Method for preparing uniform three dimensional nanometer fluid passage by femto-second laser

A femtosecond laser, three-dimensional nanotechnology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of low inner wall finish, limited length, complex three-dimensional micro-nano hollow structure, etc., and achieve the effect of high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

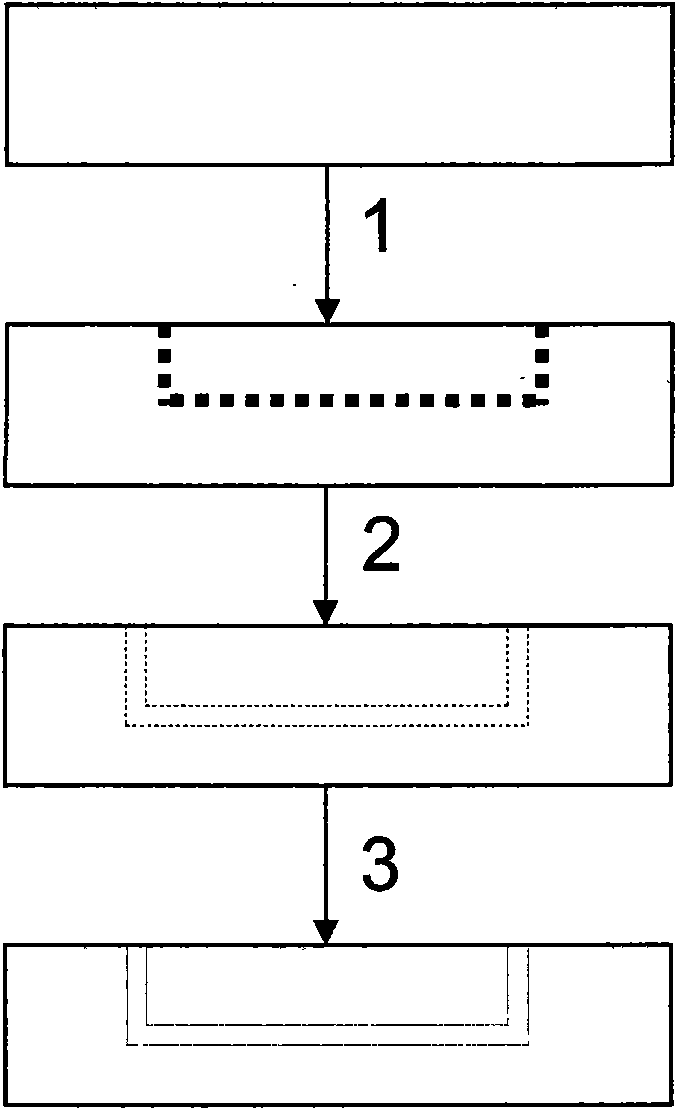

[0021] Below by embodiment the present invention will be further described, but should not limit protection scope of the present invention with this. see first figure 1 , figure 1 It is a schematic flow chart of the method for preparing a uniform three-dimensional nanofluidic channel by using a femtosecond laser in the present invention. Now, taking quartz glass as an example to illustrate the method of the present invention, it can be seen from the figure that the method for preparing a uniform three-dimensional nanofluidic channel by using a femtosecond laser in the present invention includes Follow these three steps:

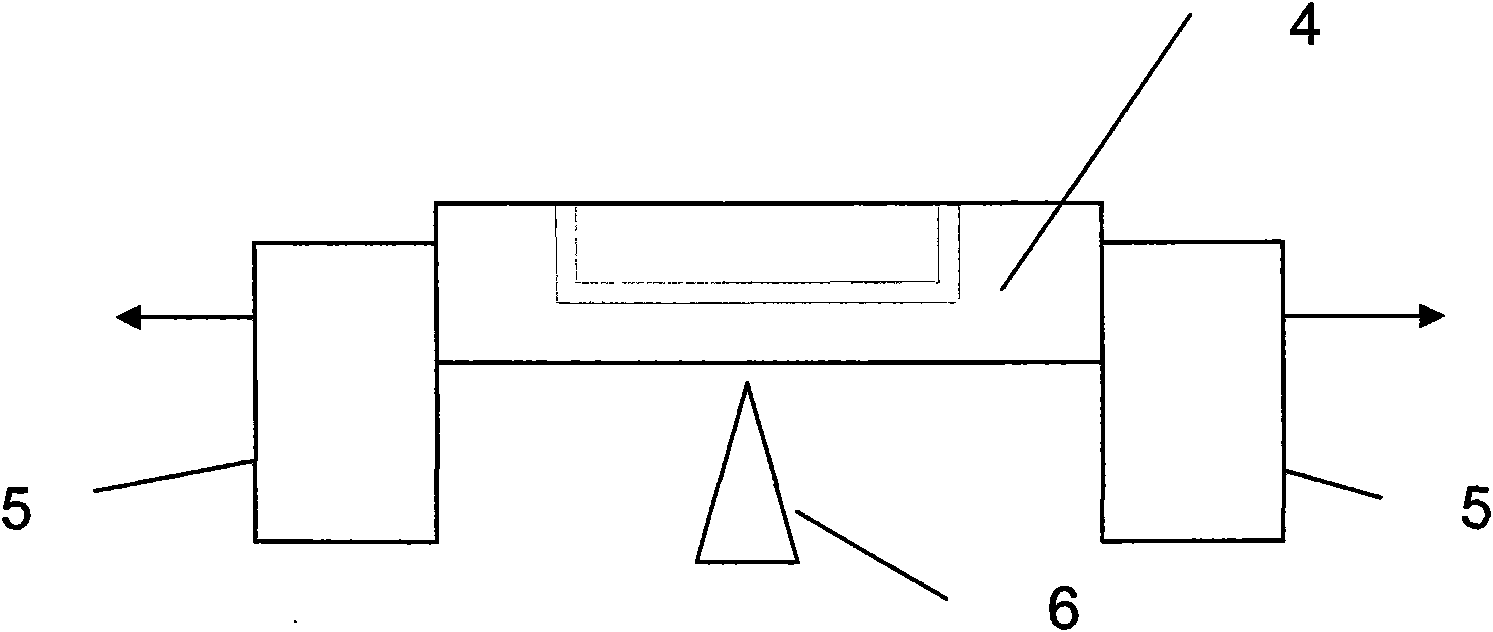

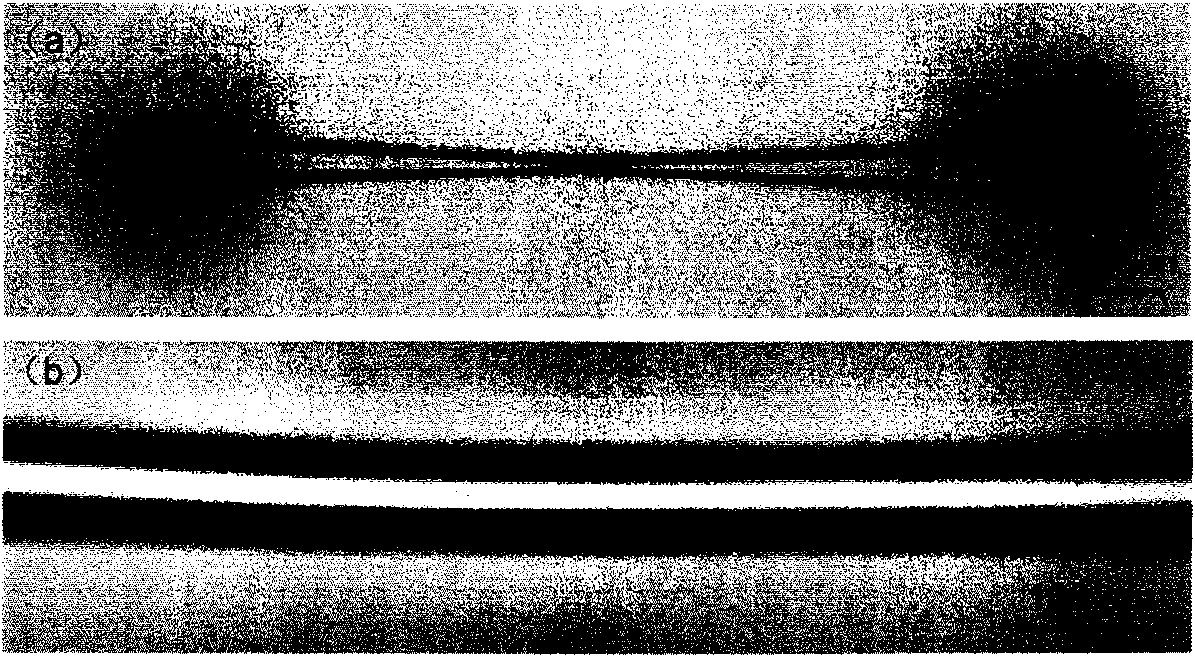

[0022] (1) Femtosecond laser irradiation: Take a quartz glass sample 4 with a size of 10mm×5mm×1mm and polish the upper and lower surfaces, and fix it on a three-dimensional displacement platform after cleaning; when the femtosecond laser directly writes a three-dimensional pattern inside the quartz glass sample 4 The pulse width is 40±2fs, the center wavel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com