High-corrosion-resistance bright electronickelling plating solution as well as preparation method and use method thereof

A bright electroplating, high corrosion resistance technology, applied in the field of nickel electroplating, can solve problems such as poor corrosion resistance, and achieve the effect of enhancing corrosion resistance, accelerating growth, improving brightness and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

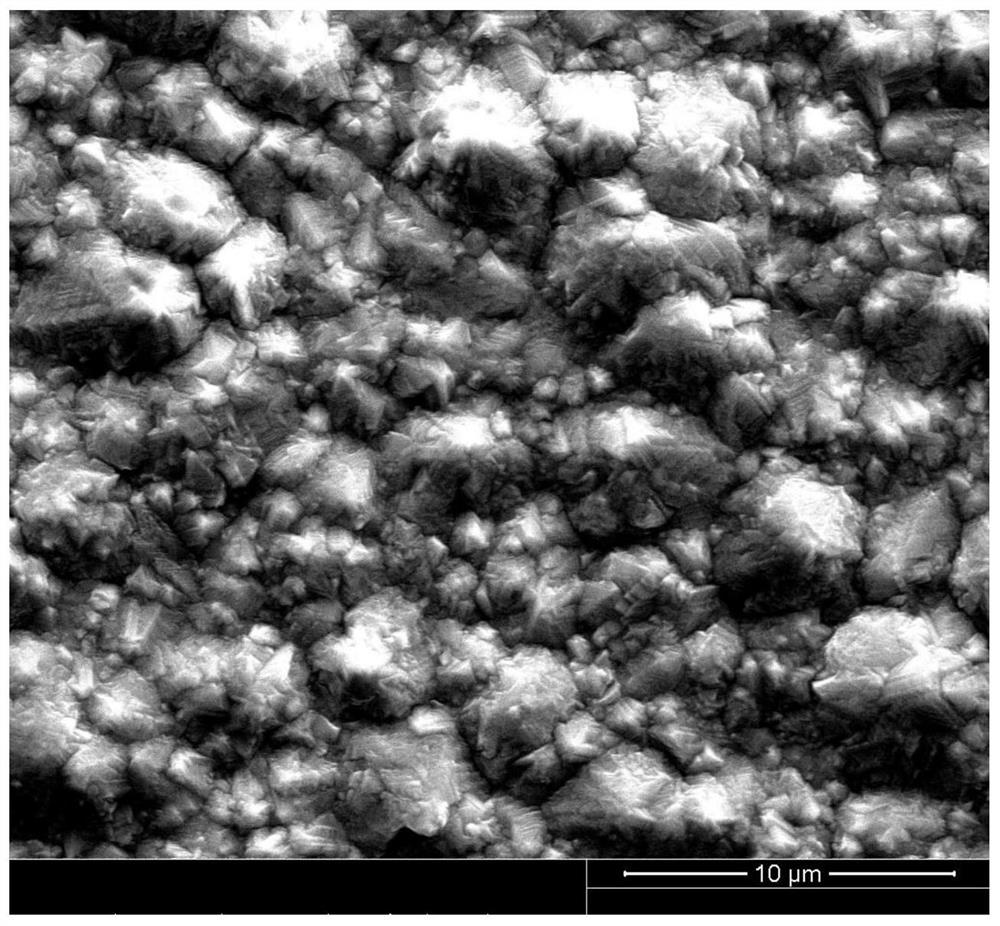

Image

Examples

preparation example Construction

[0046] The invention also discloses a preparation method of a highly corrosion-resistant bright electroplating nickel plating solution, comprising the following steps:

[0047] Step 1: Weigh nickel sulfate, nickel chloride, boric acid, sodium dodecylbenzenesulfonate, butyl ether huminate and sodium benzenesulfinate according to the concentration of each component in the high corrosion-resistant bright nickel electroplating solution;

[0048] Step 2: Mix nickel sulfate, nickel chloride, boric acid, sodium dodecylbenzenesulfonate, butyl ether sulfinate and sodium benzenesulfinate to obtain a highly corrosion-resistant bright nickel plating solution.

[0049]Compared with the prior art, the beneficial effect of the preparation method of the high corrosion-resistant bright electroplating nickel plating solution provided by the present invention is basically the same as that of the above-mentioned high corrosion-resistant bright electroplating nickel plating solution, and will not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com