Patents

Literature

73 results about "Sodium benzenesulfinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium benzenesulfinate purum, ≥97.0% (HPLC) Synonym: Benzenesulfinic acid sodium salt CAS Number 873-55-2. Linear Formula C 6 H 5 SO 2 Na . Molecular Weight 164.16 . Beilstein Registry Number 3598405 . EC Number 212-842-8. MDL number MFCD00013135. PubChem Substance ID 329749770

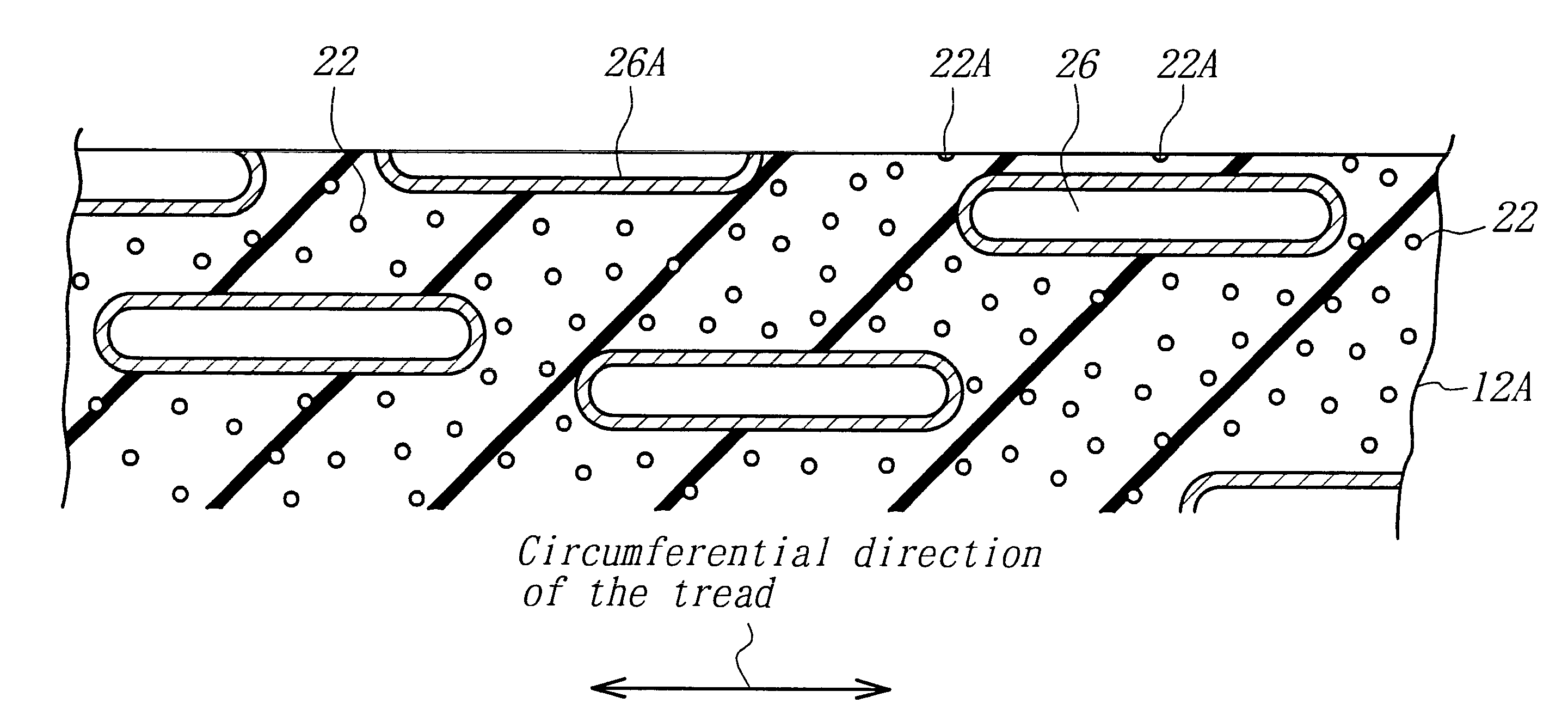

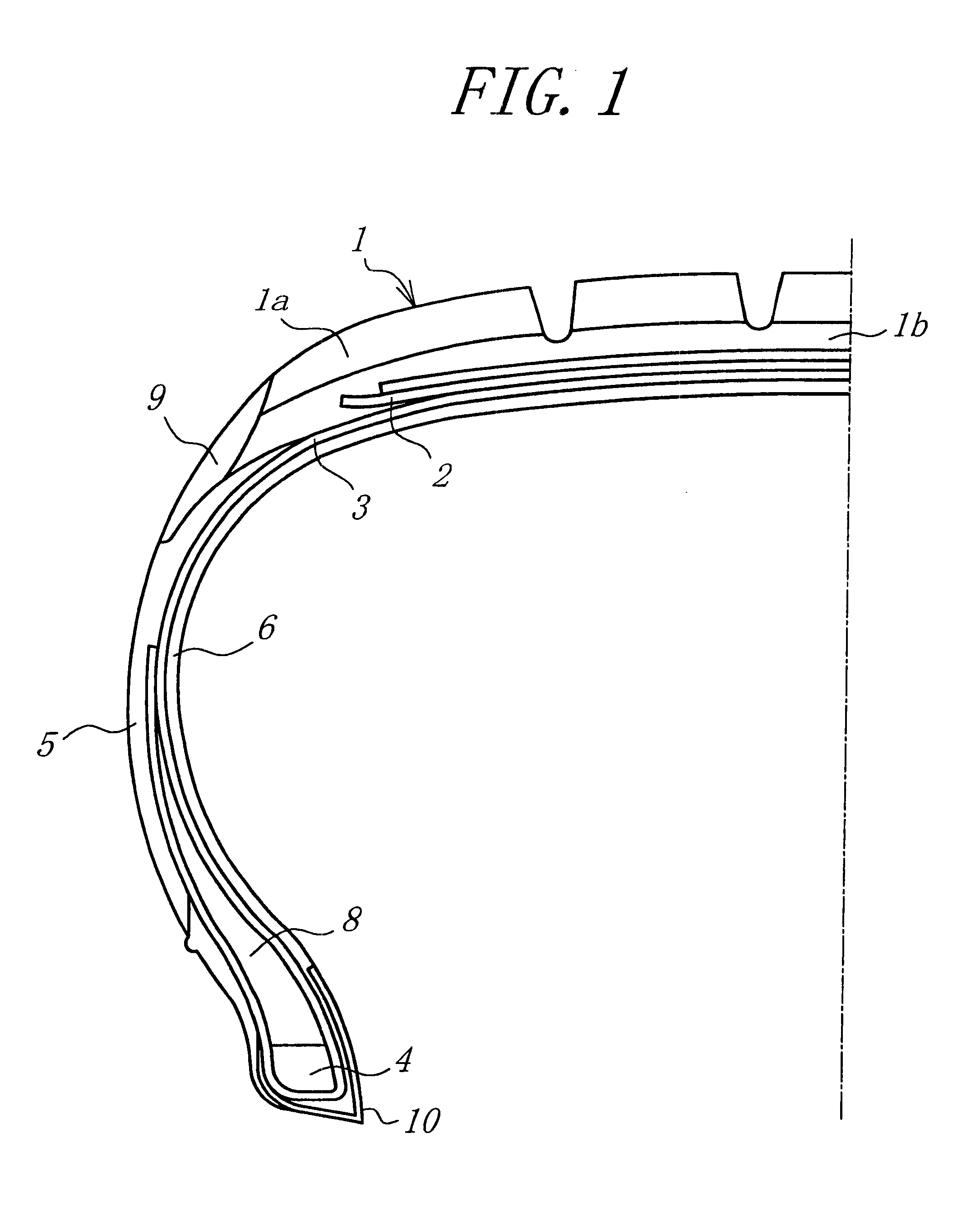

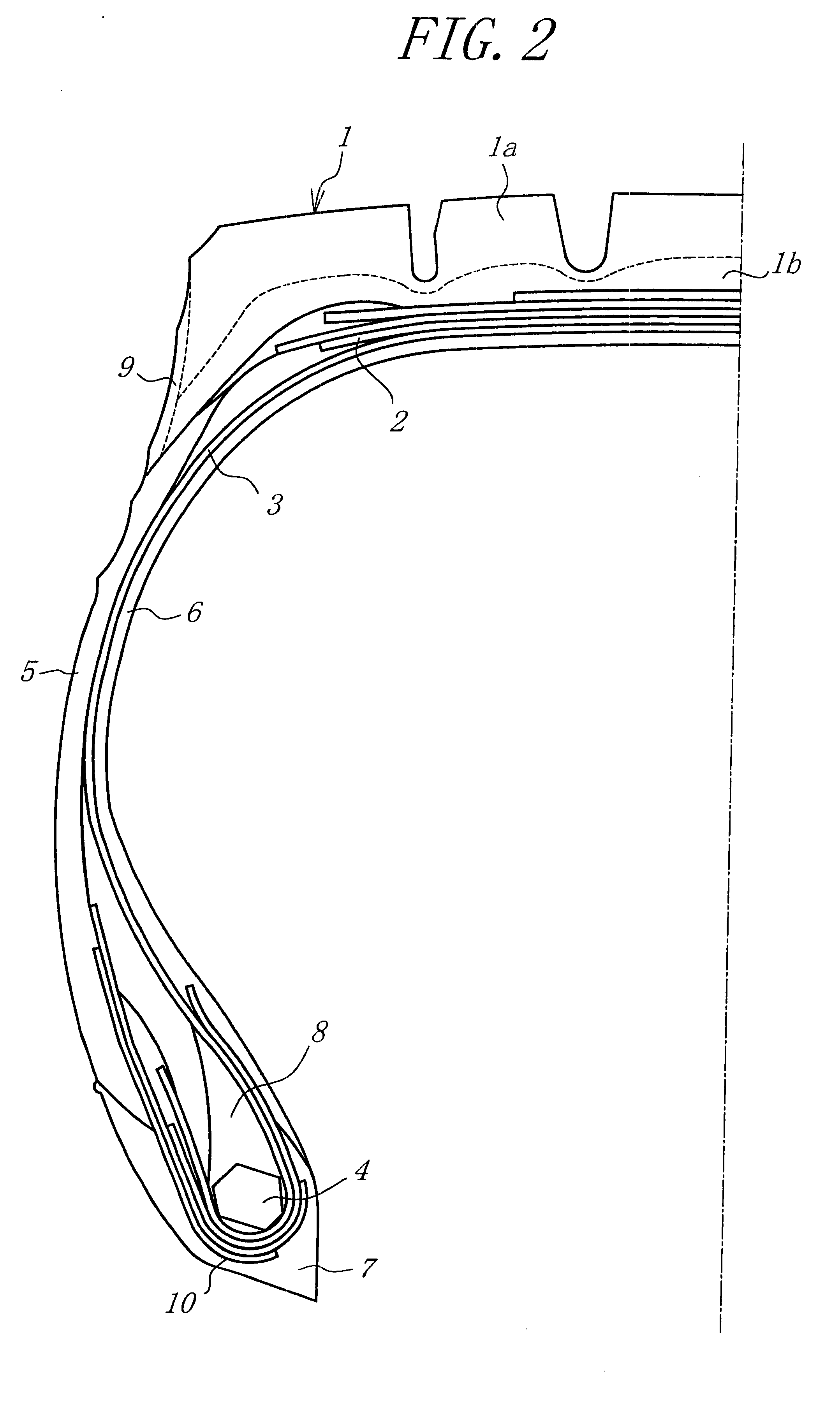

Pneumatic tire having tread made of foamed rubber composition

InactiveUS6497261B1Improve wear resistance propertyImprove performanceSpecial tyresTyre tread bands/patternsCompound aFoaming agent

This invention relates to a pneumatic tire comprising a tread at least a surface portion of which is made of a foamed rubber composition, the foamed rubber composition including closed cells formed by compounding a foaming agent and a foaming assistant which contains sodium benzenesulfinate or a combination of sodium benzenesulfinate and urea.

Owner:BRIDGESTONE CORP

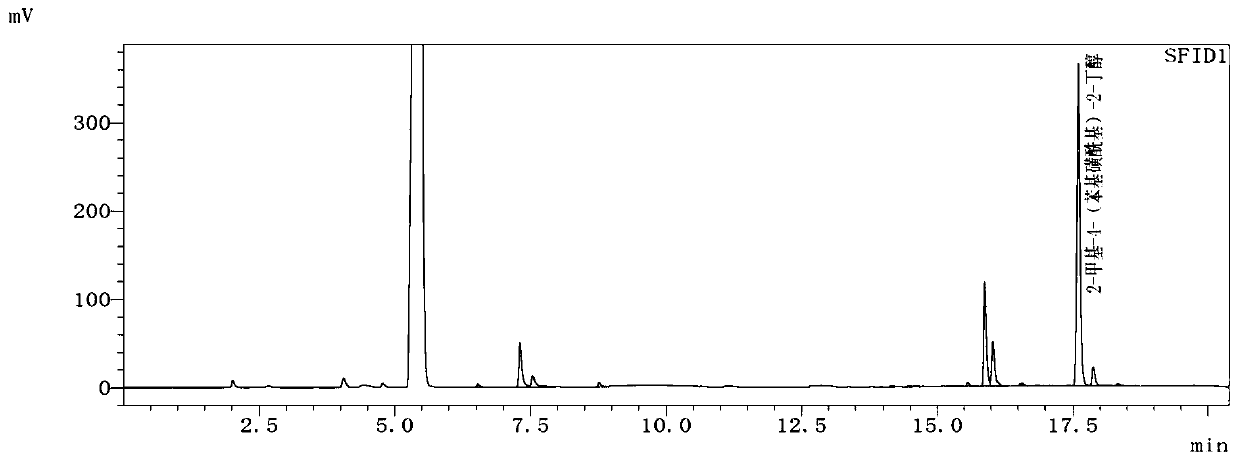

2-phenyl-3-(benzenesulfonyl)imidazo[1,2-a]pyridine compound and synthetic method thereof

InactiveCN107663209ARich types of functionalization reactionsEasy to purifyOrganic chemistryChromatographic separationLeaving group

The invention discloses a 2-phenyl-3-(benzenesulfonyl)imidazo[1,2-a]pyridine compound and a synthetic method thereof. The synthetic method comprises the following steps: adding a 2-phenyl-imidazo[1,2-a]pyridine compound and sodium benzenesulfinate into a high-pressure tube in an air environment, adding an iodine elementary substance and sodium carbonate, then adding an ethyl ether solvent, and reacting at the temperature of 100 DEG C for 24 to 48 hours; after the reaction, performing chromatographic separation and drying to obtain a target product. In the reaction, the inexpensive elemental iodine is taken as a catalyst, and ethyl ether is taken as a reaction solvent, so that sulfonylation reaction of the imidazo[1,2-a]pyridine compound and the sodium benzenesulfinate is realized, a sulfonyl group of the obtained compound can be taken as a leaving group, and further functionalization reaction is realized. The method has important significance to the research and application of the sulfonylation reaction of the imidazo[1,2-a]pyridine compound.

Owner:ZHENGZHOU UNIV

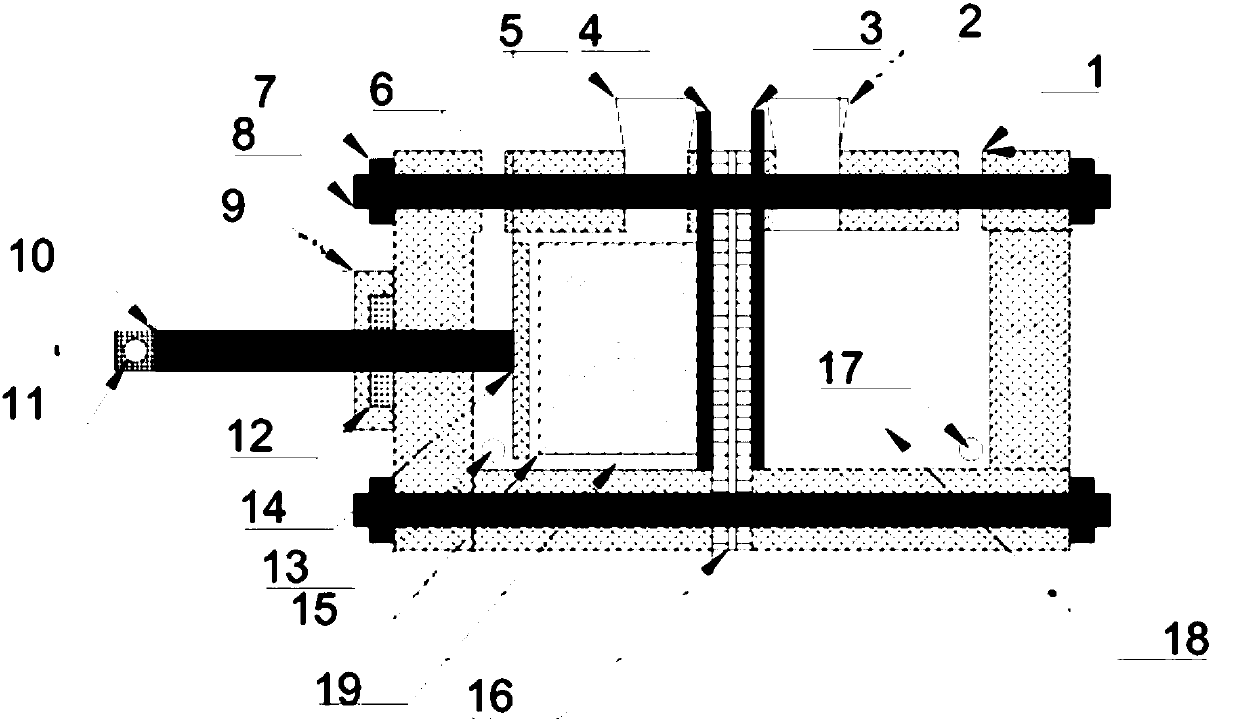

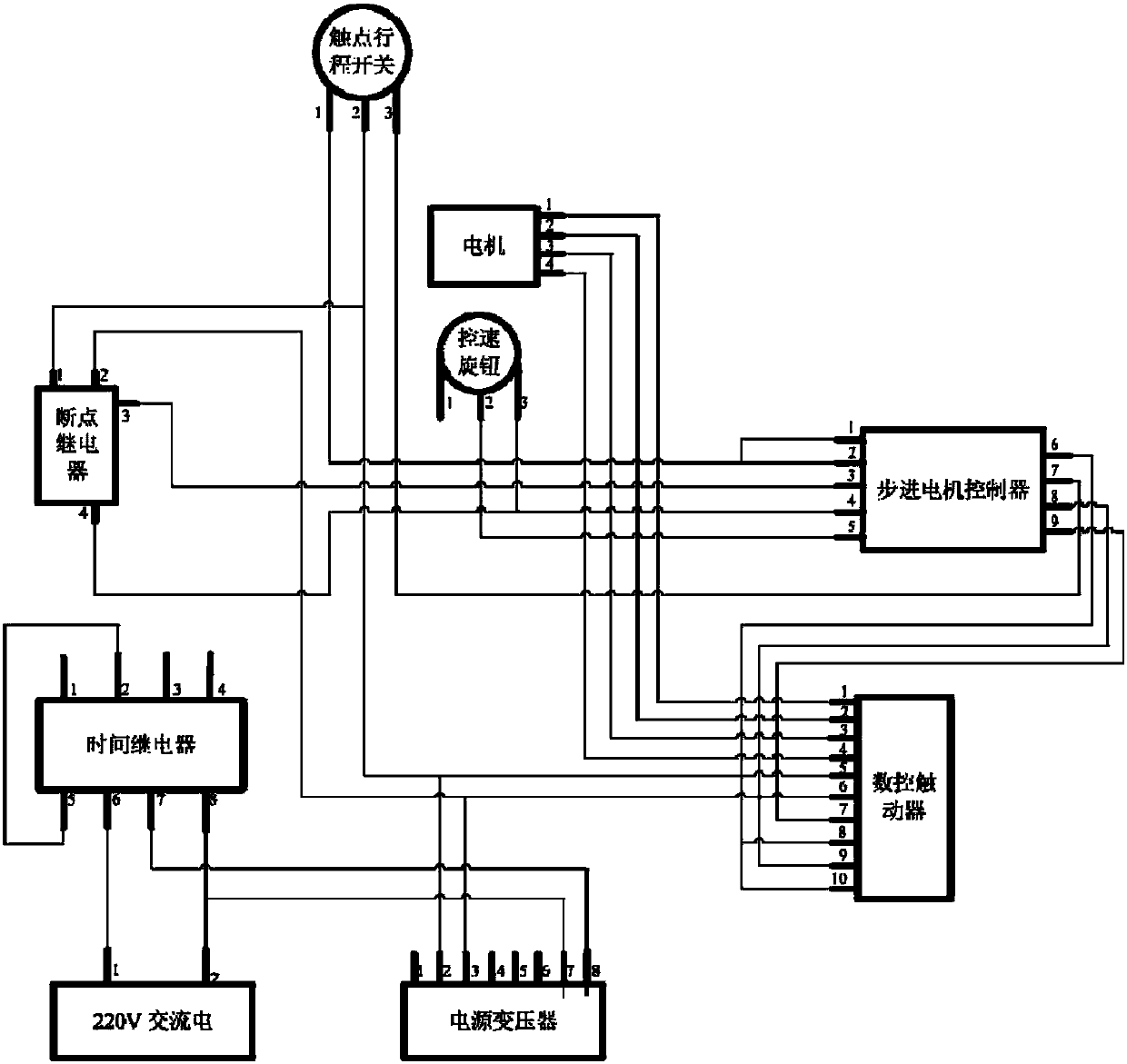

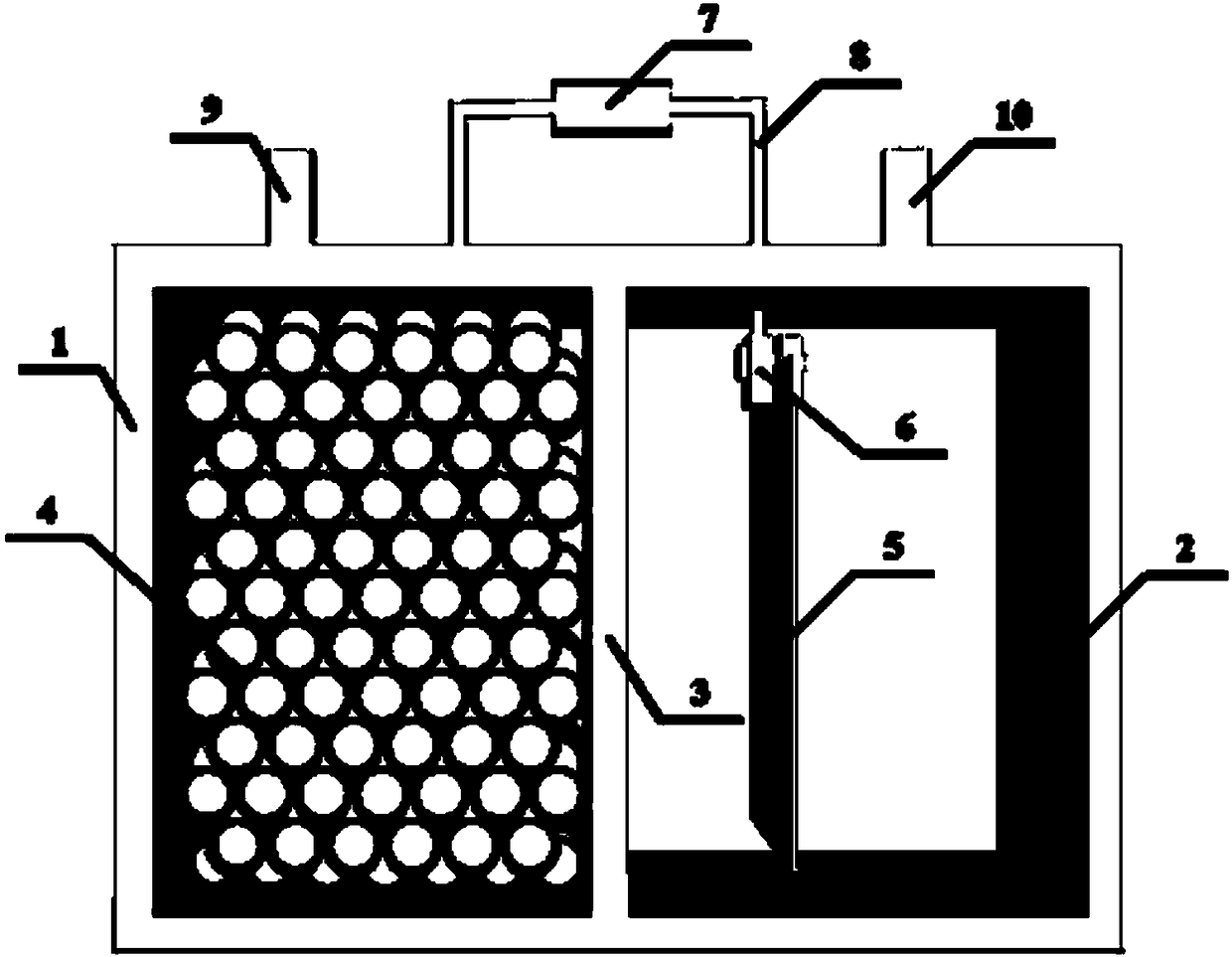

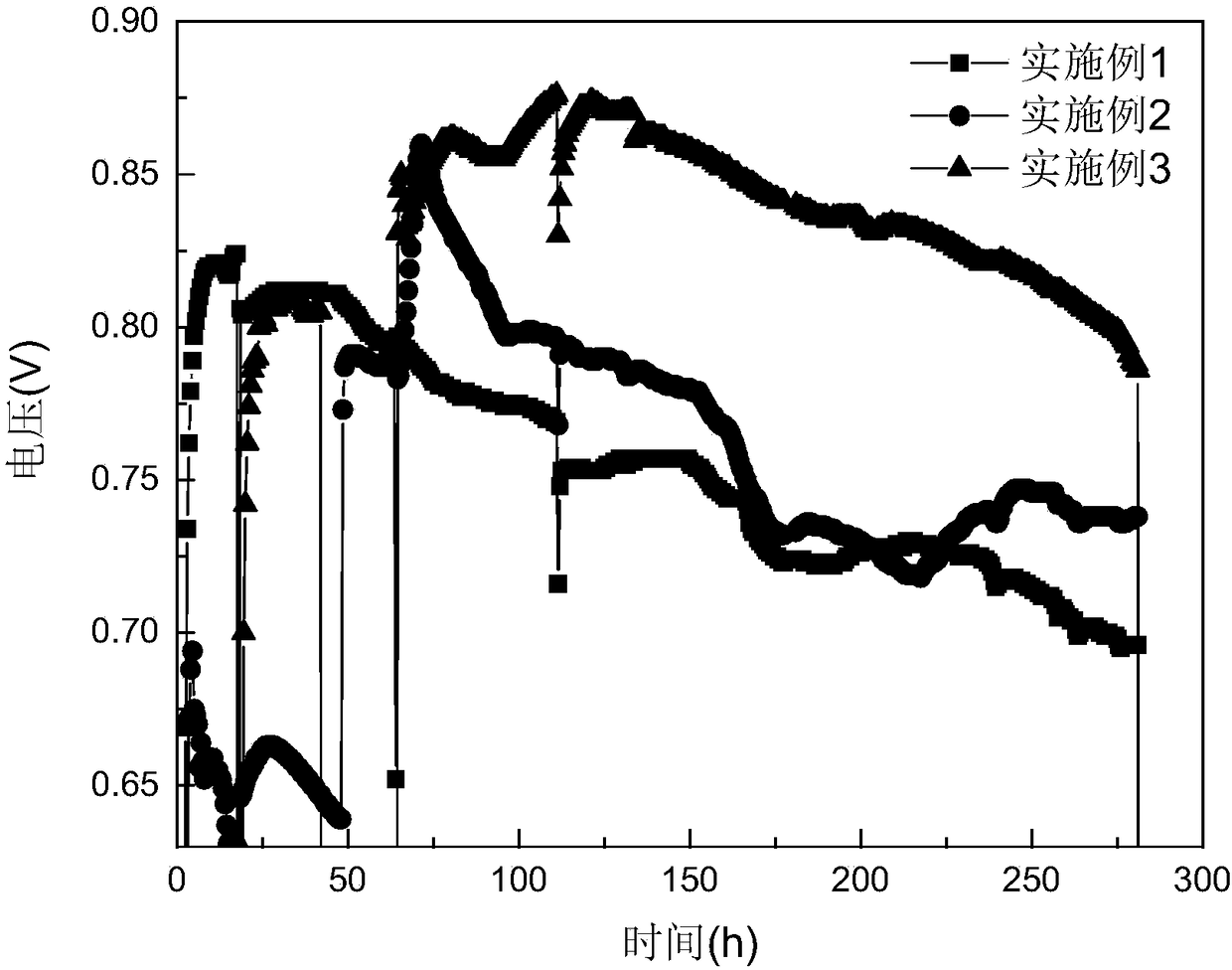

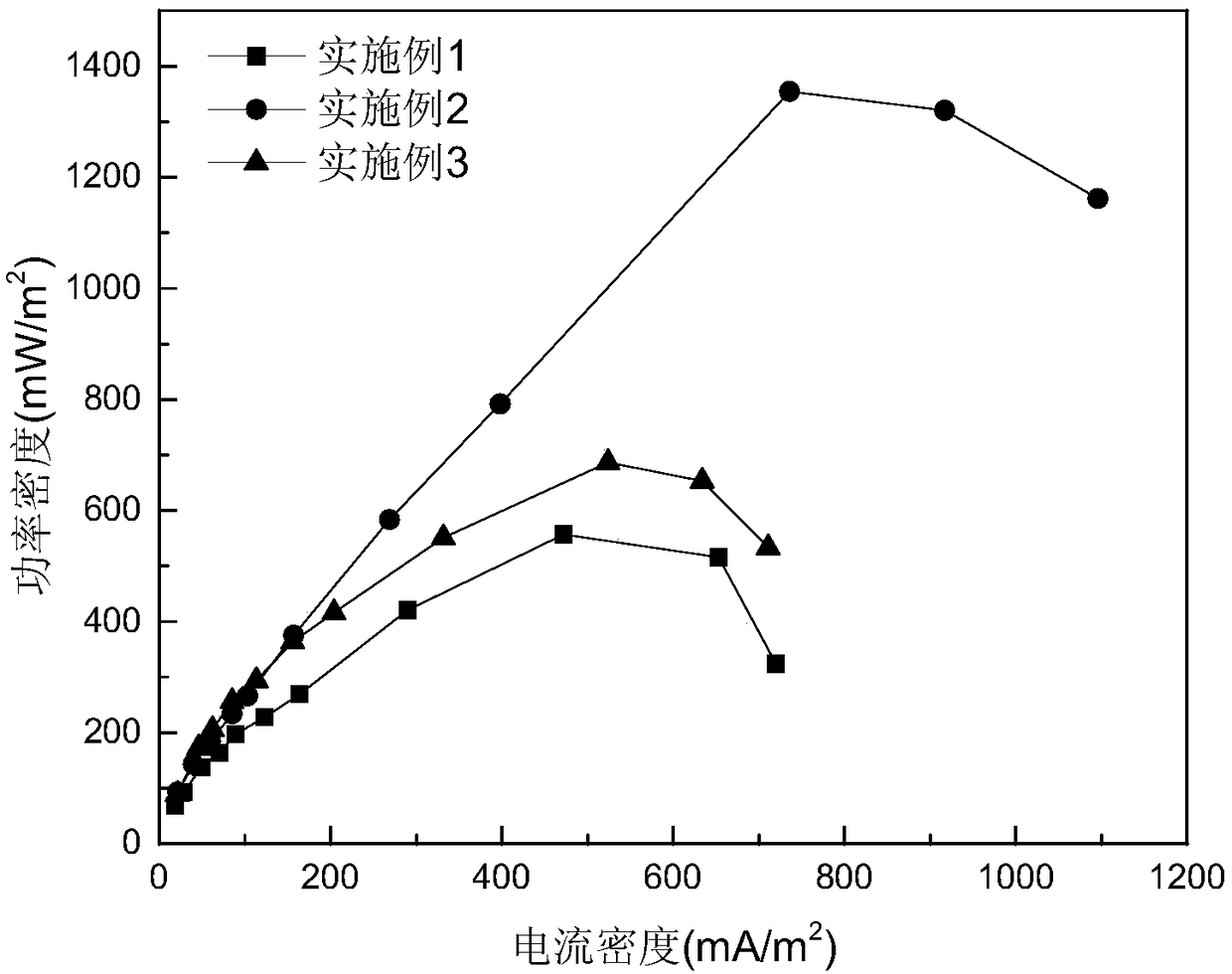

Magnetic three-dimensional gel-sphere anode material of microbial fuel cell and preparation method

ActiveCN108183243ASimple methodMild conditionsCell electrodesFinal product manufactureBiocompatibility TestingSlurry

The invention discloses a magnetic three-dimensional gel-sphere anode material of a microbial fuel cell and a preparation method. The preparation method comprises the following specific steps: (1) dropwise adding a FeCl2 solution into a graphene oxide dispersion solution to obtain a graphene oxide-FeCl2 dispersion solution; (2) dropwise adding sodium benzenesulfinate into the dispersion solution drop by drop, so as to obtain a graphene oxide-FeCl2-sodium benzenesulfinate dispersion solution; (3) adding glacial acetic acid into the dispersion solution; (4) adding chitosan into the dispersion solution to obtain slurry; (5) adding the slurry into a NaOH solution to obtain gel spheres; (6) heating the gel spheres at constant temperature to obtain a gel-sphere anode. The method disclosed by theinvention is simple and has moderate conditions and low production cost; an obtained electrode has a large specific surface area and good biocompatibility; the gel-sphere electrode is used as anode chamber filling of the microbial fuel cell; the transferring capability of extracellular electrons is increased and the space utilization rate of an anode chamber is also greatly improved.

Owner:SHANGHAI INST OF TECH

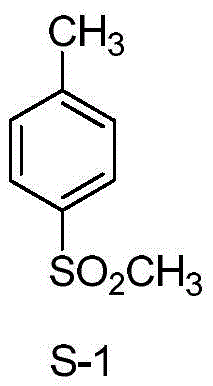

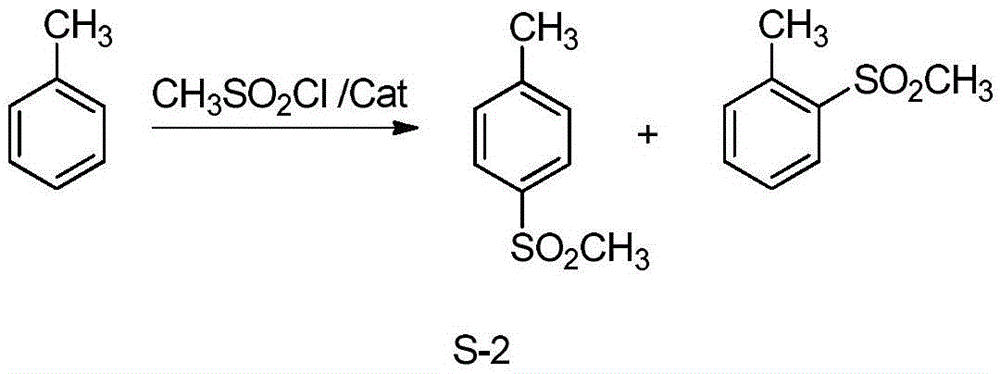

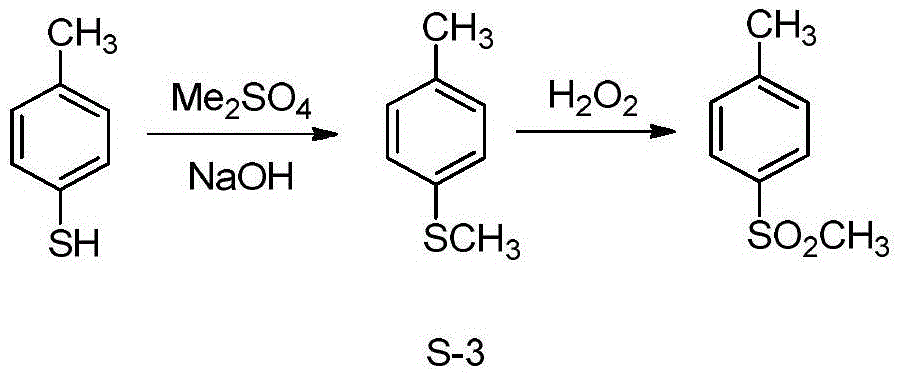

Synthetic method of 4-methylsulfonyl methylbenzene

ActiveCN105566181AReduce lossesHigh yieldOrganic chemistryOrganic compound preparationSulfonyl chlorideFiltration

The invention discloses a synthetic method of 4-methylsulfonyl methylbenzene. The method comprises the following steps in sequence: by taking 4-toluene sulfonyl chloride as a start material, feeding through fusion, performing a reduction reaction between the 4-toluene sulfonyl chloride and sodium sulfite in an alkali aqueous solution so as to generate sodium 4-methyl benzene sulfinate; performing a methylation reaction between the sodium 4-methyl benzene sulfinate and chloromethane, enabling a reaction product to be subjected to the post treatment such as filtration and recrystallization to obtain the product 4-methylsulfonyl methylbenzene. According to the invention, chlorosulfonyl is converted into methylsulfonyl in a one-pot manner; production equipment and technological operation are simplified, the loss brought about by material transfer is reduced, and the product yield is improved.

Owner:江西扬帆新材料有限公司

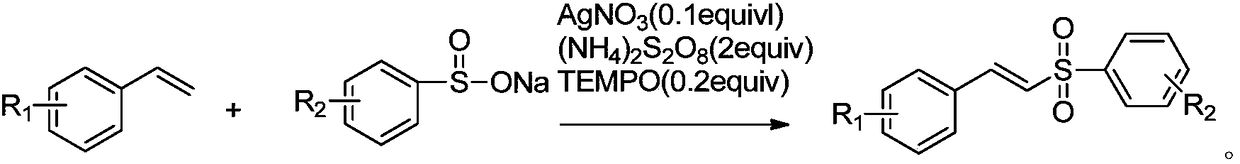

Method for synthesizing (E)-(2-(phenylsulfonyl)vinyl)benzene and derivative thereof

InactiveCN108191718AHigh yieldLow costOrganic chemistryOrganic compound preparationBenzenePersulfate

The invention provides a method for synthesizing (E)-(2-(phenylsulfonyl)vinyl)benzene and a derivative thereof. The method adopts styrene or a derivative of styrene as a reactant A and sodium benzenesulfinate or a derivative of sodium benzenesulfinate as a reactant B, and the reactant A and the reactant B react under the oxidation of persulphate to generate (E)-(2-(acyl)vinyl)benzene and the derivative thereof. Compared with the conventional method utilizing thioether oxidation, sulfur dioxide addition, Friedel-Crafts sulfonylation and transition metal catalysis coupling, the method increasesyield, and since the method utilizes relatively cheap persulphate as oxidant to carry out reaction, the cost of synthesis is reduced.

Owner:HUNAN AGRICULTURAL UNIV

Alkaline electrolyte and nickel electroplating method in alkaline system

InactiveCN105951133ASolve the problem of blackening and brittle electroplating nickelImprove bindingSurface oxidationBinding force

The invention discloses an alkaline electrolyte and a nickel electroplating method in an alkaline system. The alkaline electrolyte comprises nickel chloride, ammonium chloride, ammonium hydroxide, sodium benzene sulphinate and water, the concentration of nickel chloride is 30 to 500g / L; the concentration of ammonium chloride is 40 to 400g / L; the concentration of ammonium hydroxide is 50 to 500g / L; and the concentration of sodium benzene sulphinate is 0.05 to 2g / L. The nickel electroplating method in the alkaline system comprises the steps of (1) preparing the alkaline electrolyte; (2) carrying out surface oxidation layer removing and deoiling treatment on a cathode material, and soaking an anode material in hydrochloric acid to remove surface impurities; and (3) putting the cathode material and the anode material subjected to pretreatment in an electrolytic bath holding the alkaline electrolyte for electrodeposition, taking out the cathode material, washing with water, and drying the cathode material by blowing with cold air to obtain a bright and flat nickel-plated layer. According to the alkaline electrolyte and the nickel electroplating method, the problem that a deposited nickel layer is black and brittle can be effectively solved through the alkaline electrolyte, flat and bright nickel is electroplated successfully, and the method has the advantages that the current efficiency is high and the prepared nickel is bright in color and good in toughness and binding force.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH

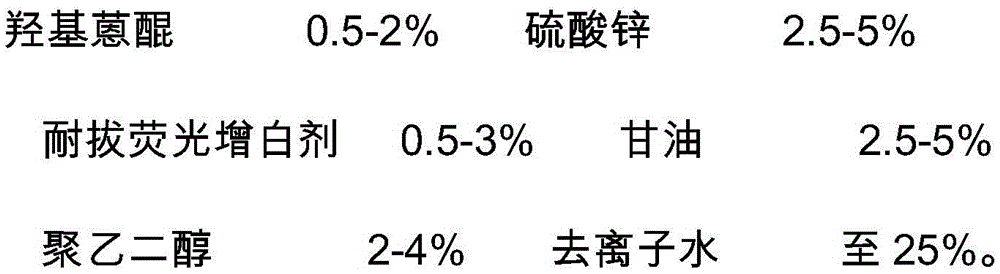

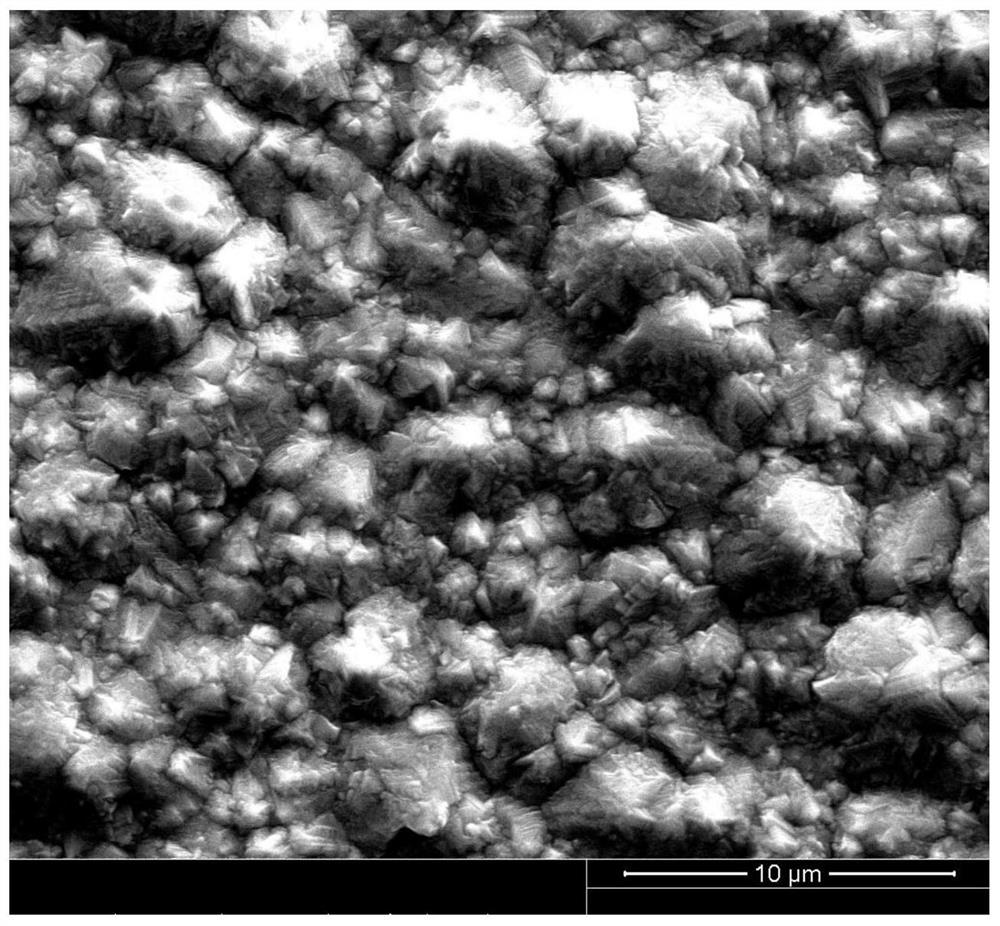

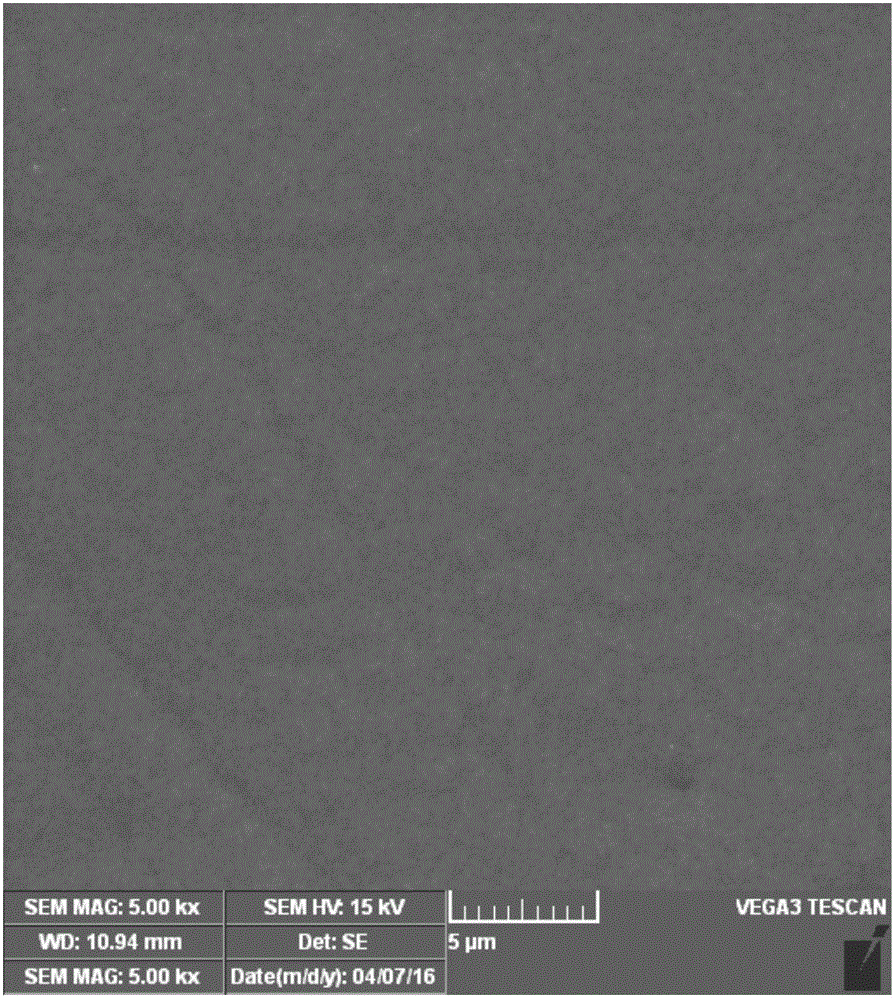

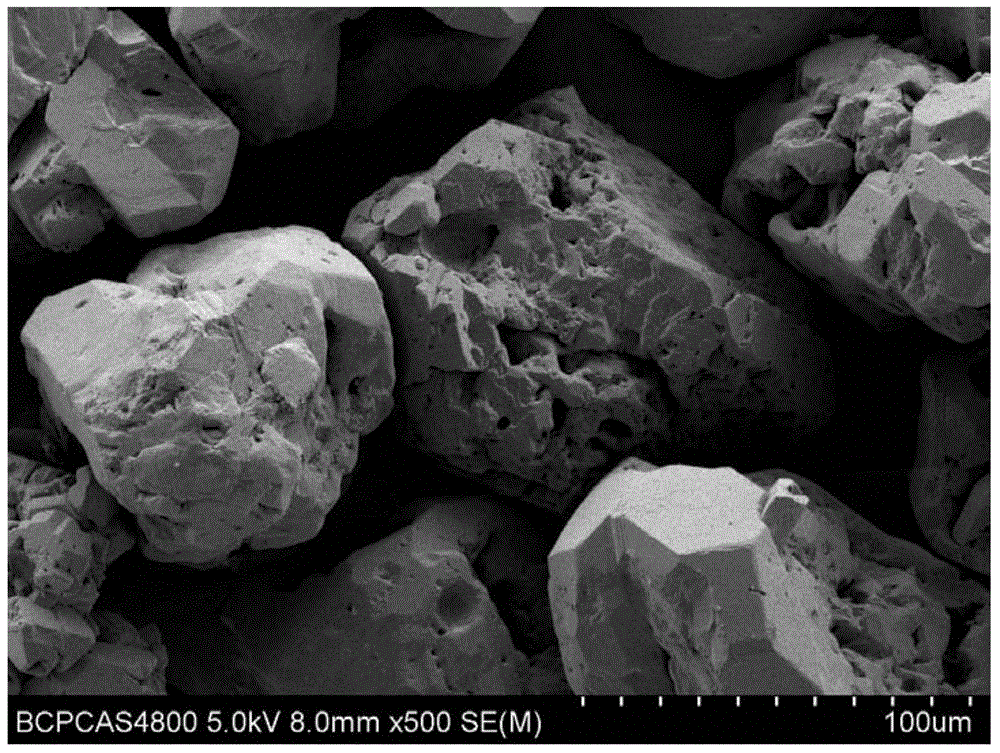

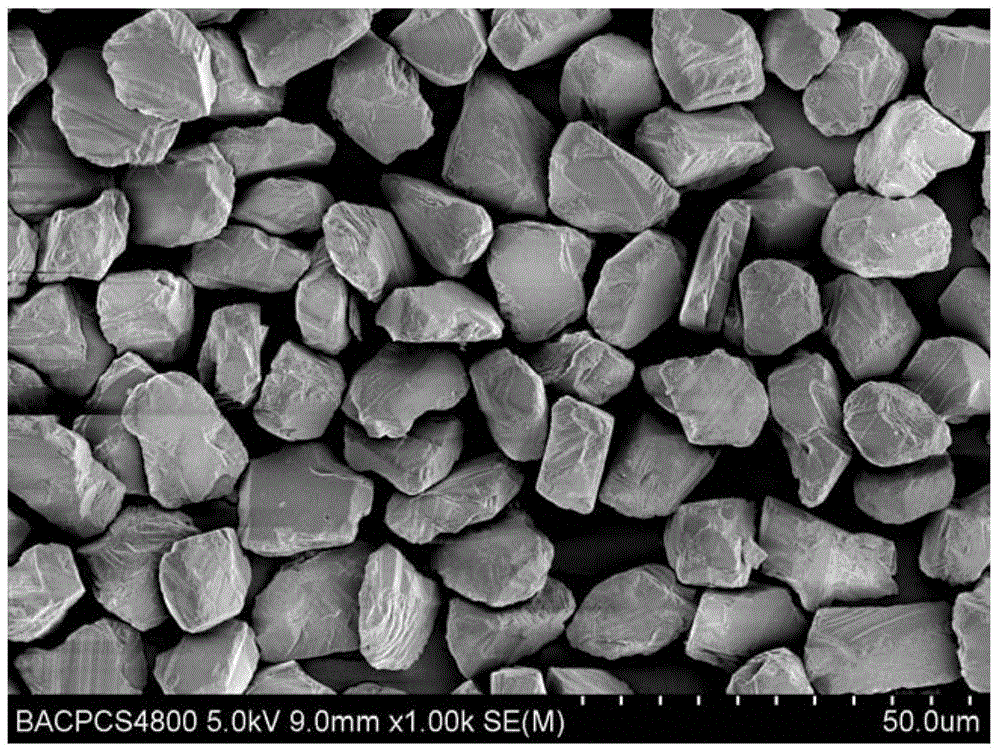

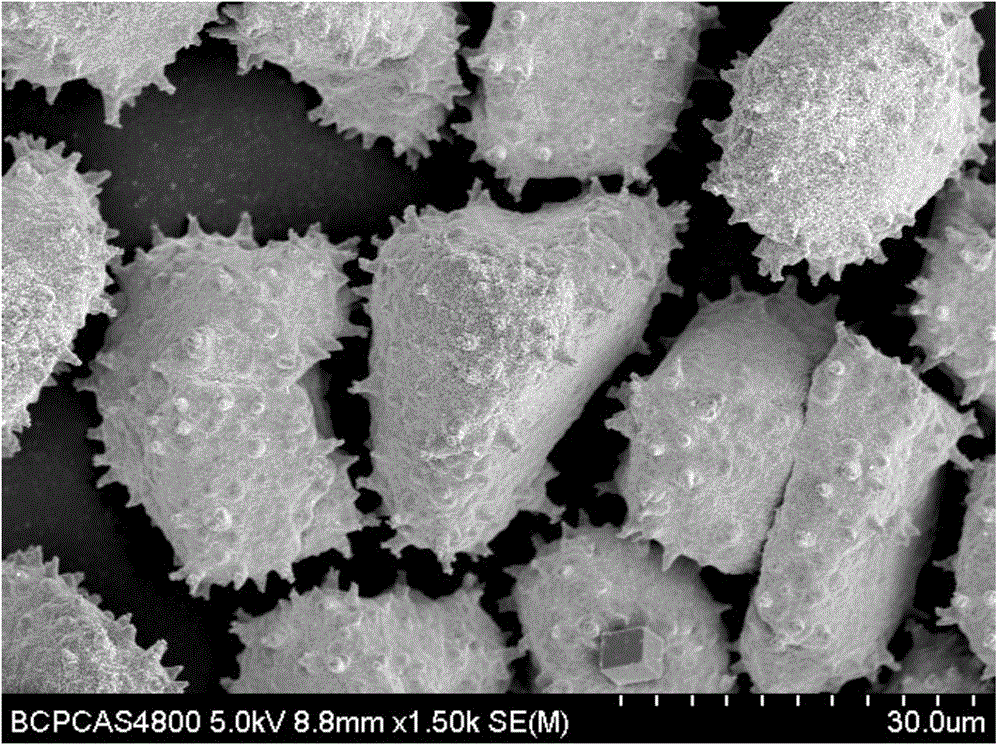

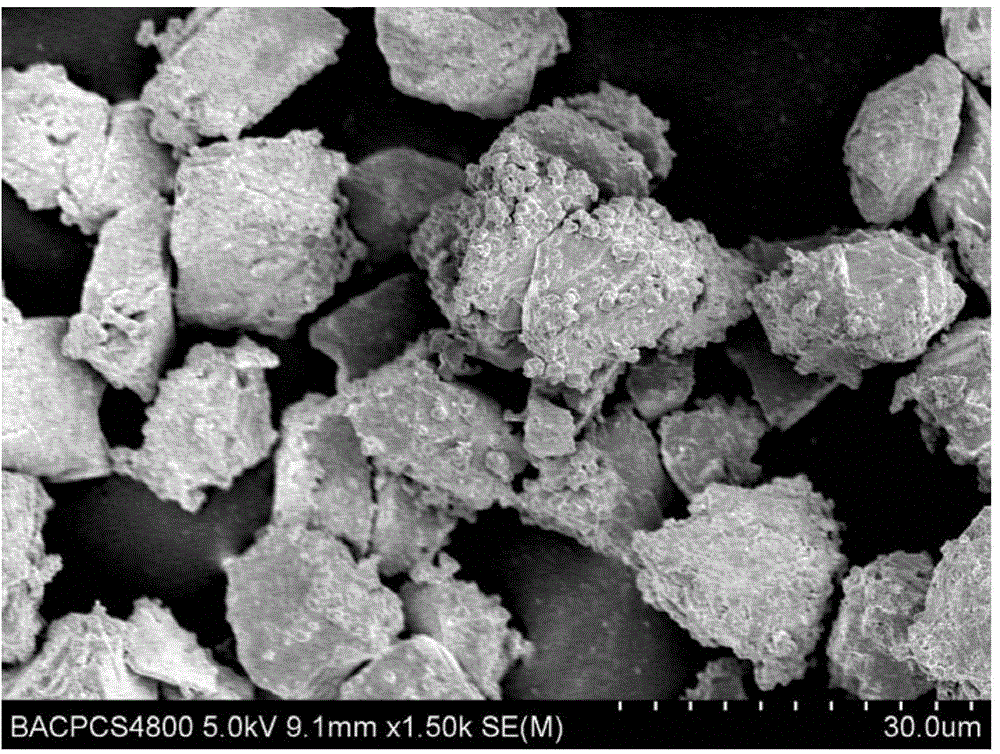

Chemical plating solution for preparing nickel splinter plated diamond abrasive particle, and chemical plating method

ActiveCN104947095AReduce deposition rateFast depositionLiquid/solution decomposition chemical coatingSodium acetateChemical plating

The invention relates to a chemical plating solution for preparing a nickel splinter plated diamond abrasive particle, and a chemical plating method. The chemical plating solution is an aqueous solution containing nickel sulfate, sodium hypophosphate, sodium citrate, sodium acetate, a stabilizing agent, aminobenzenesulfonic acid and sodium benzenesulfinate. A layer of metallic nickel is deposited on the surface of a diamond particle by using an oxidation reduction reaction through adopting the chemical plating method to form splinter-shaped protrusions in order to prepare diamond abrasive particle with a nickel splinter layer. The abrasive particle has high specific surface area, and can be widely used in diamond tools made of a resin binder to increase the holding force between diamond and the resin and increase the heat conductivity of products of the tools in order to enhance the grinding efficiency of produced tools and prolong the life of the tools.

Owner:北京国瑞升精机科技有限公司

Alkaline electrolyte and method for preparing bright nickel by means of electrolysis in alkaline electrolyte

InactiveCN105908223ASolve the problem of blackening and brittle electrolytic nickelImprove toughnessSodium saltImpurity

The invention discloses an alkaline electrolyte and a method for preparing bright nickel by means of electrolysis in the alkaline electrolyte. The alkaline electrolyte comprises nickel chloride, ammonium chloride, ammonia water, benzene sulfinic acid sodium salt and water, wherein the concentration of nickel chloride is 50g / L to 400g / L; the concentration of ammonium chloride is 80g / L to 450g / L; the concentration of ammonia water is 30g / L to 350g / L; the concentration of benzene sulfinic acid sodium salt is 0.03g / L to 1g / L. The method for preparing bright nickel by means of electrolysis in the alkaline electrolyte comprises the following steps: (1) preparing the alkaline electrolyte; (2) removing surface oxide layers of a cathode material, degreasing the cathode material, and soaking an anode material in nitric acid to remove the surface oxide layers and impurities; (3) performing electro-deposition on the pretreated cathode material and anode material in an electrolytic cell containing the alkaline electrolyte to obtain a bright and smooth nickel layer. The alkaline electrolyte disclosed by the invention is capable of effectively solving the difficult problem that a deposited nickel layer is black and fragile and can be used for successfully preparing bright nickel; the method has the advantages that the current efficiency is high, the prepared nickel is bright and good in toughness and the like.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH

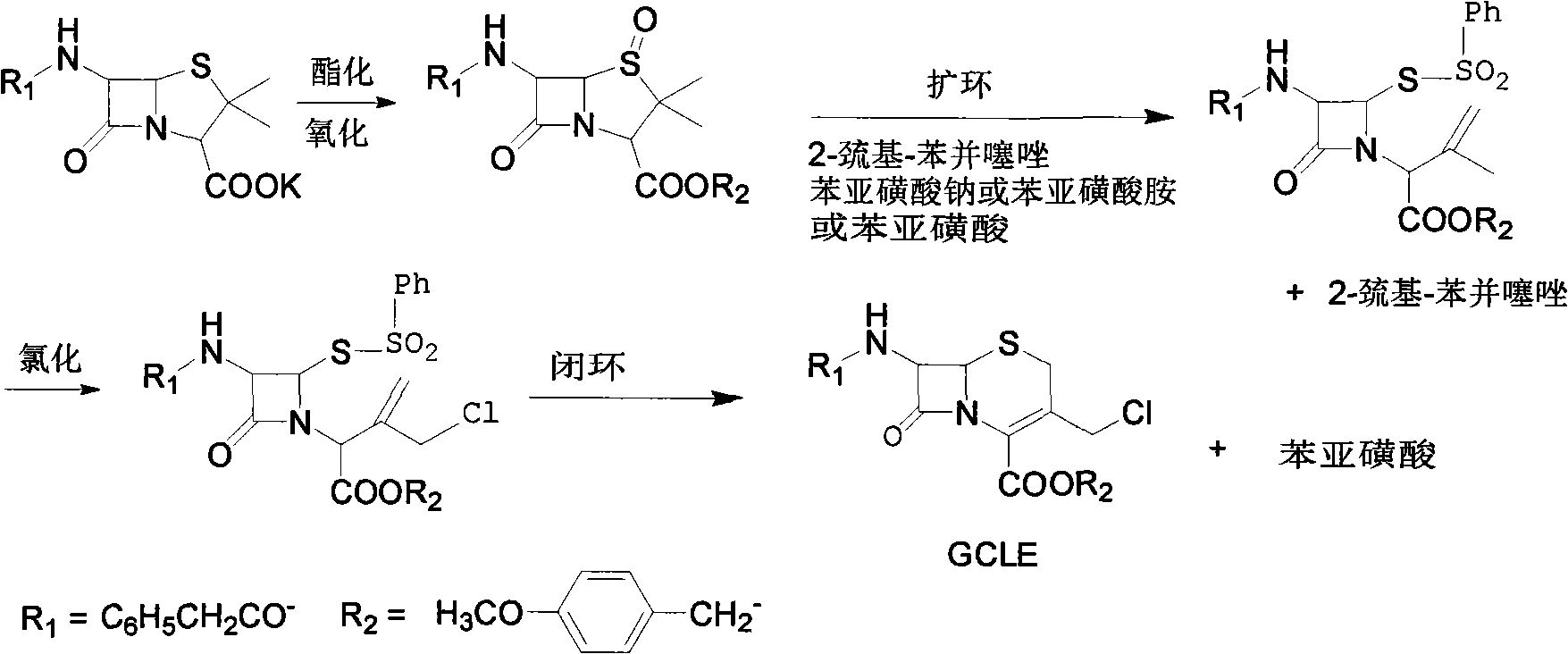

Method for recovering raw materials in preparation process of 7-phenylacetamide-3-chloromethyl-3-cephem-4-carboxylic acid p-methoxybenzyl

The invention provides a method for recovering raw materials in a preparation process of 7-phenylacetamide-3-chloromethyl-3-cephem-4-carboxylic acid p-methoxybenzyl (GCLE); the recovering method provided by the invention comprises steps of subjecting the obtained solution to certain aftertreatment to recover 2-mercaptobenzothiazole in the aftertreatment of the step of preparation of aza-butanone sulfinic acid intermediates in the technical process of GCLE; and then post-processing layered water phase in the step of preparation of final product GCLE, so as to recover benzene sulfinic acid sodium salt and benzene sulfinic acid amine. The method for recovering raw materials in the preparation process of CCLE is beneficial to mass production, by adopting the method, on one hand, the needed chemical products are recovered, and on the other hand, the pressure to the environment is reduced, so that great economic and social benefits are provided.

Owner:YILI CHUANNING BIOTECH CO

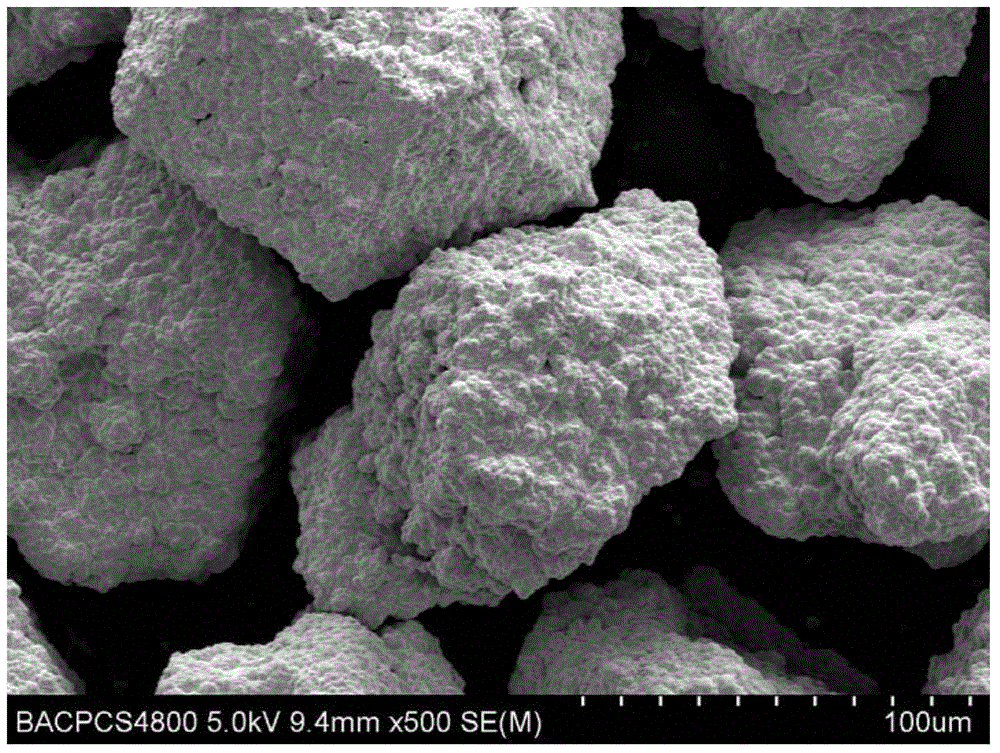

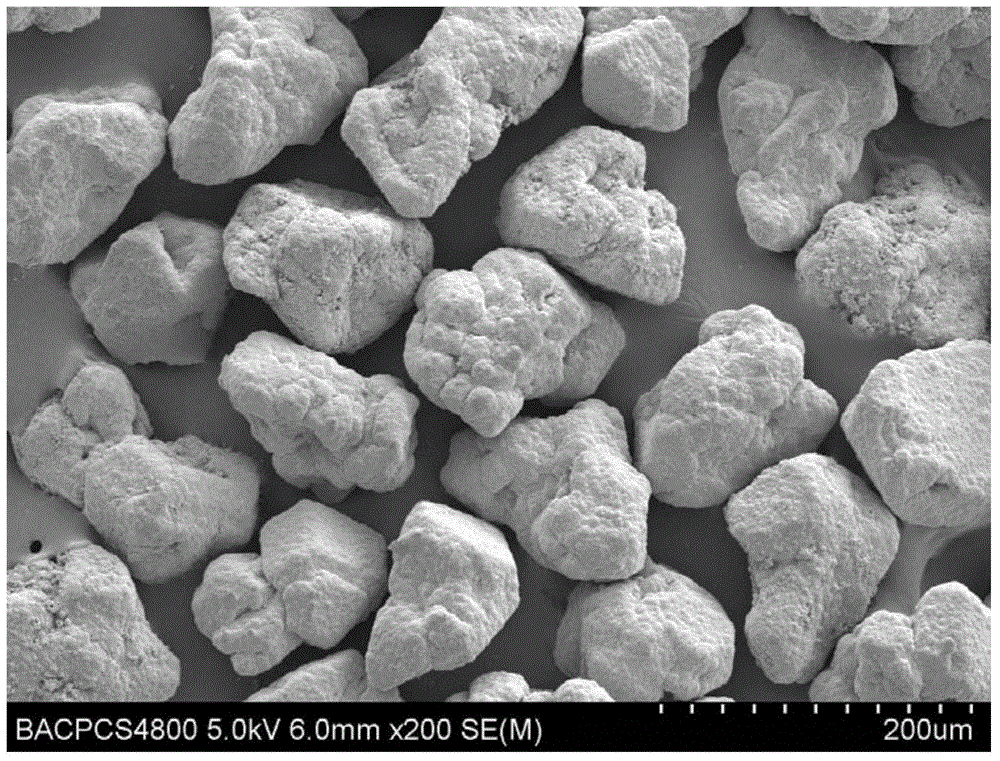

Electroplating liquid for preparing nickel plating thorn abrasive grains and electroplating method

The invention relates to electroplating liquid for preparing nickel plating thorn abrasive grains and an electroplating method; and the electroplating liquid contains water solution of the following components: nickel sulfate, boric acid, sodium chloride, aminobenzenesulfonic acid and benzene sulfinic acid sodium salt. The nickel plating thorn abrasive grains, prepared by the electroplating liquid, have a lot of needle-shaped or rod-shaped nickel thorns on the surfaces; the binding force of the nickel plating thorn abrasive grains and a resin binding agent is improved by 50-200% compared with general nickel plating abrasive grains; and the service life of resin binding agent abrasive tools, prepared by the product, is prominently prolonged.

Owner:北京国瑞升精机科技有限公司

2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid synthetic method

ActiveCN104402782AHigh synthesis efficiencyReduce manufacturing costOrganic chemistryOrganic compound preparationSodium hydroxideSulfinic acid

The present invention discloses a 2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid synthetic method which comprises the following steps: 1), reflux reaction of phenol, halogenated dodecane, an inorganic acid binding agent and an inorganic salt in organic solvent I to obtain dodecyl benzene ether; 2), reaction of the dodecyl benzene ether, sodium chloride and chlorosulfonic acid in dichloromethane to obtain 4-dodecyloxy benzene sulfonyl chloride; 3), reduction reaction of the 4-dodecyloxy benzene sulfonyl chloride, a reducing agent and a pH regulator in a mixture of water and organic solvent II to obtain 4-dodecyloxy benzene sulfinic acid sodium salt; 4), reflux reaction of the 4-dodecyloxy benzene sulfinic acid sodium salt, halogenated butyric acid methyl ester and a catalyst in methanol, then filtration of reaction liquid to obtain filtrate; 5), mixing of the filtrate and an aqueous sodium hydroxide solution for reaction to finally obtain 2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid.

Owner:江西扬帆新材料有限公司

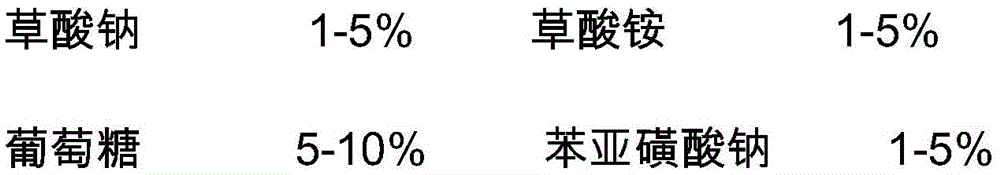

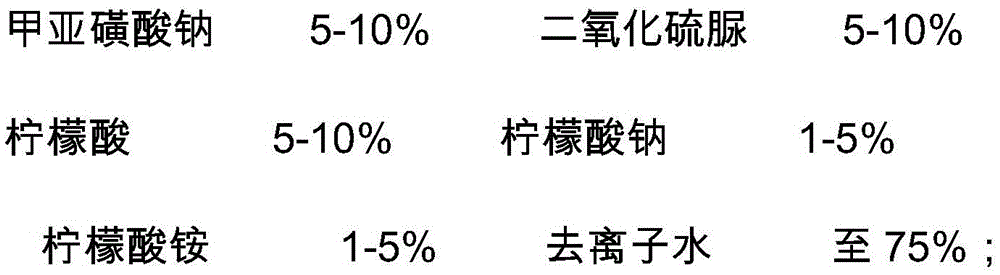

Laser heat thermal induction reduction reaction type discharge printing agent as well as preparation method and application thereof

The invention discloses a laser heat thermal induction reduction reaction type discharge printing agent as well as a preparation method and application thereof. The laser heat thermal induction reduction reaction type discharge printing agent is composed of an active component and a catalytic component, wherein the active component comprises sodium oxalate, ammonium oxalate, glucose, sodium benzene sulfinate, sodium methanesulphinate, thiourea dioxide, citric acid, sodium citrate, ammonium citrate and de-ionized water; the catalytic component comprises hydroxyanthraquinone, zinc sulfate, a discharging-resisting fluorescent whitening agent, glycerin, polyethylene glycol and de-ionized water. According to the laser heat thermal induction reduction reaction type discharge printing agent, respective technical advantages of traditional chemical-method discharge printing and modern laser etching printing and graphic image digital control are combined together to create a new discharge printing technology which is different from the traditional chemical-method discharge printing, is also different from the present new laser etching printing, and has the characteristics of good white discharge effect, less damages on fabric fibers, less drop of fabric strength, short technical flow, convenience in operation, flexibility, energy conservation, environmental friendliness and the like.

Owner:CHENGDU TEXTILE COLLEGE

Method for electrolytically preparing bright nickel in alkaline electrolyte

InactiveCN106283128ASolve the problem of blackening and brittle electrolytic nickelImprove toughnessElectrolysisImpurity

The invention relates to a method for electrolytically preparing bright nickel in alkaline electrolyte. The method comprises the following steps: (1) an electrobath comprises a cathode chamber and an anode chamber, high-grade nickel matte is immersed in 1 to 5mol / L nitric acid for 15 to 50 minutes to remove the surface oxide layer and impurities, a cathode material is electrodeposited to remove the surface oxide layer and deoiled, and the previously treated high-grade nickel matte and cathode material are respectively placed into the cathode chamber and the anode chamber; the electrolyte of the anode chamber is aqueous ammonium chloride solution, the ammonium chloride concentration of which ranges from 30g / L to 300g / L; the electrolyte of the cathode chamber is purified high-grade nickel matteanolyte, wherein the concentration of nickel chloride content ranges from 20g / L to 400g / L, the concentration of ammonium chloride ranges from 30g / L to 300g / L, the concentration of ammonia ranges from 25g / L to 250g / L, and the concentration of sodium benzenesulfinate ranges from 0.02g / L to 1.5g / L; (2) electrodeposition is carried out in the electrobath, the cathode is taken out after electrodeposition is complete, washed with deionized water and dried by cold wind, and thereby a bright and smooth nickel layer is obtained.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH

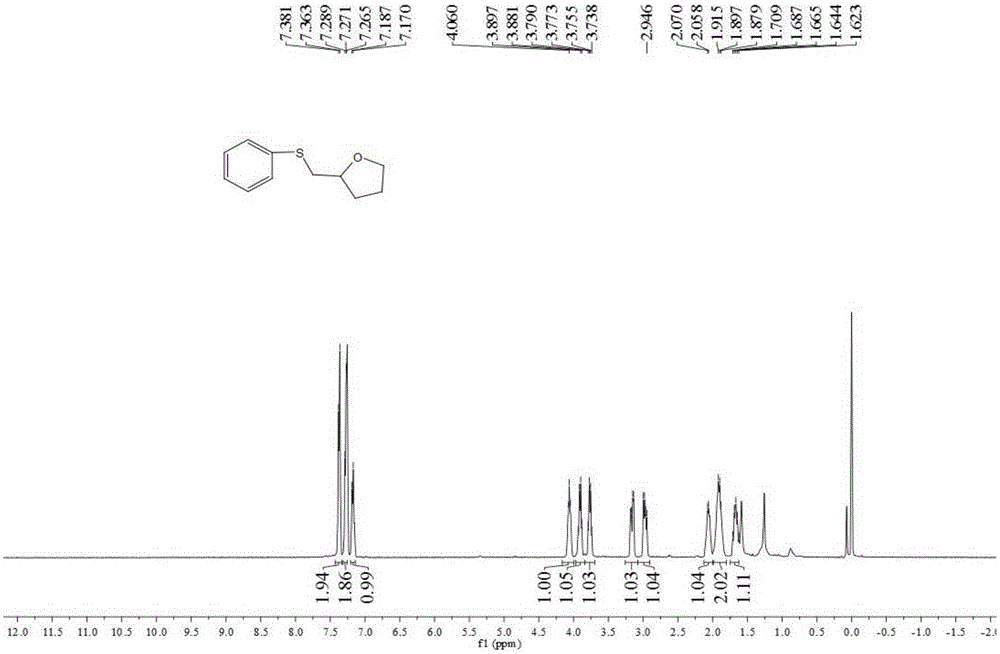

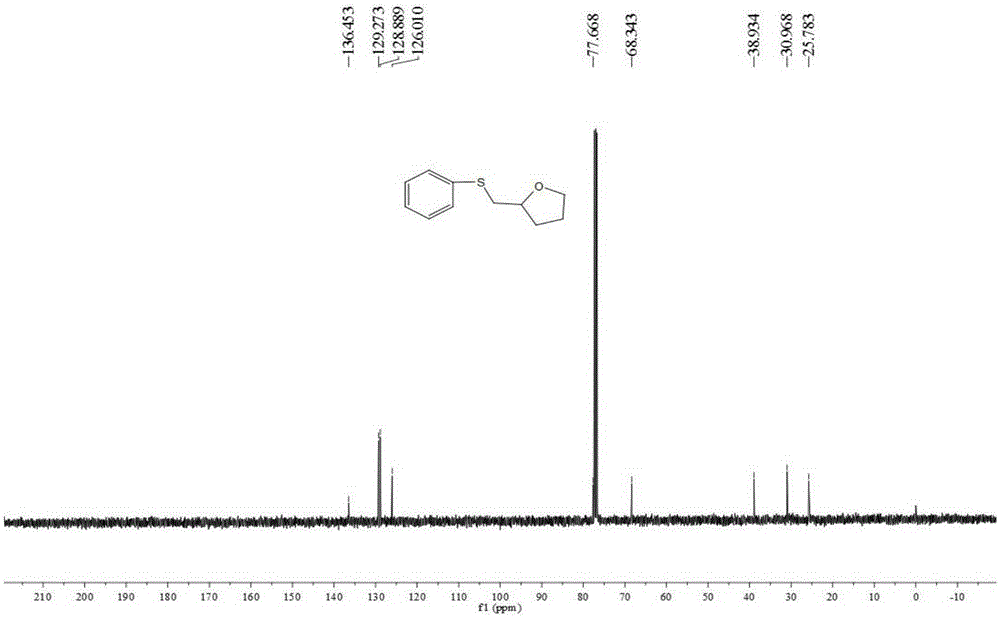

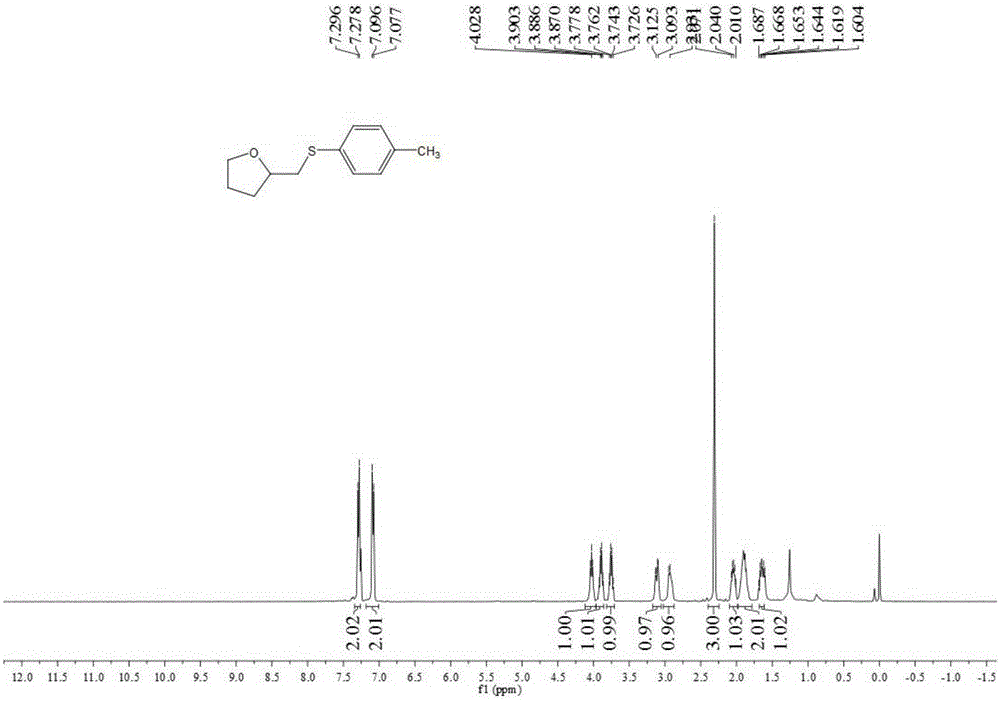

Thiooxacycloalkane compound and synthetic method therefor

ActiveCN105153078ALow toxicity of raw materialsLow priceOrganic chemistryNatural productOrganic synthesis

The invention belongs to the technical field of organic synthesis and discloses a thiooxacycloalkane compound and a synthetic method therefor. The synthetic method comprises the following steps: adding enol, substituted or unsubstituted sodium benzenesulfinate and a solvent into a reactor; adding copper salt as a catalyst, and carrying out a stirring reaction for 3-48 hours at 50-150 DEG C; after reaction, cooling the reactor to room temperature; evaporating the solvent at a reduced pressure to obtain a coarse product; and purifying the coarse product through column chromatography to obtain the thiooxacycloalkane compound. The synthetic method provided by the invention is safe and simple to operate, the raw materials are low in price and are easily available, and the method is good in adaptability to functional group, wide in substrate adaptability and environmental-friendly, so that industrial production is facilitated, and the method is widely applied to synthesis of pesticides, medicines and natural products.

Owner:SOUTH CHINA UNIV OF TECH

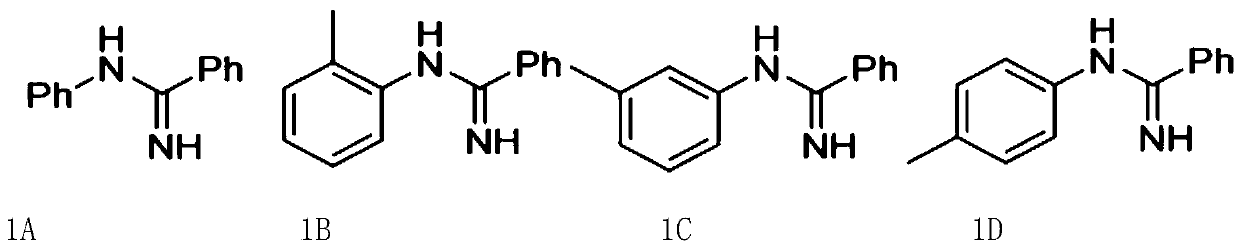

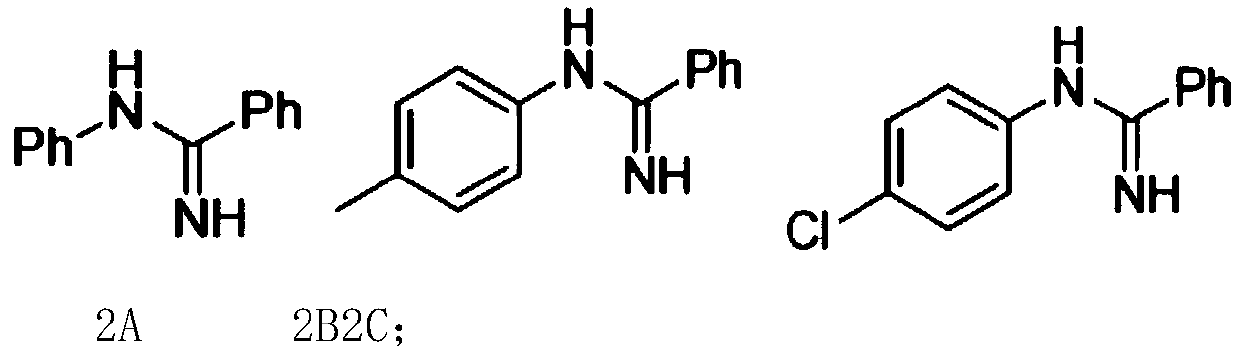

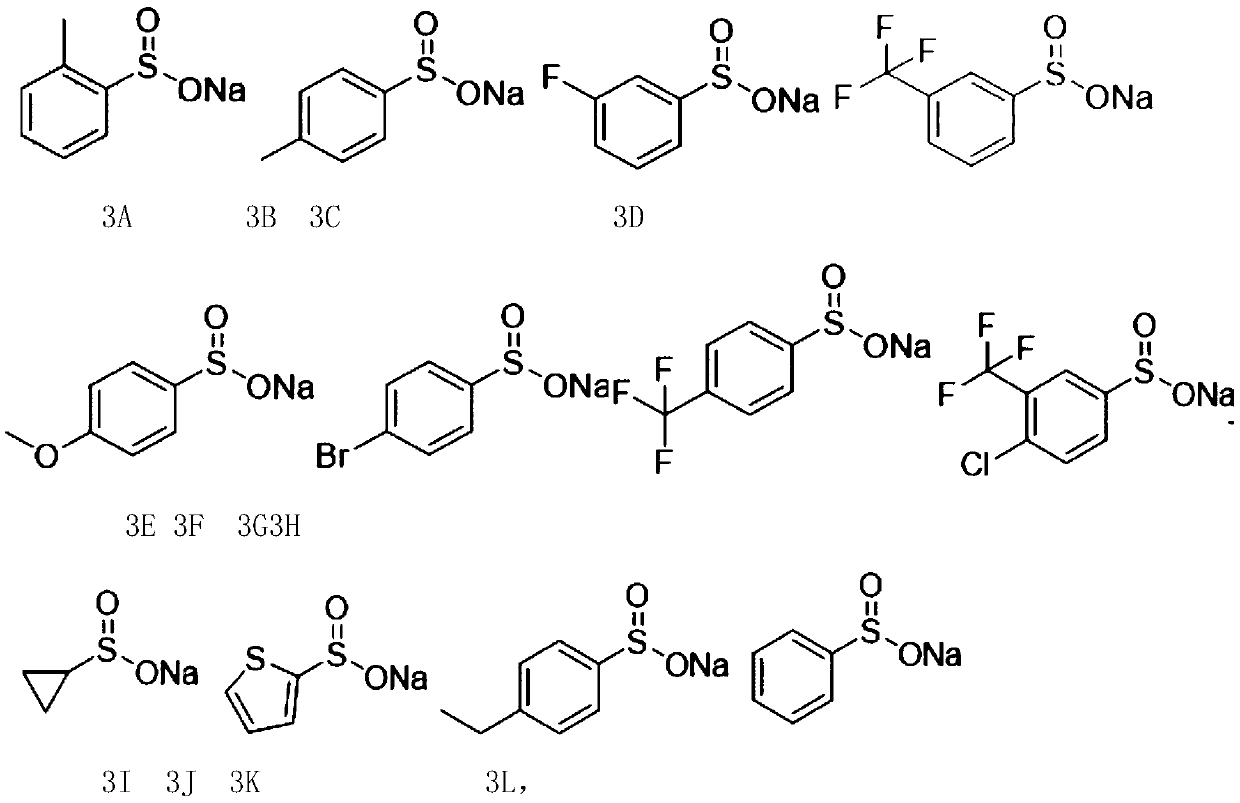

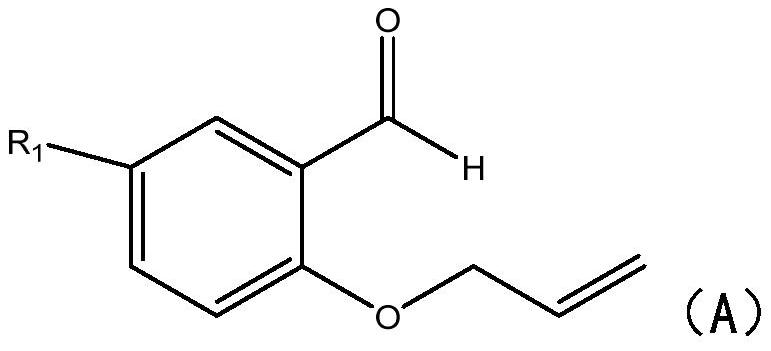

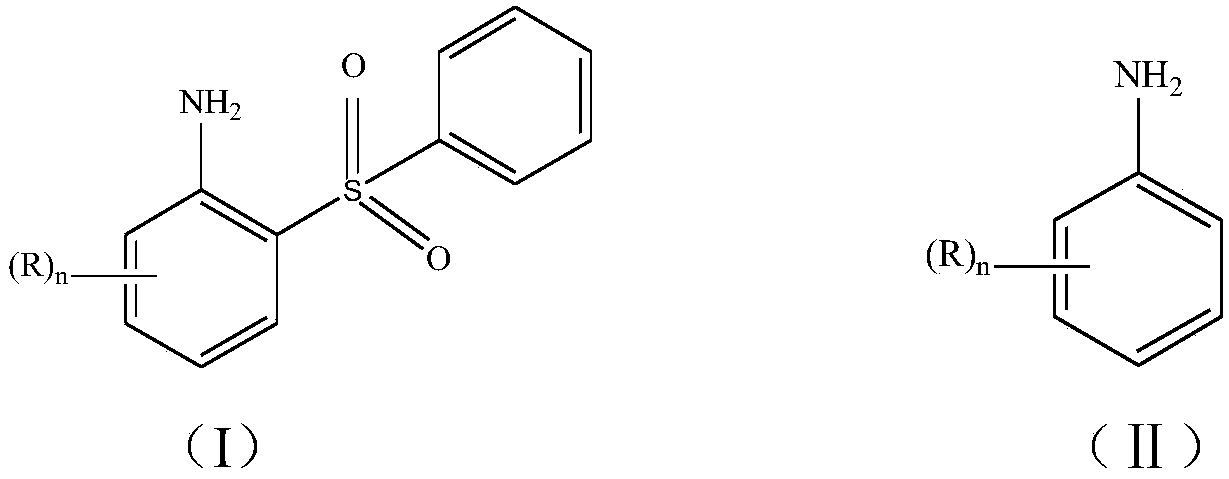

Arylamidine compounds and synthetic method thereof

The invention provides a synthetic method for arylamidine compounds. With the synthetic method provided by the invention, arylamidine is prepared by using aniline and benzonitrile as raw materials through a series of reactions; arylamidine compounds 4A to 4Z are prepared by a reaction of a compound 1 with phenylpropiolaldehyde, sodium benzene sulphinate, acetic acid and ethanol; arylamidine compounds 5A to 5M are prepared by a reaction of a compound 2 with a compound 9, a compound 3, acetic acid and ethanol; arylamidine compounds 6A to 6L are prepared by a reaction of a compound 4 with phenylpropiolaldehyde, sodium benzene sulphinate, tert-butyl hydroperoxide and acetonitrile; arylamidine compounds 6M to 6Z are prepared by a reaction of a compound 5 with a compound 6, a compound 7, tert-butyl hydroperoxide and acetonitrile; and an arylamidine compound 7A is prepared by a reaction of phenylpropiolaldehyde, a compound 8, acetonitrile and ethanol. The invention also provides the arylamidine compounds obtained by using the synthetic method provided by the invention. The synthetic method provided by the invention can synthesize the arylamidine compounds with various structures; and thearylamidine compounds all can be applied in the field of resisting of microorganisms.

Owner:GUANGDONG PHARMA UNIV

Combined nickel-plating liquid for electroplating nickel on magnesium alloy and method for electroplating nickel on surface of magnesium alloy

ActiveCN106245070AImprove corrosion resistanceImprove bindingLiquid/solution decomposition chemical coatingSuperimposed coating processAcid washingSodium sulfate

The invention discloses combined nickel-plating liquid for electroplating nickel on magnesium alloy. The combined nickel-plating liquid is aqueous solution with the following components of nickel sulfate, water-soluble fluoride, ammonium citrate, sodium saccharin, sodium benzene sulphinate, 1,4-butynediol, lauryl sodium sulfate and a pH regulating agent. In addition, the invention also provides a method for electroplating the nickel on the surface of the magnesium alloy. The method comprises the following steps: mechanically polishing the magnesium alloy, removing oil on the surface of the magnesium alloy, carrying out alkaline washing and acid washing as well as activating treatment, chemically plating zinc for one time or multiple times, and electroplating nickel in the combined nickel-plating liquid to obtain the magnesium alloy with the nickel electroplated on the surface. The combined nickel-plating liquid and the nickel plating method disclosed by the invention are applicable to various magnesium-alloy substrates, and the plated part prepared is higher in bonding force between a matrix thereof and a plated layer, better in corrosion resistance, and flat and attractive in surface.

Owner:XIANGTAN UNIV

High-corrosion-resistance bright electronickelling plating solution as well as preparation method and use method thereof

The invention discloses a high-corrosion-resistance bright electronickelling plating solution as well as a preparation method and a use method thereof, belongs to the technical field of electronickelling, and solves the problem of poor bright electronickelling corrosion resistance of a plating solution taking nickel sulfate as a main component in the prior art. The plating solution is prepared from 200 g / L-300 g / L of nickel sulfate, 30 g / L-50 g / L of nickel chloride, 30 g / L-50 g / L of boric acid, 0.006 g / L-0.10 g / L of sodium dodecyl benzene sulfonate, 5 mg / L-70 mg / L of MOSS, and 0.01 g / L-0.2 g / Lof sodium benzenesulfinate, and water serves as a solvent. The preparation method comprises the following steps: weighing the components according to the concentrations of the components in the high-corrosion-resistance bright electronickelling plating solution solution; and mixing the components to obtain the high-corrosion-resistance bright electronickelling plating solution. The use method comprises the following steps: carrying out pretreatment on a base material; heating the high-corrosion-resistance bright electronickelling plating solution; putting the base material into the high-corrosion-resistance bright electroplating nickel plating solution for nickel plating; and obtaining the base material with a nickel plating layer. According to the plating solution as well as the preparation method and the use method thereof, the brightness and the corrosion resistance of the nickel plating layer can be effectively improved.

Owner:ZHEJIANG INNUOVO MAGNETICS +1

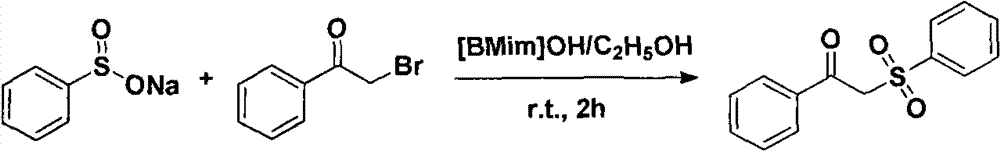

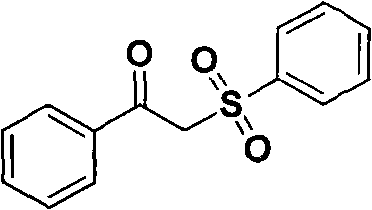

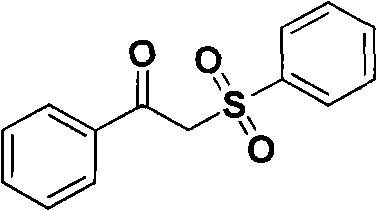

Novel method for preparing 1-phenyl-2-benzene sulfonyl acetophenone

InactiveCN102766077AShort reaction timeHigh yieldOrganic chemistryOrganic compound preparationBenzeneOrganic synthesis

The invention relates to a novel method for preparing intermediate of organic synthesis 1-phenyl-2-benzene sulfonyl acetophenone. The invention uses alkaline ionic liquid 1-butyl-3-methyl imidazole hydroxide as a catalyst directly, and 1-phenyl-2-benzene sulfonyl acetophenone is prepared by one-step method through 2-bromo-acetophenone and sodium benzene sulfinate. The invention provides a novel method for preparing 1-phenyl-2-benzene sulfonyl acetophenone which has the advantages of short reaction time, mild condition, simple operation and high yield.

Owner:INNER MONGOLIA UNIV OF TECH

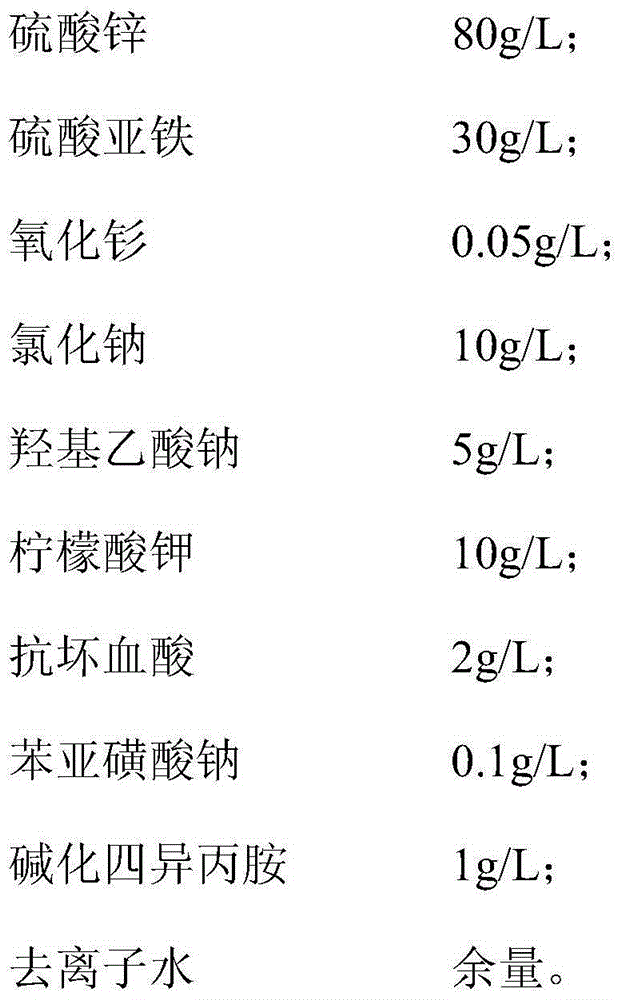

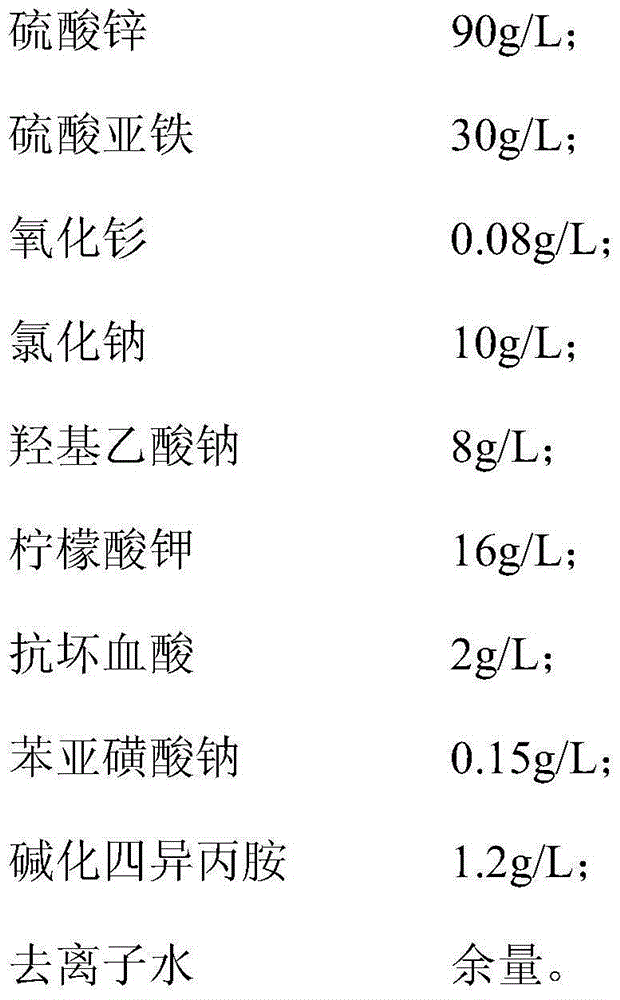

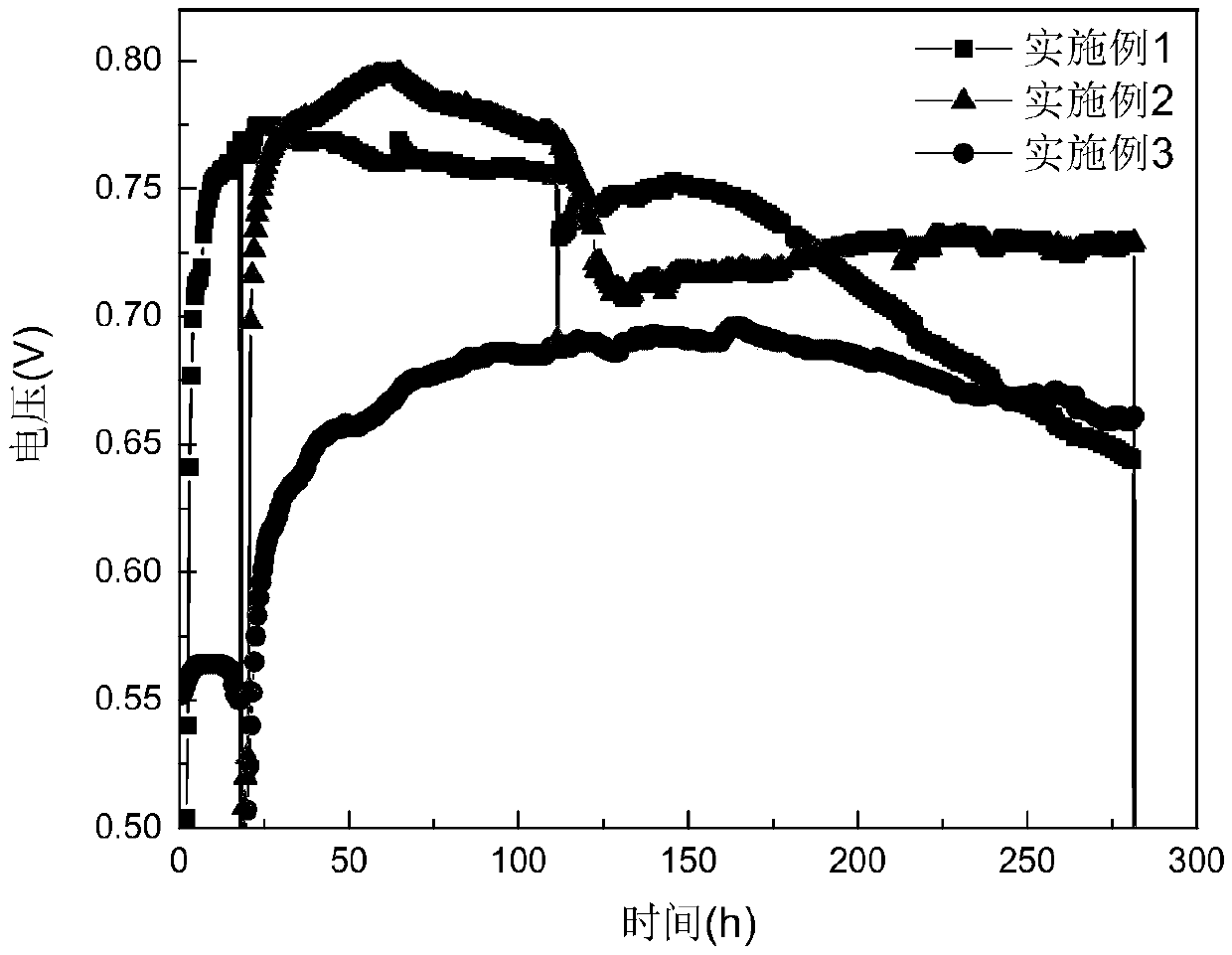

Samarium-zinc-iron alloy electroplating liquid and electroplating method thereof

The invention discloses samarium-zinc-iron alloy electroplating liquid and an electroplating method thereof. The samarium-zinc-iron alloy electroplating liquid comprises the following components: 80-120 g / L of zinc sulfate, 30-50 g / L of ferrous sulfate, 0.05-0.3 g / L of samarium oxide, 10-15 g / L of sodium chloride, 5-10 g / L of glycolic acid sodium, 10-20 g / L of potassium citrate, 2-5 g / L of ascorbic acid, 0.1-0.3 g / L of benzene sulfinic acid sodium salt and 1-1.5 g / L of alkalified tetraisopropylamine. The rare earth metal samarium is added in the samarium-zinc-iron alloy electroplating liquid, so that the electroplating liquid is excellent in stability, high in electroplating efficiency, safe and environment-friendly; and a samarium-zinc-iron alloy plating layer obtained through electroplating is excellent in corrosion resistance and levelness.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Chitosan-graphene oxide sponge, preparing method and application

The invention discloses a chitosan-graphene oxide sponge, a preparing method and application. The preparing method includes the following steps of taking a graphene oxide solution, sequentially addingglacial acetic acid, a FeCl2 solution, a benzene sulfinic acid sodium salt solution and chitosan to the graphene oxide solution, vacuumizing the solution to obtain bubble-free slurry, freeze-drying the slurry, placing the slurry in an NaOH solution to be soaked to primarily obtain a sponge body, heating the sponge body at a constant temperature to obtain the chitosan-graphene oxide sponge. The chitosan-graphene oxide sponge prepared through the method can be used for preparing a breathable microbial fuel battery; the preparing method is simple, cost is low, and the prepared sponge has quite good elasticity, has a rich pore structure, is large in specific surface area, has a plentiful of active sites, and is beneficial for adhesion of microorganisms. By adding FeCl2, the degradation and decomposition of the sponge by the microorganisms can be effectively prevented, and ferroferric oxide is formed and has conductivity and biocompatibility.

Owner:SHANGHAI INST OF TECH

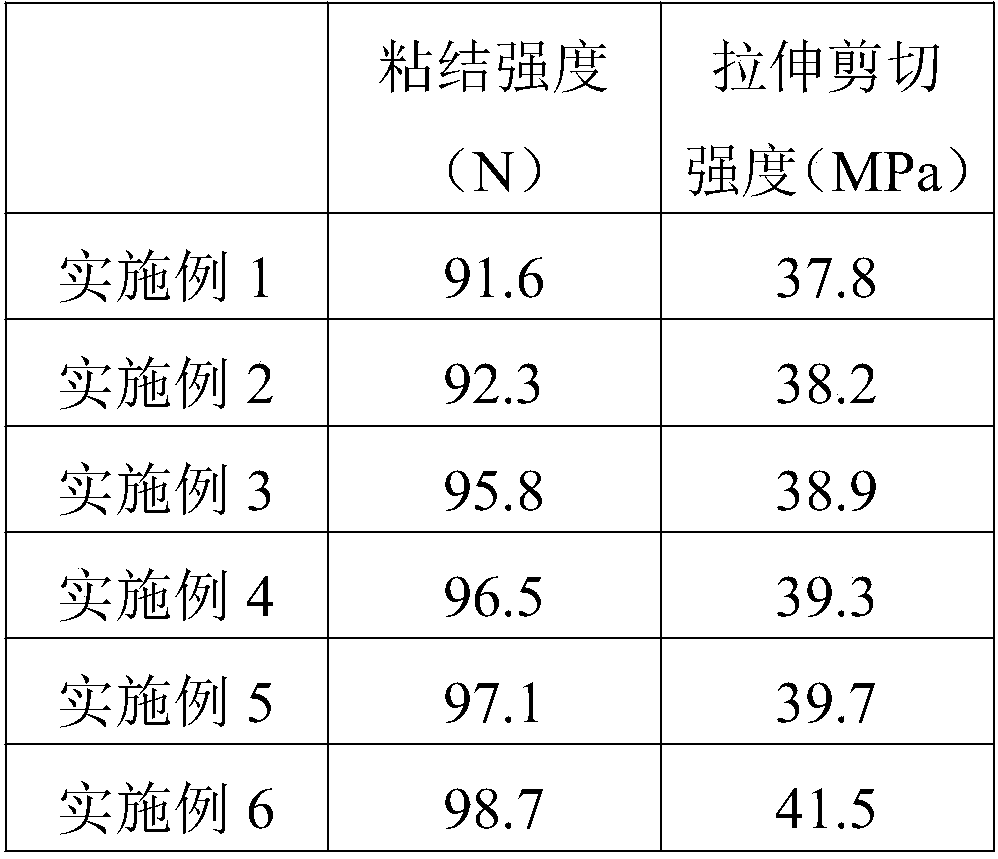

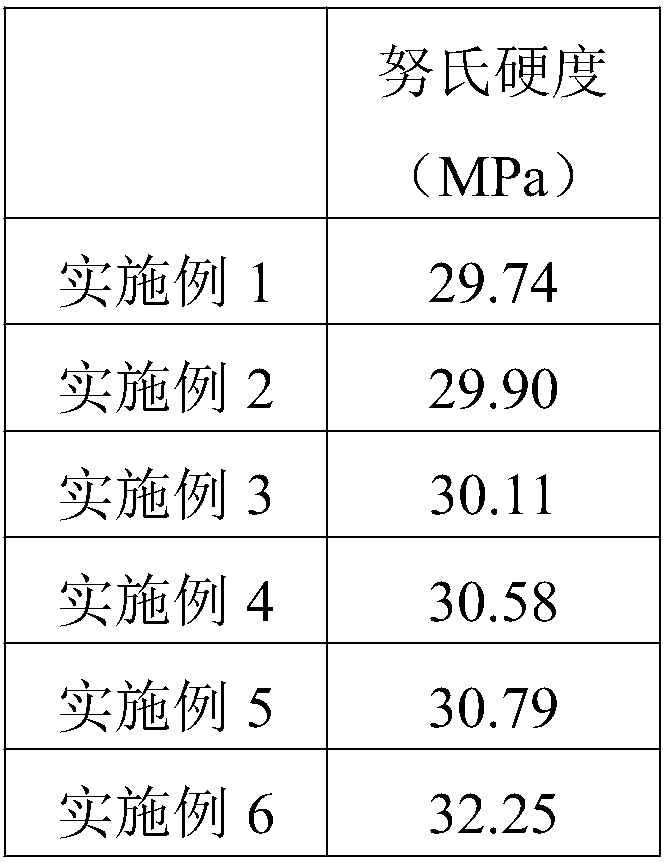

Safe adhesive for dental implants and preparation method of adhesive

InactiveCN108186371AHigh bonding strengthFast bondingImpression capsDentistry preparationsTriclosanAdhesive

The invention provides a safe adhesive for dental implants and a preparation method of the adhesive. The safe adhesive for dental implants is prepared from raw materials as follows: polyethylene glycol-acrylate, 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylphenylacetone, benzene sulfinic acid sodium salt, a biological compound, aluminum oxide, crosslinked polymethyl methacrylate, pretreated zirconium oxide, triclosan and the balance of a solvent. The safe adhesive for dental implants has no harm to tooth tissue and oral mucosa, does not decompose and age under the action of bacteria and enzyme in saliva, has higher adhesion for a dental material and has high bonding strength.

Owner:上海御齿台医疗科技有限公司

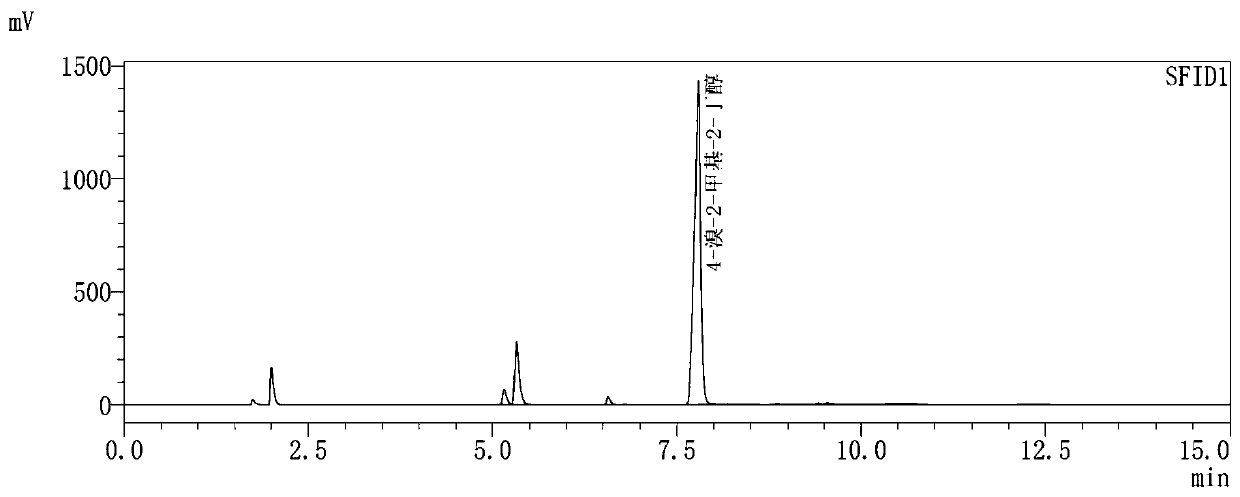

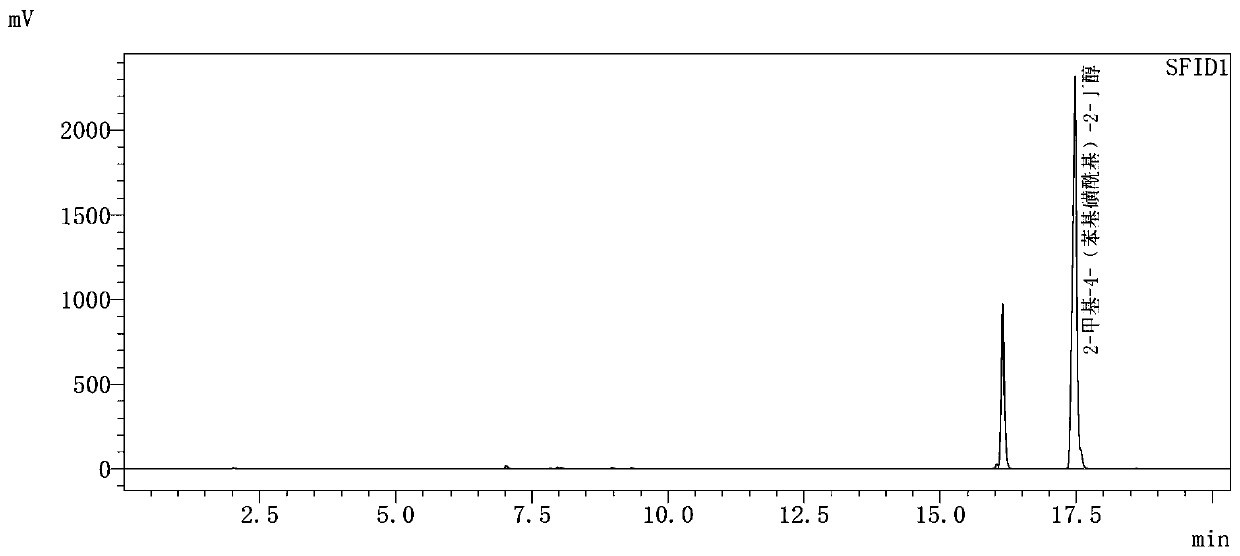

Preparation method of a 25-hydroxy vitamin D3 intermediate

PendingCN110981765ASimple process routeMild reaction conditionsOrganic compound preparationPreparation by halogen introductionMethyl benzeneAcyl group

The invention discloses a preparation method of a 25-hydroxy vitamin D3 intermediate, wherein the 25-hydroxy vitamin D3 intermediate is 2-methyl-4-(phenylsulfonyl)-2-butanol, and is prepared from 3-methyl-3-butanol-p-toluenesulfonate, a halide and sodium benzenesulfinate in a solvent. According to the invention, the synthesis route of the 25-hydroxyvitamin D3 intermediate is short, raw materials are easy to obtain, separation is simple, anhydrous conditions are not needed in synthesis operation, and a new and safe C5-fragment is provided for synthesis of 25-hydroxyvitamin D3.

Owner:肇庆巨元生化有限公司

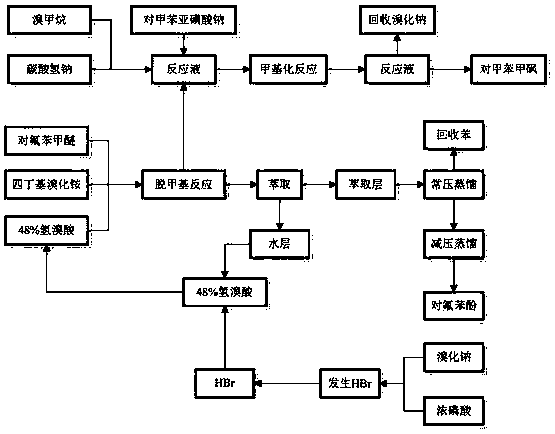

Preparation method of fluorophenol

InactiveCN108658730AEliminate emissionsLow reaction temperatureOrganic compound preparationHalogenated hydrocarbon preparationRaffinateDemethylation

The application relates to a preparation method of fluorophenol. The preparation method comprises the following steps: carrying out demethylation reaction on p-fluoroanisole and hydrobromic acid to generate fluorophenol and methyl bromide; separating the synthesized fluorophenol from a reaction system by using an extraction method; recycling raffinate through hydrogen bromide; directly introducingthe methyl bromide subjected to the demethylation reaction into an aqueous solution containing 15 percent p-methyl sodium benzenesulfinate to generate p-methyl phenylsulfone; concentrating mother liquor from which the p-methyl phenylsulfone is separated to obtain sodium bromide. The obtained sodium bromide can be applied to the step of generating hydrogen bromide. Therefore, the discharge of acid-containing wastewater and byproducts is fundamentally eliminated, and the requirements of clean production are met.

Owner:CHANGZHOU UNIV

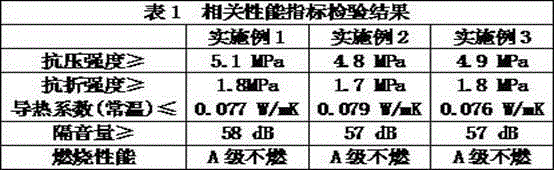

High-strength fire-proofing insulating plate for construction and preparation method thereof

The invention provides a high-strength fire-proofing insulating plate for construction. The insulating plate is prepared from the following raw materials in parts by weight: 20-25 parts of boric sludge, 16-20 parts of palygorskite, 6-8 parts of dickite, 12-15 parts of baddeleyite, 25-30 parts of gypsum powder, 2-3 parts of p-hydroxybenzenesulfonic acid, 3-4 parts of benzene sulfinic acid sodium salt, 5-7 parts of polyacrylamide, 4-6 parts of high-substituted hydroxyproxyl cellulose, 9-13 parts of lignocellulose and 30-40 parts of water. The high-strength fire-proofing insulating plate for construction has the characteristics of high tensile strength, temperature preservation and heat insulation, good fire-proofing performance, corrosion resistance, damp resistance and the like, and is very suitable for construction separators.

Owner:山西绅美陶瓷纤维股份有限公司

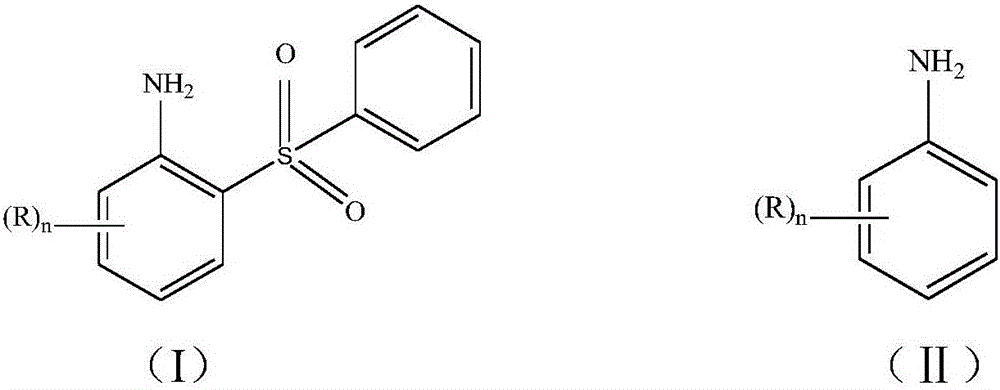

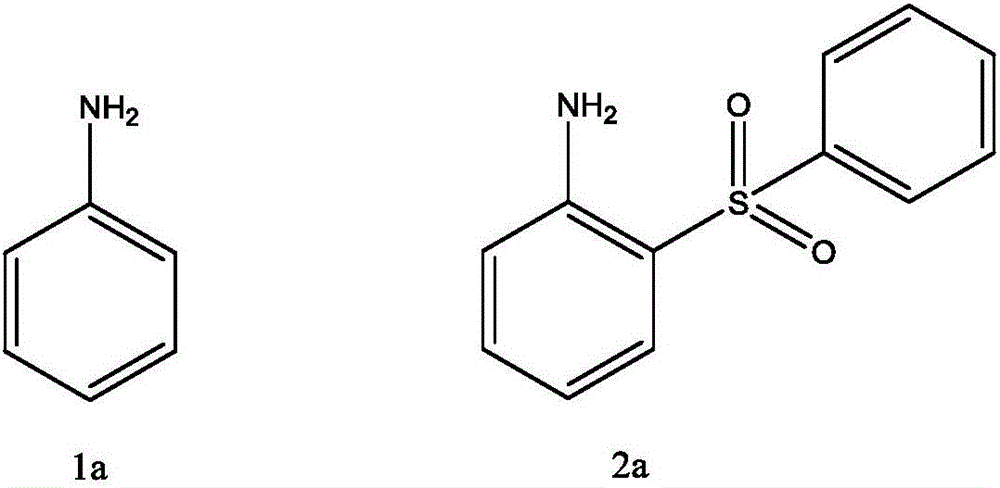

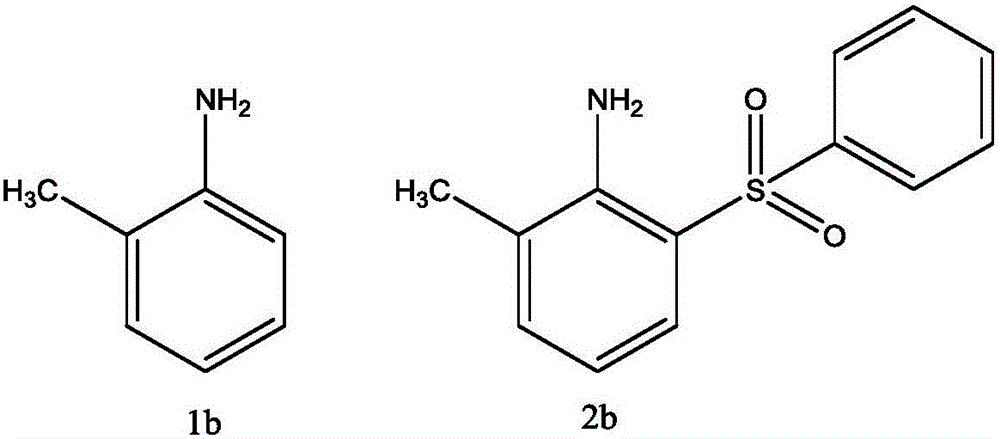

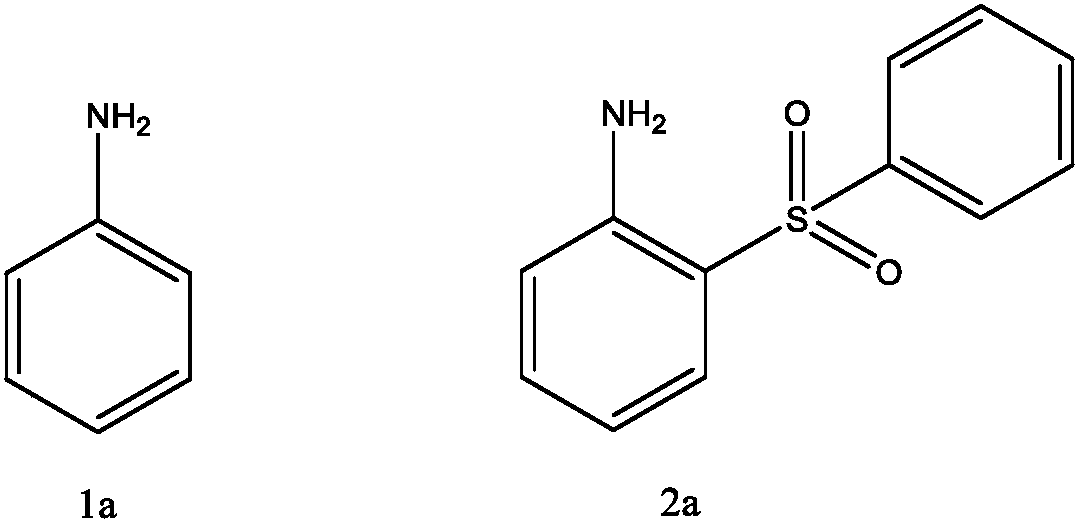

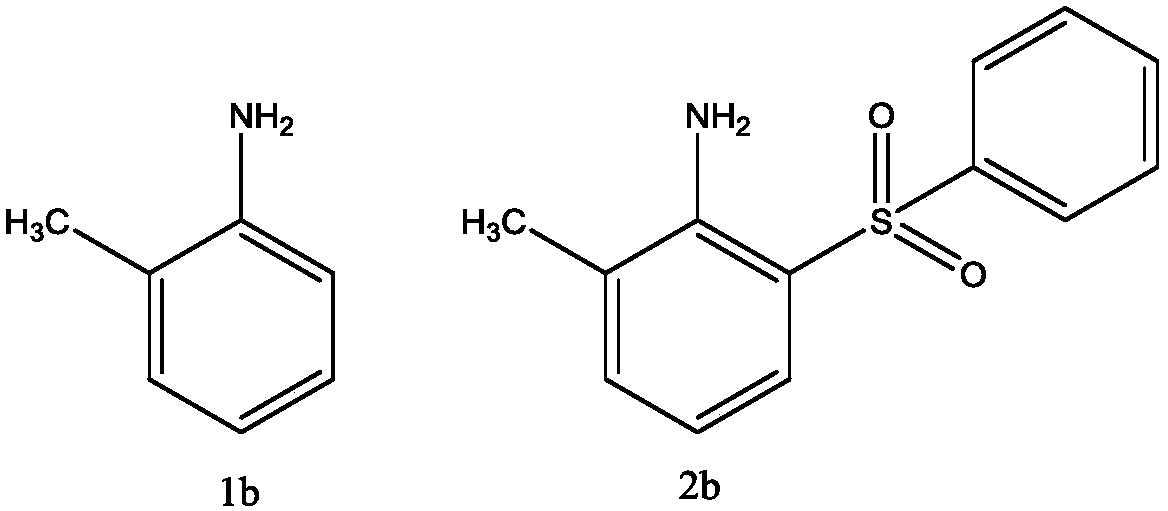

Method for preparing aryl sulfonic acid compound based on C-H activated arylamine

ActiveCN106810478AEasy to operateOrganic chemistryOrganic compound preparationEthyl acetateHydrogen peroxide

The invention belongs to the technical field of organic chemistry and particularly relates to a method for preparing an arylamine sulfonic acid compound from C-H activated arylamine. The method comprises the following steps: with anhydrous copper acetate as a reaction catalyst and hydrogen peroxide as an oxidizing agent, adding an aniline compound and sodium benzene sulfinate into water; reacting at room temperature for two hours; extracting with ethyl acetate; performing vacuum concentration to obtain a corresponding crude product of arylamine sulfonic acid compound; and performing column chromatographic isolation and purification to obtain a corresponding pure product. The method provided by the invention has the characteristics of easy operation, mild reaction conditions, short reaction time and environmental friendliness.

Owner:ZHEJIANG UNIV OF TECH

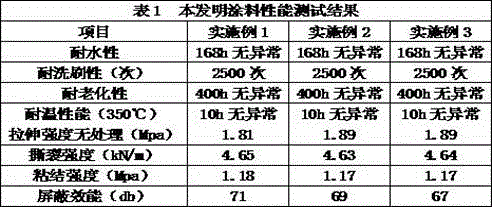

A kind of polymer composite paint for building and preparation method thereof

InactiveCN104371438BImprove electromagnetic shielding performanceImprove waterproof performanceCoatingsPhosphogypsumElectromagnetic shielding

Owner:ZHENGZHOU UNIV OF IND TECH

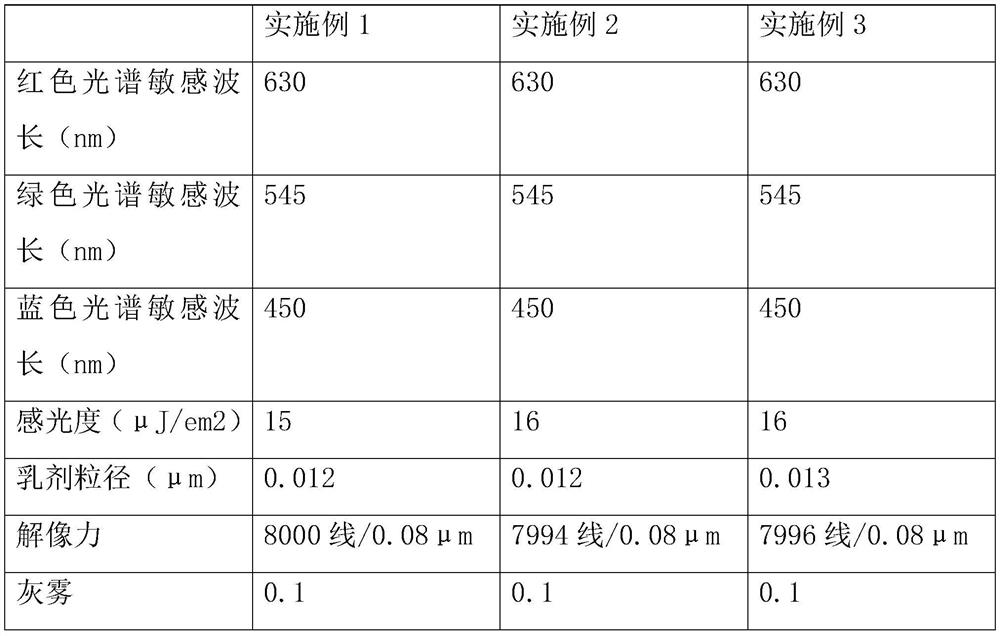

Laser holographic ultramicron silver salt photosensitive material and preparation method thereof

The invention discloses a laser holographic ultramicron silver salt photosensitive material and a preparation method thereof, and relates to the technical field of silver salt photosensitive materials. The material is prepared from distilled water, gelatin, benzotriazole, potassium chromium sulfate dodecahydrate, metronidazole, silver nitrate, citric acid, p-tert-butylphenol, sodium benzenesulfinate, potassium bromide, magnesium chloride, disodium ethylene diamine tetraacetate, nitrophenylhydrazine, sodium sulfonate, phenol, formamide, thymol, methanol and ethanol. The laser holographic ultramicron silver salt photosensitive material provided by the invention has excellent performances of low noise, high resolution, high sensitivity and high transparency, is sensitive to red light spectral line wavelength of 630 nm, green light spectral line wavelength of 545 nm and blue light spectral line wavelength of 450 nm, and has the sensitivity of 10-20 [mu]J / em<2>.

Owner:北京镭思顿科技开发公司

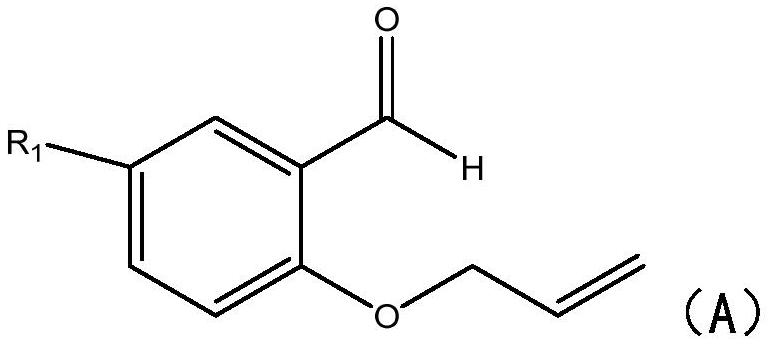

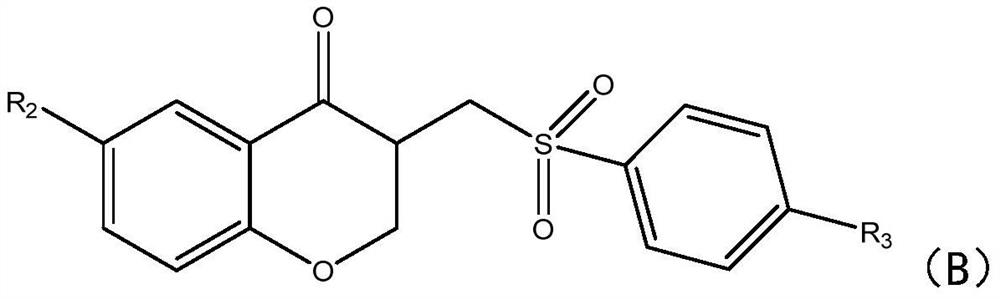

Synthetic method of chromanone compounds

ActiveCN111943925ASimple reaction systemEfficient recyclingOrganic chemistryChemical recyclingPtru catalystOrganic synthesis

The invention provides a synthesis method of chromanone compounds, belongs to the field of organic synthesis, and aims at solving the technical problems that in the prior art, expensive metal silver catalysts are mostly used and are large in dosage when chromanone compounds are synthesized, and adopted organic solvents are not environmentally friendly. According to a technical scheme, the method comprises the following steps: respectively adding a 2-(allyloxy) benzaldehyde compound and a sodium benzenesulfinate compound into a reactor, and carrying out a closed reaction for 6-8 hours under theair condition at 60-100 DEG C under the action of a catalyst and a eutectic solvent; and after the reaction is finished, carrying out column chromatography separation to obtain the chromanone compound. The synthesis method provided by the invention is simple in reaction system, and does not need to use an expensive metal catalyst, the solvent can be recycled, so that a brand-new method is provided for green synthesis of chromanone compounds.

Owner:吉林警察学院 +1

Trivalent chromium electroplating method of cold-rolled sheet

The invention discloses a trivalent chromium electroplating method of a cold-rolled sheet. Plating liquid is prepared from chromium sulfate with the density being 135-145 g / L, sodium sulfate with the density being 210-230 g / L, potassium sulfate with the density being 30-40 g / L, magnesium sulfate with the density being 20-30 g / L, boric acid with the density being 65-75 g / L, formic acid with the density being 0.1-0.3 mol / L, oxalic acid with the density being 0.2-0.4 mol / L, sodium citrate with the density being 0.3-0.5 mol / L, sodium dodecyl sulfate with the density being 0.001-0.002 mol / L, benzene sulfinic acid sodium salt with the density being 0.0015-0.0025 mol / L, gamma-methacryloxypropyltriethoxysilane with the density being 0.2-0.4 mol / L and dibutyltin diacetate with the density being 0.5-0.7 g / L. The electroplating technology includes the steps that a graphite anode is adopted, the work temperature is about 50-55 DEG C, the pH is 3.5-4.5, the current density is 22-24 A / dm<2>, the electroplating time is 60-90 min, and the rotating speed of a stirrer is 100-120 r / min.

Owner:泉州方寸新材料科技有限公司

A method for preparing arylsulfonic acid compounds based on c-h activation of arylamines

ActiveCN106810478BEasy to operateOrganic chemistryOrganic compound preparationEthyl acetateAromatic amine

Owner:ZHEJIANG UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2-phenyl-3-(benzenesulfonyl)imidazo[1,2-a]pyridine compound and synthetic method thereof 2-phenyl-3-(benzenesulfonyl)imidazo[1,2-a]pyridine compound and synthetic method thereof](https://images-eureka.patsnap.com/patent_img/fadcd079-f072-46ac-b48a-386d42357f58/DEST_PATH_IMAGE001.png)

![2-phenyl-3-(benzenesulfonyl)imidazo[1,2-a]pyridine compound and synthetic method thereof 2-phenyl-3-(benzenesulfonyl)imidazo[1,2-a]pyridine compound and synthetic method thereof](https://images-eureka.patsnap.com/patent_img/fadcd079-f072-46ac-b48a-386d42357f58/RE-GDA0001441517690000021.png)

![2-phenyl-3-(benzenesulfonyl)imidazo[1,2-a]pyridine compound and synthetic method thereof 2-phenyl-3-(benzenesulfonyl)imidazo[1,2-a]pyridine compound and synthetic method thereof](https://images-eureka.patsnap.com/patent_img/fadcd079-f072-46ac-b48a-386d42357f58/RE-GDA0001441517690000051.png)

![2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid synthetic method 2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid synthetic method](https://images-eureka.patsnap.com/patent_img/7e4a6206-92f4-462a-bd04-f56898fd8e4f/BDA0000607409820000011.PNG)

![2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid synthetic method 2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid synthetic method](https://images-eureka.patsnap.com/patent_img/7e4a6206-92f4-462a-bd04-f56898fd8e4f/BDA0000607409820000041.PNG)

![2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid synthetic method 2-[(4-dodecyloxy phenyl) sulfuryl] butyric acid synthetic method](https://images-eureka.patsnap.com/patent_img/7e4a6206-92f4-462a-bd04-f56898fd8e4f/BDA0000607409820000042.PNG)