Patents

Literature

73results about How to "Smooth hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polyporous material for biological medicine tissue engineering scaffold

InactiveCN101455862ACause extrusion stressCause mechanical stressStentsSurgeryPorosityMetallic materials

The invention relates to the technical field of biomaterials, is particularly suitable for the field of preparation of biomedical tissue engineering support materials, in particular to a method for preparing porous materials used by a tissue engineering support. The method is to adopt mechanical processing technology to prepare the porous materials, to use the porous materials in the tissue engineering support, and to provide a three-dimensional space for adhesion, growth and so on of cells. The mechanical processing method comprises laser processing technology and digital control drilling processing technology. The porous materials prepared by the mechanical processing method have a permeable porous structure, wherein the porosity is between 5 and 99 percent, and the aperture is between 50 and 900 mu m. The method can prepare various metallic materials, wherein the laser drilling technology can also prepare porous polymer materials, ceramic materials, composite materials and so on and have wide application scope.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for machining slotted holes on carbon fiber laminated boards

The invention discloses a method for machining slotted holes on carbon fiber laminated boards, which belongs to a machining method for nonmetallic materials, solves the problem that by the existing milling and drilling methods, carbon fiber laminated boards are easy to laminate, split and burn, and aims at improving the machining precision of carbon fiber composite products and reducing the surface roughness of carbon fiber composite products. The method disclosed by the invention comprises a clamping step, a machining step and a post-processing step, wherein the machining step is one or two of a milling machining step and a drilling machining step. According to the invention, in the machining process, a non-deformed clamping mode is used, and through selecting reasonable cutting tool materials, geometric parameters of cutting tools, and milling and drilling machining parameters, the appearance allowances in machining are reasonably arranged, thereby solving the quality problems of laminating, splitting and burning and the like existing in the process of opening or drilling carbon fiber thin-wall revolution bodies and carbon fiber laminated boards by using the traditional methods, so that the qualified rate of carbon fiber parts is increased from 50% to more than 99%.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

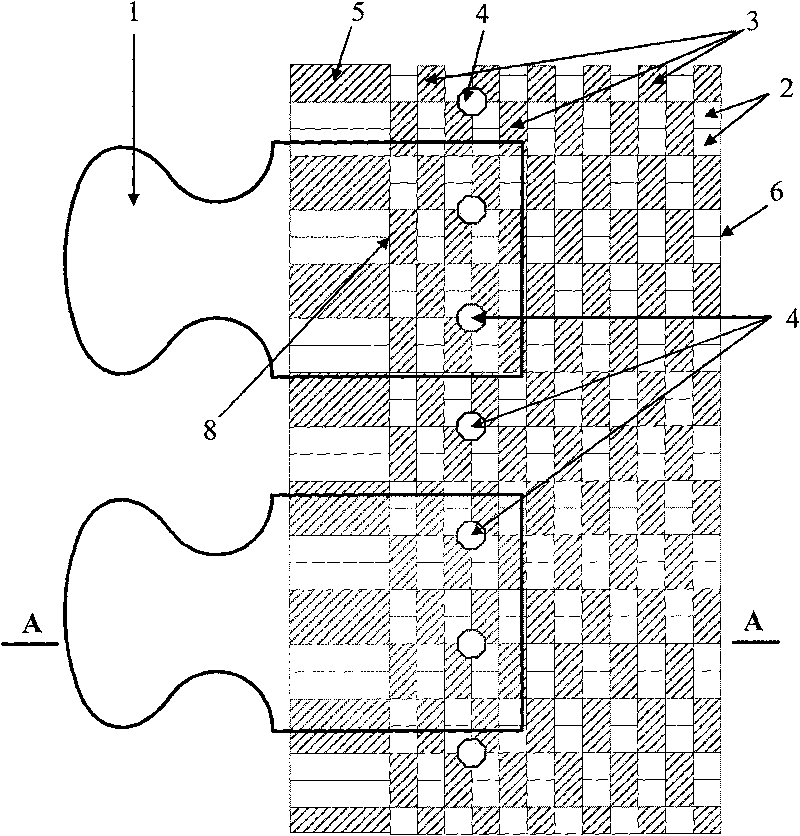

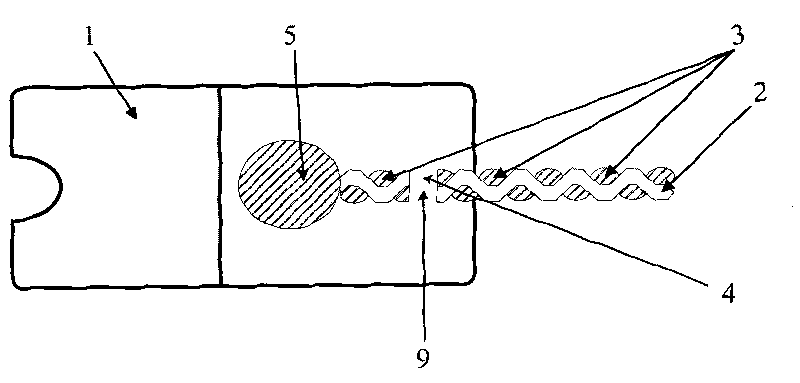

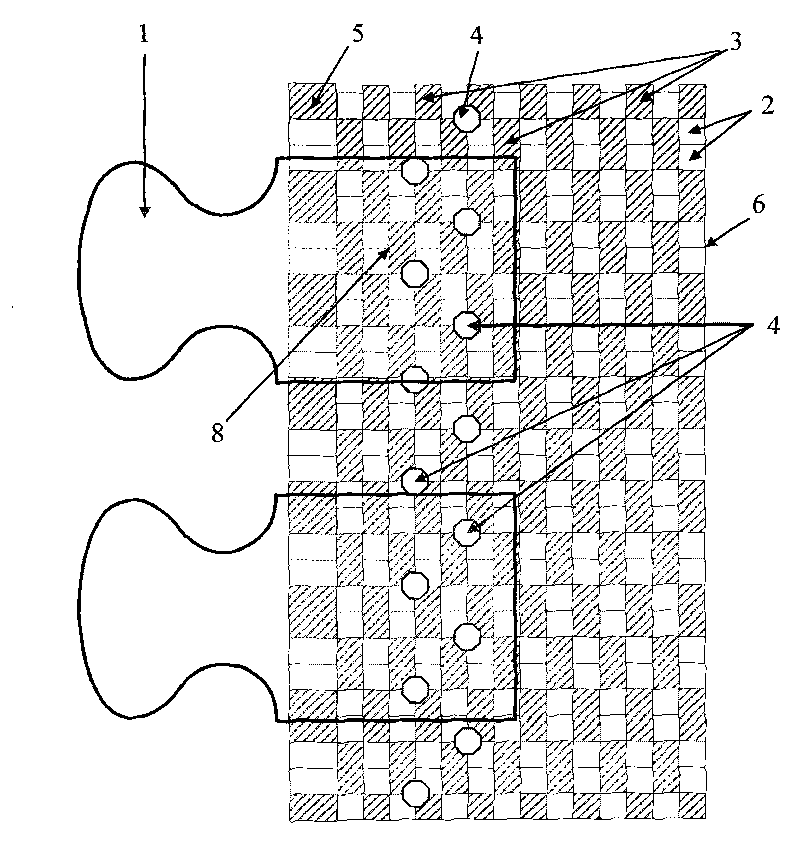

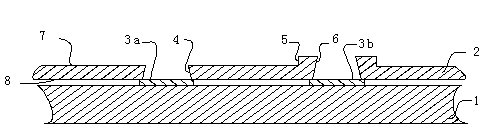

Injection molding zipper

InactiveCN101721019ALarge double-teaming forceImprove bindingSlide fastenersEngineeringInjection moulding

The invention aims to overcome the defect of insufficient binding force between the zipper teeth and the strap of the injection molding zipper in the prior art, and provides an injection molding zipper in a novel structure. In the injection molding zipper of the invention, the strap in the binding face region between the zipper teeth and the strap is provided with a small hole, at least one small hole or more than more small holes is / are arranged in the binding face region between the strap and each single zipper tooth, and the small holes are uniformly distributed in the arrangement direction of the zipper teeth. The small holes can ensure the injection molding material liquid, which is melted by the injection molding machine, to pass through in the production process of the injection molding zipper, so that the injection molding material liquid forms molding upright posts in the small holes after being cooled, and the molding upright posts and the zipper teeth can form an integral body. The injection molding zipper of the invention fundamentally changes the binding mode between the zipper teeth and the zipper strap of the injection molding zipper, which means to change the mode of the injection molding material wrapping the central line in the binding face region of the zipper strap, thereby obviously enhancing the binding force between the zipper teeth and the zipper strap of the injection molding zipper.

Owner:崔逸泉

Millisecond laser processing and postprocessing process for no-recasting-layer micro-deep holes

InactiveCN102126087ASmooth holeClear outlineLaser beam welding apparatusHigh power lasersCeramic coating

The invention provides a millisecond laser processing and postprocessing process for no-recasting-layer micro-deep holes, which comprises the following steps of: spraying a high temperature resistant ceramic coating on the surface of a turbine blade, and performing micro-deep hole deep processing by using a high-power millisecond laser according to optimized laser parameters obtained through an orthogonal experiment to obtain micro-deep holes with the minimum recasting layer depth; soaking the processed micro-deep holes in chemical acid solution for corrosion; and obtaining the no-recasting-layer micro-deep holes. The micro-deep holes are processed by using parameter-optimized laser, and the micro-deep holes with the thinnest recast layer are obtained; the micro-deep holes are corroded by specially prepared acid solution for a certain period of time, and the recast layer is thoroughly etched off; and the composite processing method has the characteristics of low cost, high efficiency and simple operation, problems of recast layers and microcracks when the micro-deep holes are processed on metals through high-power laser are solved, and high-quality micro-deep holes with smooth hole walls and clear outlines are obtained.

Owner:XI AN JIAOTONG UNIV

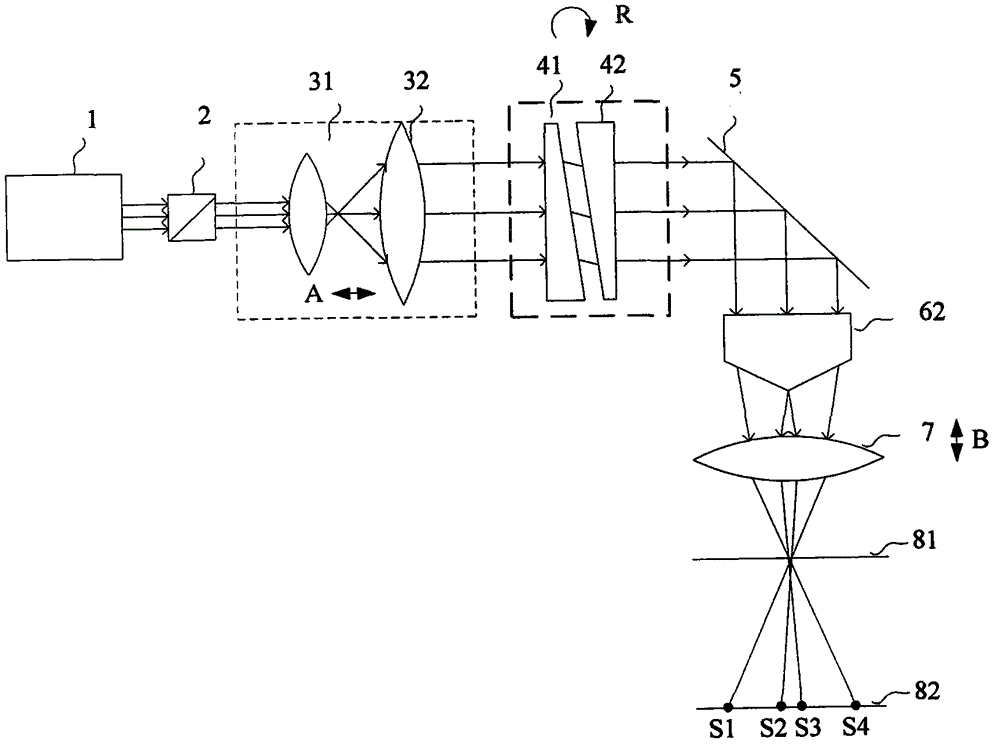

Beam forming device and method

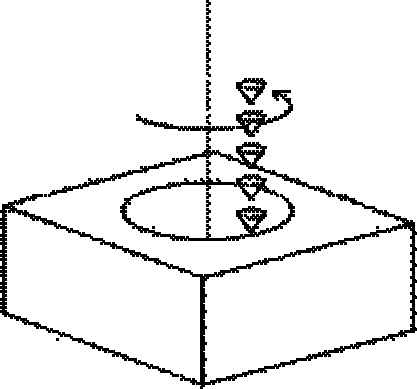

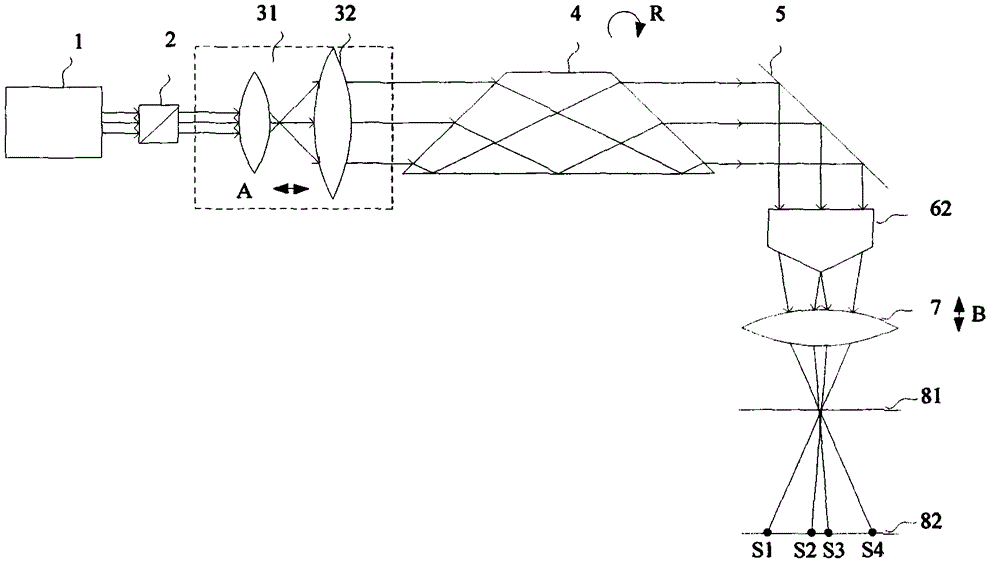

ActiveCN104148802AIncrease profitFine hole qualityLaser beam welding apparatusOptical axisPlane mirror

The invention provides a beam forming device and method. The beam forming device is formed by arranging a laser device, a pair of lenses, a Dove prism, a plane mirror, a regular axicon and a focusing lens in sequence in the direction of an optical axis. The distance between the lenses is adjustable so that the spot size and divergence angle of outgoing beams of the laser device can be adjusted. The Dove prism is installed in a hollow shaft rotary motor and rotates with the optical axis serving as the center, and the outgoing beams from the Dove prism also rotate with the Dove prism. The plane mirror is used for deflecting the transmission direction of the beams. The position of the focusing lens in the transmission direction of the beams is adjustable, and the outgoing beams are a bunch of rotary hollow annular beams after passing through the focusing lens.

Owner:北京中科镭特电子有限公司

Preparation of small pore diameter carbon foam

InactiveCN101434388AIncrease cell densitySmall average pore sizeChemical industryHeat conductingCarbonization

The invention discloses a method for preparing foam carbon by a supercritical technology, which pertains to the preparation technology of foam carbon and comprises the following processes: high softening point asphalt and a foaming agent are subjected to foaming through fast pressure relief under a supercritical condition, then the foamed asphalt is in put in an oxidizing furnace for being subjected to oxidation stabilization treatment, then carbonization and graphitization hot treatments are carried out under the protection of inert gases, thus obtaining the foam carbon product. The invention has the advantages that: by adopting the supercritical fluid technology, the aperture of the prepared foam carbon is greatly reduced compared with other methods and generally ranges from 10 to 200 mu m with narrow aperture distribution; the hole wall is smooth and the microcracks are less; and the foam carbon of the pore structure not only can be used as the materials of heat conducting, heat insulation, electromagnetic shielding and electrodes, but also can be applied to the fields of biological sewage treatment, catalysis, energy saving buildings and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

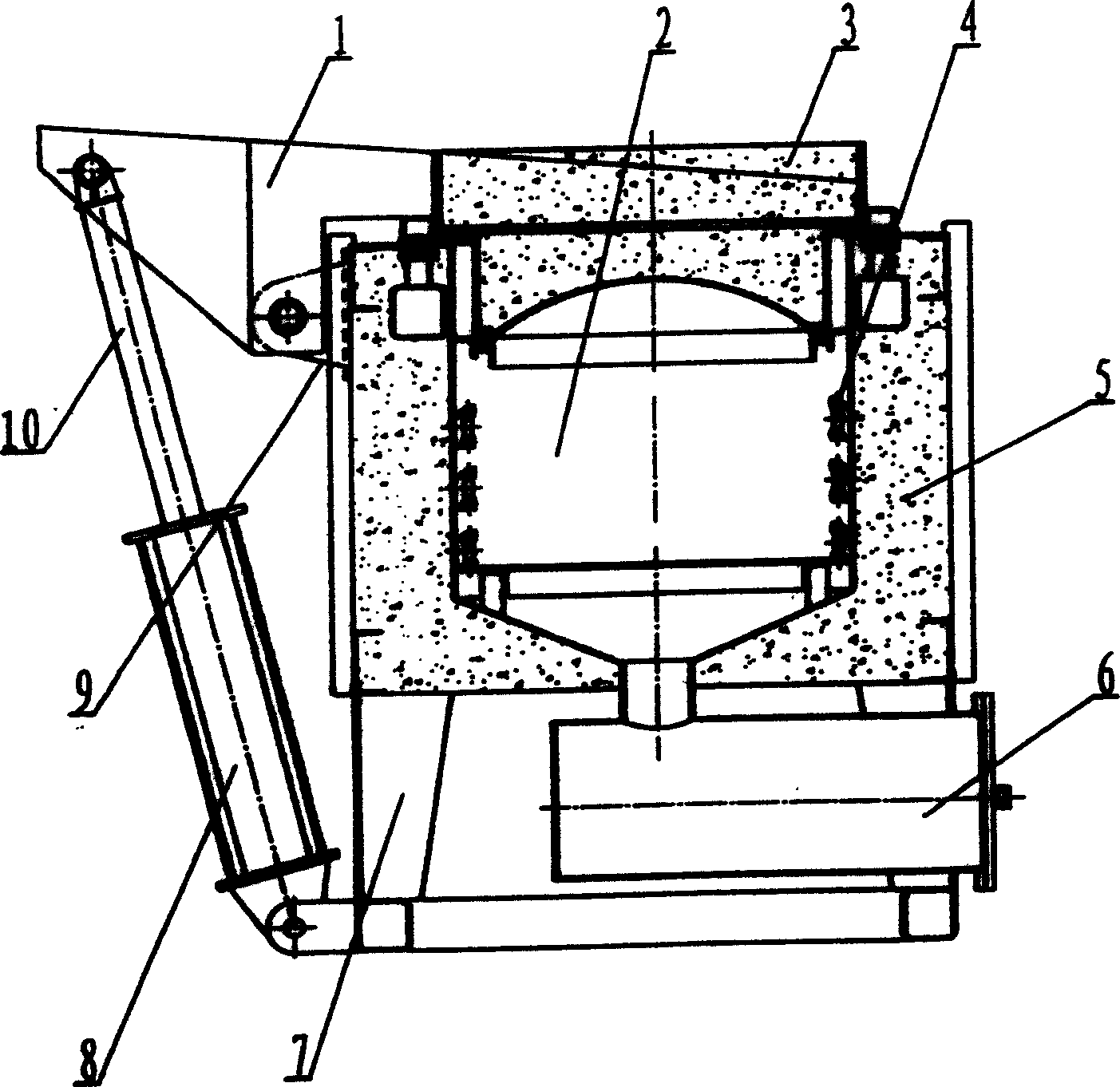

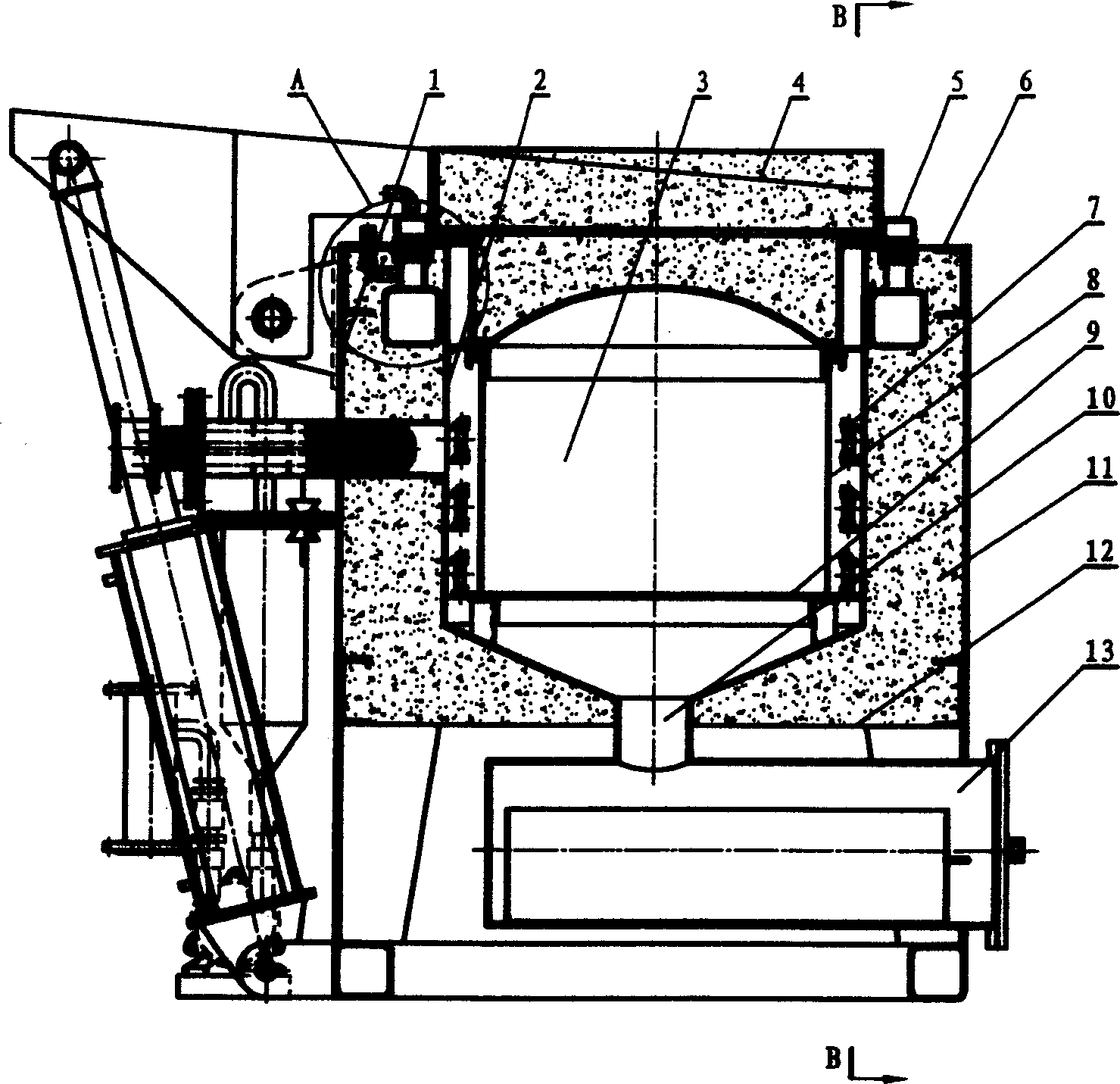

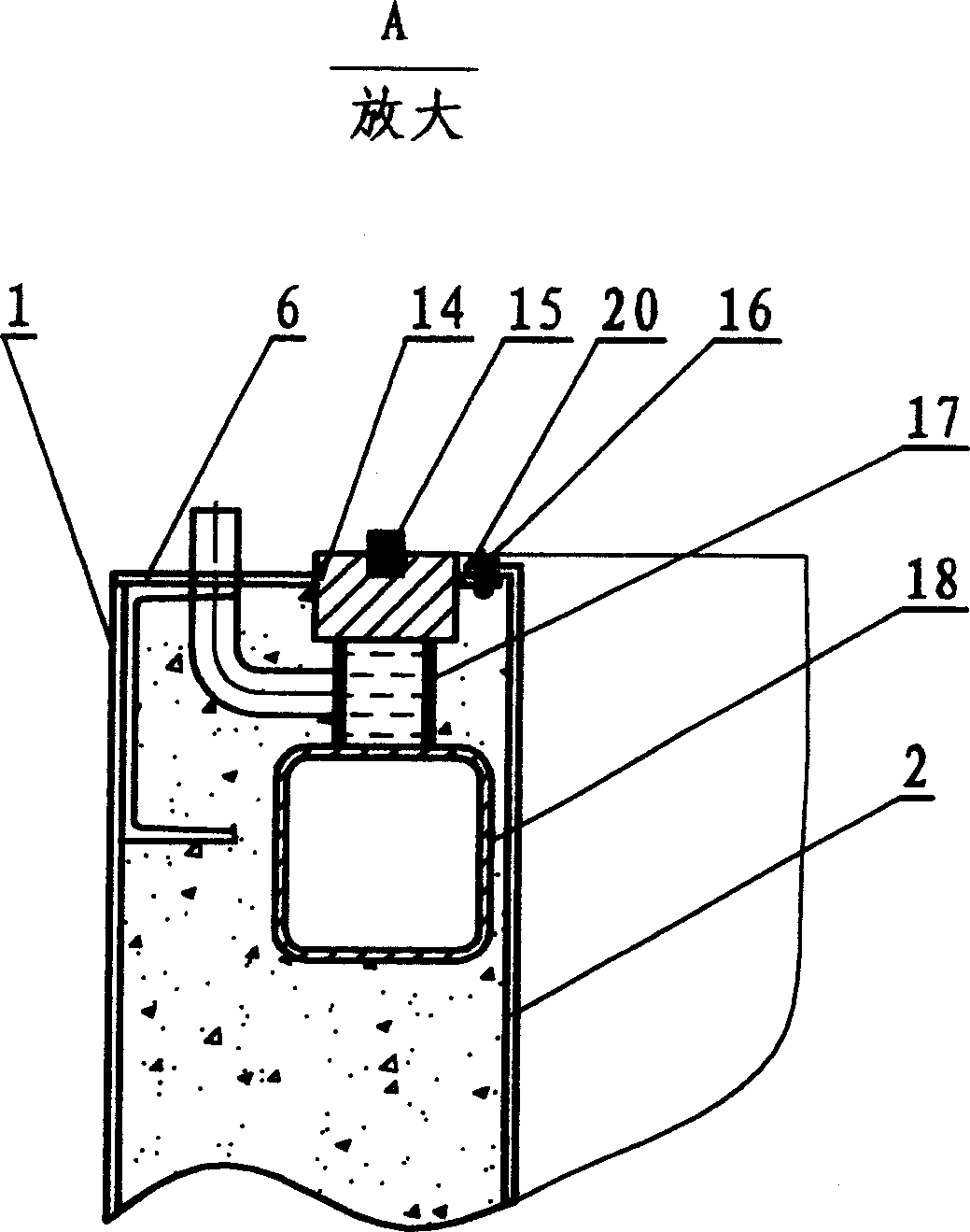

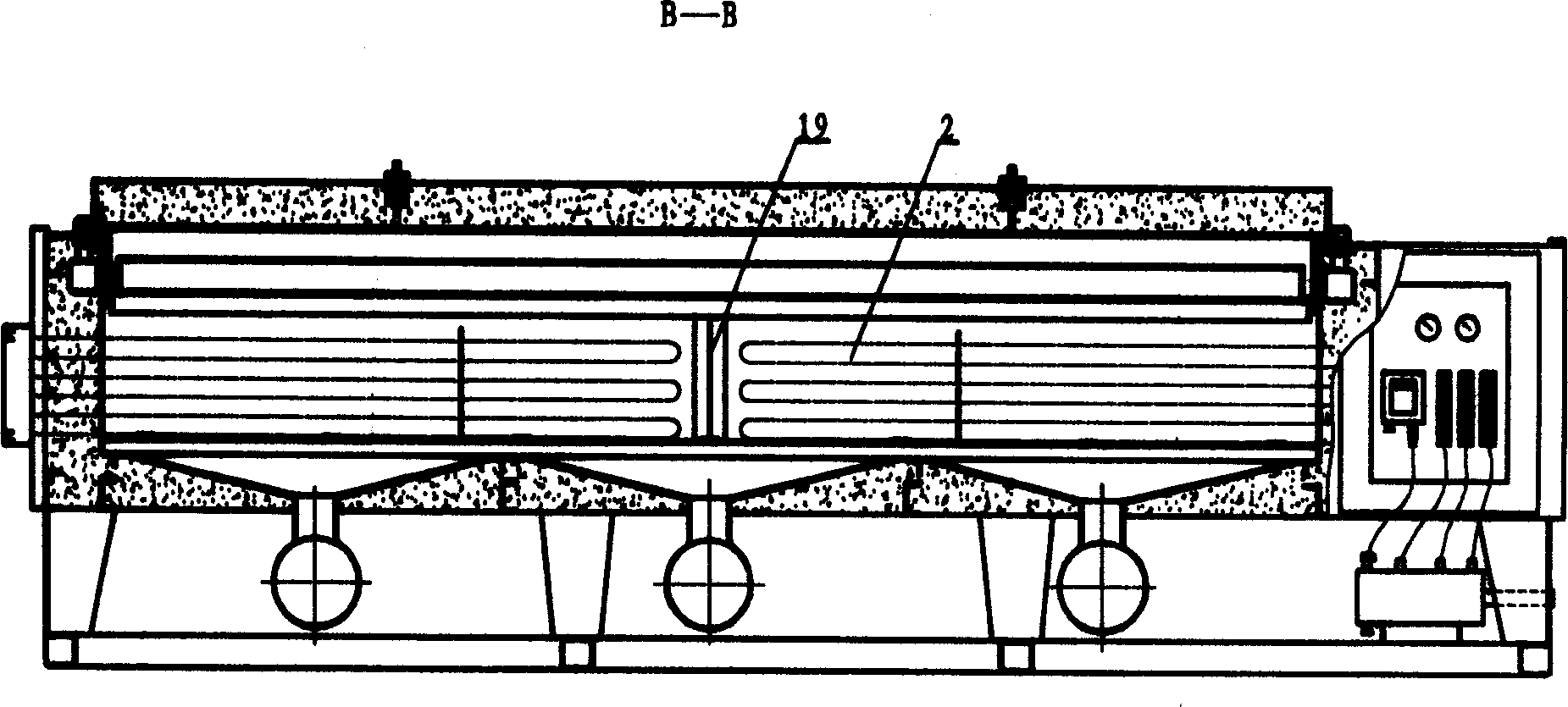

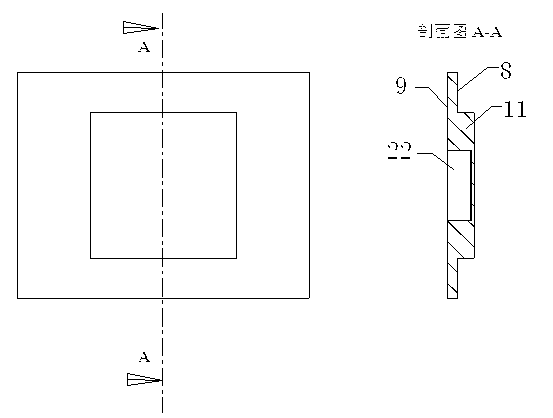

Rectangular vacuum cracking washing furnace with conveniently opening and closing lid

InactiveCN1752297AShort cleaning timeEasy to cleanFurnace componentsSpinnerette packsReciprocating motionEngineering

The invented rectangular vacuum cracking cleaning furnace contains vertical furnace cavity, furnace body, furnace cover, heating element, waste material collecting tank, in which the vertical furnace cavity is communicated with waste material collecting tank, on the furnace body a lever is movably mounted, one end of the lever is fixed on the furnace cover, another end of said lever is movably connected with piston rod, the cylinder body is movably matched with piston rod, one end of said cylinder body is movably connected with furnace body support, and the heating element is placed on the inner wall of vertical furnace cavity.

Owner:盐城化纤机械有限公司

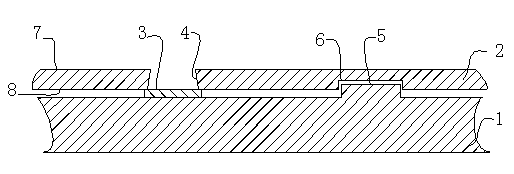

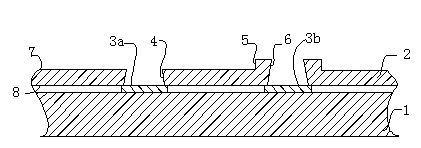

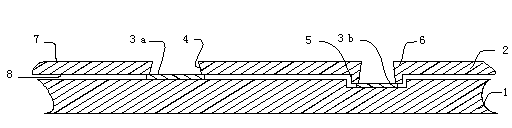

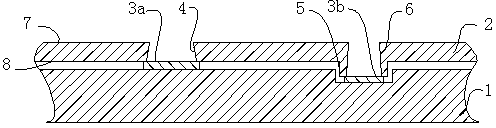

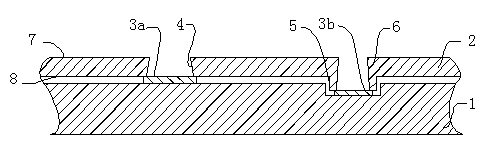

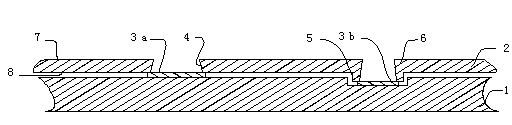

A hybrid production process for a step stencil

InactiveCN103203955AMix crafting improvementsQuality improvementPhotomechanical apparatusPlate printingEngineeringPre treatment

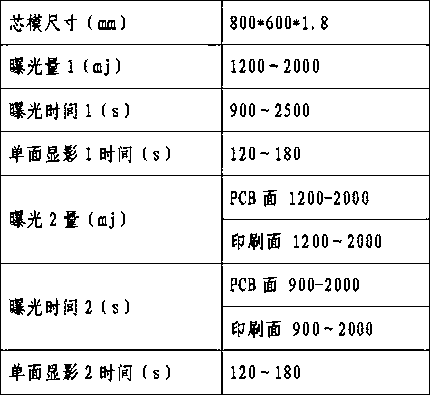

A hybrid production process for a step stencil. Specifically, The process flow is as follows: electroforming a first electroformed layer: core mold treatment->pre-treatment (degreasing, pickling and sandblasting)->film mounting 1->exposure 1->single sided development 1-> electroforming 1->stripping; electroforming up steps on a printing surface: pre-treatment (pickling and sandblasting)->double sided film mounting->double sided exposure->double sided development->electroforming 2->stripping; and etching down steps on a PCB surface: PCB surface etching->film stripping->follow-up treatment (degreasing and pickling). By employing the process, a metal stencil having the PCB surface with down steps and the printing surface with up steps can be produced. The pattern areas of the metal stencil have openings with good quality, smooth hole walls, and no undesirable phenomena of blurs, jags, etc.; the position precision of the opening pattern area is high; and the thickness uniformity of the stencil is good, uniformity COV being less than 10%.

Owner:KUN SHAN POWER STENCIL

A production process for a step stencil

A step stencil and a hybrid production process thereof. The step stencil is a metal mask having up steps on a PCB surface, and the base material of the mask is one of stainless steel, pure nickel and a nickel-iron alloy. The hybrid production process flow is as follows: (1) the fabrication of the up step area on the stencil PCB surface; (2) the fabrication of a half-etched blind hole of the stencil; (3) the fabrication of stencil openings; and (4) subsequent processing of the stencil openings. The hybrid production process includes three processes of etching, laser cutting and electropolishing, by using which the metal stencil having the PCB surface with up step can be produced. Through the fabrication of the half-etched blind holes, alignment holes for precise alignment can be produced; the metal screen has an opening pattern both in the flat area and the up step area; and the opening has good quality, smooth hole walls, and no blurs; by using the etching process, the stencil surface can be made to be flat and no-tilting phenomenon; and the flat area of the metal stencil has good thickness uniformity.

Owner:KUN SHAN POWER STENCIL

Preparation method of tungsten carbide/cobalt system porous material

The invention discloses a preparation method of a tungsten carbide / cobalt system porous material. The preparation method comprises the following steps of: taking tungsten oxide powder, cobalt oxide powder and carbon powder as raw materials; weighing the powder according to a certain proportion, evenly mixing the prepared materials by a ball milling method, then drying the powder and screening; performing reducing treatment on the dried powder in a hydrogen furnace to obtain tungsten carbide / cobalt composite powder; blending the composite powder into a gasoline paraffin solution for granulation; pressing the granulated composite powder by a pressure forming process to form green bodies with a certain shape; and degreasing and putting the green bodies into a high-temperature low-pressure sintering furnace for sintering, and cooling in the furnace to obtain the tungsten carbide / cobalt system porous material. The invention has the characteristics that: (1) the process is simple and pollution-free; and (2) the porous powder metallurgy material prepared by the process has many through holes and smooth hole walls. The porous material prepared by the process can be used for manufacturing originals for filtration, separation, current diversion, current limiting and the like.

Owner:CENT SOUTH UNIV

A hybrid production process for a printing stencil used in surface-mounting technology (SMT)

InactiveCN103203965AMix crafting improvementsGood opening qualityForme preparationEtchingSurface mounting

A hybrid production process for a printing stencil used in surface-mounting technology (SMT). The process flow is as follows: the fabrication of the up step area on a PCB surface and the down step area on a printing surface: substrate processing -> pretreatment (degreasing and pickling) -> double sided film mounting -> PCB surface exposure -> printing surface exposure -> double sided developing -> double sided etching; and the fabrication of the openings of the stencil: printing surface laser cutting. A metal stencil having the PCB surface with up steps, and the printing surface with down steps can be produced by using the process. According to the metal stencil produced by using the process, the openings of the substrate pattern area and the up step pattern area have good quality, smooth hole walls and no phenomena of blurs or slag; the surface of the metal stencil is good in quality and flat, the opening areas thereof without phenomena of protruding deformation; and the position precision of the pattern opening area of the up steps with the opening area of the substrate is high.

Owner:KUN SHAN POWER STENCIL

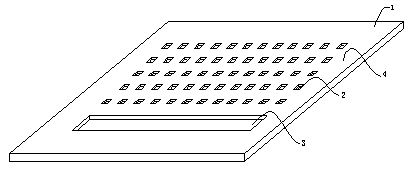

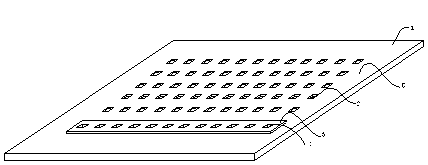

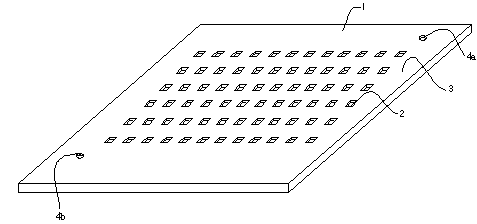

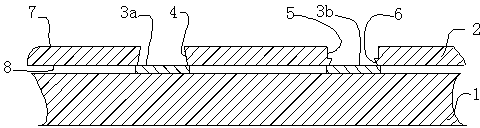

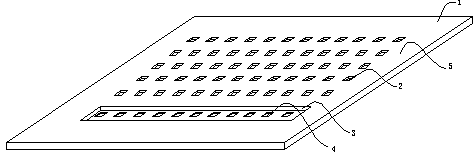

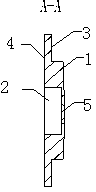

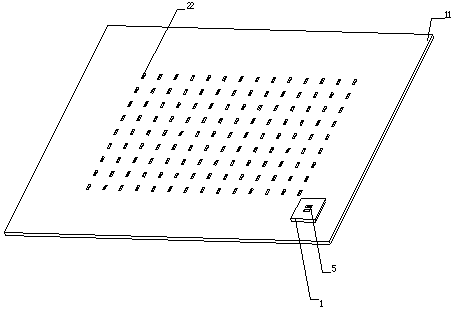

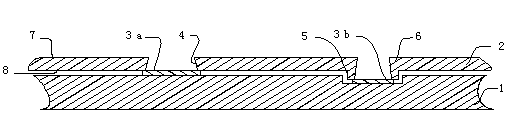

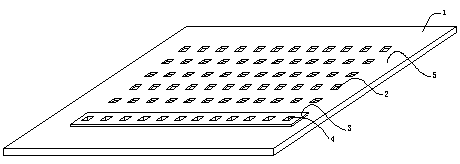

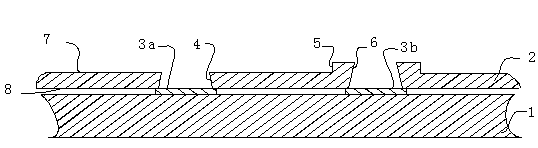

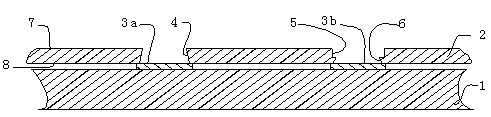

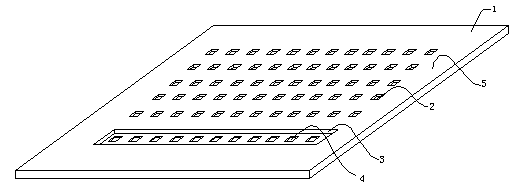

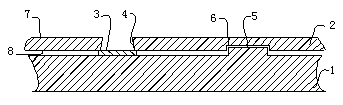

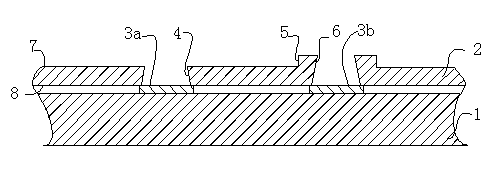

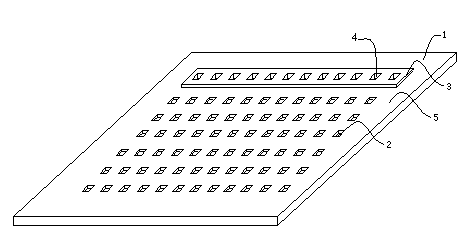

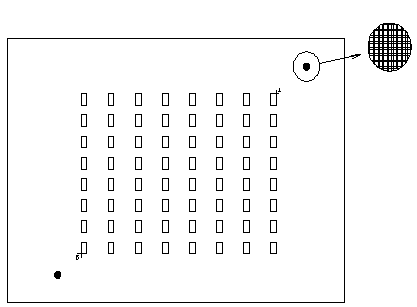

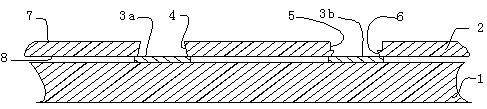

Three-dimensional mask plate for printing

InactiveCN103203984AHigh precisionImprove uniformityScreen printersSolid-state devicesGraphicsMechanical engineering

The invention discloses a three-dimensional mask plate for printing. The three-dimensional mask plate comprises a substrate, and a printing surface and a printed circuit board (PCB) surface, which are arranged on two sides of the substrate, wherein the mask plate is provided with a plurality of graphic openings and a three-dimensional structure, the three-dimensional structure comprises a projection area which is arranged on the printing surface and a concave area which is arranged on the PCB surface. The mask plate is provided with the three-dimensional projection part and the three-dimensional concave part, the height of the projection is 0.1mm to 10mm, the concave depth is 0.1mm to 10mm, and angles formed between the projection part and the plate surface and between the concave part and the plate surface are 80 to 90 DEG; the mask plate is made of pure nickel, and the precision is high; the uniformity is high, the quality is good, and high brightness, no rough spot, no scratch and no pin hole can be realized; and the opening quality is good, and the wall is smooth and free from burrs; and the mask plate is low in production cost, simple in process and low in energy consumption.

Owner:KUN SHAN POWER STENCIL

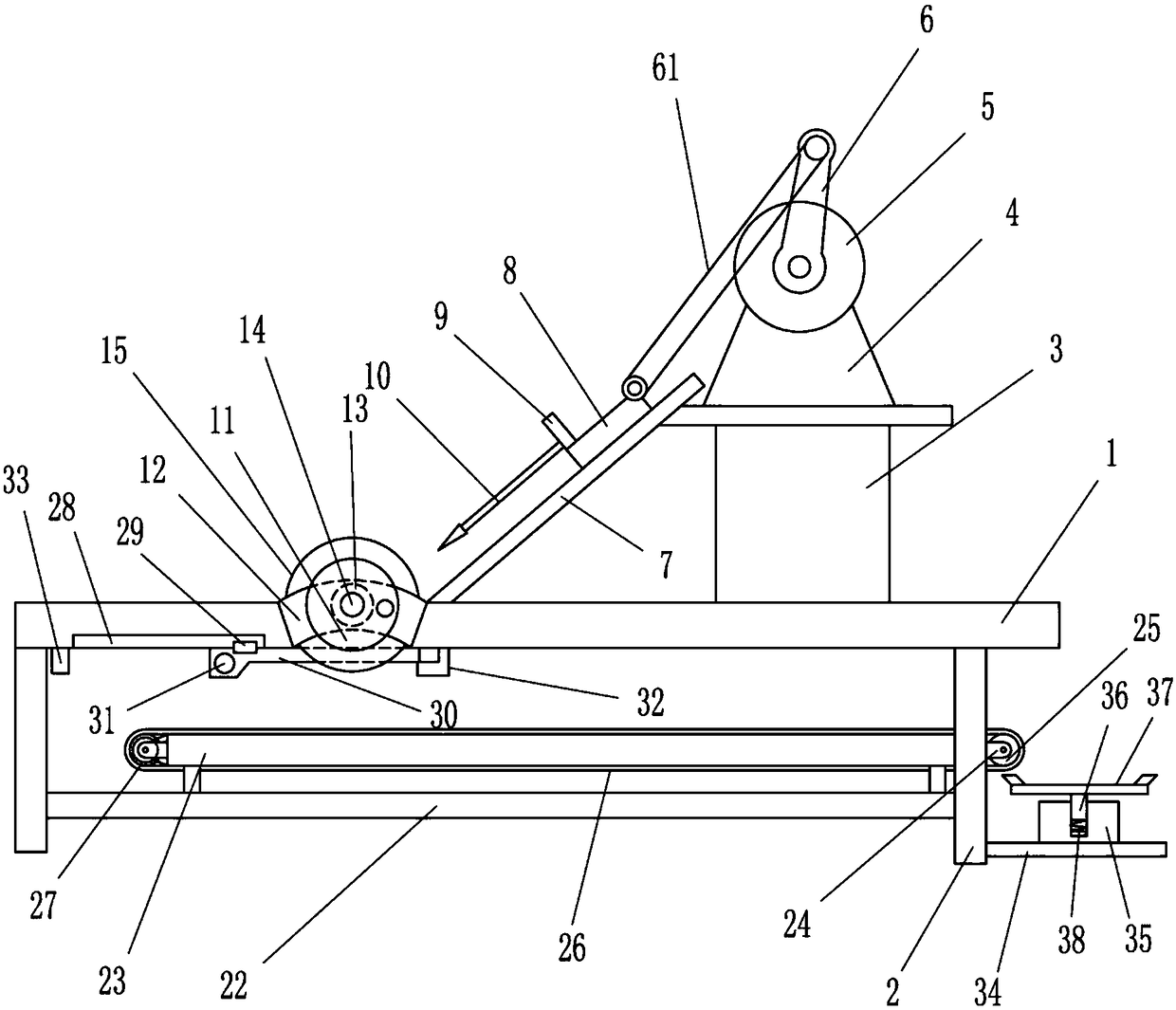

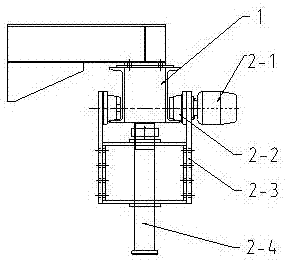

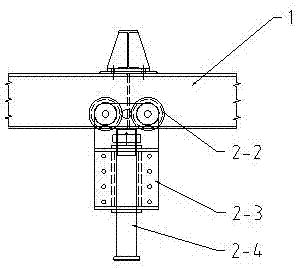

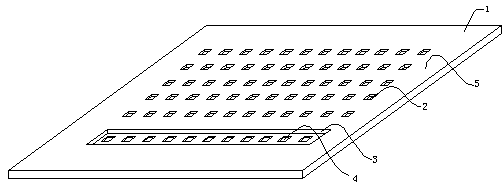

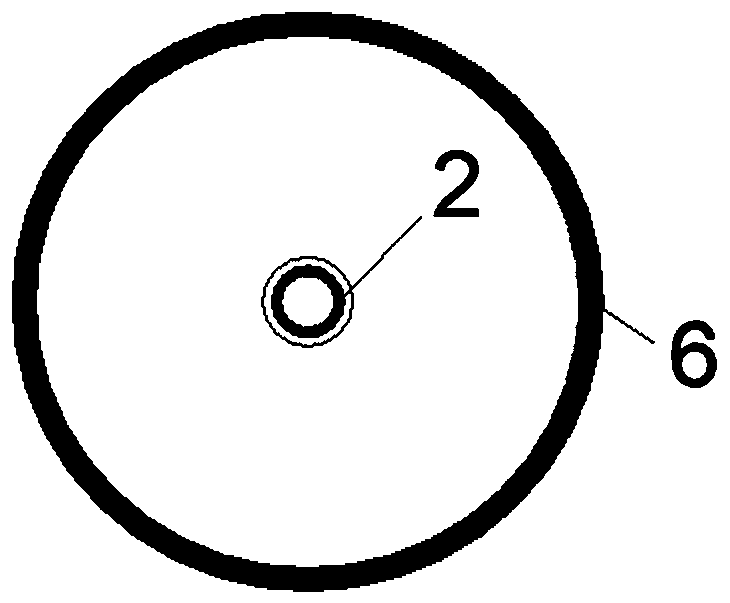

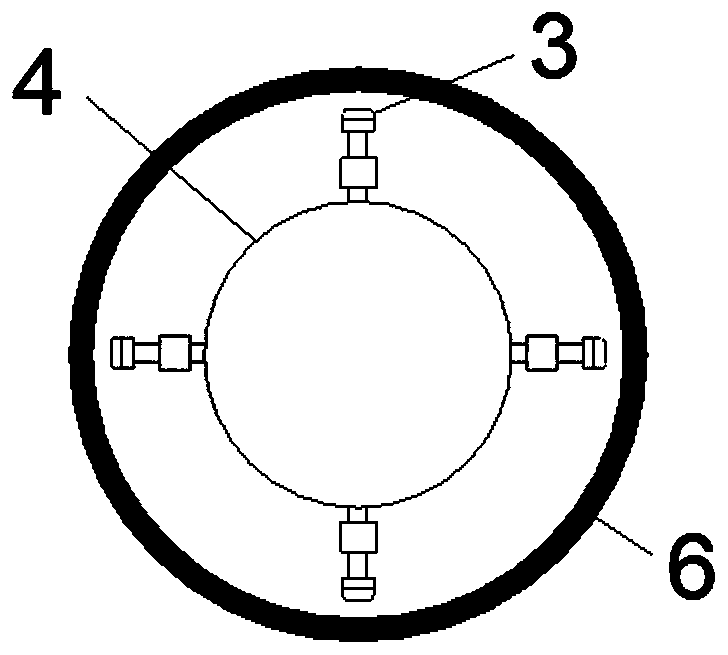

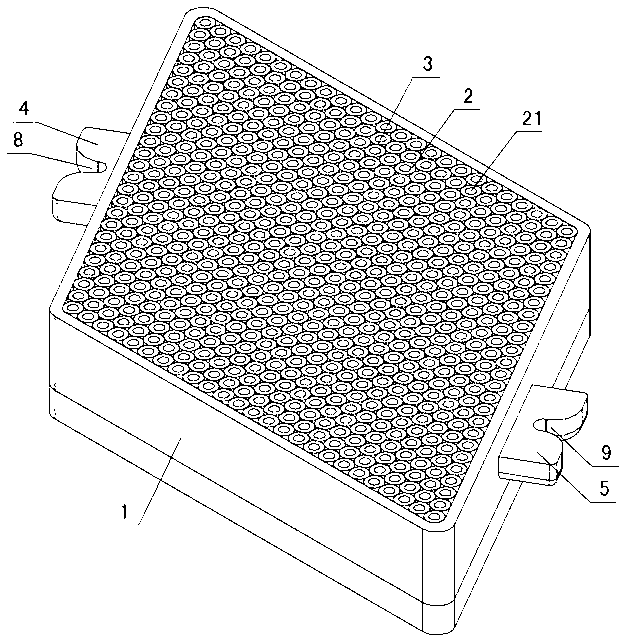

Mushroom bag punching device

InactiveCN108782025AReduce vibrationPlay a buffer roleCultivating equipmentsMushroom cultivationPunchingEngineering

The invention relates to a puncturing device, in particular to a mushroom bag puncturing device. The object of the invention is to provide the mushroom bag puncturing device capable of punching a plurality of holes simultaneously, having high puncturing efficiency and punching the holes with uniform densities. According to the technical scheme, the mushroom bag puncturing device comprises a mounting plate, brackets, a fixing table, a mounting seat, a rotating motor, a crank, a connecting rod, a first sliding rail, a first sliding block, a first mounting block, a second mounting blocks and thelike; the brackets are arranged on the left and right sides of the bottom of the mounting plate, the fixing table is arranged on the top right side of the mounting board, the mounting seat is arrangedon the top of the fixing table, the rotating motor is mounted on the mounting seat, and an output shaft of the rotating motor is provided with the crank. The device can punch a plurality of holes ata time by arranging a plurality of inserting rods on the first mounting block, thereby greatly improving the efficiency of the hole puncturing, the size of each of the inserting rods is uniform, the spacing of the adjacent inserting rods is the same, and the hole densities of the holes punched are uniform.

Owner:李苏

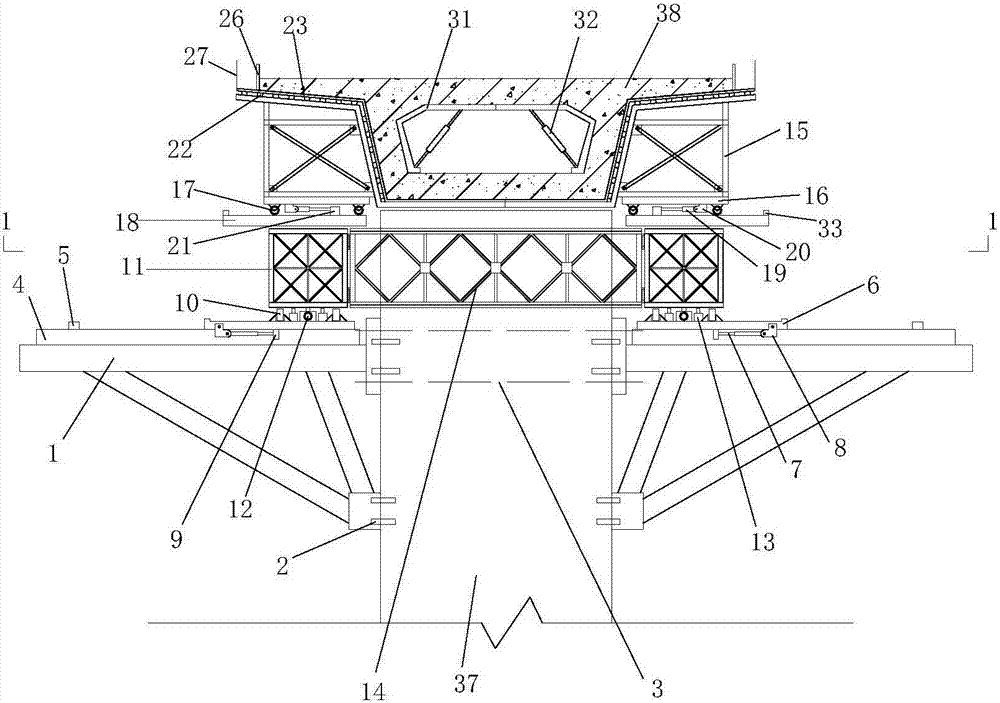

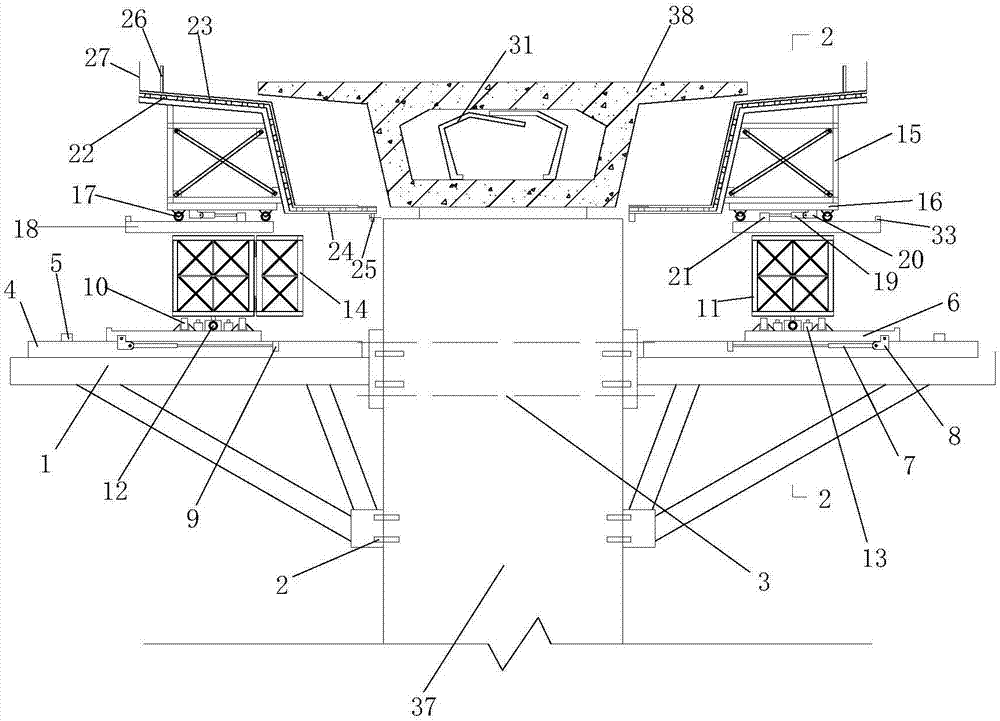

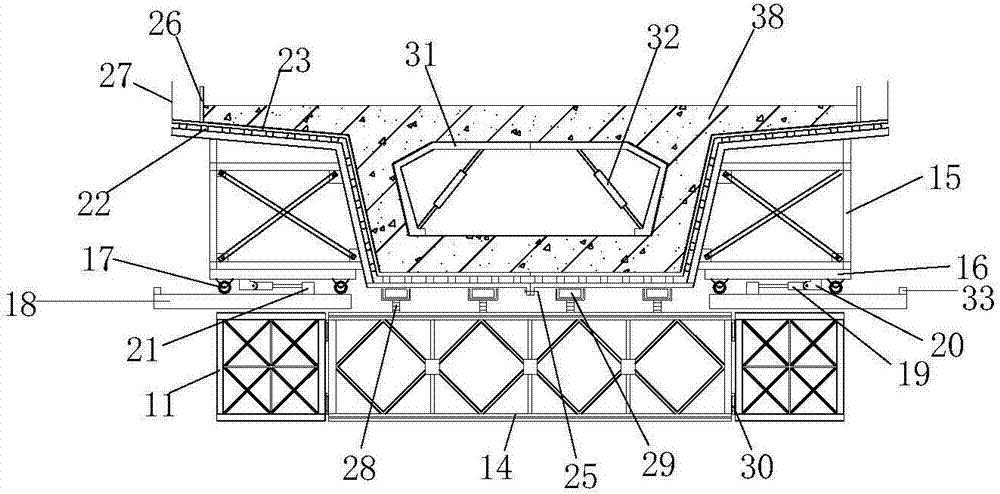

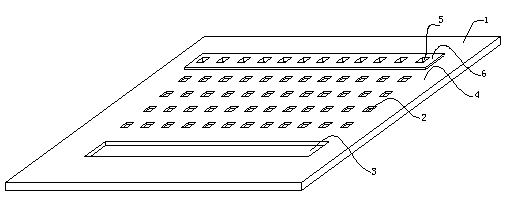

Construction method of cast-in-place box girder based on composite mobile formwork

ActiveCN106120563BSmooth holeLongitudinal movement achievedBridge erection/assemblyBlock and tackleEngineering

The invention relates to a composite movable mold frame for a cast-in-situ box beam. The composite movable mold frame mainly comprises a corbel supporting bracket, a horizontal movement railway, pulley block platforms, longitudinal bailey beams, horizontal bailey beams, external mold brackets, horizontal movement platforms, horizontal movement jacks A, a longitudinal movement jack and horizontal movement jacks B, wherein the horizontal movement jacks A are arranged on the side surface of the pulley block platforms and the side surface of the horizontal movement railway, one ends of the horizontal movement jacks A are fixed on the pulley block platforms, and the other ends of the horizontal movement jacks A are fixed on the horizontal movement railway; the longitudinal movement jack is arranged under the longitudinal bailey beams in a longitudinal direction; a base of the longitudinal movement jack is fixed on the pulley block platforms, and the other end of the base is fixed on a longitudinal movement guide rail beam through a connecting fitting E; and the external mold brackets adopt a structure that two sides of the external mold bracket are in symmetry and separation, and bottom mold plates on two sides are fixed together through bolts. The structure of the composite movable mold frame disclosed by the invention is convenient to disassemble and assemble and high in construction efficiency, repeated disassembling of supports and mold frame structures is not needed, automated hole penetration of the movable mold frame and a main beam can be realized, the serial construction of the cast-in-situ box beam is realized, and good economic and technical benefits are achieved.

Owner:德达交通建设发展集团有限公司

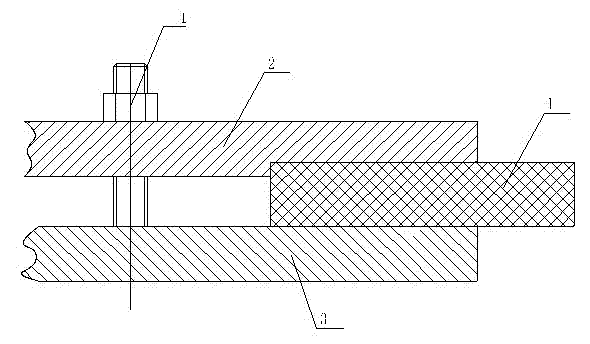

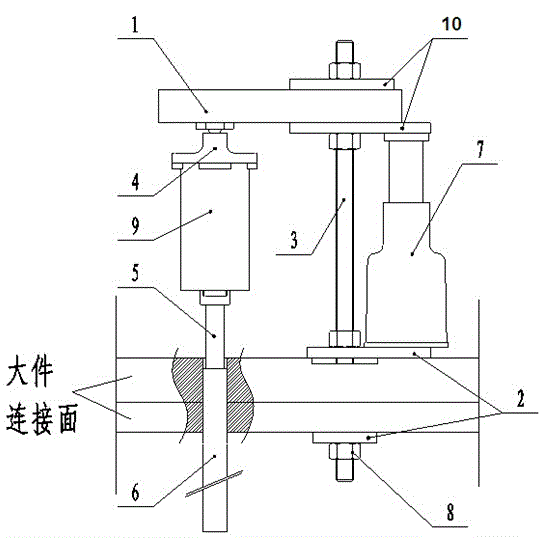

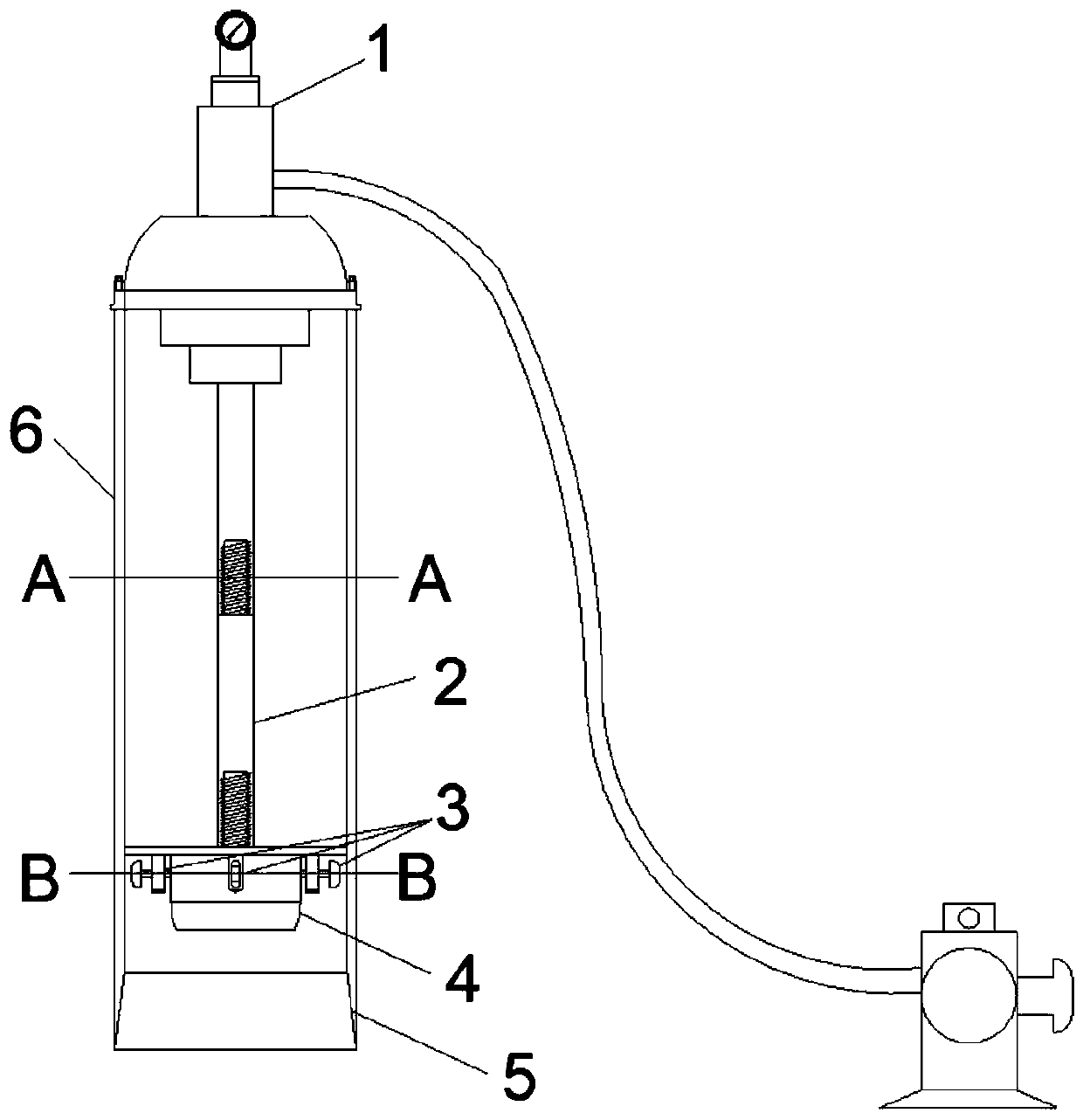

Reaming fixture and method of marine low speed diesel engine

The invention relates to a reaming fixture and method of a marine low speed diesel engine. The reaming fixture comprises a cross beam plate with a waist-shaped hole, first base plates, a screw bolt, a guiding rod, a broaching cutter for reaming, a screw jack, a hexagon nut and an oil cylinder, wherein the oil cylinder is connected with a hydraulic pump through an oil pipe; the top parts of the oil cylinder and the screw jack are respectively fixed below the two ends of the cross beam plate; the cross beam plate is kept horizontal; and one end of the screw bolt penetrates through the waist-shaped hole of the cross beam plate, and the other end of the screw bolt is fastened with a workpiece to be machined through the hexagon nut and the first base plates. A cylinder block and a rack on a station or connecting bolt holes in the rack and a machine seat are stranded and corrected without affecting the assembly work of other mainframes, thus the reaming method is convenient, the overall effect is greatly improved, and the mainframes are guaranteed to be smoothly folded.

Owner:HUDONG HEAVY MACHINERY

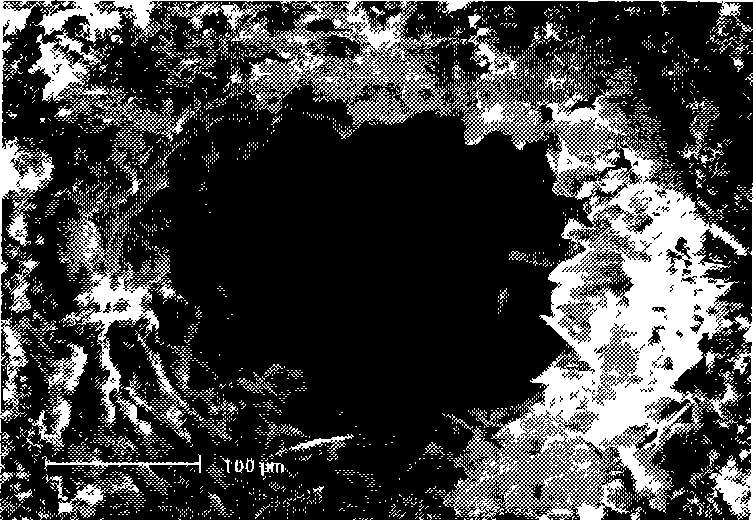

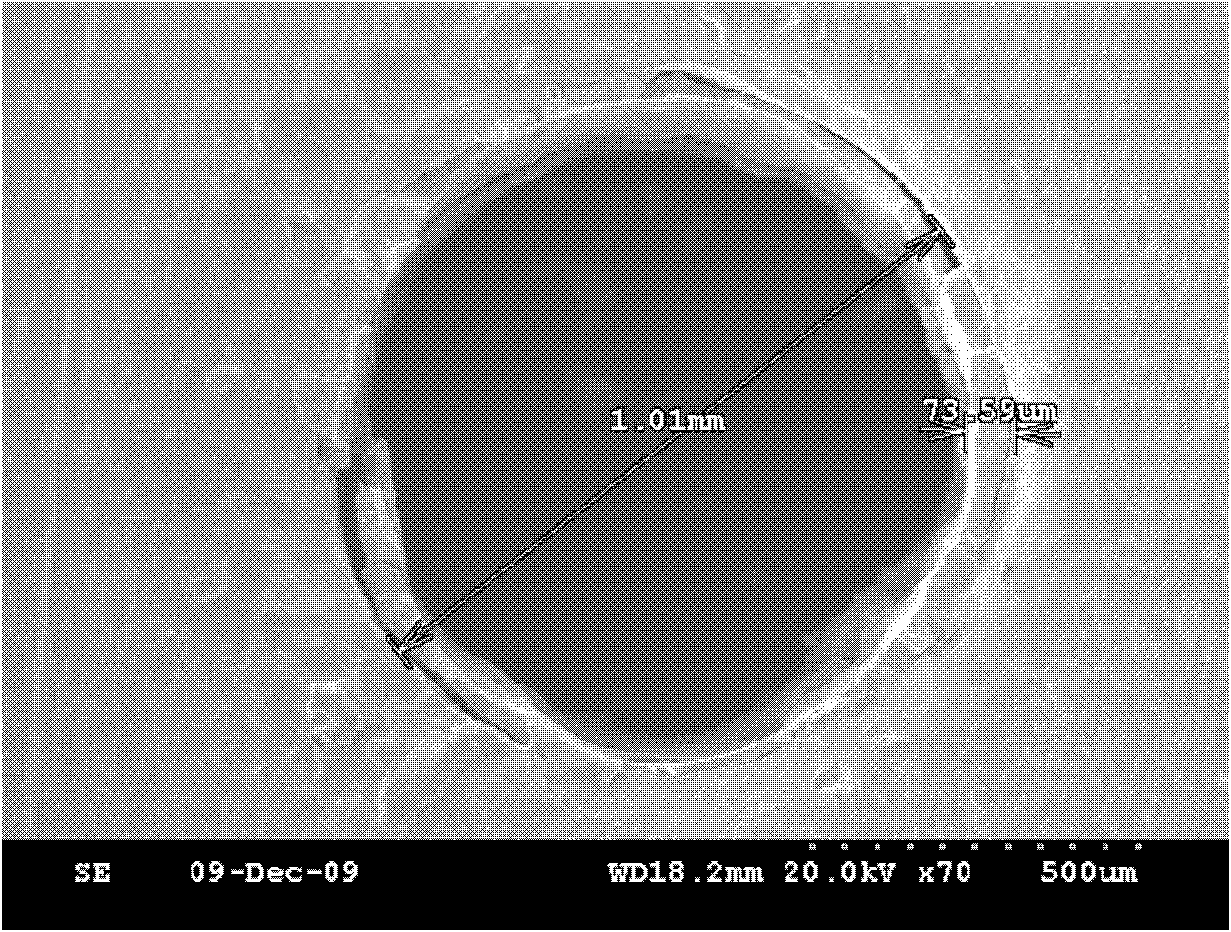

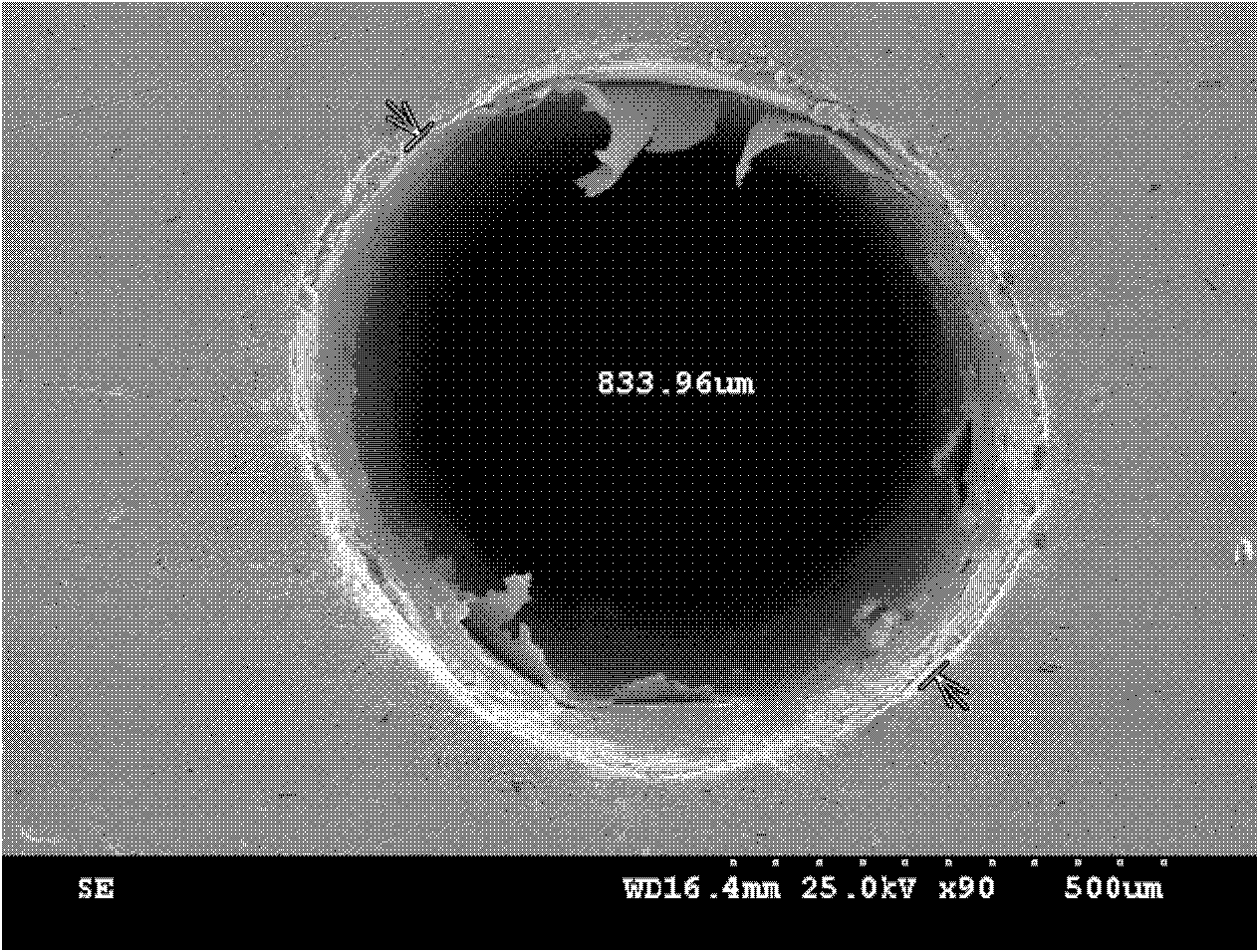

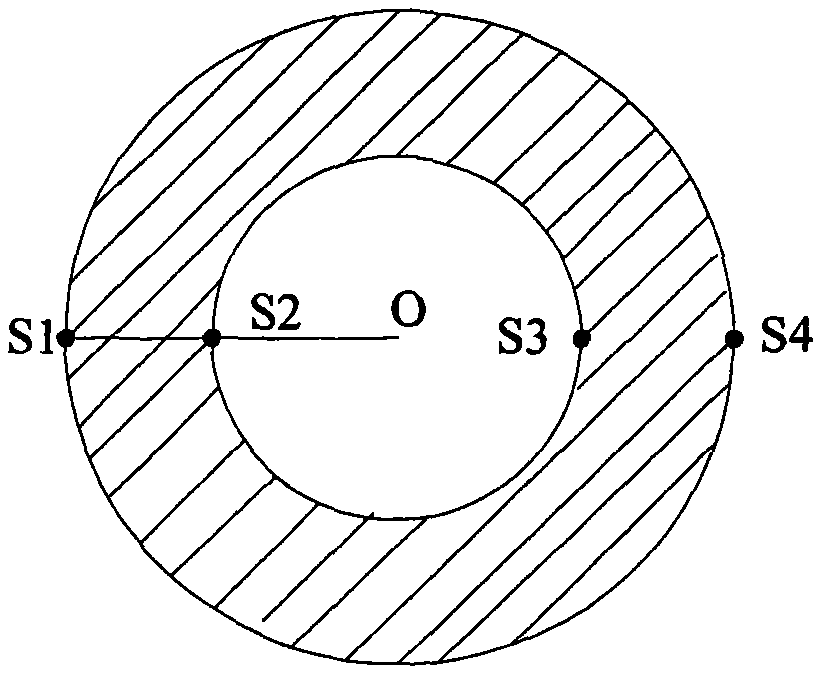

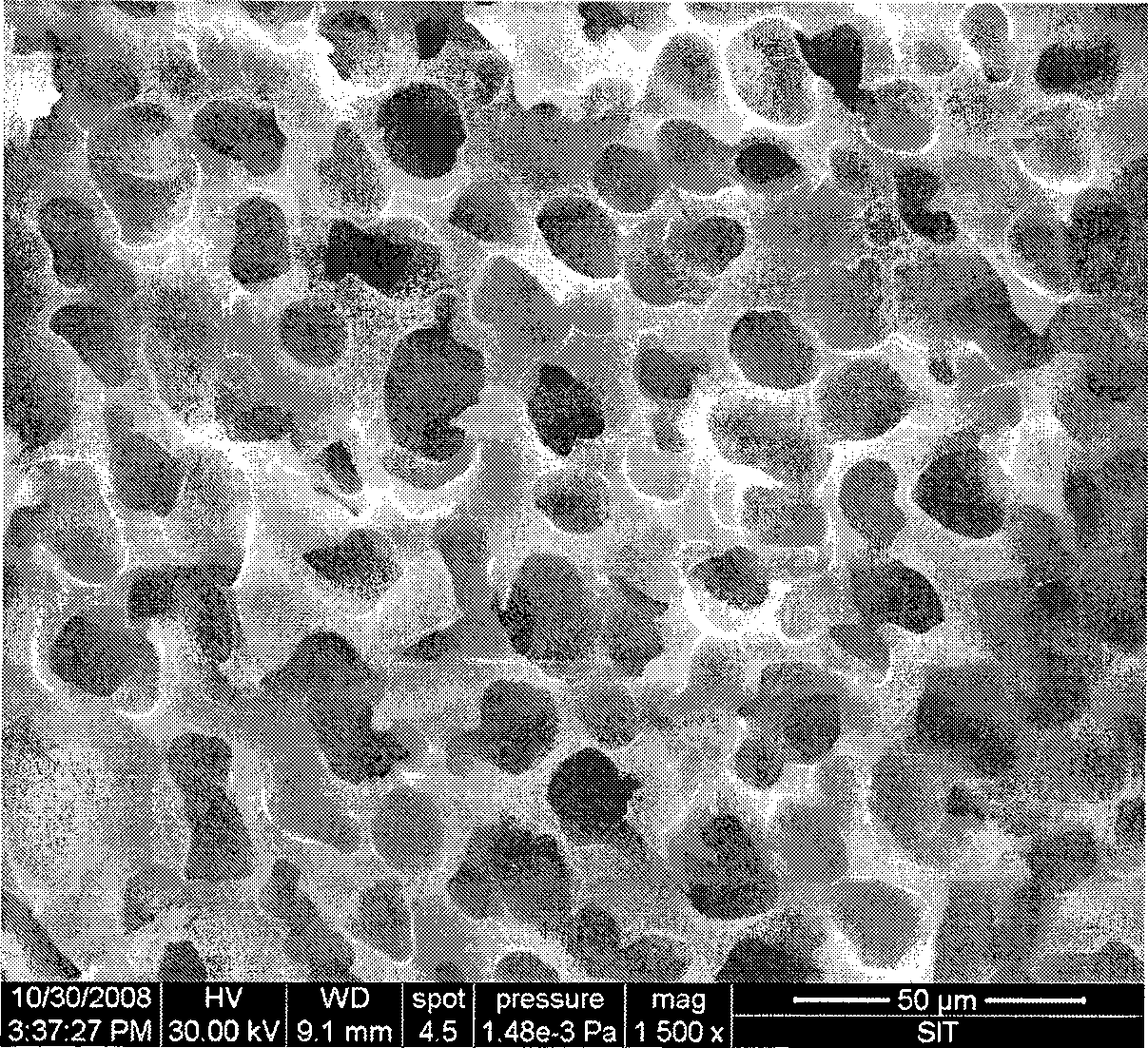

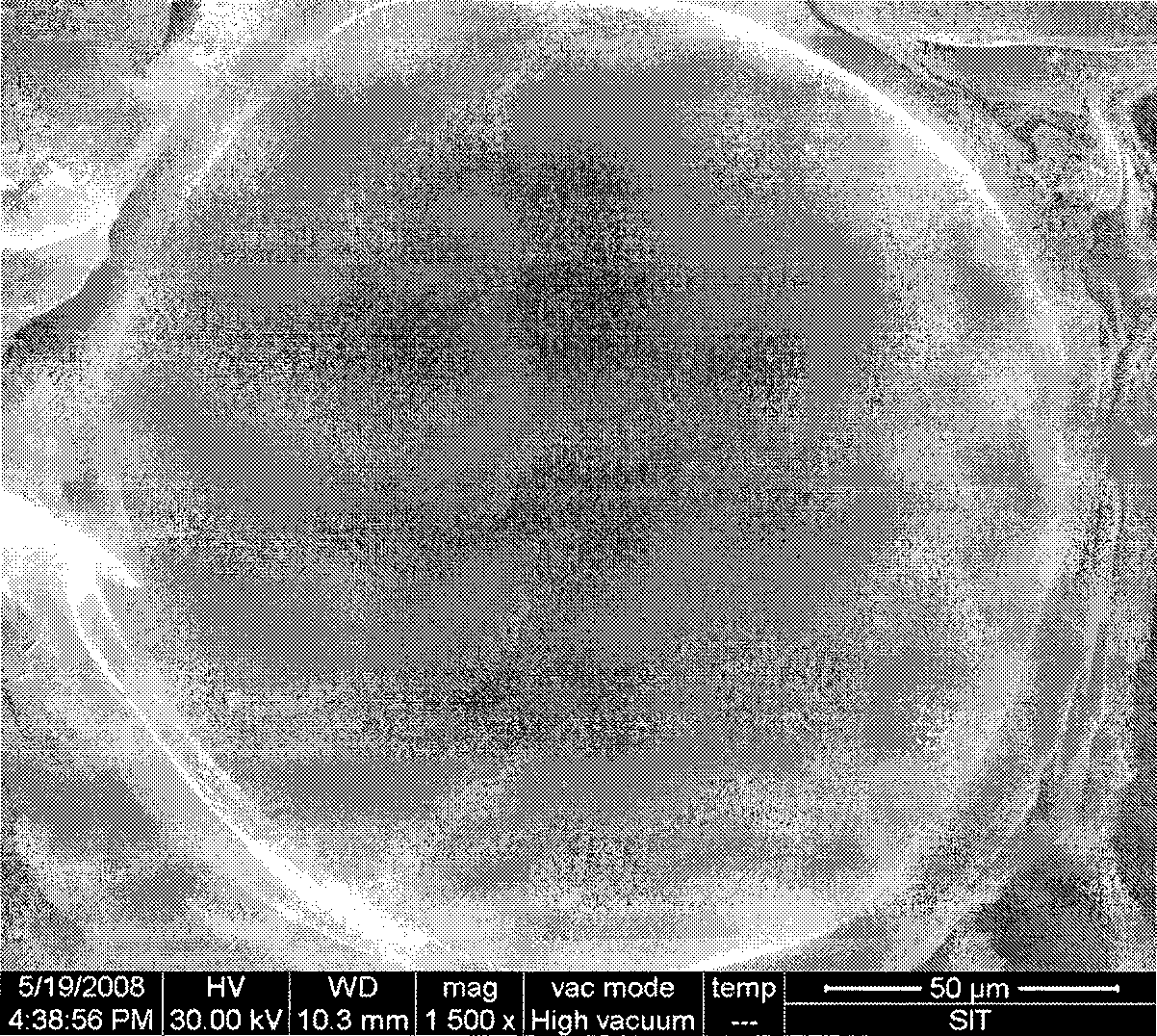

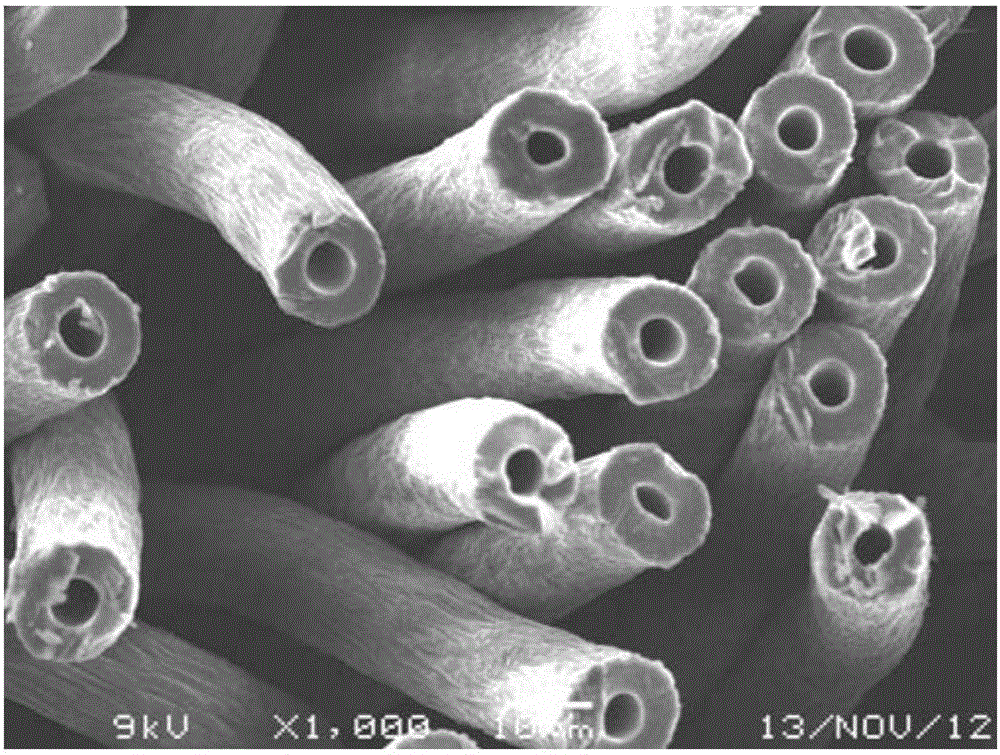

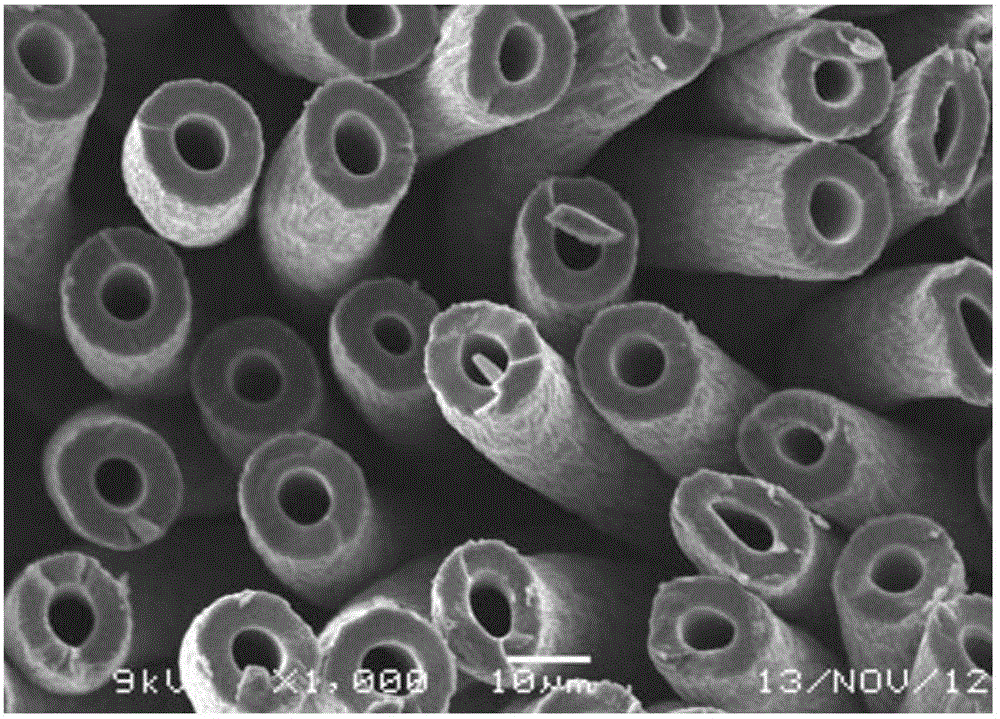

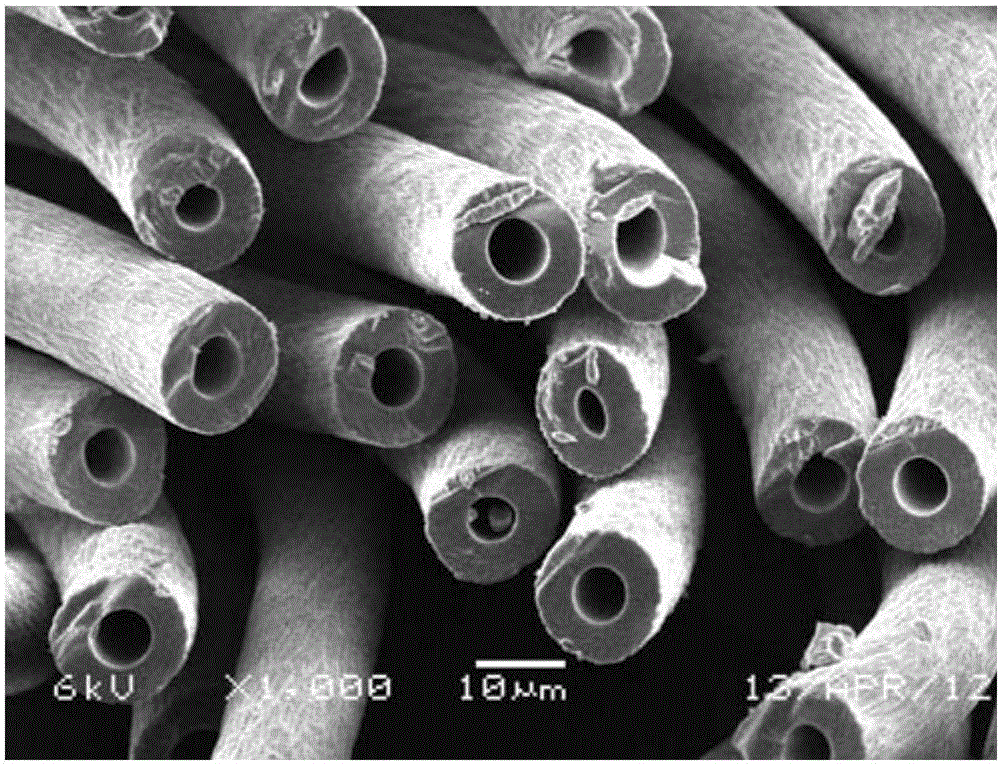

Polyacrylonitrile preoxidized fiber skin-core structure detection method

InactiveCN106596614AReduce toughnessCross-sectional holes are obviousMaterial analysis using wave/particle radiationPreparing sample for investigationRoom temperatureFiber diameter

A polyacrylonitrile preoxidized fiber skin-core structure detection method includes impregnating preoxidized short fibers in a sulfuric acid solution, heating to be boiling, performing refluxing treatment for 0.1-2 hours, washing the treated sample to be neutral, drying the washed sample, and cooling the dried sample to the room temperature; scanning the sections of the treated preoxidized short fibers by an SEM, storing pictures, subjecting the pictures to fiber diameter and core diameter measurement by SEM measuring software, averaging, and determining the core proportion. The polyacrylonitrile preoxidized fiber skin-core structure detection method is simple and convenient to operate and capable of detecting a PAN (polyacrylonitrile) preoxidized fiber skin-core structure accurately and quickly.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

High vacuum degree rectangular vacuum cracking washing furnace

InactiveCN1752298AExtended service lifeEasy to cleanSpinnerette packsFurnace typesEngineeringWater jacket

The present invention relates to a high-vacuity rectangular vacuum cracking cleaning furnace. It contains vertical furnace cavity, furnace body, furnace cover, heating element and waste material collecting tank. The vertical furnace cavity is communicated with waste material collecting tank. Said invention also provides the concrete structure of the vertical furnace cavity, furnace body and furnace cover. After the invention is adopted, when the internal high temperature makes the furnace cavity produce deformation, the furnace mouth can not be deformed so as to fully ensure vacuity of furnace interior.

Owner:盐城化纤机械有限公司

A production method for a step stencil

InactiveCN103203960AGood opening qualitySmooth holePhotomechanical apparatusPlate printingLaser cuttingEngineering

A production method for a step stencil and the specific process flow of the method is as follows: substrate processing (cutting)->pre-treatment (degreasing, pickling, and sandblasting)->film mounting->double sided exposure->double sided developing->etching (up step areas on a PCB surface, and a printing surface)->film stripping->pre-treatment (degreasing and pickling)->laser cutting (flat openings and openings of the up step areas). By using the method, a metal stencil having up step areas on the PCB surface and the printing surface can be produced. The pattern area of the metal stencil has good opening quality, smooth hole walls, no undesirable phenomena such as blurs or jags; the position alignment precision of the opening pattern area is high; and the thickness uniformity is good, with uniformity COV less than 10%.

Owner:KUN SHAN POWER STENCIL

A hybrid production process and a step stencil produced by using the process

InactiveCN103203959AGood opening qualitySmooth holePhotomechanical apparatusPlate printingL&D processEngineering

A hybrid production process and a step stencil produced by using the process. The hybrid production process is as follows: electroforming a first electroformed layer; electroforming the up step area on a PCB surface; and etching a down step area on a printing surface. The hybrid production process is characterized by comprising two techniques of electroforming and etching. The stencil produced by the process has external characteristics of: the PCB surface having up steps, and the printing surface having down steps and having an opening pattern. According to the metal stencil, the produced electroformed layer of the up step area has a relatively high bonding strength with the plane electroformed layer; the produced entire electroformed stencil has smooth opening walls, good surface quality and has no pinholes or pittings; the thickness uniformity of the opening pattern area of the produced entire electroformed stencil is good; and a special spreader plate used in the second electroforming process can effectively reduce the current density, thereby reducing the edge effect of the up step area.

Owner:KUN SHAN POWER STENCIL

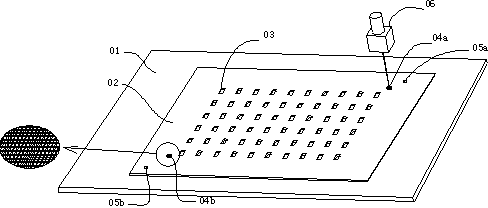

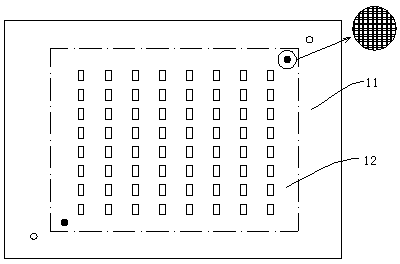

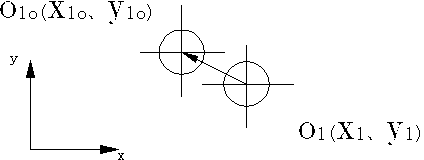

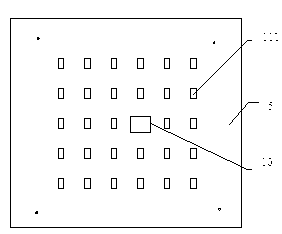

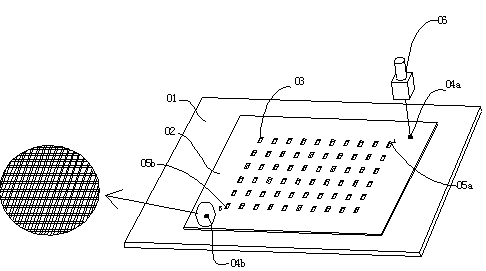

Production method for an electroformed stencil with mark points

InactiveCN103203977AImprove surface qualityImprove taperLaser beam welding apparatusForme preparationEngineeringLaser cutting

The present invention relates to a production method for an electroformed stencil with mark points, including the production of the electroformed stencil and the production of the mark points. The production method is characterized in that the stencil surface area outer the opening pattern area of the electroformed stencil is provided with two round holes diagonally positioned for determining the coordinates of the mark points. The production of the mark points comprises the steps of: placing the fixed electroformed stencil on a cutting base platform; then determining the coordinates of the mark points; adjusting cutting parameters and the vertical height of a laser cutting head to enable a laser focus to fall on the surface of the electroformed stencil; emitting laser light through the laser cutting head to perform cutting at the mark point area on the surface of the electroformed stencil. According to the production method for the electroformed stencil with mark points, the obtained electroformed stencil has good surface quality, no pinholes or pittings, thereby improving printing quality; and the mark points have high positioning accuracy, and relatively high degrees of recognition, improving alignment accuracy of a PCB with the electroformed stencil.

Owner:KUN SHAN POWER STENCIL

A production method for a step stencil

InactiveCN103203957AGood opening qualitySmooth holePhotomechanical apparatusPlate printingEngineeringPre treatment

A production method for a step stencil. Specifically, the production process flow is as follows: electroforming a first electroformed layer: core mold treatment->pre-treatment (degreasing, pickling and sandblasting)->film mounting 1->exposure 1->single sided development 1-> electroforming 1; electroforming up steps on a PCB surface: pretreatment (pickling and sandblasting)->double sided film mounting 2->double sided exposure 2->double sided development 2t->electroforming 2->film stripping->mold stripping; and etching down steps on the PCB surface: double sided film mounting on the electroformed layer->PCB surface exposure->PCB surface development->PCB surface etching ->film stripping->follow-up treatment (degreasing and pickling). By employing the method, the produced electroformed stencil has the PCB surface with up steps and down steps, and the step areas have opening patterns. The method of the invention solves the following technical problems: the pattern openings of the obtained up step area are in high position alignment precision with the openings of the first electroformed layer; the produced entire electroformed stencil has smooth opening hole walls, no undesirable phenomena such as blurs and diffusion coating, good surface quality, no undesirable defects such as pinholes and pittings; the stencil thickness uniformity COV is less than 10%; the stencil surface is in first grade brightness; and the bonding strength of the electroformed layer of the up step area and the first electroformed layer is strong, without the proneness of falling off.

Owner:KUN SHAN POWER STENCIL

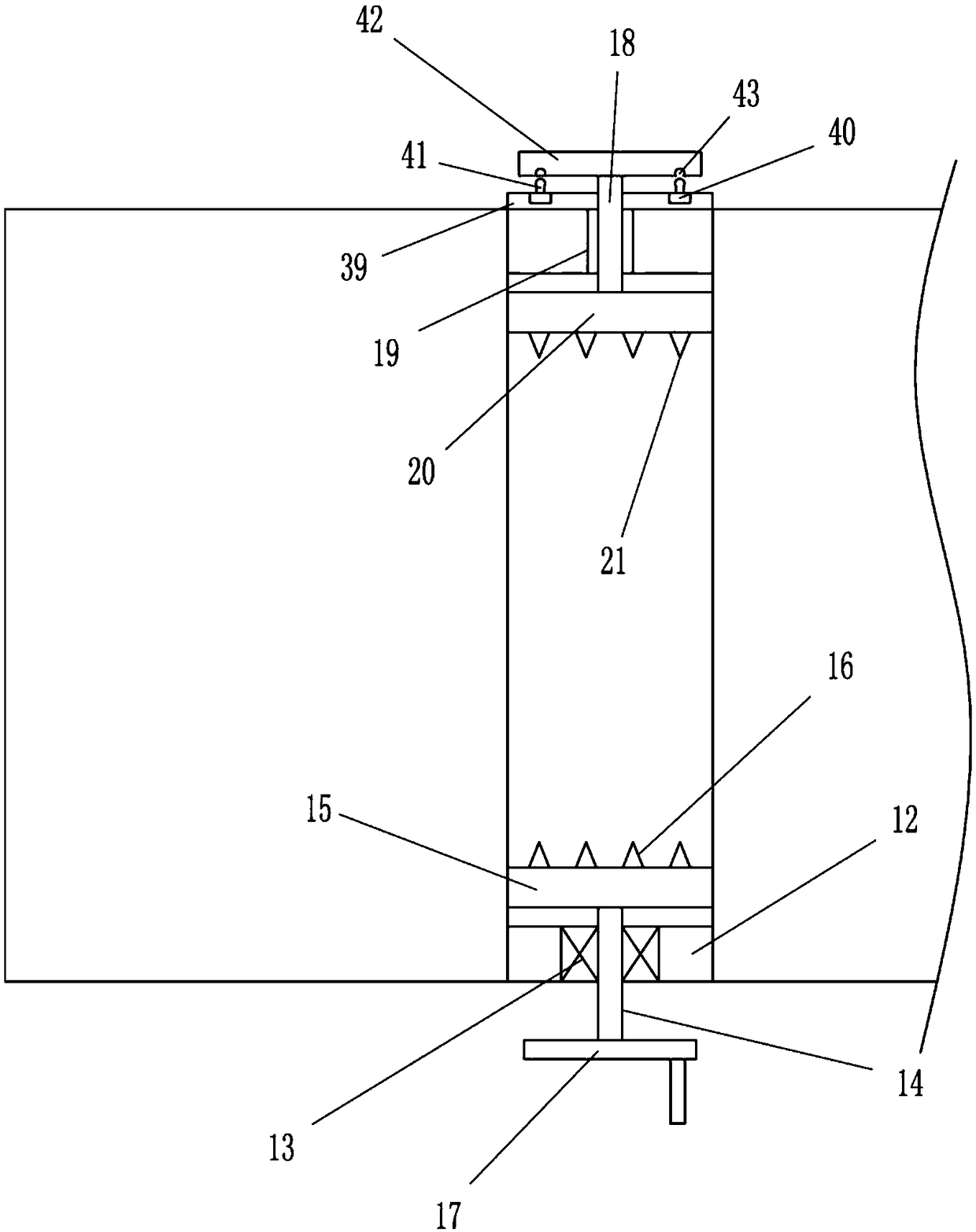

Movable formwork bottom-die working vehicle and hole-passing construction method

ActiveCN107268452AEasy to operateNo need to disassembleHydro energy generationBridge erection/assemblyStructural engineeringMechanical engineering

Owner:SHANDONG LUQIAO GROUP

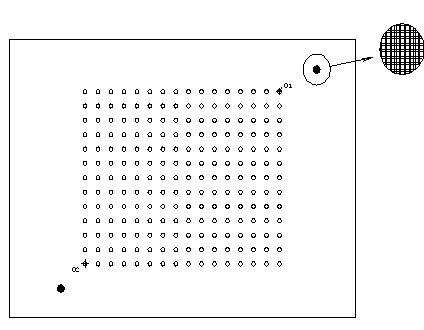

A production process for an electroformed stencil

InactiveCN103203964AHigh positioning accuracyImprove bindingPhotomechanical apparatusPlate printingEngineeringPre treatment

A production process for an electroformed stencil. The process flow is as follows: electroforming a first electroformed layer: core mold treatment -> pre-treatment (degreasing, pickling and sandblasting 1) -> film mounting 1 -> exposure 1 -> single sided developing 1 -> electroforming 1-> film stripping -> mold stripping; and electroforming up steps on a printing surface: printing surface pre-treatment (pickling and sandblasting 2) -> film mounting 2 -> exposure 2 -> single sided developing sided 2 -> electroforming 2 -> film stripping. By using the process, the electroformed stencil having an up step area on the printing surface, wherein the up step area has an opening pattern, can be produced. The stencil has the following advantages: deposition thickness uniformity COV of the stencil is 10% or less; the stencil surface has good quality, grade-one surface brightness, no pinholes or pitting; the binding strength between the up step area and the first electroformed layer is large, without the proneness of falling off; and the position precision of the pattern opening area of the up steps with the opening area of the first electroformed layer is high.

Owner:KUN SHAN POWER STENCIL

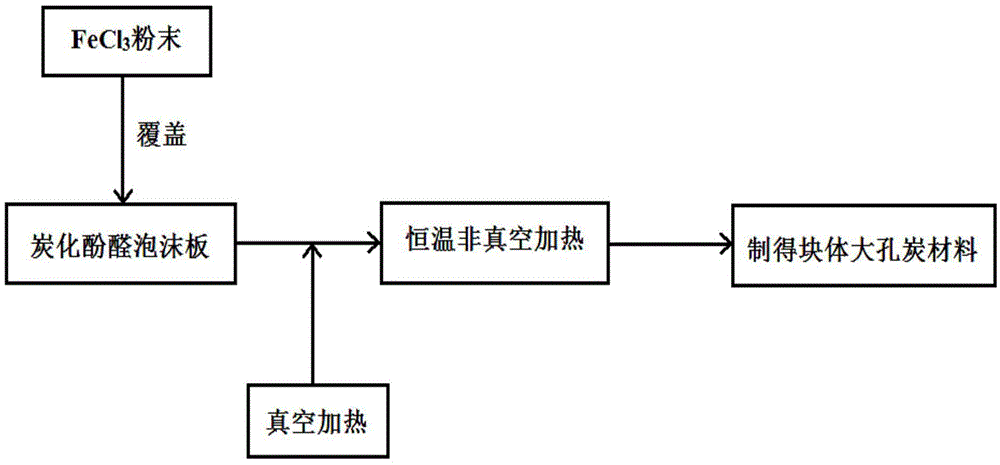

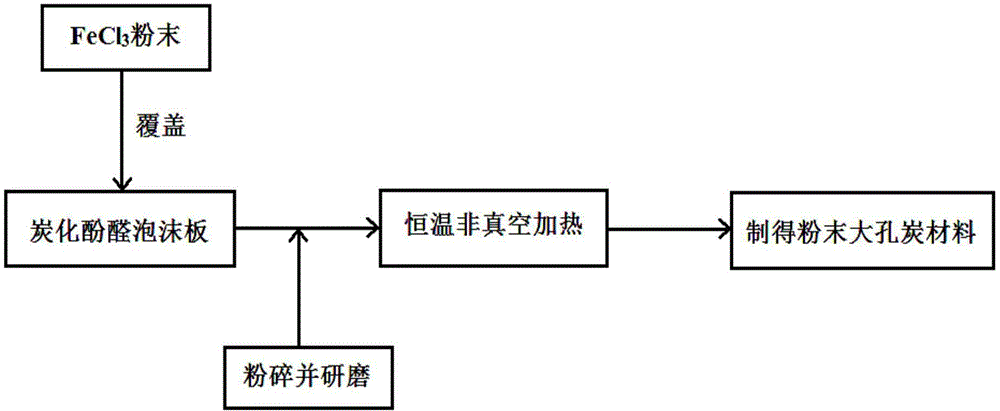

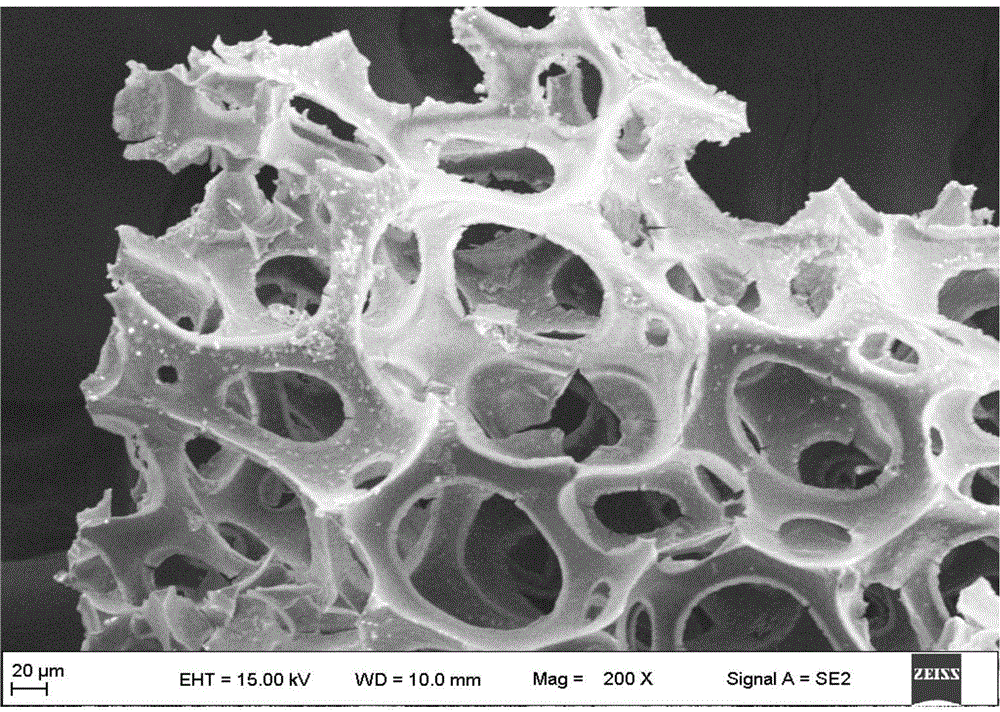

Preparation method and products of novel macroporous carbon material

The invention discloses a preparation method and products of a novel macroporous carbon material. According to the preparation method comprises the following steps of carbonizing and heating macroporous phenolic resin serving as a carbon source and FeCl3 serving as a catalyst to obtain the novel macroporous carbon material. By adopting the macroporous phenolic resin serving as the carbon source and FeCl3 serving as the catalyst, slow oxidation, catalysis and carbonization are simultaneously performed; by the structure-directing effect of the macroporous phenolic resin and the kirkendall diffusion effect of Fe element in FeCl3, the Fe element enters the phenolic resin plate to modify carbon pores, and the regular and hard macroporous carbon material having more smooth pore walls is finally prepared; and meanwhile, the distribution of pores in the prepared macroporous carbon material is more uniform.

Owner:NORTHEASTERN UNIV

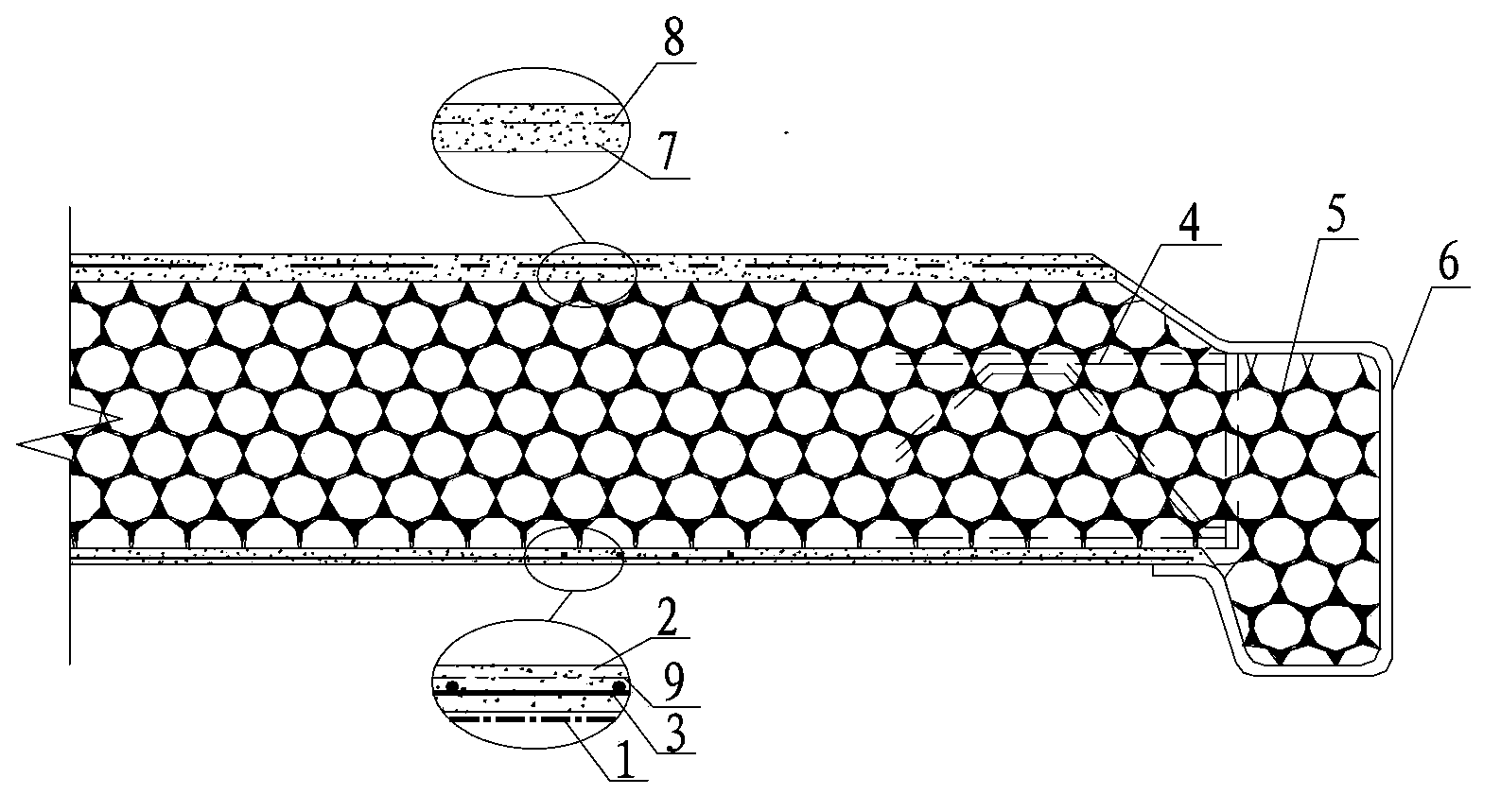

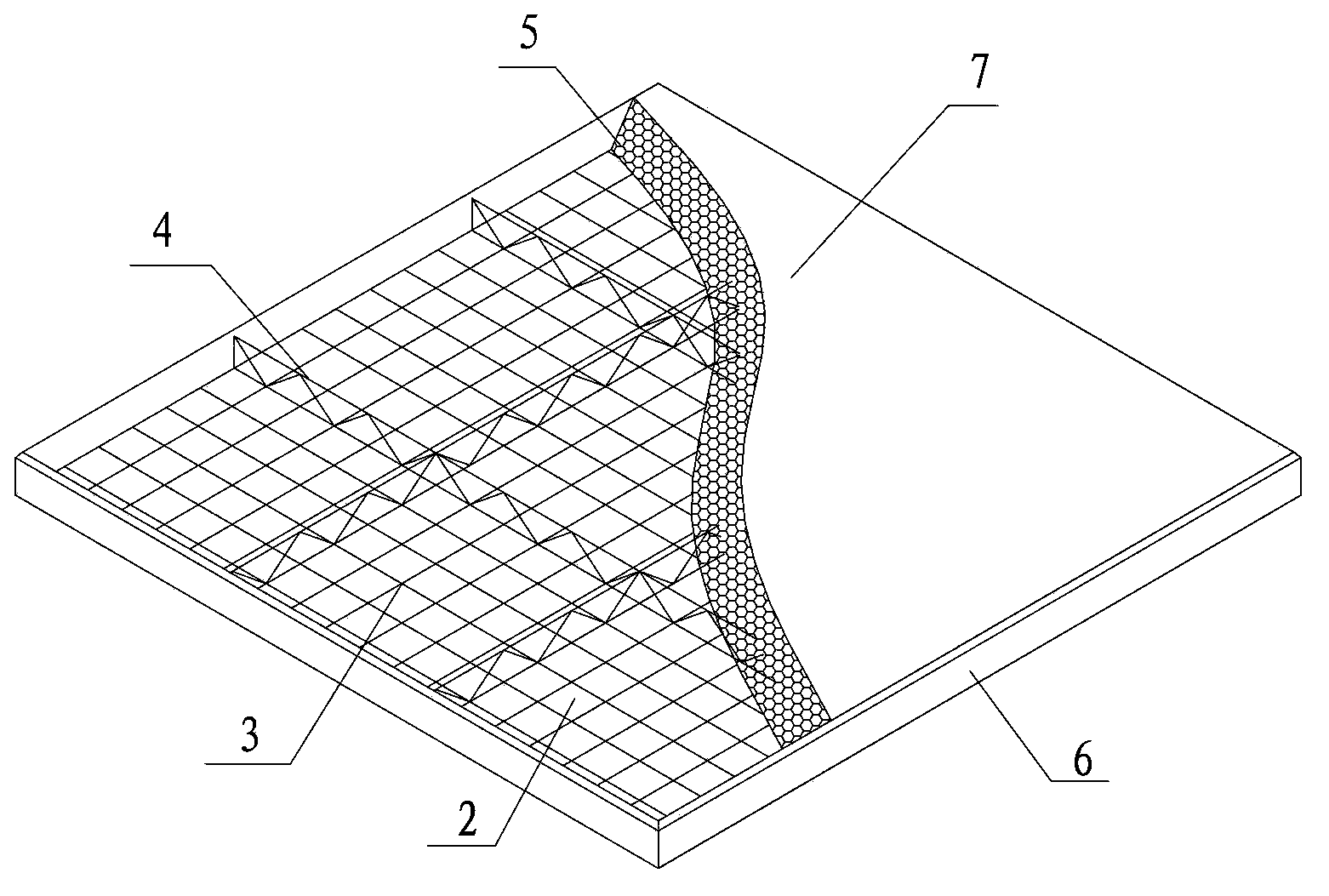

Light-weight and high-strength roof panel and production method thereof

InactiveCN104141357AUltra-lightHigh strengthBuilding roofsLayered productsCrack resistanceThermal insulation

The invention provides a light-weight and high-strength roof panel and a production method thereof. The light and high-strength roof panel has the characteristics of super light weight, high strength, corrosion resistance, high thermal insulation, high heat insulation, noise resistance, durability, crack resistance, shock resistance and the like, and facilitates environment protection. The technical scheme is that the light-weight and high-strength roof panel has a light steel enclosure frame, wherein built-in reinforcement bars and a nano inorganic foam insulating layer are arranged in the light steel enclosure frame, the built-in reinforcement bars are fixedly connected mutually and fixedly connected with the light steel enclosure frame, an upper protective layer and a lower protective layer are arranged on the upper side and the lower side of the light steel enclosure frame respectively and are composited into a whole by the nano inorganic foam insulating layer, and totally-enclosed spherical holes are formed in the nano inorganic foam insulating layer.

Owner:马榕颖 +1

Composite preparation process of three-dimensional vapor plating mask plate

InactiveCN103205671ALow shedding costImprove surface qualityVacuum evaporation coatingPhotomechanical apparatusNanotechnology

The invention relates to a composite preparation process of a three-dimensional vapor plating mask plate. The invention is characterized in that the preparation process comprises the steps of: A. a preparation technology of a three-dimensional core mould; and B. a preparation technology of the three-dimensional vapor plating mask plate. The three-dimensional vapor plating mask plate produced by the composite preparation process of a three-dimensional vapor plating mask plate provided by the invention has a recessed area and a raised area, the plating layer has good surface quality, no pit or pinhole, the raised area is not easy to fall off, the cost is low, the process is simple and saves energy, the opening precision is high, the opening quality is good, and the hole wall is smooth, so that the process has broad market prospects.

Owner:KUN SHAN POWER STENCIL

A production method for an electroformed stencil with mark points

InactiveCN103203974AImprove surface qualityImprove taperPhotomechanical apparatusPlate printingEngineeringLaser cutting

The present invention relates to a production method for an electroformed stencil with mark points, including the production of the electroformed stencil and the production of the mark points. The production method is characterized by comprising the steps of: placing the fixed electroformed stencil on a cutting base platform; selecting any two openings diagonally positioned on the electroformed stencil, reading coordinates of specific points of the openings, positioning the electroformed stencil through the coordinates of specific points, and determining coordinates of the mark points via comparing with an original file; adjusting cutting parameters and the vertical height of a laser cutting head to enable a laser focus to fall on the surface of the electroformed stencil; and emitting laser light through the laser cutting head to perform cutting at the mark point area on the surface of the electroformed stencil. According to the production method for the electroformed stencil with mark points, the obtained electroformed stencil has good surface quality, no pinholes or pittings, thereby improving printing quality; and the mark points have high positioning accuracy, and relatively high degrees of recognition, improving alignment accuracy of a PCB with the electroformed stencil.

Owner:KUN SHAN POWER STENCIL

A production process for a step stencil by using an electroforming method

InactiveCN103203967AGood opening qualitySmooth holeForme preparationPre treatmentElectrical and Electronics engineering

A production process for a step stencil by using an electroforming method. The specific process flow is as follows: electroforming a first electroformed layer: core mold processing -> pre-treatment (degreasing, pickling and sandblasting) -> film mounting 1 -> exposure 1 -> single sided developing 1 -> electroforming 1; electroforming an up step area on a PCB surface: pre-treatment (pickling and sandblasting) -> film mounting 2 -> exposure 2 -> single sided developing 2 -> electroforming 2 -> film stripping; electroforming a second electroformed layer (forming a down step area on a printing surface): printing surface film mounting -> exposure 3 -> single sided developing 3 -> electroforming 3 -> film stripping -> mold stripping -> subsequent treatment (degreasing and pickling). By using the process, the electroformed stencil having the PCB surface with up steps and the printing surface with up steps, wherein the up step areas has an opening pattern, can be produced. The openings of the pattern areas of the substrate and the step area have good quality, smooth hole walls and no blurs; the stencil surface has good quality, first class brightness, and no pinholes or pittings; the position precision of the opening area of the step area pattern and the opening area of the first electroformed layer is high; the binding strength between the up step area and the substrate is large, without the proneness of falling off; the thickness uniformity of the pattern areas of the electroformed stencil is good.

Owner:KUN SHAN POWER STENCIL

Multifunctional sampling, soil breaking and hole forming device

PendingCN110644460AAchieve replacementEasy to sampleIn situ soil foundationStructural engineeringMechanical engineering

The invention discloses a multifunctional sampling, soil breaking and hole forming device which comprises a hydraulic power device, a hydraulic telescopic rod, a protection barrel, a ring knife, soilbreaking cones and a hole forming barrel. The hydraulic telescopic rod is connected with the hydraulic power device and penetrates into the protection barrel through the top of the protection barrel.A threaded hole is formed in the output end of the hydraulic telescopic rod. The output end of the hydraulic telescopic rod is connected with the ring knife, the soil breaking cones or the hole forming barrel. A connecting plate is arranged at the top of the ring knife, and the ring knife is connected with the output end of the hydraulic telescopic rod through the connecting plate. The soil breaking cones and the hole forming barrel are connected with the lower end of the hydraulic telescopic rod through a threaded connecting rod. A circular ring is arranged on the outer side of the protectionbarrel. Three functions are integrated, the device controls the hydraulic telescopic rod to ascend and descend through the hydraulic power device, and the lower end of the device is detachably connected with the ring knife, the soil breaking cones or the hole forming barrel; and the circular ring on the outer side of the protection barrel is used as the reference of whether the protection can bevertically inserted into soil or not, deviation is avoided, hydraulic pressure is adopted as power, and the efficiency of sampling, soil breaking and hole forming is effectively improved.

Owner:CHANGAN UNIV

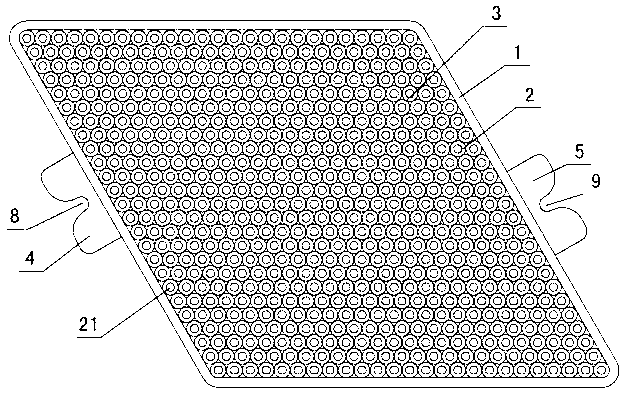

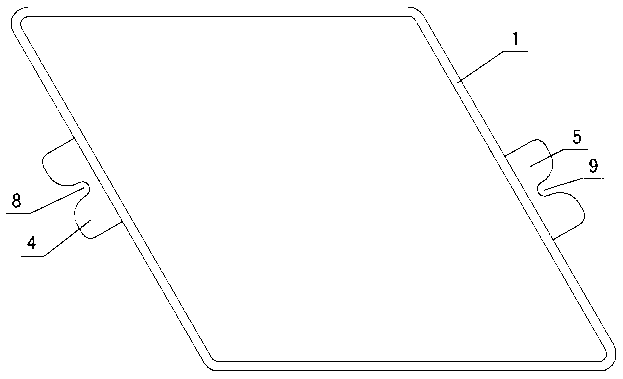

Method for machining honeycomb-shaped lead guider

A honeycomb-shaped lead guider is characterized by comprising pipes, bonding layers and an outer frame. A method for machining the honeycomb-shaped lead guider includes a first step of machining the pipes, a second step of machining the outer frame, a third step of arranging the pipes, a fourth step of taking out the pipes, a fifth step of coating the bonding layers on the pipes, a sixth step of blowing off cyclohexanone in the inner holes of the pipes, a seventh step of removing a prismatic fixing frame and an eighth step of forming the honeycomb-shaped lead guider. All the pipes of the lead guider with the structure and the outer frame of the lead guider with the structure are made by dies through injection moulding, production and manufacturing are convenient to conduct, the formed pipes are the same in size, the hole walls are smooth so that threading can be facilitated, the pipes are connected with one another through the bonding layers, the pipes are arranged in a compact and neat mode, labor is saved in the machining process, the machining is easy to conduct, the operation is convenient to conduct, and the percent of pass is high.

Owner:ZHEJIANG NANTAI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com