Preparation method for gold plating on surface of silicon carbide particle reinforced aluminum-based composite material

A technology of silicon carbide particles and reinforced aluminum base, which is applied in the direction of surface reaction electrolytic coating, metal material coating process, liquid chemical plating, etc., can solve the problem of affecting the test and evaluation results of the sealing of the tube shell, the porosity of the gold plating layer is large, The problem of large helium adsorption capacity can achieve the effect of achieving the density of the coating, improving the density of the coating, and reducing the internal stress of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

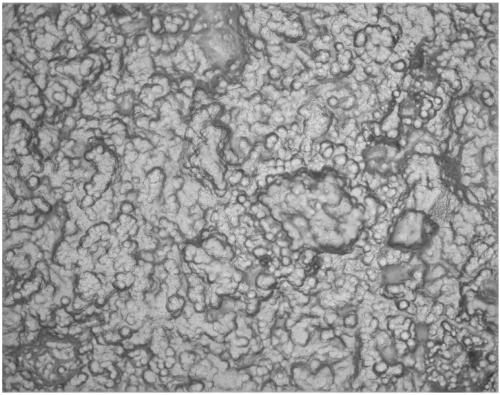

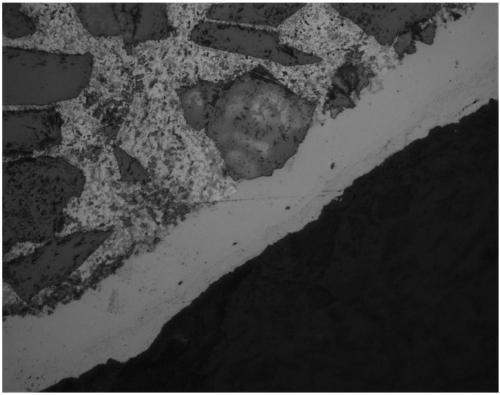

Image

Examples

preparation example Construction

[0053] The embodiment of the present invention provides a method for preparing a gold coating on the surface of a silicon carbide particle reinforced aluminum matrix composite material, comprising the following steps:

[0054] Step (1), carrying out pretreatment to SiCp / Al composite material;

[0055] Specifically, the SiCp / Al composite material described in the embodiments of the present invention can be either a low-volume SiCp / Al composite material with a relatively low volume percentage (<40%) of silicon carbide particle components, or a silicon carbide High-volume SiCp / Al composite material with a relatively high volume percentage of particle components (40% to 70%);

[0056] The pretreatment may include various pretreatment processes before gold plating of such materials, preferably organic degreasing, chemical degreasing, light extraction and chemical roughening are performed on the SiCp / Al composite material, wherein:

[0057] The preferred process for organic degreas...

Embodiment 1

[0080] 1) Wipe the surface of the high volume fraction (60%) SiCp / Al composite material so that the surface of the high volume fraction SiCp / Al composite material is completely wetted by water and the water film is continuous within 30s;

[0081] 2) The surface of the high volume SiCp / Al composite material obtained in step 1) is chemically degreased, and the formula and operating conditions of the chemical degreasing solution are as follows:

[0082]

[0083] After the chemical degreasing is completed, the high volume SiCp / Al composite material is taken out of the solution;

[0084] 3) washing the residual solution on the surface of the high volume SiCp / Al composite material obtained in step 2) with water;

[0085] 4) Light-emitting the surface of the high-volume SiCp / Al composite material obtained in step 3), the formula and operating conditions of the light-emitting solution are as follows:

[0086] Nitric acid 400g / L

[0087] Solution temperature room temperature

[0...

Embodiment 2

[0136] 1) Wipe the surface of the high volume fraction (60%) SiCp / Al composite material so that the surface of the high volume fraction SiCp / Al composite material is completely wetted by water and the water film is continuous within 30s;

[0137] 2) The surface of the high volume SiCp / Al composite material obtained in step 1) is chemically degreased, and the formula and operating conditions of the chemical degreasing solution are as follows:

[0138]

[0139] After the chemical degreasing is completed, the high volume SiCp / Al composite material is taken out of the solution;

[0140] 3) washing the residual solution on the surface of the high volume SiCp / Al composite material obtained in step 2) with water;

[0141] 4) Light-emitting the surface of the high-volume SiCp / Al composite material obtained in step 3), the formula and operating conditions of the light-emitting solution are as follows:

[0142] Nitric acid 500g / L

[0143] Solution temperature room temperature

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com