Pickling line scale breaking withdrawal and straightening machine

A technology of scale drawing and leveling machine and pickling line, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of poor descaling effect and poor surface quality of strips, etc., and achieve good effect and high quality of plate surface. The effect of improving and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

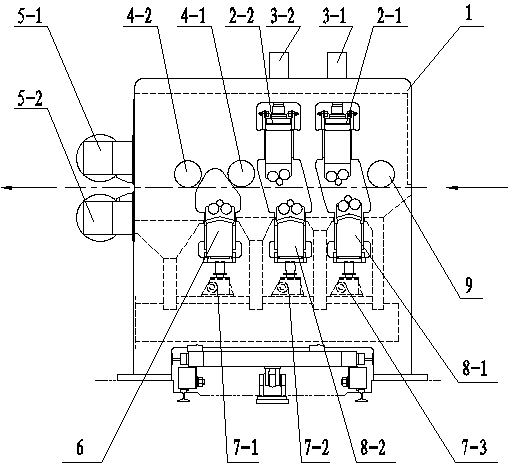

[0009] In the accompanying drawings, the present invention includes two sets of bending rolls arranged on an integral airtight frame, a feed roll 9 positioned at the inlet side of the strip, a set of straightening rolls positioned at the exit side, and a set of straightening rolls positioned at the exit of the strip. A dust removal device 5-1, B dust removal device 5-2.

[0010] The A upper bending roller system 2-1 and the B upper bending roller system 2-2 of the two bending roller groups are respectively suspended on the beam of the integral frame 1 through the oil cylinder 3-1 of the A lifting mechanism and the oil cylinder 3-2 of the B lifting mechanism , A upper bending roller system 2-1 and B upper bending roller system 2-2 can be quickly lifted and lowered by A lifting mechanism oil cylinder 3-1 and B lifting mechanism oil cylinder 3-2 respectively; A lower bending roller system of two sets of bending rollers 8-1, B lower bending roller system 8-2 is connected with A wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com