A cone machine

A technology of tapered pipe machine and machine base, which is applied in the field of tapered pipe machine, which can solve the problems of high machine noise, high mold matching precision, inconvenient axial adjustment, etc., and achieve convenient position adjustment, improved service life, and good taper Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

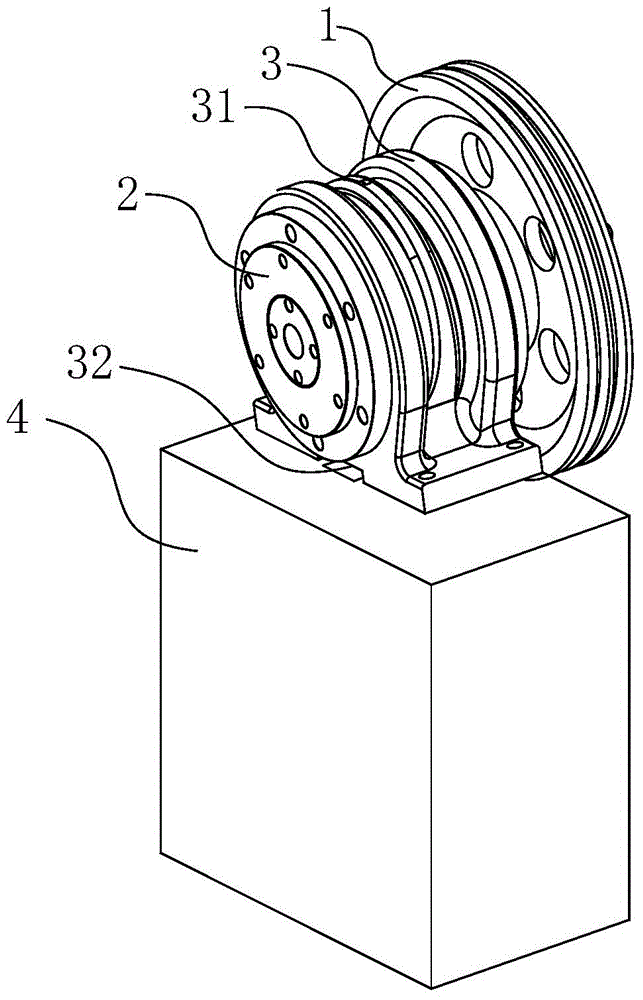

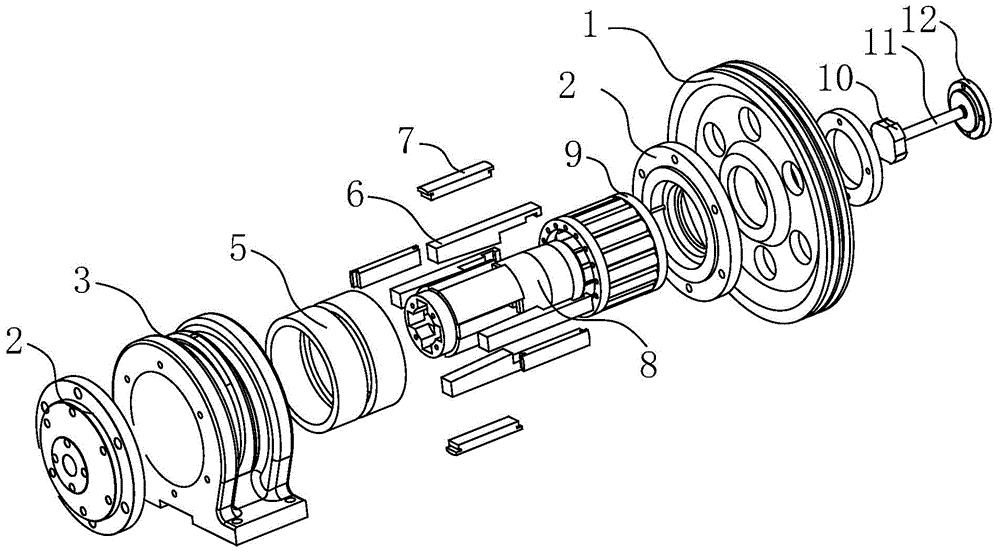

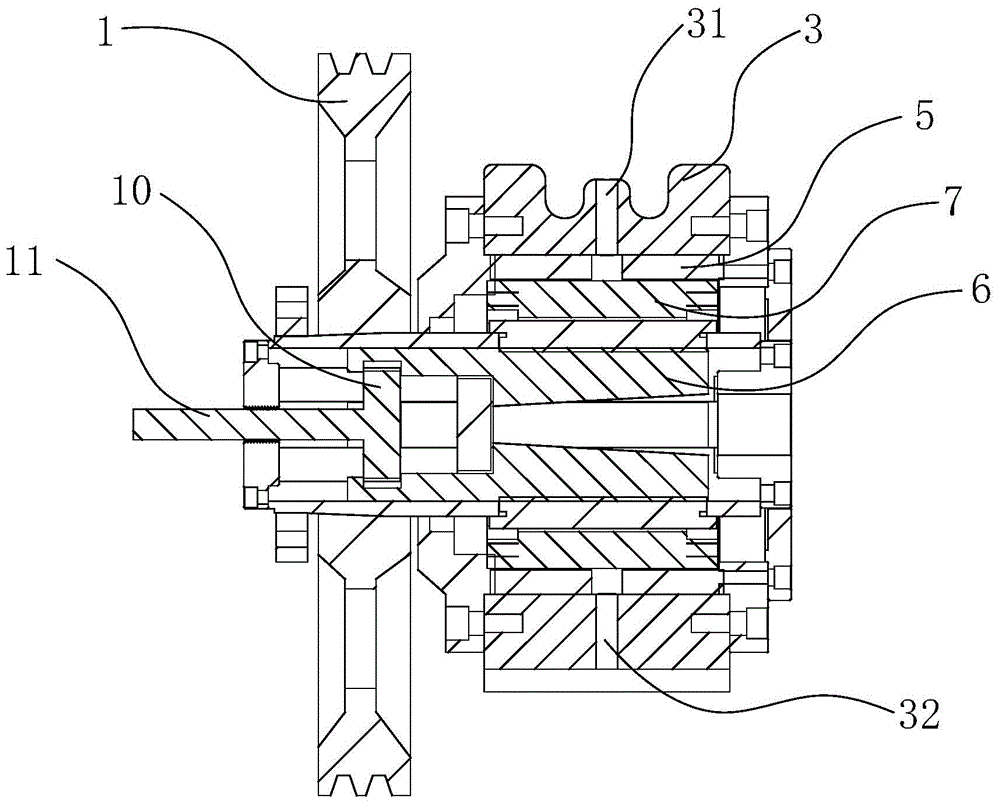

[0029] Examples, see e.g. Figure 1 to Figure 3 As shown, the present invention relates to a tapered tube machine, comprising a machine base 3, a main shaft 8 and a roller 9 installed in the machine base 3, the machine base 3 is installed on an oil tank 4, and lubricating oil is arranged in the oil tank 4, and the machine base 3 Placed vertically with the fuel tank 4 on the ground, an oil inlet 31 is arranged above the machine base 3, a pipeline connected to the fuel tank 4 is installed on the oil inlet 31, and an oil outlet is arranged below the machine base 3 32, the oil outlet 32 is connected to the oil tank 4.

[0030] Such as Figure 1 to Figure 7 As shown, a main shaft 8 is installed in the machine base 3, the main shaft 8 includes a mold part 82 and a power part 81, the mold part 82 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com