Oil agent used for polyester industrial filament

A technology of polyester industrial yarn and oil agent, which is applied in textiles and papermaking, fiber treatment, fiber type, etc. It can solve the problems of oil agent heat resistance, poor cohesion and adhesion, etc., and achieve high strength of raw silk, No color difference, less smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

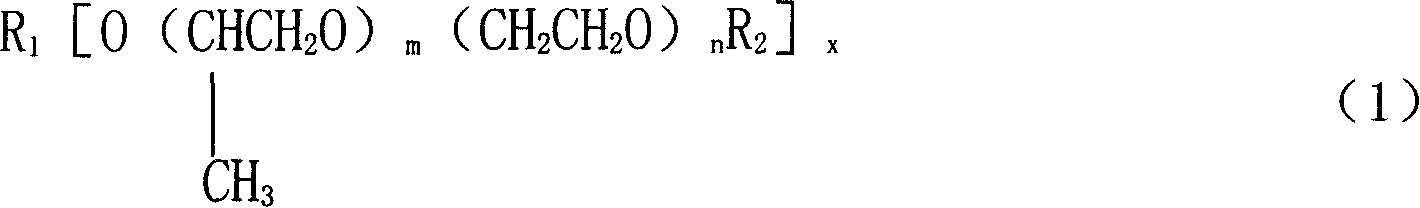

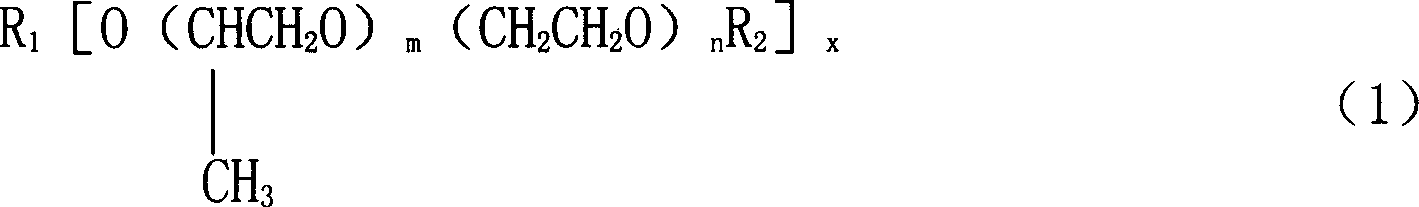

[0025] Get 20 grams of refined mineral oil successively (40 ℃ kinematic viscosity is 15.0mm 2 / S), 32 grams of glycerol trilaurate, 30 grams of polyether (m=16, n=38, R 1 is n-octyl, R 2 is octadecyl, x=1), 10 grams of fatty acid polyoxyethylene ester (fatty acid is C 18 Stearic acid, the mol ratio of fatty acid and oxirane is 1: 12), 3 gram lauryl phosphate potassium salts, 5 gram polyethylene glycol oleates (polyethylene glycol molecular weight is 600) in reaction In the kettle, heat to 47±2°C, stir at constant temperature for 40 minutes, and then cool to 25°C to obtain the invented oil agent A.

Embodiment 2

[0027] Get 20 grams of refined mineral oil successively (40 ℃ kinematic viscosity is 35.0mm 2 / S), 50 grams of glycerol trilaurate, 20 grams of polyether (m=16, n=38, R 1 is n-octyl, R 2 is octadecyl, x=1), 5 grams of fatty acid polyoxyethylene ester (fatty acid is C 18Stearic acid, the molar ratio of fatty acid to ethylene oxide is 1: 12), 3 grams of potassium lauryl phosphate, 2 grams of vulcanized vegetable oil in a reaction kettle, heated to 88 ± 2 ° C, stirred at constant temperature for 40 minutes , and then cooled to 25°C to obtain the invented oil agent B.

Embodiment 3

[0029] Get 47 grams of refined mineral oil successively (40 ℃ kinematic viscosity is 50.0mm 2 / S), 15 grams of glycerol tristearate, 20 grams of polyether (m=16, n=38, R 1 is n-decyl, R 2 Be lauryl, x=1), 5 grams of fatty acid polyoxyethylene esters (fatty acid is C 18 Stearic acid, the mol ratio of fatty acid and oxirane is 1: 12), 8 gram lauryl phosphate potassium salts, 5 gram polyethylene glycol oleates (polyethylene glycol molecular weight is 600) in reaction In the kettle, heat to 60±2°C, stir at constant temperature for 30 minutes, and then cool to 30°C to obtain the invented oil agent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com