Opener

A technology of opening machine and loosening mechanism, which is applied in the direction of fiber opening and cleaning machine, electromechanical device, control mechanical energy, etc. It can solve the problems of affecting product quality, broken needles, damage of carding machine and acupuncture machine, etc., and achieves convenient installation or replacement components, avoiding loose connections, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

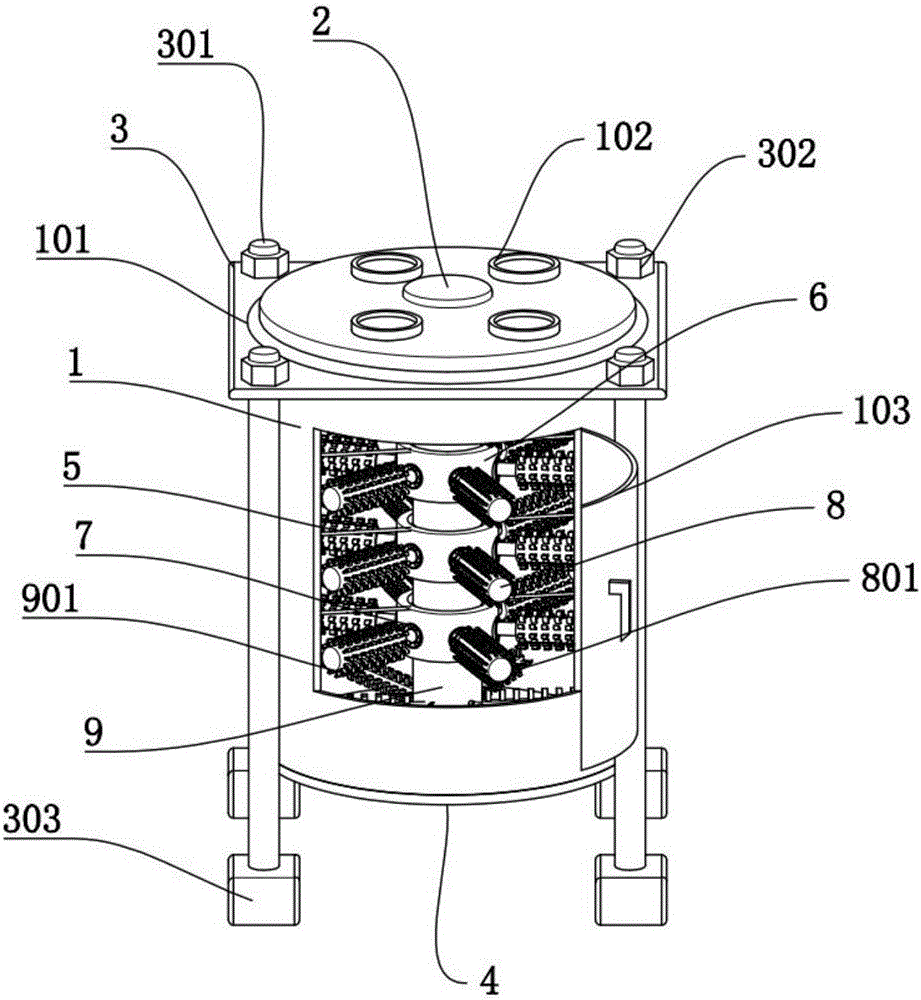

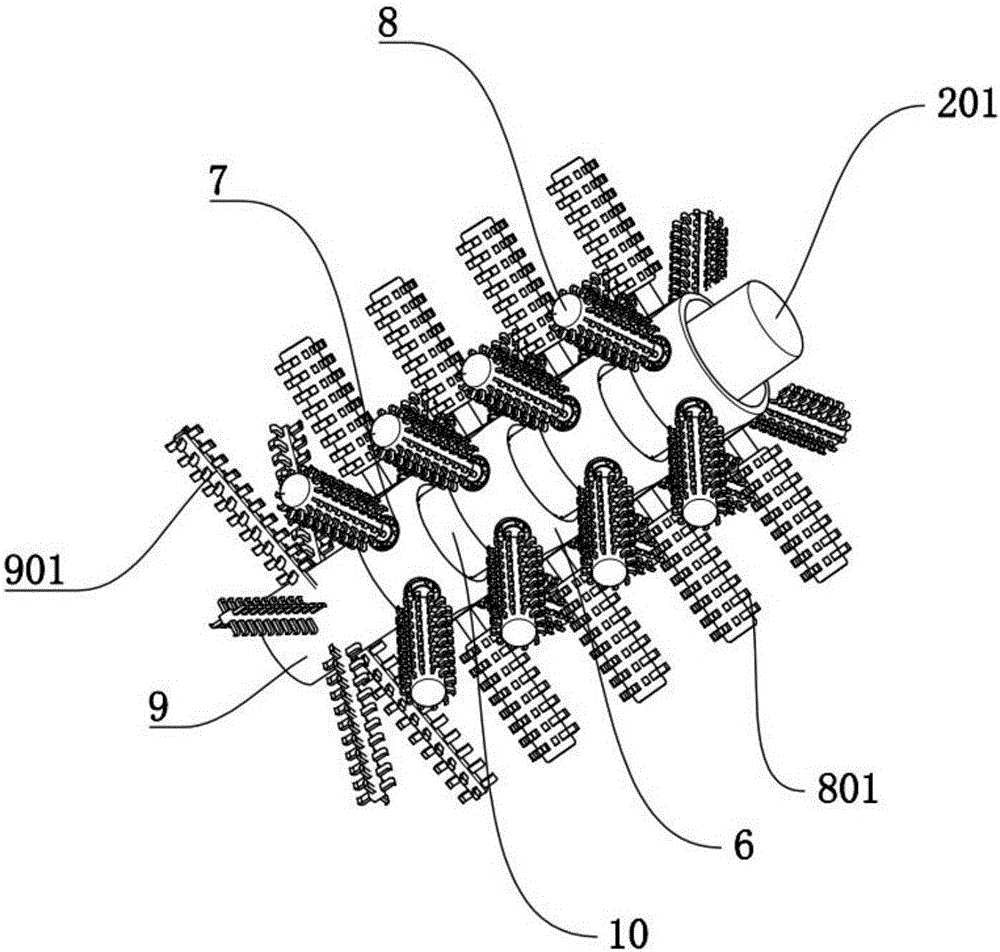

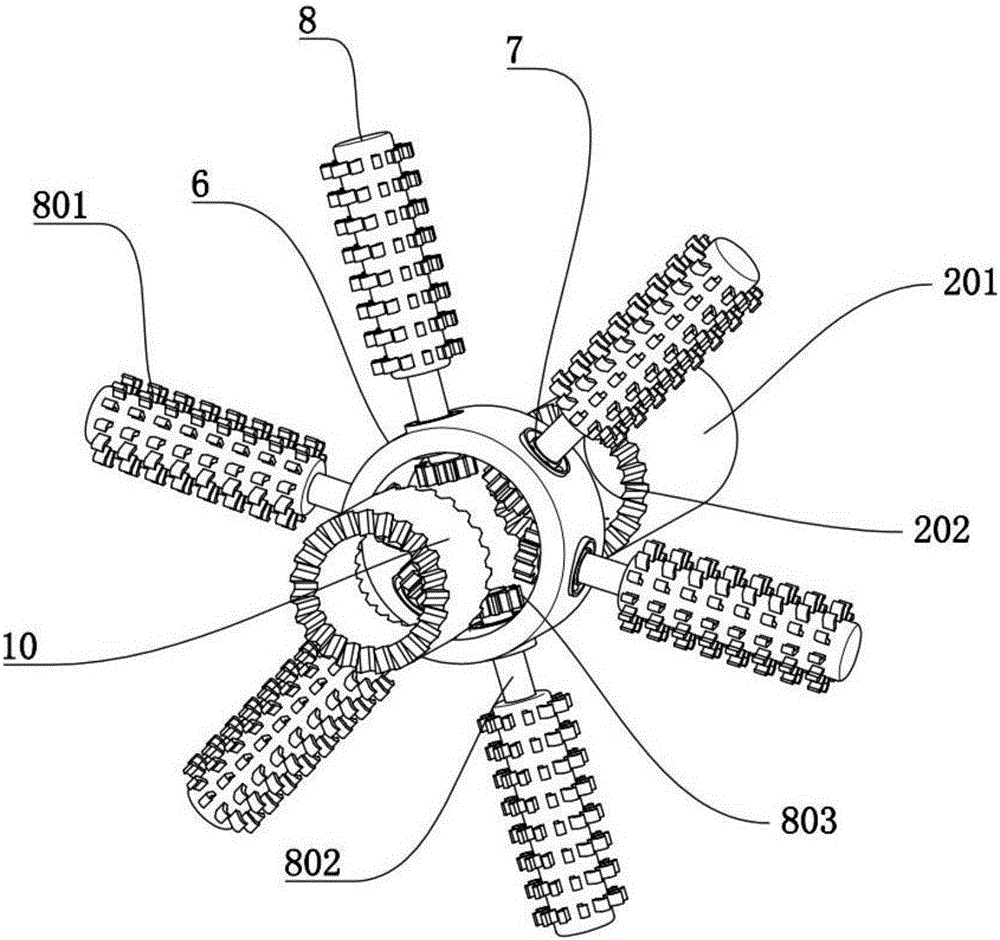

[0034]The invention discloses an opener, which includes a housing 1 and a driving mechanism. A sliding door 103 that can open or close the housing 1 is provided on the side wall of the housing 1. The upper end of the housing 1 is symmetrically arranged with multiple Each feeding port is provided with a feeding cover 102 that can open or close the feeding port. The driving mechanism includes a motor 2 positioned at the center of the upper end surface of the housing 1 and an opening mechanism driven by the motor 2. The opening mechanism A plurality of fixed rings 6 fixed inside the housing 1 and double-sided rotors 10 with meshing teeth 202 at both ends are distributed longitudinally at intervals, and the fixed ring 6 is fixedly connected to the inner wall of the housing 1 through a plurality of circularly distributed The support rod 5 is fixed, and a plurality of opening blocks 8 with hook-shaped opening teeth 801 are annularly installed on the fixed ring 6. The opening blocks 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com