Patents

Literature

41results about How to "Improve taper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

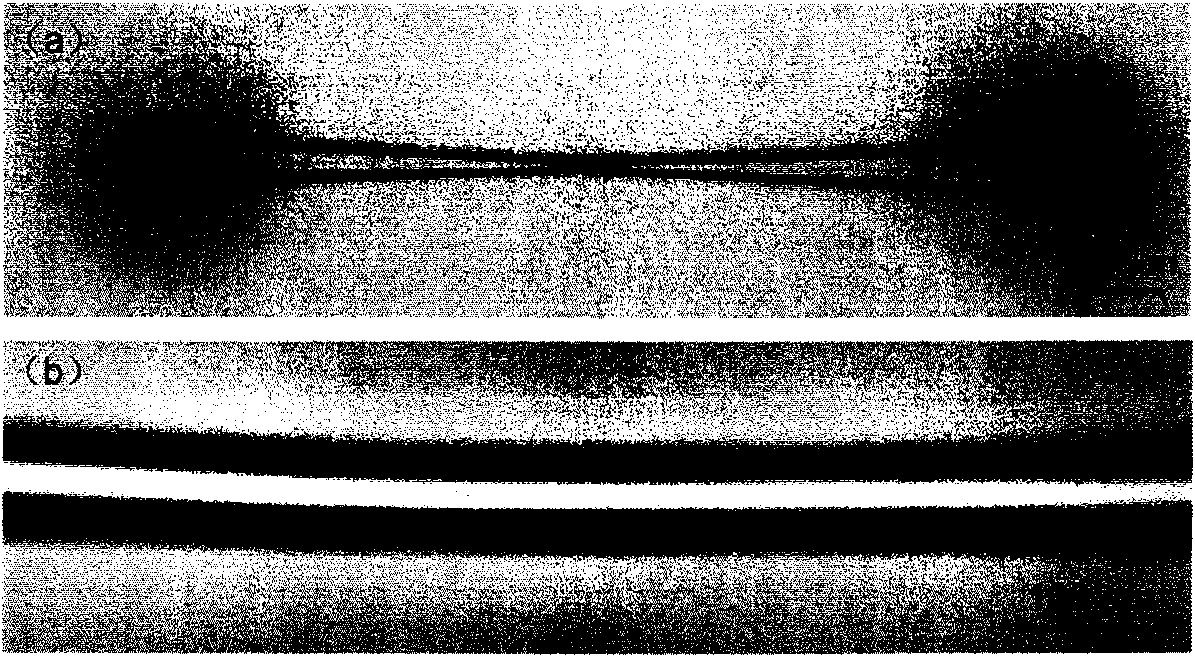

Method and device for cutting transparent material by using ultra-short pulse laser

ActiveCN102785031AAccelerateSmall kerfFine working devicesGlass severing apparatusMaterial consumptionTransfer procedure

The invention provides a method for cutting a transparent material by using ultra-short pulse laser. The ultra-short pulse laser output by an ultra-short pulse laser generating device is condensed by a condensation device so as to form a bunching laser beam; the bunching laser beam enters from the surface of the transparent material to be machined, so that the center refractive index at a laser application point is increased to form a waveguide structure along a laser emitting direction; the laser is transmitted to the inside of the transparent material along the waveguide structure, and continuously generates a waveguide structure along the laser emitting direction in a transmission process until the entire waveguide structure and the laser penetrate through the transparent material; and therefore, the laser moves in a direction which is vertical to the surface of the transparent material at uniform speed, so that a waveguide plane is formed in the transparent material. The invention further provides a device for cutting the transparent material by using the ultra-short pulse laser. The method and the device for cutting the transparent material by using the ultra-short pulse laser provided by the invention have the advantages of fast cutting speed, small cutting seam, no material consumption and no powder pollution. When the machined material bears a suitable external force, the material is cracked only along a stress fault surface; the broken surface nearly has no conical degree; and the roughness is good.

Owner:WUHAN JUNNO TECH

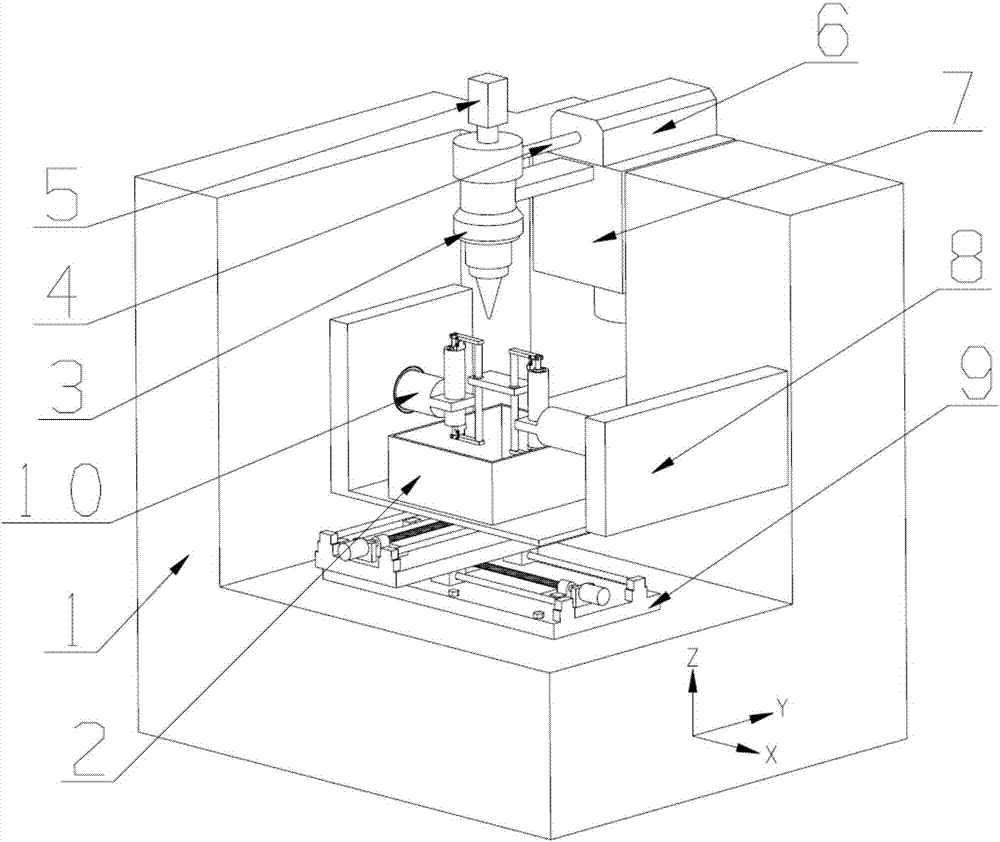

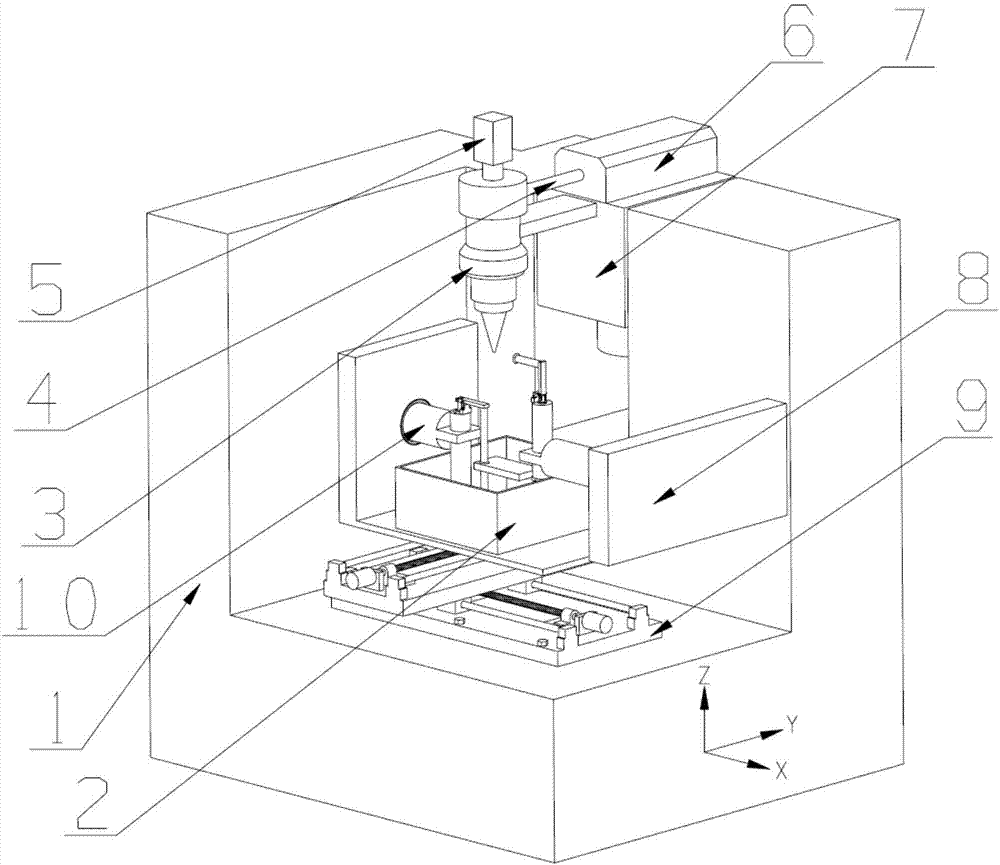

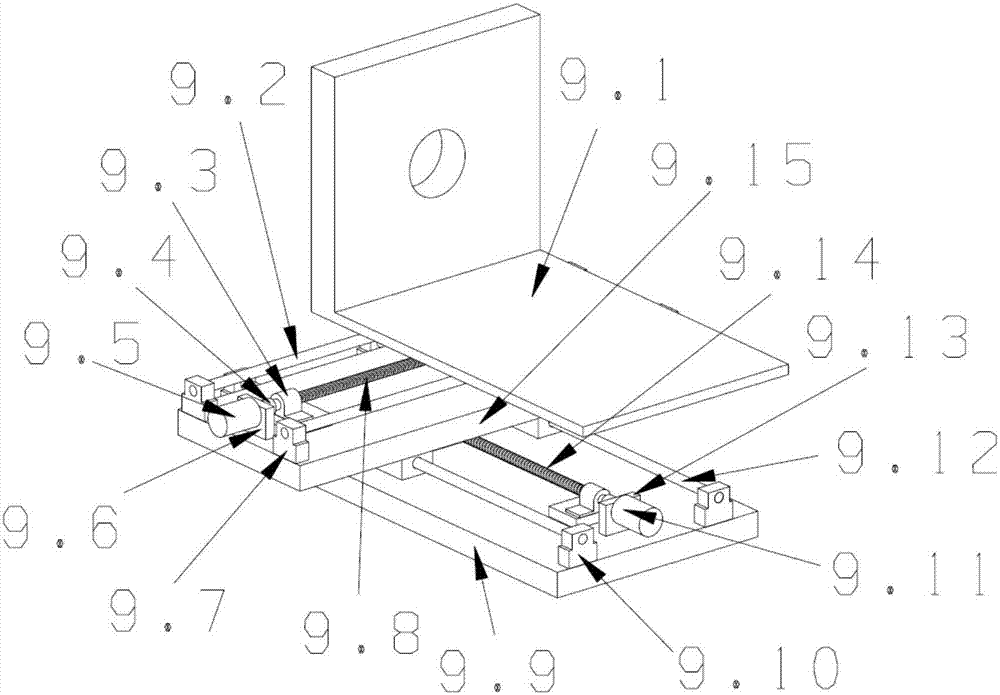

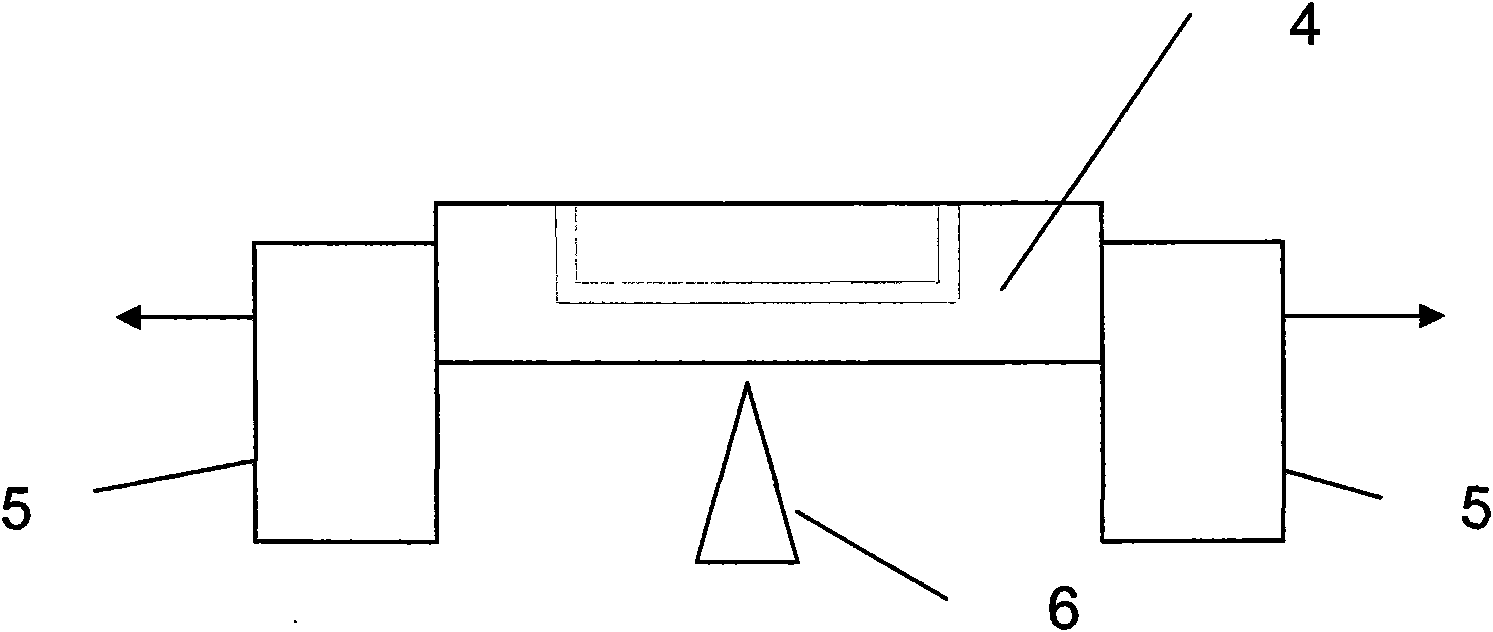

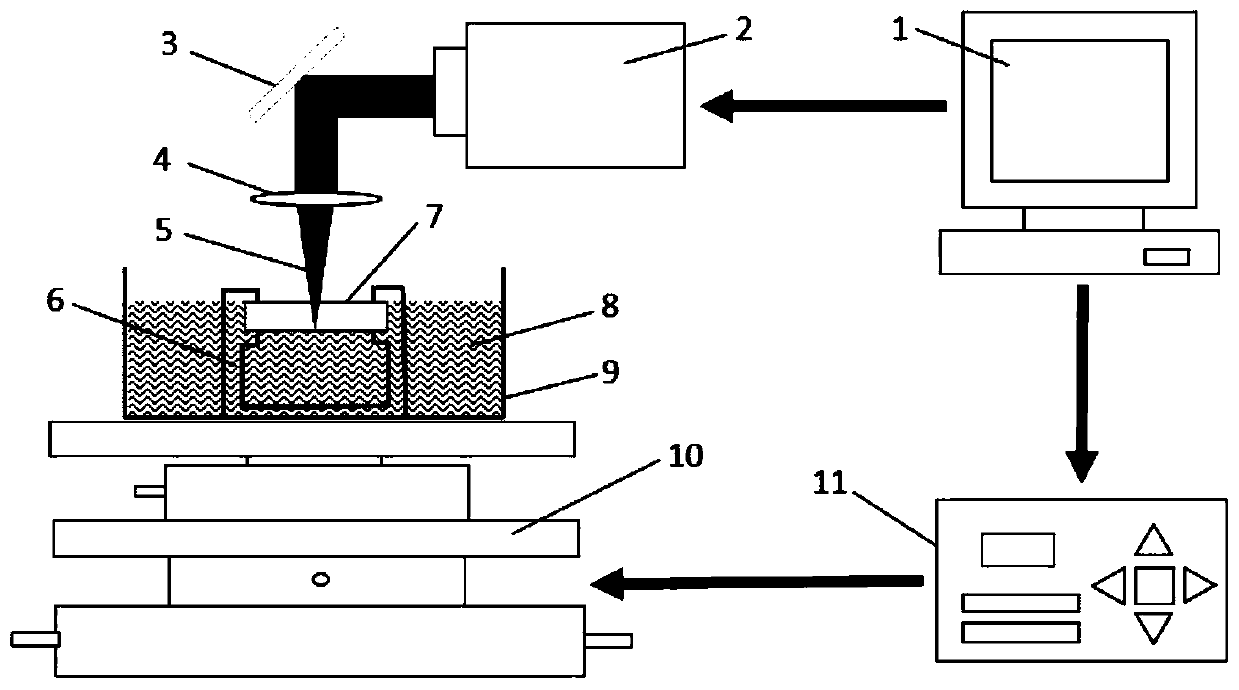

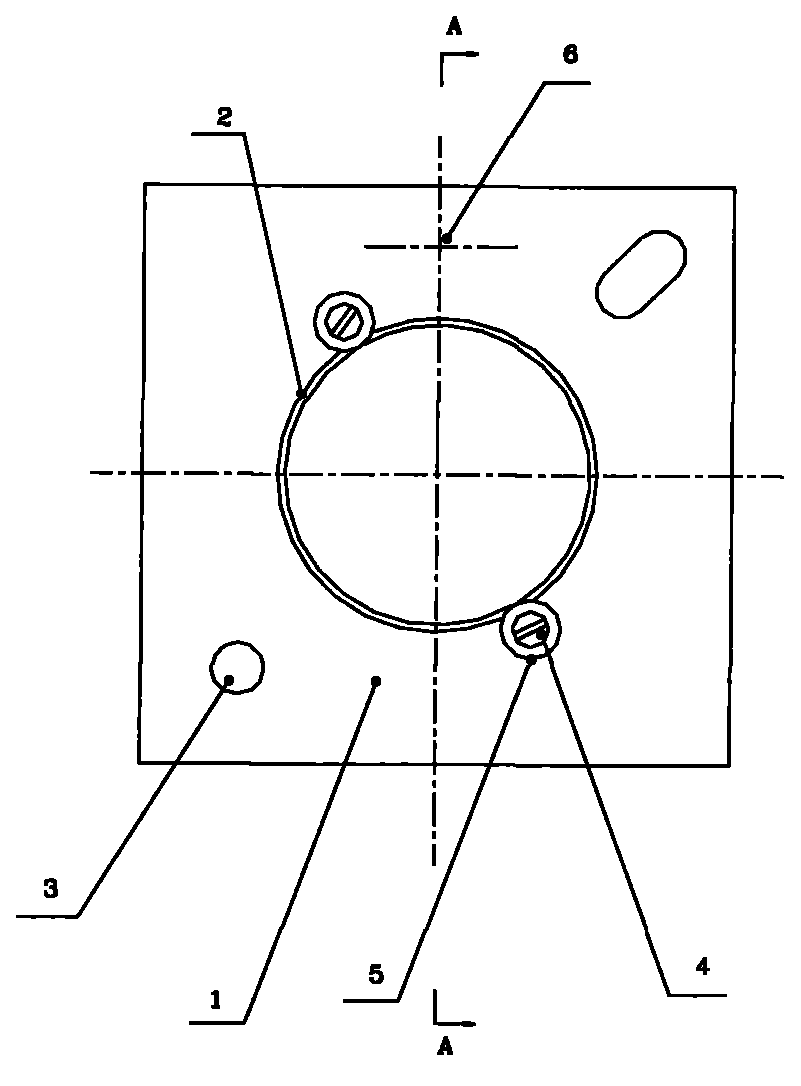

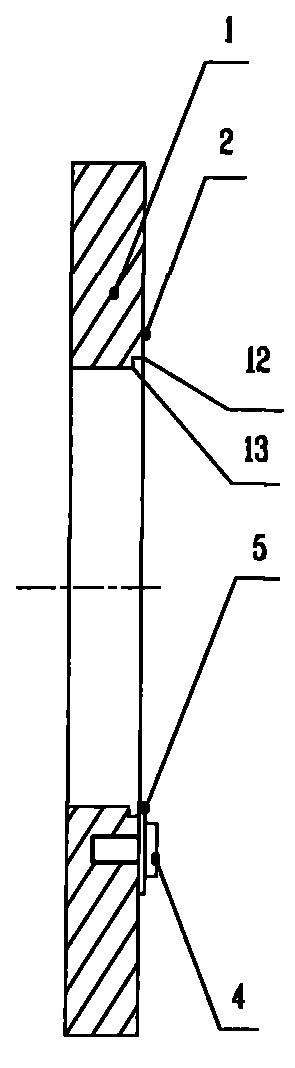

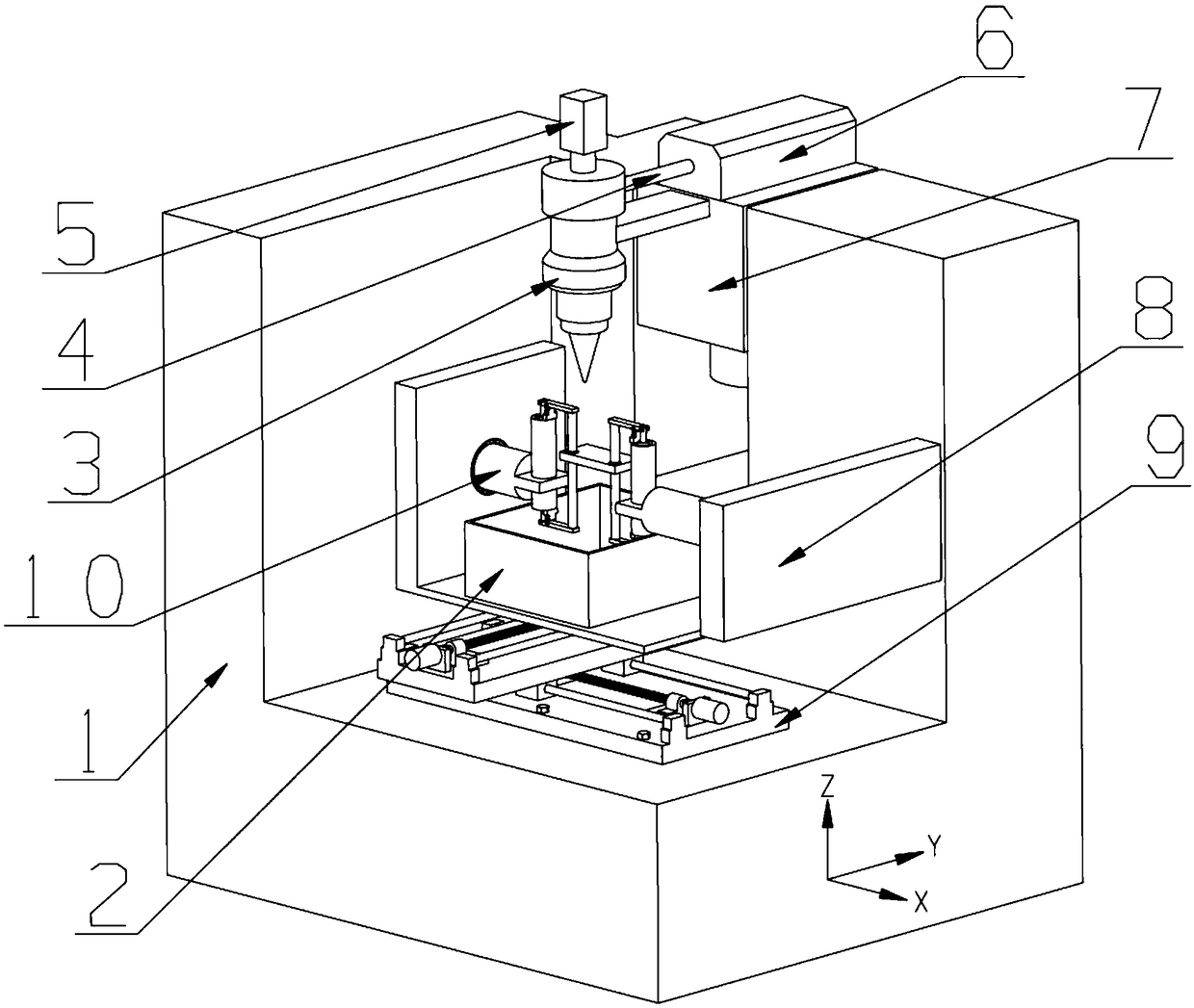

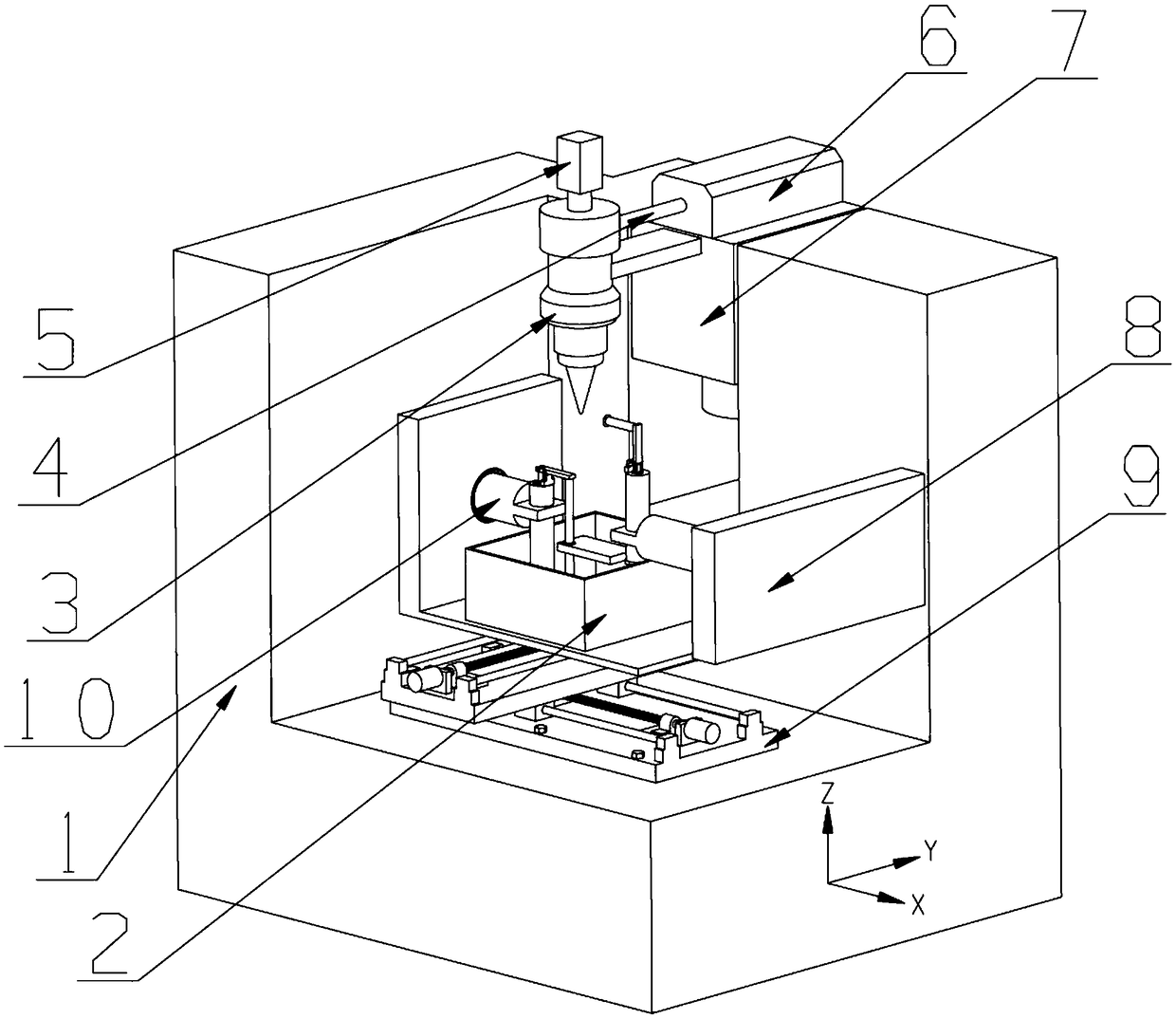

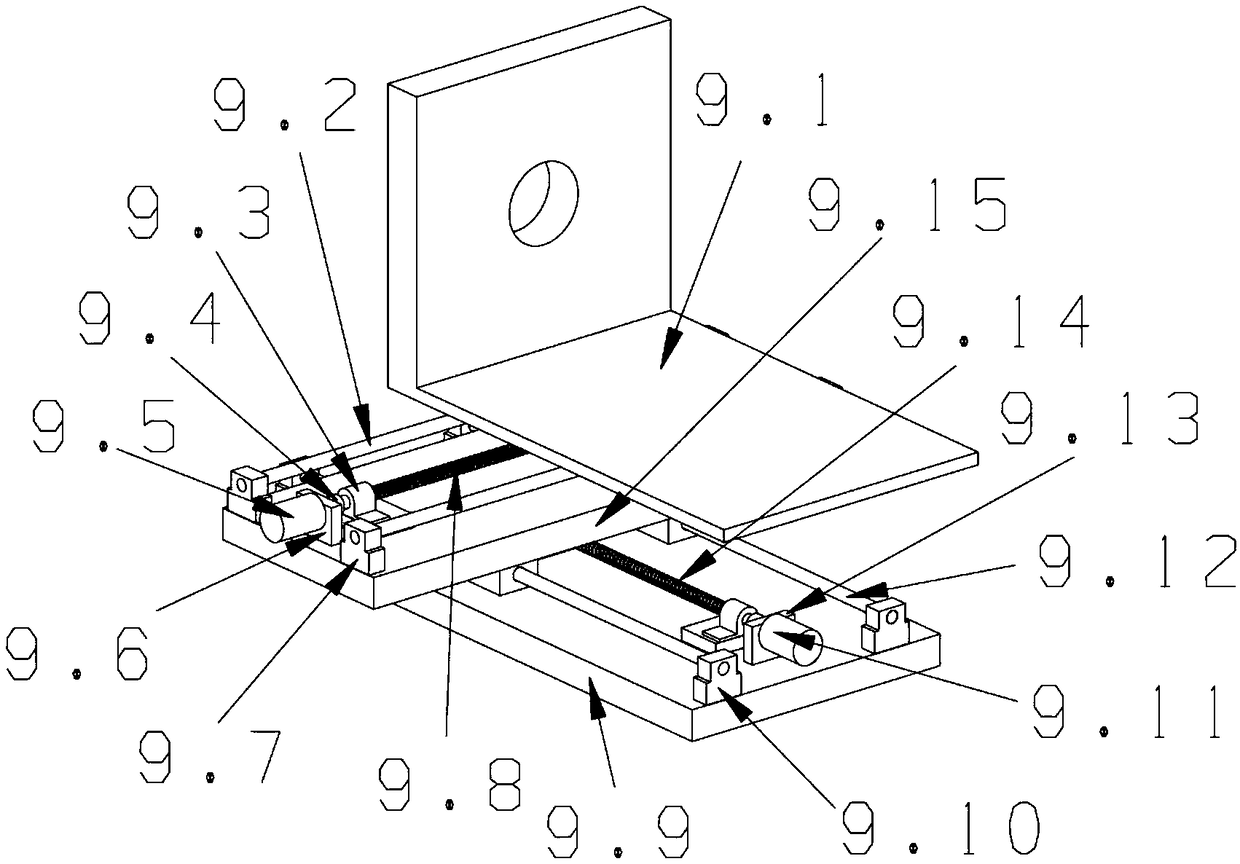

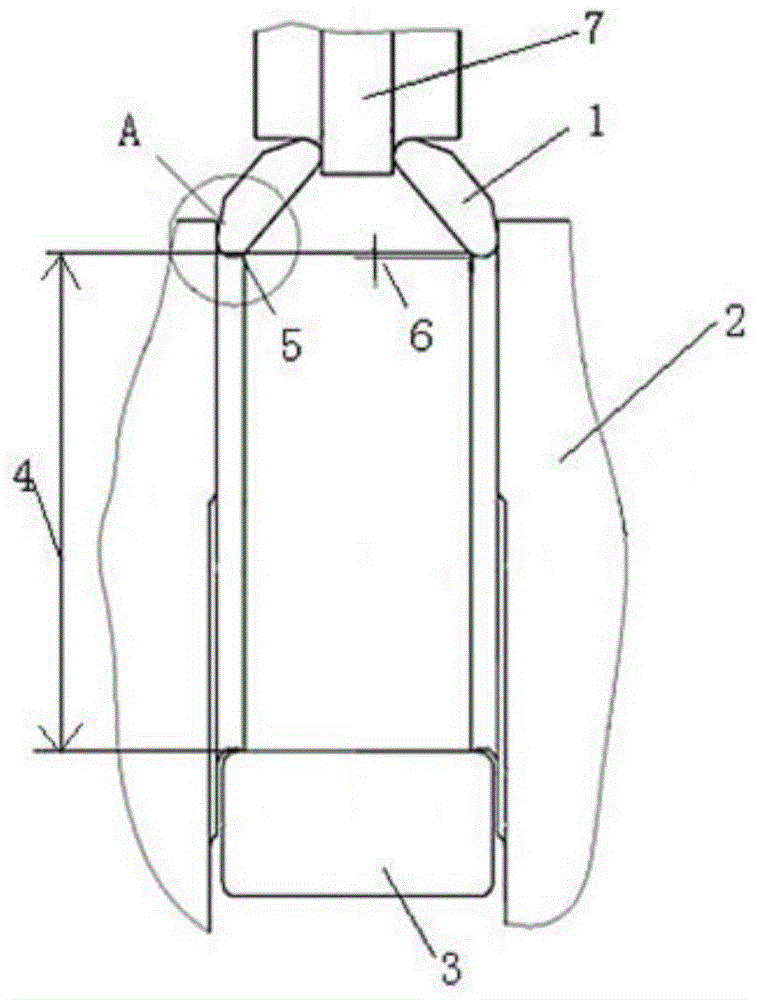

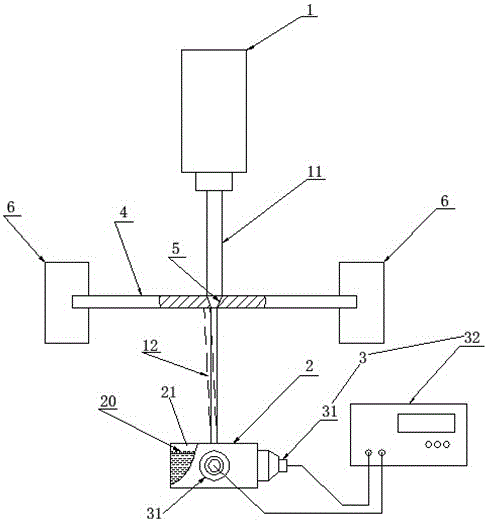

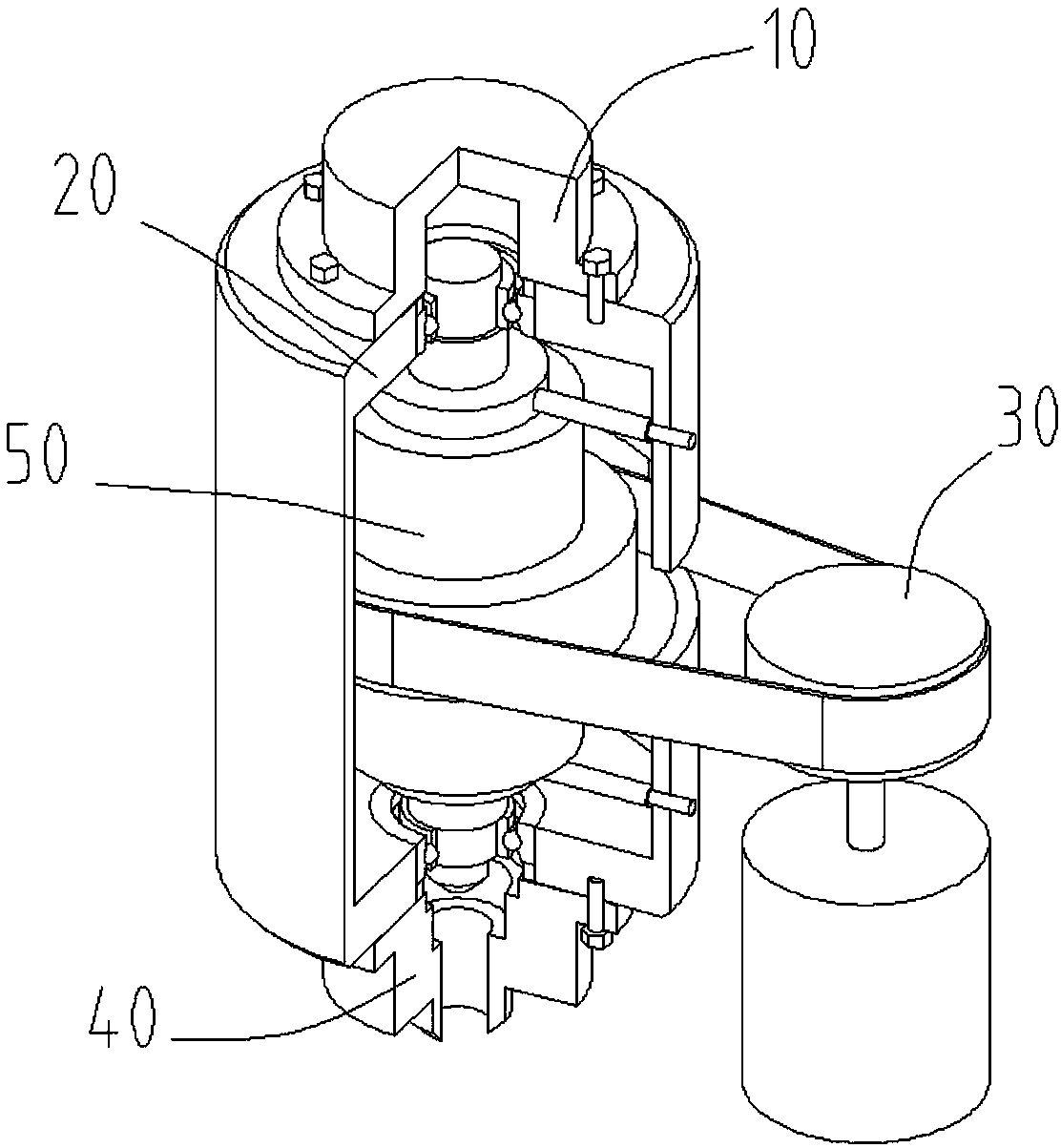

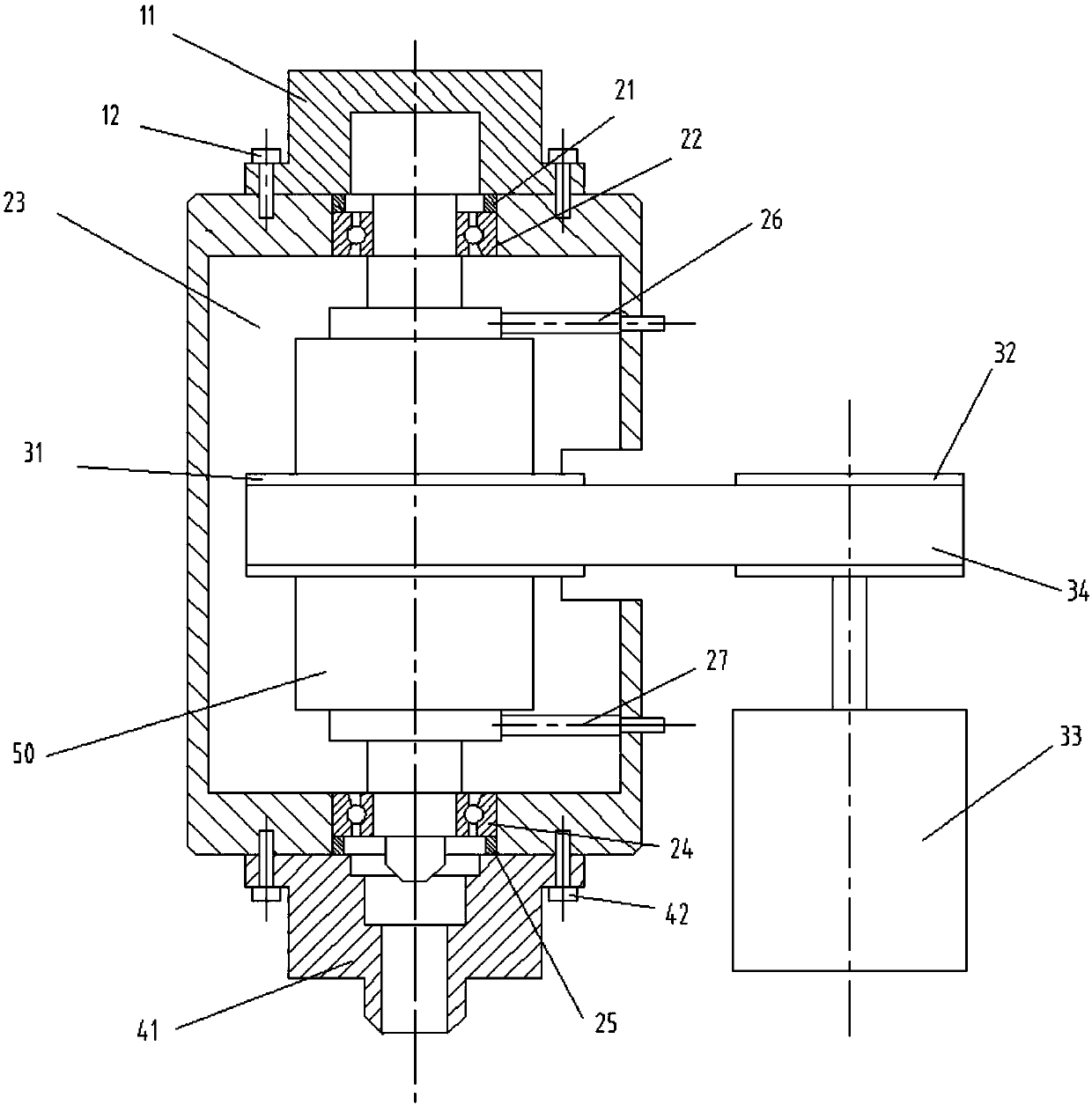

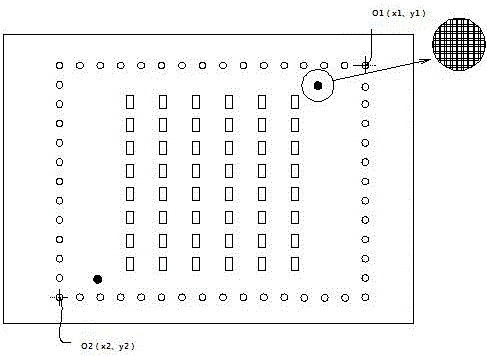

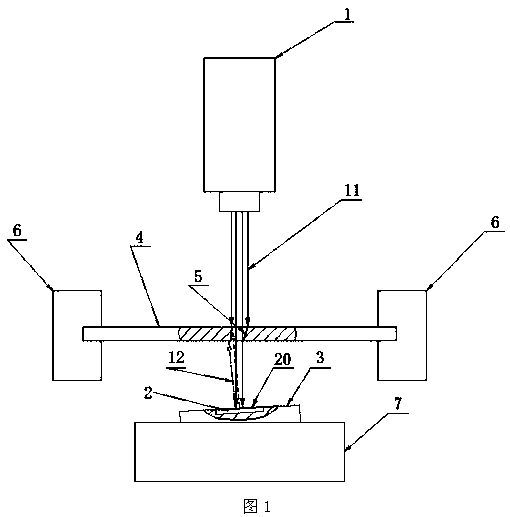

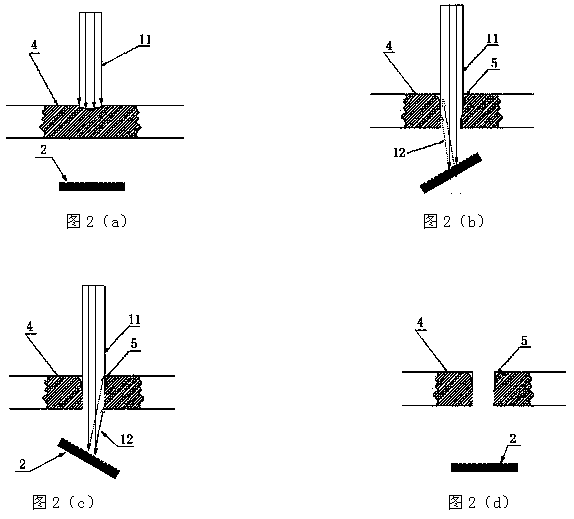

Laser perforating device capable of improving conical degree and inner wall quality of hole and method

ActiveCN107486640AImprove taperSuitable for group hole processingWelding/cutting auxillary devicesAuxillary welding devicesCavitationOptoelectronics

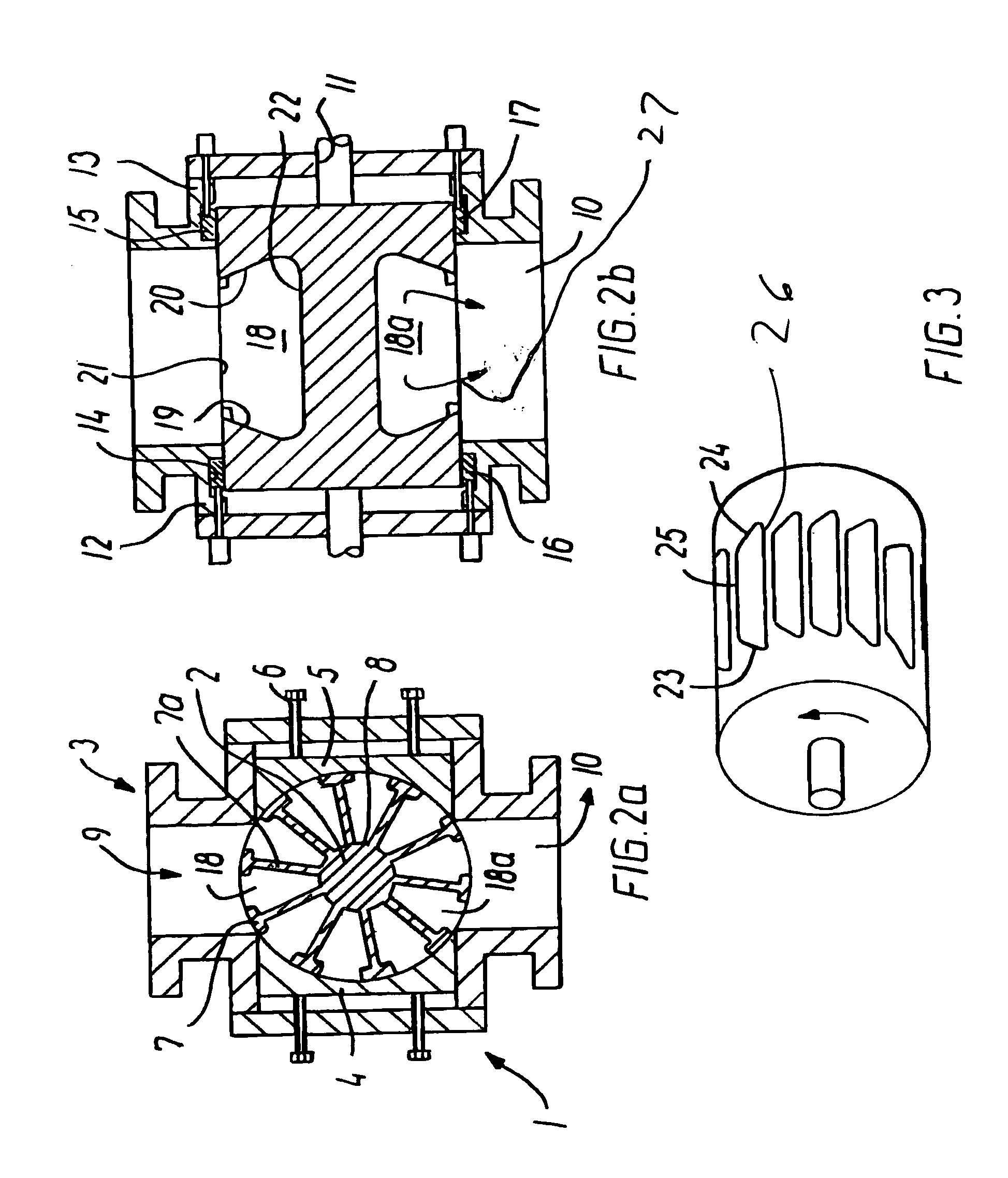

The invention discloses a laser perforating device capable of improving the conical degree and the inner wall quality of a hole, and a method. According to the method of the laser perforating device, a workpiece is subjected to primary laser perforating and then rotates 180 degrees in the x direction of the hole through a rotatable clamp, so that the workpiece is just soaked into water, x and y coordinates of the small hole are not changed, and then secondary laser perforating is conducted through a laser-induced cavitation technology; and in addition, the laser perforating device capable of improving the conical degree and the inner wall quality of the hole is designed and comprises a power box, an uncovered cuboid container, a laser head, a laser guide pipe, a CCD camera, a laser device, a z-direction moving mechanism, a fixing clamp device, an x-y moving platform and a rotatable clamp device. According to the laser perforating device and the method thereof, the mode of conducting laser perforating in air and the mode of conducting laser perforating in water are coupled, secondary perforating is completed by turning over the workpiece so that the conical degree of the hole can be improved, the laser perforating technology and the laser-induced cavitation technology are combined in the secondary perforating process, and the inner wall of the hole is strengthened by impact waves generated through cavitation.

Owner:JIANGSU UNIV

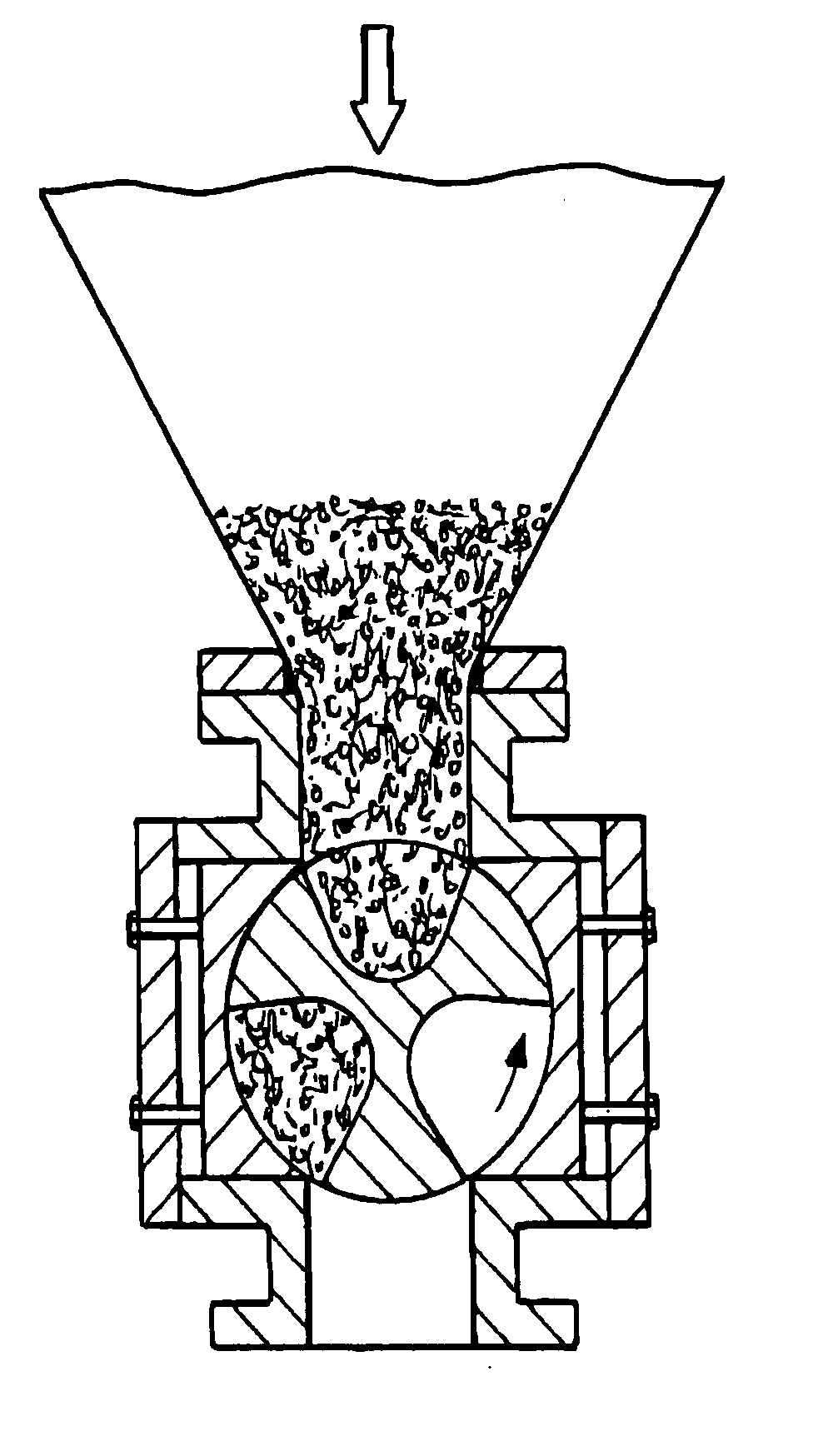

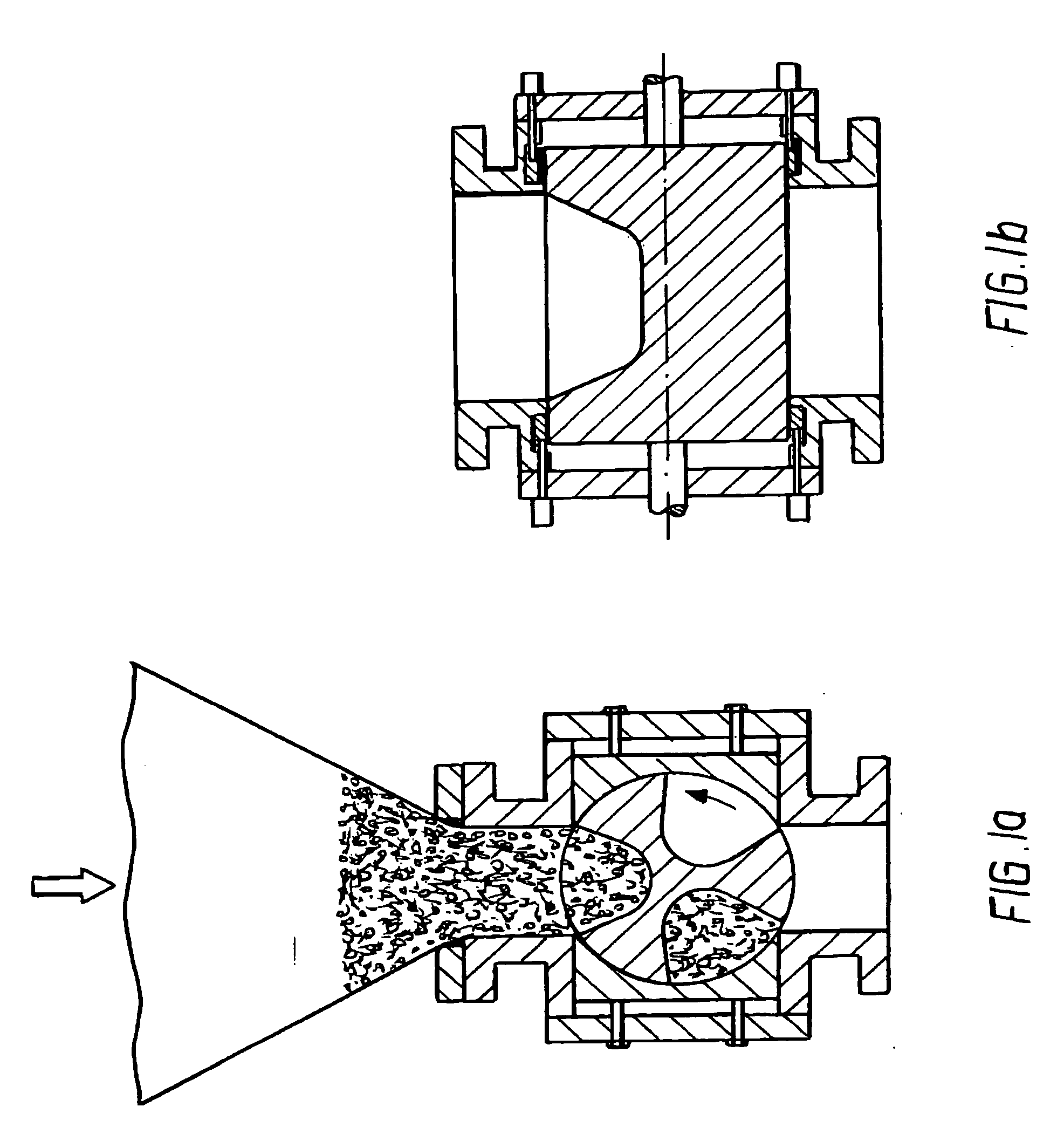

Rotary airlock valve

ActiveUS20050098586A1Reduce wearDifficult to handleMovable measuring chambersBulk conveyorsLeading edgeTrailing edge

A rotary airlock valve has a plurality of material receiving pockets having leading edges that are narrower than the trailing edges thereof, preferably having walls tapering inwardly so as to define a narrowed pocket opening for directing any material expansion due to pressurization to a center of a discharge outlet, to reduce wear and increase seal life.

Owner:ASJ HLDG

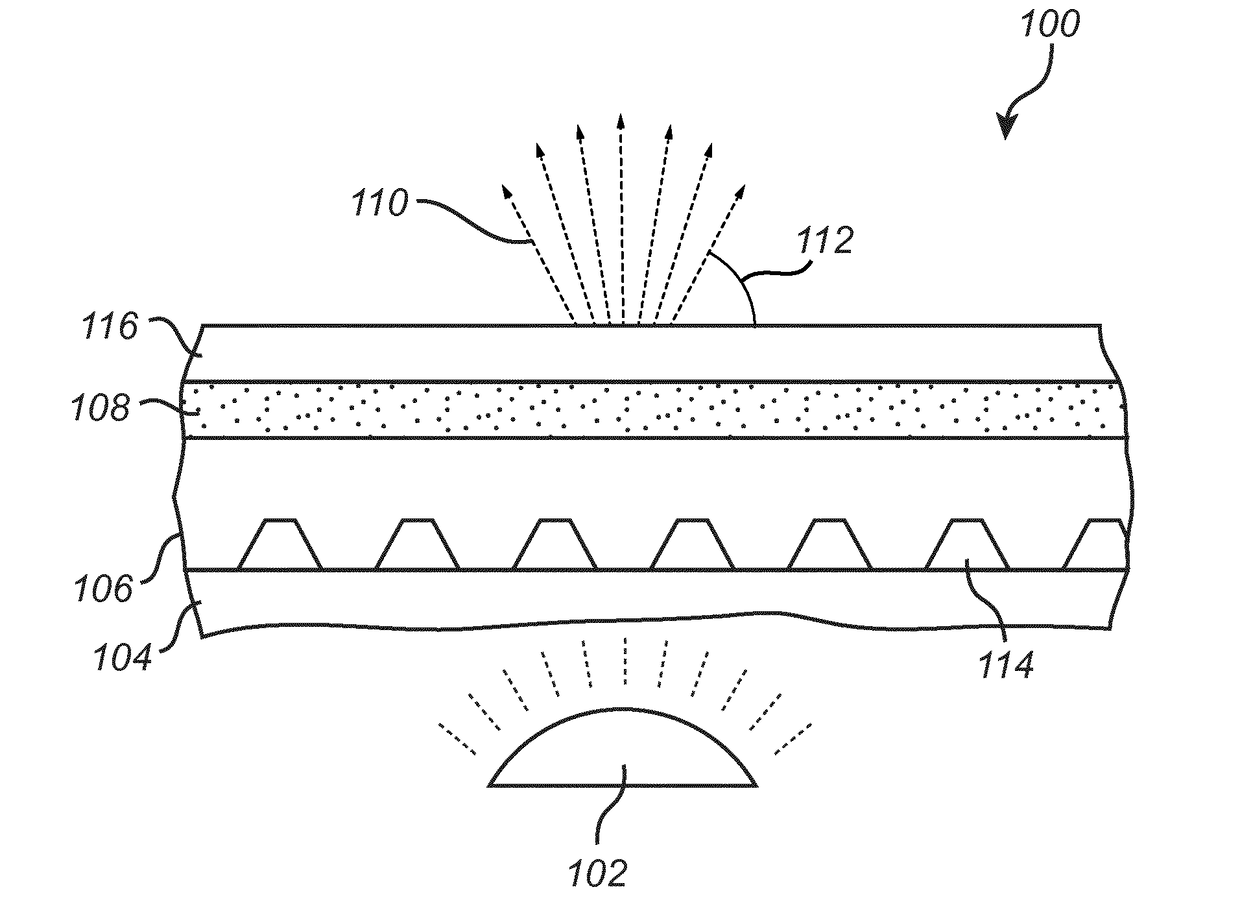

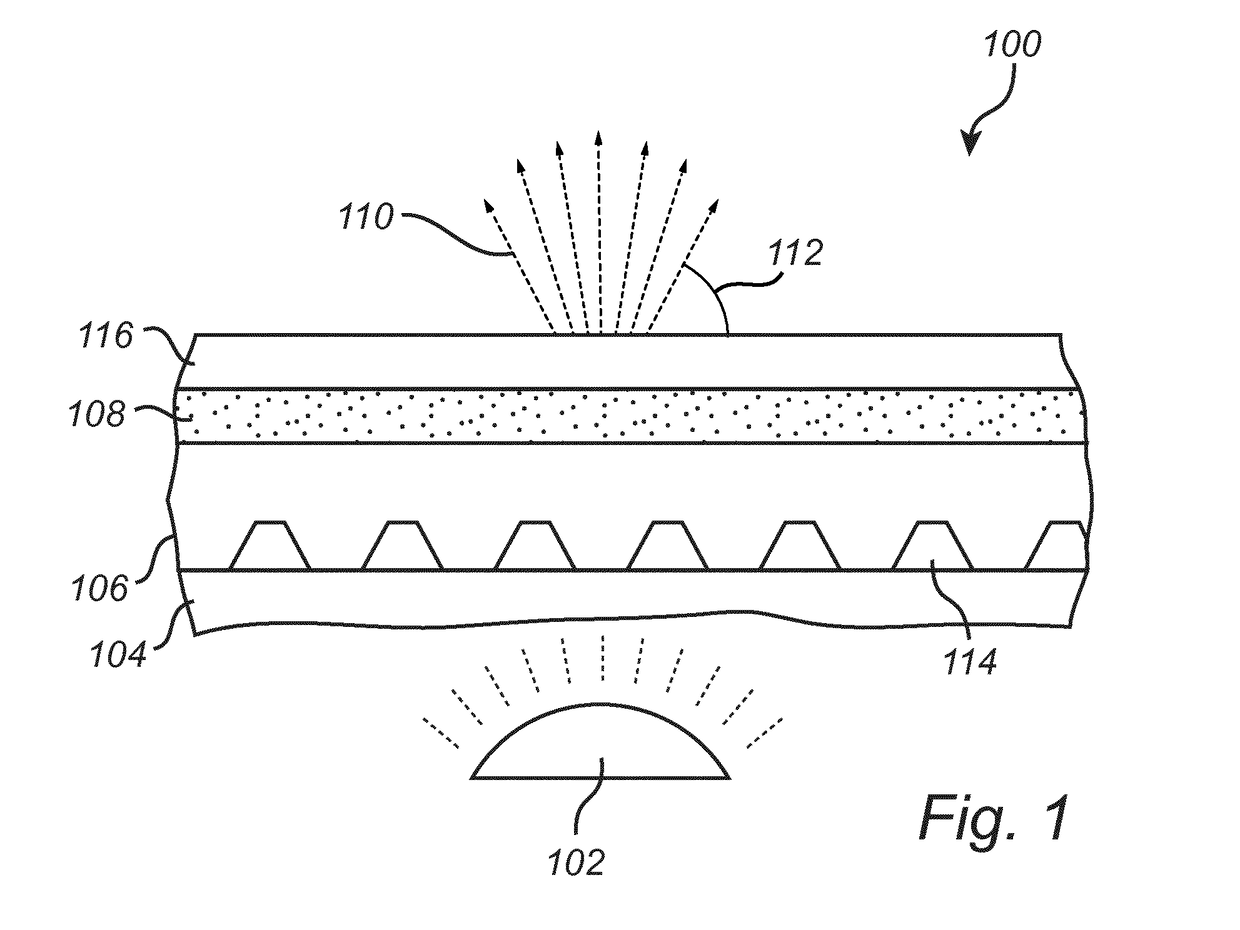

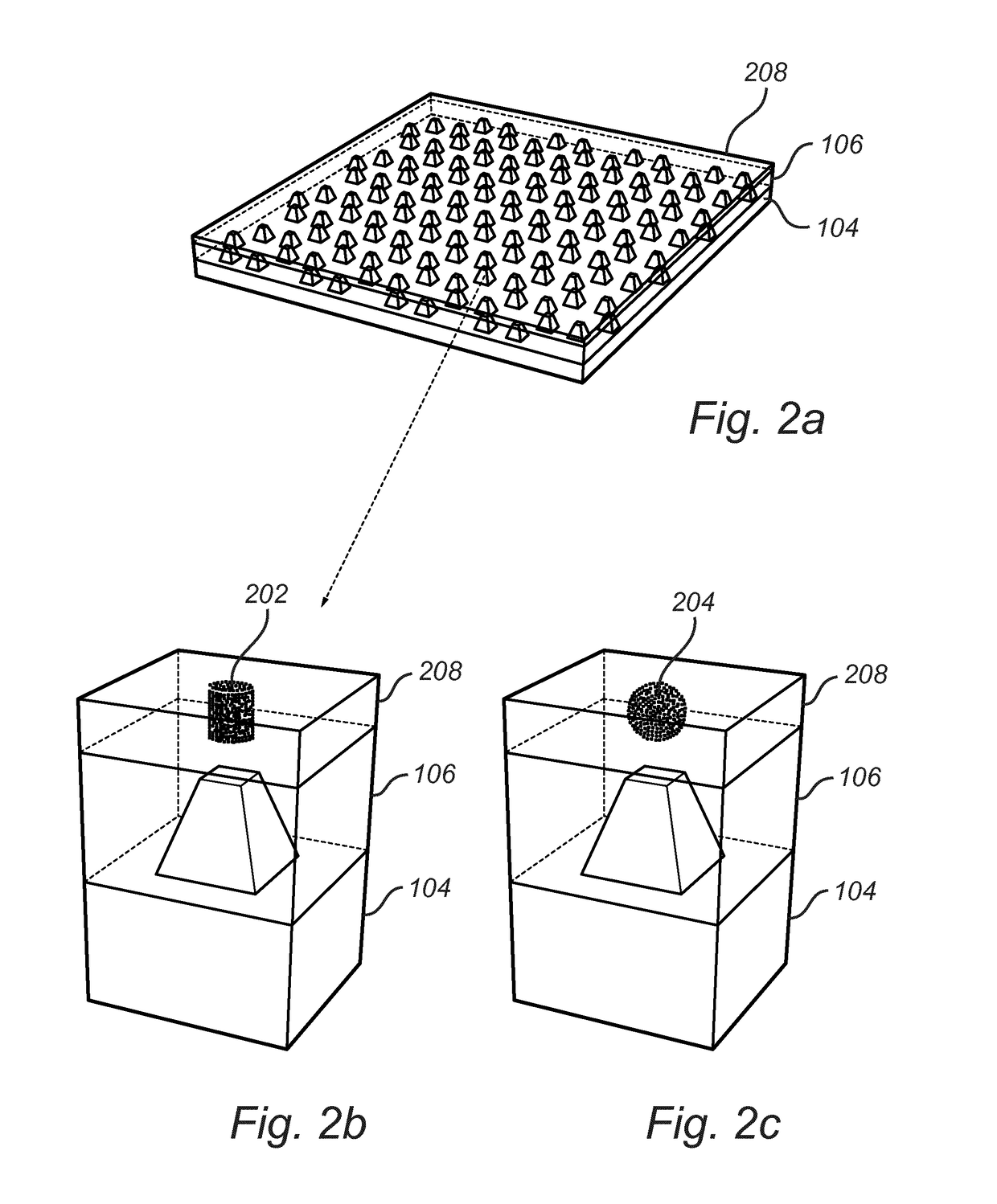

Spatial positioning of photon emitters in a plasmonic illumination device

ActiveUS20170082785A1Improve responseImprove taperSpectral modifiersNon-linear opticsSpatial positioningPhoton emission

There is provided an illumination device (100) comprising: a substrate (104); an optically transmissive first layer (106) arranged on the substrate; a photon emitting layer (108), arranged on the optically transmissive first layer and comprising a photon emitting material configured to receive energy from an energy source and to emit light having a predetermined wavelength; a periodic plasmonic antenna array, arranged on the substrate and embedded within the first layer, and comprising a plurality of individual antenna elements (114) arranged in an antenna array plane, the plasmonic antenna array being configured to support a first lattice resonance at the predetermined wavelength, arising from coupling of localized surface plasmon resonances in the individual antenna elements to photonic modes supported by the system comprising the plasmonic antenna array and the photon emitting layer, wherein the plasmonic antenna array is configured to comprise plasmon resonance modes such that light emitted from the plasmonic antenna array has an anisotropic angle distribution; and wherein the photon emitting layer is arranged at a distance from the antenna array plane corresponding to a location of maximum field enhancement for light out-coupling resulting from the plasmonic-photonic lattice resonances.

Owner:LUMILEDS

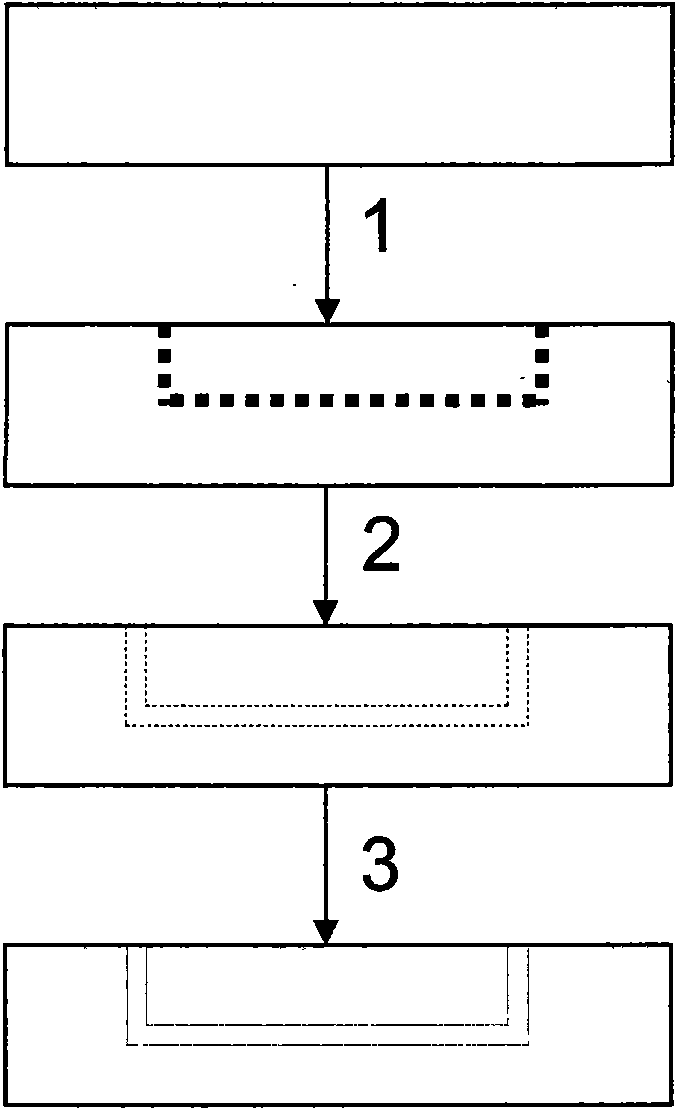

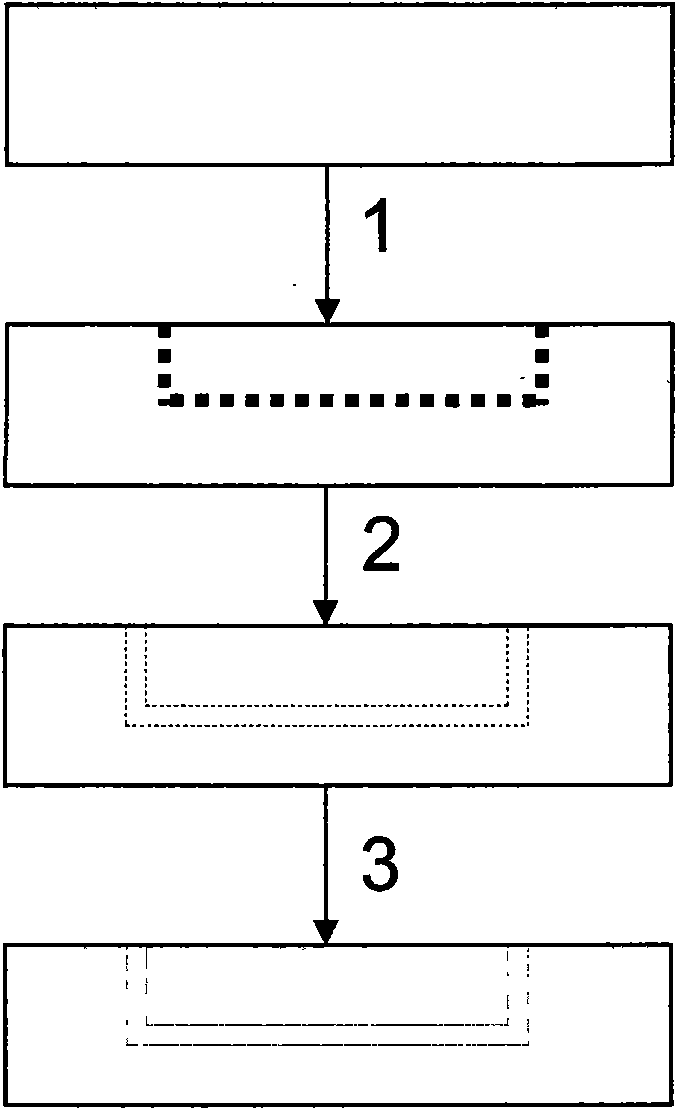

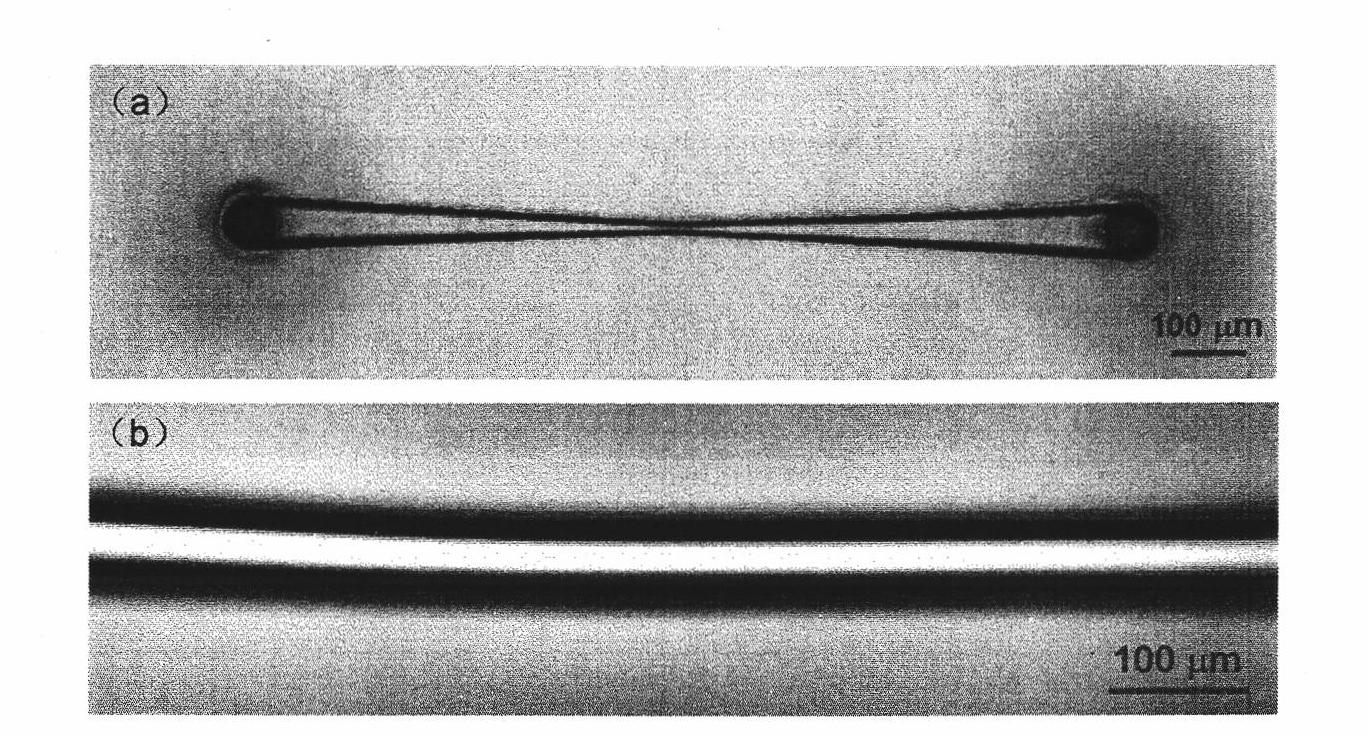

Method for preparing uniform three dimensional nanometer fluid passage by femto-second laser

InactiveCN101549852AUniform longitudinal shapeImprove taperNanostructure manufactureFemto second laserCompound (substance)

A method for preparing uniform three dimensional nanometer fluid passage by femto-second laser comprises the steps of irradiating transparent material by femto-second laser, chemical attacking and hot drawing. the three dimensional nanometer fluid passage prepared by the method in the invention achieves the advantages of uniform longitudinal appearance, good roundness of passage cross section, high smoothness of the passage inner wall and small passage inner diameter to nanometer scale.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

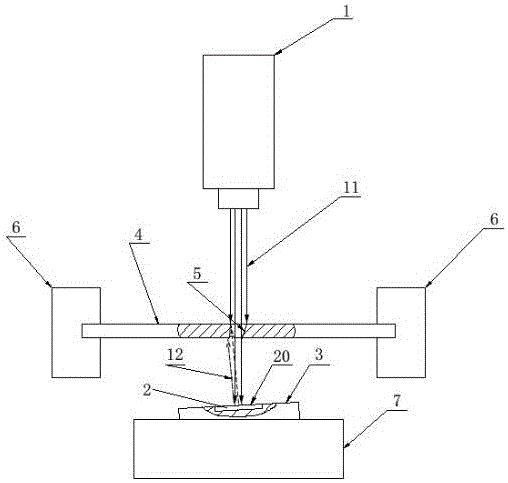

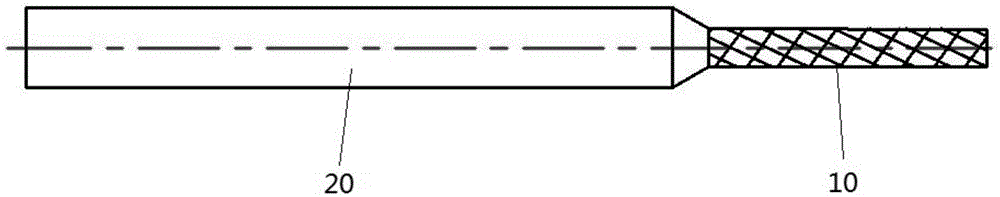

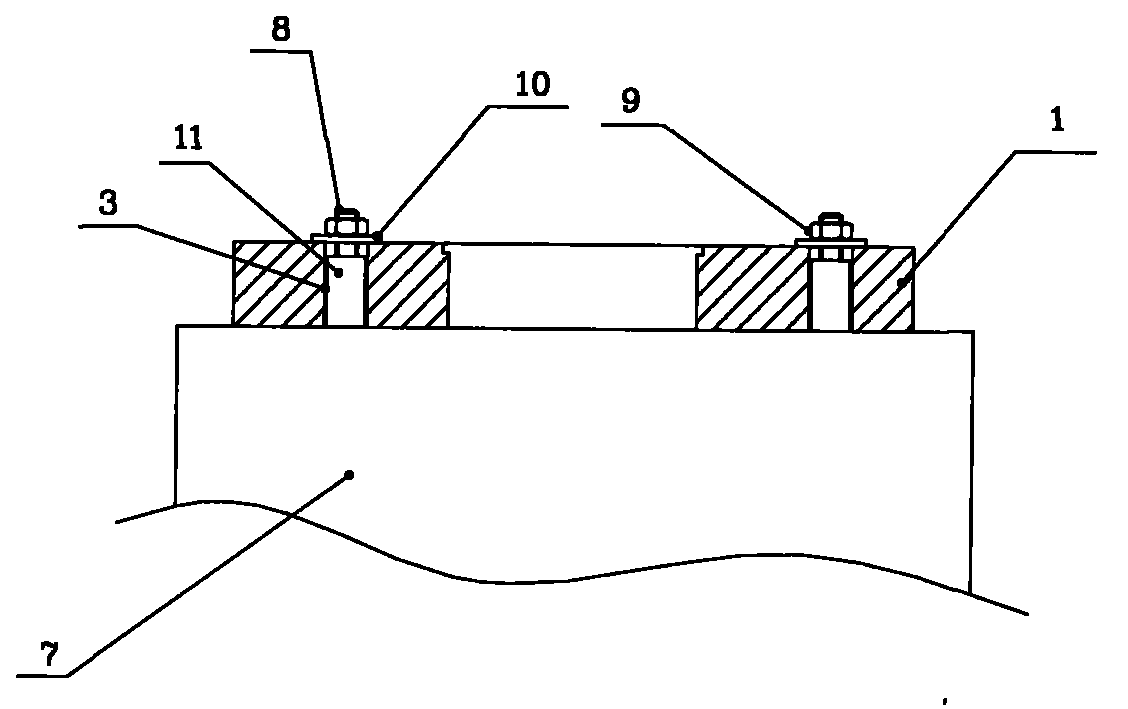

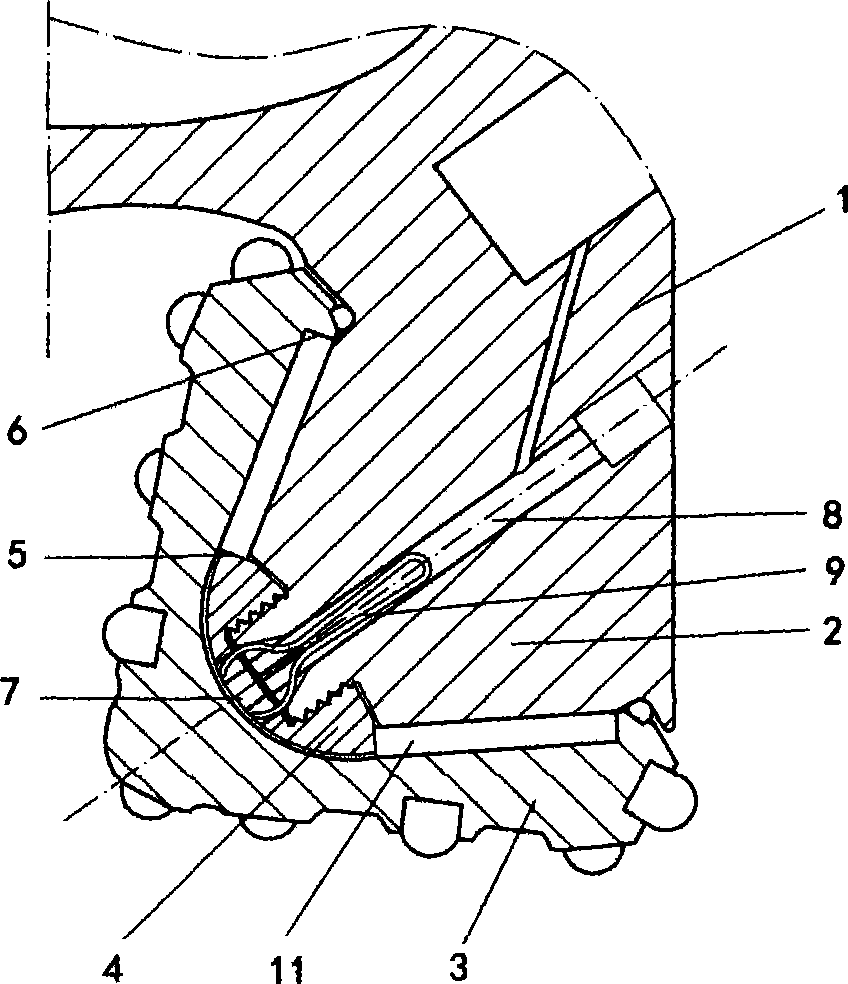

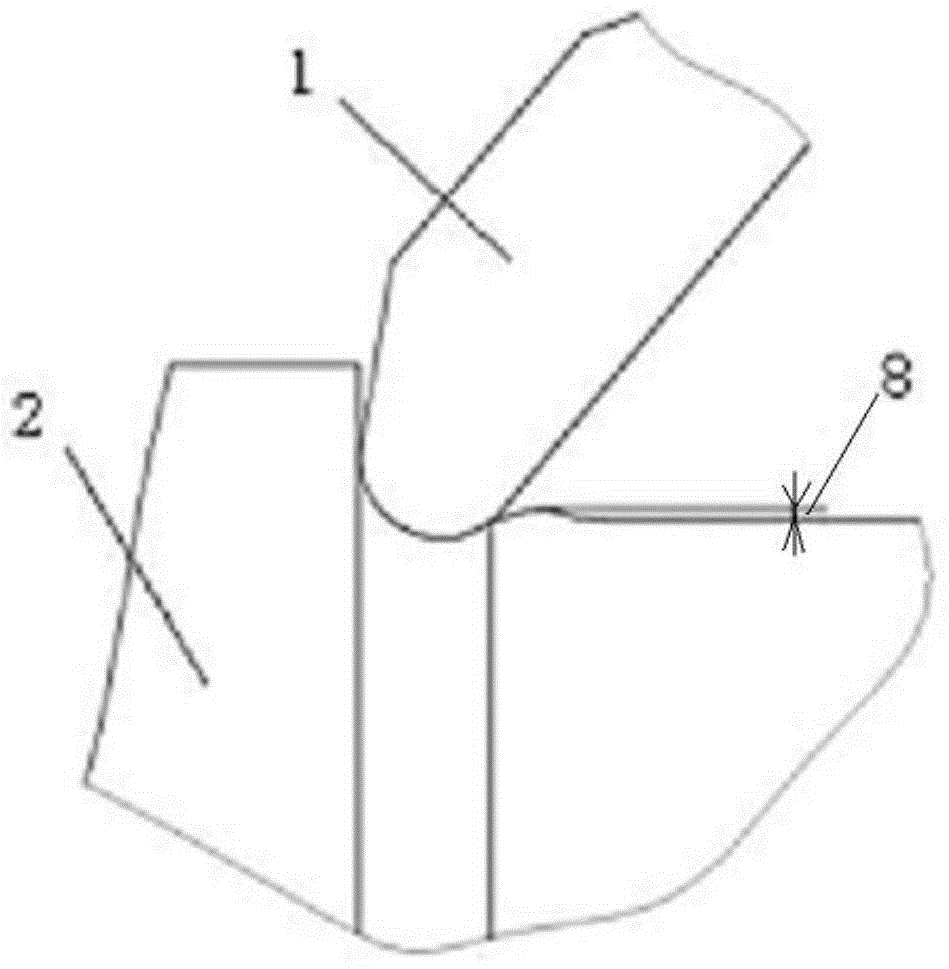

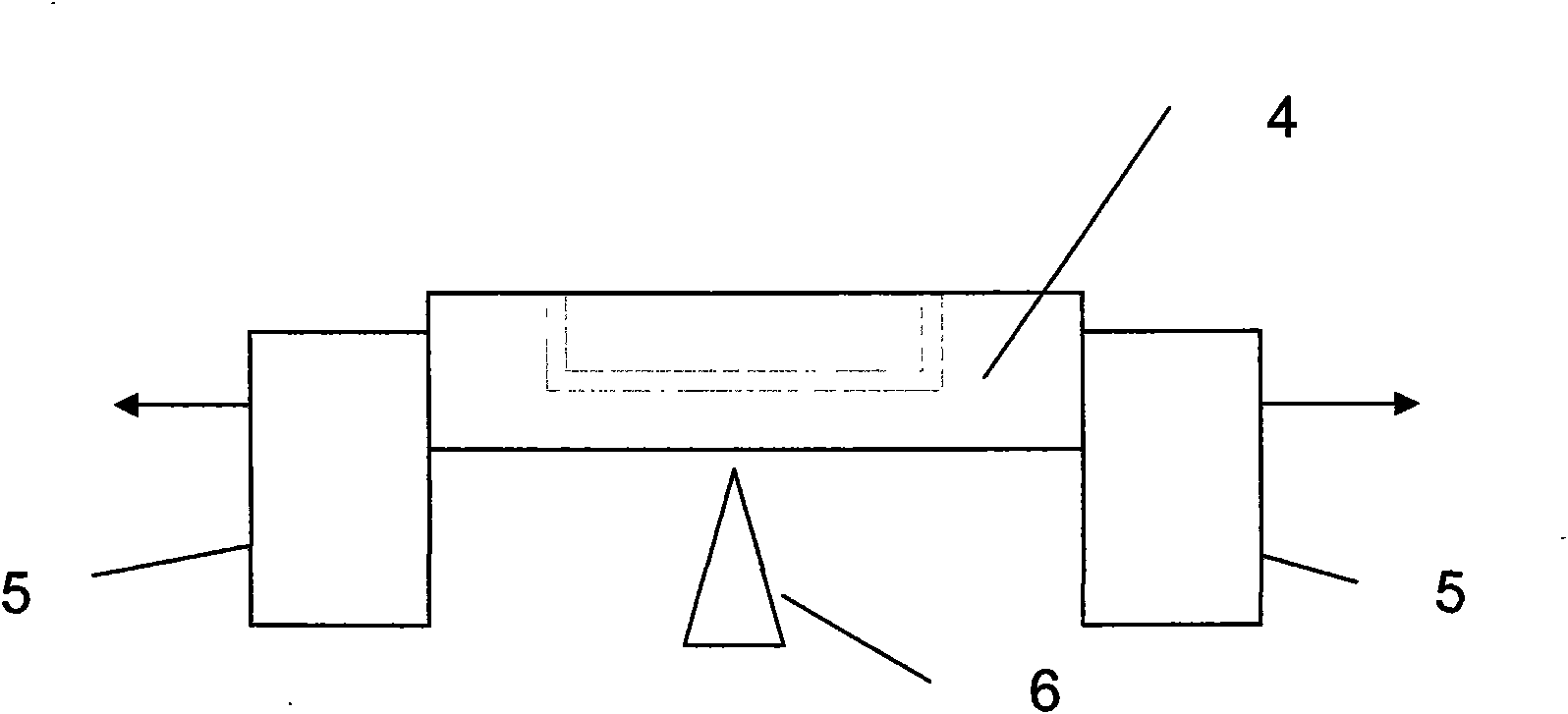

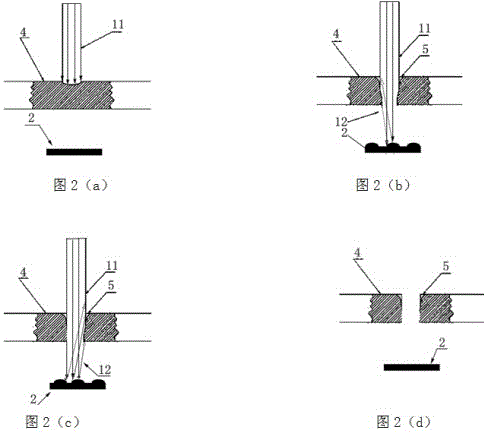

Laser drilling device and method capable of improving hole taper

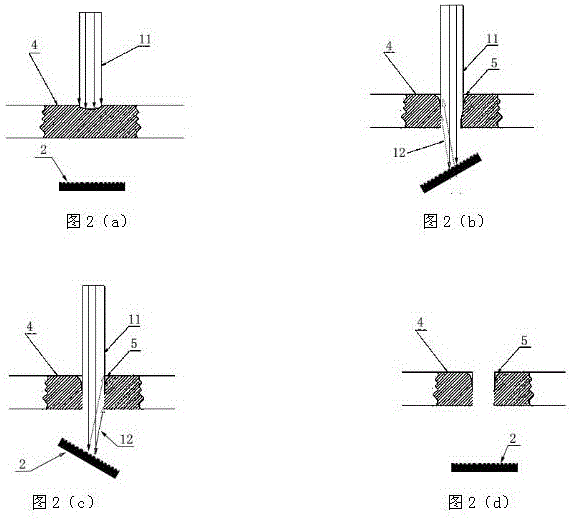

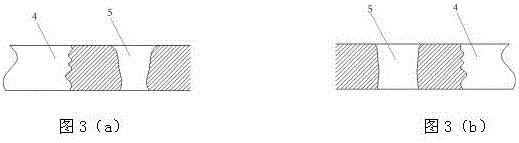

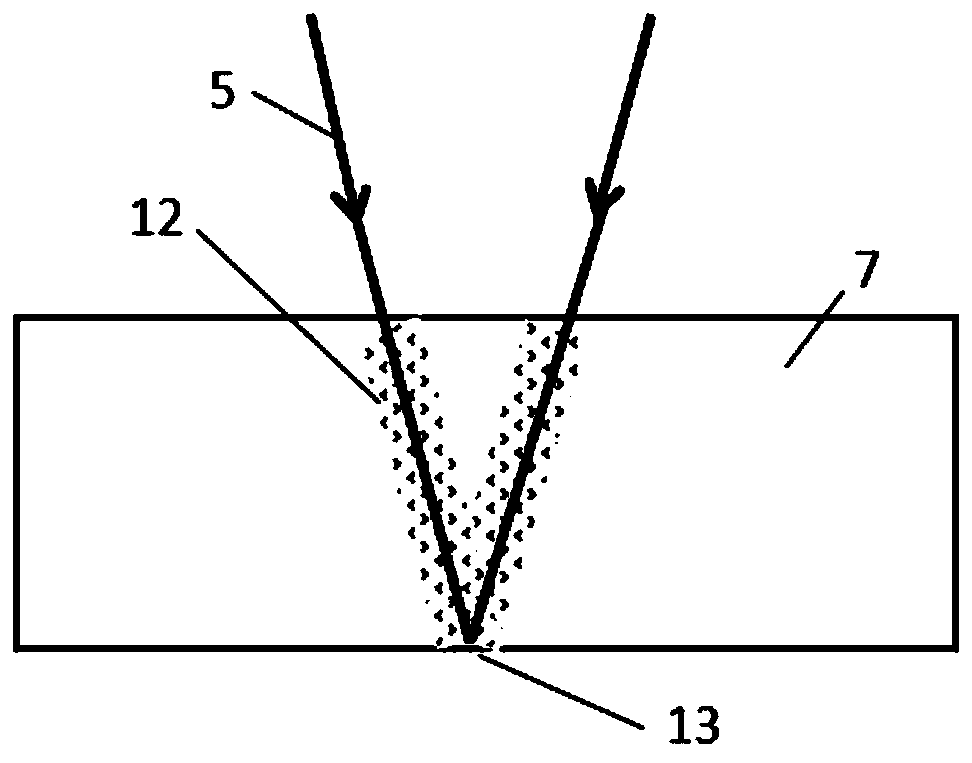

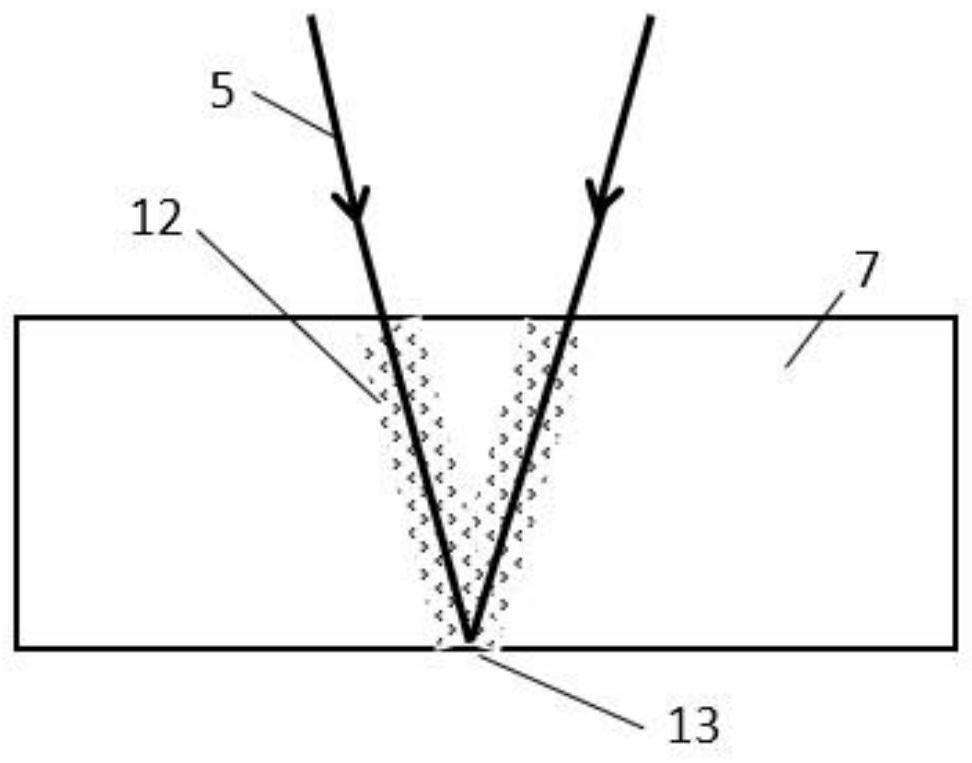

ActiveCN105904105AImprove taperOvercoming problems that require extremely high motion precision requirementsLaser beam welding apparatusOptoelectronicsLaser beams

The invention discloses a laser drilling device capable of improving hole taper. The laser drilling device comprises a laser generator and further comprises a reflection unit and a reflection regulating mechanism, wherein the laser generator is fixedly arranged on one side of a workpiece in a relative manner; the reflection unit and the reflection regulating mechanism are arranged on the other side of the workpiece; after the laser generator machines a through hole with a taper in the workpiece, the laser beams penetrate through the through hole, fall on the reflection plane of the reflection unit, and finally fall on the circumference and the inner wall of the through hole after being reflected on the reflection plane; the reflection regulating mechanism drives the reflection unit to move to enable the reflected laser beams to fall on different positions of the circumference and the inner wall of the through hole so as to gradually eliminate the taper in the through hole. Only the same laser generator is adopted to machine the target workpiece and improve dimensionality of the target workpiece so as to avoid the defects of complicated device, higher cost and difficulty in control caused by introduction of a magnetic field, a flow field and other energy fields, and simplify installation and application.

Owner:GUANGDONG UNIV OF TECH

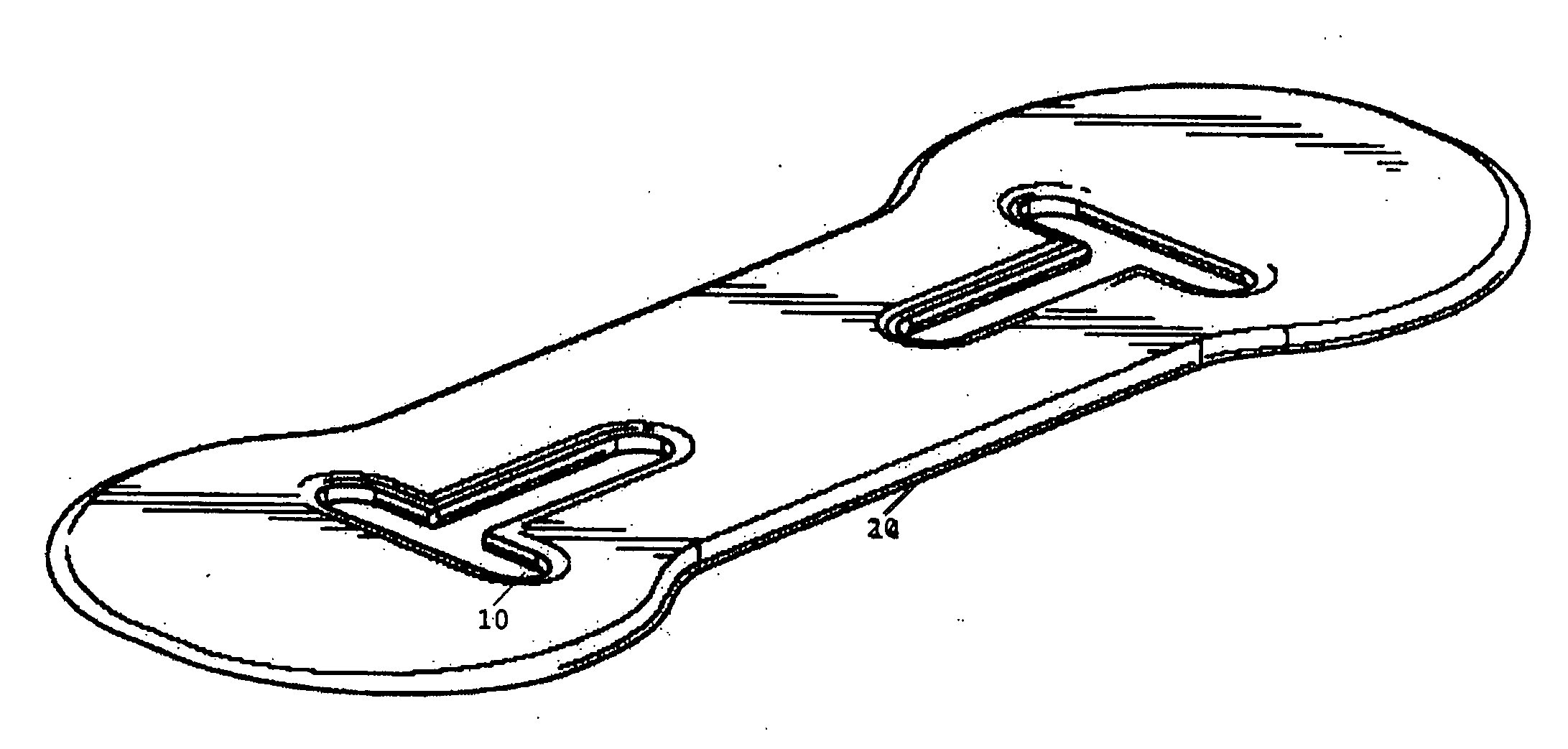

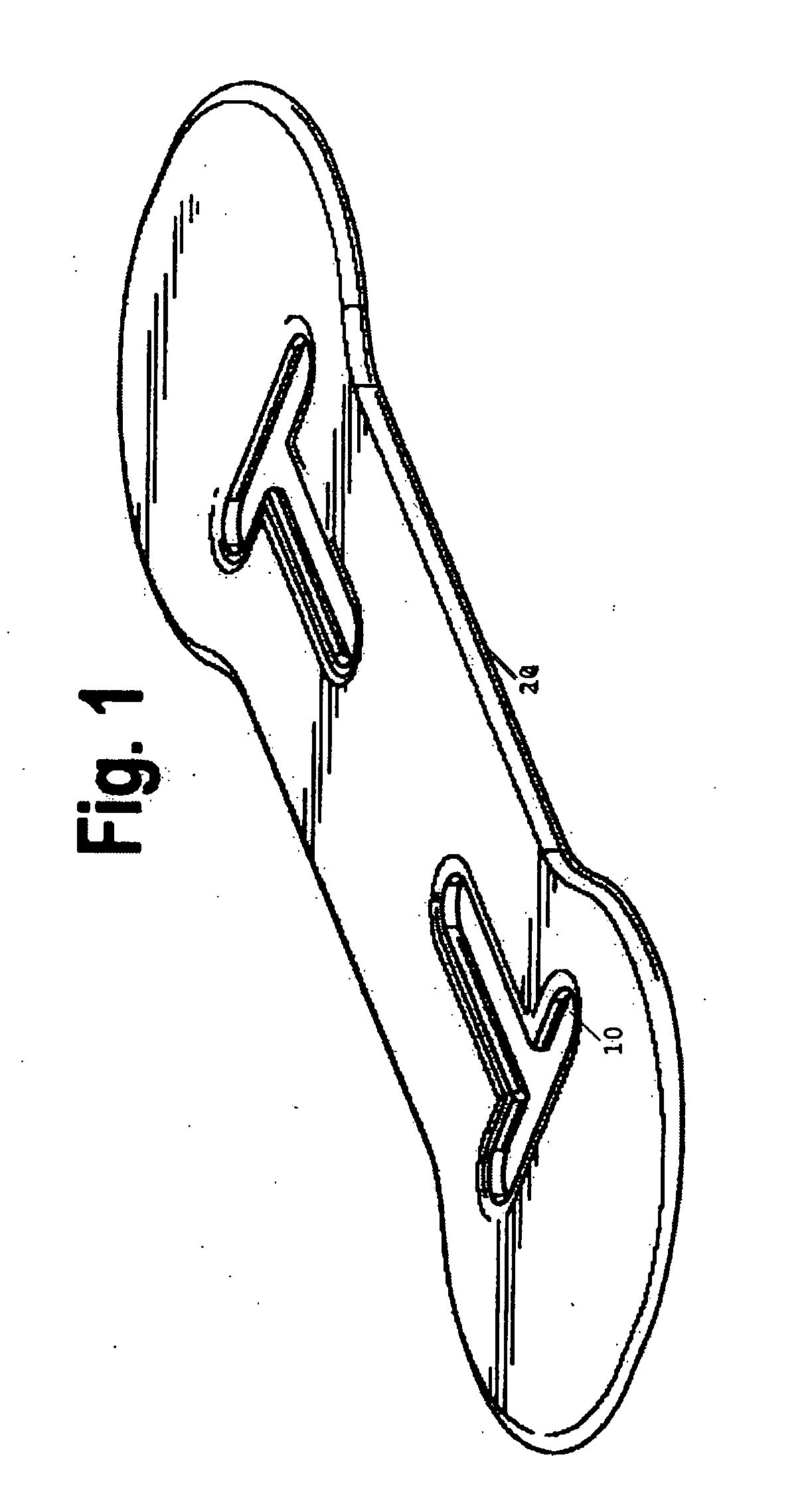

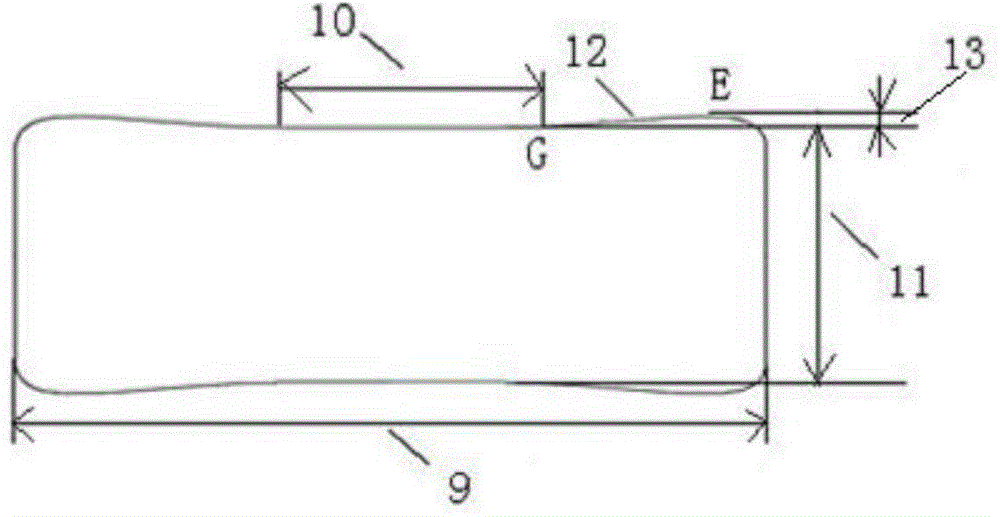

Patient transfer board

The patient transport board is a device that aids in the mobility of individuals who may be handicapped, patient recovering from surgery, undergoing physical therapy, or a number of other reasons. The patient transport board is slid under the individual. The patient transport board forms a bridge to the next location, which the individual slides across to. The individual can use the patient transport board on his or her own or with the help of an assistant or assistants. The patient transport board is a structure that can be made out of a number of suitable materials such as but not limited to wood, plastic, carbon fiber, fiberglass, composite covered honeycomb.

Owner:RAK JAMES

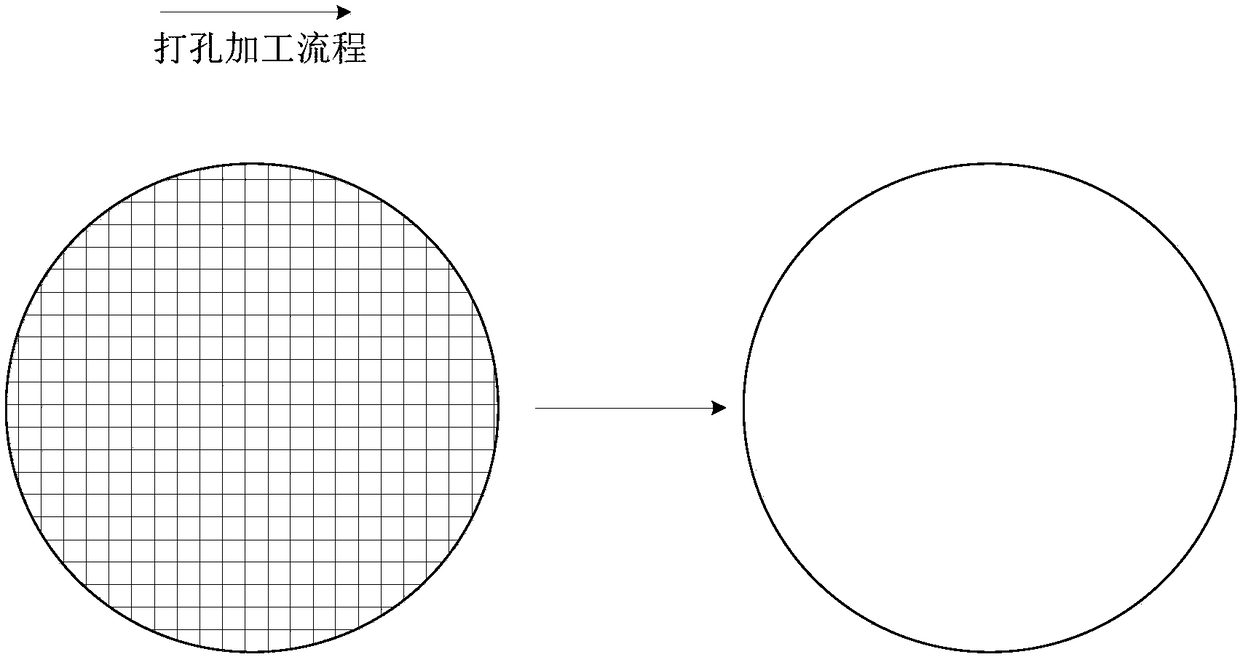

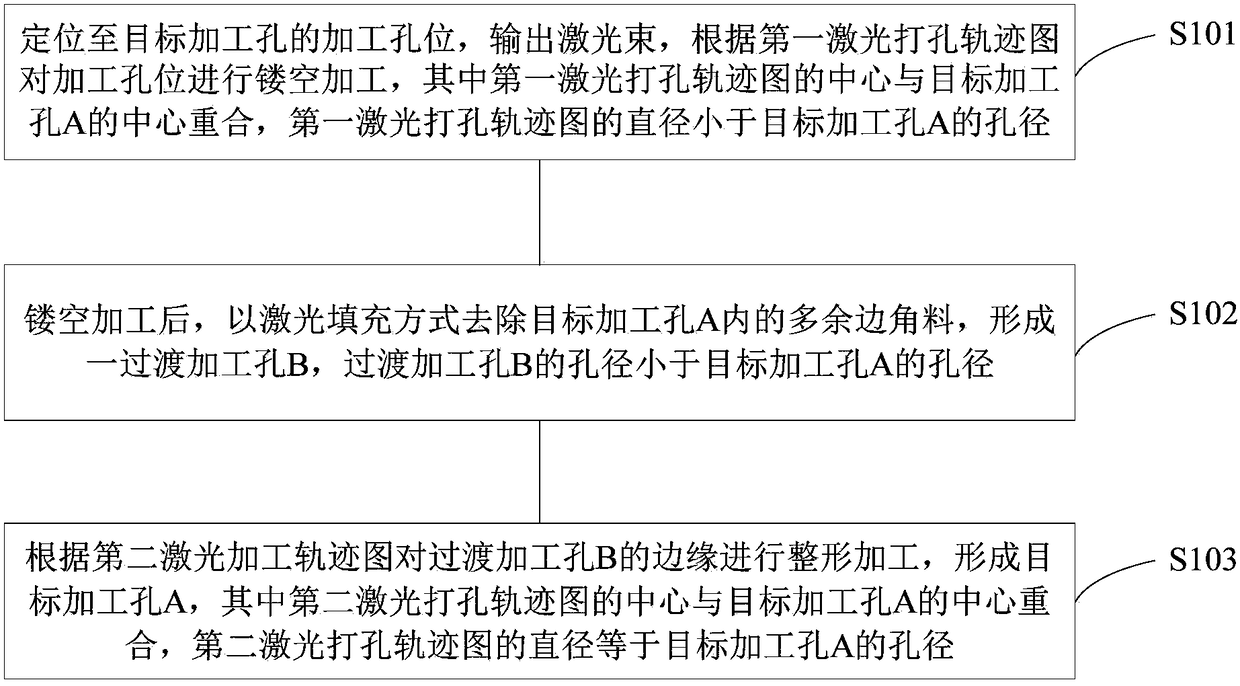

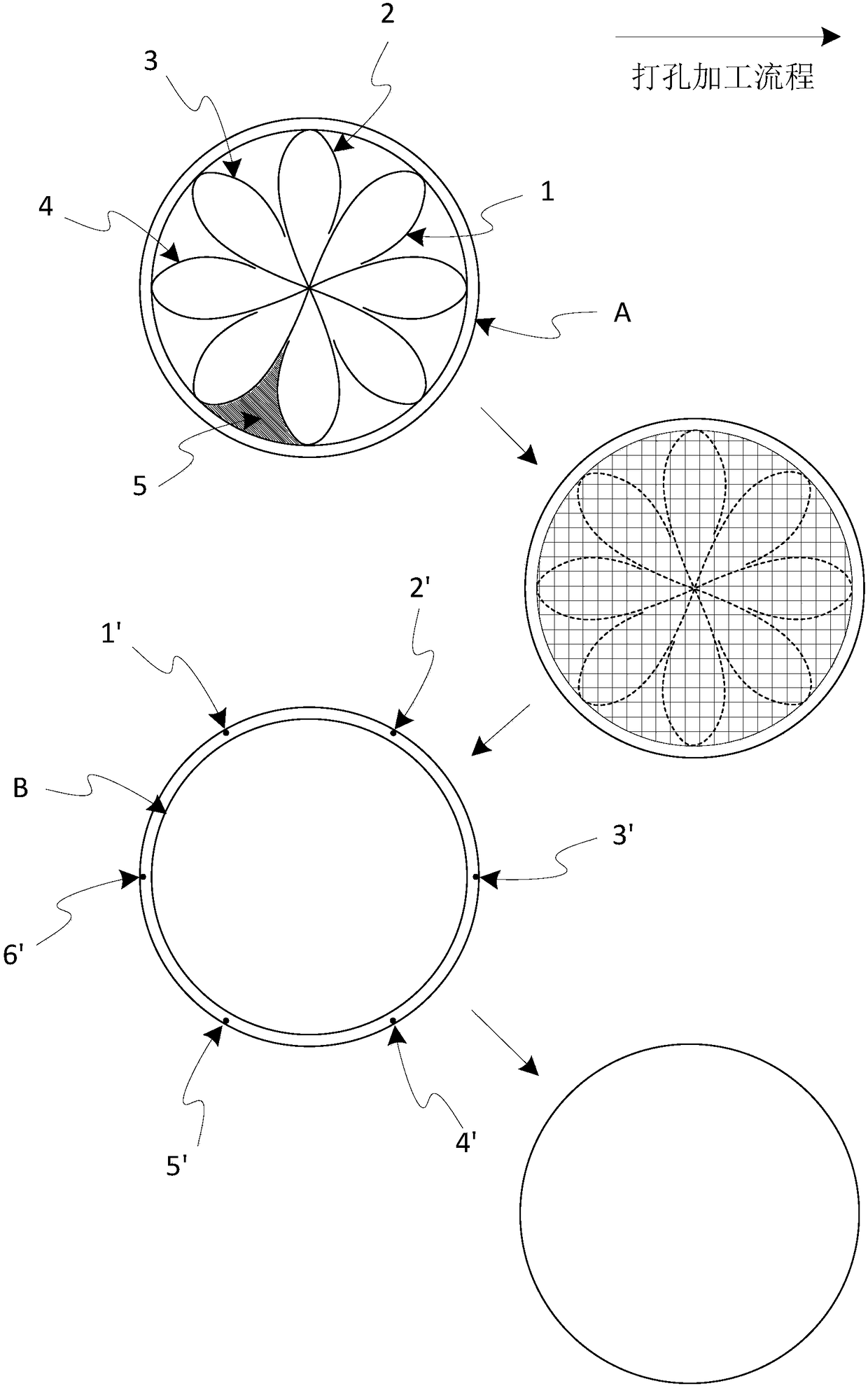

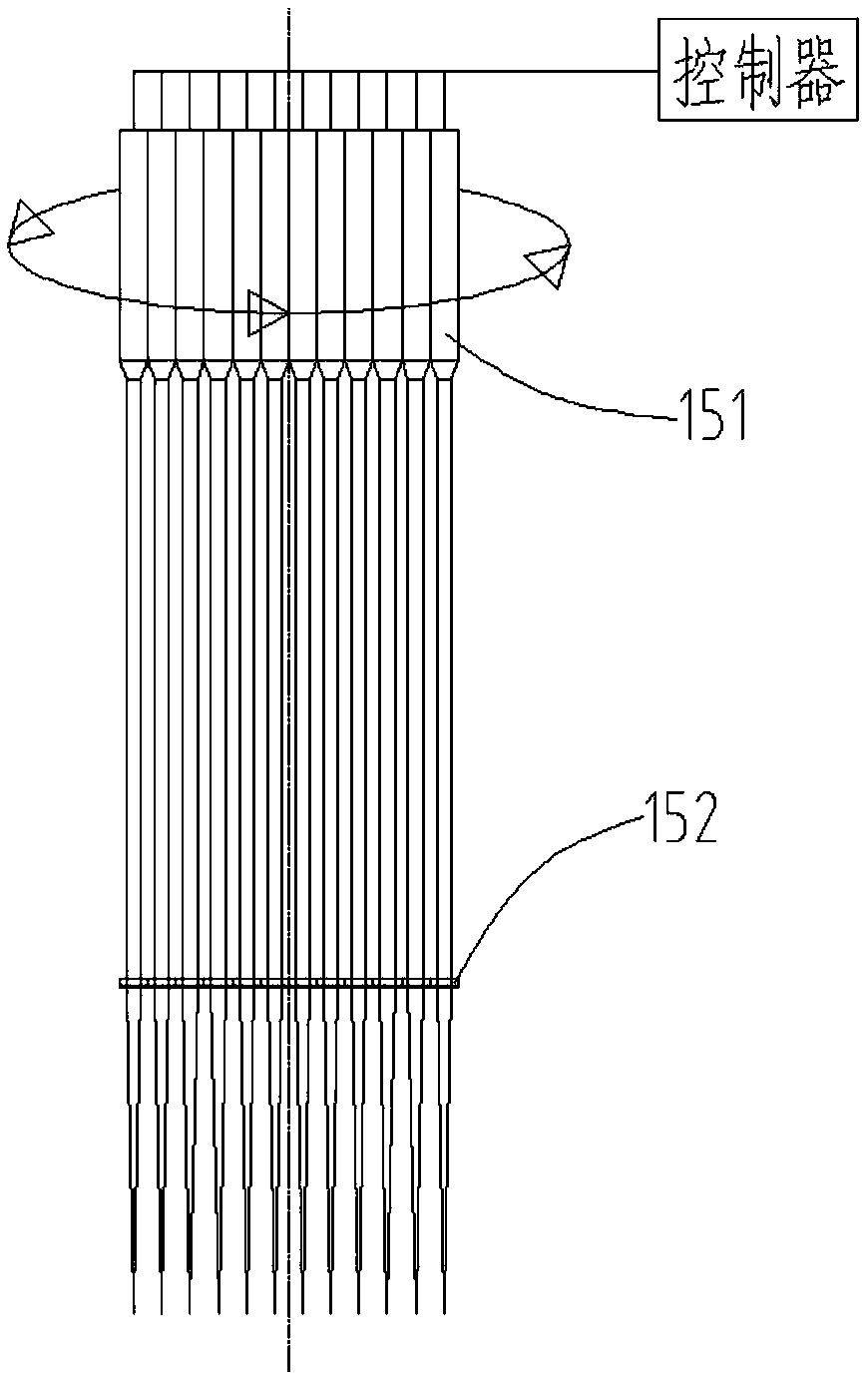

Laser punching method and device for metal

ActiveCN108971775AImprove roundnessImprove taperLaser beam welding apparatusLaser processingPunching

The embodiment of the invention belongs to the technical field of laser machining and relates to a laser punching method and device for metal. The laser punching method comprises the steps that a laser beam is positioned to the machining hole position of a target machining hole and output, and the machining hole position is hollowed out according to a first laser punching trajectory chart; after hollow-out machining, redundant leftover materials in the target machining hole are removed in a laser filling mode, a transition machining hole is formed, and the hole diameter of the transition machining hole is smaller than that of the target machining hole; and the edge of the transition machining hole is reshaped according to a second laser machining trajectory chart, and the target machininghole is formed. The laser punching device is used for executing the laser punching method and comprises an electrical control part, a laser, a beam expanding mirror, a galvanometer system, a telecentric focusing lens, a working platform and a cleaning device. According to the laser punching method and device, the machining efficiency can be improved effectively, thermal deformation is prevented from occurring to a machined product, and meanwhile the circular degree and taper of the hole are effectively improved.

Owner:HANS LASER TECH IND GRP CO LTD

Device and method for auxiliary laser back etching of low-taper glass deep hole by means of liquid flowing coating

ActiveCN110640337AReduce taperReduce crackingLaser beam welding apparatusLaser processingControl system

The invention discloses a device and method for auxiliary laser back etching of a low-taper glass deep hole by means of a liquid flowing coating, and belongs to the field of laser machining in non-traditional machining. The device comprises a laser chemical combined machining system and a control system. The problem that the laser absorption efficiency of transparent hard and brittle material is low is solved. By adopting an alkaline solution added with a colorant, the laser absorptivity of the material machining region can be increased, and the material internal stress accumulation can be reduced. Compared with the prior art that a common solid coating can only achieve the effect at the moment of laser impact, the liquid flowing coating can achieve self-adaptation laser machining of marks, the coating can achieve the continuous effect along with depth changes of laser drilling, and the coating is particularly applicable to machining deep holes. The method sufficiently utilizes the laser pre-machining front face effect, compared with existing methods, the method is low in cost, the deep hole taper can be remarkably lowered, the deep hole wall quality is improved, and the laser energy utilization rate is increased.

Owner:JIANGSU UNIV

Method and device for cutting transparent material by using ultra-short pulse laser

ActiveCN102785031BNo pollution in the processNo generationFine working devicesGlass severing apparatusTransfer procedureRefractive index

The invention provides a method for cutting a transparent material by using ultra-short pulse laser. The ultra-short pulse laser output by an ultra-short pulse laser generating device is condensed by a condensation device so as to form a bunching laser beam; the bunching laser beam enters from the surface of the transparent material to be machined, so that the center refractive index at a laser application point is increased to form a waveguide structure along a laser emitting direction; the laser is transmitted to the inside of the transparent material along the waveguide structure, and continuously generates a waveguide structure along the laser emitting direction in a transmission process until the entire waveguide structure and the laser penetrate through the transparent material; and therefore, the laser moves in a direction which is vertical to the surface of the transparent material at uniform speed, so that a waveguide plane is formed in the transparent material. The invention further provides a device for cutting the transparent material by using the ultra-short pulse laser. The method and the device for cutting the transparent material by using the ultra-short pulse laser provided by the invention have the advantages of fast cutting speed, small cutting seam, no material consumption and no powder pollution. When the machined material bears a suitable external force, the material is cracked only along a stress fault surface; the broken surface nearly has no conical degree; and the roughness is good.

Owner:WUHAN JUNNO TECH

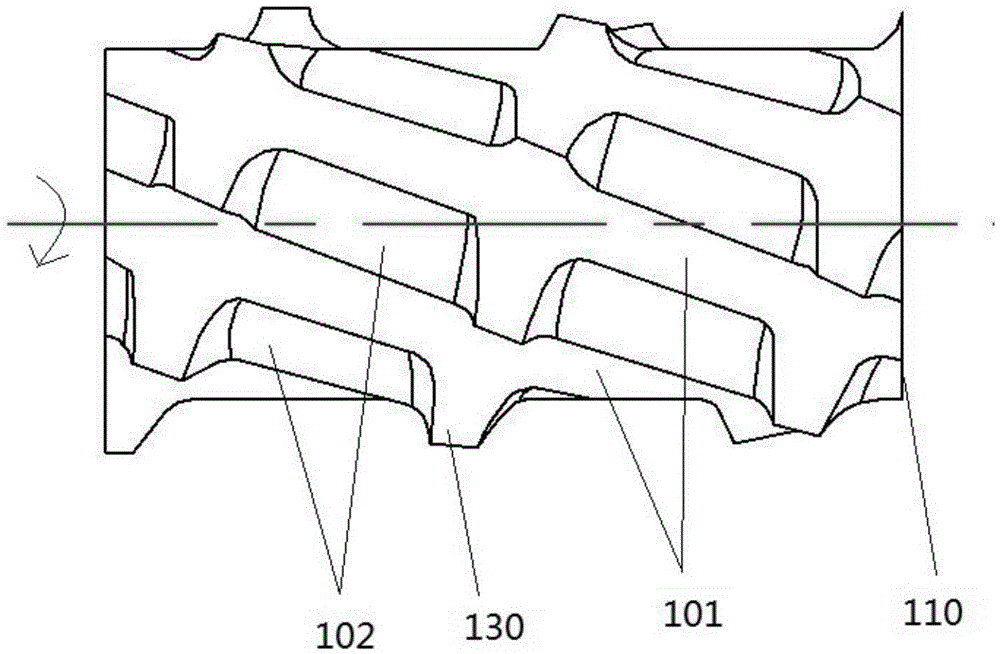

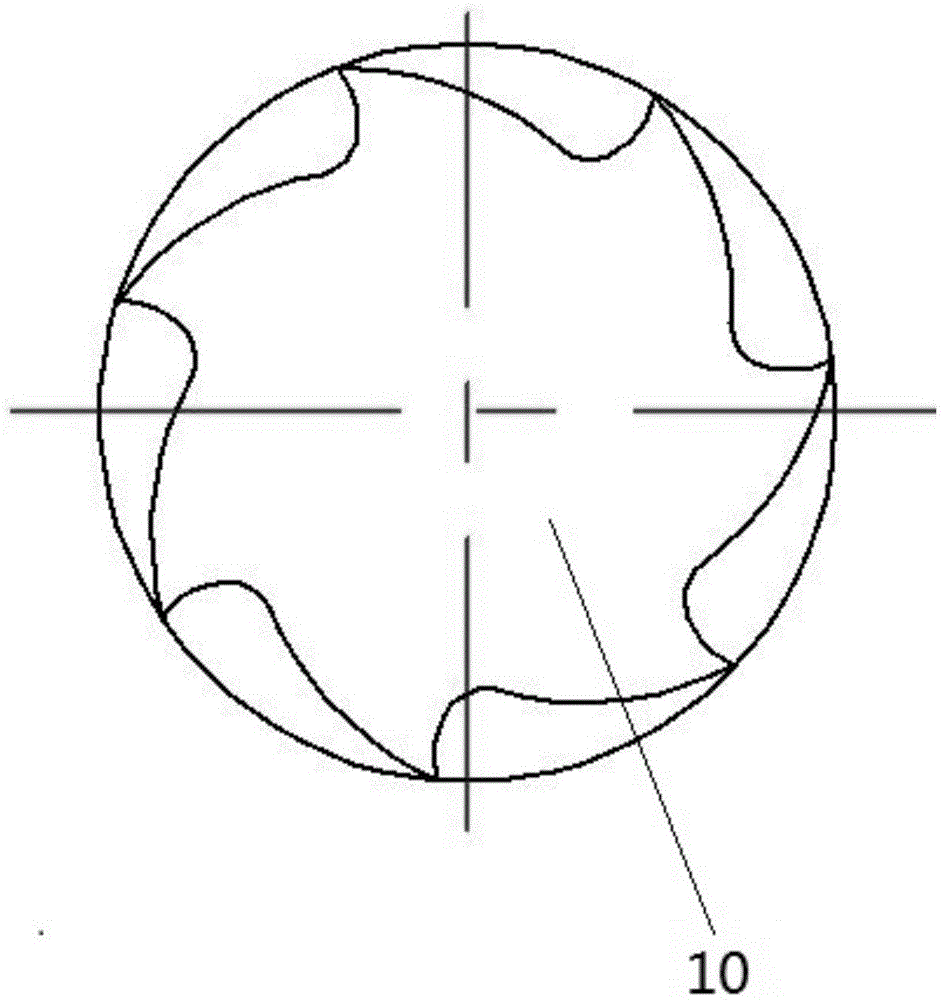

Rotary cutting tool

InactiveCN105642983AIncrease the cross-sectional areaGuarantee the actual processing benefitsMilling cuttersMilling cutting insertsEngineeringHelix angle

The invention is suitable for the technical field of cutting tools and particularly suitable for the technical field of micro drill bits for milling edges of printed circuit boards, and discloses a rotary cutting tool. The rotary cutting tool comprises a cutting part which has a taper; the diameter of the front end of the cutting part is smaller than that of the rear end of the cutting part; the cutting part is provided with a plurality of main spiral grooves of the same spiral angle; the main spiral grooves are evenly distributed in the circumferential direction, and the screwing direction of each main spiral groove is rightwards; the cutting part is further provided with an auxiliary spiral groove which comprises a leftwards-screwed spiral groove spirally ascending from the front end to the rear end of the cutting part; the auxiliary spiral groove spirally ascending and the main spiral grooves form a plurality of cutting teeth on the cutting part; and in the spiral direction of the auxiliary spiral groove, the tooth width portions between the adjacent cutting teeth coincide with one another. According to the rotary cutting tool, the auxiliary spiral groove of the cutting part is of a leftwards-screwed structure, and the main spiral grooves of the cutting part are of rightwards-screwed structures. The actual area of the cross section of each spiral groove is increased, chip blockage is not likely to happen, the service life can be prolonged by 86.24%, and precision can be improved by 33.89%.

Owner:SHENZHEN JINZHOU PRECISION TECH

Method for improving laser cutting quality of pendulous reed of accelerometer

ActiveCN103086597AEliminate dross defectsImprove energy unevennessGlass severing apparatusGlass productionSlagLaser cutting

The invention provides a method for improving laser cutting quality of a pendulous reed of an accelerometer. The method is the method comprising the steps of manufacturing a cutting assisting device, installing, fixing, vibrating, cutting by laser and the like, so that the adhering slag is reduced, the taper of a cut is improved, and thus the laser cutting quality of the pendulous seed is improved. According to the method, the assisting device is provided and used for precisely positioning on real time, a sacrificial plate is added during cutting the pendulous reed through the laser, thus the residues without being taken away by the assisting gas can be attached on the sacrificial plate, and the defect due to the adhering slag close to the kerf of the pendulous reed can be removed, and the taper of the cut due to the scattering of the laser on the surface of a glass can be improved; the vibration is carried out during cutting through the laser, so that a laser focus can upwards and downwards move within the thickness range of the pendulous reed, and as a result, the problem that uniform energy in the thickness direction of the pendulous reed due to the concentrating of the laser energy in the focus cannot be realized can be greatly reduced, the purposes of reducing the taper of the kerf, improving the processing precision of the pendulous reed structure as well as improving the graphs and sizes of two surfaces can be realized, and the yield of processing is increased by more than 10%.

Owner:航天科工惯性技术有限公司

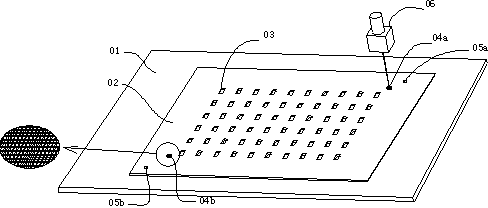

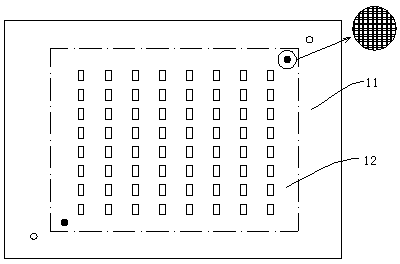

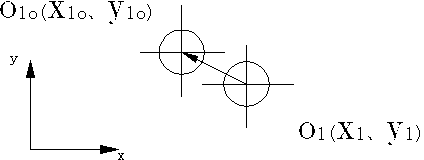

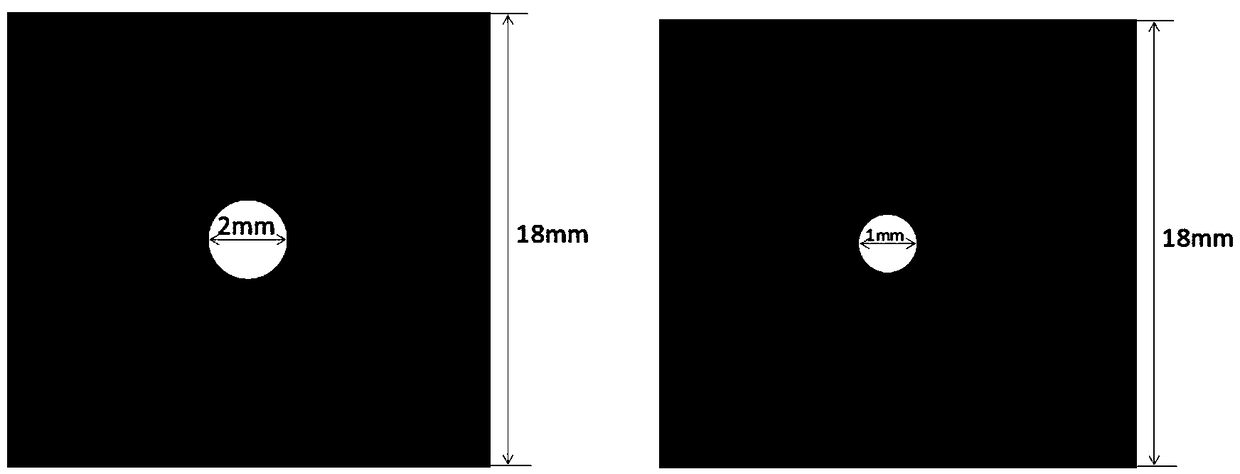

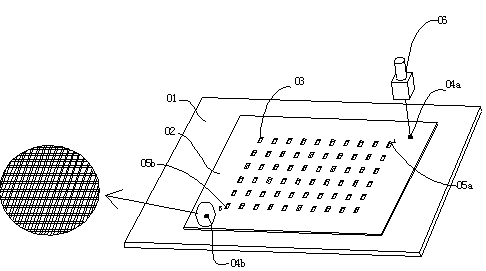

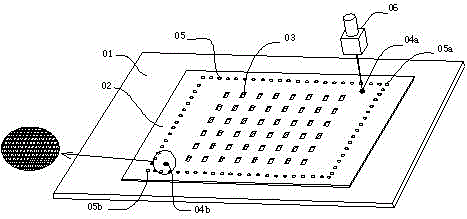

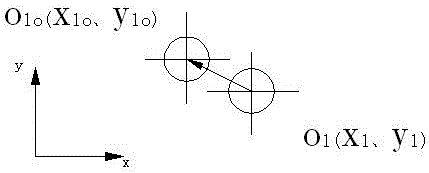

Production method for an electroformed stencil with mark points

InactiveCN103203977AImprove surface qualityImprove taperLaser beam welding apparatusForme preparationEngineeringLaser cutting

The present invention relates to a production method for an electroformed stencil with mark points, including the production of the electroformed stencil and the production of the mark points. The production method is characterized in that the stencil surface area outer the opening pattern area of the electroformed stencil is provided with two round holes diagonally positioned for determining the coordinates of the mark points. The production of the mark points comprises the steps of: placing the fixed electroformed stencil on a cutting base platform; then determining the coordinates of the mark points; adjusting cutting parameters and the vertical height of a laser cutting head to enable a laser focus to fall on the surface of the electroformed stencil; emitting laser light through the laser cutting head to perform cutting at the mark point area on the surface of the electroformed stencil. According to the production method for the electroformed stencil with mark points, the obtained electroformed stencil has good surface quality, no pinholes or pittings, thereby improving printing quality; and the mark points have high positioning accuracy, and relatively high degrees of recognition, improving alignment accuracy of a PCB with the electroformed stencil.

Owner:KUN SHAN POWER STENCIL

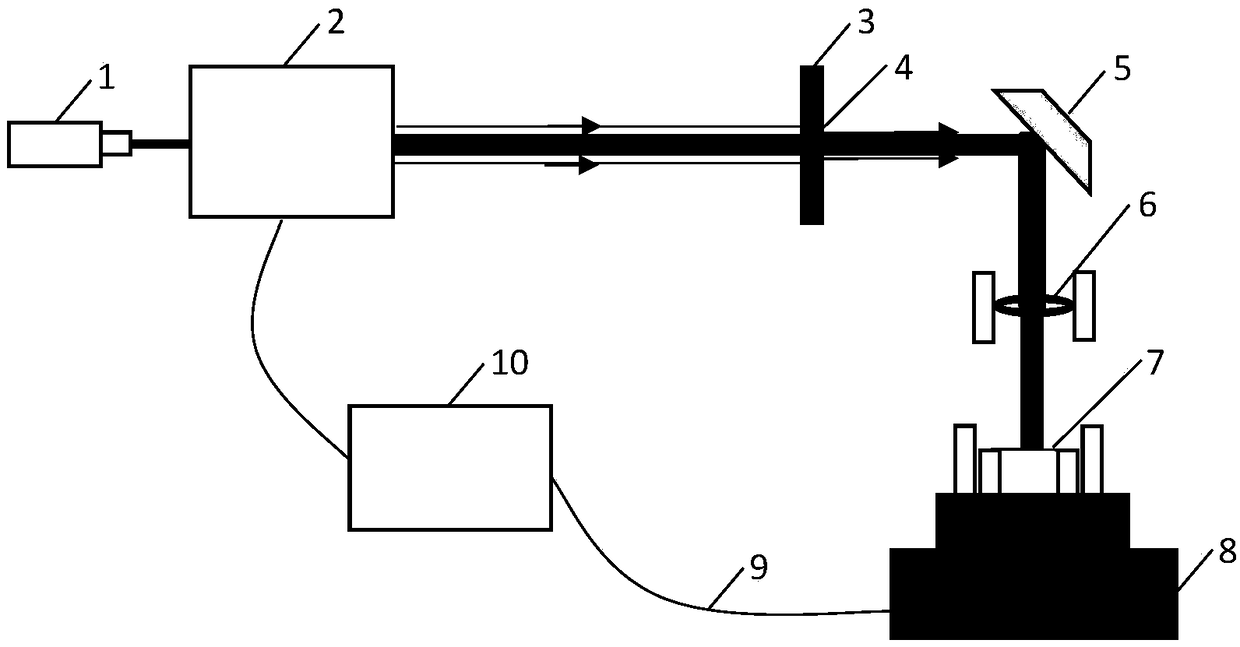

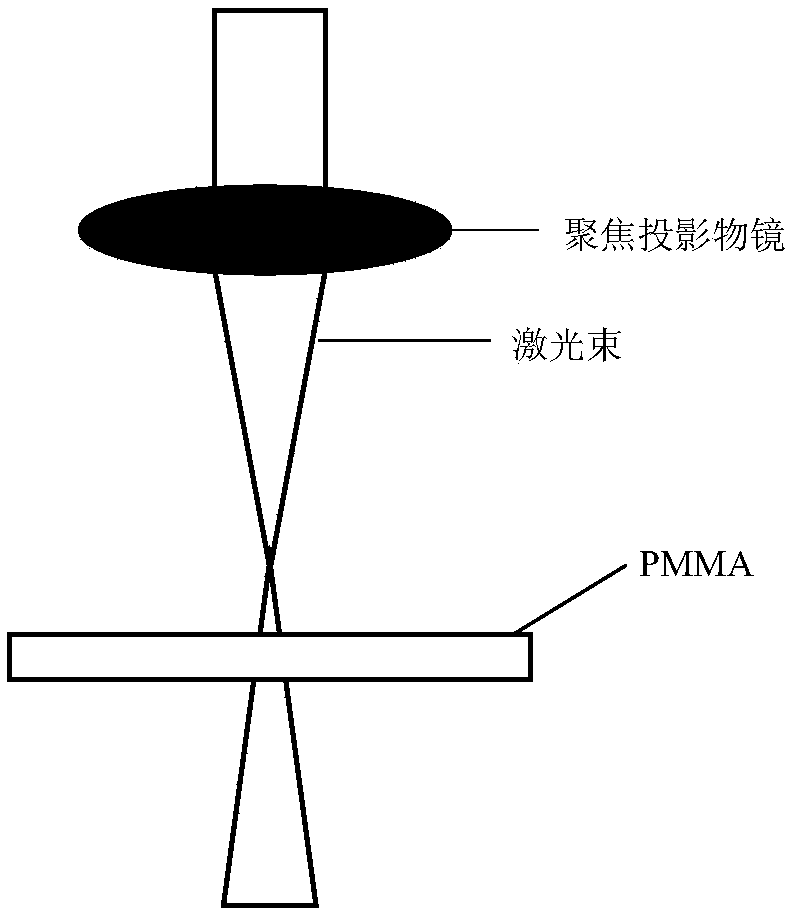

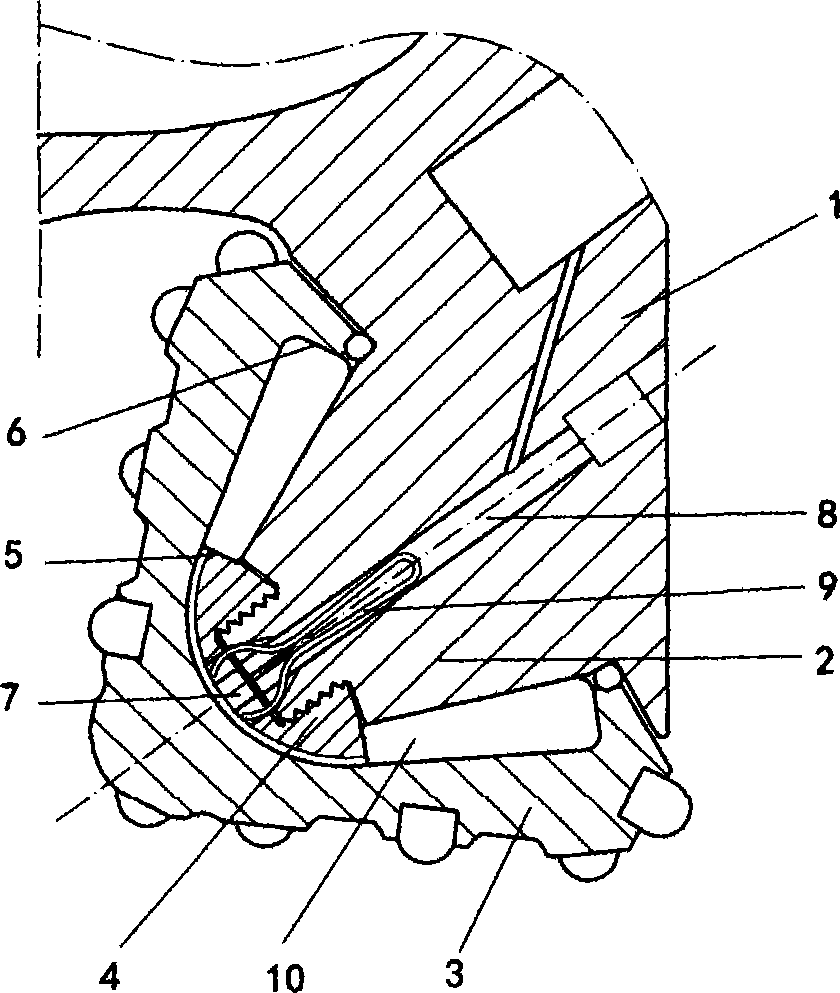

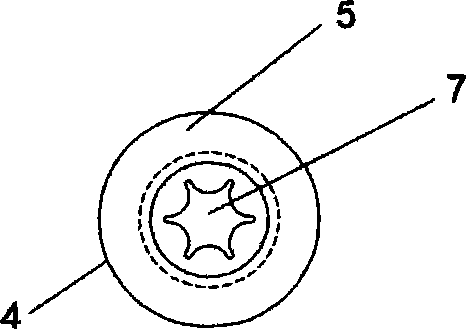

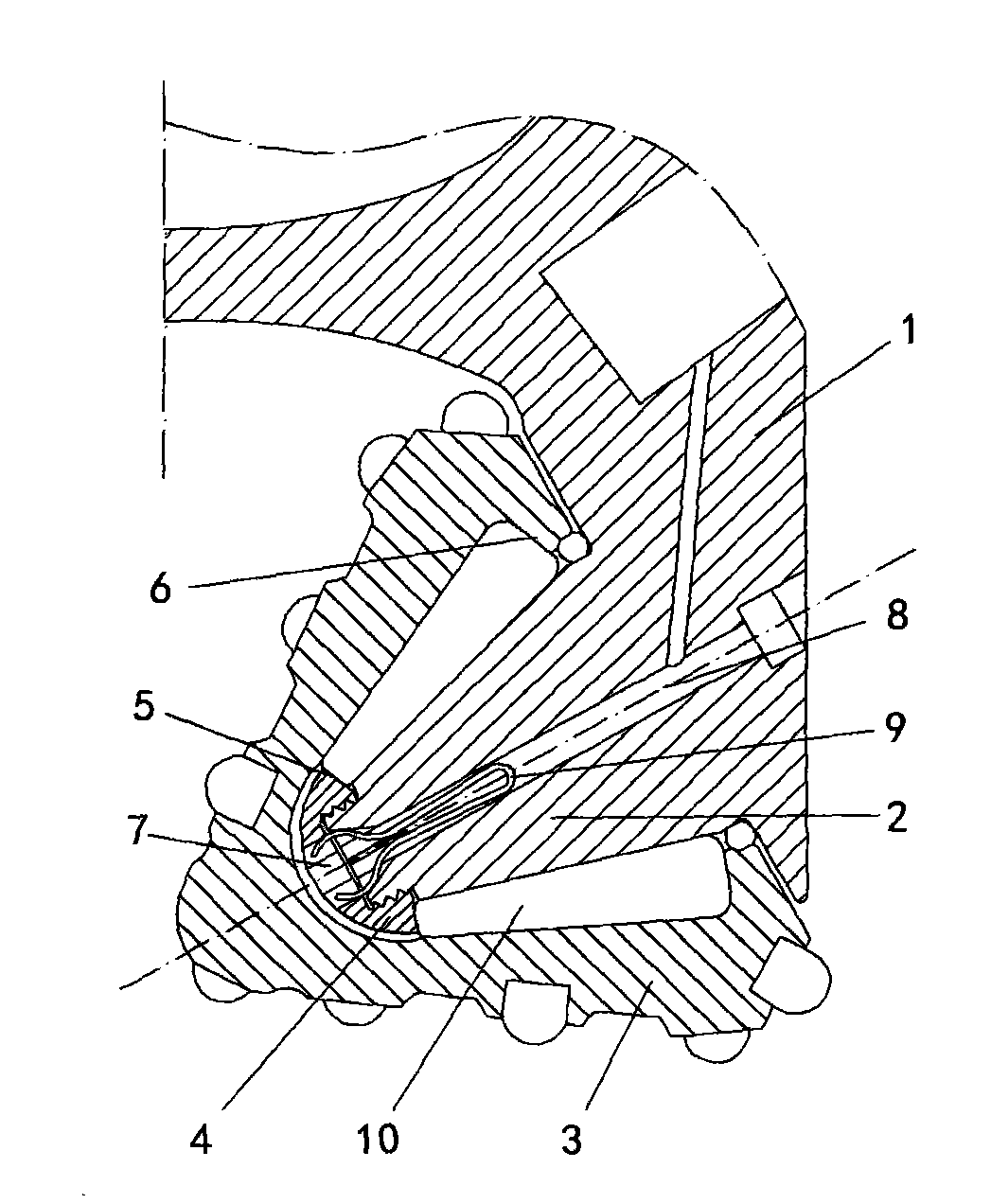

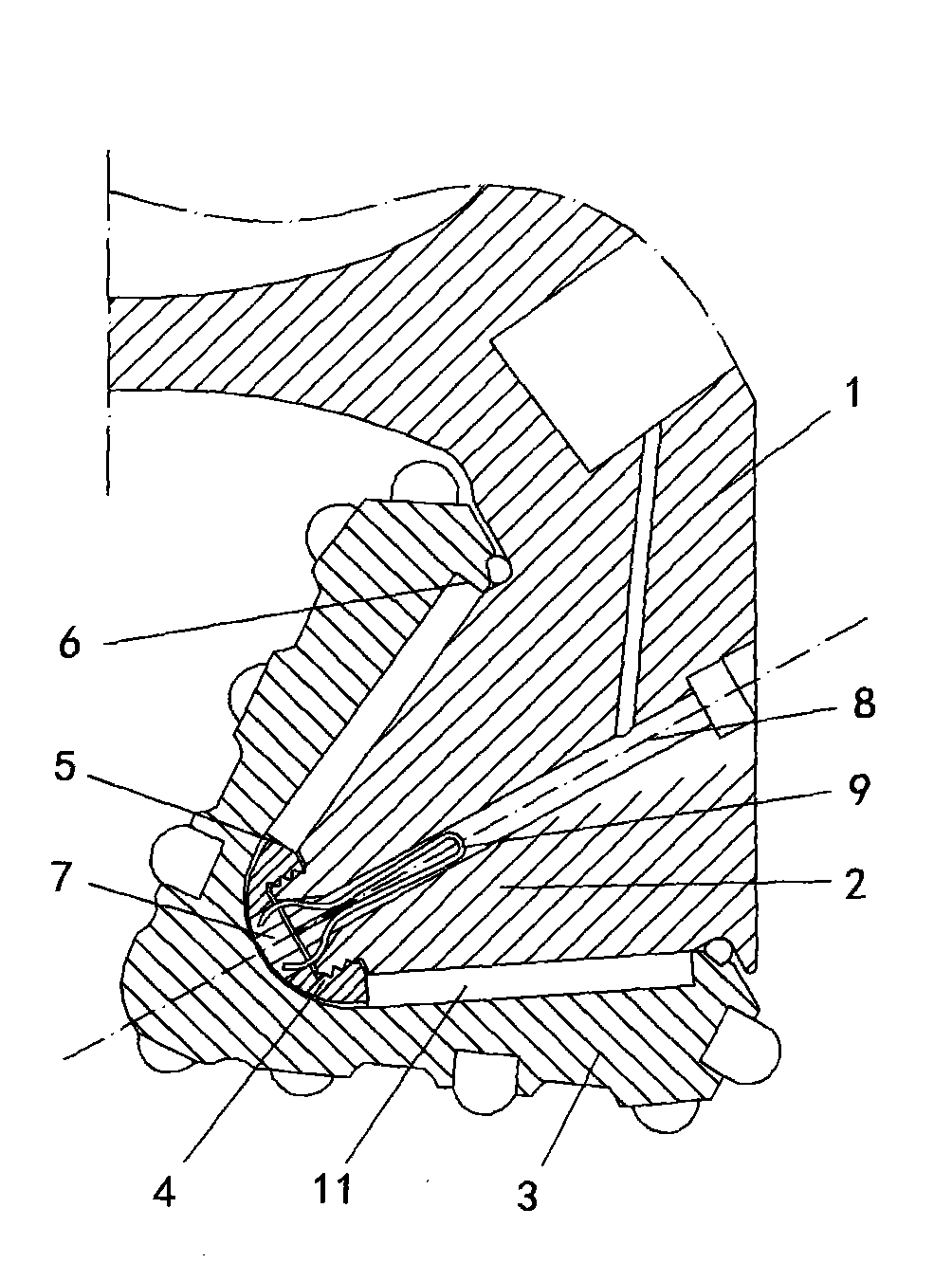

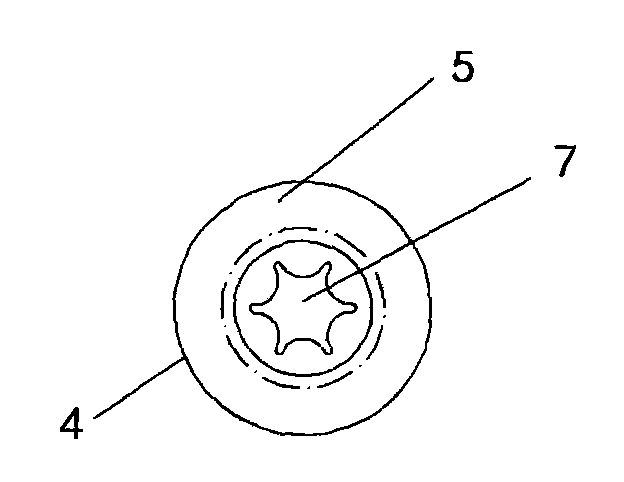

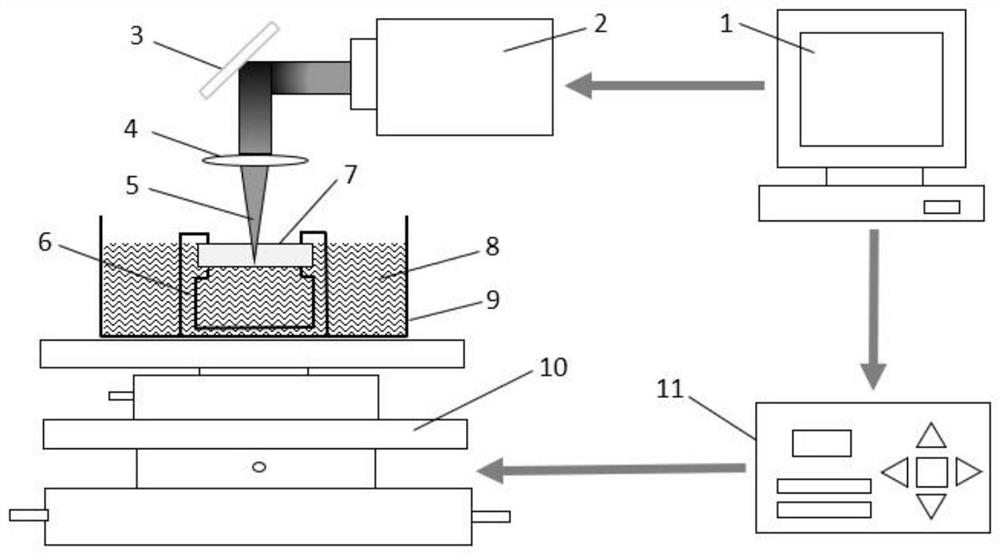

Method and device for excimer laser processing tapered micropores

InactiveCN108838515AImprove absorption rateImprove surface qualityLaser beam welding apparatusLaser lightControl table

The invention discloses a method and device for excimer laser processing tapered micropores. The device comprises an indicator light (1), an excimer laser (2), a mask exchange table (3), a mask (4), areflection mirror (5), a focused projection objective (6), a sample placement table (7), a three-dimensional electronically controlled table (8), a motor driver (9) and a computer (10). According tothe method and device, the taper of the micropores is enlarged by changing the size of the mask during the processing, the defects that the taper of fine taper holes is small and is difficult to control at present are overcome, and the purpose of obvious improving of the taper of the micropores is achieved; a gas laser such as the excimer laser is used as a laser light source to process the taperholes, because the gas photon energy is larger than the chemical bond energy among materials, chemical bonds of the materials can be directly broken to achieve cold processing, and the better surfaceprocessing quality is achieved; and the method and device have the advantages that the processing precision and reliability are high, the materials have a high absorption rate of light, and no heat affected zone exists.

Owner:BEIJING UNIV OF TECH

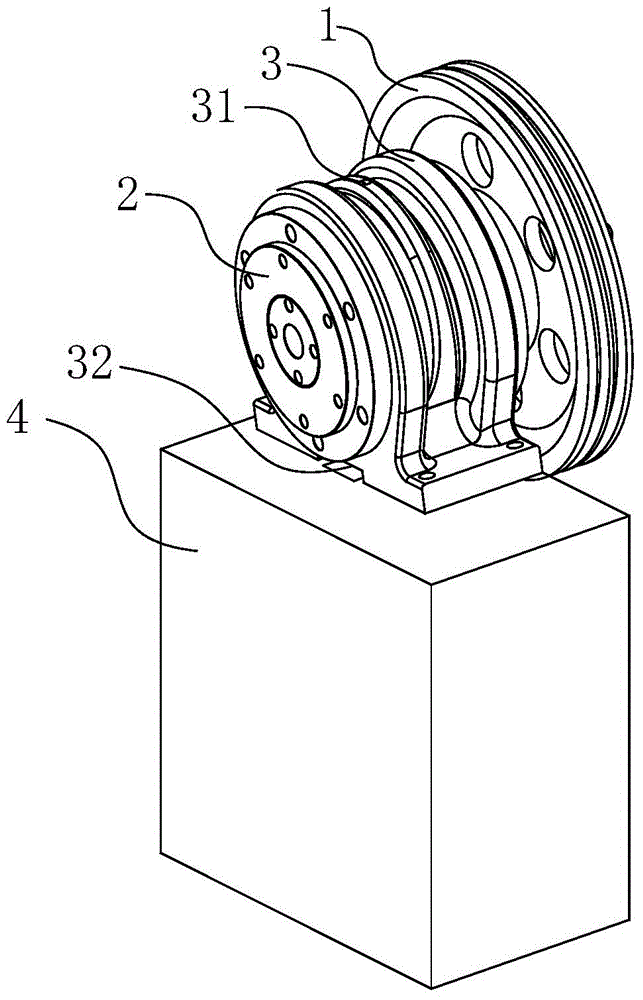

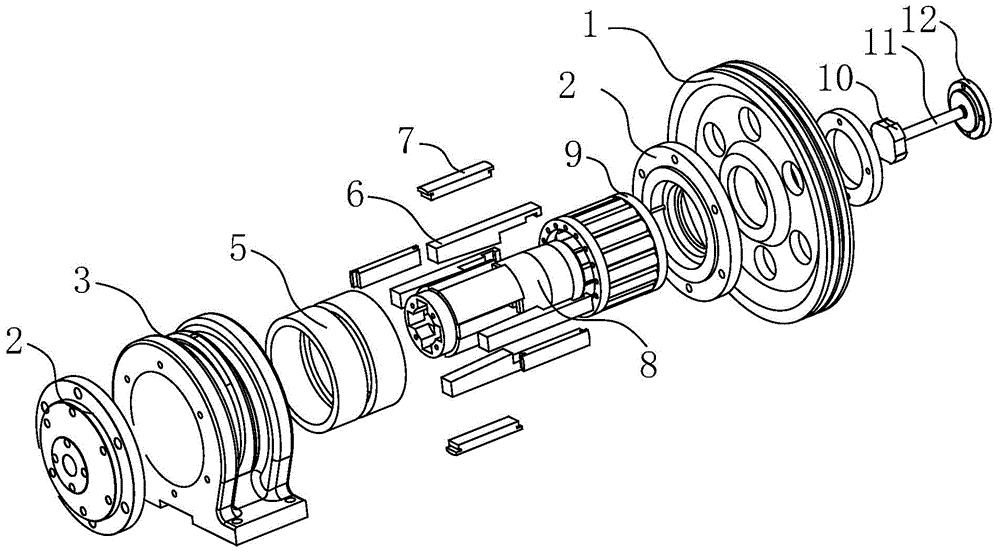

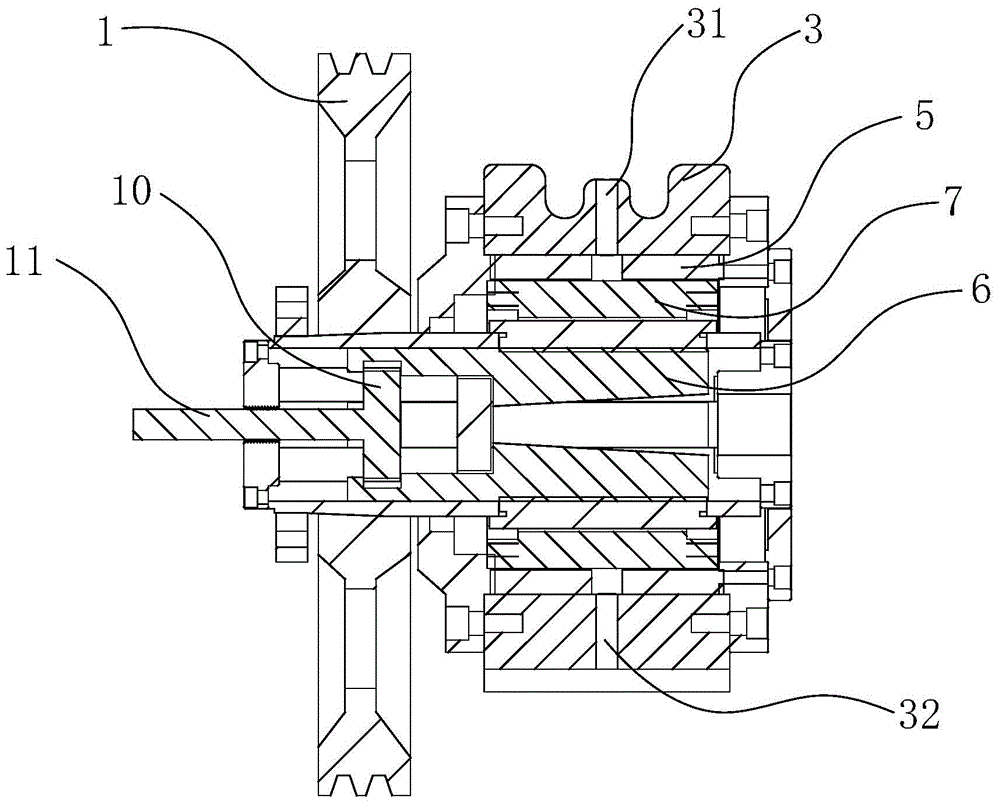

Roller bit and manufacturing method thereof

The invention discloses a roller bit and a manufacturing method thereof. A rolling cone bearing or a conical arc-shaped slide block flap is taken as a bearing system; a conical rolling or sliding bearing system is arranged tightly in a way that the thrust surface of a locking nut is adjacent to the small-end end face of a rolling cone or the slide block flap, and the large-end end face of the rolling cone or the slide block flap is adjacent to the inner thrust surface of a cone shell; meanwhile, a reliable locking function of the cone shell is realized. An efficient boring process is adopted for processing by means of the characteristic of simple structure of a conical claw shaft. The service life of the bearing system of the roller bit is prolonged, and the manufacturing efficiency is increased.

Owner:李荟敏

A laser drilling device and method for improving hole taper and inner wall quality

ActiveCN107486640BImprove taperSuitable for group hole processingWelding/cutting auxillary devicesAuxillary welding devicesCavitationOptoelectronics

Owner:JIANGSU UNIV

A production method for an electroformed stencil with mark points

InactiveCN103203974AImprove surface qualityImprove taperPhotomechanical apparatusPlate printingEngineeringLaser cutting

The present invention relates to a production method for an electroformed stencil with mark points, including the production of the electroformed stencil and the production of the mark points. The production method is characterized by comprising the steps of: placing the fixed electroformed stencil on a cutting base platform; selecting any two openings diagonally positioned on the electroformed stencil, reading coordinates of specific points of the openings, positioning the electroformed stencil through the coordinates of specific points, and determining coordinates of the mark points via comparing with an original file; adjusting cutting parameters and the vertical height of a laser cutting head to enable a laser focus to fall on the surface of the electroformed stencil; and emitting laser light through the laser cutting head to perform cutting at the mark point area on the surface of the electroformed stencil. According to the production method for the electroformed stencil with mark points, the obtained electroformed stencil has good surface quality, no pinholes or pittings, thereby improving printing quality; and the mark points have high positioning accuracy, and relatively high degrees of recognition, improving alignment accuracy of a PCB with the electroformed stencil.

Owner:KUN SHAN POWER STENCIL

Etch combination

InactiveCN1873054BReduce surface tensionFacilitated DiffusionAnionic surface-active compoundsDetergent mixture composition preparationAcetic acidEtching

The invention provides a etching compound, using said compound to carry out wet etching for TFT grid wiring material Al-Nd / Mo bilaminar membrane or Mo / Al- Nd / Mo three-layer membrane, which forms film transistor liquid crystal displayer, the wet etching employs single process by way of no undercut by lower membrane Al- Nd or Mo; the taper is good and configuration of Mo monolayer film of source / drain wiring material is outstanding. The etching compound comprises phosphoric acid, aqua fortis, acetic acid, acetic acid surface activator and water.

Owner:DONGJIN SEMICHEM CO LTD

Supporting rolling post and method for correcting crankshaft journal cylindricity

InactiveCN104646456ADoes not weaken the effect of strengtheningImprove straightnessEngineeringMachining

The invention relates to the technical field of crankshaft machining, in particular to a supporting rolling post and a method for correcting crankshaft journal cylindricity. The supporting rolling post comprises a cylindrical part positioned on the middle part and a rotary curve surface part positioned on the end part; in a rolling process, the rotary curve surface part on the end part is in contact with a crankshaft journal rolling bump line. The supporting rolling post and the method have the advantages that rolling bump caused by plastic deformation nearby a crankshaft journal fillet can be corrected, and then the crankshaft journal cylindricity is corrected.

Owner:BINZHOU HEAD CRANKSHAFT

Photosensitive resin composition

ActiveCN109901361AReduce roughnessImprove TaperPhotosensitive materials for photomechanical apparatusAcrylatePolymerization

The invention relates to a photosensitive resin composition. The photosensitive resin composition comprises a flatting agent I, wherein the flatting agent I is prepared by polymerization of the following monomers in parts by weight: (a) 20-40 parts of hexafluorobutyl acrylate, (b) 20-40 parts of monomers with glass transition temperature greater than 100 DEG C, (c) 10-20 parts of maleimide, and (d) 10-20 parts of C8-C18 olefin monomers. When the photosensitive resin composition is used for preparing a color filter, the surface roughness of a photoresist material can be remarkably lowered, Taper is effectively improved, and the photosensitive resin composition is excellent in slope.

Owner:GUAN ETERNAL MATERIAL TECH

Roller bit and manufacturing method thereof

The invention discloses a roller bit and a manufacturing method thereof. A bearing system of the roller bit is a rolling cone bearing or a cone arc sliding block, the thrust surface of a locking nut abuts against a rolling cone or the small-head end face of the sliding block, the rolling cone or the big-head end face of the sliding block abuts against an inner thrust surface of a cone shell, and therefore a conical rolling or sliding bearing system is tightly arranged, and meanwhile a reliable cone shell locking function is achieved. A cone shell locking device is assembled through the method that a screwdriver or an inside hexagon spanner penetrates through a bit jaw shaft central hole to screw a bit jaw shaft tightly inside a nut instead of the method of screwing the bit jaw shaft outside the nut. According to the characteristic that the conical bit jaw shaft structure is simple, an efficient boring technology is used for machining.

Owner:李荟敏

Method for preparing uniform three dimensional nanometer fluid passage by femto-second laser

InactiveCN101549852BUniform longitudinal shapeImprove taperNanostructure manufactureFemto second laserCompound (substance)

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

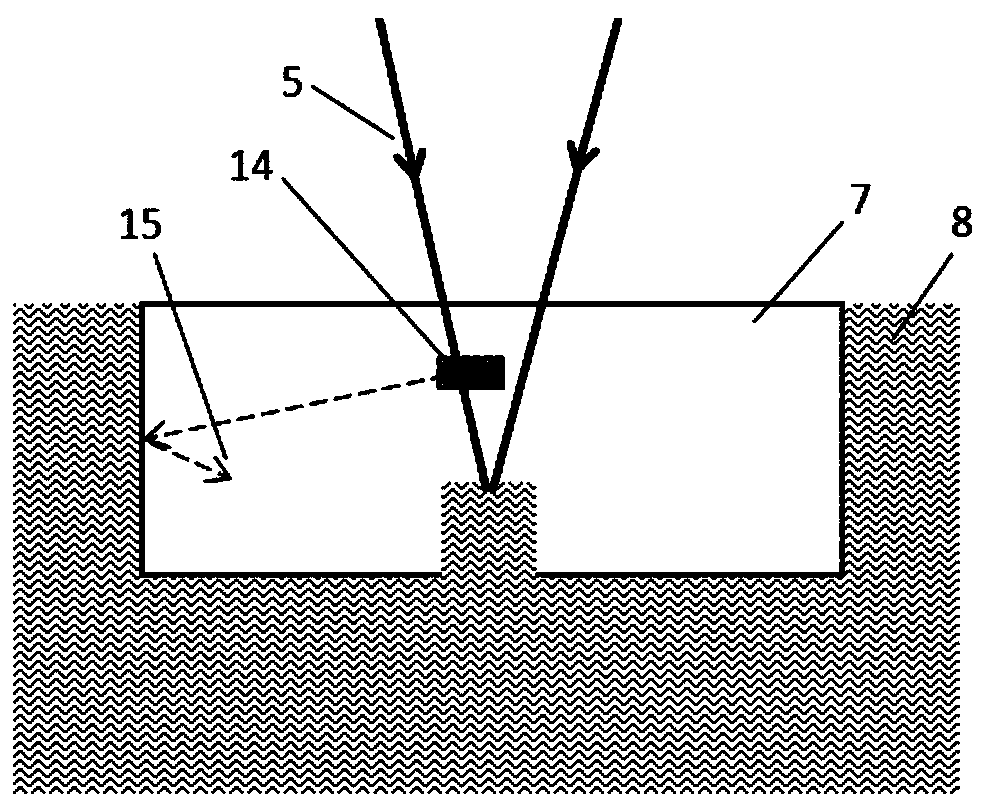

A device and method for improving through-hole taper by liquid scattering

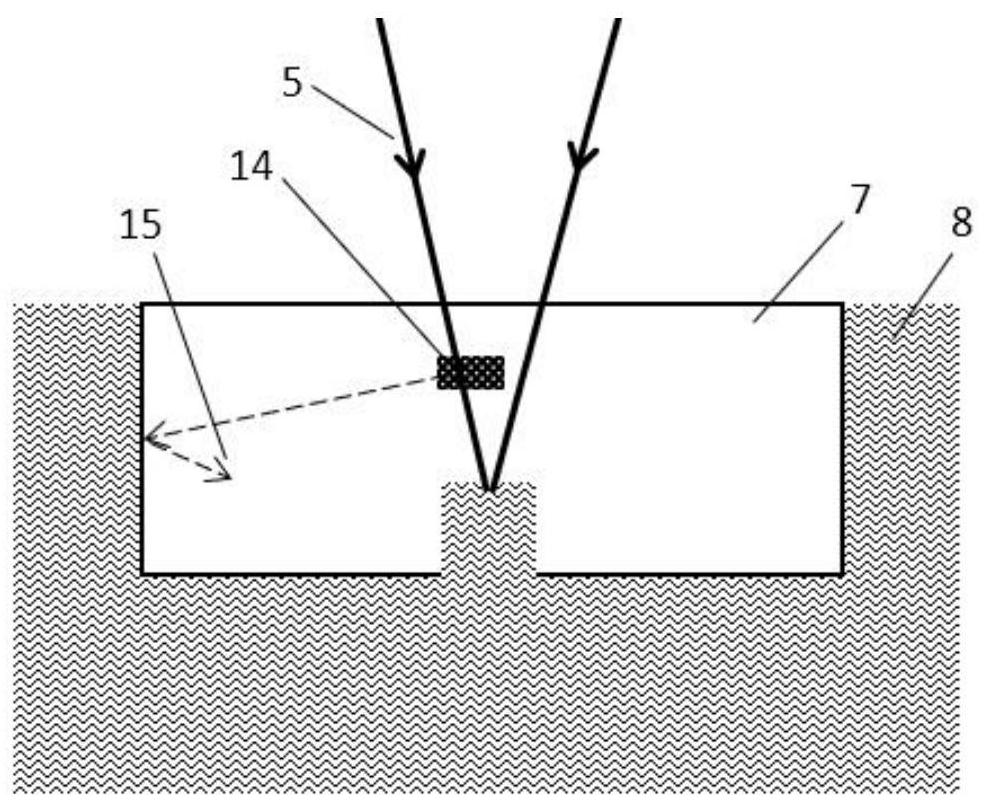

ActiveCN105772955BIncrease scatteringImprove taperLaser beam welding apparatusOptoelectronicsLaser beams

The invention relates to a device for improving taper of a through hole through liquid scattering. The device comprises a laser generator and further comprises a reflection device and a reflective regulation mechanism, wherein the laser generator is relatively fixedly arranged on one side of a workpiece, and the reflection device and the reflective regulation mechanism are arranged on the other side of the workpiece; the reflection device comprises a cavity for containing a liquid, and the liquid level of the liquid is a reflective plane for reflecting a laser beam; after the laser generator processes the through hole with taper on the workpiece, the laser beam penetrating through the through hole falls to the reflective plane of the reflection device, is reflected through the reflective plane and falls to the hole circumference and the inner wall of the through hole; and the reflection device is regulated through the reflective regulation mechanism to generate ripples with different amplitudes on the reflective plane, so that the laser beam reflected by the reflective plane falls to different positions of the hole circumference and the inner wall of the through hole so as to gradually eliminate taper in the through hole.

Owner:GUANGDONG UNIV OF TECH

A device and method for drilling a hole using a laser beam

Owner:GUANGDONG UNIV OF TECH

Method for making electroformed stencil with positioning points

InactiveCN103203973BImprove surface qualityImprove taperPhotomechanical apparatusPlate printingLaser cuttingEngineering

The present invention relates to a production method for an electroformed stencil with mark points, including the production of the electroformed stencil and the production of the mark points. The production method is characterized in that the opening pattern area of the electroformed stencil is surrounded by hanging holes arranged in a rectangular area, used to determine the coordinates of the mark points. The production of the mark point comprises the steps of: placing the fixed electroformed stencil on a cutting base platform; then determining the coordinates of the mark points; adjusting cutting parameters and the vertical height of a laser cutting head to enable a laser focus to fall on the surface of the electroformed stencil; emitting laser light through the laser cutting head to perform cutting at the mark point area on the surface of the electroformed stencil. According to the production method for the electroformed stencil with mark points, the obtained electroformed stencil has good surface quality, no pinholes or pittings, thereby improving printing quality; and the mark points have high positioning accuracy, and relatively high degrees of recognition, improving alignment accuracy of a PCB with the electroformed stencil.

Owner:KUN SHAN POWER STENCIL

Device and method for processing low-taper glass deep holes by liquid flow coating assisted laser back wet etching

ActiveCN110640337BImprove absorption rateEnhanced Erosion EfficiencyLaser beam welding apparatusLaser processingControl system

The invention discloses a device and method for processing low-taper glass deep holes assisted by liquid flow coating, which belongs to the field of laser processing in special processing, and includes a laser chemical composite processing system and a control system; For the problem of low laser absorption efficiency of brittle materials, the present invention uses an alkaline solution added with dyeing agent, which can improve the laser absorption rate of the material processing area and reduce the internal stress accumulation of the material. Compared with ordinary solid coatings that can only work at the moment of laser shock, the liquid flow coating proposed by this method can adapt to the laser processing marks, and the coating can achieve continuous action with the depth of laser drilling, especially suitable for For machining deep holes. The method makes full use of the positive effect of laser preprocessing, and compared with the existing method, the cost is low, the taper of the deep hole can be significantly reduced, the quality of the wall of the deep hole can be improved, and the energy utilization rate of the laser can be improved.

Owner:JIANGSU UNIV

A laser drilling device and method for improving hole taper

ActiveCN105904105BImprove taperOvercoming problems that require extremely high motion precision requirementsLaser beam welding apparatusOptoelectronicsLaser beams

Owner:GUANGDONG UNIV OF TECH

A cone machine

The invention discloses a tapered pipe machine. The tapered pipe machine comprises an engine base, a main shaft and an idler wheel, wherein the main shaft comprises a mould part and a power part; a mould cavity is formed in the radial direction of the mould part, and is internally provided with a mould plate; the main shaft is sleeved with the idler wheel; the mould plate comprises an impacting plate and a striking plate; the impacting plate is mounted in the mould cavity and can slide along the radial direction of the main shaft; the mould part is provided with a mould hole; the power part is provided with a positioning hole; the mould hole and the positioning hole are separated by a separation plate; a plurality of adjusting holes are formed in the axial direction of the main shaft; the striking plate is provided with a positioning part and is arranged inside the mould hole along the adjusting holes and the positioning part penetrates through the separation plate to enter the positioning hole; the positioning hole is internally provided with a positioning mechanism; the positioning mechanism can drive the striking plate to move along the axial direction of the main shaft; an oil inlet is formed in one side of the engine base and an oil outlet is formed in the other side of the engine base; lubricating oil can flow in a space between the main shaft and the idler wheel. The tapered pipe machine has the advantages of convenience for adjustment, simple structure and low noises.

Owner:NINGBO LEBO INTELLIGENT MACHINERY

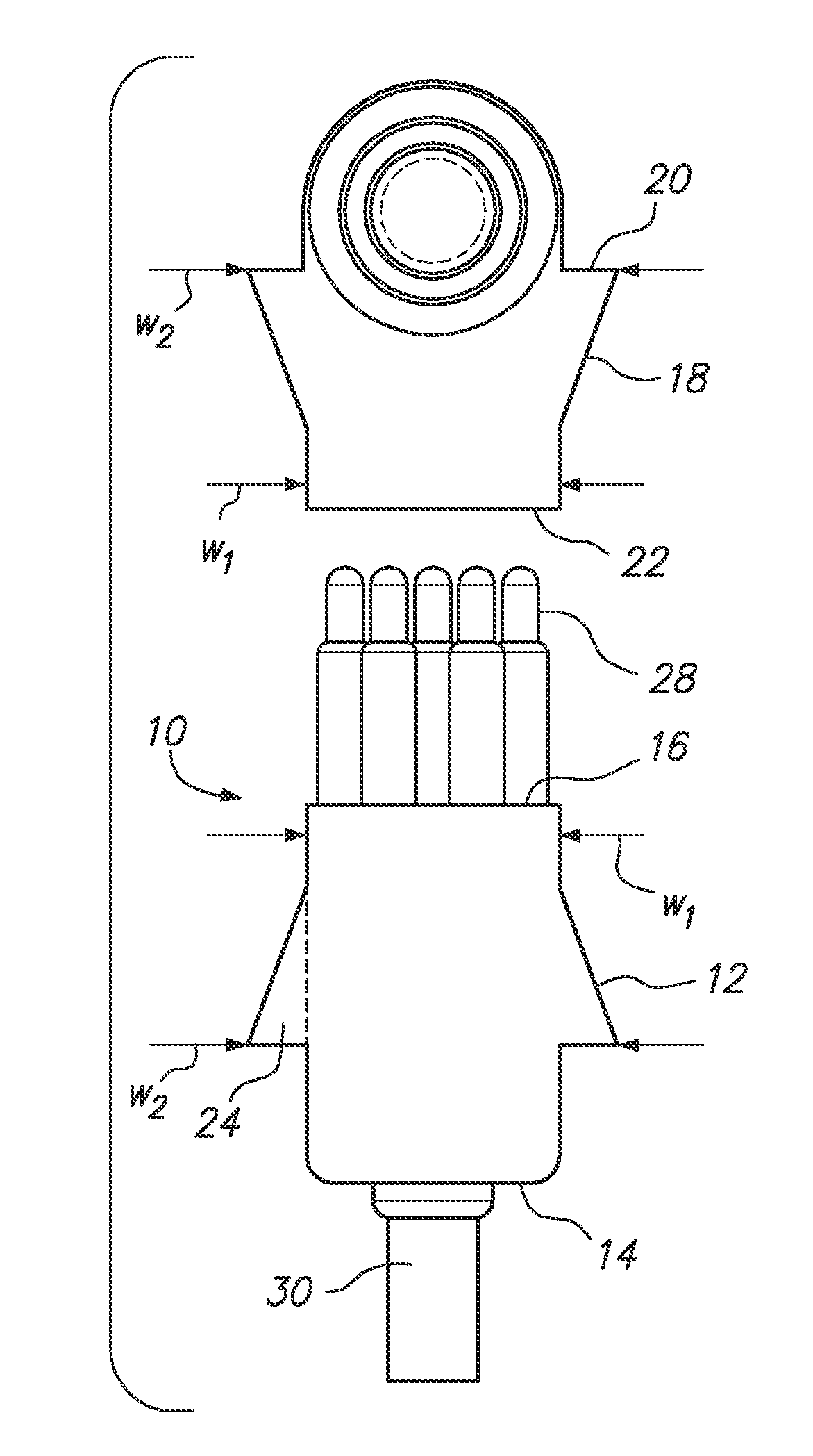

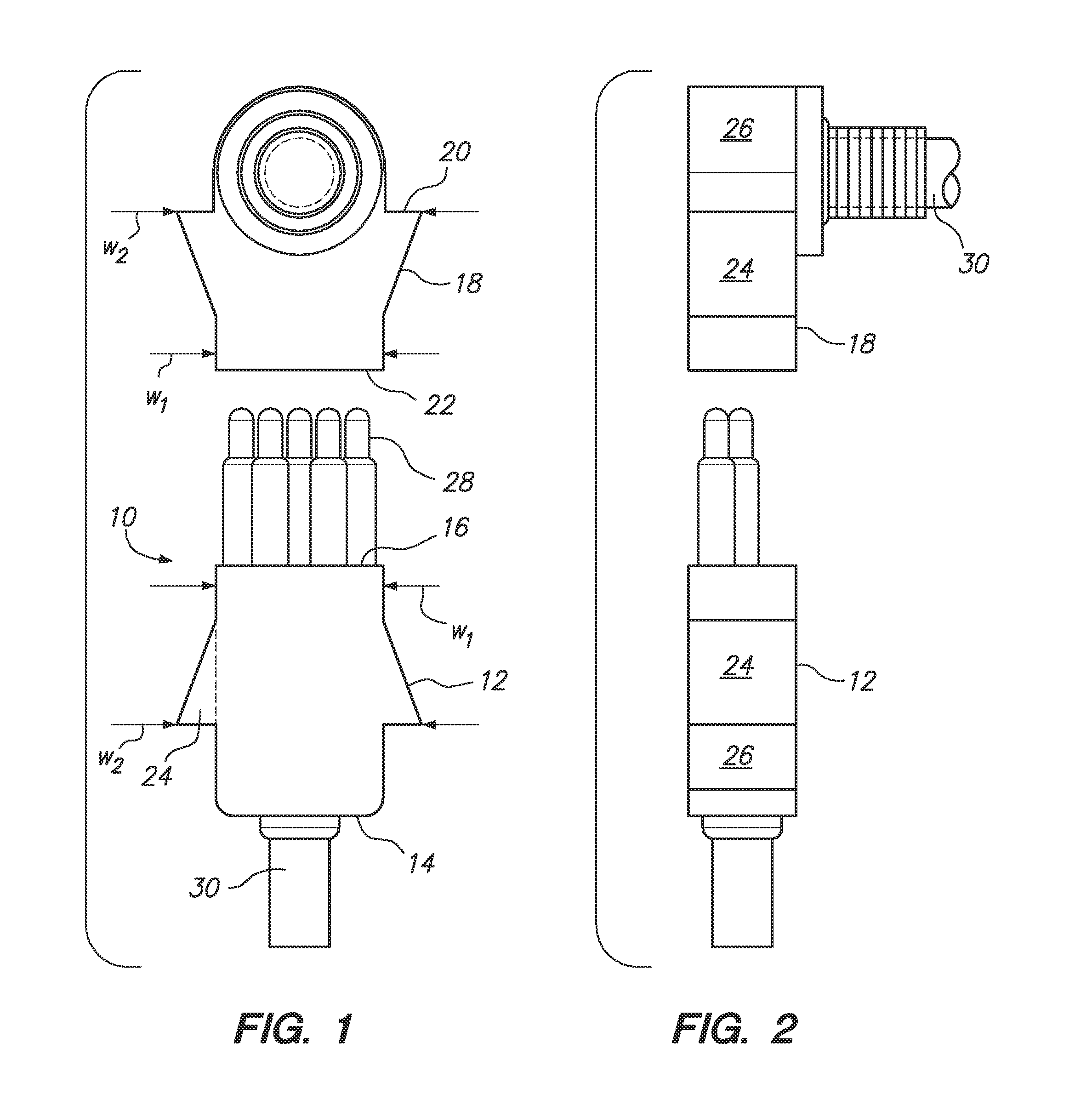

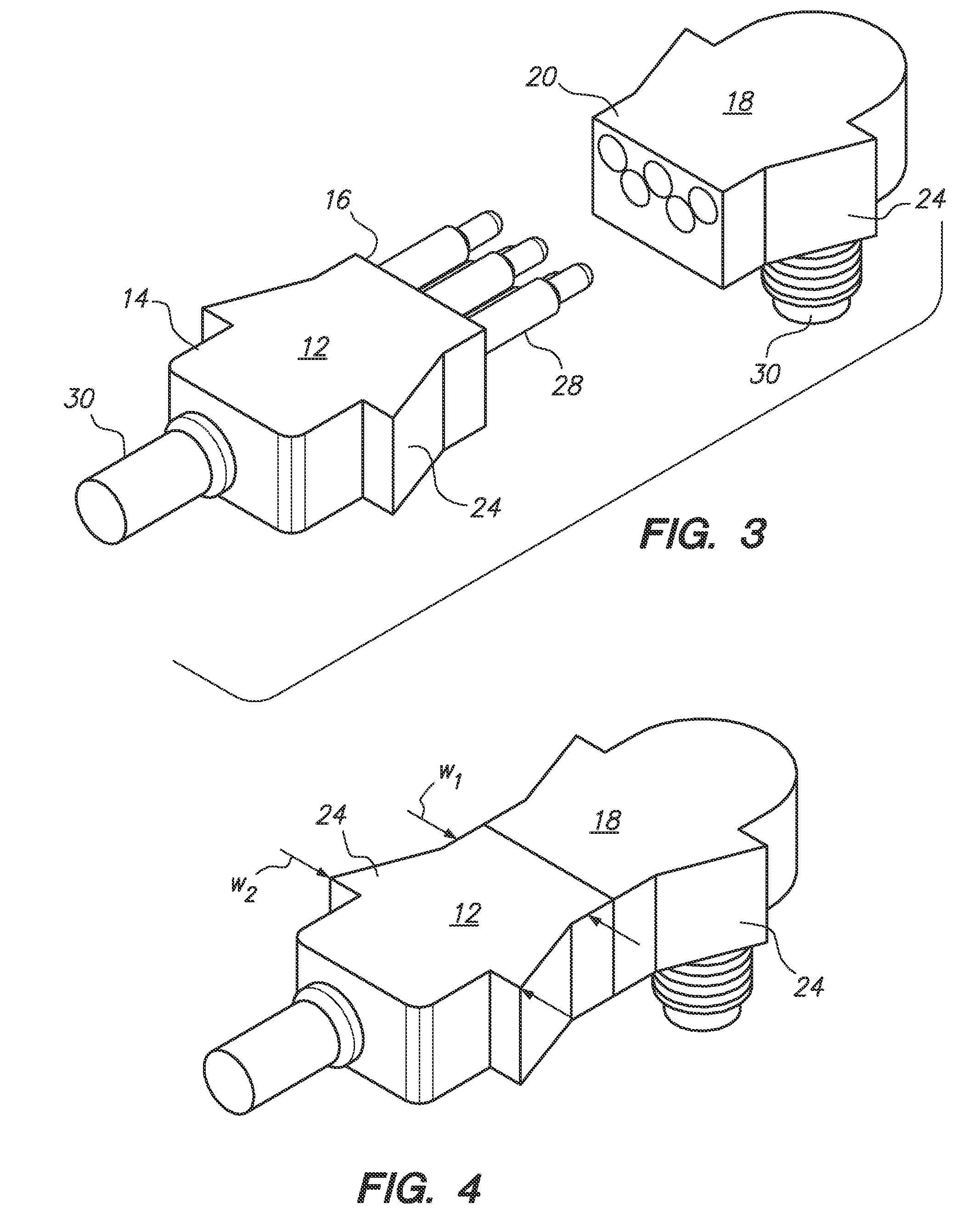

Underwater Electronics Connector and Methods

InactiveUS20150244102A1Improve taperEngagement/disengagement of coupling partsContact member manufacturingSystems designProximal point

An underwater connection system and methods can include a male connector having a proximal end and a distal end and a female connector having a proximal end and a distal end. At least one of the male connector or the female connector can have an increasing taper when viewed in top plan, from a minimum width at its distal end to a maximum width at its proximal end. To do this, the male or female connector can be formed with a surrounding rubber housing. The rubber housing can be formed with a wedge that is integral to the rubber housing to establish the increasing taper. The taper can be linear or curved, according to the needs of the user, and either or the male connector or female connector can be inline or right-angle connectors, according to the system design and space constraints.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com