Method and device for preparing microchannel in glass material

A glass material and microchannel technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as high cost, low production efficiency, and limited aspect ratio, and achieve low cost, fast processing speed, The effect of uniform longitudinal morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

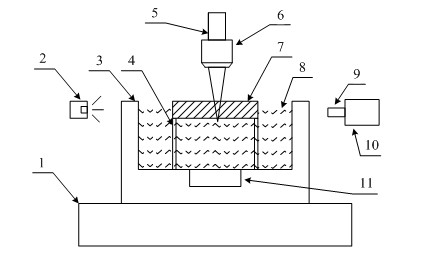

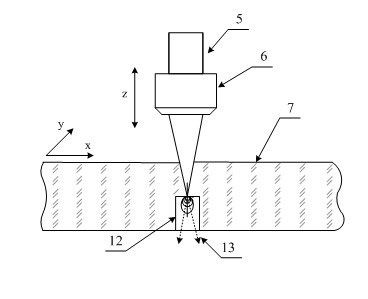

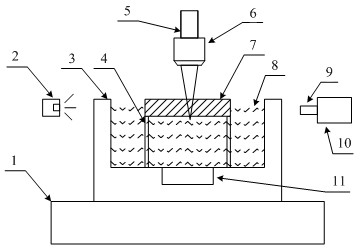

[0035] Silicate glass is now taken as an example to illustrate the inventive method, by figure 1 , 2 Visible, the present invention utilizes ultrasonic water to assist nanosecond laser to prepare the method for three-dimensional microchannel as follows:

[0036] (1) Fix the ultrasonic cleaning machine filled with distilled water on the horizontal workbench of the three-dimensional platform 1. The body of the ultrasonic cleaning machine 3 is made of transparent material, the power is 50W, and the frequency is 20KHz.

[0037] (2) Fix the silicate glass material to be processed (13mm×5mm×2mm in size) on the support 4 in the ultrasonic cleaning machine, the lower surface of the glass material 7 to be processed is immersed in distilled water, and the upper surface is exposed in the air. Simultaneously CCD camera 10 is connected on the computer so that location and real-time observation processing process;

[0038](3) Using a nanosecond laser with a center wavelength of 1064nm, a ...

example 2-4

[0041] Examples 2-4 adopt the device and process parameters in Table 1, and proceed according to the same working process as Example 1, and the microchannel parameters after processing are shown in Table 2.

[0042] The technological parameter that table one example 2-4 adopts

[0043]

[0044] Table 2 Microchannel parameters after processing

[0045]

[0046] The method of the invention is suitable for preparing three-dimensional microchannels inside various glass materials, as long as the nanosecond laser processing parameters are properly selected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com