Laser perforating device capable of improving conical degree and inner wall quality of hole and method

A laser drilling and taper technology, used in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems of inconspicuous improvement in taper, troublesome, delaying time, etc., to shorten auxiliary time, reduce labor intensity, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better illustrate the implementation details of the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

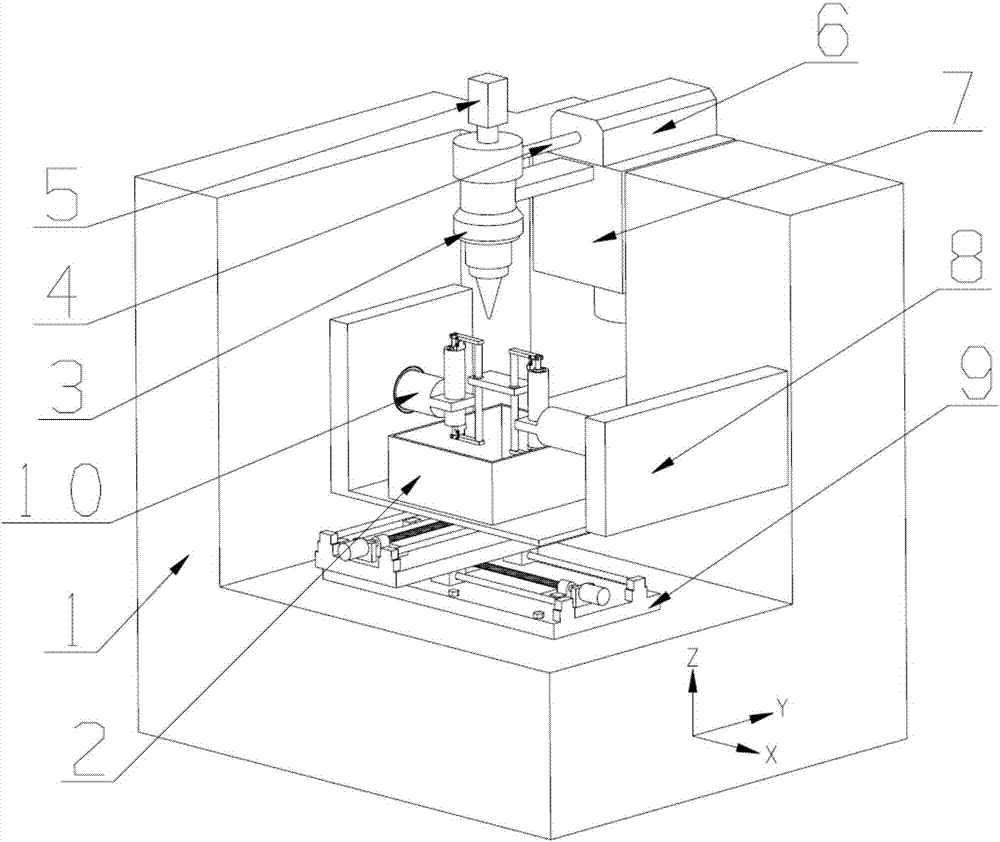

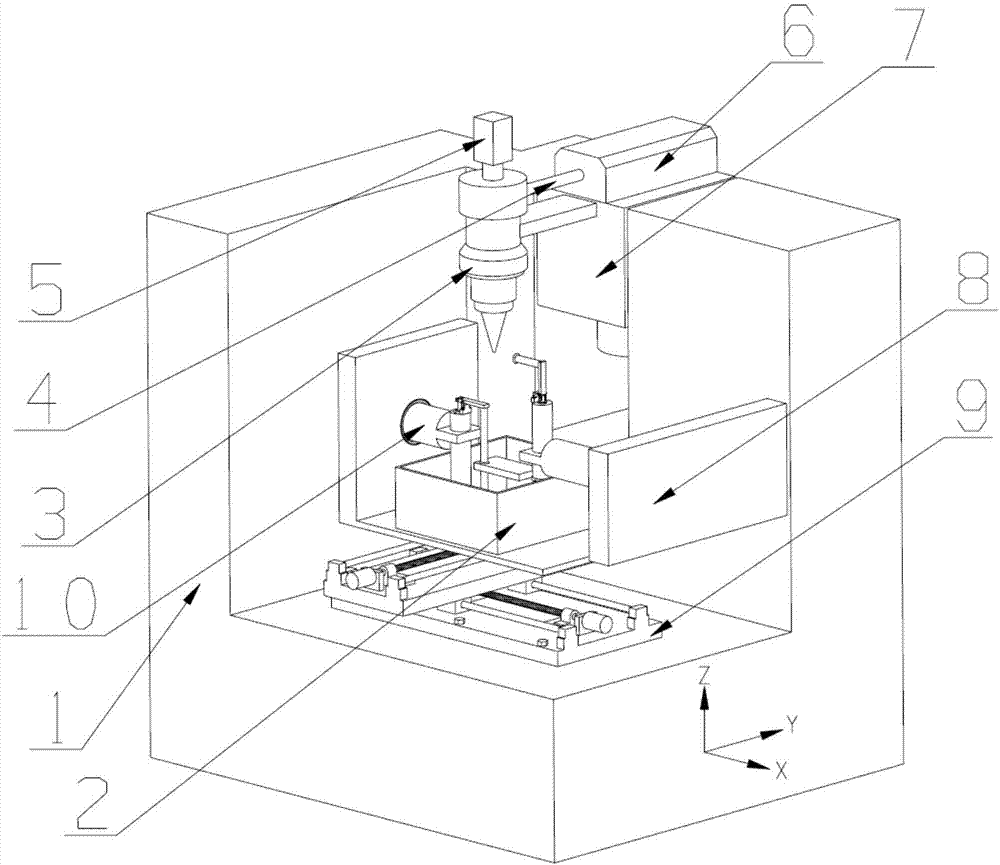

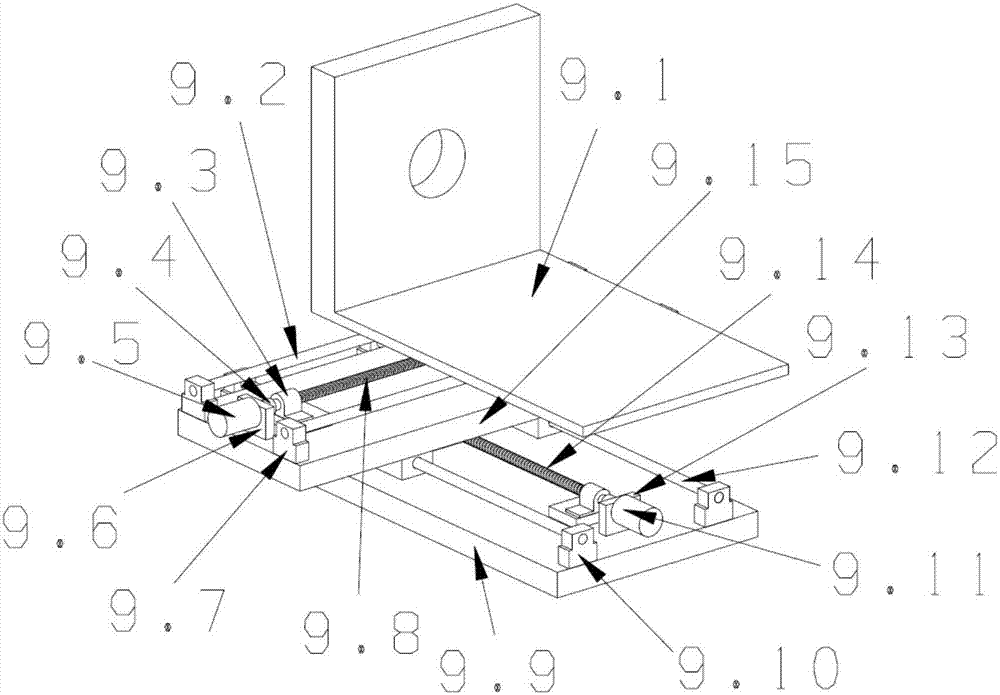

[0040] combined with figure 1 , a laser drilling device for improving hole taper and inner wall quality, characterized in that it includes a power supply box 1, a cuboid container without a cover 2, a laser head 3, a light guide tube 4, a CCD camera 5, a laser device 6, and a z-direction moving mechanism 7. Fixed fixture device 8, x-y mobile platform 9, rotatable fixture device 10;

[0041] The power supply box 1 is installed on the left vertical surface of the machine tool base, and an x-y mobile platform 9 is installed on the base upper surface of the machine tool; a coverless cuboid container 2 and a rotatable clamp device 10 are installed on the x-y mobile platform 9 The fixed fixture device 8 is directly installed on the bed of the machine tool through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com