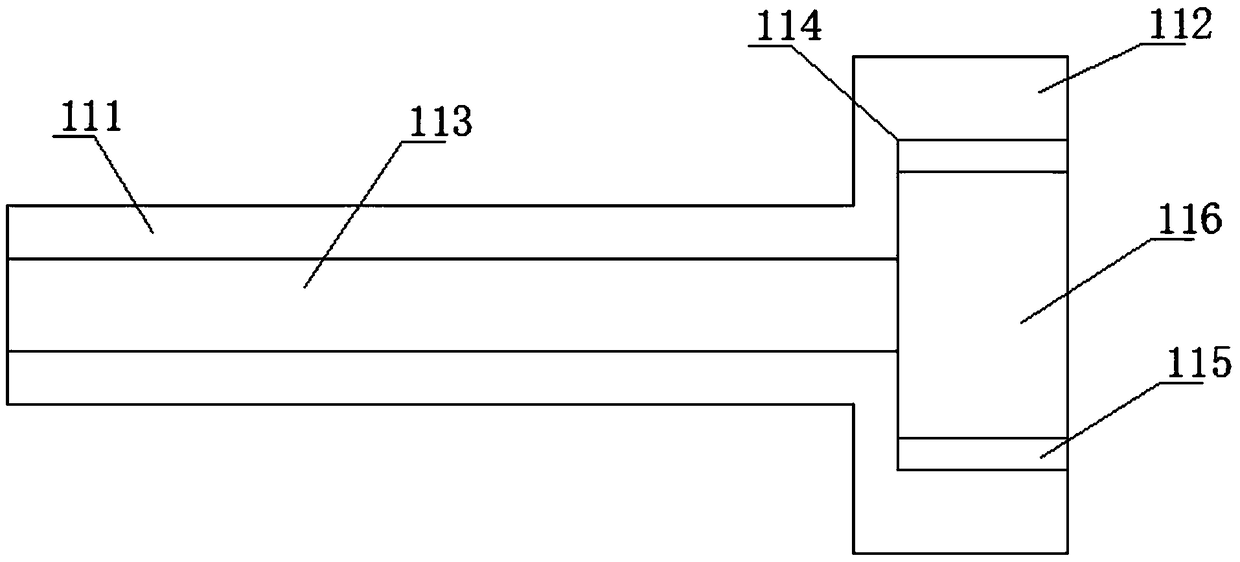

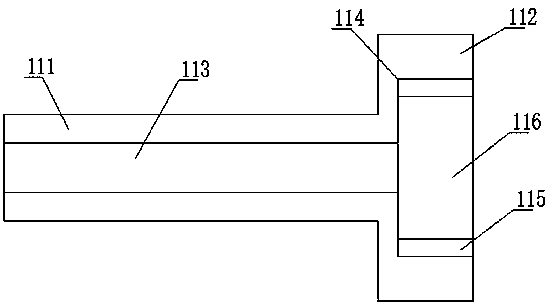

A kind of composite pig feed raw material feeding machine head material guide device

ActiveCN109618960BInvest evenlyEasy to stir and mixAnimal feeding devicesEngineeringStructural engineering

The present invention discloses a composite pig feed raw material feeding machine head material guide device which uses an eccentric structure to drive the turnover, and at the same time makes the deflection frame deflect during the turnover process through the deflection angle, and forms intermittent opening and closing with the inner installation frame, and then The head material guide device for feeding. Through the intermittent opening and closing of the deflection frame, the input raw materials are gradually and quantitatively input. It is characterized in that the dust cover is placed at one end of the outer material guide box, the top wall of the dust cover is an inclined plane, and gradually slopes upward from one end to the other end of the outer material guide box, and the gap between the inner installation frame and the inner wall of the outer material guide box The distance is twice the frame width of the inner material guide frame, and multiple springs are respectively placed between the outer side of the inner installation frame and the inner side wall of the outer material guide box, and distributed along the outer side of the inner installation frame for a circle, and the two ends of the springs are respectively connected to the inner side wall of the outer material guide box. The inner installation frame and the inner side wall of the outer material guide box are connected, and the deflection frame is placed in the inner installation frame, and one end is hinged to one end of the inner installation frame through a hinge shaft, and a placement net is placed inside the deflection frame.

Owner:徐州果姿电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com