Patents

Literature

148results about How to "Reduce deposition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

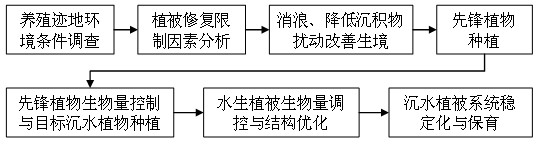

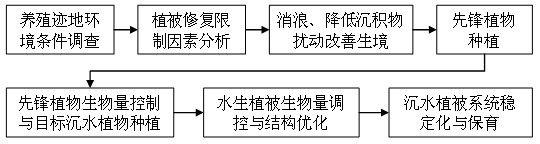

Aquatic vegetation restoration and ecological preservation method for aquaculture slash/target water areas

InactiveCN102487683AReduce resuspensionReduce food intakeClimate change adaptationPisciculture and aquariaRevegetationWater quality

The invention belongs to the technical filed of ecological restoration, relates to an aquatic vegetation restoration and ecological preservation method for aquaculture slash / target water areas, and comprises the steps of constructing wind reduction and wave attenuation facilities in aquaculture slash areas by means of original mesh enclosures of the aquaculture slash, transforming basement of the aquaculture slash, removing herbivorous fish in the aquaculture slash, creating habitat conditions suitable for submerged plants through culture of pioneer aquatic plants and regulation of biomass, preserving the submerged plants, promoting incensement of coverage of the submerged plants and improving water quality of lakes. Restoration of the submerged plants in the aquaculture slash in open water regions is achieved by means of wind speed reduction on lake surfaces, wave attenuation, basement transforming, herbivorous fish removal, the culture of the pioneer aquatic plants, the regulation of the biomass and creation of the habitat conditions suitable for growing of the submerged plants in the aquaculture slash of the lakes.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Phosphorus-free corrosion-inhibition antiscalant used for industrial circulation cooling water

InactiveCN101700935AGood corrosion inhibitionGood synergyScale removal and water softeningWater/sewage treatment bu osmosis/dialysisCarboxylic saltCarboxylic acid

The invention relates to a phosphorus-free corrosion-inhibition antiscalant used for industrial circulation cooling water treatment, which is characterized by comprising the following medicament components by weight: 10-40% of N-alkyl group-N-fat acyl amino fatty acid salt, 5-25% of hydroxy carboxylate, 5-20% of carboxylic acid copolymer, 1-4% of metal salt and the balance water.

Owner:CHINA NAT OFFSHORE OIL CORP +1

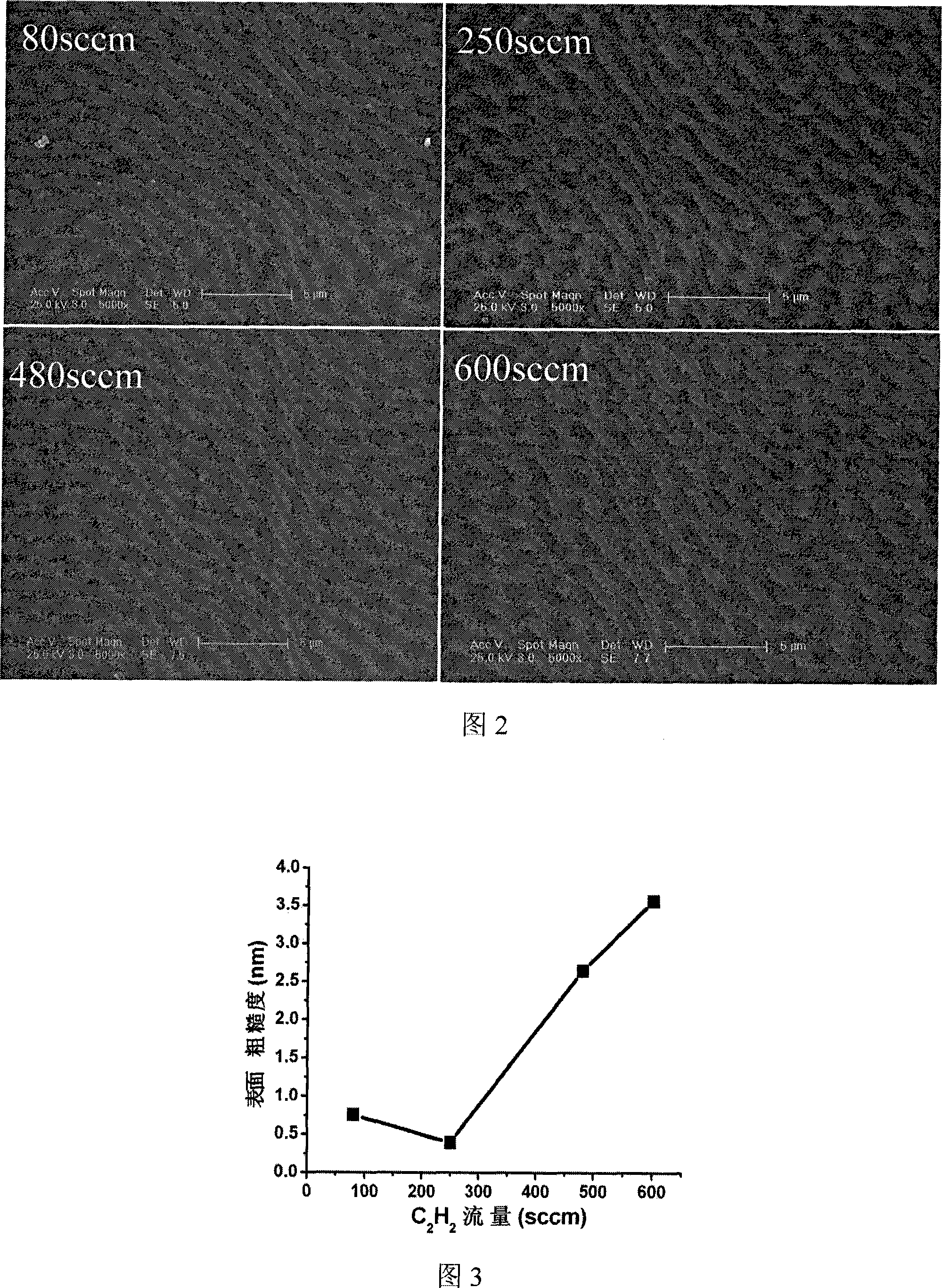

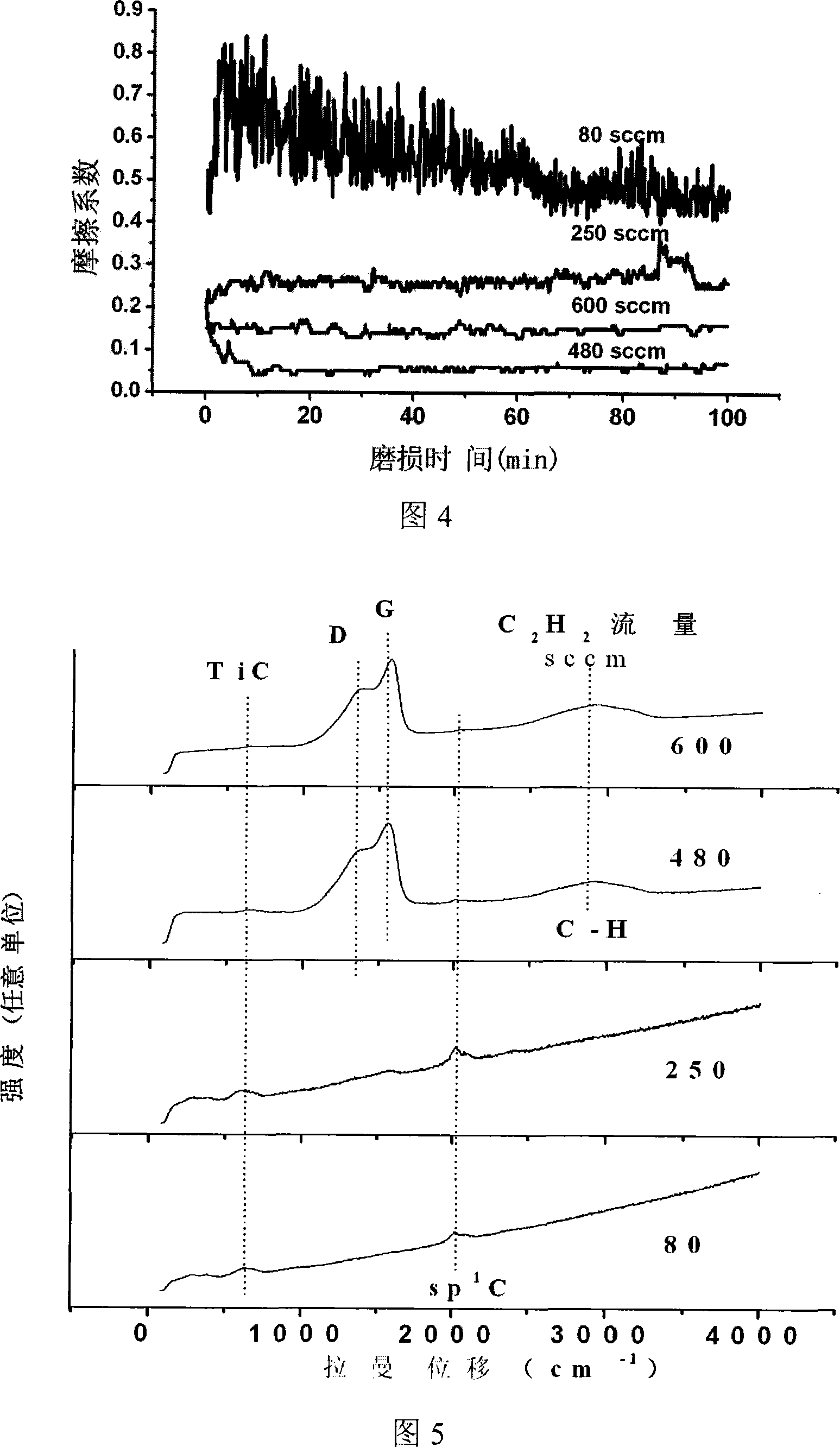

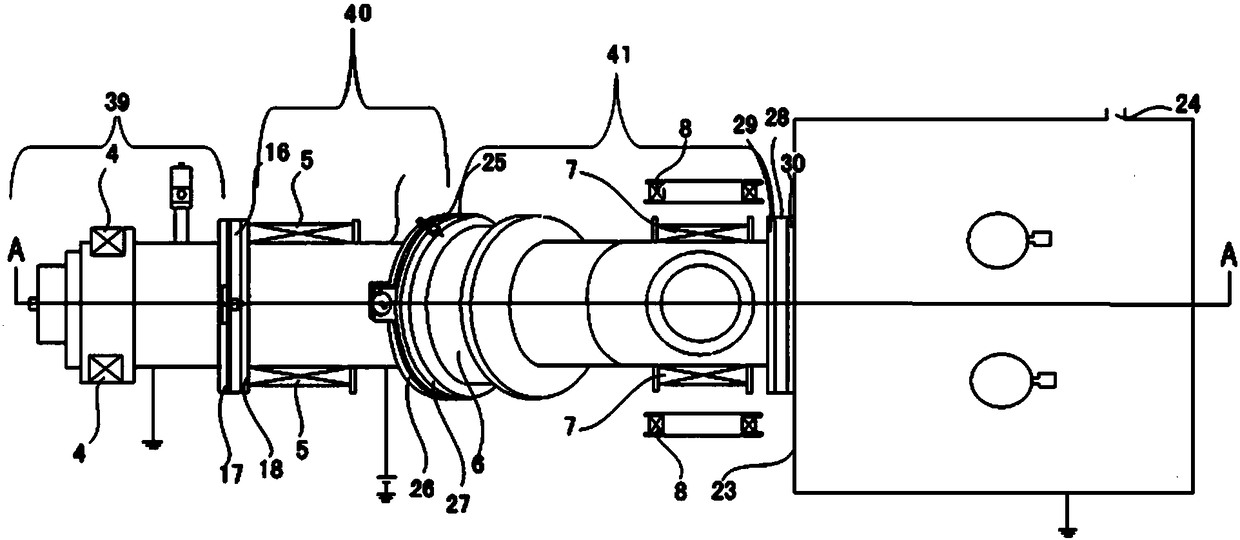

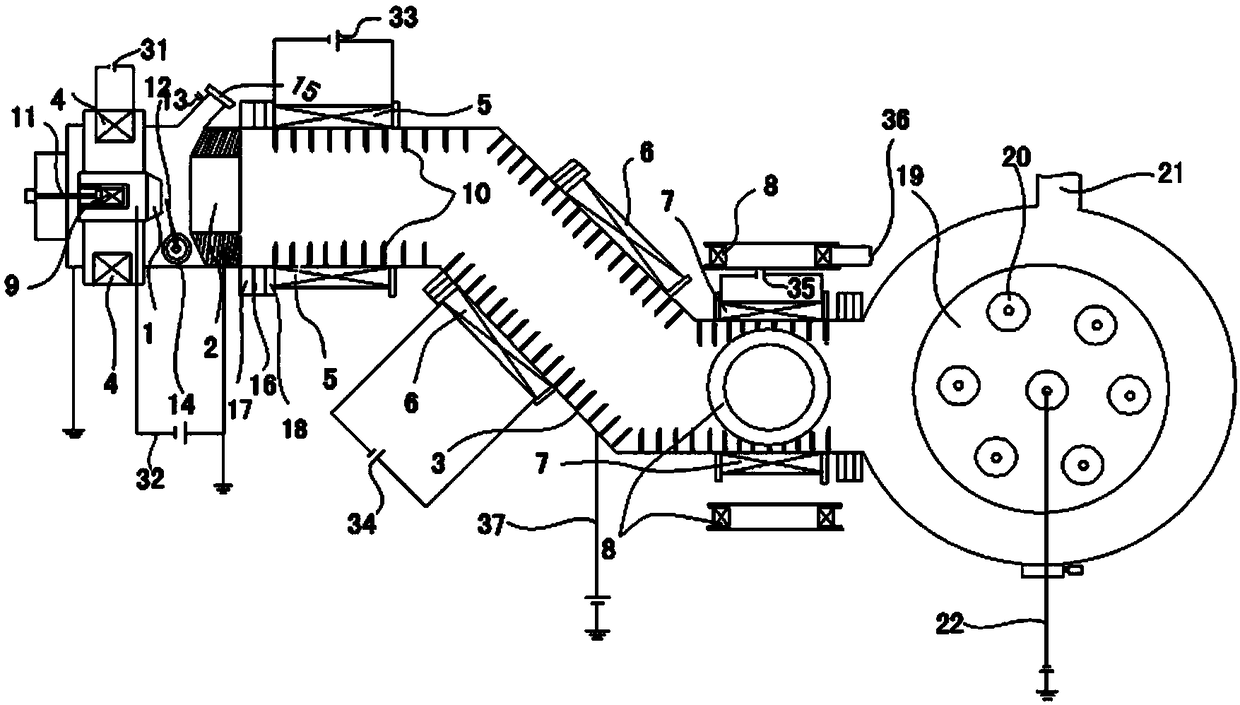

Method for preparing nano composite diamond coating

InactiveCN101113516AIncrease growth rateEliminate pollutionChemical vapor deposition coatingCarbon ionAlloy

The invention discloses a preparation method of a nano complex diamond-like coating layer. The method utilizes the cathode arc discharge controlled by a magnetic field, and excessive ethyne gas is introduced to the front of a metal target, and a metal carbide layer is formed on the target surface, metal carbide can be steamed from the target surface while the arc moves; furthermore, under the function of an auxiliary magnetic field, the front of the arc target utilizes the arc discharge to generate strong plasma ionized ethyne gas, and generate high ionized carbon ions; under the function of bias, the metal carbide steamed from the target surface and carbon ions generated by ethyne form a carbide doped nano complex diamond-like coating layer. The diamond-like coating layer prepared by the invention has the advantages of high coating hardness, strong adhesive force, high coating growing speed and production efficiency, low production cost and simple equipment structure, etc.; the invention can be applied to preparing the diamond-like coating layer of different thickness on all kinds of workpieces such as hard alloy, high speed steel, stainless steel, carbon steel, die steel, etc. according to different using requirements.

Owner:WUHAN UNIV

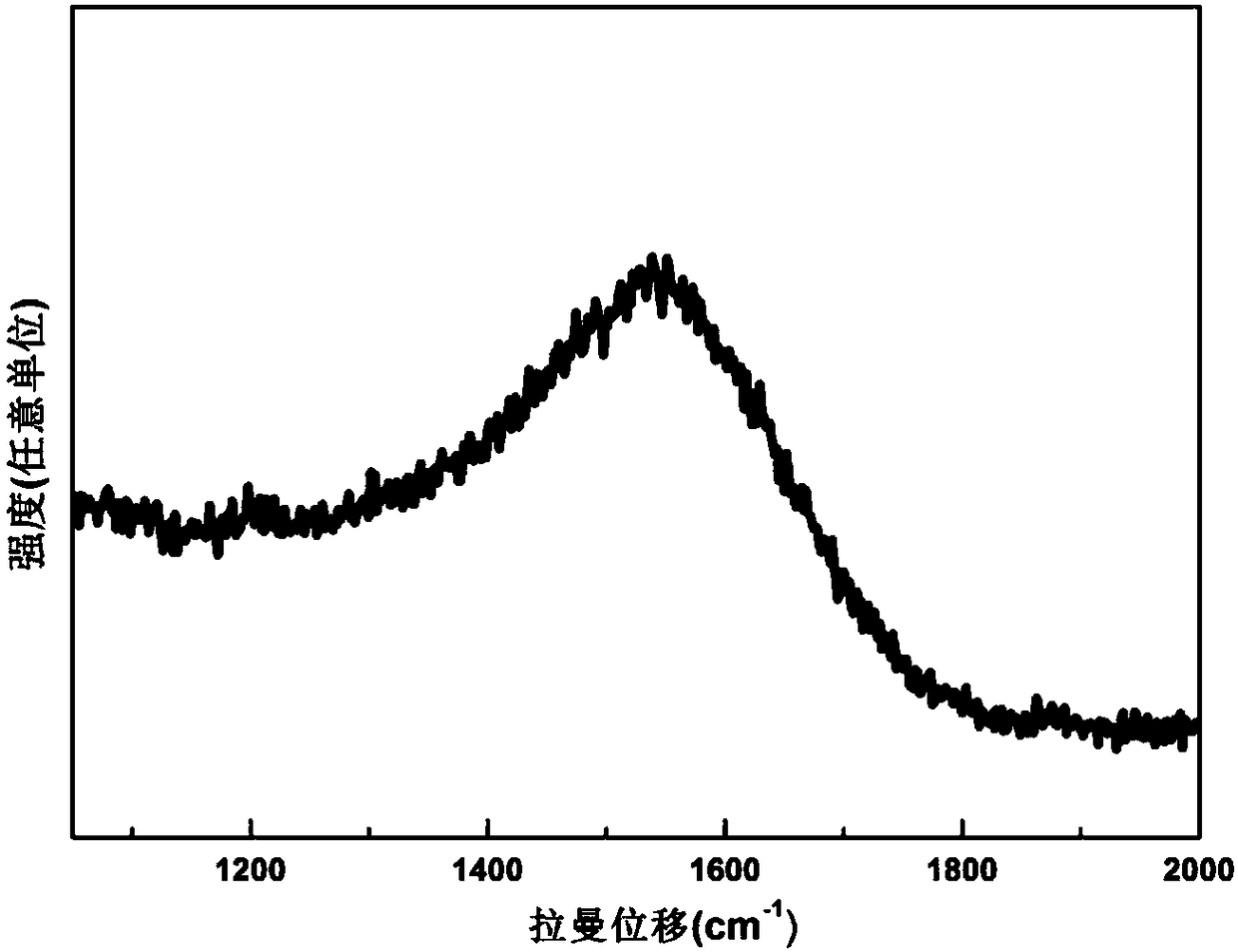

Graphene preparation method

ActiveCN108203090ASimple processLow costVacuum evaporation coatingSputtering coatingEvaporationCvd graphene

The invention provides a graphene preparation method, which combines a cathode vacuum electric arc deposition technology, an electron beam evaporation plating technology and a vacuum annealing process. According to the method, by optimizing process parameters, an amorphous carbon film with high sp3 content is deposited on the surface of a matrix, a catalyst film is subjected to evaporation platingat the surface through an electron beam, and finally annealing is performed at a temperature of 450-500 DEG C to diffuse and precipitate carbon onto the surface of the catalyst film so as to convertthe structure into the graphene structure to form the few-layer or multi-layer graphene. Compared to the existing graphene preparation process, the graphene preparation process of the invention has advantages of simpleness, easy performing, low annealing temperature and reduced cost; and the used carbon source is not the gas but the solid, and the number of the layers of graphene can be controlledby controlling the thickness of the carbon source so as to achieve the controlled preparation of graphene.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

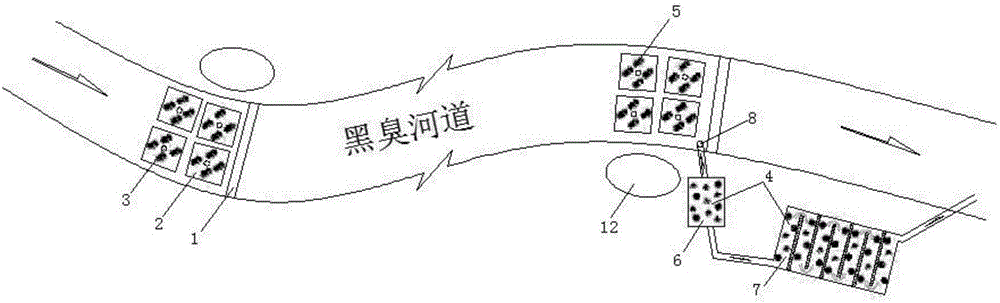

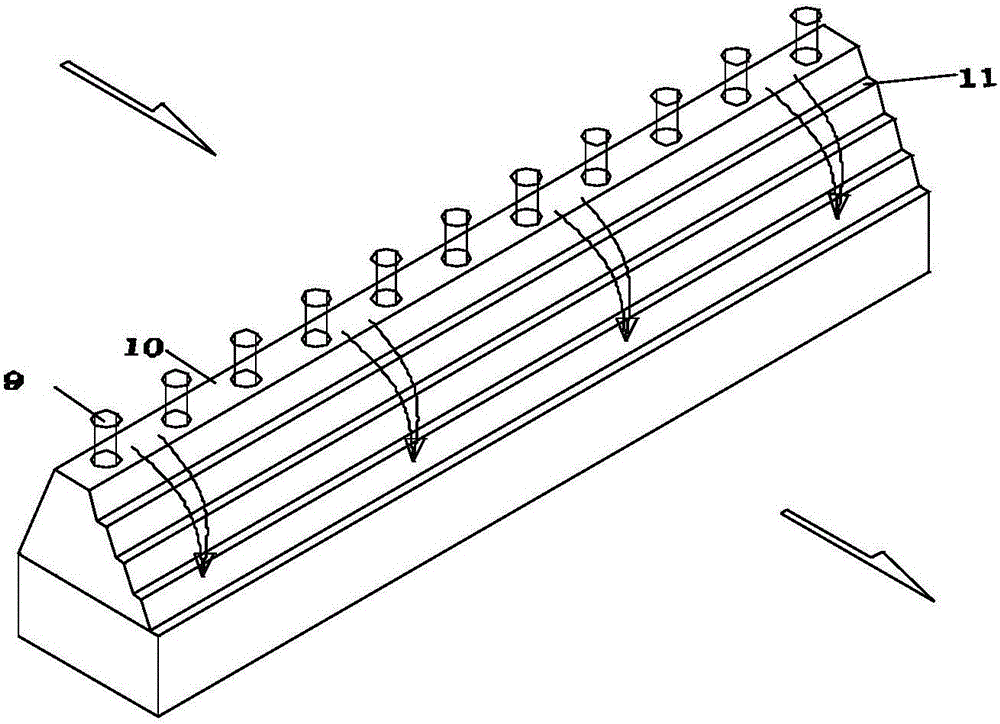

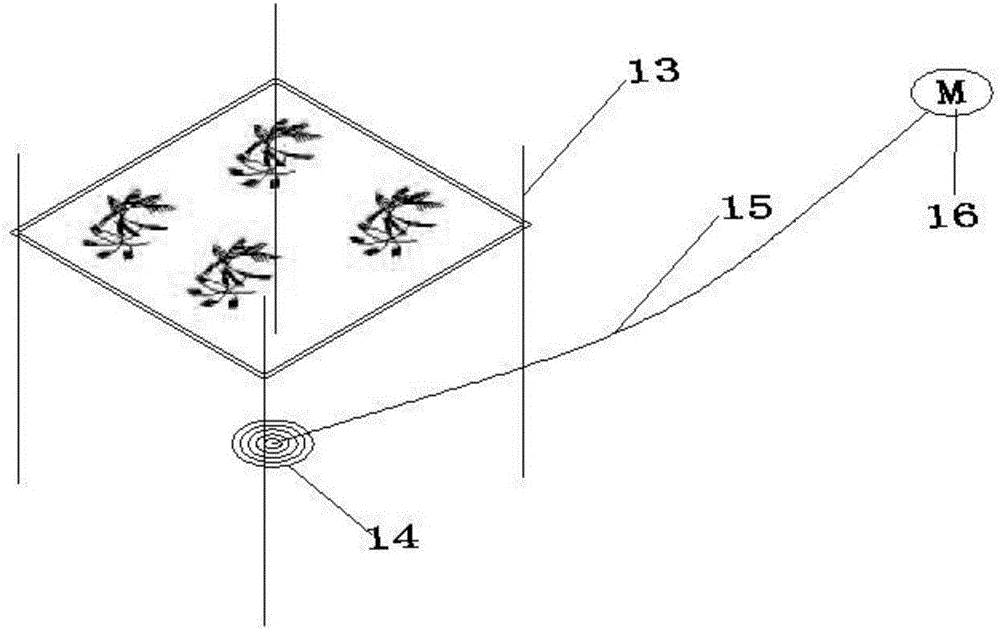

Ecological restoration device and method for urban black-odor riverway

InactiveCN106045055AAvoid cloggingEasy to settleWater resource protectionSustainable biological treatmentRestoration deviceNitrogen

The invention discloses an ecological restoration device and method for an urban black-odor riverway. The device comprises multi-stage overflow dams arranged at different water level differences of a black-odor river. A plurality of biological floating beds are arranged inside each overflow dam. A nanometer microhole aeration disc is arranged at the bottom of each biological floating bed. Floating plants are arranged inside the biological floating beds. A secondary combined subsurface wetland is arranged at the downstream part of the tail-stage overflow dam and comprises an aeration vertical flow wetland, a bending-flow type horizontal flow wetland and a water pump. Water inside the tail-stage overflow dam is lifted by the water pump and then enters the aeration vertical flow wetland, outflow water of the aeration vertical flow wetland flows into the bending-flow type horizontal flow wetland, and outflow water passing through the bending-flow type horizontal flow wetland flows back to the riverway. The device is simple in structure, low in energy consumption, and capable of efficiently removing nitrogen, phosphorus, sulphur, organic matters, heavy metal and other pollutants in the urban black-odor riverway at the same time.

Owner:WUHAN UNIV OF TECH

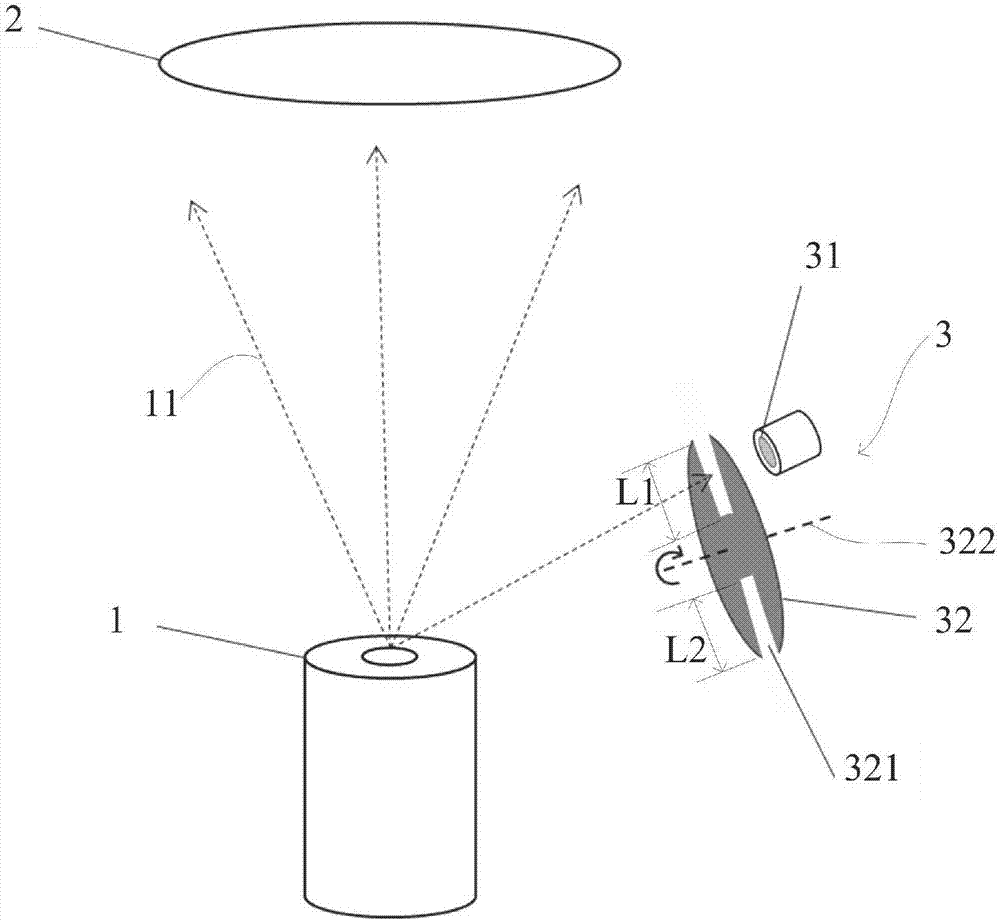

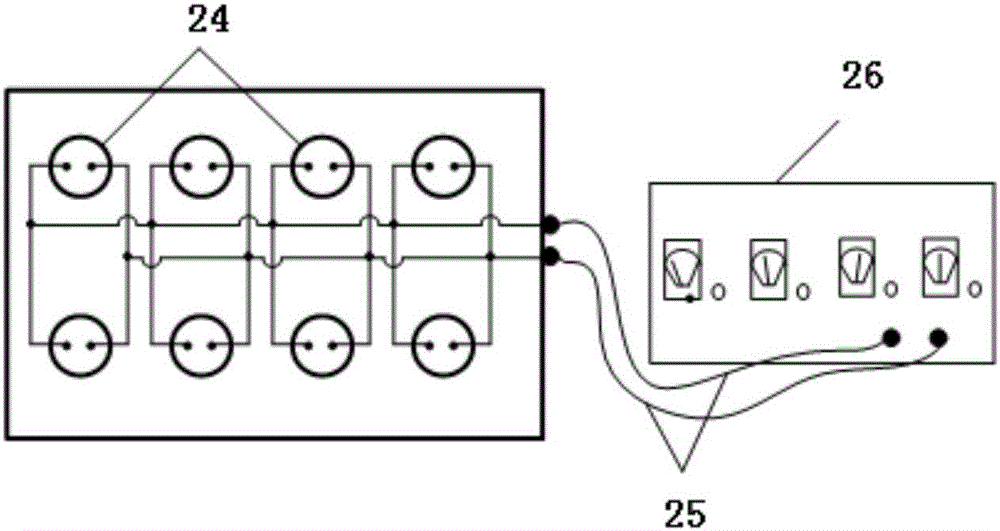

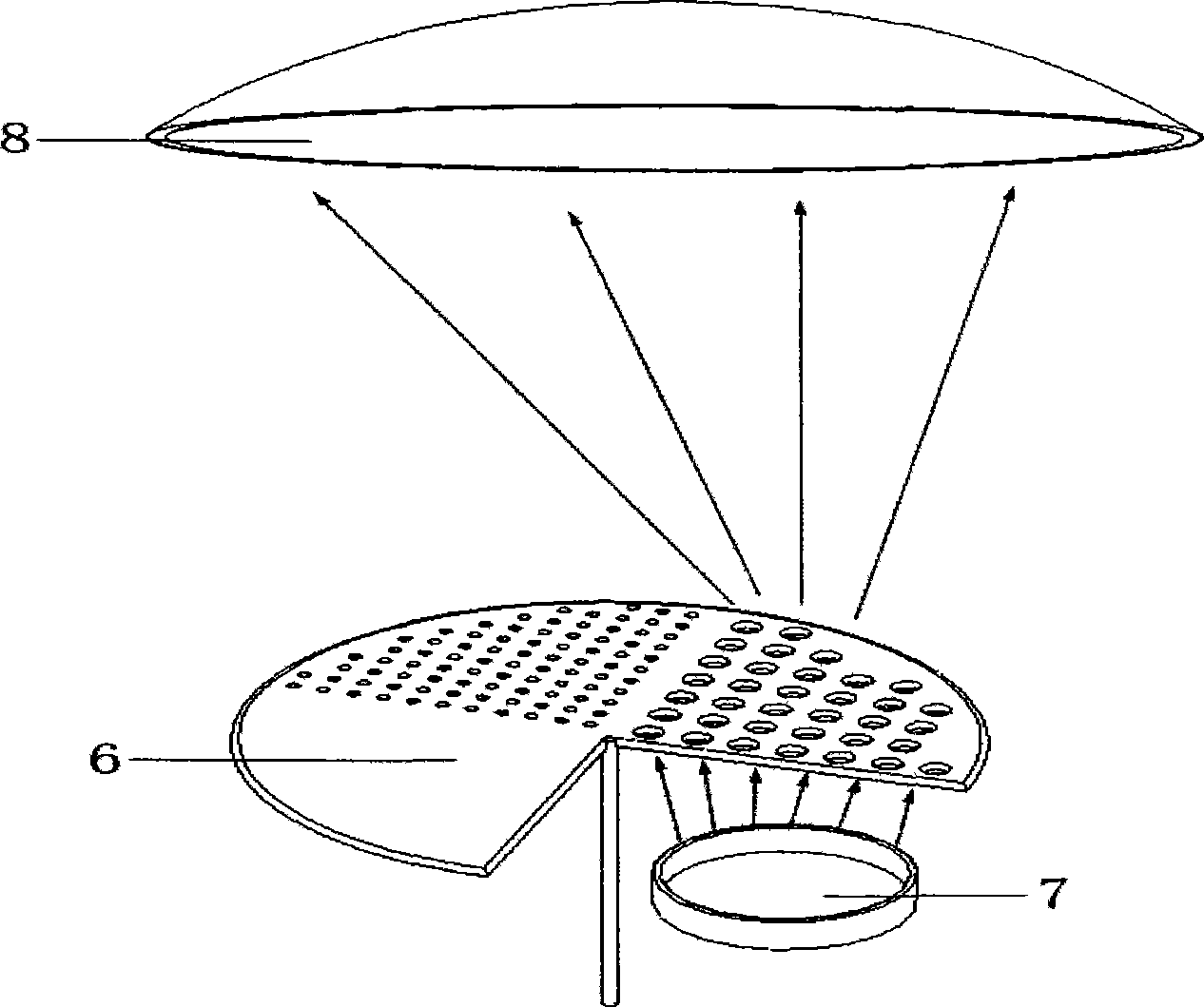

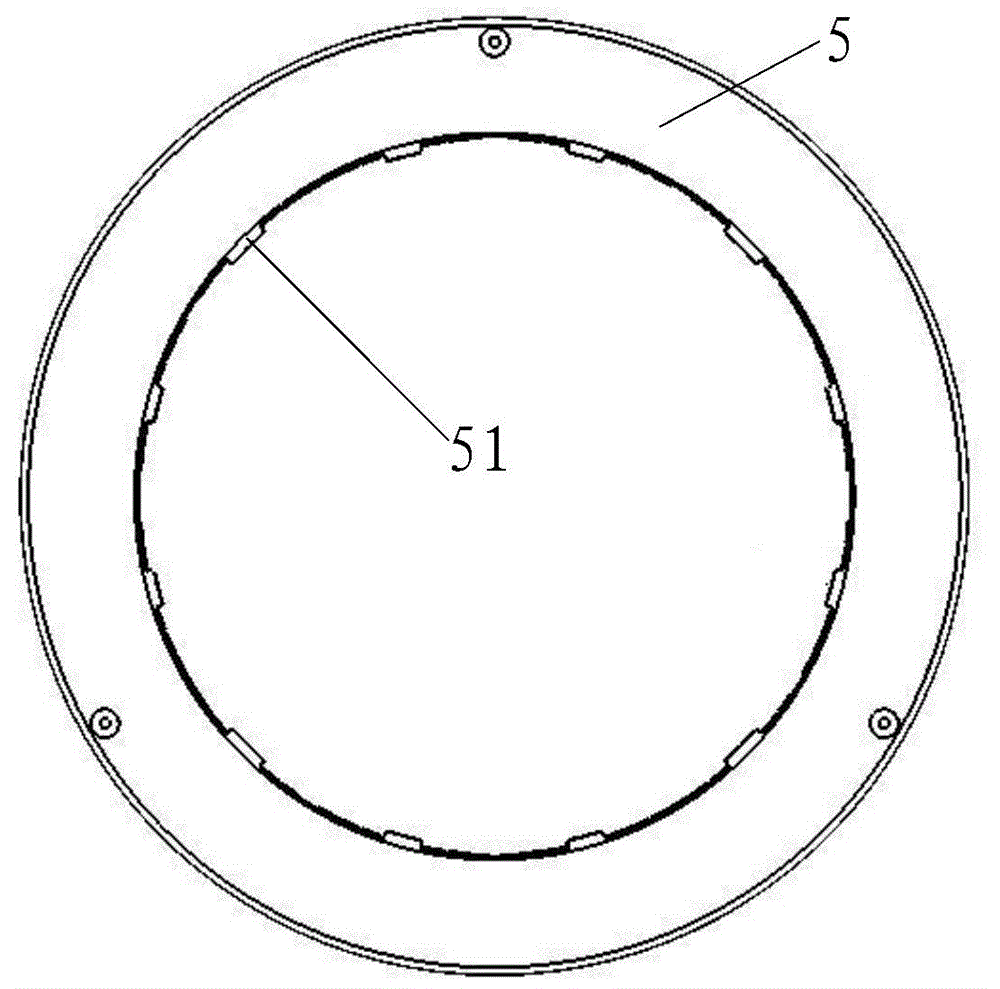

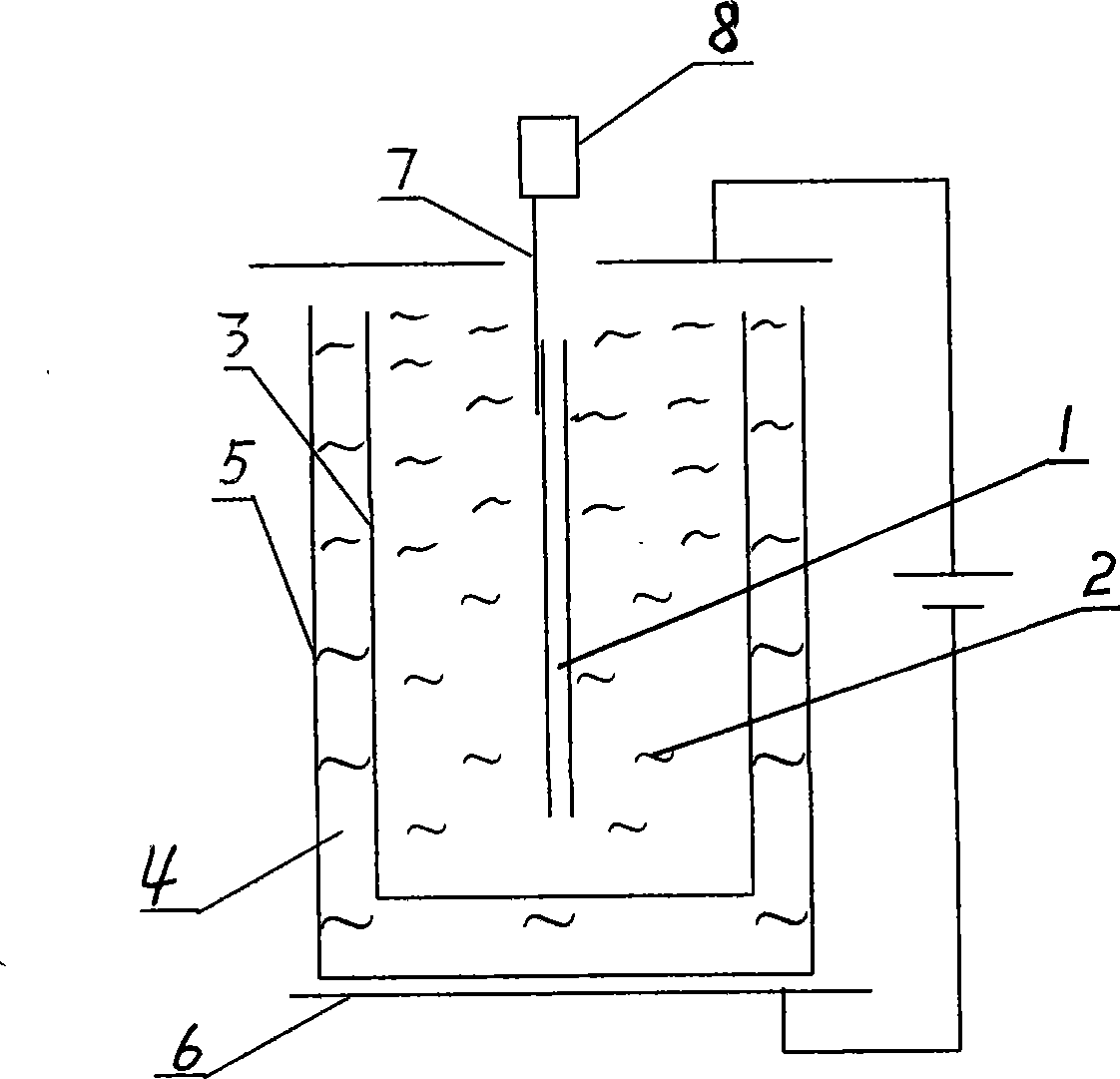

Film coating system and film thickness monitoring device thereof, and film coating method and film thickness monitoring method thereof

InactiveCN107385406AExtended use timeReduce deposition rateVacuum evaporation coatingSputtering coatingEngineeringRunning time

The invention relates to a film coating system and a film thickness monitoring device thereof, and a film coating method and a film thickness monitoring method thereof. The film thickness monitoring device comprises a shielding plate and a quartz crystal wafer, wherein the shielding plate and the quartz crystal wafer can rotate relative to each other, and the shielding plate is provided with an opening; and in the relative rotating process, the opening allows airflow of a film coating material to pass through to enable the airflow to reach the quartz crystal wafer, and other parts, except the opening, of the shielding plate block the airflow from reaching the quartz crystal wafer. The shielding plate is adopted for blocking the airflow, the deposition velocity of film on the quartz crystal wafer is slowed down, the service time of the quartz crystal wafer is prolonged, and therefore the continuous running time of the equipment is prolonged, and the cost is correspondingly reduced. In addition, the shielding plate and the quartz crystal wafer can rotate relative to each other, so that the airflow of the film coating material can pass through the opening in the rotating process and then is uniformly deposited on the quartz crystal wafer, the situation that the thickness of the film coating materials deposited on the quartz crystal wafer is not uniform due to the fact that the opening is arranged is avoided, and the monitoring accuracy is guaranteed and improved.

Owner:茆胜

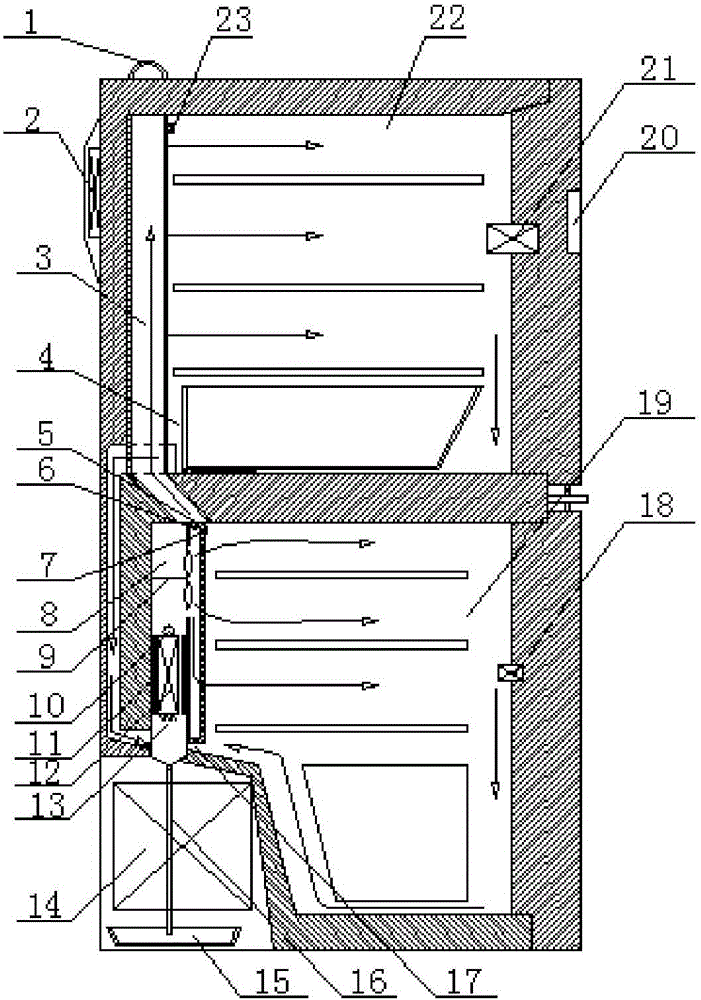

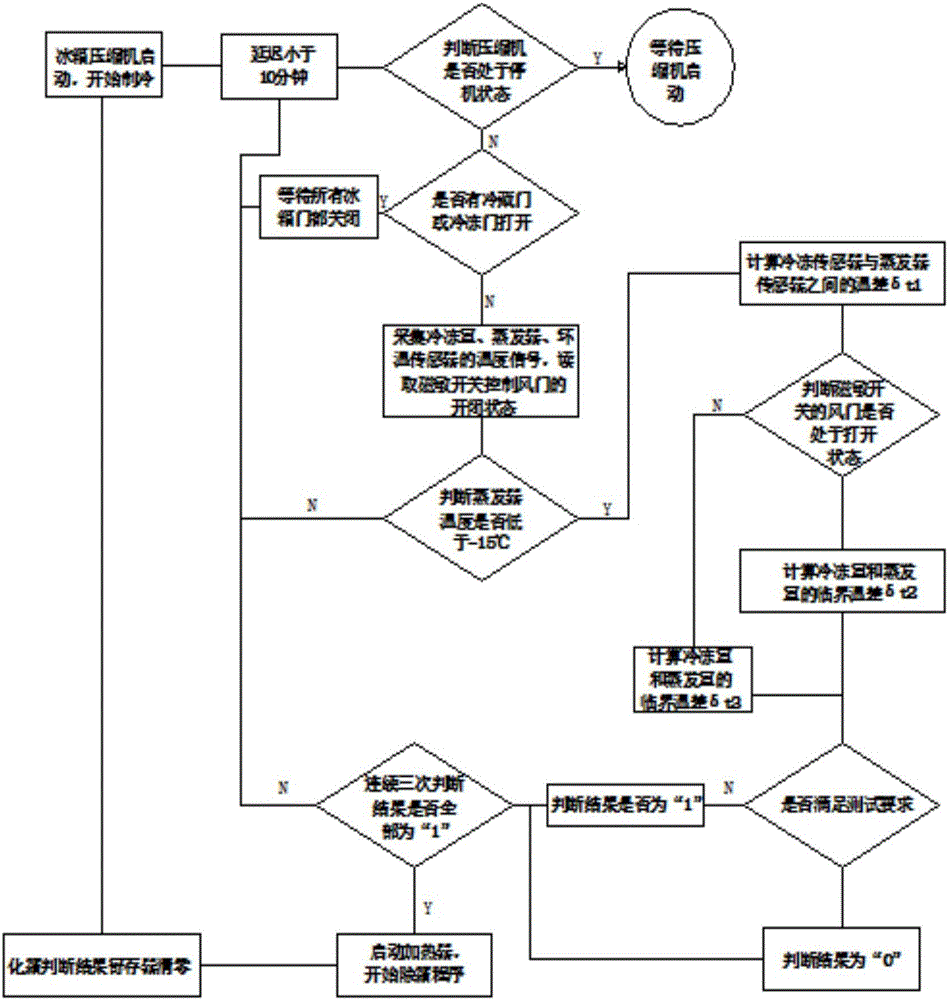

Frostless refrigerator capable of defrosting through coupling of ultrasonic waves and super-hydrophobic materials, and control method of frostless refrigerator

InactiveCN105716352AStable operating environmentExtended service lifeLighting and heating apparatusDomestic refrigeratorsEngineeringReturn channel

The invention discloses a frostless refrigerator capable of defrosting through coupling of ultrasonic waves and super-hydrophobic materials, and a control method of the frostless refrigerator. The frostless refrigerator comprises a master controller, an evaporation chamber, a refrigerating chamber, a cold storage chamber, a compressor, a drainage device, an environmental temperature sensor and a magnetic sensitive control air valve, wherein the master controller is separately connected with a ultrasonic wave oscillation system, the compressor, an electric heater, the magnetic sensitive control air valve, a fan, the environmental temperature sensor, a refrigerating chamber temperature sensor, an evaporator temperature sensor and a cold storage chamber temperature sensor, and the ultrasonic wave oscillation system and the electric heater are defrosting devices; the surface of an evaporator, the surface of a refrigerating chamber air channel, the surface of a refrigerating chamber air-return vent, the surface of a cold storage chamber air channel, and the surface of a cold storage chamber air-return channel are made from super-hydrophobic materials. According to the frostless refrigerator and the control method thereof disclosed by the invention, frosting surfaces are treated by using the super-hydrophobic materials, ultrasonic waves and electric heating are coupled, on-line defrosting is performed in a manner that the frostless refrigerator does not stop, the stable running environment of the refrigerator is guaranteed, and the service life of the refrigerator is prolonged.

Owner:NANJING NORMAL UNIVERSITY

Chemical nickeling solution, method for preparing nickeling layer and aluminium alloy hub coating thereof

InactiveCN1614087AReduced corrosion resistanceImprove bindingLiquid/solution decomposition chemical coatingAlloy wheelCorrosion

The invention was involved in a chemical nickel-plating liquid, its method and aluminum alloy wheel boss coating thereby. The said liquid contains 5.6-6.0g, / L Ni2+, 25-30g / L NaH2PO2.H2O, 10-45g / L ligand, 0-20g / L phosphorus inhibiter and 5-30g / L buffering agent. The treated aluminum alloy wheel boss was immersed into the above liquid to form chemical nickel coating by the method. The aluminum alloy wheel boss coating consist of electroplated pre-plating coating, electro-coppering, three-layer nickels, nickel closing layer, bright chrome layer and chemical nickel coating which was located in pre-plating coating or mediate layer of aluminum alloy wheel boss coating. The corrosion resistance of coating was improved obviously. It could endure over 88h on CASS test.

Owner:HARBIN INST OF TECH

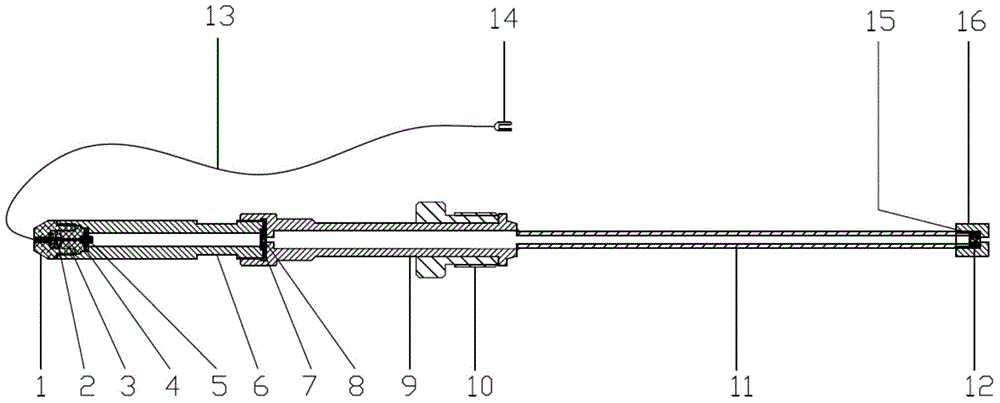

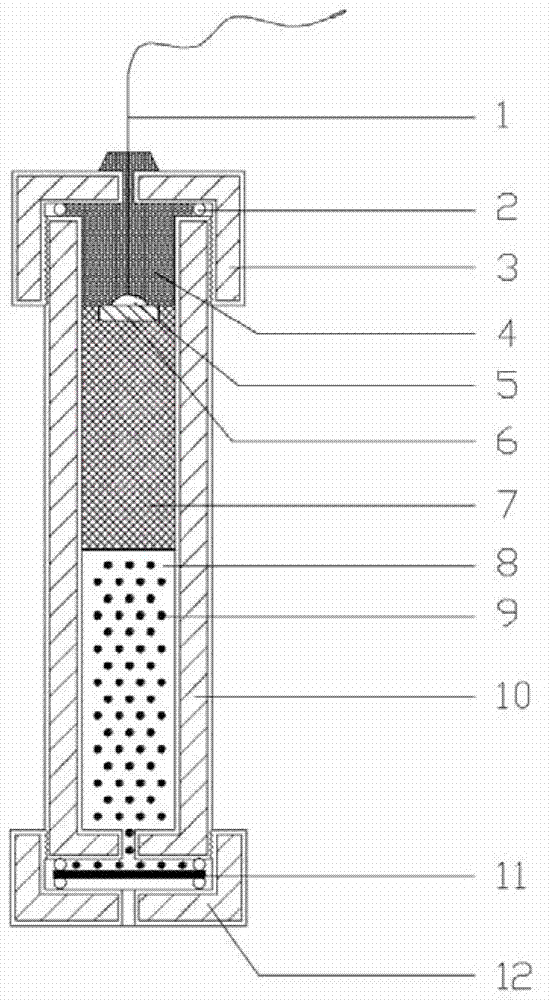

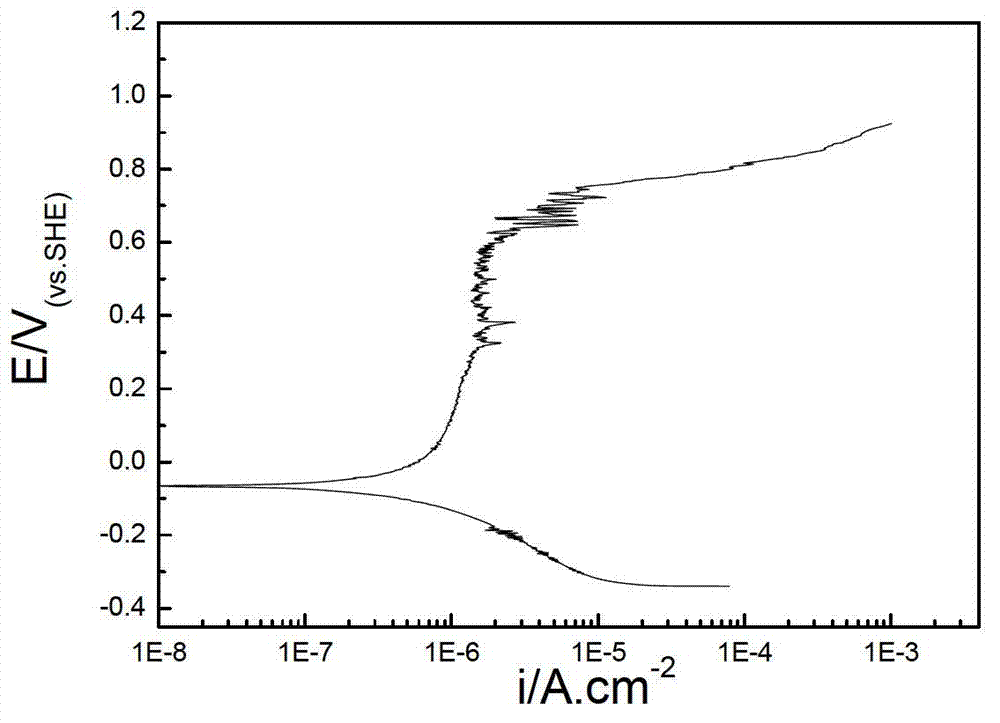

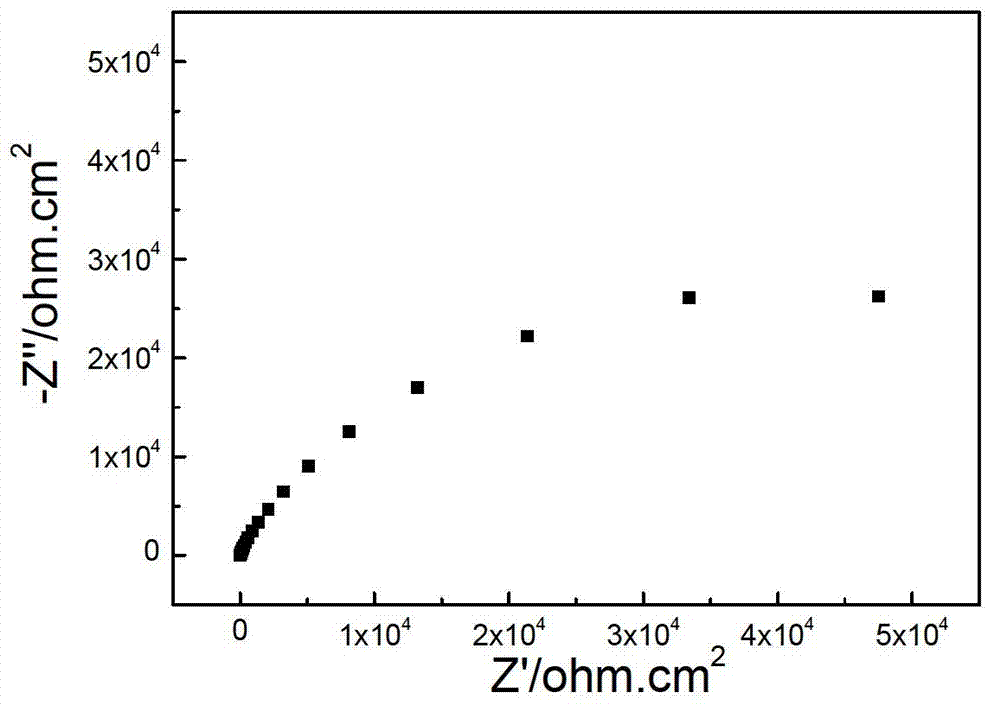

Long-service-life reference electrode applicable to high-temperature and high-voltage corrosive environment

ActiveCN104914148ASolve solubilitySolving Diffusion ProblemsMaterial electrochemical variablesEpoxyEngineering

The invention provides a long-service-life reference electrode applicable to the high-temperature and high-voltage corrosive environment. A core of the electrode is formed by hot pressed sintering, a shell of the electrode is composed of an upper end body, a middle end body and a lower end body, the middle end body is connected with the lower end body into a whole, an upper end cover is connected with the upper end body through threads, an isolation external member composed of a first fluororubber pad and first microporous ceramic is arranged between the upper end body and the middle end body, an anti-explosion pad is arranged between the upper end body and the upper end cover, one end of a high-temperature-resisting lead of the electrode penetrates through the upper end cover of the electrode and the anti-explosion pad to be connected with the core of the electrode, the core of the electrode is fixed in the upper end body by utilizing a positioning pad, the positioning pad and the anti-explosion pad are sealed by solid powder epoxy resin, a second fluororubber pad and a second microporous ceramic core are arranged between a lower end cover and the lower end body. The reference electrode can be used under the high-temperature and high-voltage environment, and the use effects of high-temperature resistance, high-voltage resistance, no need of maintenance and long service life are achieved.

Owner:HARBIN ENG UNIV

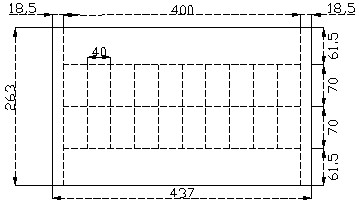

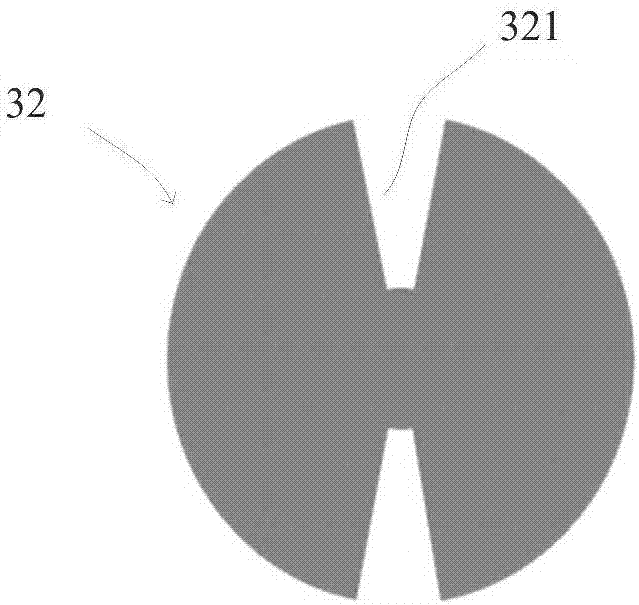

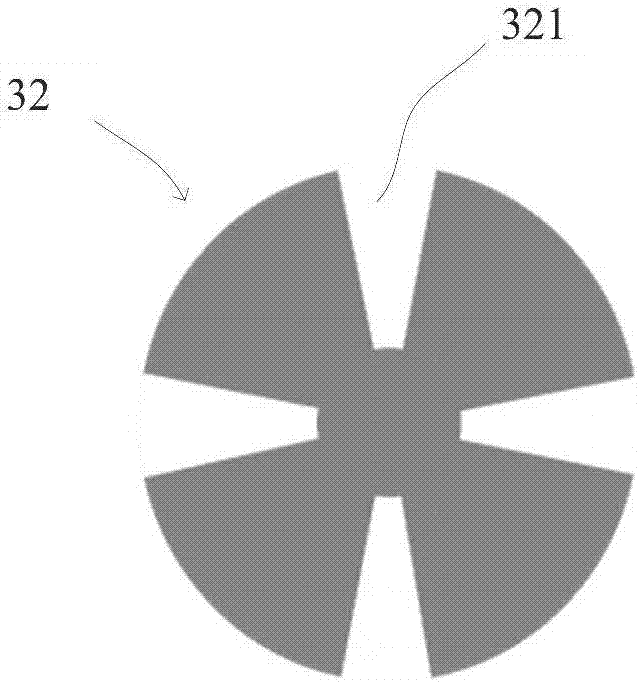

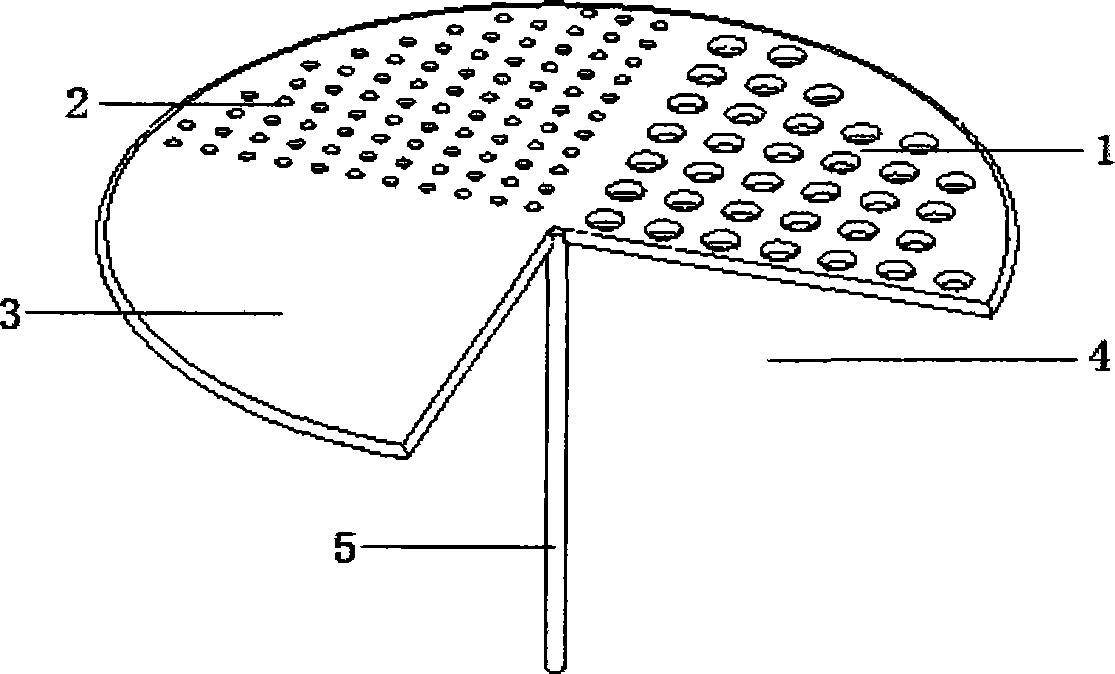

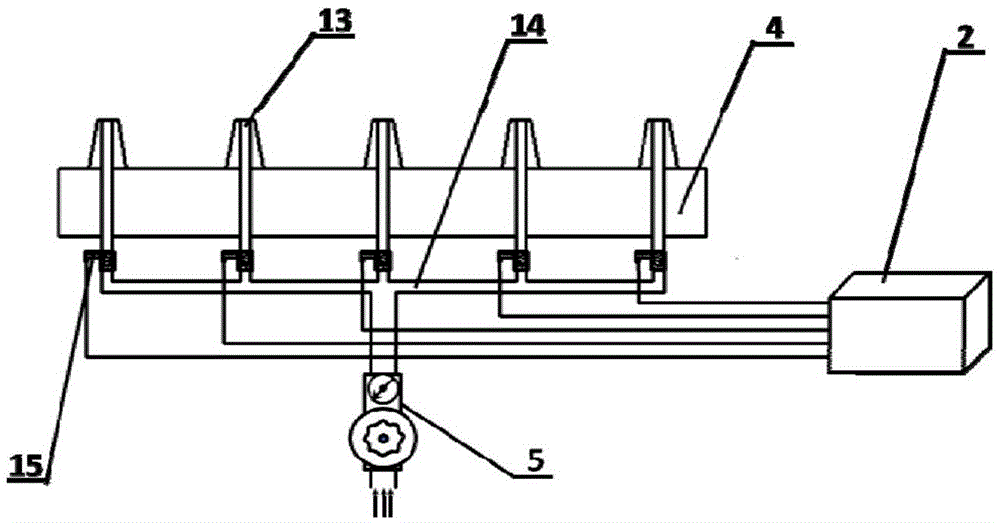

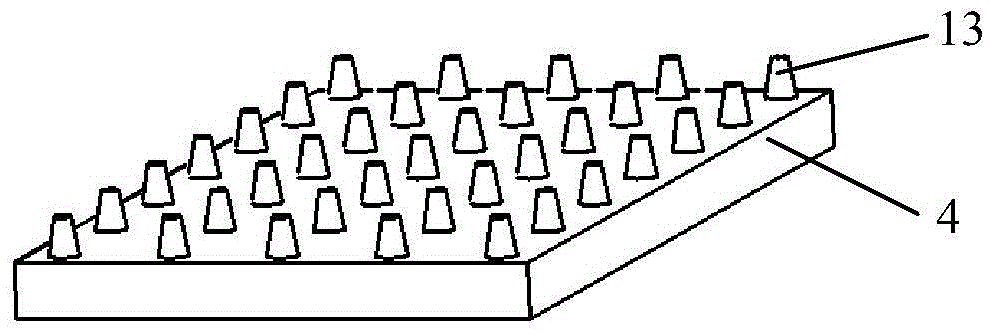

Vacuum coating machine baffle with adjustable deposition rate

InactiveCN101445910AThe preparation method is simple and easyImprove practicalityVacuum evaporation coatingSputtering coatingEngineeringVolumetric Mass Density

A vacuum coating machine baffle with adjustable deposition rate comprises a high-temperature resistant circular plate, a rotating shaft which is vertically connected at the center of the circular plate and a driving device connected at the lower end of the rotating shaft. The baffle is characterized in that the circular plate is divided into a plurality of sectors from the center of the circular plate in a radiant way, and the sectors are sequentially a full blocking area, a non-blocking area and more than one blocking areas which has the blocking degree changing from small to large and covers until the full blocking area; the non-blocking area is formed by excavating panels of the sectors, the full blocking area is formed by completely maintaining the panels of the sectors, and the sectors of the blocking area are respectively provided with a plurality of through holes that have the apertures from large to small and the densities from dense to loose, while the apertures of the through holes in the same sector are the same as each other and have even density; the sectors completely cover a coating material evaporation source. The vacuum coating machine baffle can effectively regulate the deposition rate of the film in a multistep way under the condition of not changing the evaporation method and the evaporation rate of the coating materials, thus achieving the aim of improving the performance of film deposition.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

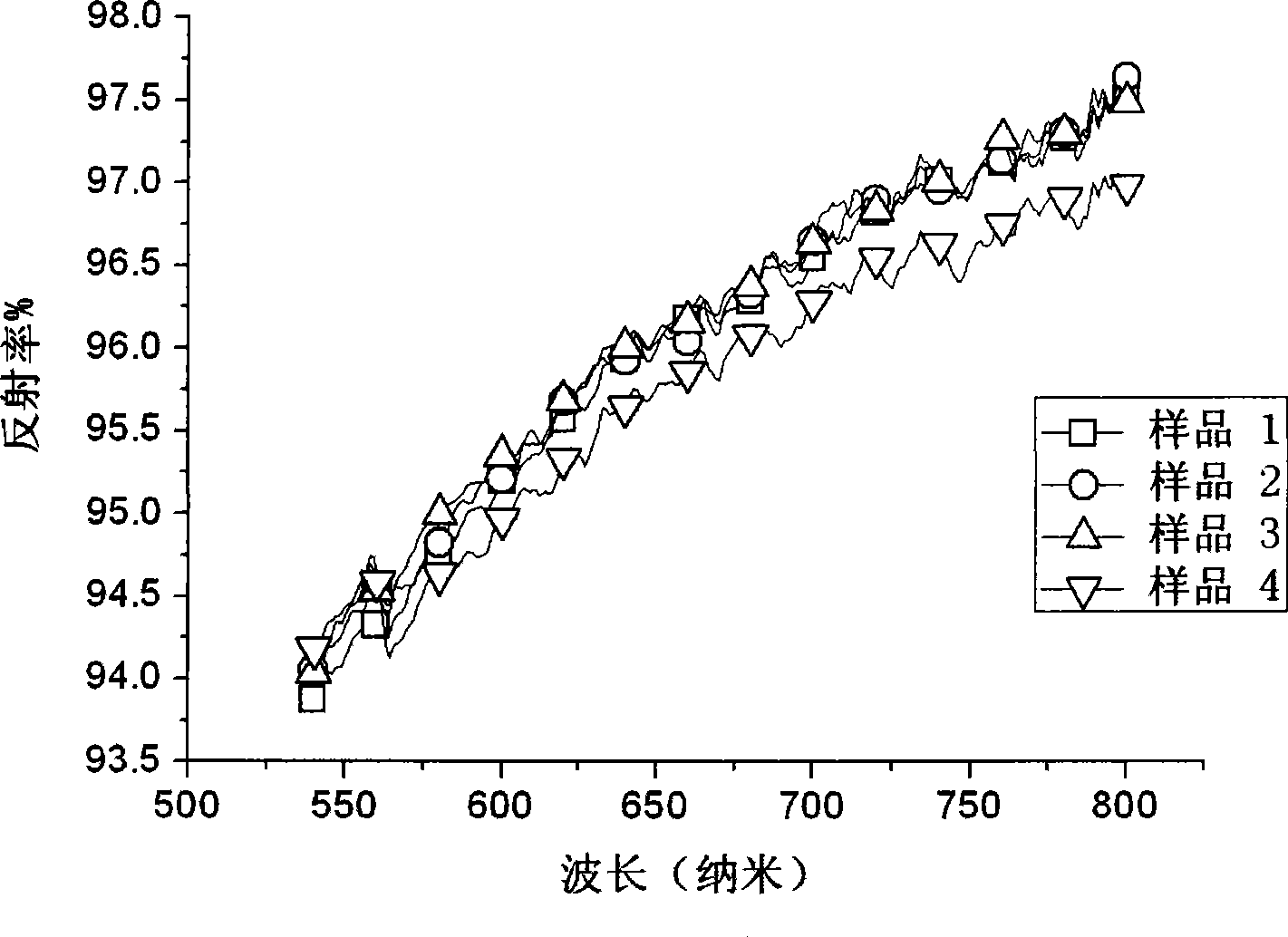

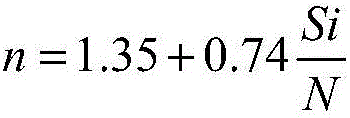

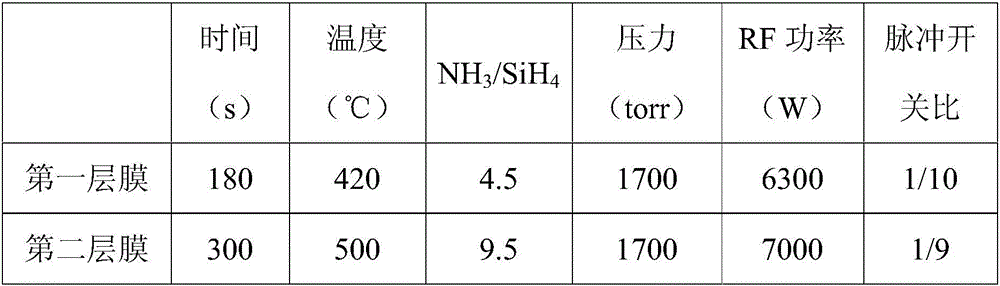

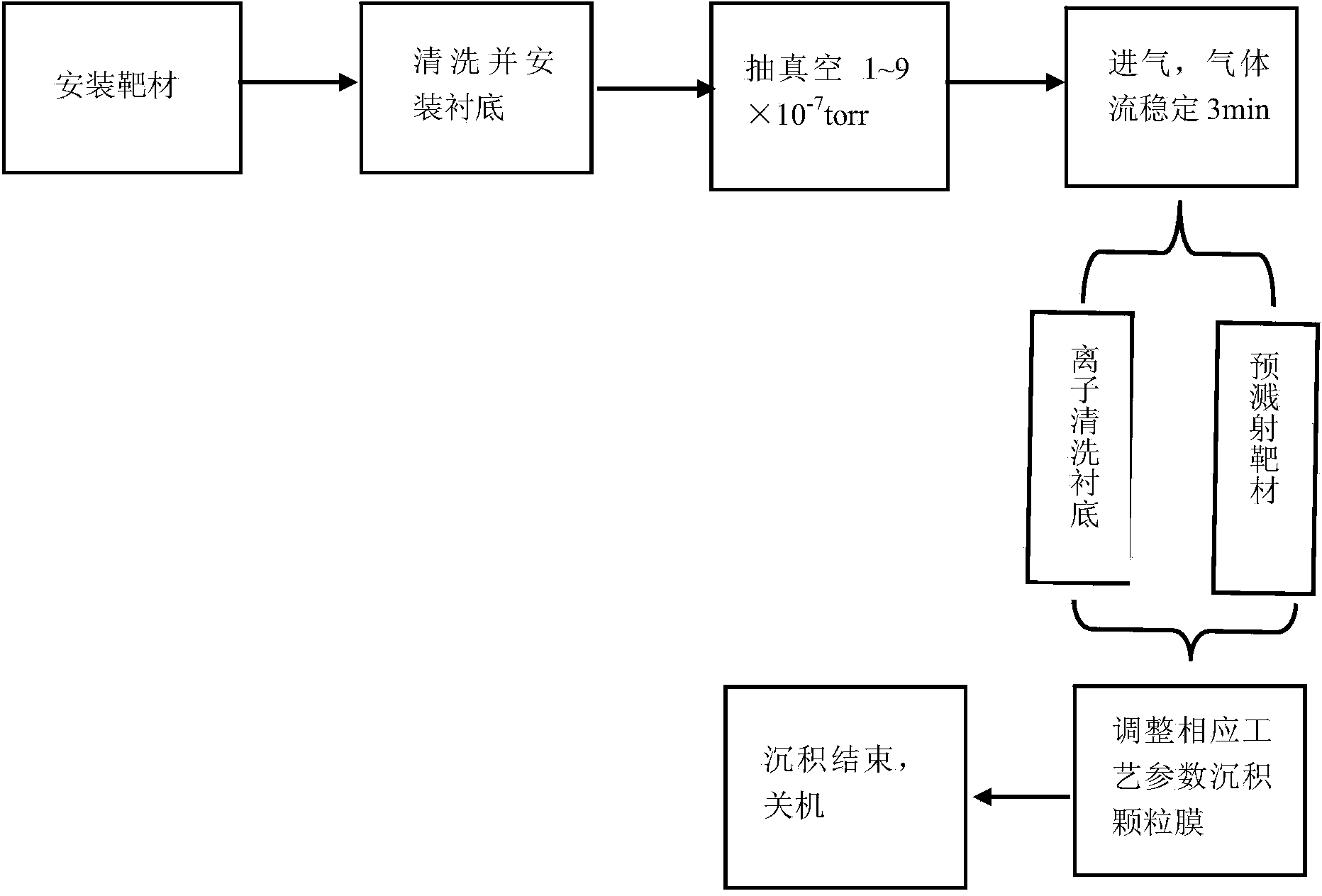

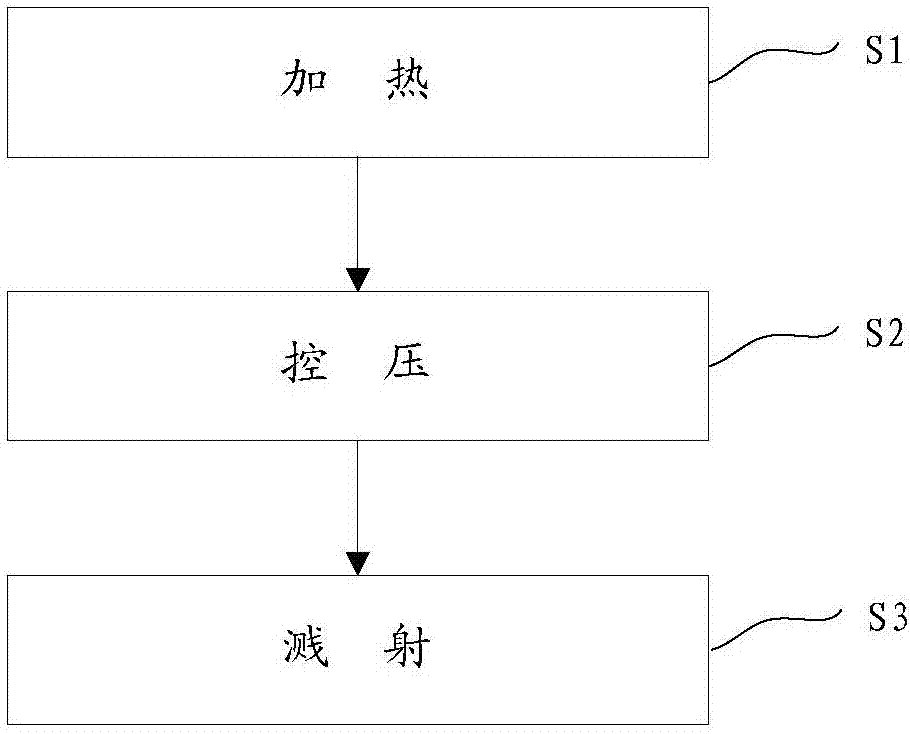

Tubular type silicon nitride PECVD technology

InactiveCN106299025AReduce deposition rateGood film qualityFinal product manufactureSemiconductor/solid-state device manufacturingSilicon nitrideSolar battery

The invention discloses a tubular type silicon nitride PECVD technology. Film plating is carried out twice, the temperature used for plating a first film is lower than the temperature used for plating a second film. The deposition technology provided by the invention improves the passivation anti-reflection effect of a tubular type PECVD silicon nitride film for a crystal silicon solar battery and reduces technology time.

Owner:成都富捷科技有限公司

Method for preparing monodisperse size-controllable nanosilver particles by using radio frequency magnetron sputtering method

ActiveCN104372301AGood size controlZero pollutionVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringAtmospheric pressure

The invention relates to a method for preparing monodisperse size-controllable nanosilver particles by using a radio frequency magnetron sputtering method. The monodisperse size-controllable nanosilver particles are prepared by using the radio frequency magnetron sputtering method under the condition that the basal spur of an equipment target is fixed by means of adjusting the process parameters such as vacuum degree, working air pressure, radio-frequency power, substrate temperature, deposition time and the like by selecting 99.999% superfine silver as a magnetron sputtering target, glass or silicon as a substrate and high purity argon (Ar) as working gas. The method which is a pure physical method has the advantages of being zero in pollution, low in cost, repeatable in operation, small in deposition rate, easily precise in control in the growth process and the like, and the prepared nanosilver particles are uniform and neat and particle size-controllable.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

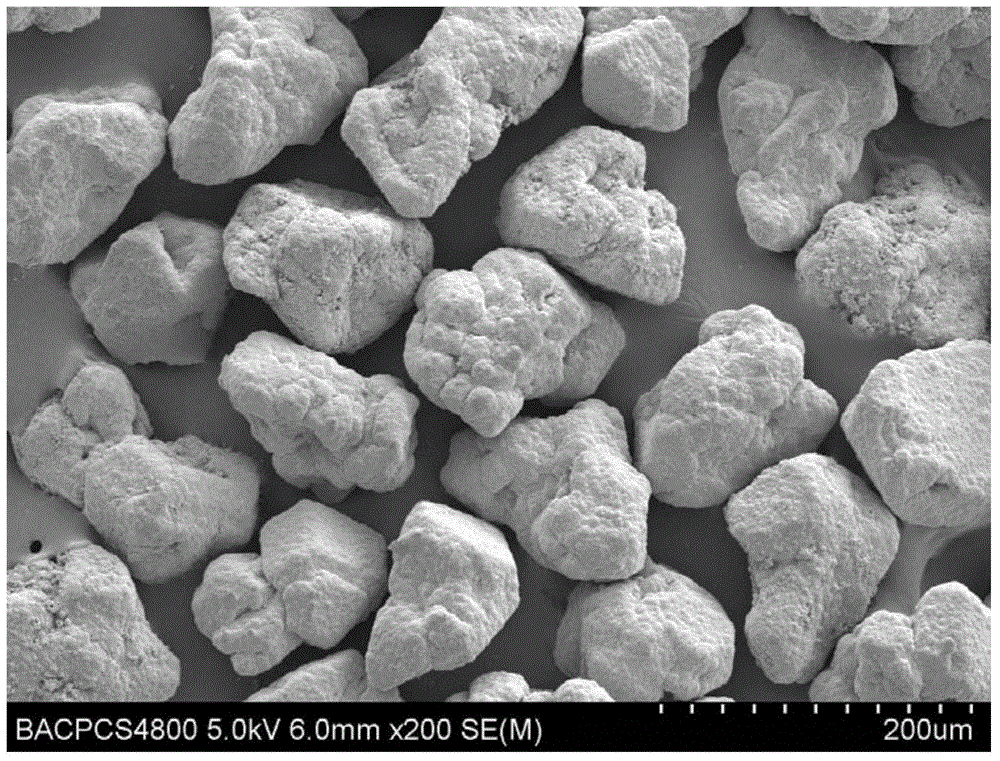

Preparation method for gold plating on surface of silicon carbide particle reinforced aluminum-based composite material

ActiveCN109371439AUniform crystallizationReduce coating porosityAnodisationLiquid/solution decomposition chemical coatingMicro arc oxidationAluminum matrix composites

The invention relates to a preparation method for a gold plating on the surface of a silicon carbide particle reinforced aluminum-based composite material, and belongs to the technical field of surface engineering. The preparation method comprises the following steps that pretreatment is performed on the silicon carbide particle reinforced aluminum-based composite material; micro-arc oxidation isperformed on the pretreated silicon carbide particle reinforced aluminum-based composite material; surface sensitization, activation and reduction treatment is performed on the material subjected to the micro-arc oxidation; chemical nickel plating is performed on the surface of the material to obtain the material with a nickel layer; and gold plating is performed on the surface of the nickel layerto obtain the gold plating located on the surface of the silicon carbide particle reinforced aluminum-based composite material. According to the preparation method, a ceramic membrane layer is formed, so that the homogenization of chemical properties of an interface of the high-volume-fraction SiCp / Al composite material is realized, it is guaranteed that the subsequent plating is uniform in crystallization, then the porosity of the subsequent plating is reduced, and the compactness of the plating is improved.

Owner:BEIJING SATELLITE MFG FACTORY

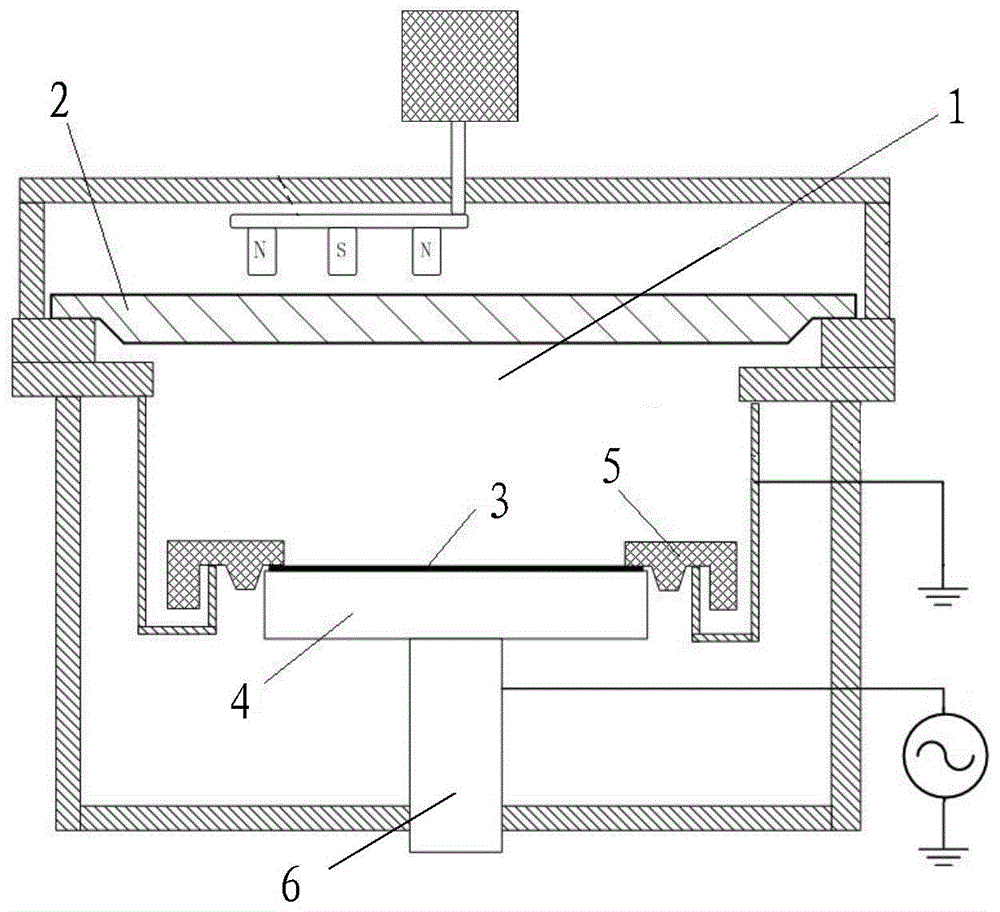

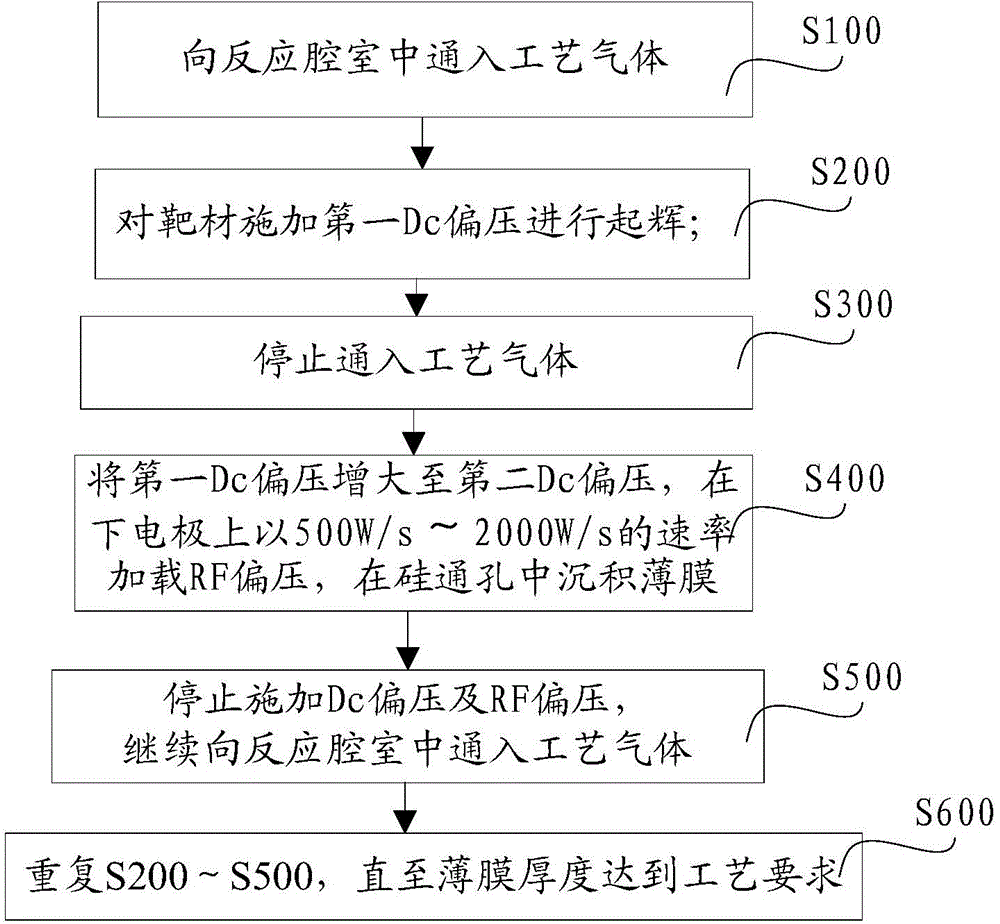

Magnetron sputtering method for depositing thin film

ActiveCN105200379AGuaranteed depositionReduce deposition rateVacuum evaporation coatingSputtering coatingOptoelectronicsSilicon

The invention discloses a magnetron sputtering method for depositing a thin film. The method comprises the following steps that within first preset time, process gas is introduced into a reaction chamber; within second preset time, first DC bias is exerted on a target material, and lighting-up is carried out; within third preset time, introducing of the process gas is stopped; within fourth preset time, the first DC bias is increased to be second DC bias, RF bias is loaded on a lower electrode at the speed of 500 W / s-2000 W / s, and the thin film is deposited into a silicon through hole; within fifth preset time, exerting of the DC bias and the RF bias is stopped, and the process gas continues to be introduced into the reaction chamber; the steps are repeated until the thickness of the thin film meets the process requirement. The magnetron sputtering method for depositing the thin film can effectively prevent the lower portion of the reaction chamber from being lightened and ensure that the thin film can deposit in the silicon through hole smoothly.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

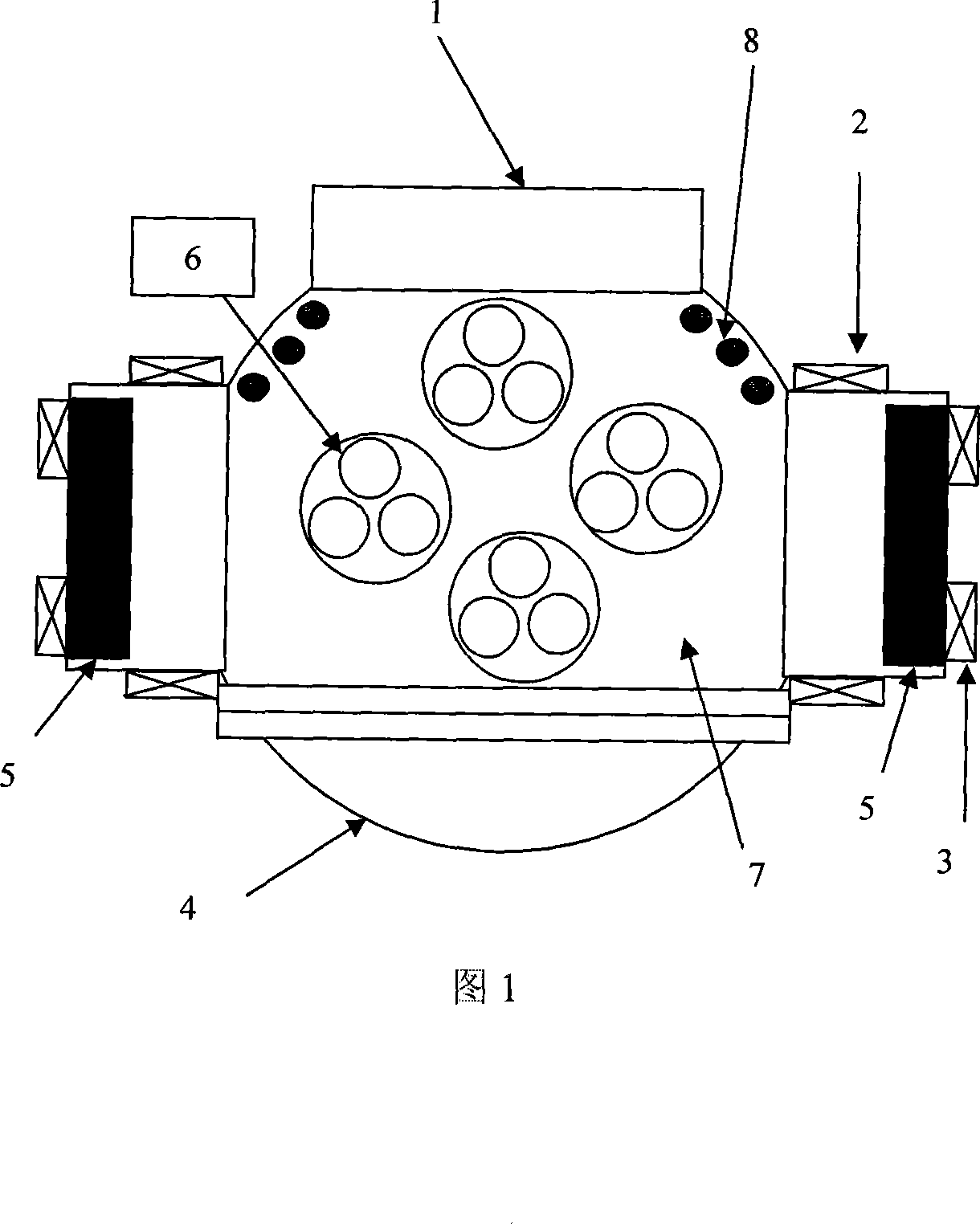

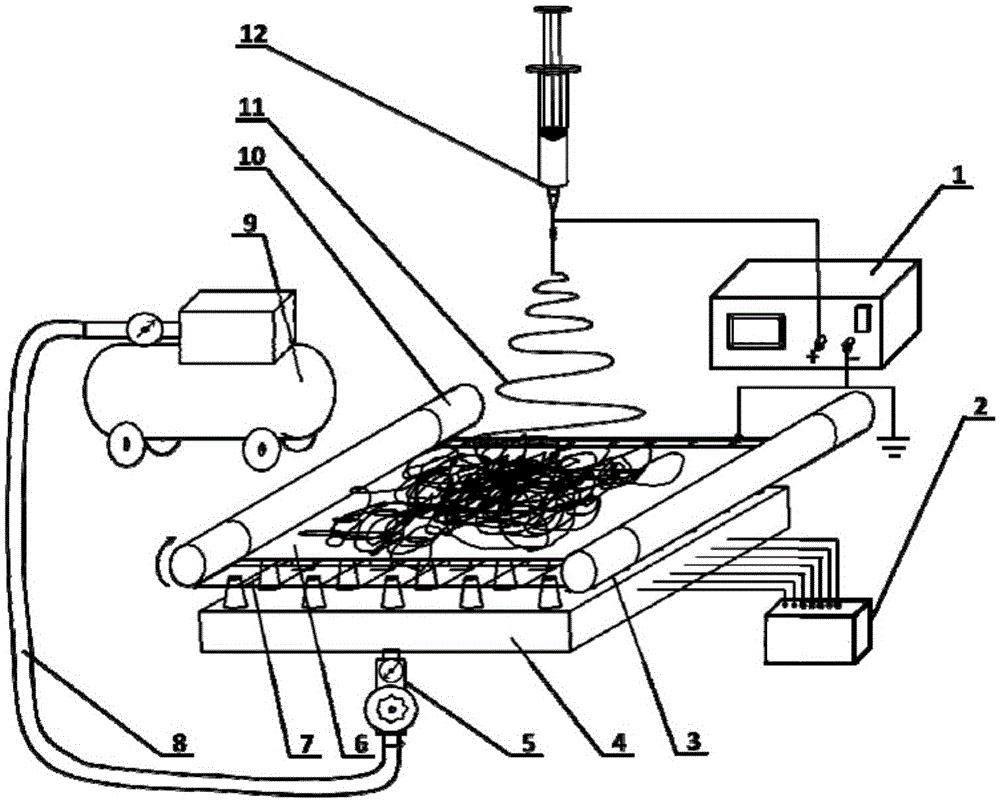

Electrospinning device for preparing fluffy nanometer fibers

InactiveCN105586644ASettle down fasterSolve the tight arrangement of fibersFilament/thread formingFiberElectrospinning

The invention provides an electrospinning device for preparing fluffy nanometer fibers and relates to electrospinning collection devices. The electrospinning device is provided with an electrostatic spinning generating device, a collection device, an air injection device, a controller, a high-pressure air generating device and an air pressure valve; the electrostatic spinning generating device is provided with a high pressure power source and a spinning nozzle, and the positive electrode of the high pressure power source is connected with the positive electrode of the spinning nozzle; the collection device is located under the spinning nozzle, the collection device is provided with collection cloth, a coiling shaft, an uncoiling shaft and a metal mesh, the two ends of the collection cloth are wound on the coiling shaft and the uncoiling shaft respectively, and the metal mesh is located below the collection cloth and grounded; the air injection device is close to the position under the metal mesh and provided with an air injection plate, the air injection plate is provided with an air injection nozzle array, an electromagnetic flow valve is arranged below each air injection nozzle, and all air injection nozzles are gathered through an air flow pipe; the controller is connected with the electromagnetic flow valves; the air generating device is connected with the air flow pipe, serving for gathering, of the air injection device, and the air pressure valve is located between an air guide pipe of the high pressure air generating device and the air flow pipe for gathering the air injection device.

Owner:XIAMEN UNIV +1

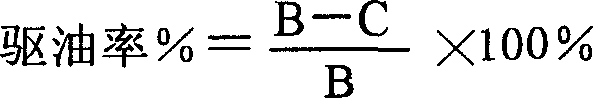

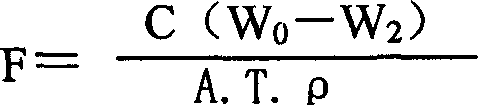

Oil repellents

ActiveCN1865172AReduce interfacial tensionReduced interphase surface energyScale removal and water softeningDrilling compositionChemistryCalcium EDTA

This invention relates to an oil displacement agent for oil-containing industrial circulation water and oil-containing waste water. With the total weight of the components as 100%, it comprises: main component(N-alkyl C8-24 p-imidogen benzene sulfonate anion surfactant)38%-62%, pH regulator(basic salt or alkaline) 0-12%, potentiating agent(chelant of calcium and magnesium ions) 7%-21%, reinforcing agent(neutral salt) 18%-30%. This invented oil displacement agent for oil-containing industrial circulation water and oil-containing waste water application has benefits of small amount, good oil displacement effect, non-toxic and environmental friendly, and easy biological degradation. Besides, the oil displacement agent has a synergic reinforcing effect on water treatment etching and deposition inhibition agent.

Owner:PETROCHINA CO LTD

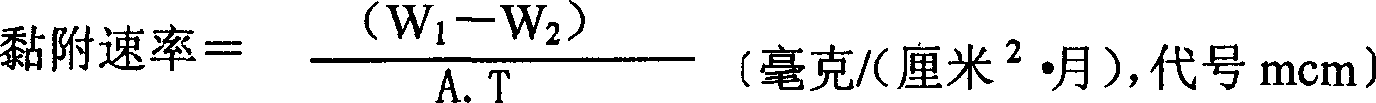

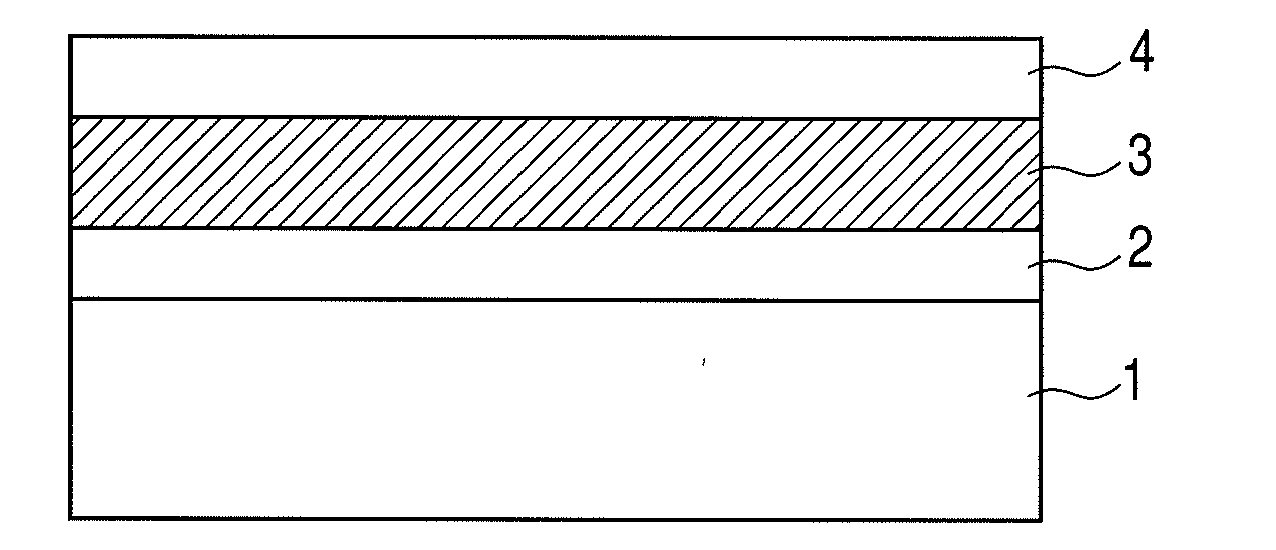

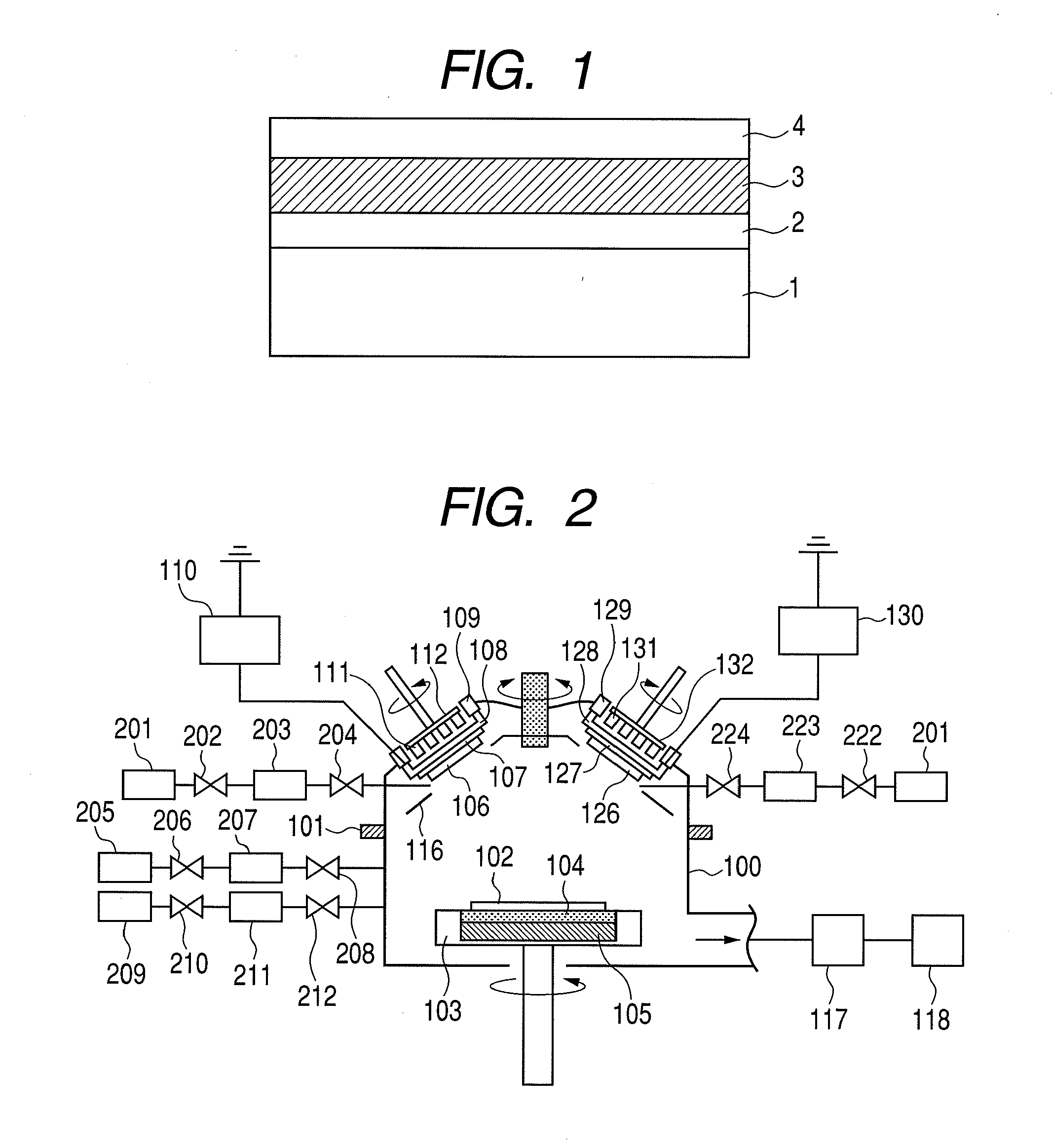

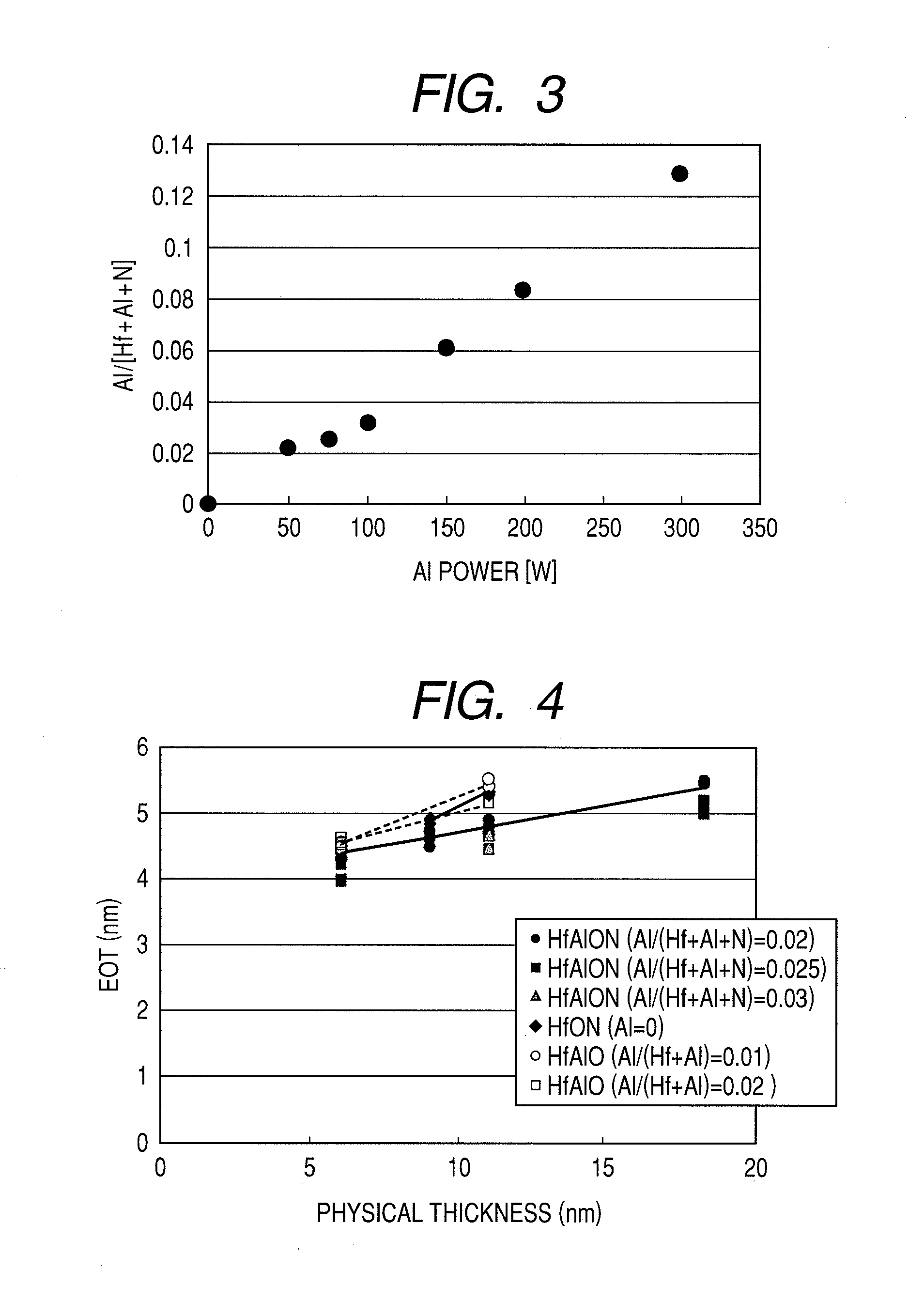

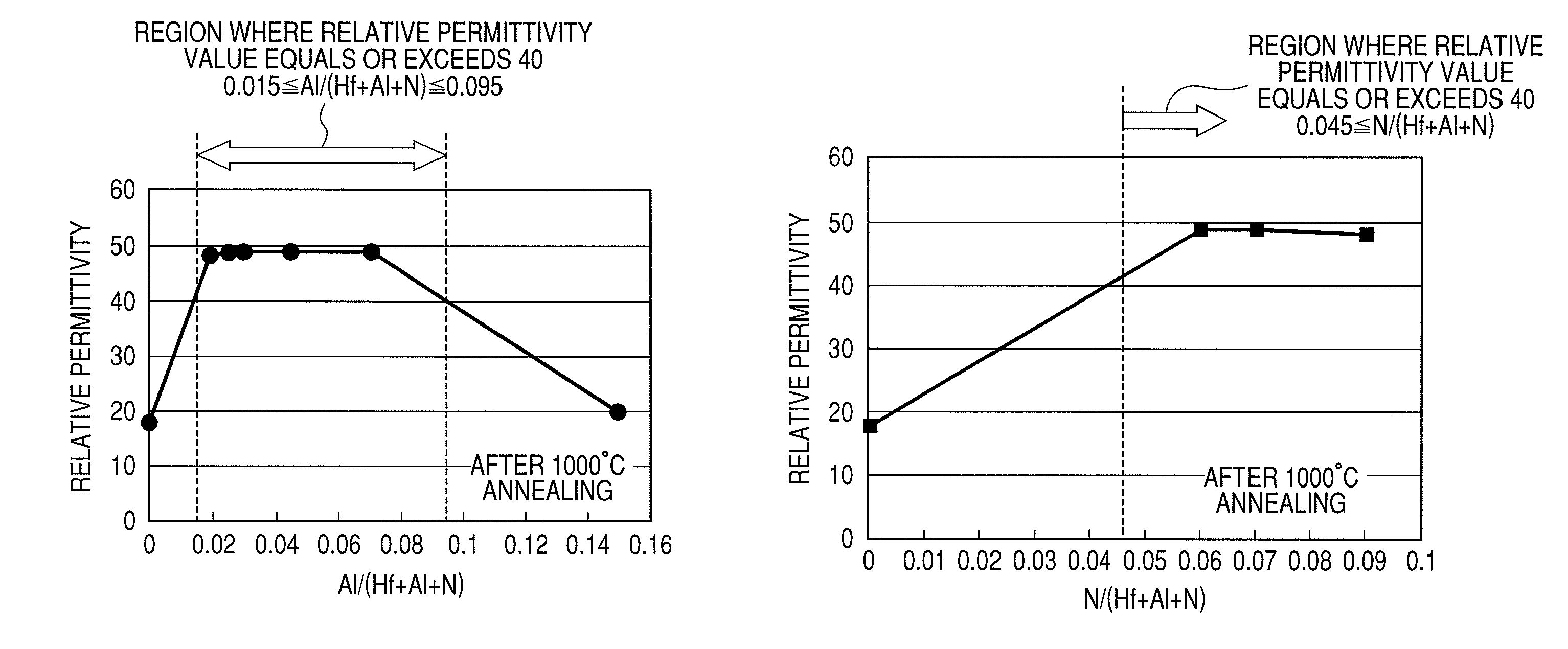

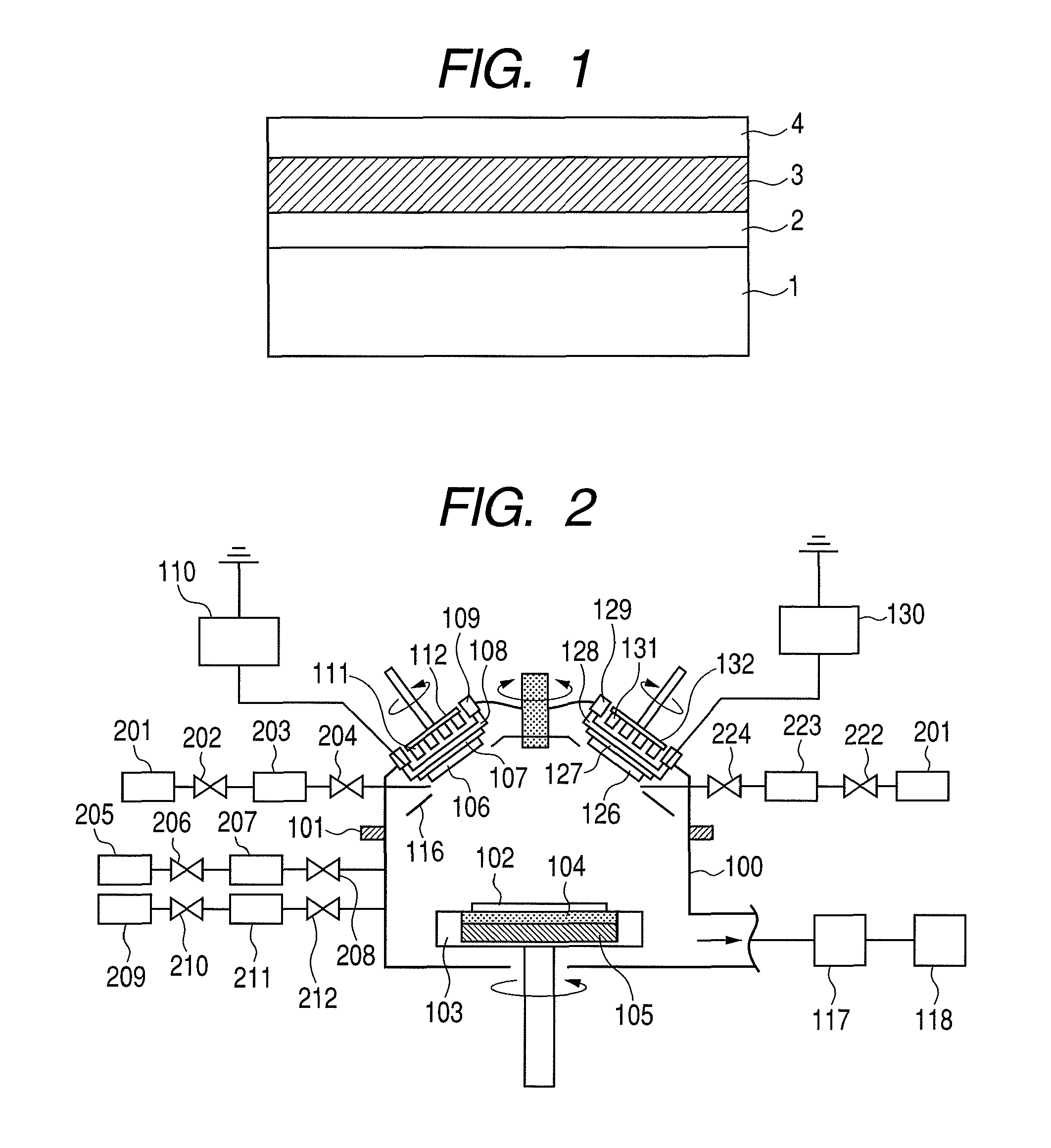

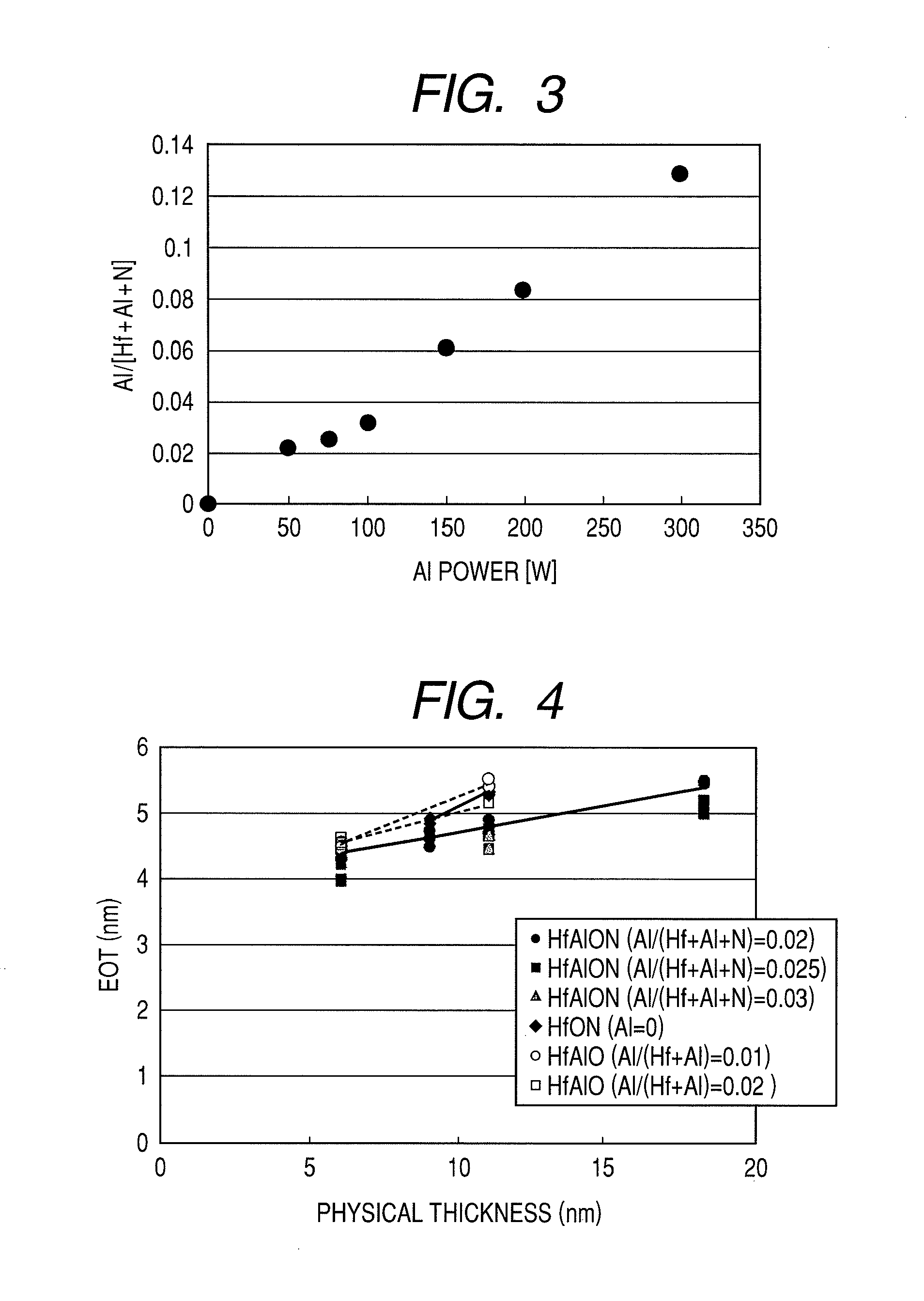

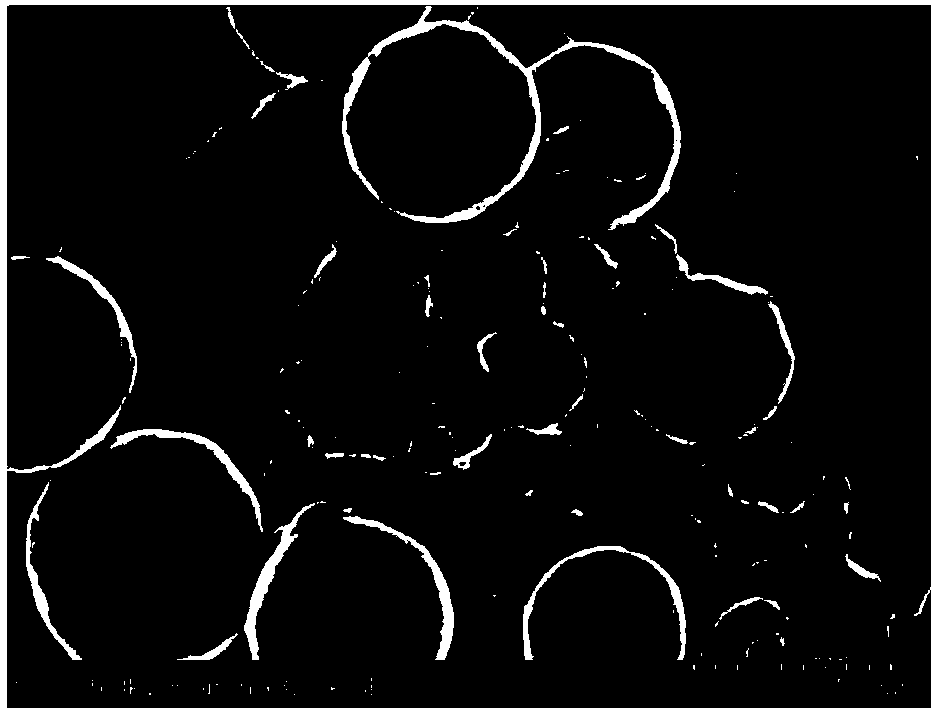

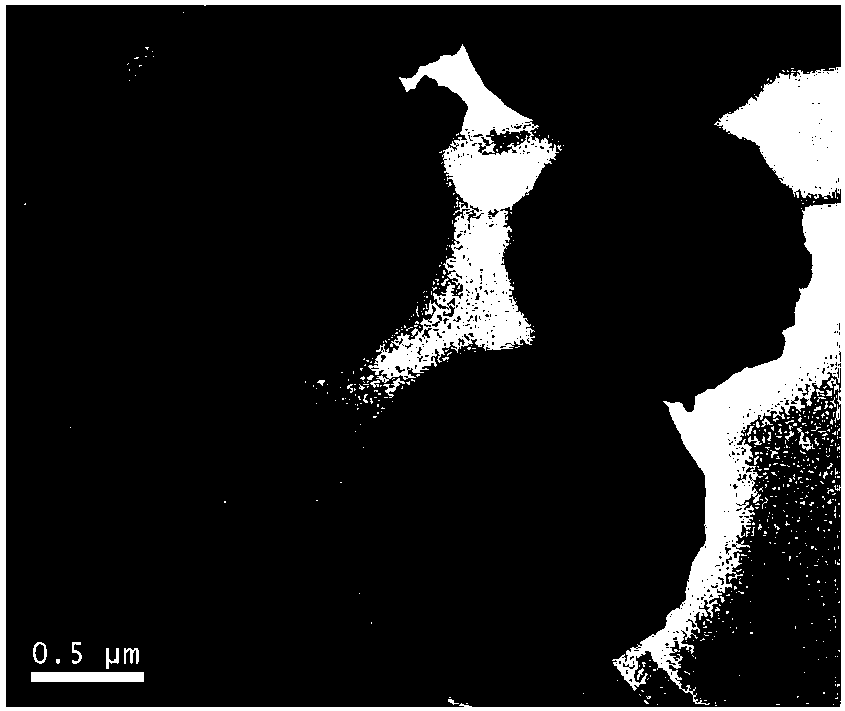

Method of manufacturing dielectric film

ActiveUS20100221885A1Improve flatnessHigh dielectric constantTransistorNitrogen compoundsPermittivityOxygen

The present invention provides a method of manufacturing a dielectric film having a high permittivity. An embodiment of the present invention is a method of manufacturing, on a substrate, a dielectric film including a metallic oxynitride containing an element A made of Hf or a mixture of Hf and Zr, an element B made of Al, and N and O. The manufacturing method includes: a step of forming a metallic oxynitride whose mole fractions of the element A, the element B, and N expressed as B / (A+B+N) has a range of 0.015≦(B / A+B+N))≦0.095 and N / (A+B+N) has a range of 0.045≦(N / (A+B+N)) and a mole fraction O / A of the element A and O has a range expressed as 1.0<(O / A)<2.0, and having a noncrystalline structure; and a step of performing an annealing treatment at 700° C. or higher on the metallic oxynitride having a noncrystalline structure to form a metallic oxynitride including a crystalline phase with a cubical crystal incorporation percentage of 80% or higher.

Owner:CANON ANELVA CORP

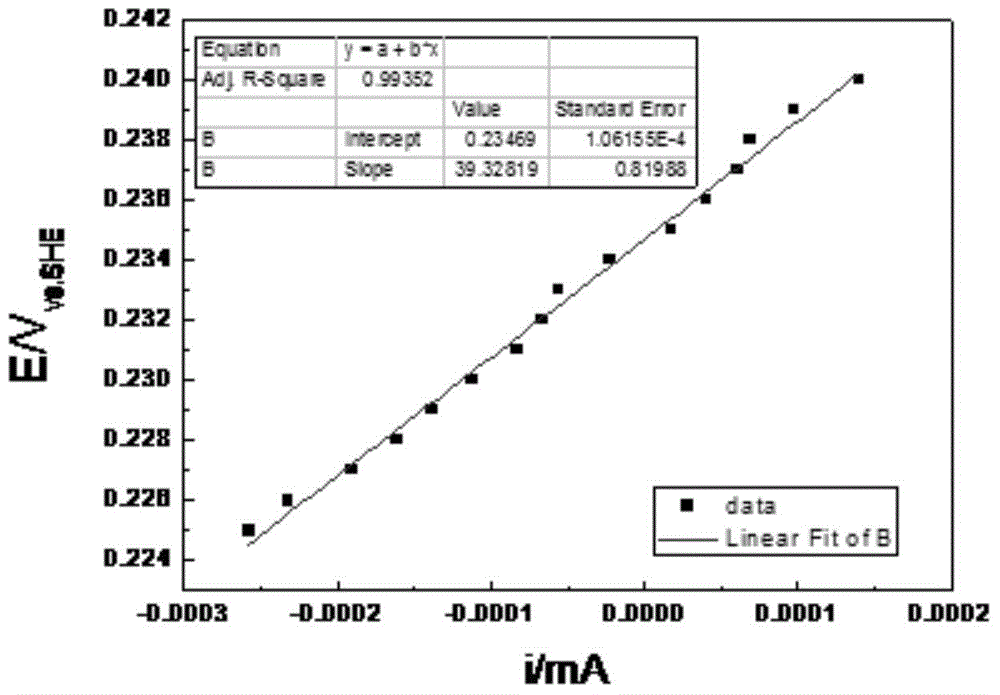

Long-life reference electrode suitable for deep-sea high hydrostatic pressure environment

InactiveCN102967639AHigh strengthStable saturated chloride ion concentrationMaterial electrochemical variablesAutomatic controlSalt bridge

The invention provides a long-life reference electrode suitable for a deep-sea high hydrostatic pressure environment. The reference electrode comprises a shell, which is internally provided with an inner electrode core body, a salt bridge and a diaphragm from top to bottom. The electrode is characterized in that: the salt bridge is composed of a saturated potassium chloride sol gel and potassium chloride particles that are uniformly and diffusely distributed in the saturated potassium chloride sol gel. The diaphragm is a super-microporous ceramic column. The upper end of the inner electrode core body is provided with an epoxy seal filler and is connected to an electrode lead wire that passes through the epoxy seal filler and then extends out of the shell. The lower end of the inner electrode core body contacts the upper end of the salt bridge, the lower end of which contacts one side of the super-microporous ceramic column diaphragm, and the other side of the super-microporous ceramic column diaphragm is in connection with the external environment. The invention can satisfy the electrochemical measurement requirements under a deep-sea high hydrostatic pressure environment, and can be widely applied to corrosion signal monitoring and detection, electrochemical protection, automatic control equipment probes, and the like of marine constructions, deep-sea petroleum pipelines, and deep-sea detection equipment.

Owner:HARBIN ENG UNIV

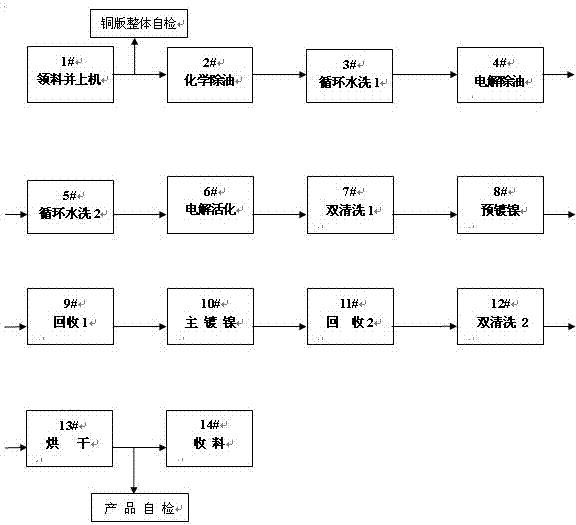

Nickel plating method of steel belts for steel battery shells

The invention relates to the field of steel battery shell processing, in particular to a nickel plating method of steel belts for steel battery shells. The nickel plating method comprises the steps of unwinding the steel belts through buffering pits; removing grease dirt on the surfaces of the steel belts; sequentially carrying out cycled water washing, activating and cycled water washing; nickel pre-plating and recycling; dull nickel plating and recycling; sequentially carrying out cycled water washing, activating and cycled water washing; semi-gloss nickel plating; full-gloss nickel plating; and sequentially carrying out recycling, cycled water washing, drying and winding. Through nickel pre-plating, the sedimentation rate of nickel ions can be lowered, the porosity of the surface of a plating layer can be lowered, the binding force between the plating layer and the steel belts can be greater, and the corrosion resistance of the steel belts can be improved; dull nickel plating is used for providing a priming plating layer, the binding force of the plating layer can be increased, and the porosity of the plating layer can be lowered; semi-gloss nickel plating and full-gloss nickel plating are added, and therefore the surface brightness of products can be adjusted according to requirements of clients well; the production efficiency can be improved, the production cost of enterprises can be lowered, and the market competitive power of the products can be enhanced.

Owner:HUNAN TOYO LEED MATERIAL SCI & TECH CO LTD

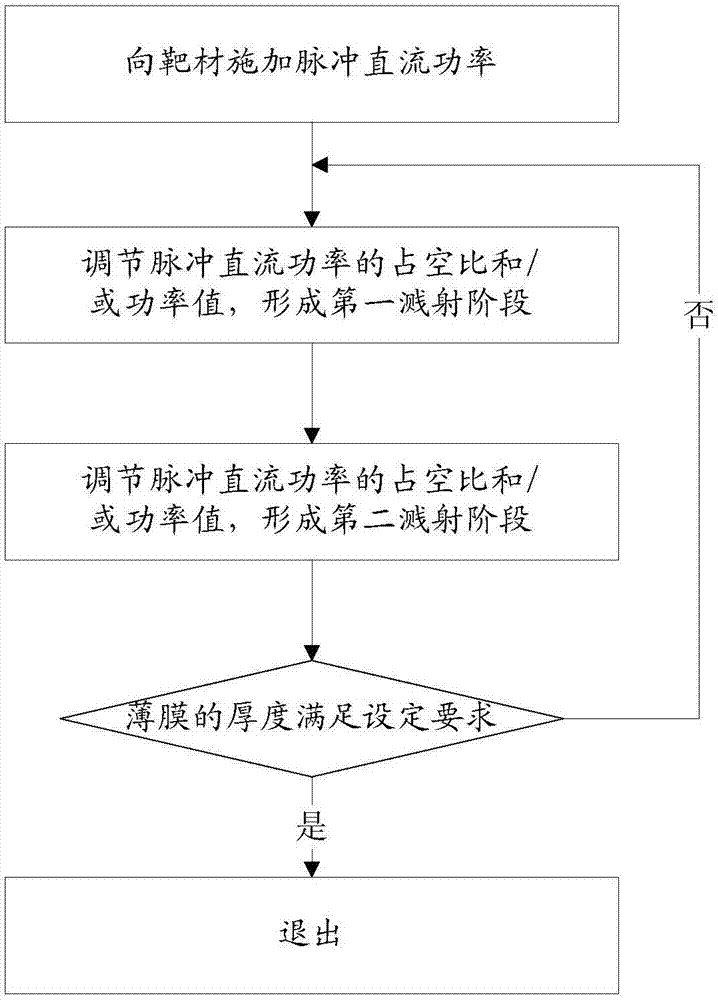

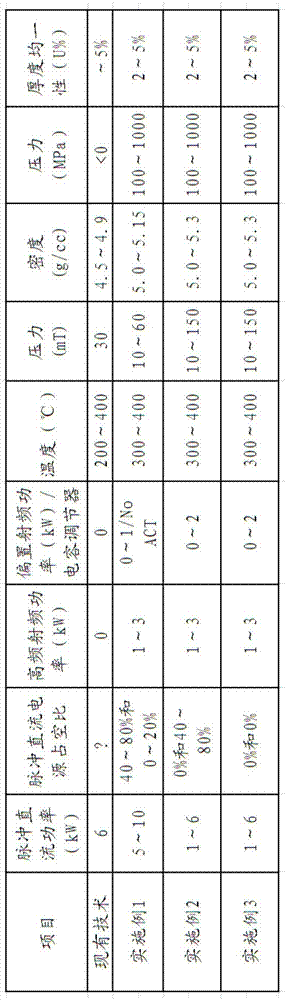

Film manufacturing method

ActiveCN107513692AImprove compactnessReduce deposition rateVacuum evaporation coatingSputtering coatingSemiconductorDirect current

The invention belongs to the technical field of semiconductor processing and particularly relates to a film manufacturing method. The film manufacturing method is used for forming a thin film on a wafer in a sputtering mode and comprises a sputtering step. The sputtering step comprises a first sputtering stage and a second sputtering stage which are circularly conducted, and thus the density and stress of the thin film are adjusted till the thickness of the thin film meets the setting requirement. According to the film manufacturing method, the mode that a pulsed direct current is applied to a target material in a sputtering mode is adopted, the duty ratio and / or the power value of the pulsed direct current power are / is adjusted to control the deposition speed rate of the thin film, the situation that under the high power, sputtering energy is increased without increasing the deposition speed rate of the thin film is achieved, the relation between the deposition speed rate and the sputtering energy is balanced, the compactness of the thin film is improved, the deposition speed rate of thin film is properly decreased, the process time of the thin film is prolonged, the production stability is improved, and the thin film with larger stress is obtained.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

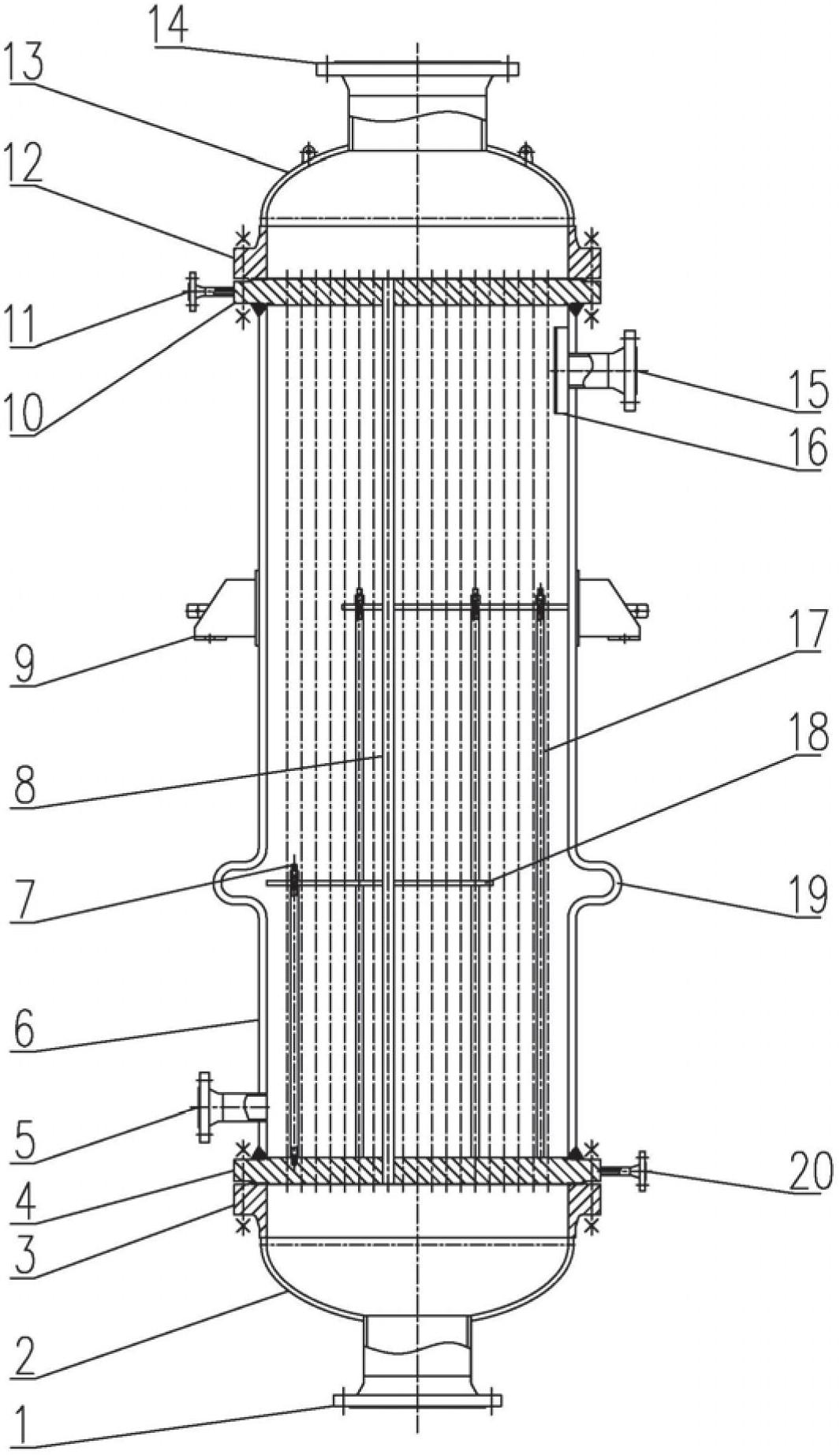

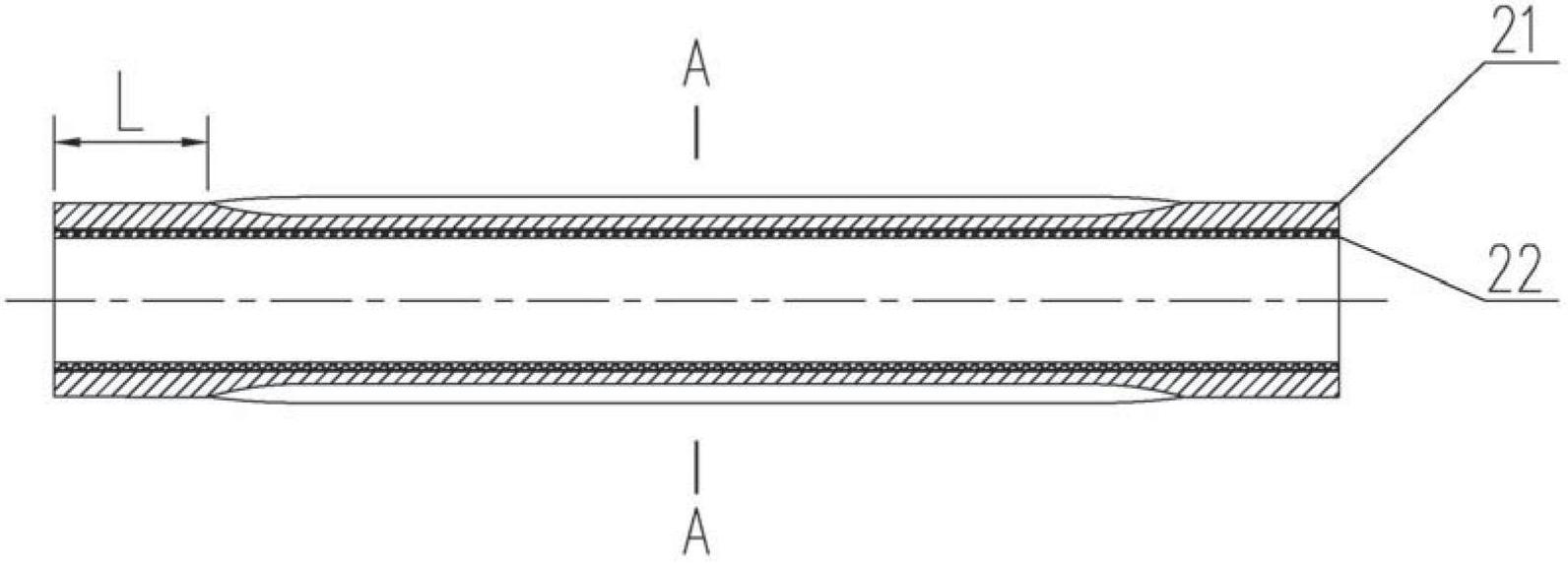

Reboiler

ActiveCN102671399AExtended cleaning cycleImprove heat transfer efficiencyBoiling apparatusReboilerPorous layer

The invention discloses a reboiler which comprises a cylinder and a plurality of heat exchange tubes, wherein a material inlet and a material outlet are arranged at two ends of the cylinder respectively; a steam inlet is arranged on the cylinder on the side of the material outlet; and a condensate outlet is arranged on the cylinder on the side of the material inlet. According to the reboiler, a porous layer is processed on inner surfaces of heat exchange tube substrates and the porous layer has a heating surface with increased roughness so as to form an artificial evaporating core, so that the heat transfer efficiency of the heat exchange tubes is increased. Meanwhile, longitudinal grooves are processed on the outer surfaces of the heat exchange tube substrates, circular bulges are arranged in the longitudinal grooves, longitudinal nicks are arranged on a teeth part, the thickness of a liquid film is reduced by utilizing a surface tension and then the condensation effect on the exteriors of the heat exchange tubes is improved. According to the invention, the total coefficient of heat transfer of the reboiler is above 3 times of that of a light tube reboiler; anti-scaling capacity of boiling sides of the heat exchange tubes is increased; the dirt deposition rate is less than that of a smooth tube, so that the cleaning period of the reboiler is prolonged.

Owner:CHINA ELEVENTH CHEM CONSTR +1

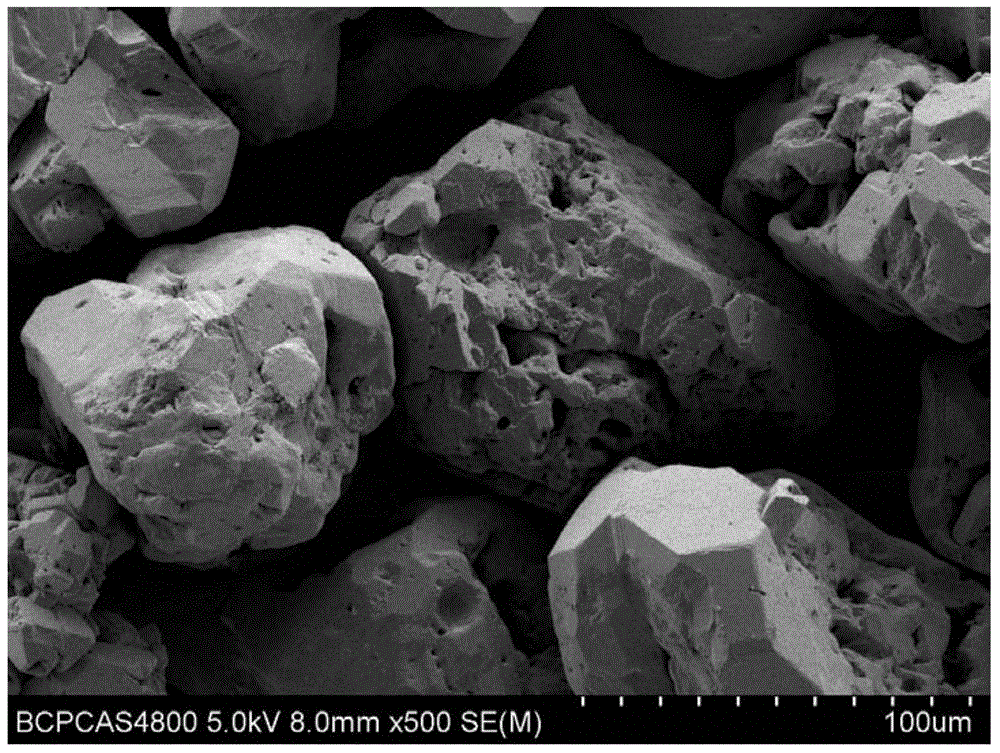

Method for plating nickel on surfaces of ceramic particles

InactiveCN107675149ALarge real surface areaHigh bonding strengthLiquid/solution decomposition chemical coatingChemical platingMegasonic cleaning

The invention provides a method for plating nickel on surfaces of ceramic particles. The method comprises the following steps: fused alumina zirconia ceramic particles are polished by using an abrasive paper; and after a preset roughness is reached, the fused alumina zirconia ceramic particles are put in anhydrous alcohol, are oscillated and cleaned by using ultrasonic waves, are put in rougheningliquid for roughening after drying, are sensitized after cleaning and drying, are put in acetone solution after sensitization, are cleaned by using the ultrasonic waves, are put in activating liquidfor activation after drying, are put in chemical plating liquid for plating after cleaning and drying, and are flushed and dried after plating to obtain finished products. The method for plating nickel on the surfaces of the ceramic particles increases real surface areas of the fused alumina zirconia ceramic particles and nickel metal, so that the bonding strength between the ceramic particles andthe nickel metal is improved; the reaction efficiency is improved; the nickel plating time is shortened; and the surfaces of the fused alumina zirconia ceramic particles after plating reach the metalgloss, are uniform in nickel plating and excellent in corrosion resistance, and achieve a certain wear resistance.

Owner:ANHUI FENGXING WEAR RESISTANT MATERIALS CO LTD +1

Production technology of fine bronzing plate with high precision and hardness

ActiveCN103484841AExtended service lifeIncrease productivityLiquid/solution decomposition chemical coatingSodium acetateBiological activation

The invention discloses a production technology of a fine bronzing plate with high precision and hardness. The production technology comprises the following steps : (1) loading materials; (2) chemical oil removal; (3) recycling washing; (4) electrolytic activation; (5) double cleaning; (6) nickel plating: carrying out chemical nickel plating by using a plating liquid containing 28 g / L nickel sulfate, 30 g / L sodium hypophosphite, 18 mL / L lactic acid (W = 85%), 13 g / L sodium acetate, 8 mg / L potassium iodate and purified water, adjusting the pH value of the plating liquid to 4.6-4.9, stirring at 85-91 DEG C for 3-5 min; (7) double cleaning; (8) drying; and (9) rolling. The invention employs electrolytic activation in advance and nickel preplating to substantially enhance firm combination degree of a nickel coating and a copper base and prolong service life of the bronzing plate.

Owner:青岛黎马敦包装有限公司

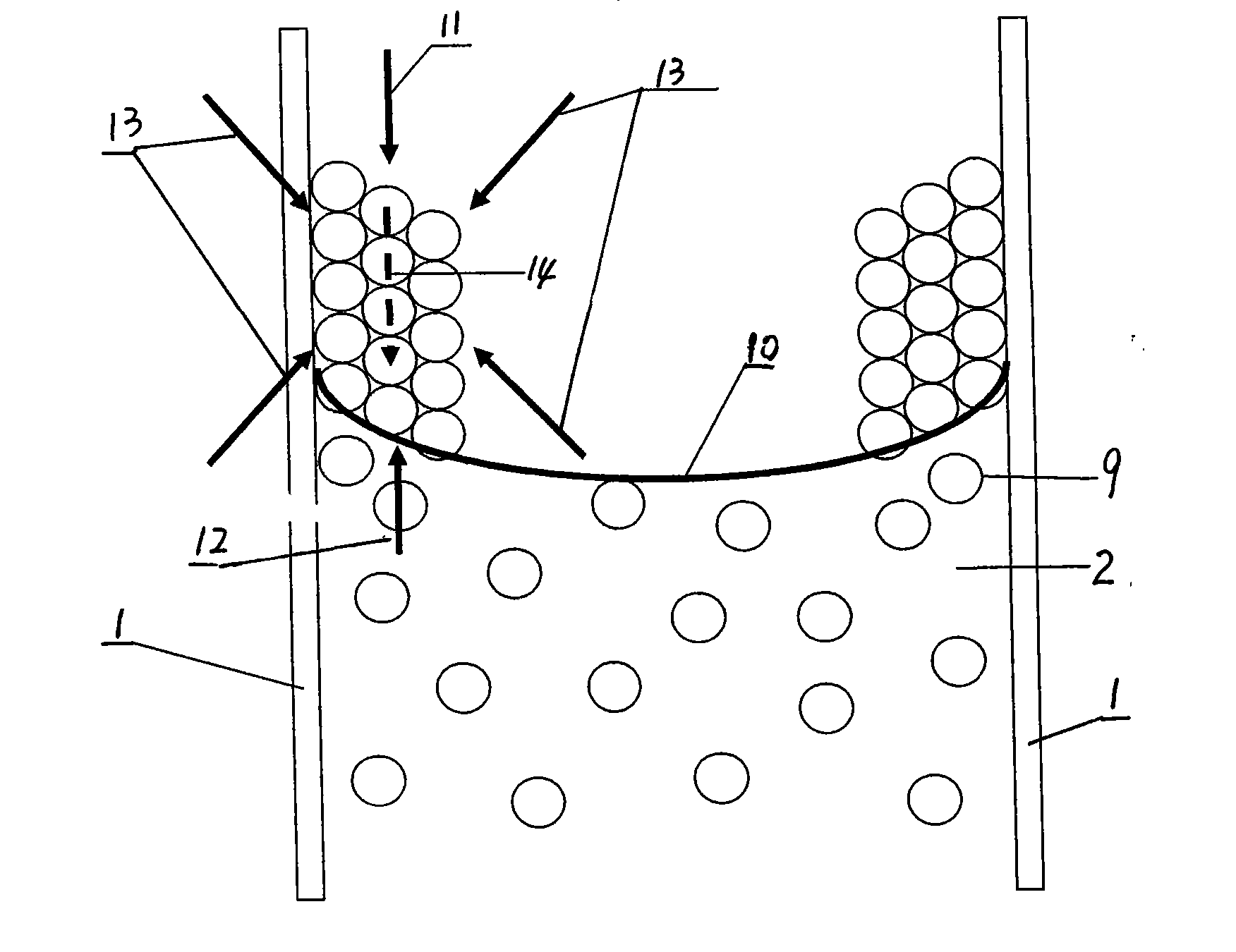

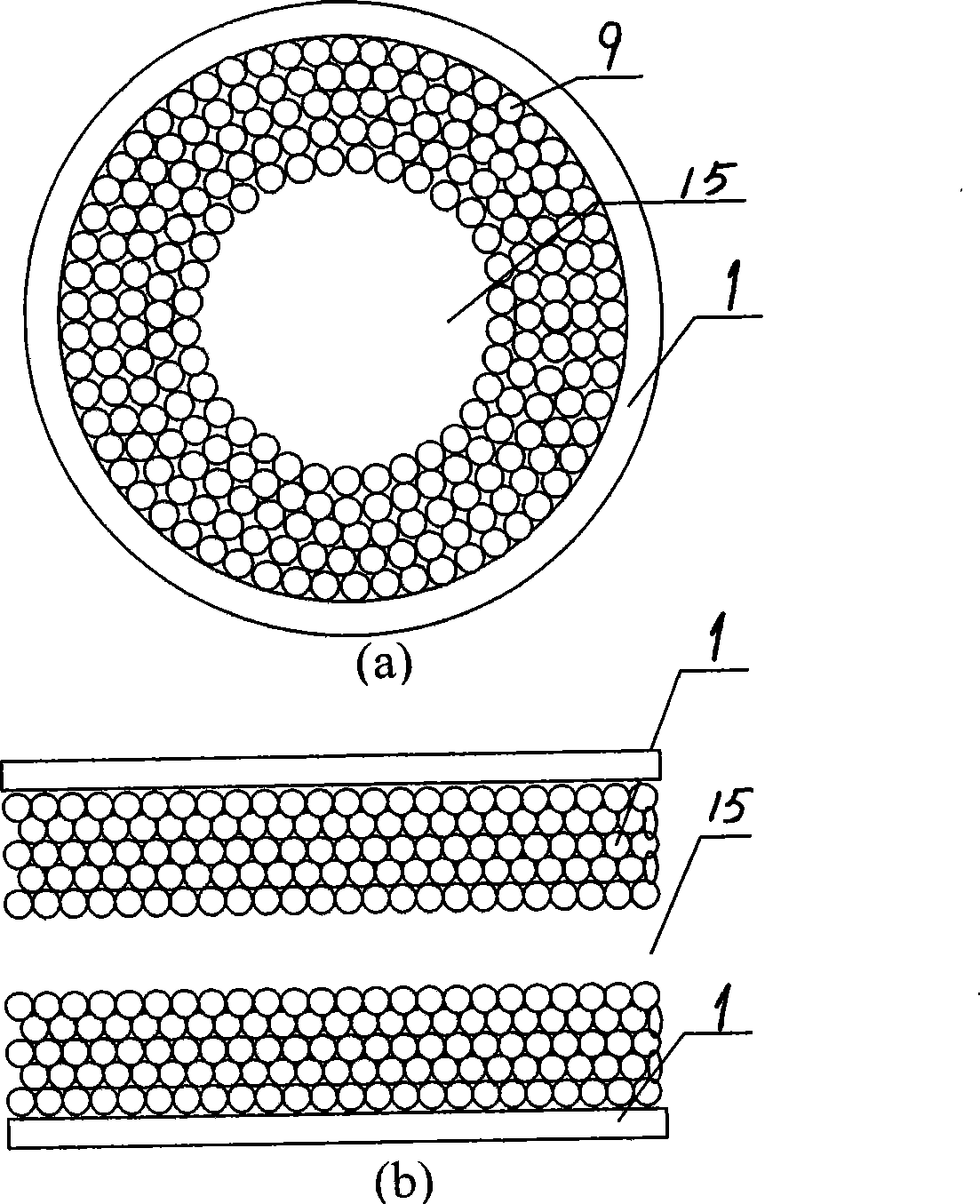

Method for preparing cylinder hollow macroporous ordered colloidal crystal

InactiveCN101392407AReduce deposition rateImprove the crystallization processFrom gel statePolycrystalline material growthMicrospherePhotonic bandgap

The invention discloses a preparation method of a cylindrical hollow macroporous ordered colloidal crystal, which comprises the steps as follows: a glass capillary is cleaned in an ultrasonic cleaner with hydrochloric acid, acetone and deionized water; the glass capillary after being cleaned is vertically inserted into a glass bottle holding colloidal microsphere water solution; the upper end of the glass capillary is fixed on a metal filament and placed stilly for 10 minutes to 20 minutes; the vertical movement of the metal filament is controlled by a stepping motor; an electric field is externally added in the vertical direction of the bottle and the strength of the electric field is 50 V / m to 100 V / m; the whole device is placed at a constant temperature of 40 DEG C to 80 DEG C; the colloidal crystal grows in the inner wall of the glass capillary in a self-assembly manner. The method utilizes the externally added electric field to balance weight, slow down the deposition speed of colloidal microspheres and prolong the crystallization process of the colloidal crystal and adopts a stretching method to overcome the defect that the layer quantity of the colloidal crystal is uncontrollable; the colloidal crystal prepared has photonic bandgaps, and hollow structure of the colloidal crystal is adopted as a good linear defect, thus needing no introduction of any defect to the colloidal crystal.

Owner:NANJING NORMAL UNIVERSITY

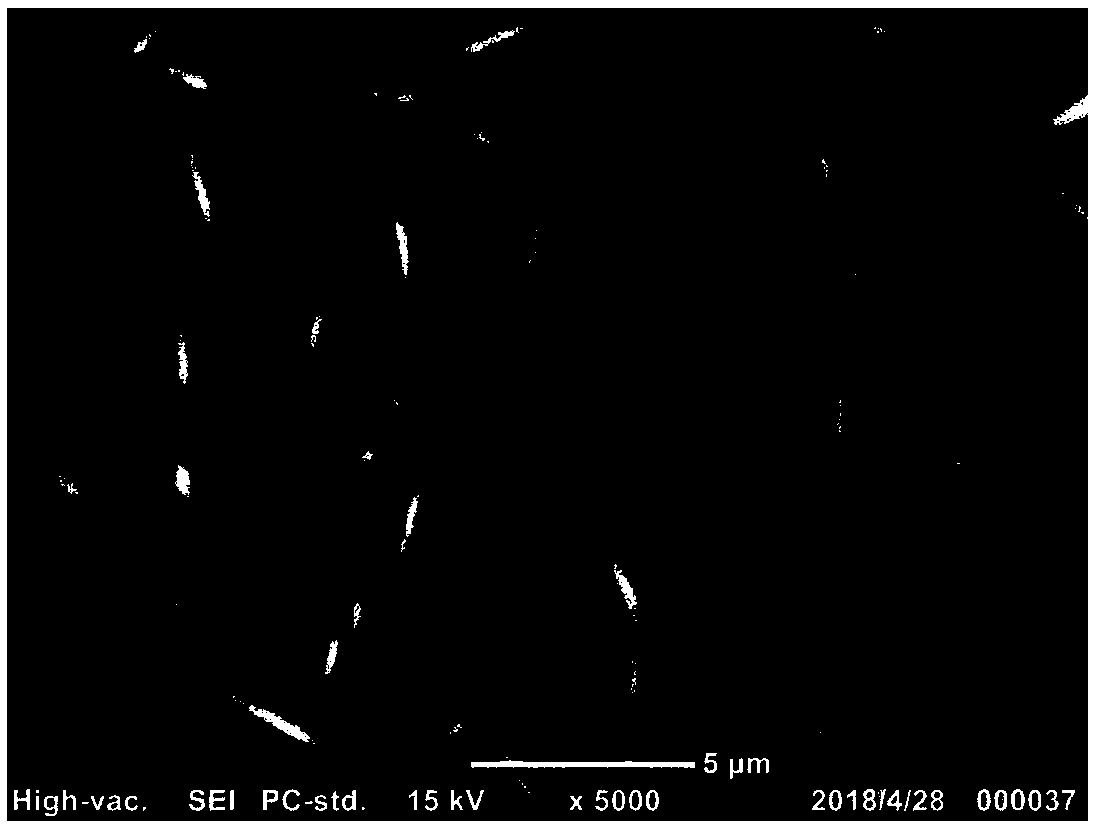

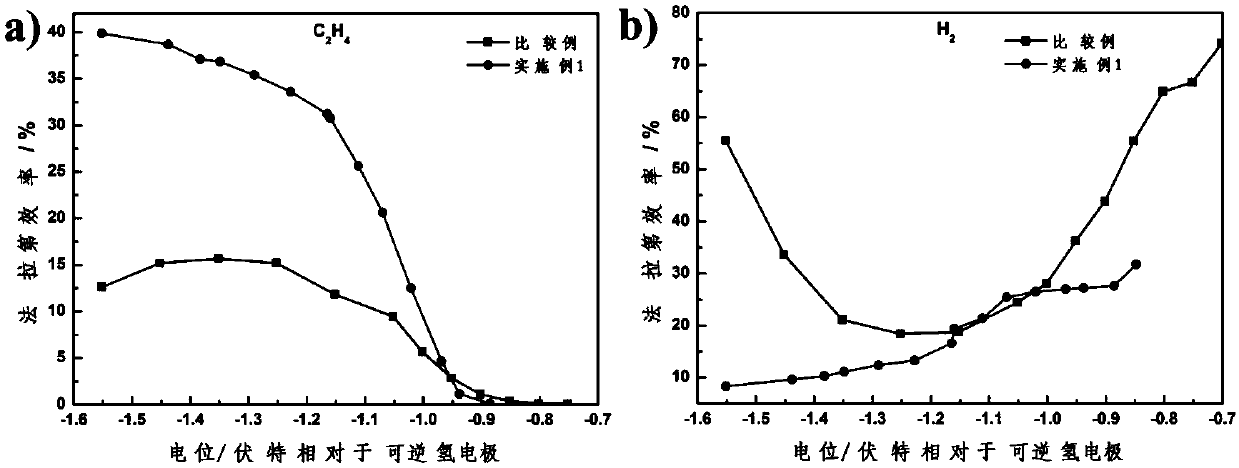

Electrode for CO2 electrochemical reduction and preparation and application thereof

ActiveCN110938846AImprove surface roughnessIncrease the electrochemical reaction areaElectrolytic organic productionElectrodesHydrogenation reactionElectroplating

The invention relates to an electrode for CO2 electrochemical reduction and preparation and application of the electrode for CO2 electrochemical reduction. The preparation process of the electrode includes the steps of soaking a substrate material into an electroplating liquid containing main salt and additives after performing impurity removal on the substrate material, and performing electrochemical deposition under inert atmosphere protection and stirring conditions to obtain the electrode with micrometer Cu particles growing on the surface. The proportion of side atoms of the Cu particlesdeposited on the substrate surface of the prepared electrode is much higher than that of corner atoms, which is beneficial to improving the coverage of CO* on the surface of the electrode and providesa favorable environment for a subsequent CO* dimerization reaction and a hydrogenation reaction; and the electrode has a significant effect of inhibiting the side reaction of hydrogen evolution and meanwhile has high C2H4 selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

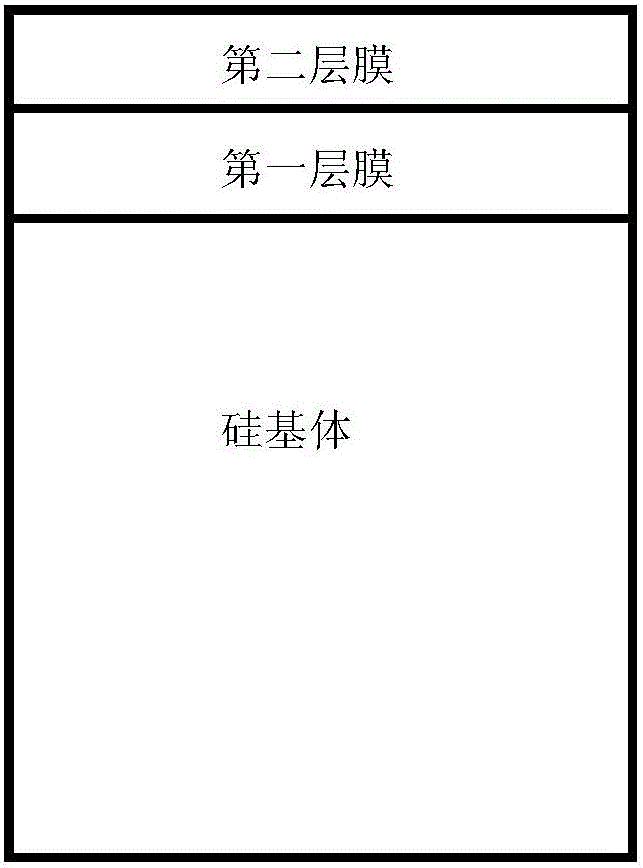

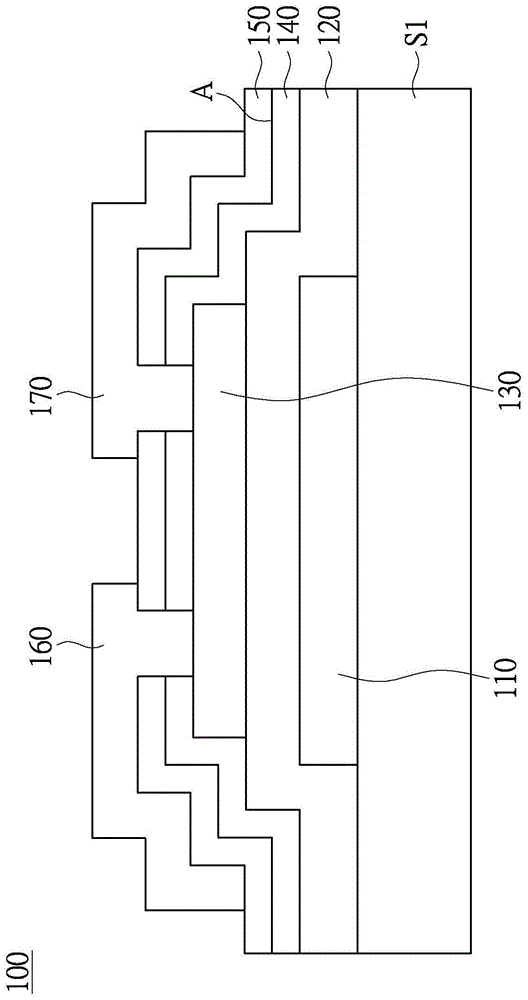

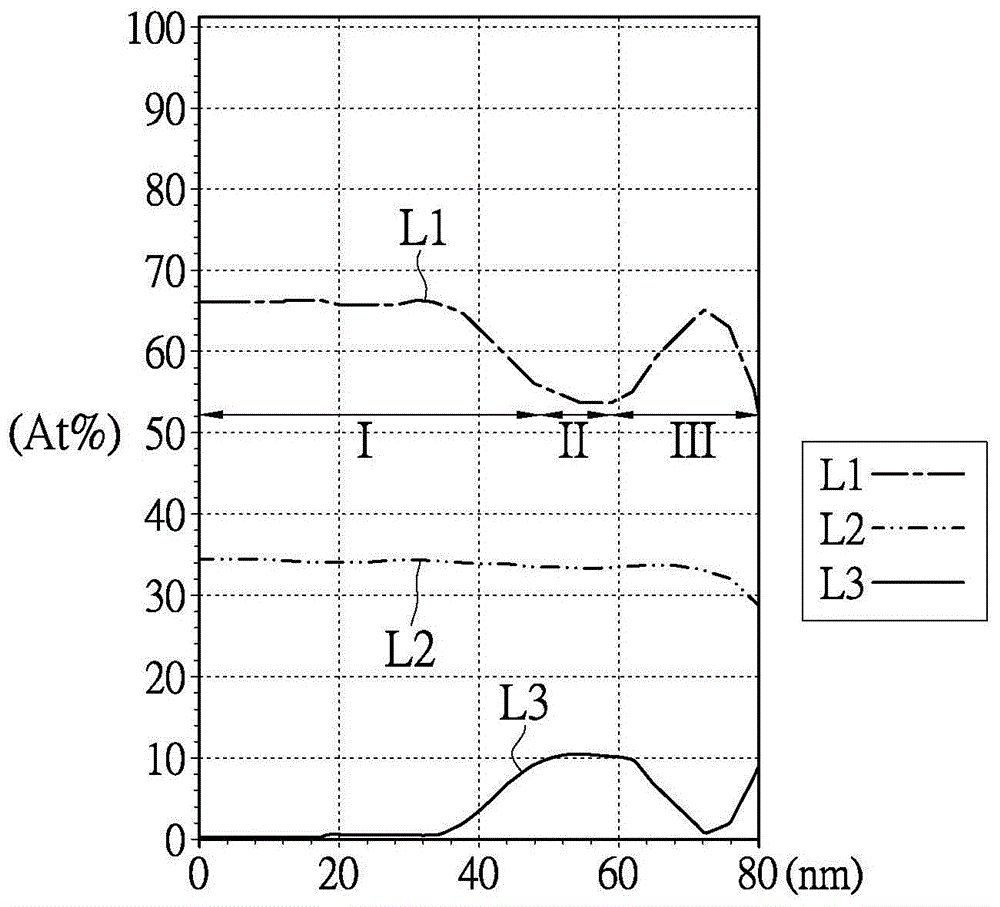

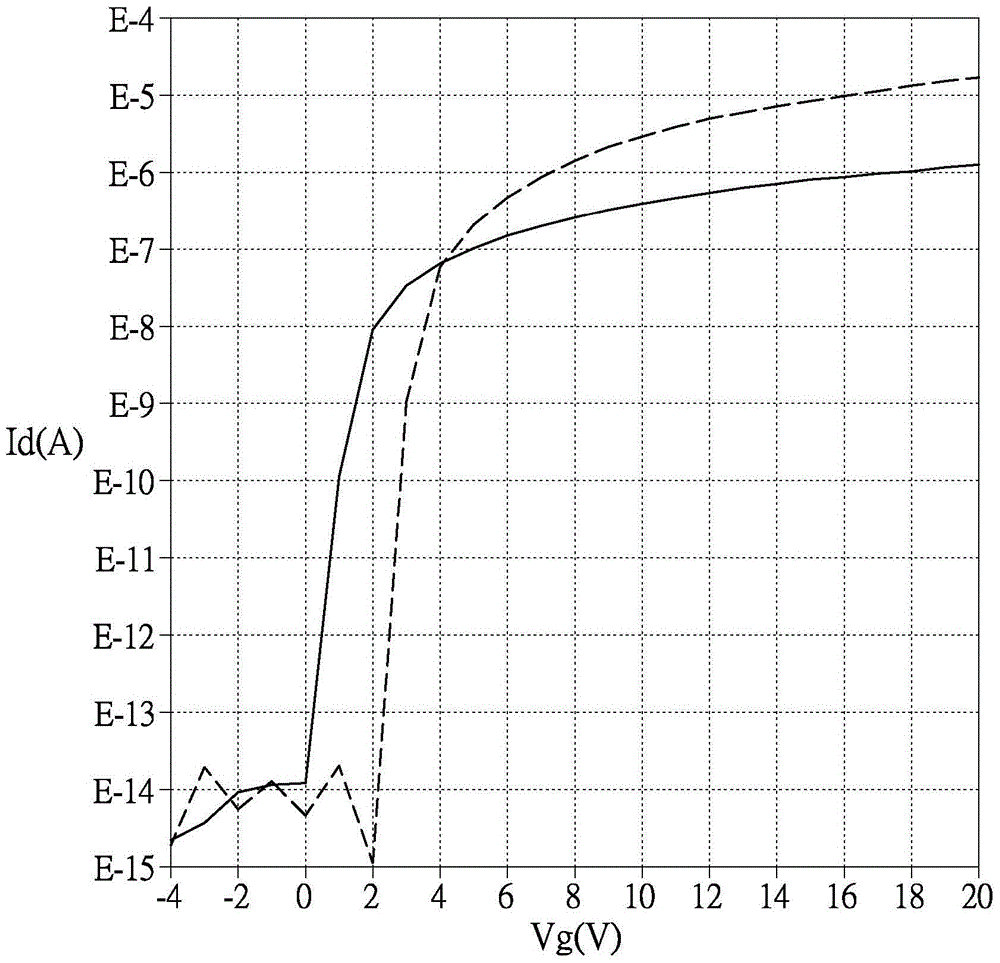

Film transistor substrate and display panel

ActiveCN105336743AImprove hysteresisReduce deposition rateStatic indicating devicesSolid-state devicesOxygen vacancyProtection layer

The invention relates to a film transistor substrate and a display panel. The substrate provided by the embodiment of the invention comprises a substrate, a grid electrode, a semiconductor layer, a source electrode, a drain electrode, a first protection layer, and a second production layer. The grid electrode is configured to be on the substrate. The semiconductor layer is electrically isolated from the grid electrode. The source electrode and the drain electrode are electrically connected with the semiconductor layer. The first protection layer is configured to be on the semiconductor layer, and is provided with a first oxygen vacancy concentration. The second protection layer is configured to be on the first layer, and is provided with a second oxygen vacancy concentration. A junctional zone is located between the first protection layer and the second protection layer, and has a third oxygen vacancy concentration. The third oxygen vacancy concentration is greater than the first and second oxygen vacancy concentrations.

Owner:INNOLUX CORP

Method of manufacturing dielectric film that has hafnium-containing and aluminum-containing oxynitride

ActiveUS7867847B2High dielectric constantReduce deposition rateTransistorNitrogen compoundsPermittivityHafnium

Owner:CANON ANELVA CORP

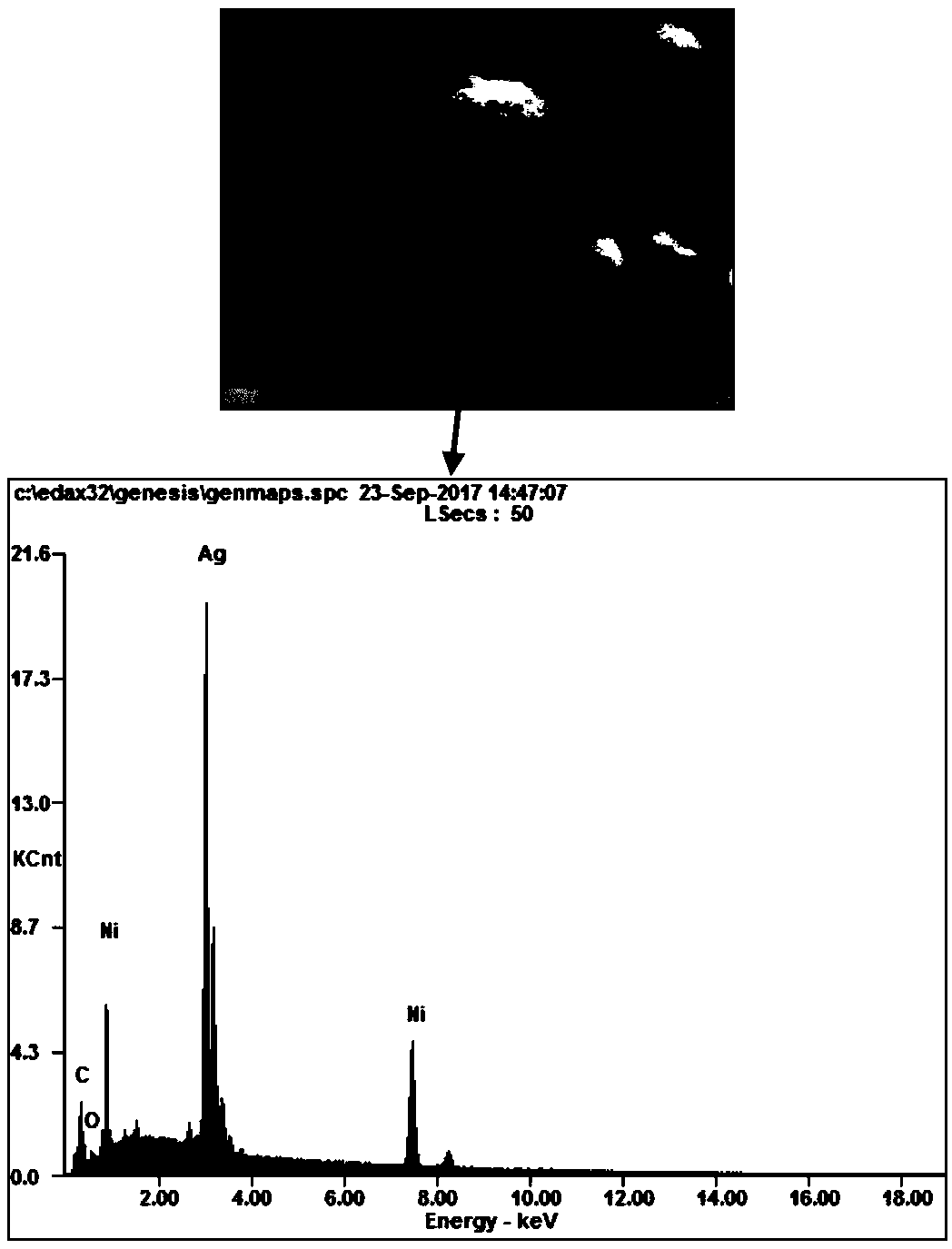

Production method of silver coated nickel powder

ActiveCN108326293AEasy to PlatingReduce deposition rateTransportation and packagingMetal-working apparatusElectricityChemical plating

The invention discloses a production method of silver coated nickel powder. The method comprises three main steps of surface preprocessing, plating and surface post-processing to prepare the nickel powder, wherein the preprocessing include washing and surface modifying of the nickel powder; the plating is performed by a chemical plating method using a silver-ammonia solution; the nickel powder isactivated through a surfactant containing water solution and is subjected to surface modification before silver plating, so that the nickel powder is easily plated; a complexing agent is added to a reduction solution in the plating process so as to decrease the deposition speed of silver atoms, and the nickel powder can be coated with the silver atoms; after plating, the surface is further processed through a thermal processing method in order to repair few coating defects in the silver plating link by a reductive thermal treatment technology, and thus the coating density is improved; and meanwhile, the processes are environmentally friendly, and easily operated; and industrial massive production is realized. The silver coated nickel powder prepared by the method is uniform and dense in ametal plating layer, free from exposed pores, and high in electricity conductivity while being used in an electrical material.

Owner:宁波广新纳米材料有限公司

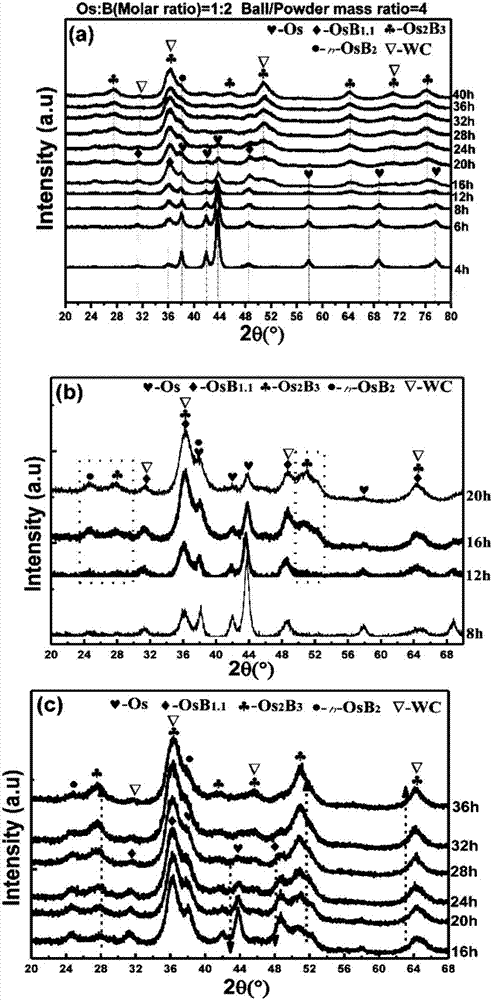

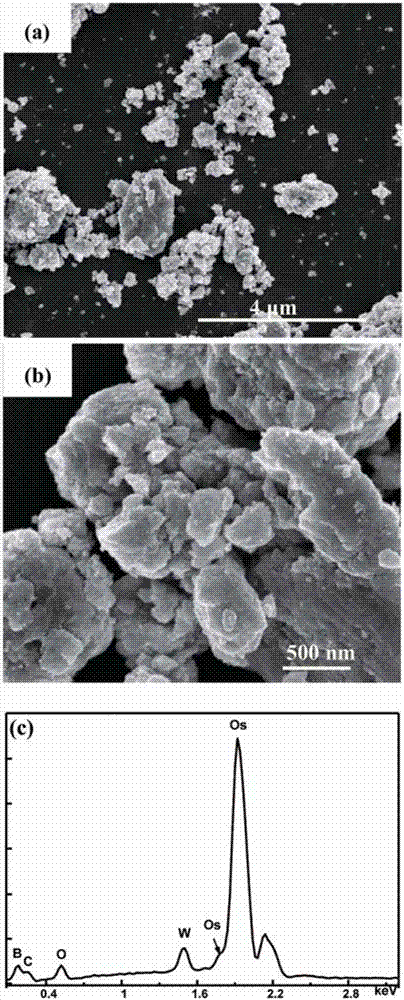

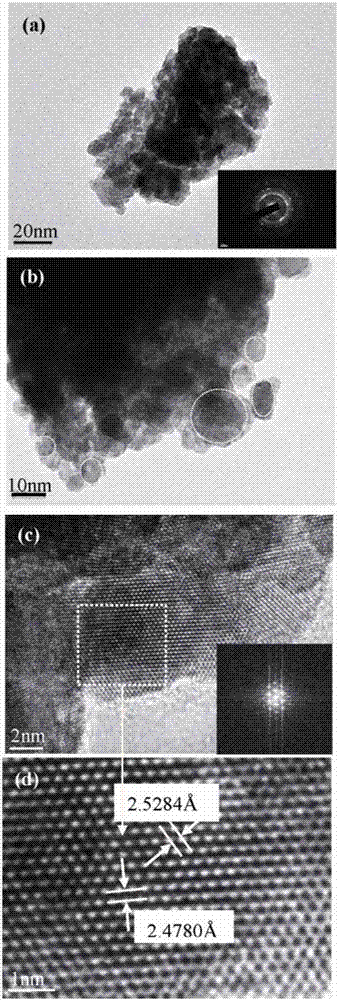

Os2B3 hard material and preparation and application thereof

The invention belongs to the field of inorganic nonmetallic hard materials, and particularly relates to an Os2B3 hard material and a preparation method and application thereof. The preparation method comprises the following steps: by a mechanochemical method, with high-purity Os powder and B powder as raw materials, synthesizing Os2B3 powder at room temperature by using high-energy ball milling equipment; then, by high-temperature sintering technology, and performing compacted sintering on the synthesized Os2B3 powder under the protection of an argon atmosphere to obtain a high-compactness and high-hardness block material. By the preparation method, the Os2B3 powder is synthesized at room temperature, and the Os2B3 block material adopting a hexagonal structure and having high temperature stability is prepared. The Os2B3 material prepared by the preparation method provided by the invention can be applied to the industrial fields of cutting tools, machine manufacturing, aerospace, automobiles and the like.

Owner:GUANGDONG UNIV OF TECH

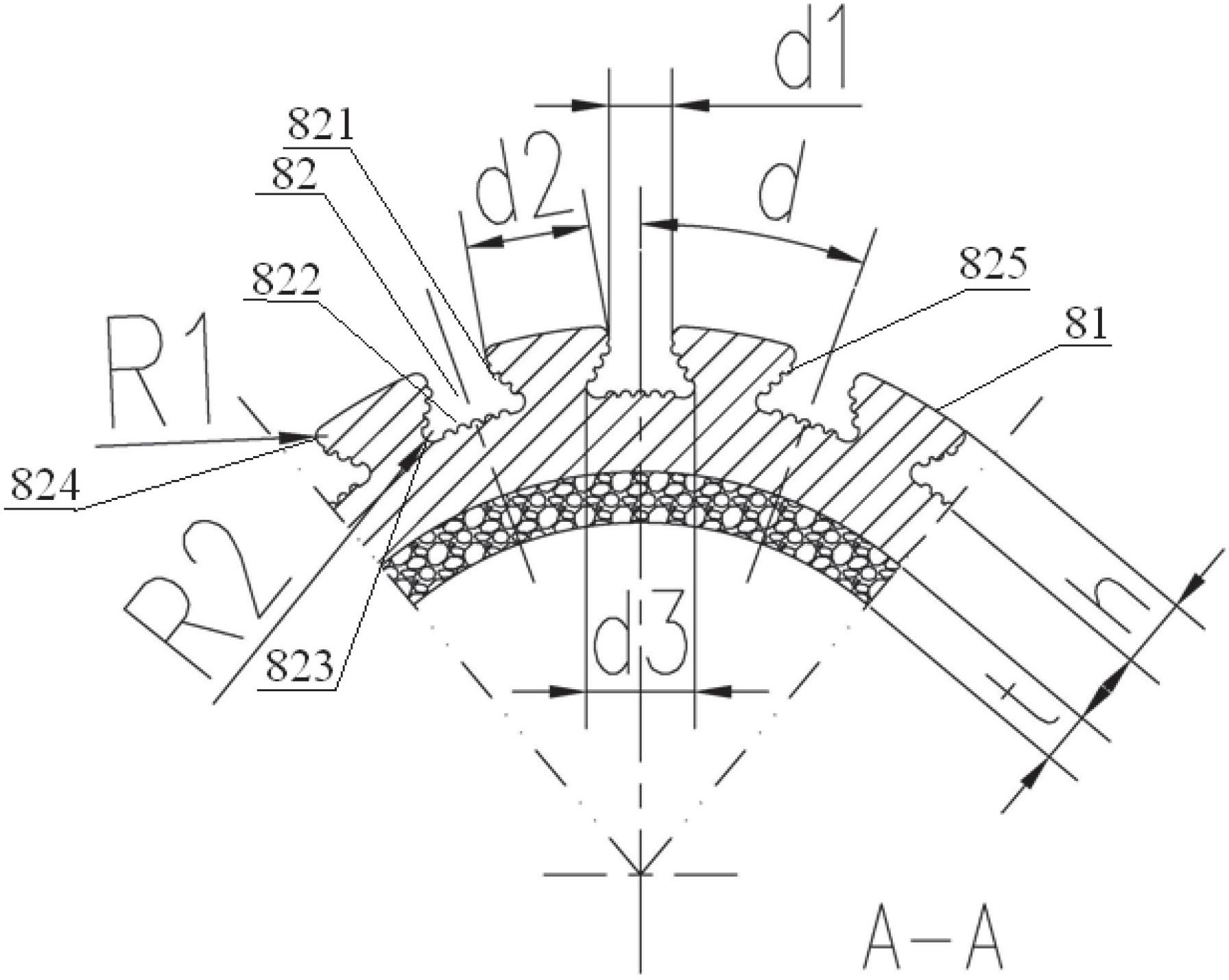

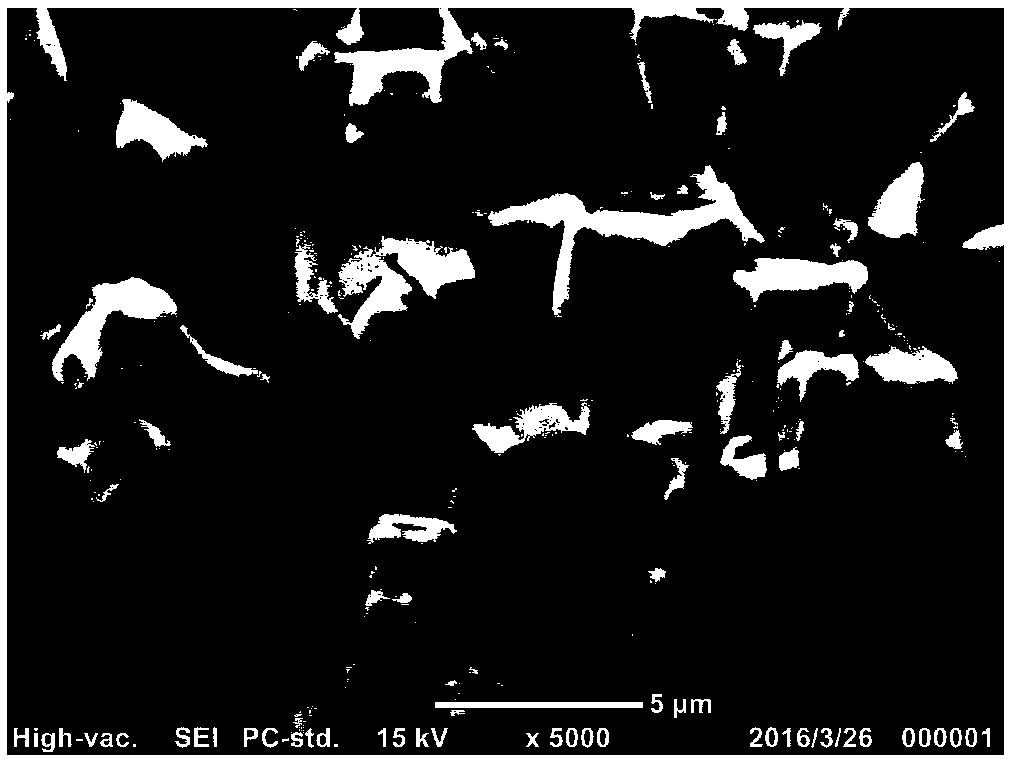

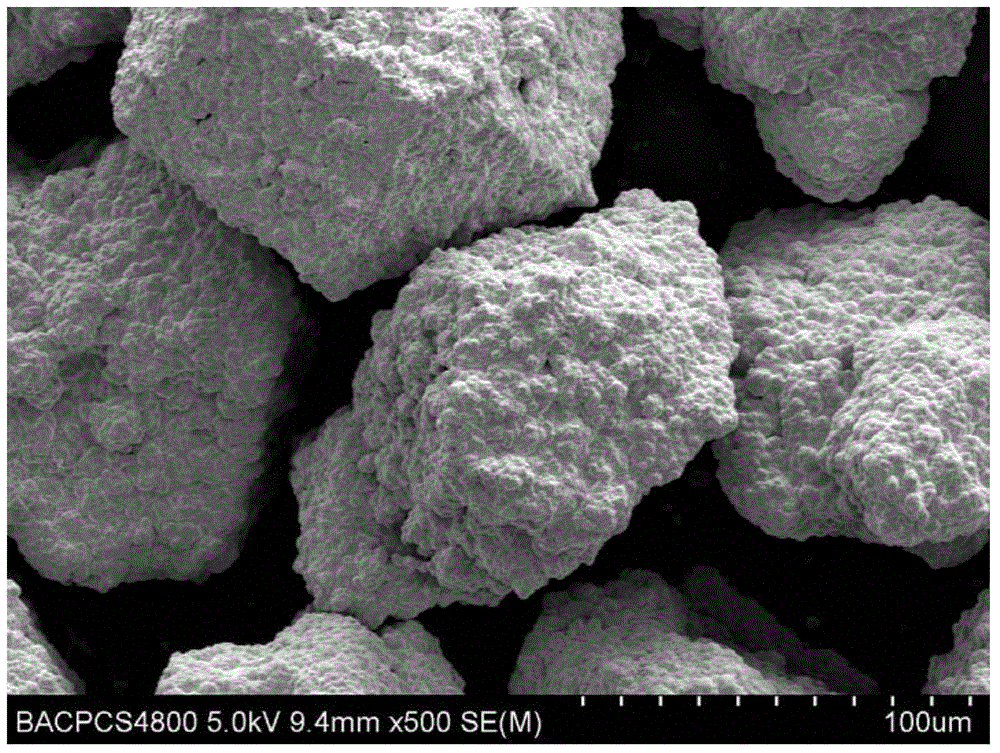

Chemical plating solution for preparing nickel splinter plated diamond abrasive particle, and chemical plating method

ActiveCN104947095AReduce deposition rateFast depositionLiquid/solution decomposition chemical coatingSodium acetateChemical plating

The invention relates to a chemical plating solution for preparing a nickel splinter plated diamond abrasive particle, and a chemical plating method. The chemical plating solution is an aqueous solution containing nickel sulfate, sodium hypophosphate, sodium citrate, sodium acetate, a stabilizing agent, aminobenzenesulfonic acid and sodium benzenesulfinate. A layer of metallic nickel is deposited on the surface of a diamond particle by using an oxidation reduction reaction through adopting the chemical plating method to form splinter-shaped protrusions in order to prepare diamond abrasive particle with a nickel splinter layer. The abrasive particle has high specific surface area, and can be widely used in diamond tools made of a resin binder to increase the holding force between diamond and the resin and increase the heat conductivity of products of the tools in order to enhance the grinding efficiency of produced tools and prolong the life of the tools.

Owner:北京国瑞升精机科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com