A kind of composite pig feed raw material feeding machine head material guide device

A material guide device and pig feed technology, applied in the field of livestock breeding, can solve the problems of increased mixing resistance, no pre-mixing, broken, simple structure, etc., to achieve the effect of easy mixing and avoiding the transmission of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

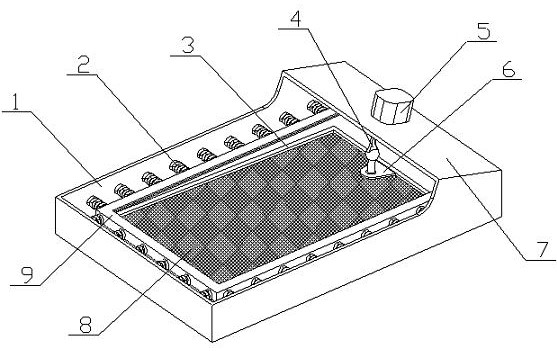

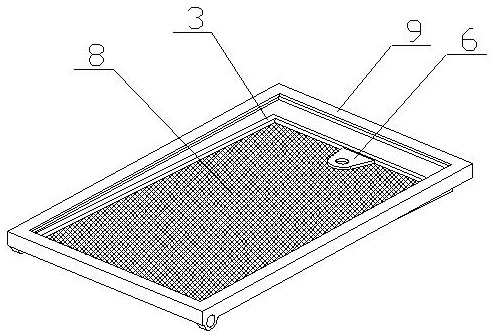

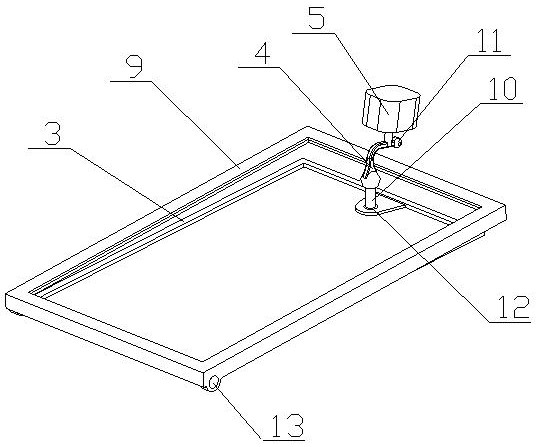

[0017] A kind of composite type pig feed raw material feeding machine head material guide device of the present invention is realized in this way, consists of outer material guide box (1), spring (2), deflection frame (3), connecting rod (4), drive motor ( 5), connecting plate (6), dust cover (7), placement net (8), inner mounting frame (9), deflection shaft (10), counterweight (11), bearing (12), hinge shaft (13 ), the drive rod (14) and the hinged ball head (15), the dust cover (7) is placed at one end of the outer material guide box (1), the top wall of the dust cover (7) is inclined, and the material is guided from the outside One end of the box (1) is gradually inclined upwards to the other end, the distance between the inner installation frame (9) and the inner wall of the outer material guide box (1) is twice the width of the frame of the inner material guide frame, and multiple springs (2) They are respectively placed between the outer side of the inner installation fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com