A water purifier rapid heating structure

A water purifier and water pipe technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as energy waste, and achieve the effects of improving safety, significant energy saving, and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

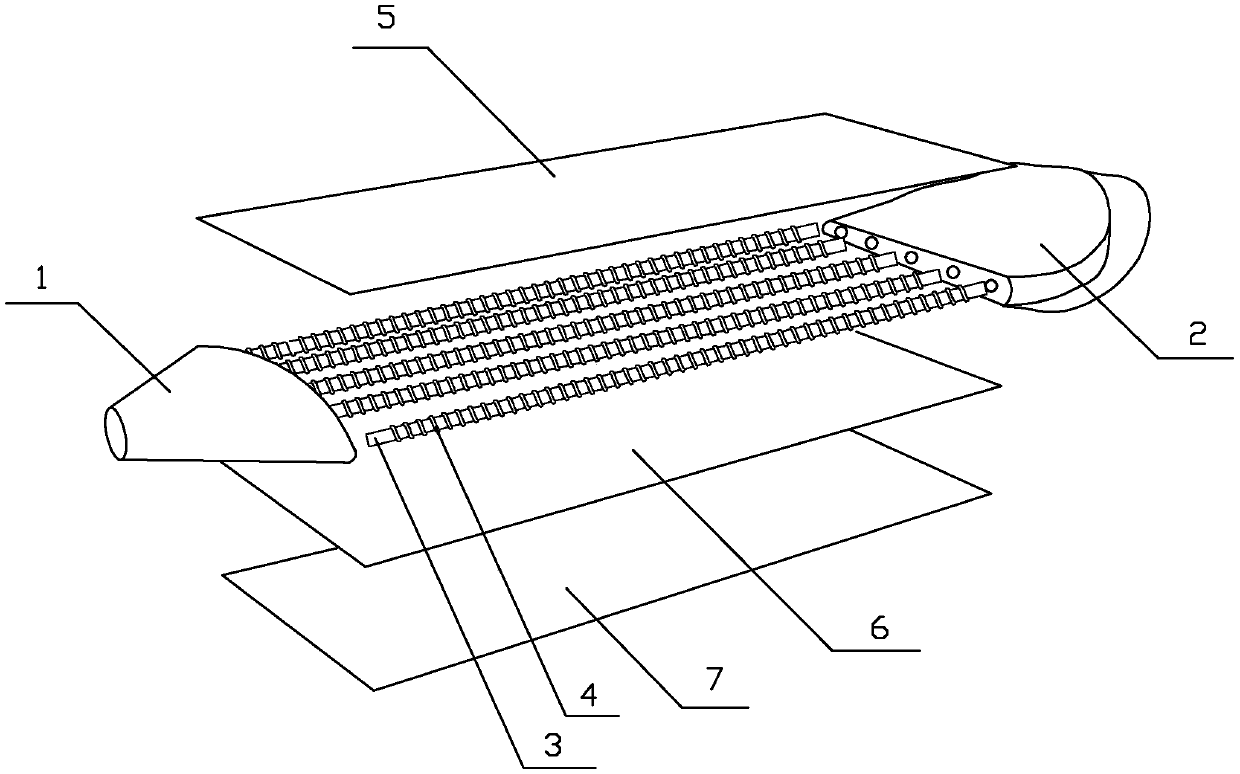

[0025] Embodiment: a kind of rapid heating structure of water purifier of this embodiment, such as figure 1 As shown, including 200 capillary tubes 3 between the water inlet cabin 1 and the water outlet cabin 2 of the water purifier, the 200 capillary tubes 3 are arranged side by side, and all the capillary tubes 3 are located on the same plane to form a heating layer, and each capillary tube 3 The inner diameter of the capillary is 0.5 mm, and the outer circumference of the wall of each capillary 3 is spirally wound with a carbon fiber infrared quartz electric heating tube 4 from the inlet of the capillary 3 to the outlet of the capillary 3 . A covering layer 5 is covered above the heating layer, an insulating layer 6 is placed below the heating layer, and a layer of stainless steel substrate 7 is placed below the insulating layer 6 . The water inlet compartment 1 is in the shape of a flattened horn. The water inlet of the water inlet compartment 1 is at the small head of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com