Patents

Literature

74results about How to "Improve board quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

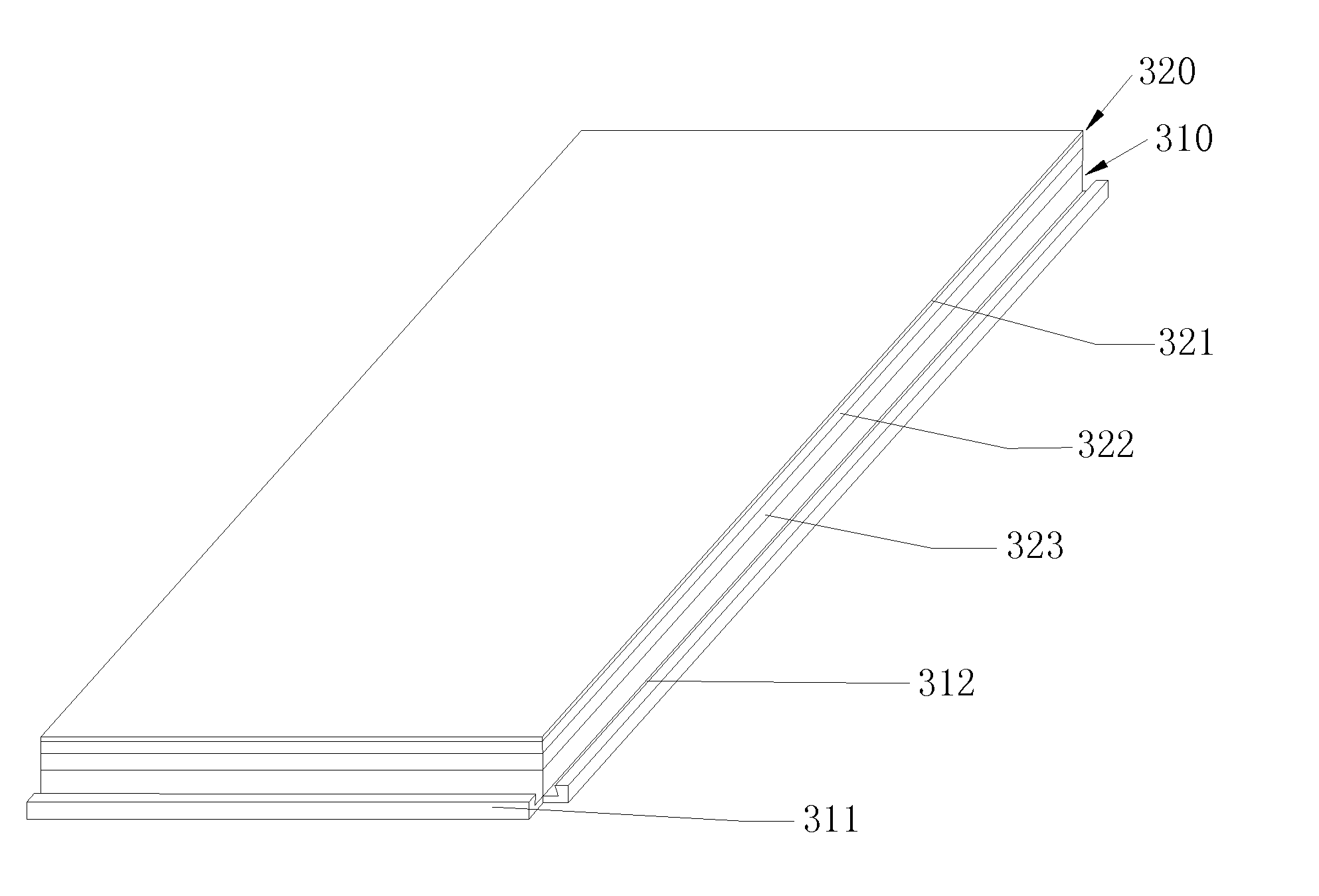

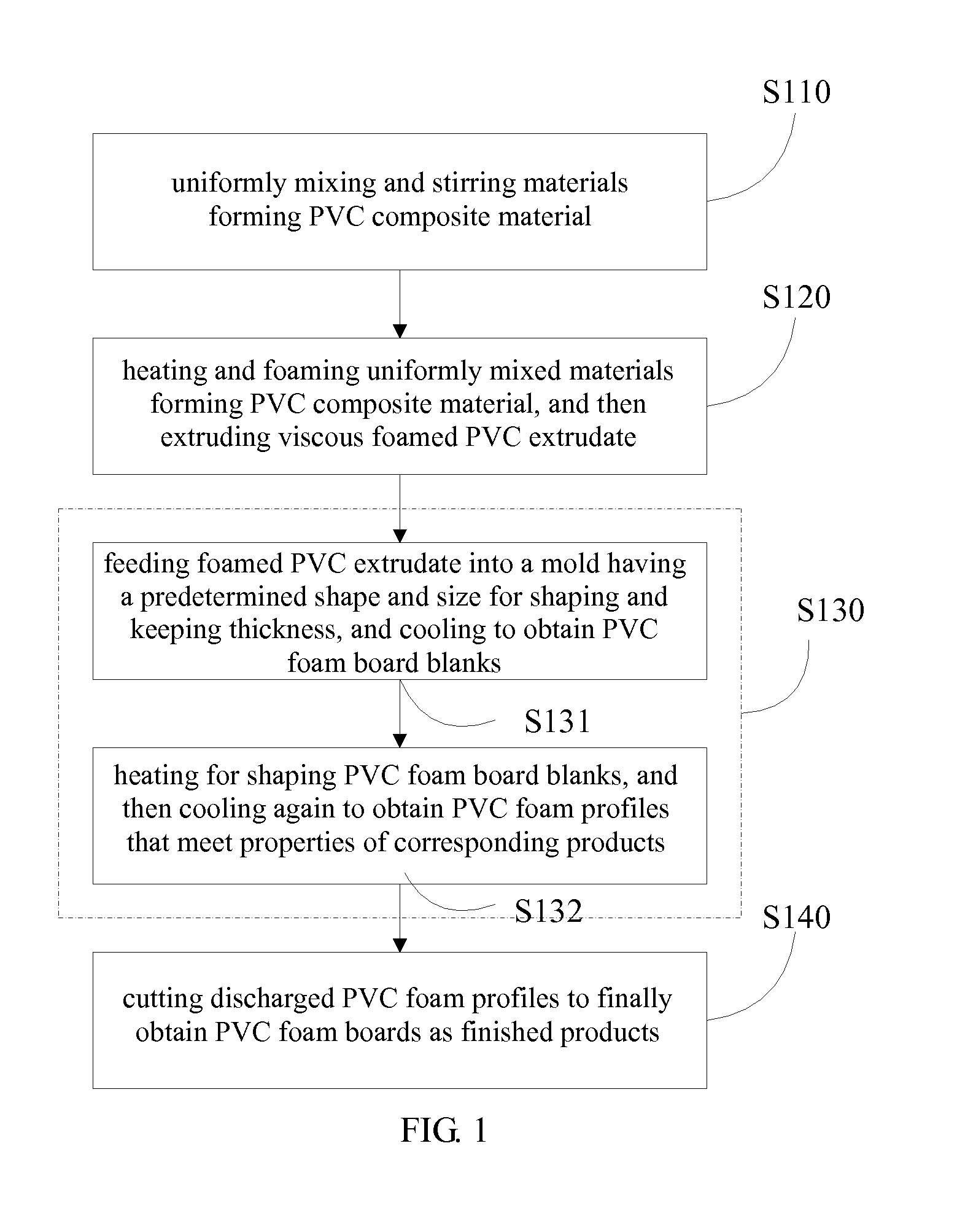

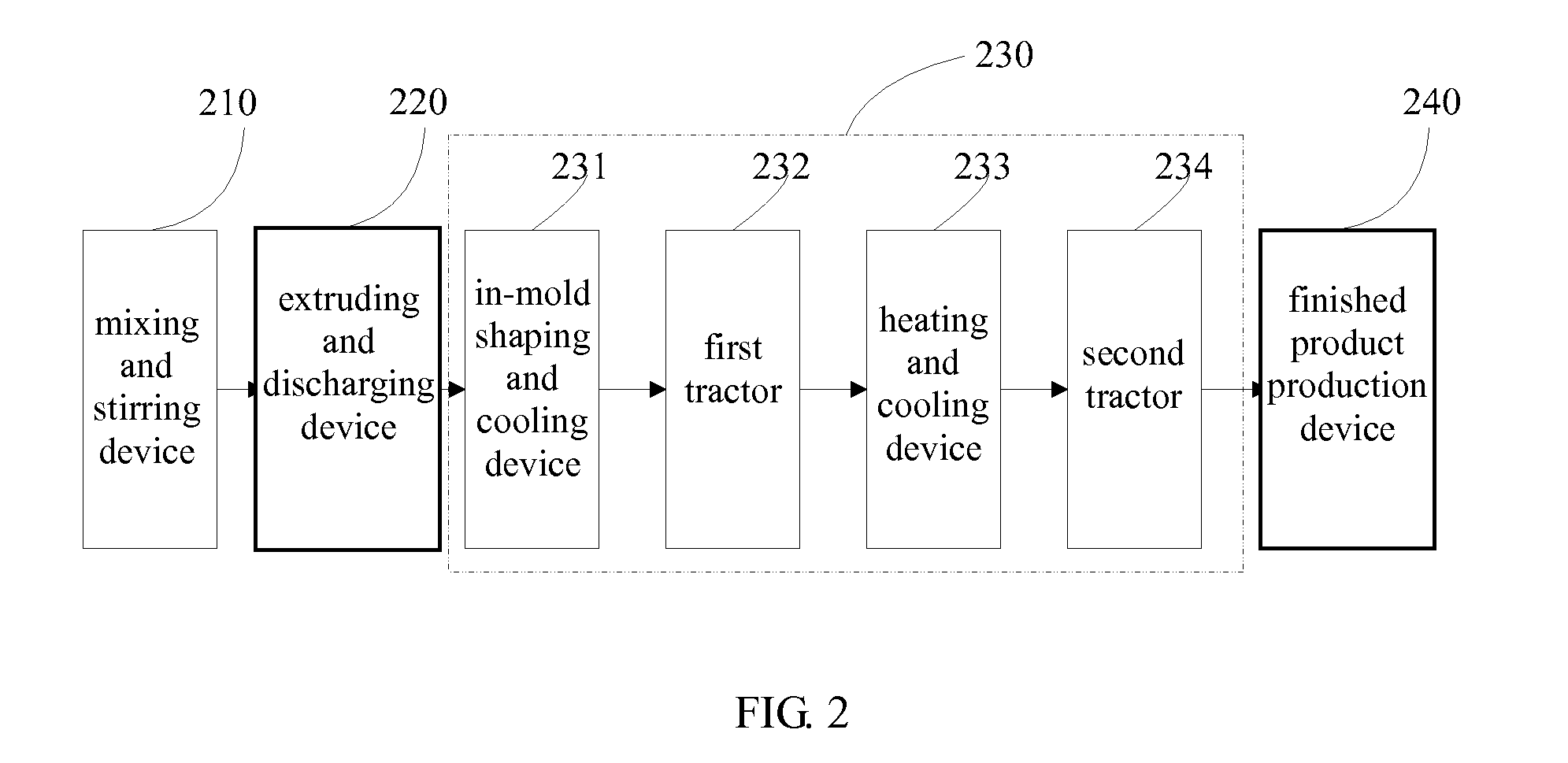

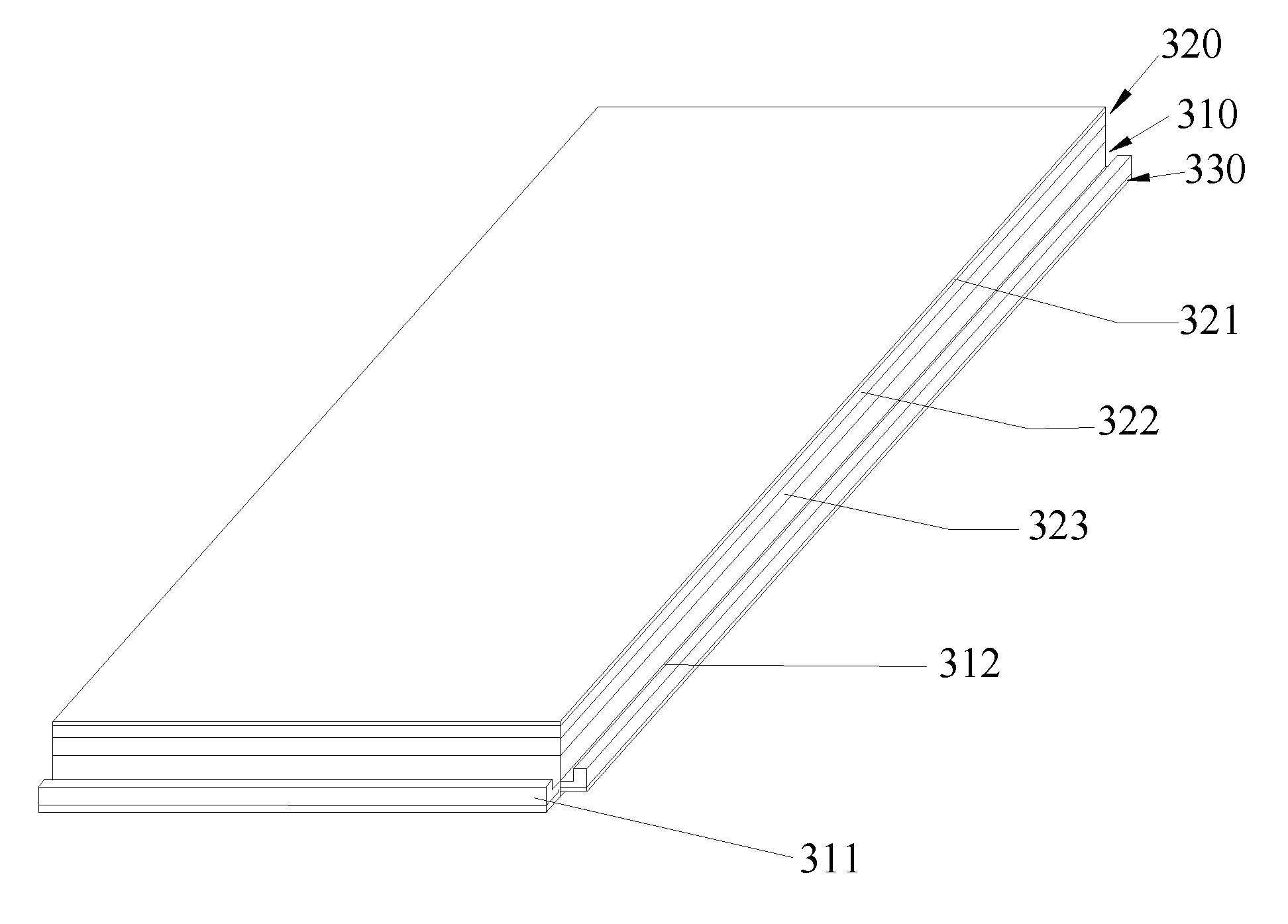

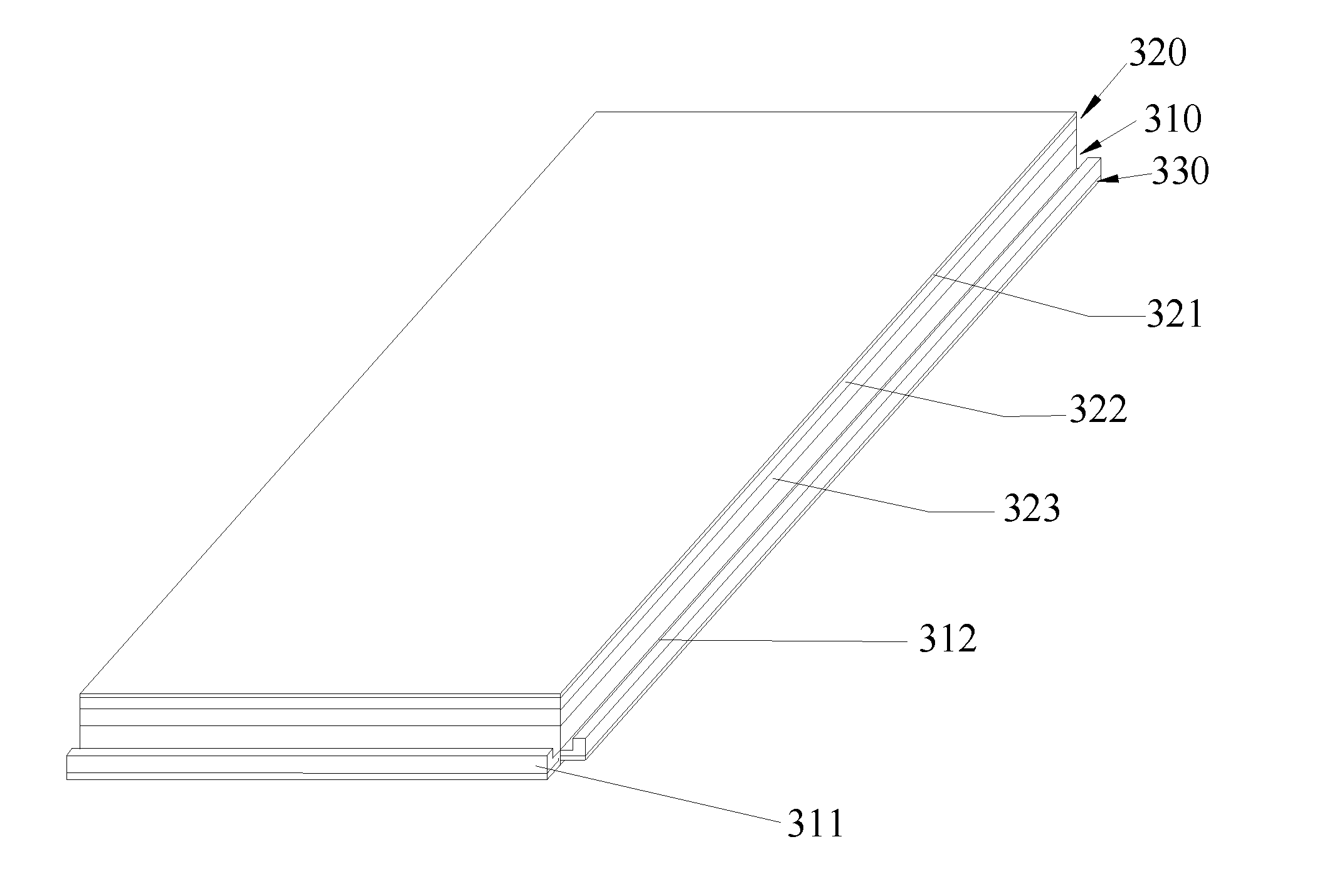

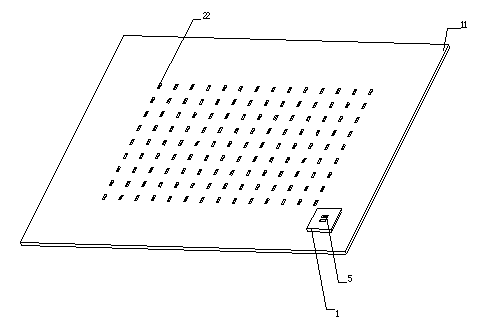

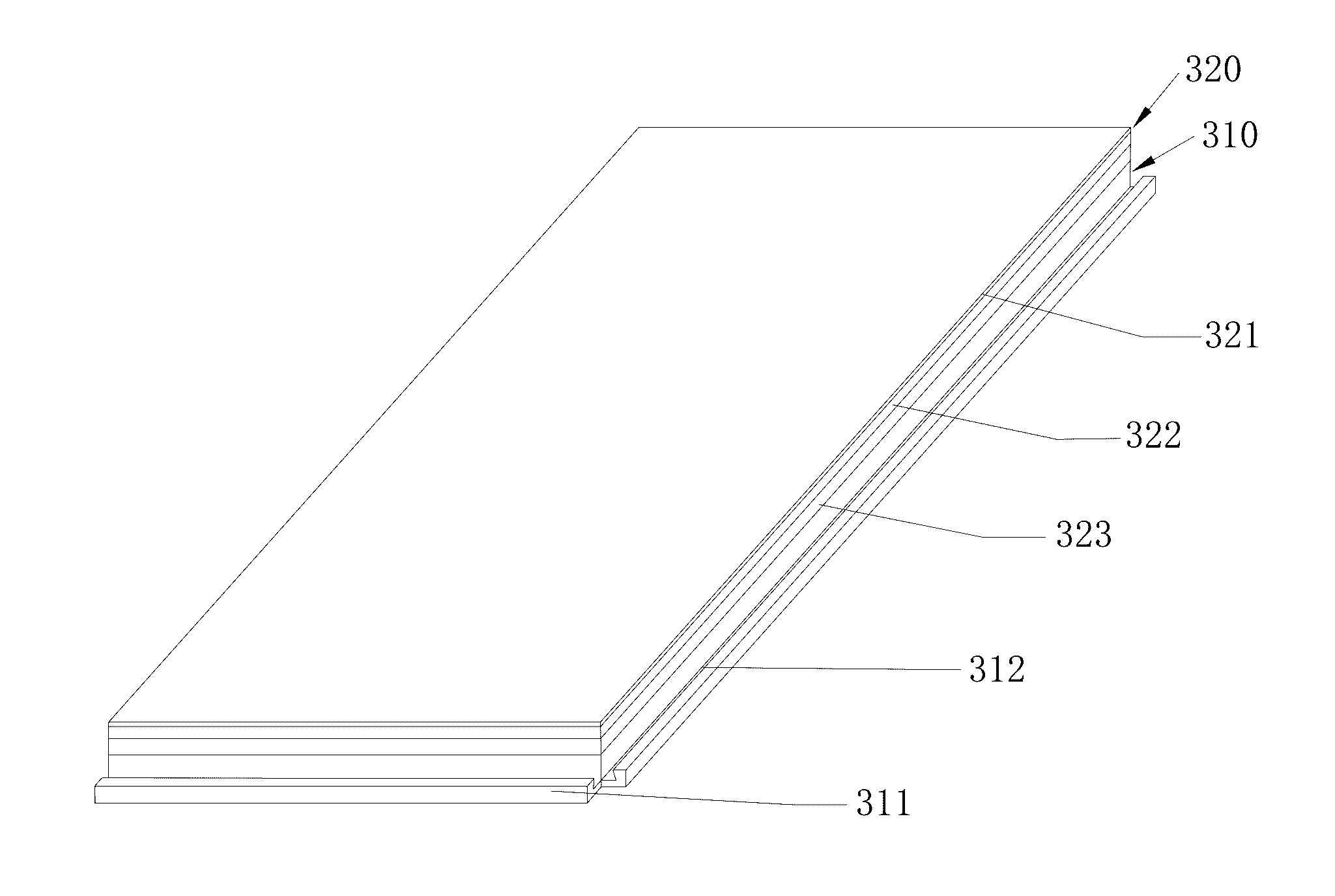

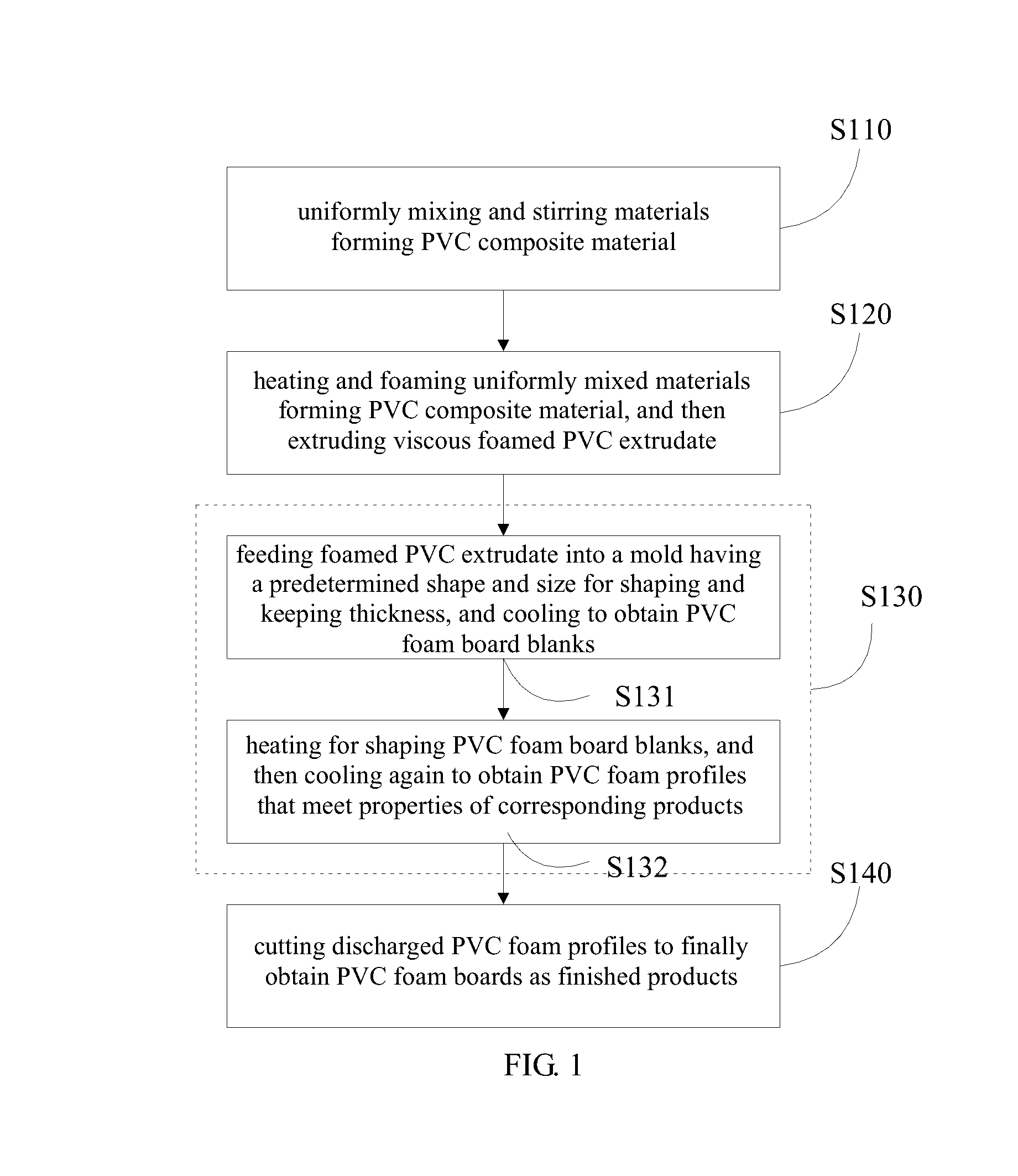

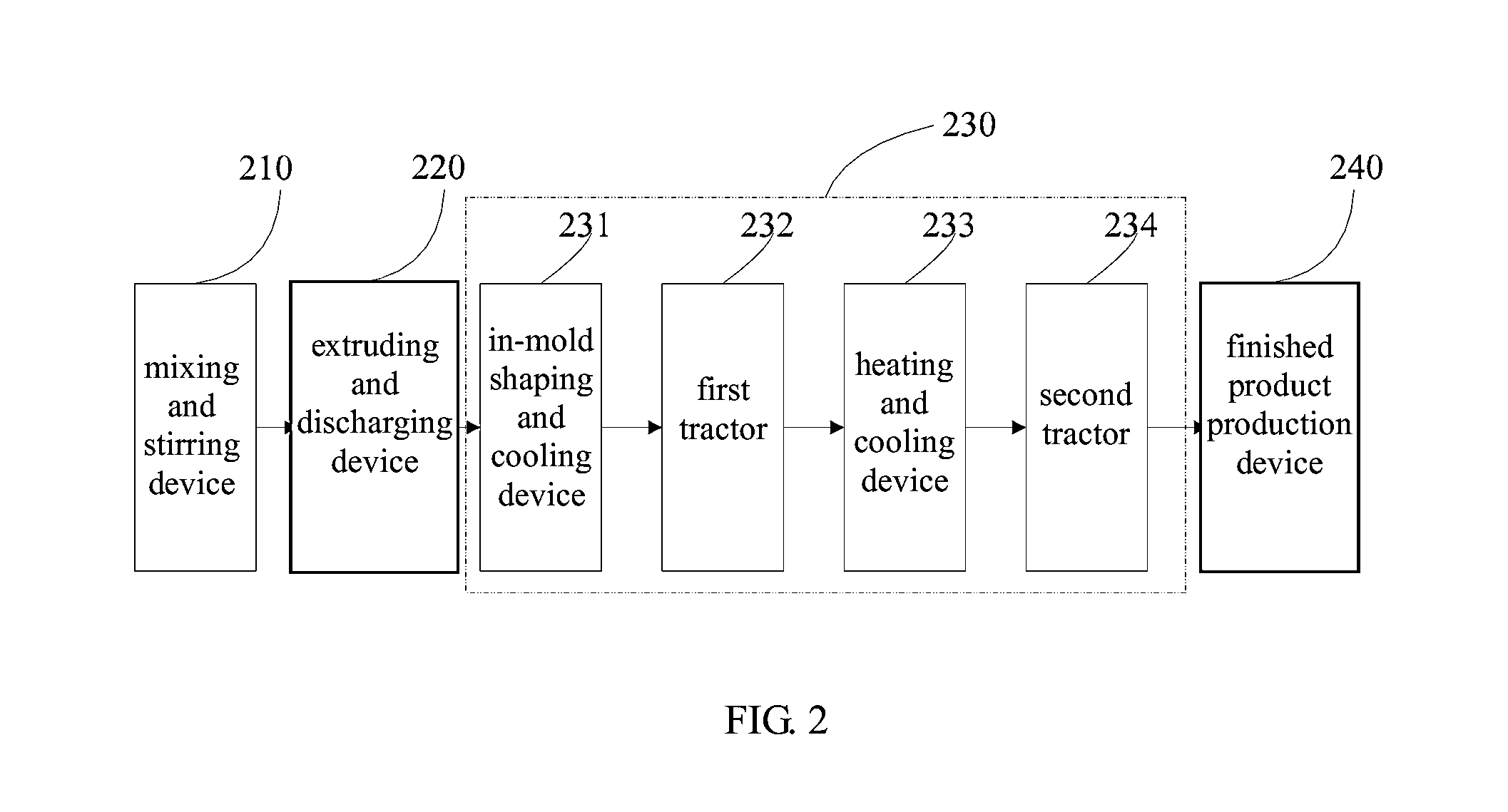

PVC composite material, foam board, production method and apparatus thereof, and flooring

ActiveUS20150267025A1Quality improvementImprove propertiesMouldsConfectioneryFoaming agentPolyvinyl chloride

The present invention provides a polyvinyl chloride polymer (PVC) composite material including 40-60 parts by weight of PVC, 40-60 parts by weight of light calcium carbonate, 0.8-1.2 parts by weight of composite foaming agent including an inorganic foaming agent and an organic foaming agent, 3-5 parts by weight of foam regulator, 2-4 parts by weight of toughener, 0.8-1.2 parts by weight of lubricant, and 1.5-2.5 parts by weight of stabilizer. The ratio of the inorganic foaming agent to the organic foaming agent by weight in the composite foaming agent is 1 / 2-1. Meanwhile, the present invention provides a foam board made of the PVC composite material, an associated production method, an apparatus, and flooring. The resulting PVC products have a high-strength structure and a good foaming property, thus having a satisfied mute effect.

Owner:FLOORING IND LTD

Inkjet recording sheet

InactiveUS20020176970A1Improve abilitiesGood ink absorptionCoatingsThermographyPolyvinyl alcoholAcyl group

Disclosed is an inkjet recording sheet having a colorant-receiving layer on the surface of its support, in which the colorant-receiving layer contains at least one of compounds represented by the following general formula (1) and compounds represented by the following general formula (2), and contains a vapor-phase-process silica, a polyvinyl alcohol, a boron compound, and a mordant. In the formulae, R represents a saturated hydrocarbon group having from 1 to 12 carbon atoms, an unsaturated hydrocarbon group having from 1 to 12 carbon atoms, a phenyl group, or an acyl group, and n indicates an integer of 1 to 3. <paragraph lvl="0"><in-line-formula>RO(CH2CH2O)nH (1) < / in-line-formula><paragraph lvl="0"><in-line-formula>RO(CH2CH(CH3)O)nH (2) < / in-line-formula>

Owner:FUJIFILM HLDG CORP +1

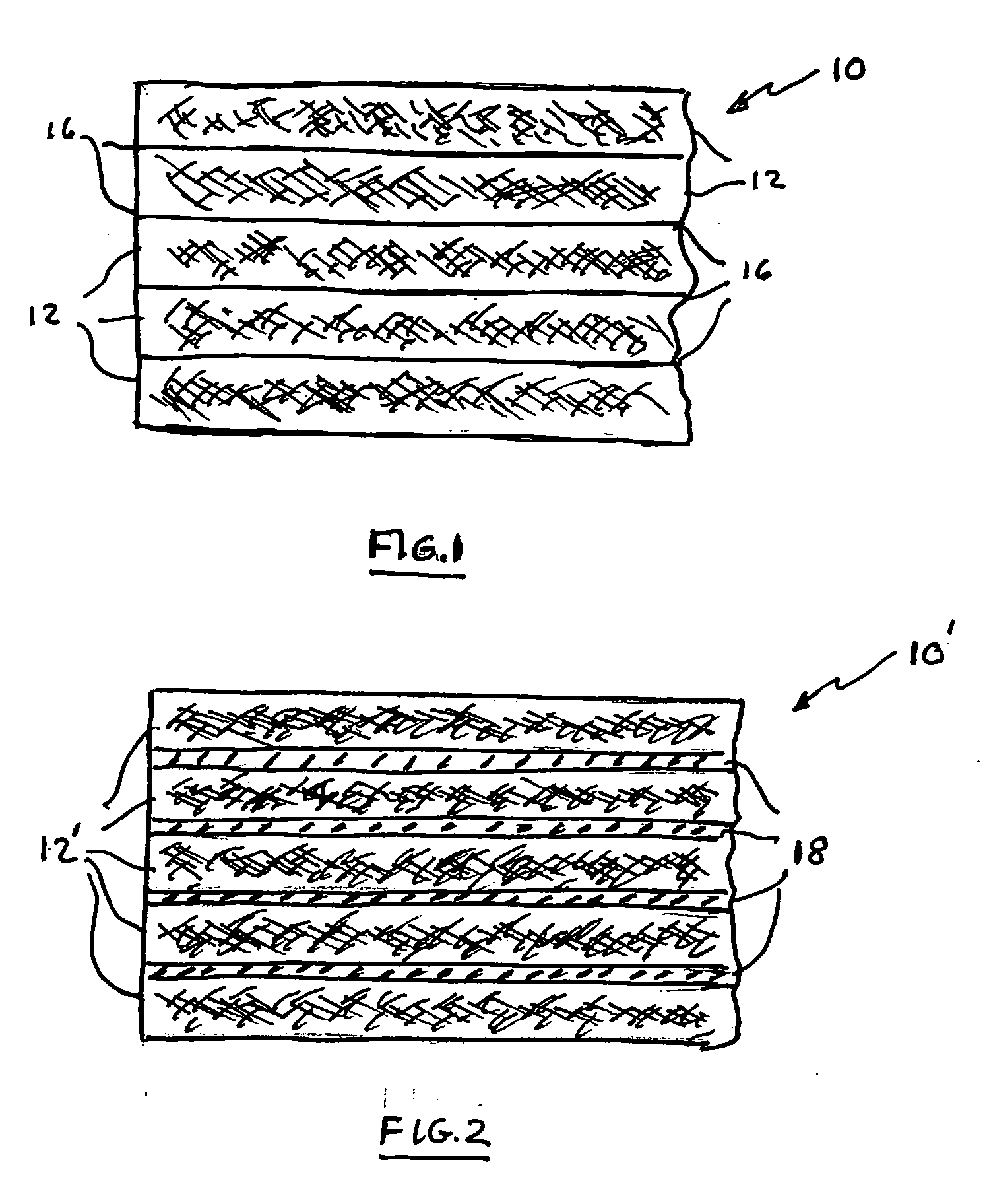

Planar elements for use in papermaking machines

InactiveUS20050279478A1Improve ultraviolet ray blocking propertyImprove performanceMaterial nanotechnologyLiquid surface applicatorsPolymer resinNanoparticle

A planar element for use in a papermaking machine comprising a synthetic construction incorporating nanoparticles in a polymeric resin matrix.

Owner:KADANT WEB SYSTEMS INC

Method for controlling and treating bottom roller dross of carbon sleeve furnace

ActiveCN101906529AReduce running speed varianceReduce nodulationFurnace typesHeat treatment process controlDrossDew point

The invention discloses a method for controlling and treating bottom roller dross of a carbon sleeve furnace. The possibility of dross occurrence is reduced by effective preventive measures for controlling the brushing current of a brush roller, reducing the use of a severely-oxidized transition strip, controlling appropriate furnace pressure, dew point and hydrogen content according to the difference of process speeds and process temperatures, periodically adjusting the rotating speed of a furnace roller, reducing running speed difference between the furnace roller and band steel, controlling the temperature raising and lowering rates of process temperature transformation during steel transformation and the like. Simultaneously, different treatment methods are used according to different dross states, so that treatment time is shortened greatly. The problems of long treatment time, single treatment method, no distinguished treatment according to different dross states, grinding of all furnace bottom rollers during treatment, damage to the furnace bottom rollers without dross, effect on service life and the like are solved, the plate surface quality of a cold-rolled and annealed product is enhanced and product percent of pass is increased.

Owner:ANGANG STEEL CO LTD

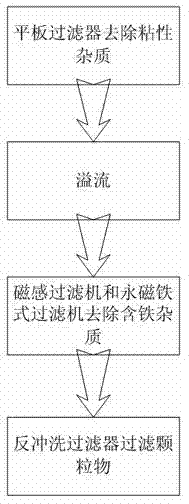

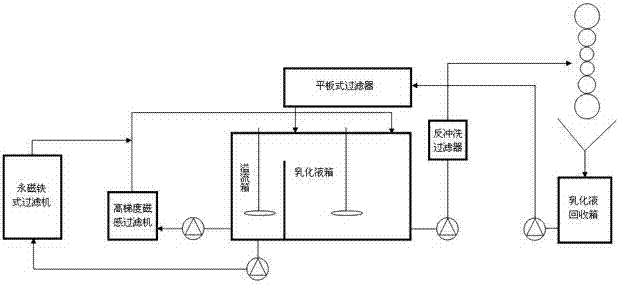

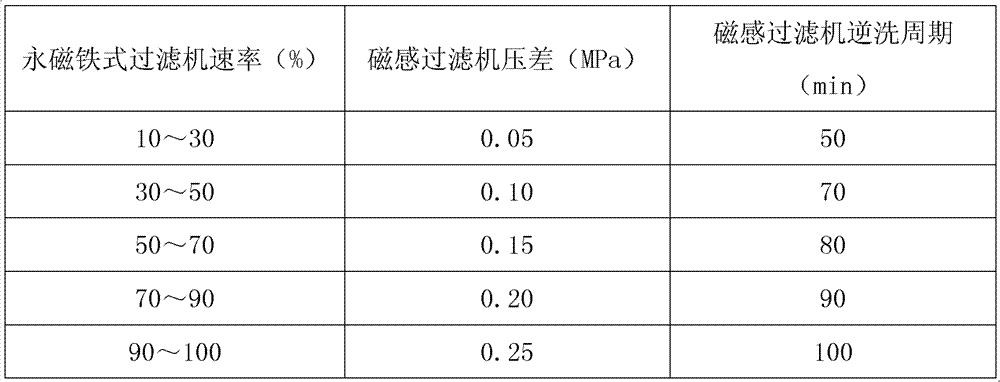

Deep filtration method of emulsion used by cold-rolling unit

The invention discloses a deep filtration method of an emulsion used by a cold-rolling unit. The deep filtration method comprises the following steps of pumping an emulsion used by a cold-rolling unit into a flat plate filter, removing sticky impurities in the emulsion by the flat plate filter, feeding the emulsion without the sticky impurities into an emulsion tank, carrying out overflow filtration of the emulsion in the emulsion tank so that impurities floating on the surface of the emulsion enter into an overflow tank, feeding the emulsion in the overflow tank into a magnetic induction filter and a permanent magnet-type filter, carrying out further filtration so that iron-containing impurities in the emulsion are removed, feeding back the emulsion filtered by the magnetic induction filter and the permanent magnet-type filter into the emulsion tank, feeding the emulsion in the emulsion tank into a cold-rolling machine, wherein a backwash filter is arranged in a passage for conveying the emulsion to the cold-rolling machine, and filtering the emulsion by the backwash filter to remove particles before the emulsion enters into the cold-rolling machine.

Owner:BAOSHAN IRON & STEEL CO LTD

PVC composite material, foam board, and flooring

PendingUS20160177579A1Improved propertyLarge market shareConstruction materialFloorsCalcium carbonatePolymer

A polyvinyl chloride polymer (PVC) composite material is described herein. The PVC composite material includes 40-60 parts by weight of PVC, 40-60 parts by weight of calcium carbonate, 0.2-0.6 parts by weight of composite foaming agent, 3-5 parts by weight of foam regulator, 2-4 parts by weight of toughener, 0.8-1.2 parts by weight of lubricant, and 2-3 parts by weight of stabilizer. Meanwhile, the present invention provides a foam board made of the PVC composite material and flooring. The resulting PVC products have a high-strength structure and a good foaming property, bring the comfort to feet as the resilient flooring does, have a satisfied sound reduction and can be easily installed as the hard flooring could.

Owner:FLOORING IND LTD

Inkjet recording sheet

InactiveUS6761941B2Good ink absorptionImprove productivityLayered productsCoatingsPolyvinyl alcoholUnsaturated hydrocarbon

Owner:FUJIFILM HLDG CORP +1

Super-thick aluminum alloy cast-rolled plate production method

The invention relates to the technical field of nonferrous metallurgy, in particular to a super-thick aluminum alloy cast-rolled plate production method for producing aluminum alloy cast-rolled plates through a horizontal cast-rolling machine. The super-thick aluminum alloy cast-rolled plate production method includes the steps of furnace charging, batching, melting through temperature rise, stir for slagging-off, sampling, furnace discharging, refinement through a holding furnace, slagging-off, online refinement, online degassing, filtration, cast rolling and reeling-up. The super-thick aluminum alloy cast-rolled plate production method has the advantages that distribution uniformity of a cast lip is improved, and temperature distribution is uniform; Al-5Ti-1B grain refinement filament adding technological parameters are reasonably determined; all rolling technological parameters are reasonably determined; fourth, qualified 11.5 mm thick and 1550 mm wide plates are successfully cast-rolled; the optimal ratio of cold material to liquid material for batching is reasonably determined; sixth, quality defects causing instable and unqualified thick plates are overcome; seventh, the limit of rolling thickness of the original design of a cast-rolling device is broken through.

Owner:QINGHAI QIAOTOU ALUMINUM & POWER CO LTD

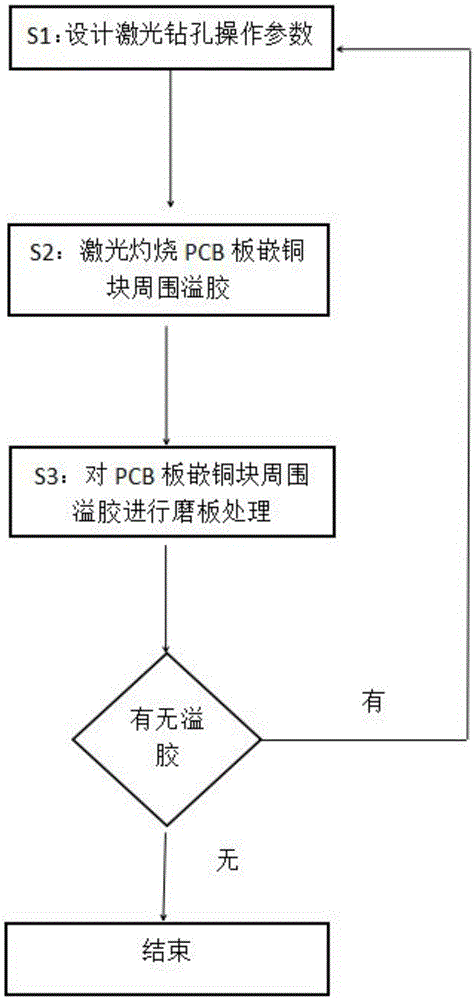

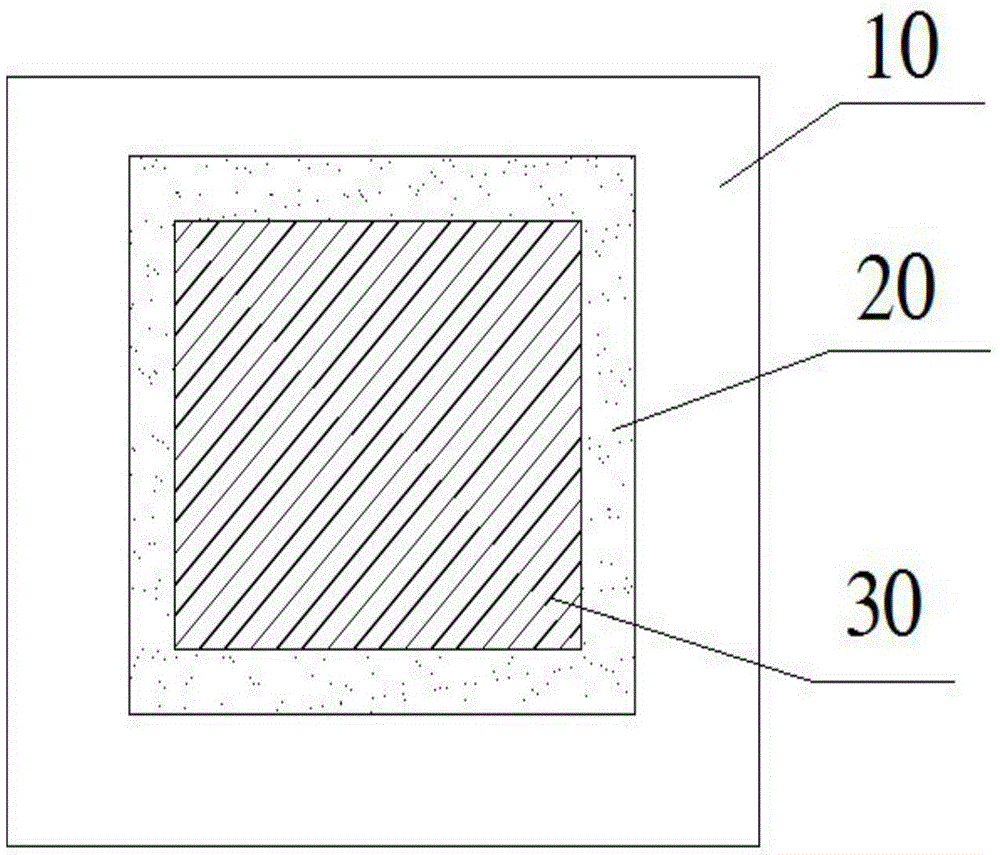

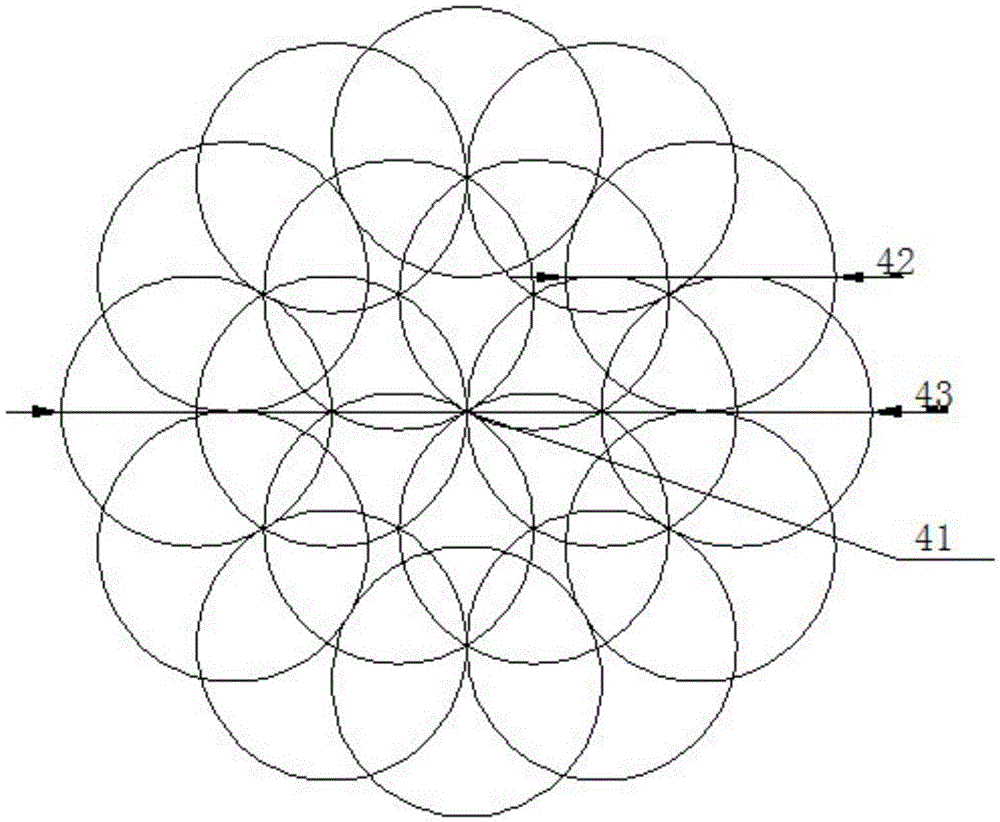

Method for eliminating edge squeezed-out resin of buried-copper-coin PCB

InactiveCN105491806AReduce scrap rateReduce intensityPrinted circuit aspectsPrinted circuit secondary treatmentCarbideEngineering

The invention provides a method for eliminating edge squeezed-out resin of a buried-copper-coin PCB. The method comprises the following steps of S1, setting an operation parameter of a laser drilling machine according to the thickness and width of the resin which is squeezed out of the buried-copper-coin PCB; S2, performing firming on the squeezed-out resin around the buried-copper-coin PCB by means of the laser drilling machine according to the operation parameter; and S3, grinding a carbide generated after firing the squeezed-out resin around the buried-copper-coin PCB by the laser drilling machine and the residual squeezed-out resin, thereby eliminating the carbide and the residual squeezed-out resin from the PCB; and a step of checking whether residual squeezed-out resin exists at the periphery of the buried-copper-coin PCB, and repeating the steps S1 to S3 until the squeezed-out resin is totally eliminated. The method of the invention has advantages of efficiently eliminating the edge squeezed-out resin of the buried-copper-coin PCB, reducing board surface wearing of the PCB, improving quality of manufactured PCB, and reducing rejection rate of the PCB.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

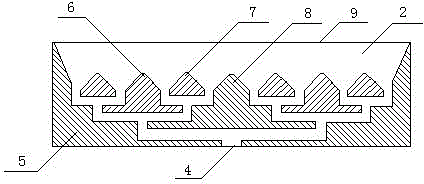

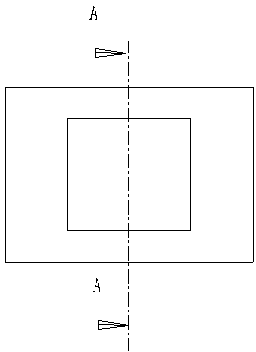

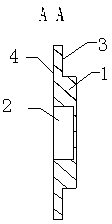

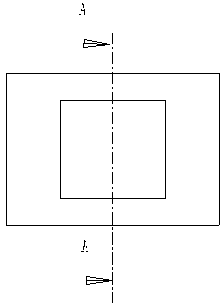

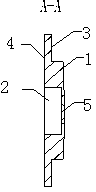

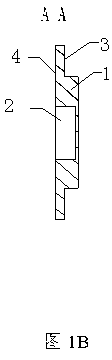

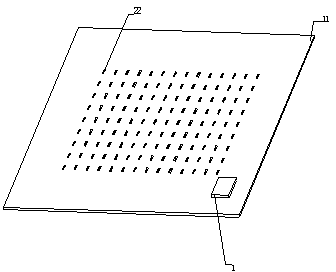

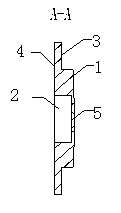

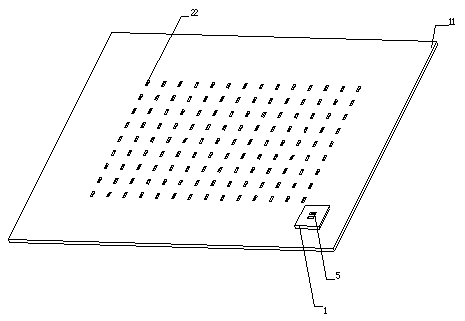

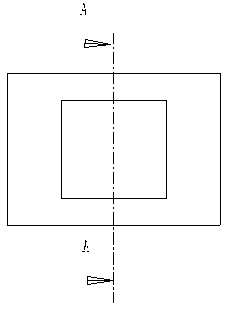

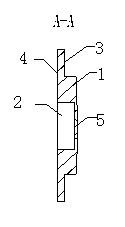

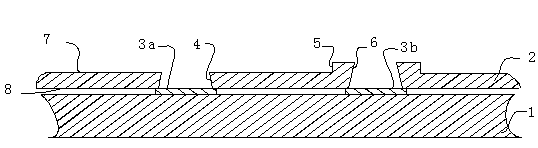

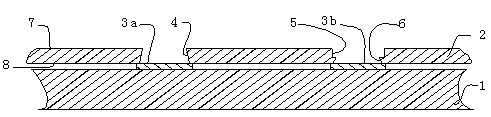

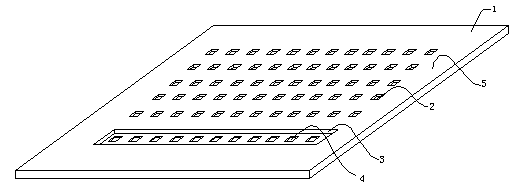

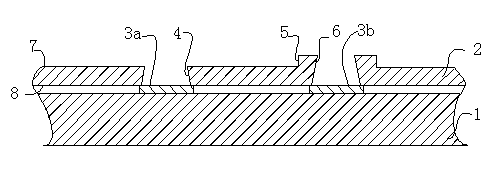

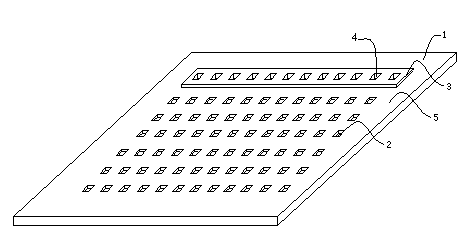

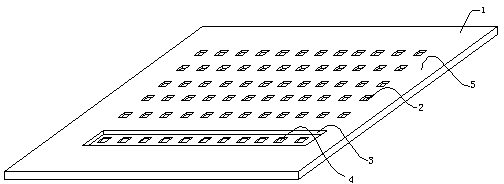

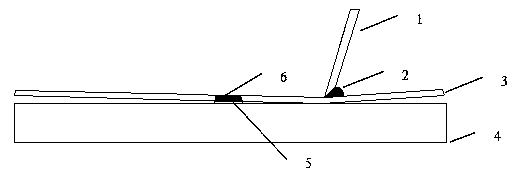

Three-dimensional mask plate for printing

InactiveCN103203982AHigh precisionImprove uniformityScreen printersPlate printingEngineeringPrinted circuit board

The invention discloses a three-dimensional mask plate for printing. The three-dimensional mask plate comprises a substrate, and a printing surface and a printed circuit board (PCB) surface, which are arranged on two sides of the substrate, and the mask plate is provided with a plurality of graphic openings and a three-dimensional structure, and the three-dimensional structure comprises a projection area on the printing surface and a concave area on the PCB surface. The mask plate is provided with the three-dimensional projection part and the three-dimensional concave part, the projection height is 0.1 to 10mm, the concave depth is 0.1 to 10mm, and angles formed between the projection part and the plate surface and between the concave part and the plate surface are 80 to 90 DEG; the composition of the mask plate is 56 to 62 percent of iron and 38 to 44 percent of nickel, and the mask plate is high in precision; the mask plate is high in uniformity, good in plate surface quality, bright and free from rough spots, scratches and pin holes; the opening quality is good, and the hole wall is smooth and free from burrs; and the mask plate is low in production cost, simple in process and low in energy consumption.

Owner:KUN SHAN POWER STENCIL

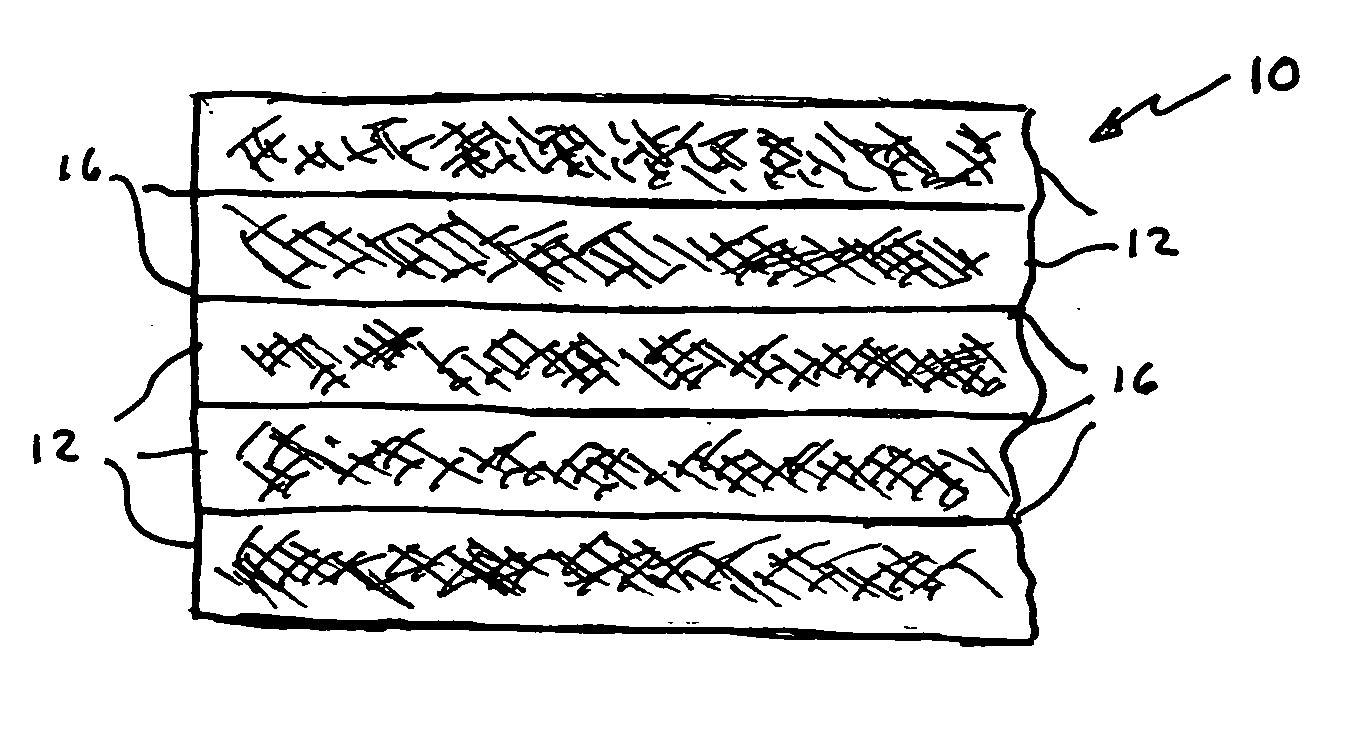

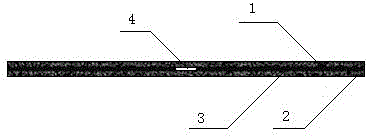

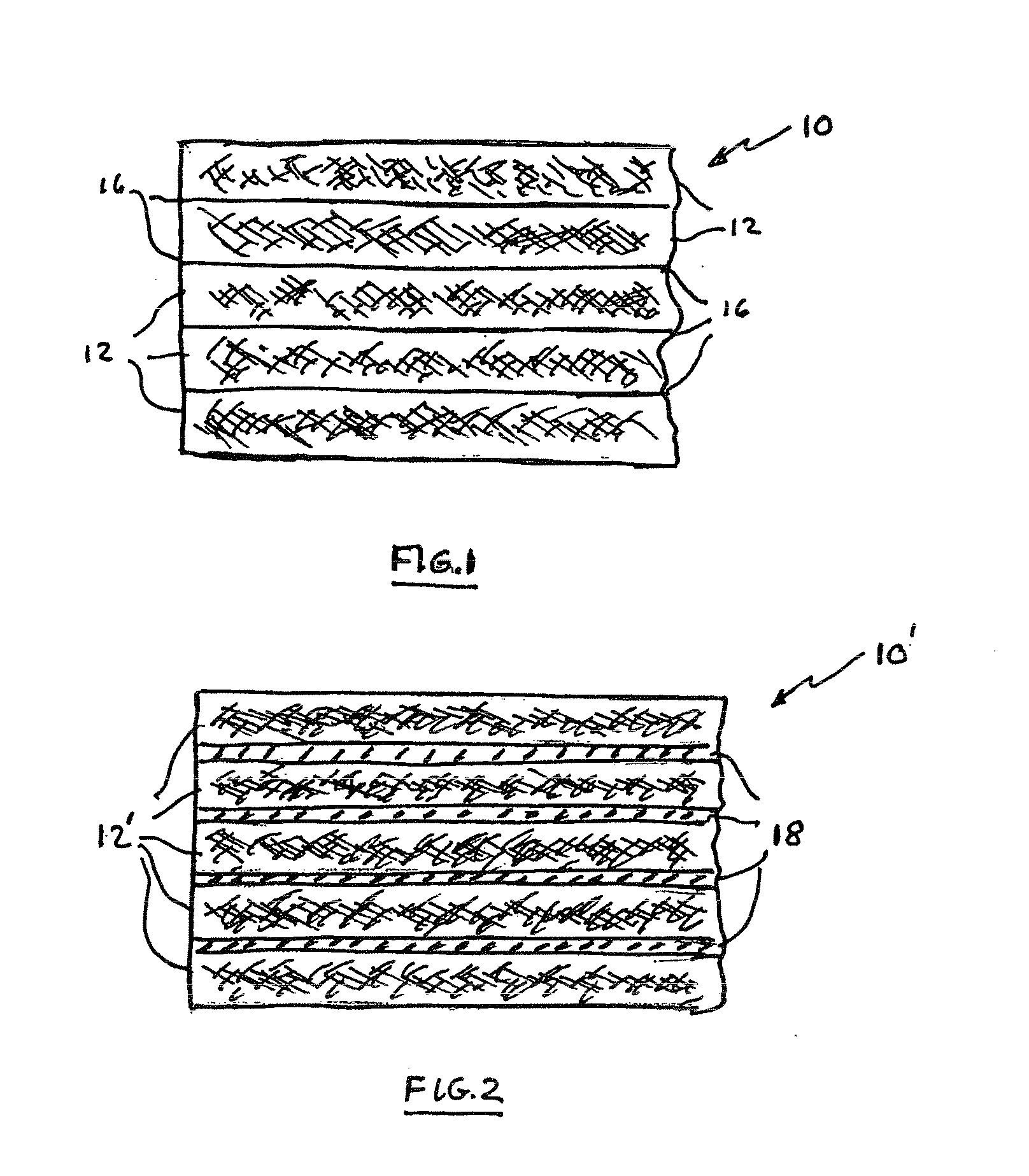

Polyvinyl chloride laminated soft sheet and preparation technology thereof

InactiveCN101735528AImprove board qualityLow costSynthetic resin layered productsLaminationPolymer sciencePlasticizer

A polyvinyl chloride (PVC) laminated soft sheet is prepared by the following raw materials by weight ratio: 90-110 of PVC resins, 15-20 of calcium carbonate, 30-40 of plasticizers, 3-4 of tribasic copper sulfate and 10-12 of paraffins. The laminated soft sheet is prepared by low toxic materials, has similar properties with the extrusion soft sheets, is widely used as a waterproof and anticorrosive material and can be also used as a flooring material. The laminated soft sheet has the following advantages: the sheet quality is superior to that of the extrusion soft sheets, and the laminated soft sheet can also use the recycled materials or reclaimed materials as the inner layer to lower the cost. The length specification of the laminated products is often limited by the size of the press.

Owner:张文财

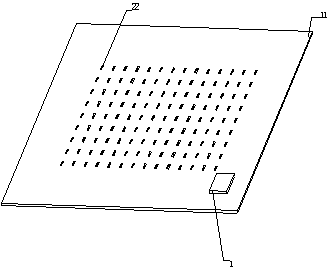

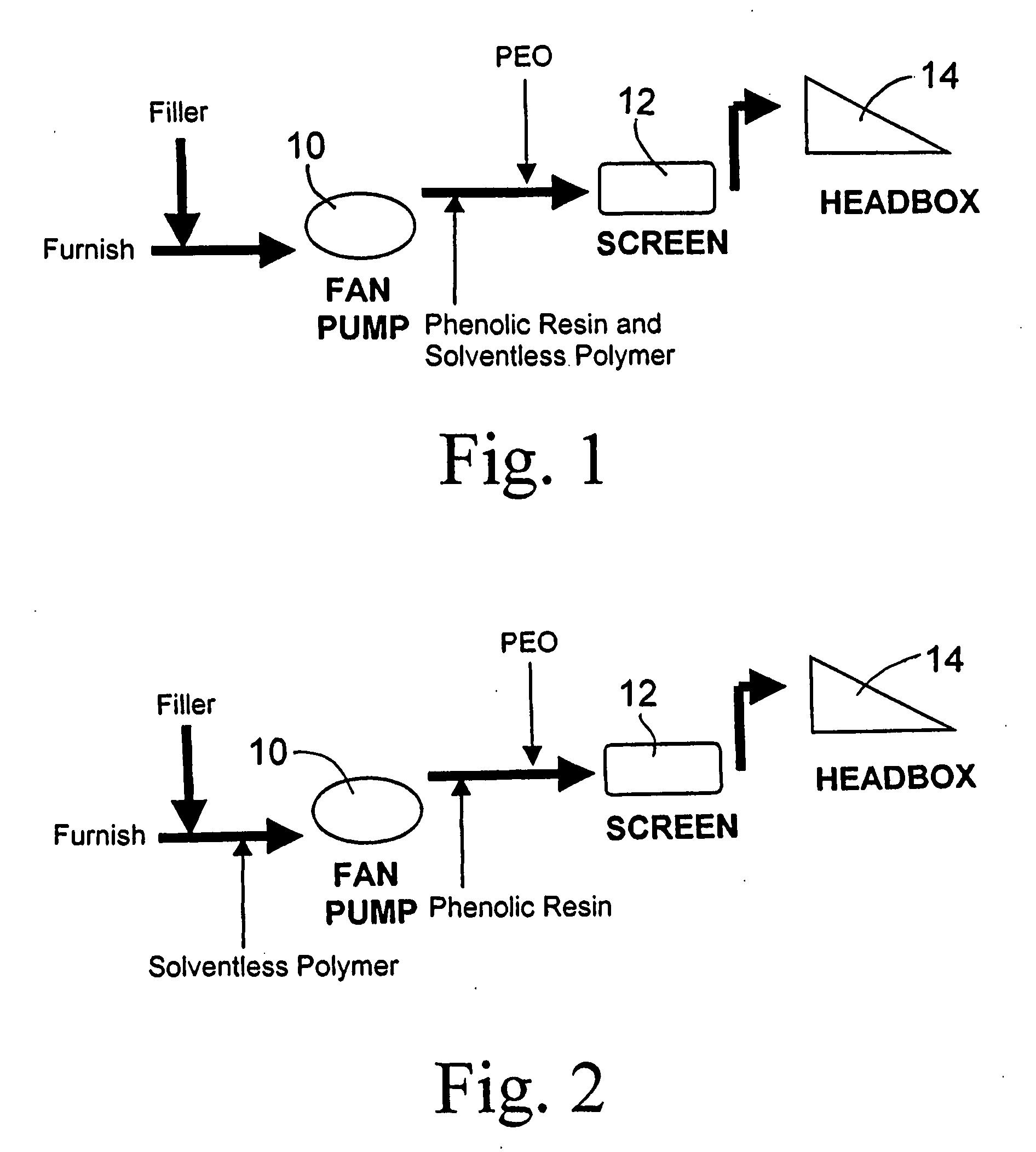

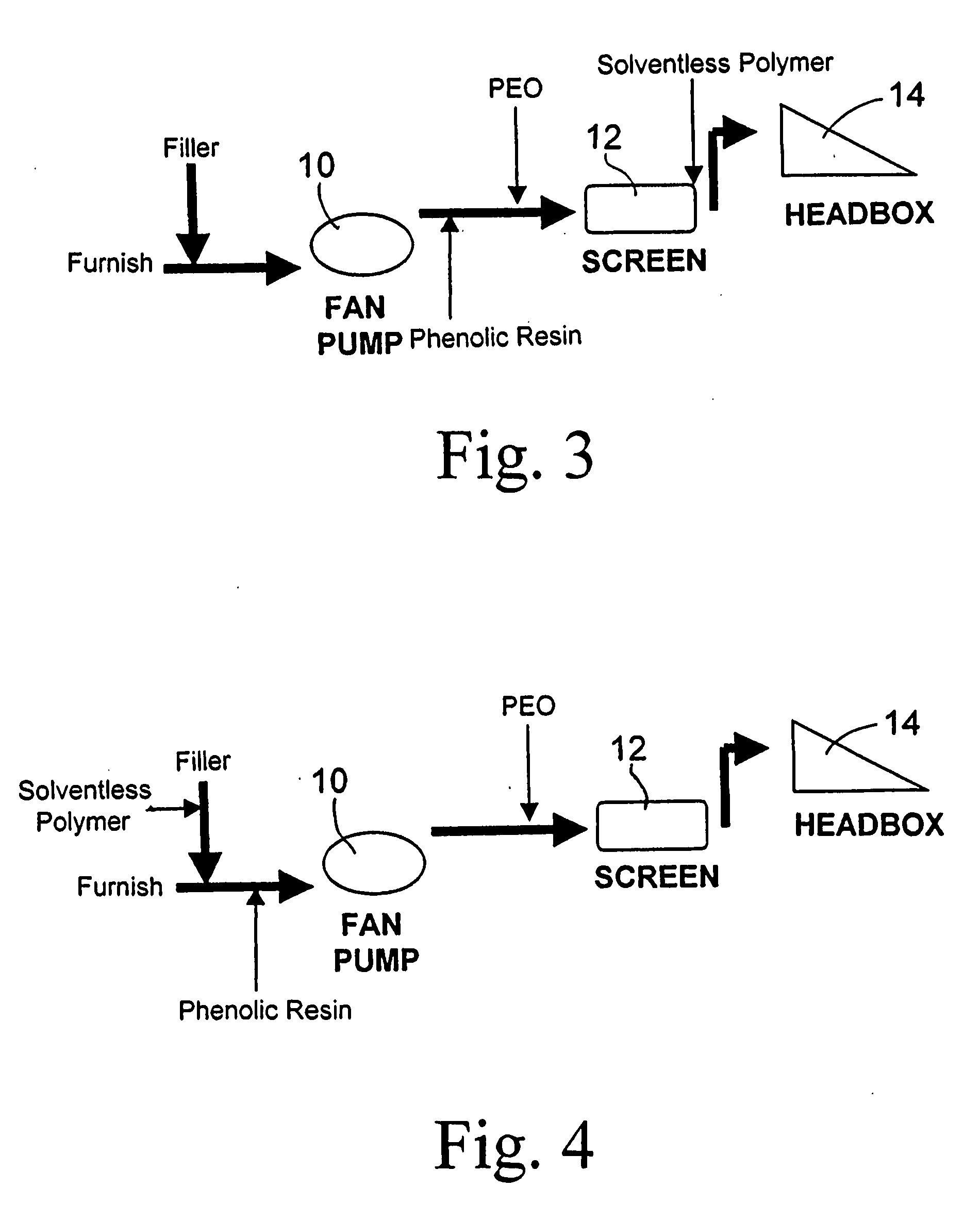

Papermaking furnish comprising solventless cationic polymer retention aid combined with phenolic resin and polyethylene oxide

InactiveUS20060000568A1Increased retention rate and drainageIncreasing retention rate and drainageNatural cellulose pulp/paperSpecial paperPolyethylene oxidePapermaking

A papermaking furnish is provided with a phenolic resin / polyethylene oxide retention system in combination with a solventless cationic polymer retention aid which increases retention rate and drainage in the paper sheet. The retention aid may be added to the furnish together with the phenolic resin or separately from it at a different point of addition. It can also be used for pretreating a filler which is added to the furnish.

Owner:POLVERARI MARCO +2

Three-layer structure wooden composite board material and mfg method

InactiveCN1502464AGood board qualityThe product has high environmental protection performanceWood layered productsStructural unitAdhesive

The present invention relates to a three-layer structure wooden composite plate material and its production method, belonging to the field of building decorative technology. Said composite plate material is formed from surface layer and core layer, in which the core layer material formed from flat structure unit adopts wood material, bamboo material and straw, and said flat structure unit size is: length 45-110 mm, width 10-50 mm and thickness is 0.1-1 mm, and the thickness of core layer is 21-91% of that of plate material. Said surface layer material is made up by selecting fibre or particle structure unit, and adopting the procedures of preparing material, laying-forming, pre-pressing and hot-pressing. The adhesive used by core layer is isocyanate adhesive. Said invention also provides the steps of laying, forming process.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Three-dimensional mask plate for printing

InactiveCN103203984AHigh precisionImprove uniformityScreen printersSolid-state devicesGraphicsMechanical engineering

The invention discloses a three-dimensional mask plate for printing. The three-dimensional mask plate comprises a substrate, and a printing surface and a printed circuit board (PCB) surface, which are arranged on two sides of the substrate, wherein the mask plate is provided with a plurality of graphic openings and a three-dimensional structure, the three-dimensional structure comprises a projection area which is arranged on the printing surface and a concave area which is arranged on the PCB surface. The mask plate is provided with the three-dimensional projection part and the three-dimensional concave part, the height of the projection is 0.1mm to 10mm, the concave depth is 0.1mm to 10mm, and angles formed between the projection part and the plate surface and between the concave part and the plate surface are 80 to 90 DEG; the mask plate is made of pure nickel, and the precision is high; the uniformity is high, the quality is good, and high brightness, no rough spot, no scratch and no pin hole can be realized; and the opening quality is good, and the wall is smooth and free from burrs; and the mask plate is low in production cost, simple in process and low in energy consumption.

Owner:KUN SHAN POWER STENCIL

A metal mask plate for vapor deposition produced from a nickel-iron alloy

InactiveCN103205702ALow costLow coefficient of linear thermal expansionVacuum evaporation coatingSputtering coatingInvar alloyNickel alloy

The invention discloses a metal mask plate for vapor deposition produced from a nickel-iron alloy. The metal mask plate is produced by using an electroforming process, and from a nickel-iron alloy material; and the nickel alloy material comprises two elements of nickel and iron, wherein the iron content is 40% to 55% and the nickel content is 45% to 60%. The metal mask plate for vapor deposition of the invention has physical properties similar to an Invar alloy plate, high plate surface brightness, high uniformity, good plate surface quality, and a lower cost compared with a mask plate produced from an invar alloy, thus saving the cost. At the same time, the linear thermal expansion coefficient of the metal mask plate for vapor deposition provided by the present invention is small, thus satisfying the vapor deposition requirements; and additionally, the mask plate provided by the present invention has the properties of high hardness and high magnetism.

Owner:KUN SHAN POWER STENCIL

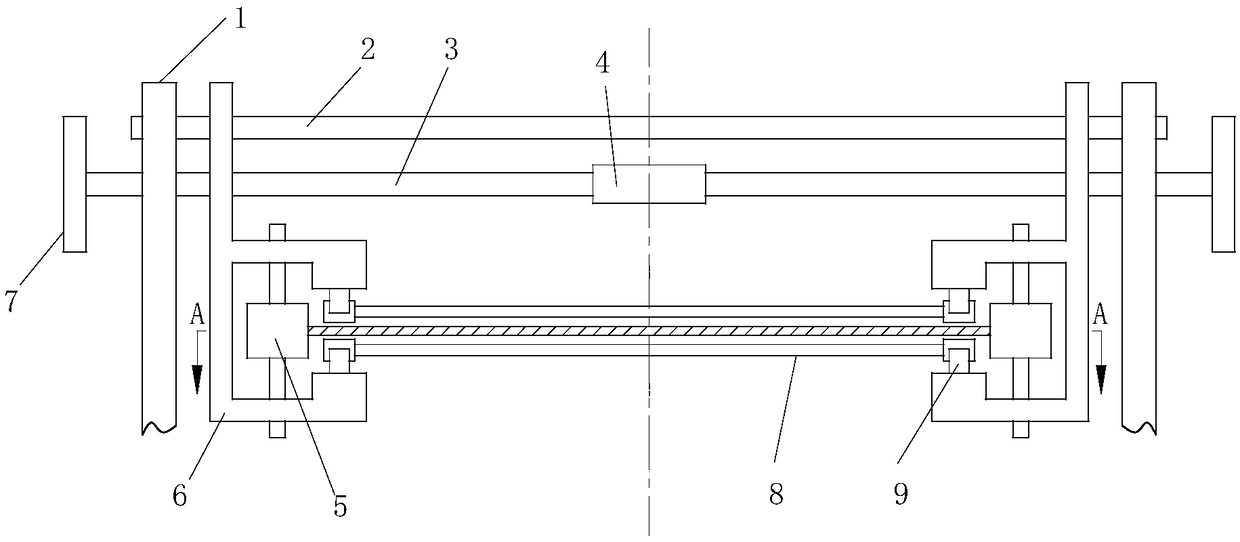

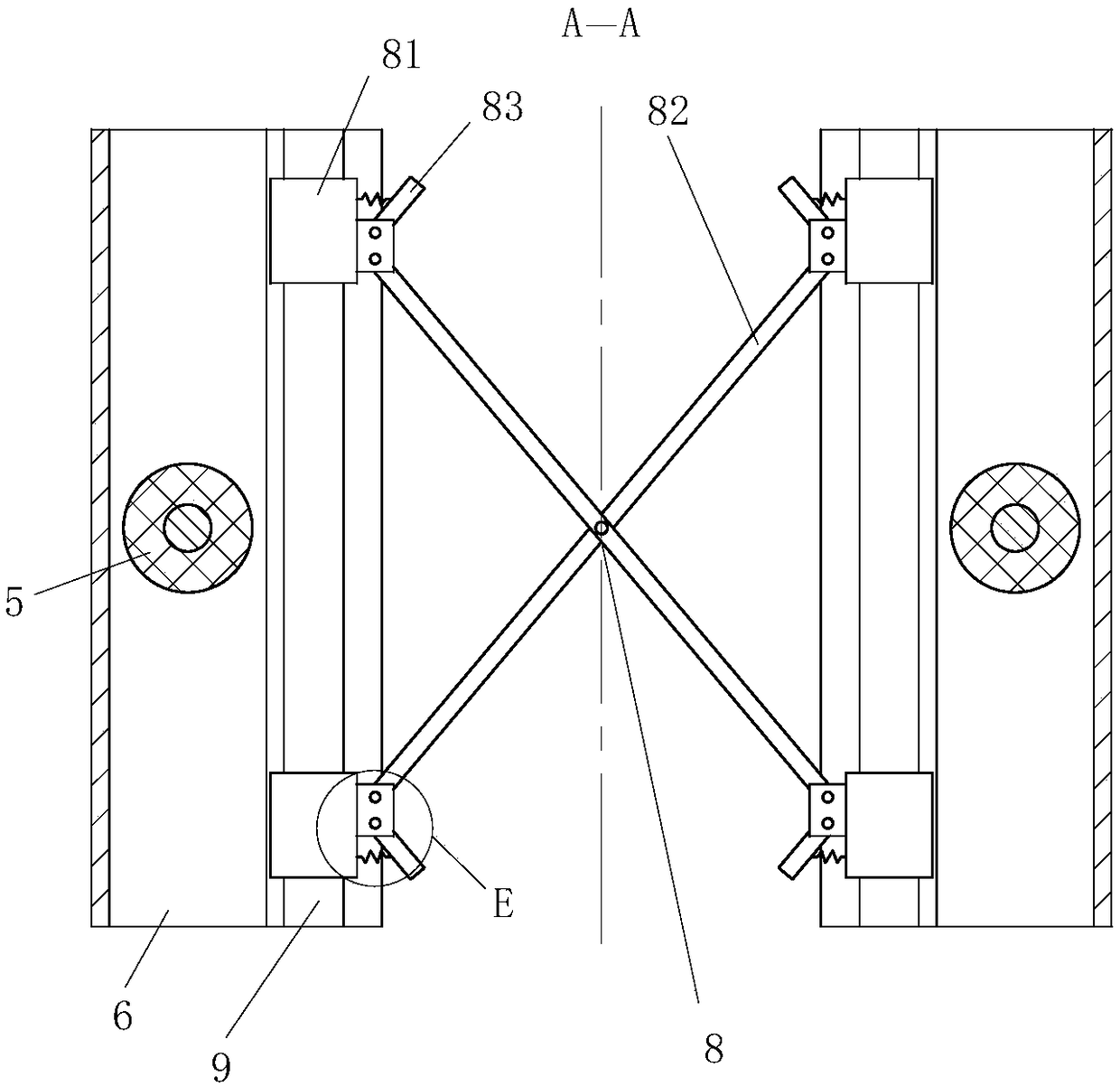

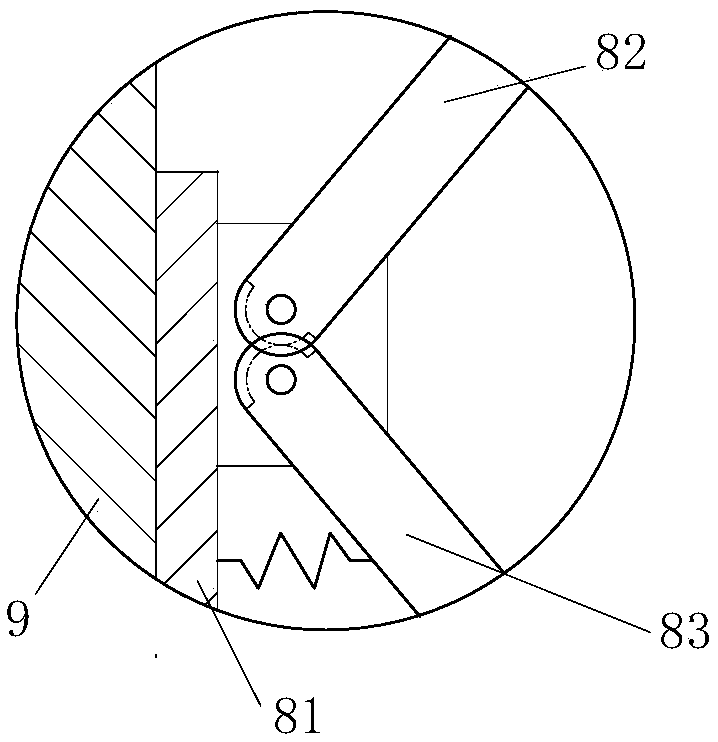

Cold-rolling sheet soft-state slitting guiding device

ActiveCN108856840AAvoid bulgingImprove board qualityShearing machinesShearing machine accessoriesEngineeringScrew thread

The invention belongs to the technical field of cold-rolling sheet processing, and particularly relates to a cold-rolling sheet soft-state slitting guiding device. The device comprises supporting seats, a guiding polish rod, transmission lead screws, a lead screw connecting tube, guiding upright rollers, upright roller supporting frames, hand wheels and pressing modules, each of the two ends of the guiding polish rod is provided with a supporting seat, the guiding polish rod is fixedly connected with the supporting seats, the hand wheels are arranged on the outer sides of the supporting seats,each of the two ends of the lead screw connecting tube is provided with an upright roller supporting frame, the upper ends of the sides of the upright roller supporting frames are slidably installedon the guiding polish rod, the upright roller supporting frames are in threaded connection with the transmission lead screw, the guiding upright rollers are perpendicularly installed in the upright roller supporting frames, the pressing modules are arranged at both upper and lower ends of the guiding upright rollers, and the pressing modules are slidably installed on the upright roller supportingframes. According to the device, by using the pressing modules, it is ensured that cold-rolling sheets do not off track before entering a slitting knife shaft, and the protruding of the cold-rolling sheets is prevented.

Owner:TANGSHAN SHOUTANG BAOSHENG FUNCTIONAL MATERIALS CO LTD

Three-dimensional mask plate for printing

InactiveCN103203976AHigh precisionImprove uniformityPhotomechanical apparatusPlate printingEngineeringPrinted circuit board

The invention discloses a mask plate for printing, which comprises a substrate, a printing surface and a PCB (Printed Circuit Board) surface, wherein the printing surface and the PCB surface are positioned on both sides of the substrate. The mask plate is provided with a plurality of pattern openings and a three-dimensional structure; and the three-dimensional structure comprises a convex region on the printing surface and a concave region on the PCB surface. The mask plate is provided with three-dimensional convex and concave parts, and a convex height is 0.1 to 10 mm while a concave depth is 0.1 to 10 mm; the outer included angles between the convex and the concave parts and the plate surface are 80 degrees to 90 degrees; the mask plate comprises the following components: 40 percent to 55 percent of iron and 45 percent to 60 percent of nickel; and the mask plate has high accuracy, high uniformity and high plate surface quality, is bright and has no coarse points, scratches or pinholes; the openings have high quality, smooth opening walls, and no burrs; and the mask plate is low in production cost and has simple process and low energy consumption.

Owner:KUN SHAN POWER STENCIL

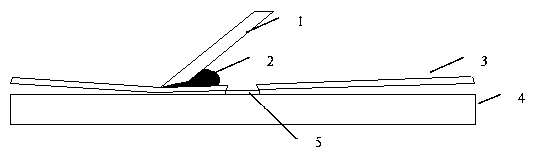

Three-dimensional mask plate with graphic openings and for printing

The invention discloses a three-dimensional mask plate with graphic openings and for printing. The three-dimensional mask plate with the graphic openings and for printing comprises a substrate, a printing face and a PCB (Printed circuit board) face, wherein the printing face and the PCB face are located on two sides of the substrate; the mask plate is provided with multiple graphic openings and a three-dimensional structure; the three-dimensional structure comprises a raised area on the printing face and a hollow area on the PCB face; the graphic openings meeting printing requirements are formed in the three-dimensional structure; the mask plate is provided with a three-dimensional raised and hollow part of which the raised height is 0.1-10mm and the hollow depth is 0.1-10mm; an external included angle between the raised and hollow part and the plate face is 80-90 degrees; and the components of the mask plate are 40% to 55% of iron and 45% to 60% of nickel. The precision of the mask plate is very high; the evenness is high and the plate face is good in quality, shining and free of coarse points, scratches and pin holes; the openings are good in quality and the hole walls are smooth and bur-free; and the mask plate is low in production cost, simple in technology and low in energy consumption.

Owner:KUN SHAN POWER STENCIL

Three-dimensional mask plate with graphic openings and for printing

The invention discloses a three-dimensional mask plate with graphic openings and for printing. The three-dimensional mask plate with the graphic openings and for printing comprises a substrate, a printing face and a PCB (Printed circuit board) face, wherein the printing face and the PCB face are located on two sides of the substrate; the mask plate is provided with multiple graphic openings and a three-dimensional structure; the three-dimensional structure comprises a raised area on the printing face and a hollow area on the PCB face; the graphic openings meeting printing requirements are formed in the three-dimensional structure; the mask plate is provided with a three-dimensional raised and hollow part of which the raised height is 0.1-10mm and the hollow depth is 0.1-10mm; an external included angle between the raised and hollow part and the plate face is 80-90 degrees; and the components of the mask plate are 56% to 62% of iron and 38% to 44% of nickel. The precision of the mask plate is very high; the evenness is high and the plate face is good in quality, shining and free of coarse points, scratches and pin holes; the openings are good in quality and the hole walls are smooth and bur-free; and the mask plate is low in production cost, simple in technology and low in energy consumption.

Owner:KUN SHAN POWER STENCIL

Inkjet recording sheet

InactiveUS20040175507A1Good ink absorptionImprove productivityDuplicating/marking methodsPretreated surfacesPolyvinyl alcoholUnsaturated hydrocarbon

Disclosed is an inkjet recording sheet having a colorant-receiving layer on the surface of its support, in which the colorant-receiving layer contains at least one of compounds represented by the following general formula (1) and compounds represented by the following general formula (2), and contains a vapor-phase-process silica, a polyvinyl alcohol, a boron compound, and a mordant. In the formulae, R represents a saturated hydrocarbon group having from 1 to 12 carbon atoms, an unsaturated hydrocarbon group having from 1 to 12 carbon atoms, a phenyl group, or an acyl group, and n indicates an integer of 1 to 3. RO(CH2CH2O)nH (1) RO(CH2CH(CH3)O)nH (2)

Owner:FUJIFILM CORP

PVC composite material, foam board, production method and apparatus thereof, and flooring

ActiveUS9527975B2Quality improvementImprove propertiesSynthetic resin layered productsConstructions elementsFoaming agentPolyvinyl chloride

The present invention provides a polyvinyl chloride polymer (PVC) composite material including 40-60 parts by weight of PVC, 40-60 parts by weight of light calcium carbonate, 0.8-1.2 parts by weight of composite foaming agent including an inorganic foaming agent and an organic foaming agent, 3-5 parts by weight of foam regulator, 2-4 parts by weight of toughener, 0.8-1.2 parts by weight of lubricant, and 1.5-2.5 parts by weight of stabilizer. The ratio of the inorganic foaming agent to the organic foaming agent by weight in the composite foaming agent is ½-1. Meanwhile, the present invention provides a foam board made of the PVC composite material, an associated production method, an apparatus, and flooring. The resulting PVC products have a high-strength structure and a good foaming property, thus having a satisfied mute effect.

Owner:FLOORING IND LTD

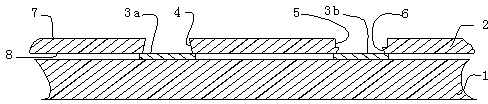

A hybrid production process and a step stencil produced by using the process

InactiveCN103203959AGood opening qualitySmooth holePhotomechanical apparatusPlate printingL&D processEngineering

A hybrid production process and a step stencil produced by using the process. The hybrid production process is as follows: electroforming a first electroformed layer; electroforming the up step area on a PCB surface; and etching a down step area on a printing surface. The hybrid production process is characterized by comprising two techniques of electroforming and etching. The stencil produced by the process has external characteristics of: the PCB surface having up steps, and the printing surface having down steps and having an opening pattern. According to the metal stencil, the produced electroformed layer of the up step area has a relatively high bonding strength with the plane electroformed layer; the produced entire electroformed stencil has smooth opening walls, good surface quality and has no pinholes or pittings; the thickness uniformity of the opening pattern area of the produced entire electroformed stencil is good; and a special spreader plate used in the second electroforming process can effectively reduce the current density, thereby reducing the edge effect of the up step area.

Owner:KUN SHAN POWER STENCIL

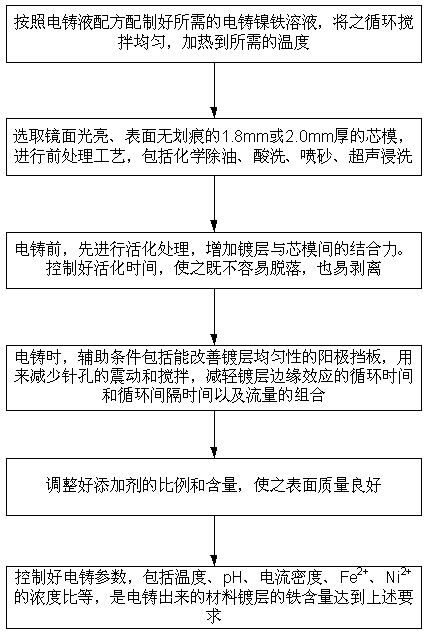

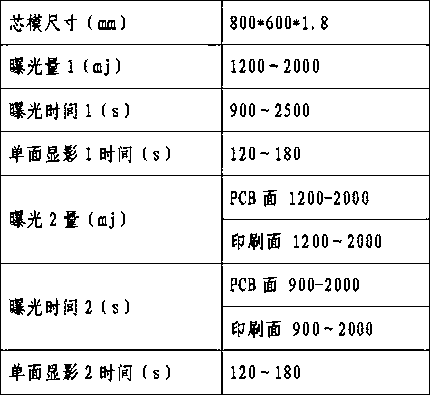

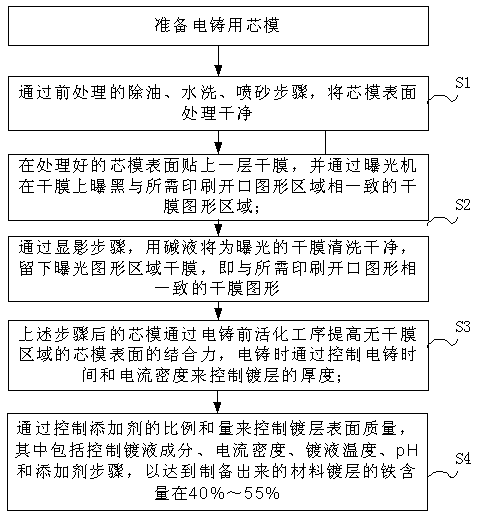

A production process for an electroformed stencil

InactiveCN103203964AHigh positioning accuracyImprove bindingPhotomechanical apparatusPlate printingEngineeringPre treatment

A production process for an electroformed stencil. The process flow is as follows: electroforming a first electroformed layer: core mold treatment -> pre-treatment (degreasing, pickling and sandblasting 1) -> film mounting 1 -> exposure 1 -> single sided developing 1 -> electroforming 1-> film stripping -> mold stripping; and electroforming up steps on a printing surface: printing surface pre-treatment (pickling and sandblasting 2) -> film mounting 2 -> exposure 2 -> single sided developing sided 2 -> electroforming 2 -> film stripping. By using the process, the electroformed stencil having an up step area on the printing surface, wherein the up step area has an opening pattern, can be produced. The stencil has the following advantages: deposition thickness uniformity COV of the stencil is 10% or less; the stencil surface has good quality, grade-one surface brightness, no pinholes or pitting; the binding strength between the up step area and the first electroformed layer is large, without the proneness of falling off; and the position precision of the pattern opening area of the up steps with the opening area of the first electroformed layer is high.

Owner:KUN SHAN POWER STENCIL

A hybrid production process for a step stencil

InactiveCN103203953ANo glitchGood opening qualityPhotomechanical apparatusPlate printingLaser cuttingPre treatment

A hybrid production process for a step stencil. The production process flow is as follows: electroforming a first electroformed layer: core mold treatment -> pre-treatment (degreasing, pickling and sandblasting) -> film mounting 1-> film exposure 1-> single sided developing 1-> electroforming 1-> film stripping -> mold stripping; etching a printing surface to form a down step area: printing surface film mounting-> exposure 2-> single sided developing 2 -> etching (forming the down step area on the printing surface); and laser cutting the opening pattern of the down step area: an electroformed stencil with a down step area->laser cutting the opening pattern of the down step area->subsequent processing. By using the production process of the invention, the stencil having the printing surface with the down step area can be produced; the openings of the pattern areas of the substrate and the down step area has good quality, smooth hole walls and no blurs; the stencil surface has good quality, first class brightness surface, and no pinholes or pittings; the position precision of the opening area of the down step area pattern and the opening area of the electroformed area is high; and the thickness uniformity of the electroformed stencil pattern area is good.

Owner:KUN SHAN POWER STENCIL

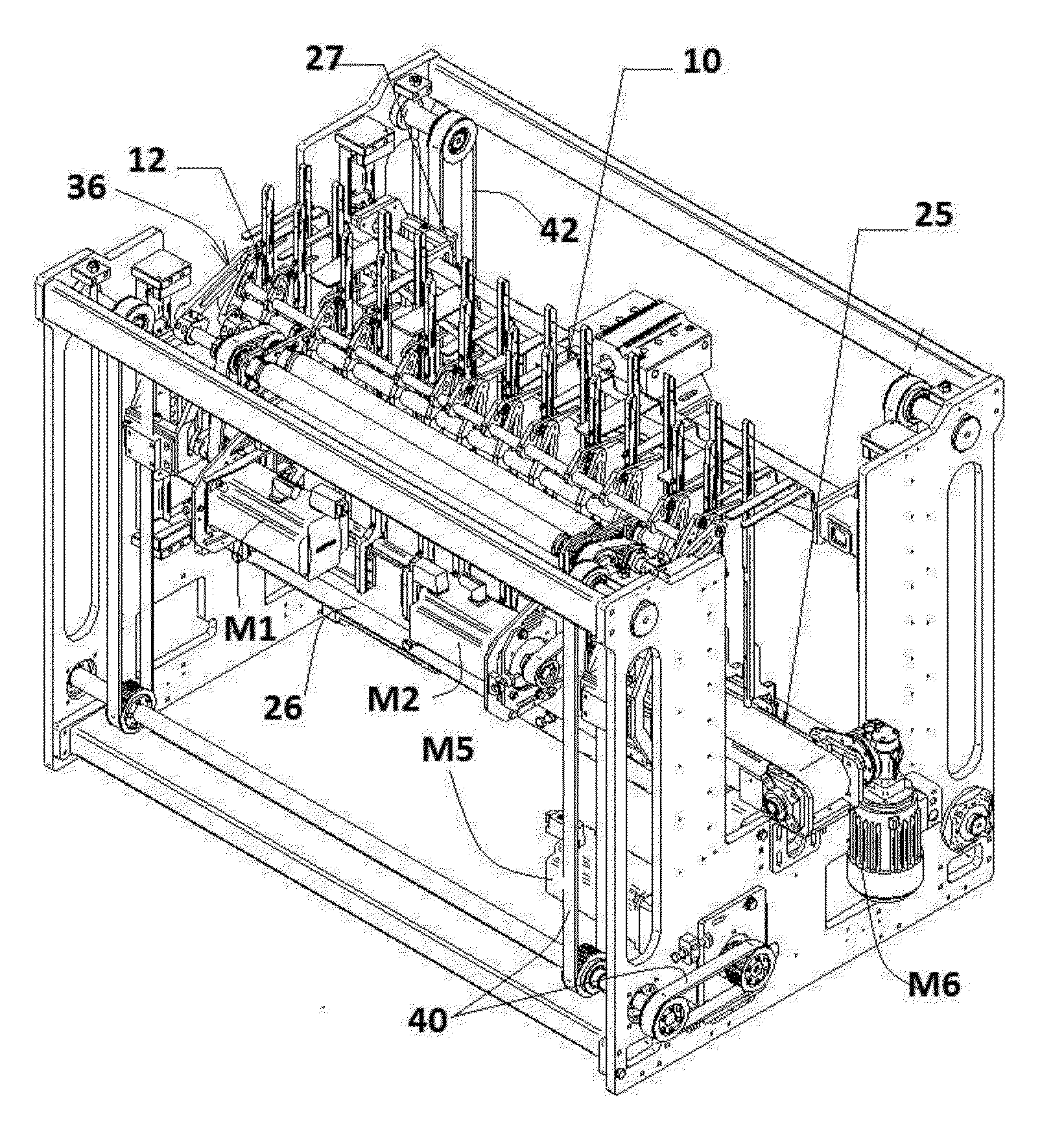

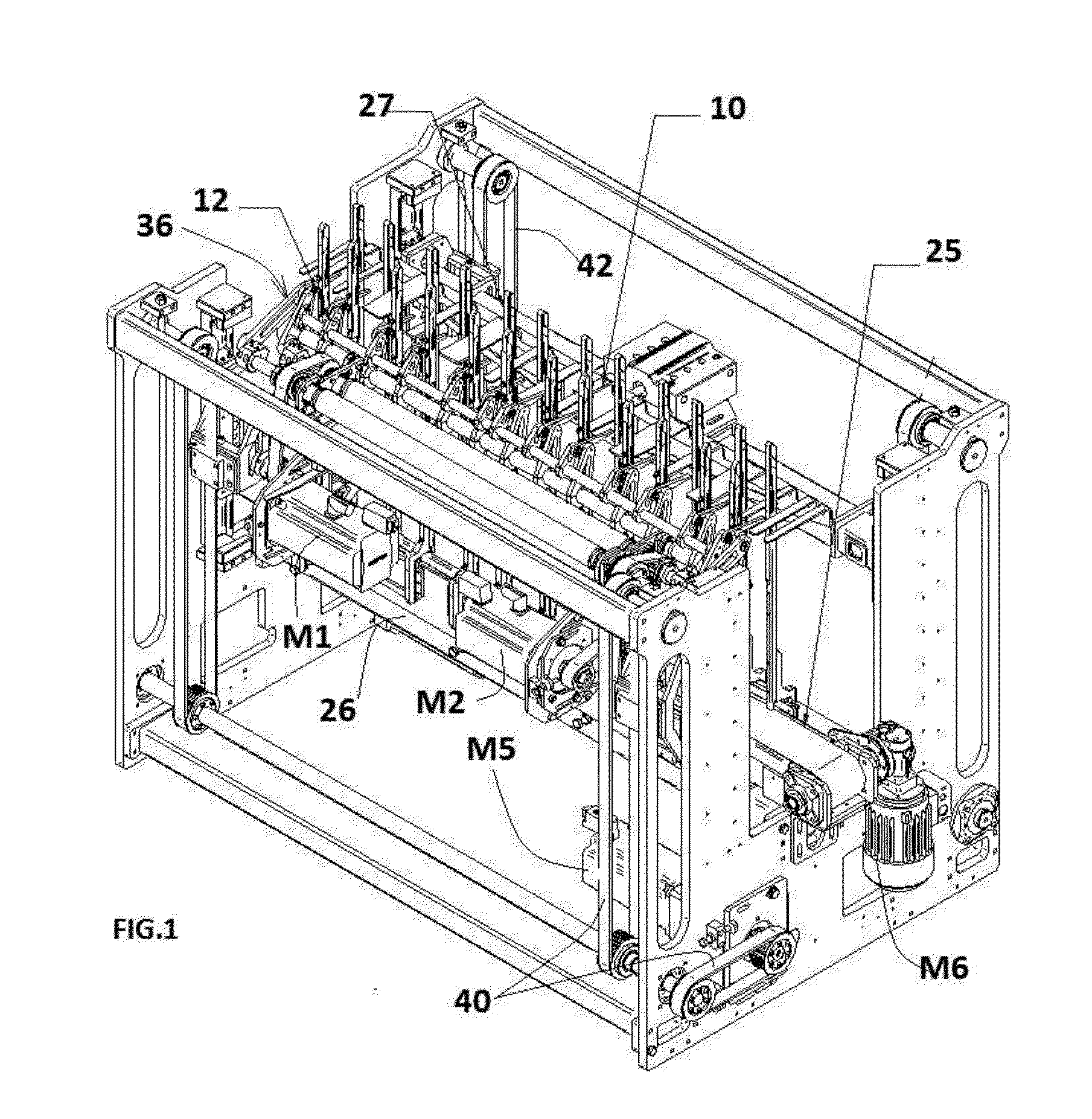

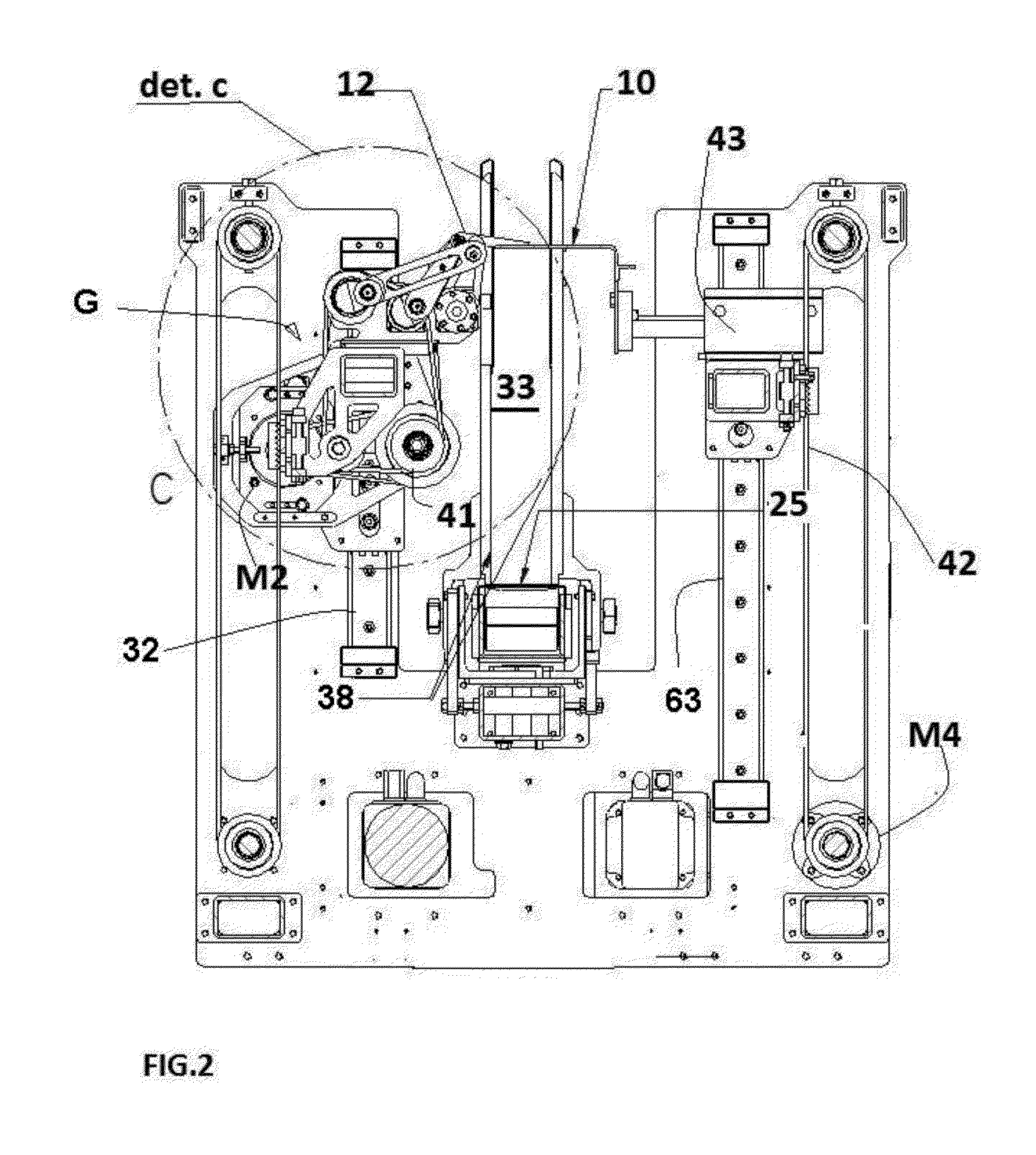

Machine for the formation of numbered packs of interleaved sheets of paper

ActiveUS20150336766A1Minimal timeProductivityMechanical working/deformationPaper/cardboard articlesCrankElectric machine

A machine for the formation of numbered packs of interleaved sheets of paper (6), includes a pair of counter-rotating motor-driven folding rollers (2,3), an interference surface (11) mobile with a to-and-fro motion between a position (P1) of non-interference and a position (P2) of interference, and a mechanism (36) of cyclic movement of the surface (11) including at least one supporting crank (13) oscillating with respect to the carriage (26) and articulated to a first axis (15) of rotation of the surface, and a first motor-driven connecting rod (19) kinematically connected to the surface (11) to bestow the to-and-fro motion thereon.

Owner:UNITED CONVERTING TISSUE SRL

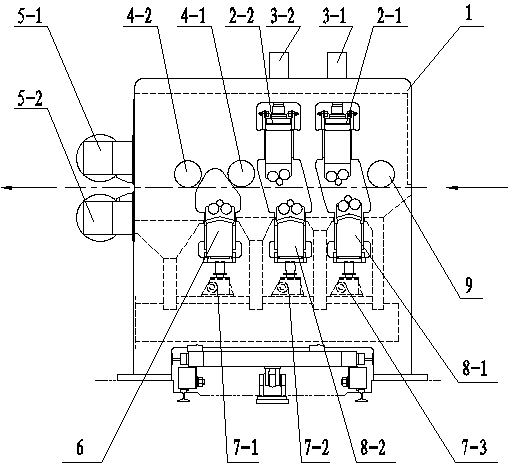

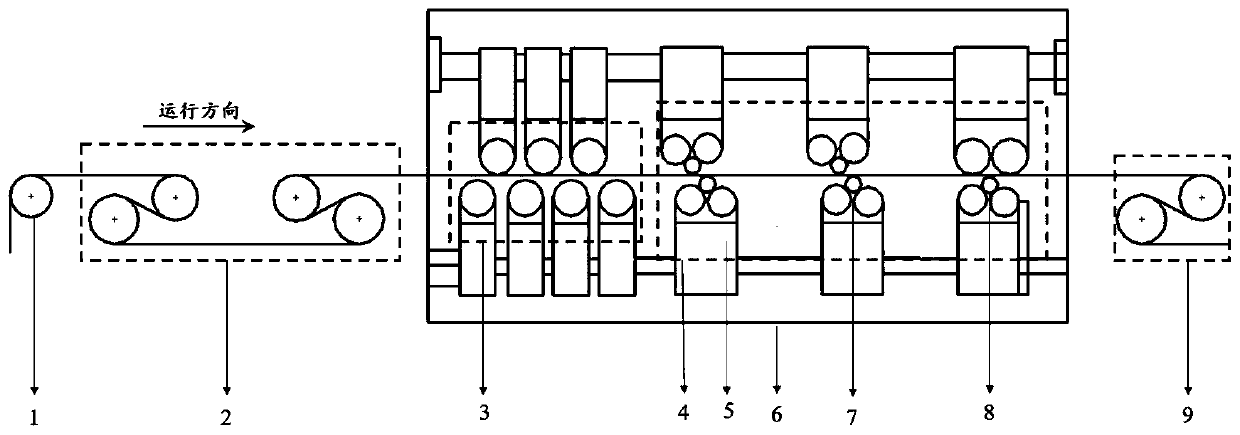

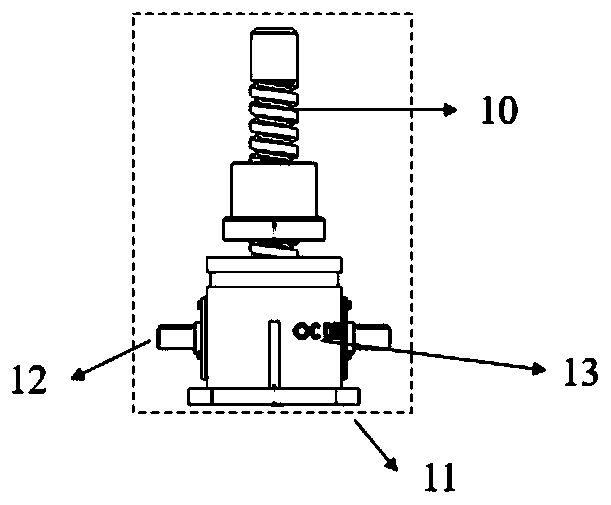

Pickling line scale breaking withdrawal and straightening machine

InactiveCN103272862AImprove board qualityElimination of wave defectsWork treatment devicesMetal rolling arrangementsPulp and paper industryCentrifugal fan

The invention discloses a pickling line scale breaking withdrawal and straightening machine. The pickling line scale breaking withdrawal and straightening machine comprises two bending roller sets, a material roller, a straightening roller set and two dedusting devices, wherein the two bending roller sets are arranged on a machine frame, the material roller is located on the inlet side of a plate strip, the straightening roller set is located on the outlet side of the plate strip, and the two dedusting devices are arranged at an outlet of the plate strip. Two upper bending roller systems of the two bending roller sets are suspended on a cross beam of the machine frame through an A lifting mechanism oil cylinder and a B lifting mechanism oil cylinder respectively, and two lower bending roller systems of the two bending roller sets are connected with an A worm gear lead screw lift and a B worm gear lead screw lift respectively. The straightening roller set comprises a lower straightening roller system and two upper straightening rollers. The lower straightening roller system is connected with a C worm gear lead screw lift. The two upper straightening rollers and the material roller are fixed on the machine frame through bearing bases on the two ends respectively. The machine frame is a sealed machine frame with the sealed periphery. The two dedusting devices are negative pressure interfaces, wherein one end of each negative pressure interface is communicated with an inner cavity of the machine frame, the other end of each negative pressure interface is connected with a centrifugal fan, and the negative pressure interfaces are installed at the upper end and the lower end of the outlet of the plate strip respectively. The pickling line scale breaking withdrawal and straightening machine is good in scale breaking and dedusting effect, high in production efficiency, and high in quality of the surface of processed strip.

Owner:XIANGYANG YUQING TRANSMISSION TECH

8K mirror board manganese nitrogen series nickel-saving austenitic stainless steel and preparation method thereof

ActiveCN113981308AIncrease production speedImprove board qualityProcess efficiency improvementManganeseSS - Stainless steel

The invention discloses 8K mirror board manganese nitrogen series nickel-saving austenitic stainless steel, and relates to the technical field of stainless steel. The austenitic stainless steel comprises, by mass, 0.15% or less of C, 0.45% or less of Si, 10% or less of Mn, 0.055% or less of P, 0.003% or less of S, 0.16% or less of N, 12%-18% of Cr, 1.00%-3.00% of Ni, 0.2%-2% of Cu and the balance Fe. Meanwhile, the invention further provides a preparation method of the 8K mirror board manganese nitrogen series nickel-saving austenitic stainless steel. By controlling the components and the preparation process of the austenitic stainless steel, the white-skin roll with the low Ra value (Ra is smaller than or equal to 2.8 microns) can be obtained, the surface of the white-skin roll is uniform, the defects such as second-class peeling and hot cracking do not exist, and the production speed and the surface quality of subsequent mirror board finish machining and grinding can be effectively improved.

Owner:广东省高端不锈钢研究院有限公司 +1

Combined type cold-rolled stretching-bending straightener

ActiveCN111185481AImprove scale breaking effectImprove flatnessWork treatment devicesMetal rolling arrangementsStructural engineeringStrip steel

The invention provides a combined type cold-rolled stretching-bending straightener, and belongs to the technical field of withdrawal and straightening equipment. The combined type cold-rolled stretching-bending straightener comprises a turning roller, an inlet tensioning roller set, a multi-roller straightening system, a stretching and straightening roller system, roller boxes, a machine frame, abending roller set, a straightening roller set, an outlet tensioning roller set and an elevator. The turning roller, the inlet tensioning roller set, the multi-roller straightening system, the stretching and straightening roller system, the bending roller set, the straightening roller set and the outlet tensioning roller set are sequentially arranged in the conveying direction of strip steel, themulti-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are installed on the machine frame, and the multi-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are provided with the roller boxes and the lower parts of the multi-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are connected with the elevator through lifting synchronous connecting rods.The combined type cold-rolled stretching-bending straightener can improve the scale breading effect on the surface of the strip steel, improve the acid pickling efficiency, reduce the acid consumptionamount in an acid pickling technology, can effectively improve the wear degree, reduce the risk of excessive withdrawal and straightening of welding lines, reduce the enterprise cost, and improve thesafety of equipment operation.

Owner:UNIV OF SCI & TECH BEIJING

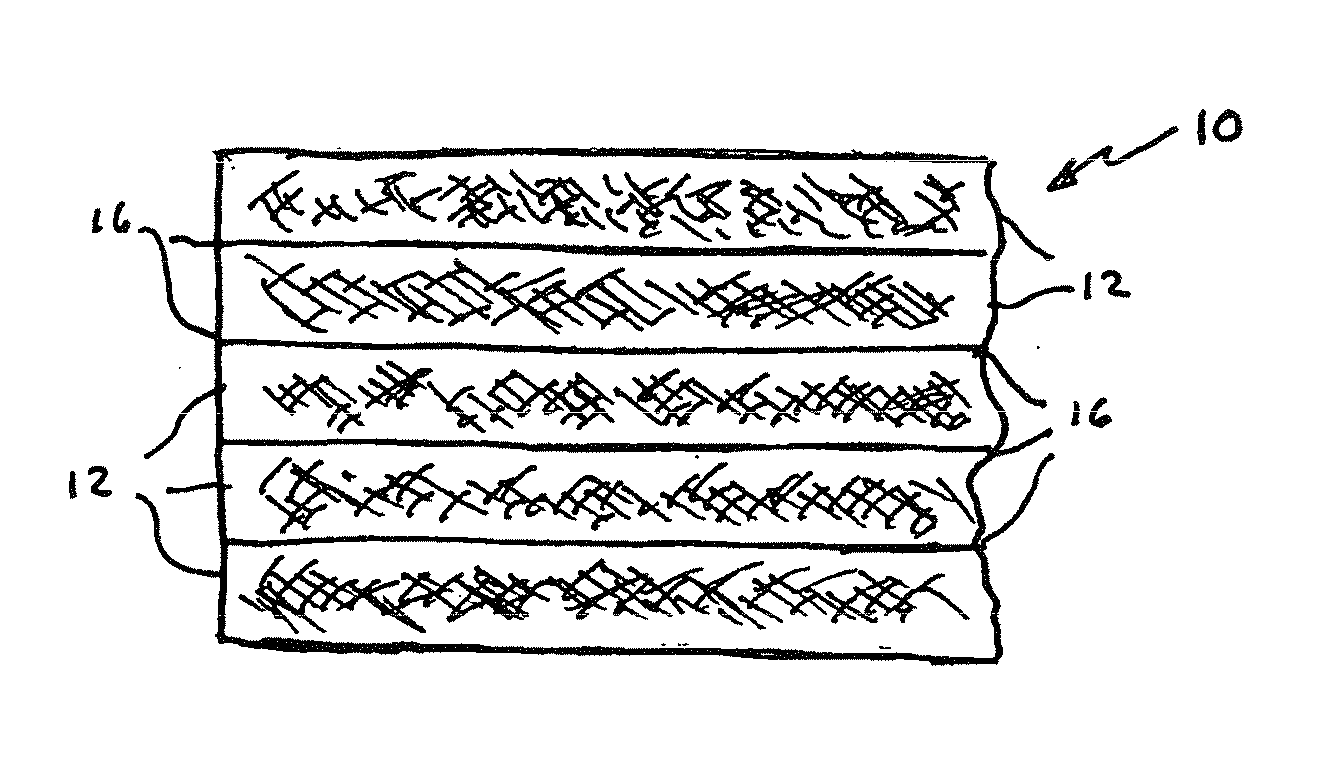

Electroforming nickel-ferrum alloy screen with high ferrum content for printing and preparation method

InactiveCN103374680AImprove uniformityReduce manufacturing costElectroforming processesSurface brightnessHardness

The invention discloses an electroforming nickel-ferrum alloy screen with high ferrum content for printing and a preparation method. An opening graphics area according with printing requirements is arranged on the surface of the screen. The nickel-iron alloy contains nickle Ni element and ferrum Fe element, and the mass percents of each element are: Ni:45-60% and Fe: 40-55%. A metal screen with high ferrum content for printing with high hardness, good screen surface brightness and good coating surface quality can be obtained. The nickel-ferrum alloy screen is low cost and saves energy compared to an electroforming nickel metal screen. The nickel-ferrum alloy screen has high opening precision. In addition, the nickel-ferrum alloy screen converts waste impurity ferrum into an alloy constituent, and reduces the solution maintenance cost and the burden of three-waste treatment.

Owner:KUN SHAN POWER STENCIL

Planar Elements for Use in Papermaking Machines

InactiveUS20130139988A1Improve ultraviolet ray blocking propertyImprove performanceMaterial nanotechnologyNon-fibrous pulp additionPolymer resinNanoparticle

A planar element for use in a papermaking machine comprising a synthetic construction incorporating nanoparticles in a polymeric resin matrix.

Owner:KADANT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com