Preparation method and products of novel macroporous carbon material

A macroporous carbon and a new type of technology, applied in the field of preparation of new macroporous carbon materials, can solve the problems of rough pore walls of macroporous carbon materials, high equipment requirements, complex preparation processes, etc., and achieve low operating difficulty and reaction conditions. , The effect of low equipment requirements and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

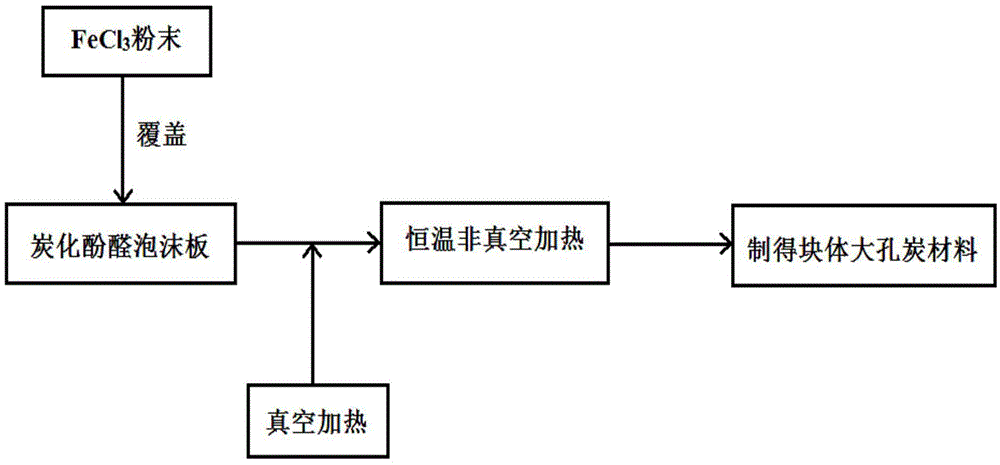

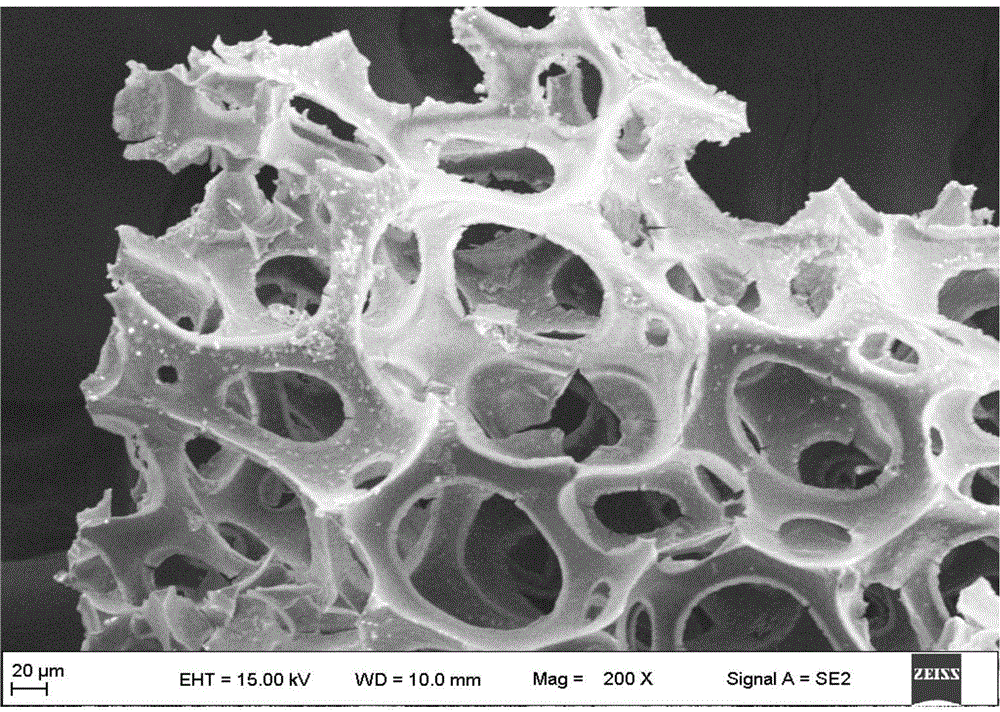

[0044] Embodiment 1 of the present invention: a kind of bulk macroporous carbon material, such as figure 1 As shown, it is prepared by the following method: using macroporous phenolic resin as carbon source, FeCl 3 It is a catalyst; it can be obtained by carbonizing and heating the phenolic resin; it specifically includes the following steps:

[0045] S11. Take the phenolic resin and perform foaming treatment to obtain a macroporous phenolic foam board with a pore size of 10-100 μm;

[0046] S21. Cut the macroporous phenolic foam board to about 0.05-0.1m3, and carbonize the macroporous phenolic foam board at 200-250°C to obtain a carbonized phenolic foam board;

[0047] S31. Take FeCl 3 About 20-30g of coarse powder is finely ground, among which FeCl 3 The mass ratio of coarse powder to carbonized phenolic foam board is 2:1; the carbonized phenolic foam board is placed in a container, and the finely ground FeCl 3 Cover the powder on the carbonized phenolic foam board to ob...

Embodiment 2

[0050] Example 2: A block macroporous carbon material prepared by the following method: using macroporous phenolic resin as the carbon source, FeCl 3It is a catalyst; it can be obtained by carbonizing and heating the phenolic resin; it specifically includes the following steps:

[0051] S11. Take the phenolic resin and perform foaming treatment to obtain a macroporous phenolic foam board with a pore size of 10-100 μm;

[0052] S21. Carbonizing the macroporous phenolic foam board at 200-250° C. to obtain a carbonized phenolic foam board;

[0053] S31. Take FeCl 3 powder, covered on the carbonized phenolic foam board, to obtain product A; wherein, FeCl 3 The mass ratio of powder to carbonized phenolic foam board is 2:1;

[0054] S41 Heat product A to 160°C under vacuum, and keep the temperature constant for 2-3 hours to obtain product B;

[0055] S51. Take out product B, heat it up to 300°C under normal pressure, and keep the temperature constant for 1-2 days to obtain a bul...

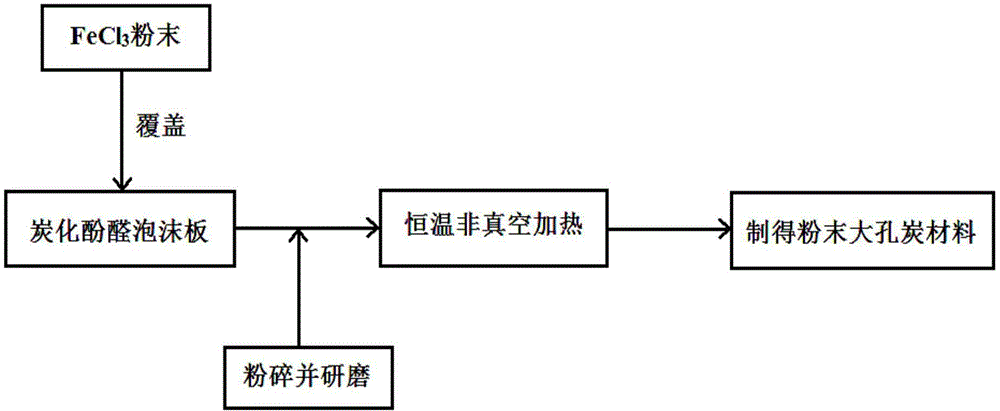

Embodiment 3

[0056] Example 3: A block macroporous carbon material prepared by the following method: using macroporous phenolic resin as the carbon source, FeCl 3 It is a catalyst; it can be obtained by carbonizing and heating the phenolic resin; it specifically includes the following steps:

[0057] S11. Get the phenolic resin, carry out foaming treatment, get macroporous phenolic foam board;

[0058] S21. Carbonizing the macroporous phenolic foam board at 200-250° C. to obtain a carbonized phenolic foam board;

[0059] S31. Take FeCl 3 About 20-30g of coarse powder is finely ground and covered on the carbonized phenolic foam board to obtain product A; wherein, FeCl 3 The mass ratio of coarse powder to carbonized phenolic foam board is 5:2;

[0060] S41 Heat product A under vacuum to 140-160°C and keep the temperature constant for 2-3 hours to obtain product B;

[0061] S51. Take out product B, after cooling, heat it up to 240°C under normal pressure, and keep the temperature constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com