Roller bit and manufacturing method thereof

A roller cone bit and roller cone technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of reducing the space of the roller cone bearing, limiting the potential of the roller cone bearing, and occupying the space of the cone shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

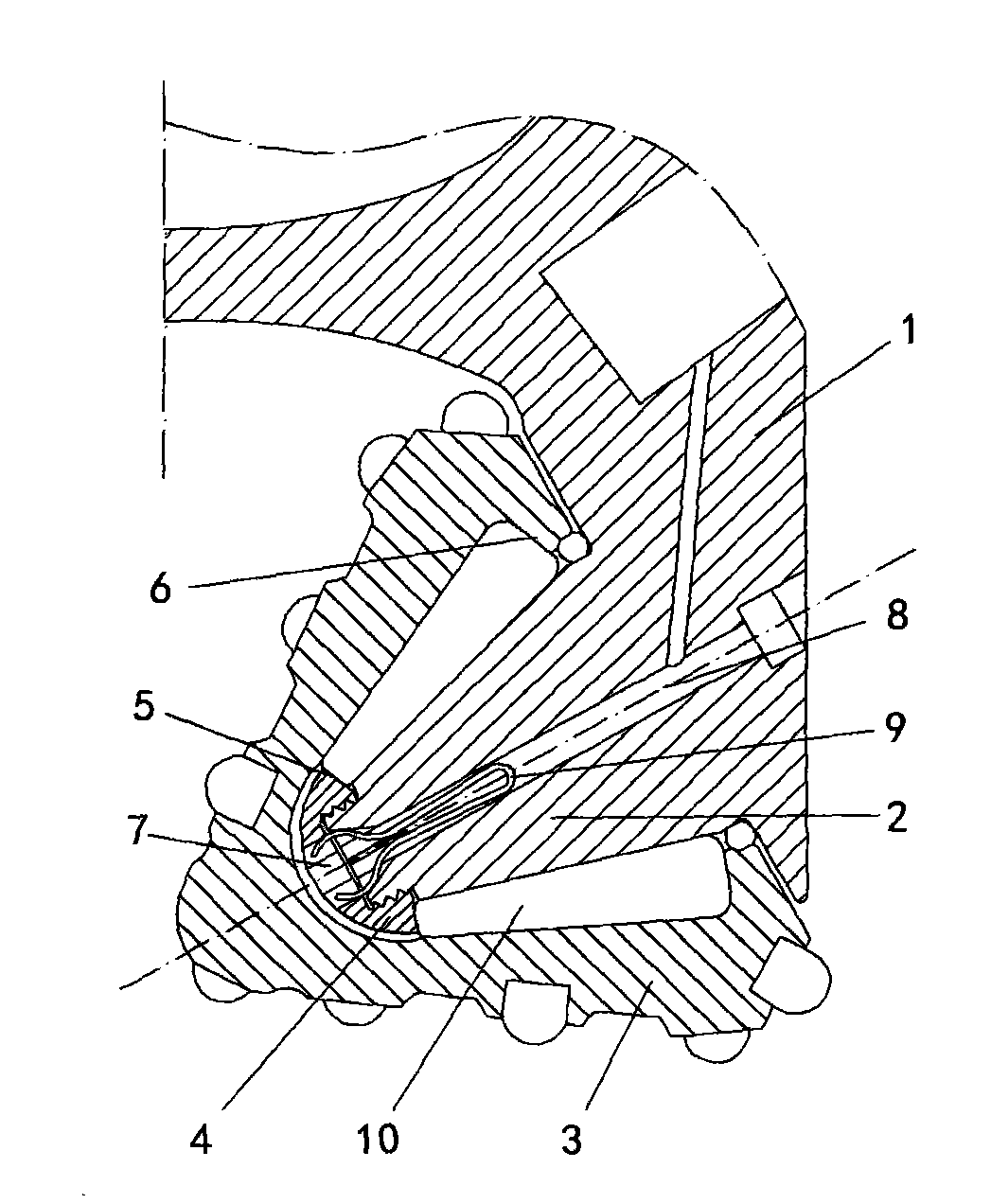

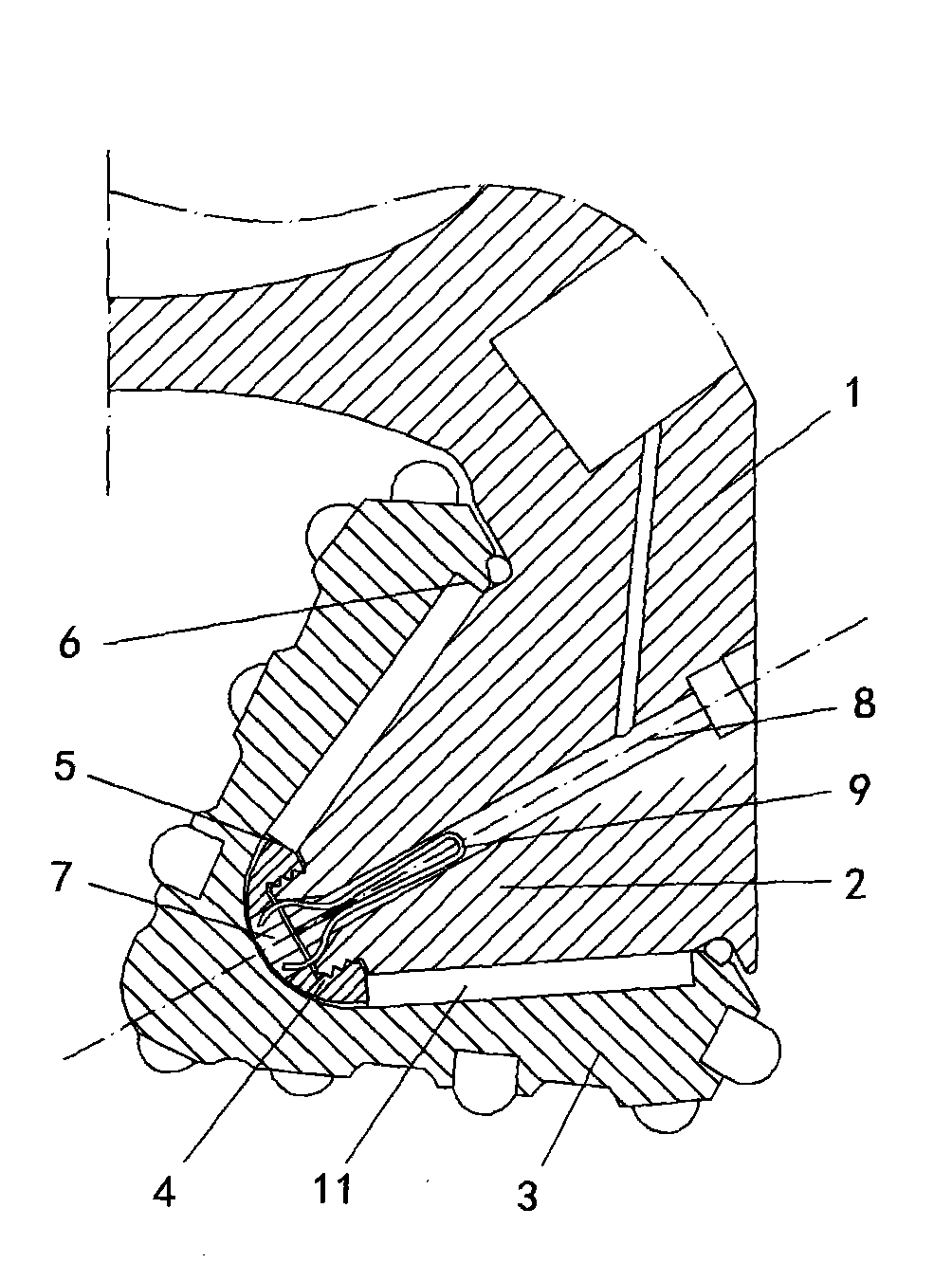

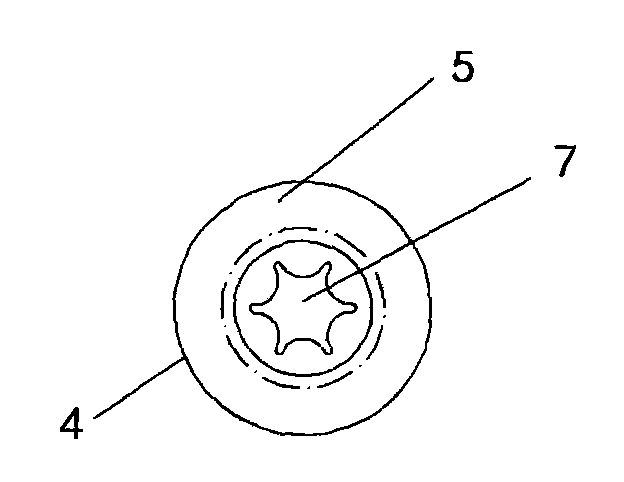

[0020] like figure 1 Shown is a partial cross-sectional schematic diagram of the roller cone bit adopting the rolling cone bearing of the present invention, wherein 1 is the claw, 2 is the claw shaft, 3 is the cone shell, 4 is the lock nut, and 5 is the thrust surface of the lock nut , 6 is the thrust surface in the cone shell, 7 is the tightening mouth, 8 is the through hole of the claw shaft axis, 9 is the pincer-shaped anti-rotation collar, 10 is the rolling cone, and the rest, especially with the inventor The previous application number is: 201210519957.8 patent and other conventional gears are similar, such as the sealing plugs, oil storage chambers and oil passages of the claw shaft axis through holes, etc. are not drawn in detail, and will not be described in detail. Wherein the outer tapered surface of claw shaft 2 is the tapered bearing runway, cooperates with the gear housing 3 and the rolling cone 10, and becomes a complete tapered bearing system under the constrain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com