Super-thick aluminum alloy cast-rolled plate production method

A production method and technology of aluminum alloy, applied in the field of non-ferrous smelting, can solve the problems of insufficient rolling force, low input current power, unqualified cast and rolled plate shape, etc., and achieve uniform upper and lower structure of the plate, uniform temperature distribution and internal quality. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

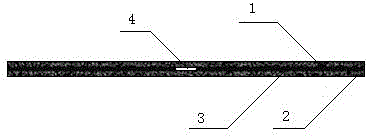

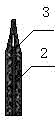

[0049] Such as figure 1 - Figure 5 As shown, the present invention is a production method of ultra-thick aluminum alloy cast-rolled plate, and the method includes furnace loading, batching, heating and melting, stirring and slag removal, sampling, furnace inversion, holding furnace refining, slag removal, on-line refinement, On-line degassing, filtering, casting and coiling steps, the invention is characterized by:

[0050] 1) The roll shape of the casting roll in the casting and rolling step is coaxiality<0.005mm, ellipticity<0.01mm, crown of a single roll 0.20-0.24mm, diameter difference between two rolls<1mm, roughness Ra0.7-0.8 μm;

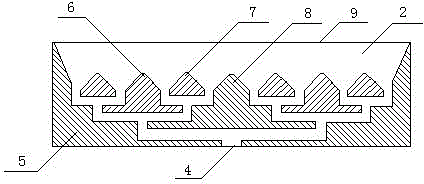

[0051] 2) Casting and rolling nozzle: the abdominal cavity block is set between the upper fan nozzle and the lower fan nozzle to form a three-stage shunt;

[0052] 3) Casting and rolling process parameters: casting nozzle opening 26mm, nozzle roll gap 0.5mm, ear roll gap 0.7mm, roll gap ws∕ds 11.51∕11.54mm, preset rolling area 78-82mm, fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com