Laser holographic ultramicron silver salt photosensitive material and preparation method thereof

A technology of laser holography and photosensitive materials, applied in photosensitive materials, optics, emulsified silver emulsion, etc., can solve the problems of particle distribution, uneven size, poor measurement accuracy of halogenation method, low resolution and diffraction efficiency, etc. and uniform distribution, suppression of fog, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

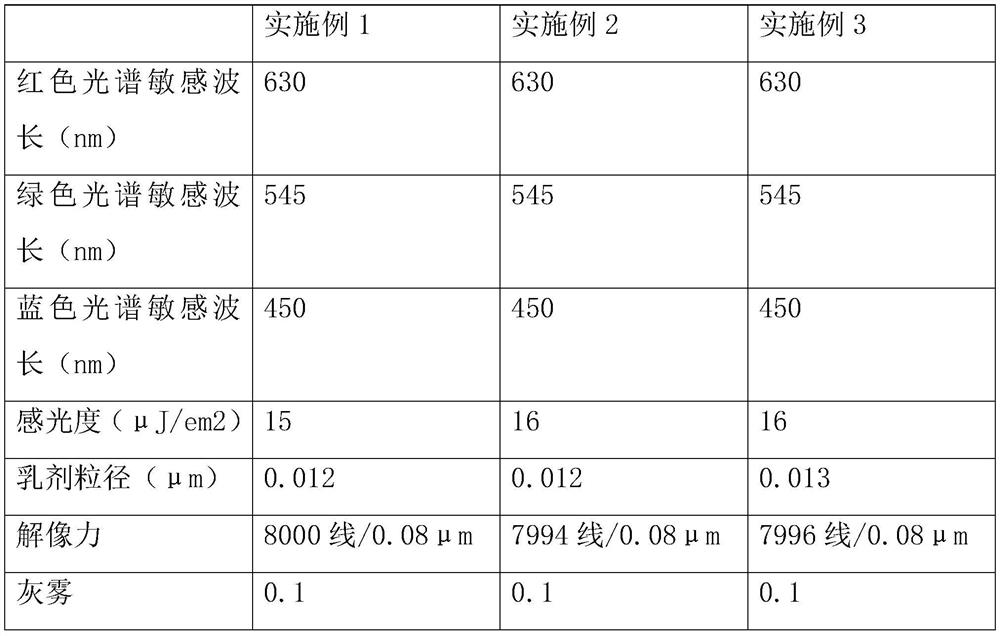

Examples

Embodiment 1

[0024] A laser holographic ultrafine silver salt photosensitive material, said laser holographic ultrafine silver salt photosensitive material is made of the following raw material components in parts by weight:

[0025] 300 parts of distilled water, 6.25 parts of gelatin, 2.35 parts of benzotriazole, 1.875 parts of potassium chromium sulfate dodecahydrate, 2.35 parts of metronidazole, 2.26 parts of silver nitrate, 4.275 parts of citric acid, 2.25 parts of p-tert-butylphenol, 1.65 parts of sodium benzenesulfinate, 2.55 parts of potassium bromide, 1.375 parts of magnesium chloride, 1.75 parts of disodium edetate, 5.615 parts of nitrophenylhydrazine, 3.725 parts of sodium sulfonate, 0.375 parts of phenol, 1.005 parts of formamide, 1.135 parts of thymol, 0.792 parts of methanol, and 0.85 parts of ethanol.

[0026] The preparation method of the above-mentioned laser holographic ultrafine particle silver salt photosensitive material, the steps are as follows:

[0027] S1. Preparat...

Embodiment 2

[0039] A laser holographic ultrafine silver salt photosensitive material, said laser holographic ultrafine silver salt photosensitive material is made of the following raw material components in parts by weight:

[0040] 290 parts of distilled water, 6.20 parts of gelatin, 2.30 parts of benzotriazole, 1.850 parts of potassium chromium sulfate dodecahydrate, 2.30 parts of metronidazole, 2.20 parts of silver nitrate, 4.270 parts of citric acid, 2.20 parts of p-tert-butylphenol, 1.6 parts of sodium benzenesulfinate, 2.5 parts of potassium bromide, 1.370 parts of magnesium chloride, 1.70 parts of disodium edetate, 5.610 parts of nitrophenylhydrazine, 3.720 parts of sodium sulfonate, 0.370 parts of phenol, 1.000 parts of formamide, 1.130 parts of thymol, 0.790 parts of methanol, and 0.80 parts of ethanol.

[0041] The preparation method of the above-mentioned laser holographic ultrafine particle silver salt photosensitive material, the steps are as follows:

[0042] S1. Preparatio...

Embodiment 3

[0054] A laser holographic ultrafine silver salt photosensitive material, said laser holographic ultrafine silver salt photosensitive material is made of the following raw material components in parts by weight:

[0055] 310 parts of distilled water, 6.30 parts of gelatin, 2.40 parts of benzotriazole, 1.900 parts of potassium chromium sulfate dodecahydrate, 2.40 parts of metronidazole, 2.30 parts of silver nitrate, 4.280 parts of citric acid, 2.30 parts of p-tert-butylphenol, 1.7 parts of sodium benzenesulfinate, 2.6 parts of potassium bromide, 1.380 parts of magnesium chloride, 1.80 parts of disodium edetate, 5.620 parts of nitrophenylhydrazine, 3.730 parts of sodium sulfonate, 0.380 g of phenol, 1.010 parts of formamide, 1.140 g of thymol, 0.795 parts of methanol, and 0.90 parts of ethanol.

[0056] The preparation method of the above-mentioned laser holographic ultrafine particle silver salt photosensitive material, the steps are as follows:

[0057] S1. Preparation of liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com