Laser heat thermal induction reduction reaction type discharge printing agent as well as preparation method and application thereof

A heat-induced and reactive technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of fabric strength decline, fabric fiber damage, fabric scorching, etc., to achieve the effect of reducing strength loss, reducing emissions, and unique style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

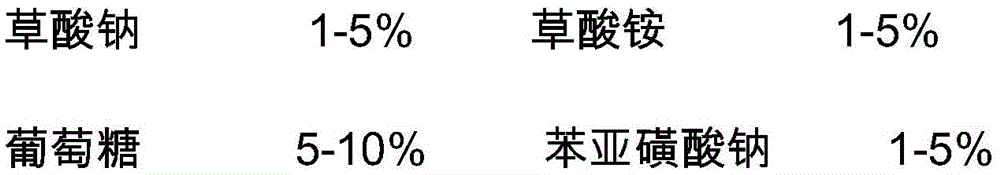

[0086] Prepare laser heat-induced reduction reaction type dye discharge agent according to the following ratio

[0087] Active ingredient:

[0088]

[0089]

[0090] Catalytic components:

[0091]

[0092] The hydroxyanthraquinone used therein may be 2-hydroxyanthraquinone, 1,4-dihydroxyanthraquinone and hydroxymadizin.

[0093] Prepare as follows:

[0094] First mix the active components together and stir evenly; then add water to make a solution of zinc sulfate and anti-pulling fluorescent whitening agent, then add glycerin and polyethylene glycol, mix thoroughly, add hydroxyanthraquinone, Grind in the grinder at room temperature for 48-72 hours until a uniform thick suspension is formed; finally, add the prepared active components into the above grinder, and continue to grind at room temperature for 2-4 hours together with the catalytic component until a uniform suspension is obtained. Liquid colloid mixture.

Embodiment 2

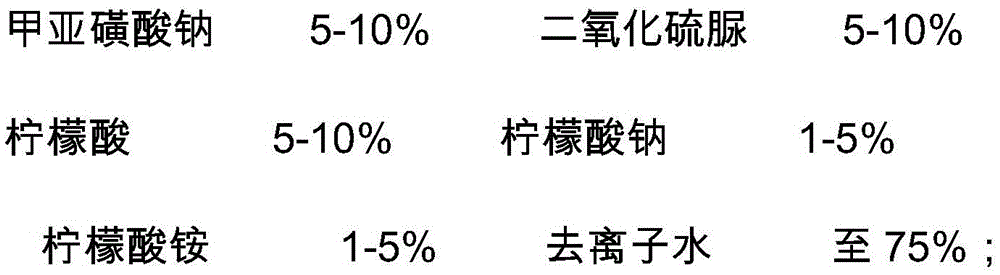

[0096] Prepare laser heat-induced reduction reaction type dye discharge agent according to the following ratio

[0097] Active ingredient:

[0098]

[0099] Catalytic components:

[0100]

[0101] Wherein said hydroxyanthraquinone can be 1,8-dihydroxyanthraquinone, 1,4,5,8-tetrahydroxyanthraquinone, chrysophanol or emodin, if the two are used in combination now, the ratio of the two is 1:1.

[0102] First mix the active components together and stir evenly; then add water to make a solution of zinc sulfate and anti-pulling fluorescent whitening agent, then add glycerin and polyethylene glycol, mix thoroughly, add hydroxyanthraquinone, Grind in a grinder at room temperature for 60 hours until a uniform thick suspension is formed; finally, add the prepared active components into the above grinder, and continue grinding for 3 hours at room temperature together with the catalytic component to a uniform liquid colloid mixture.

Embodiment 3

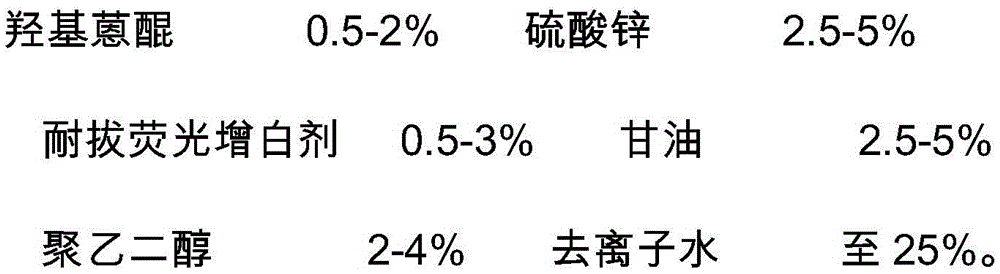

[0104] Prepare laser heat-induced reduction reaction type dye discharge agent according to the following ratio

[0105] Active ingredient:

[0106]

[0107] Catalytic components:

[0108]

[0109] The hydroxyanthraquinones mentioned therein are anthraquinone, 2-hydroxyanthraquinone, 1,4-dihydroxyanthraquinone, rubidin, hydroxyrubidin, and pseudohydroxylrubidin.

[0110] First mix the active components together and stir evenly; then add water to make a solution of zinc sulfate and anti-pulling fluorescent whitening agent, then add glycerin and polyethylene glycol, mix thoroughly, add hydroxyanthraquinone, Grind in a grinder at room temperature for 72 hours until a uniform thick suspension is formed; finally, add the prepared active components into the above grinder, and continue grinding at room temperature for 4 hours together with the catalytic component to form a uniform liquid colloid mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com