Supporting rolling post and method for correcting crankshaft journal cylindricity

A technology of crankshaft journal and support roll, which is applied in the field of crankshaft processing, can solve the problems of weakening rolling strengthening effect, inability to roll convex correction and straightening, adverse effects of rolling strengthening, etc., and achieve the effect of weakening rolling strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

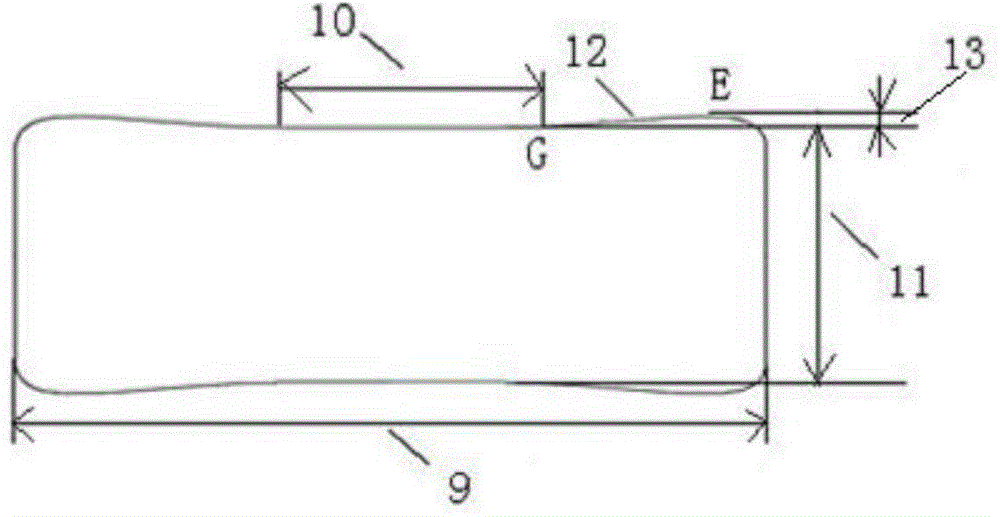

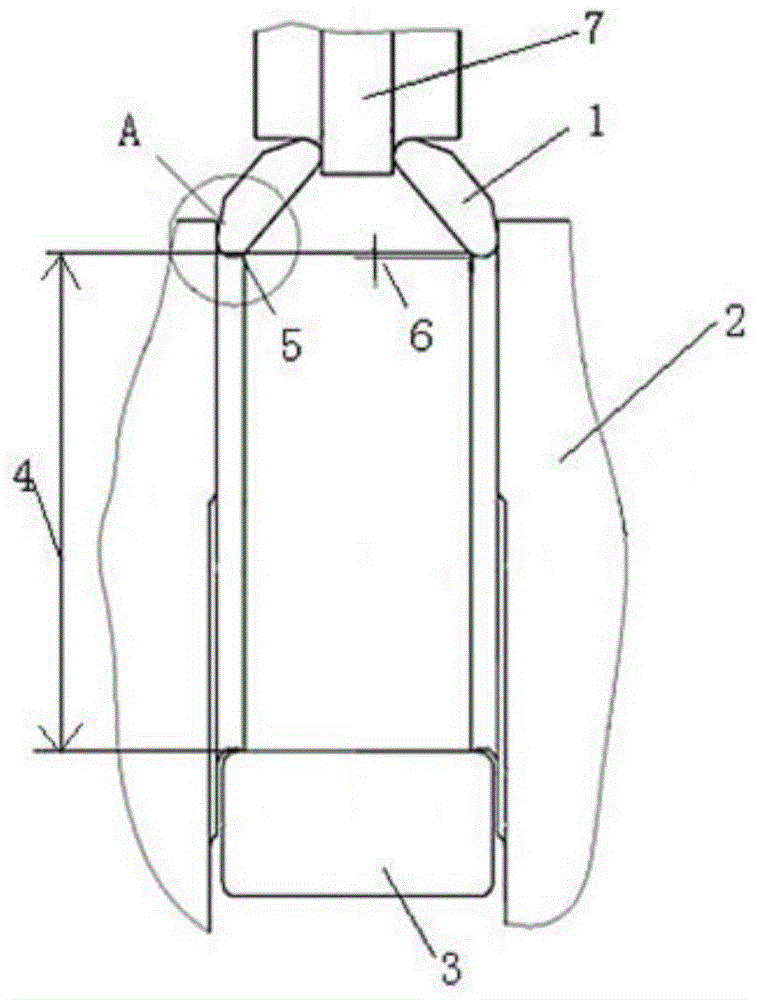

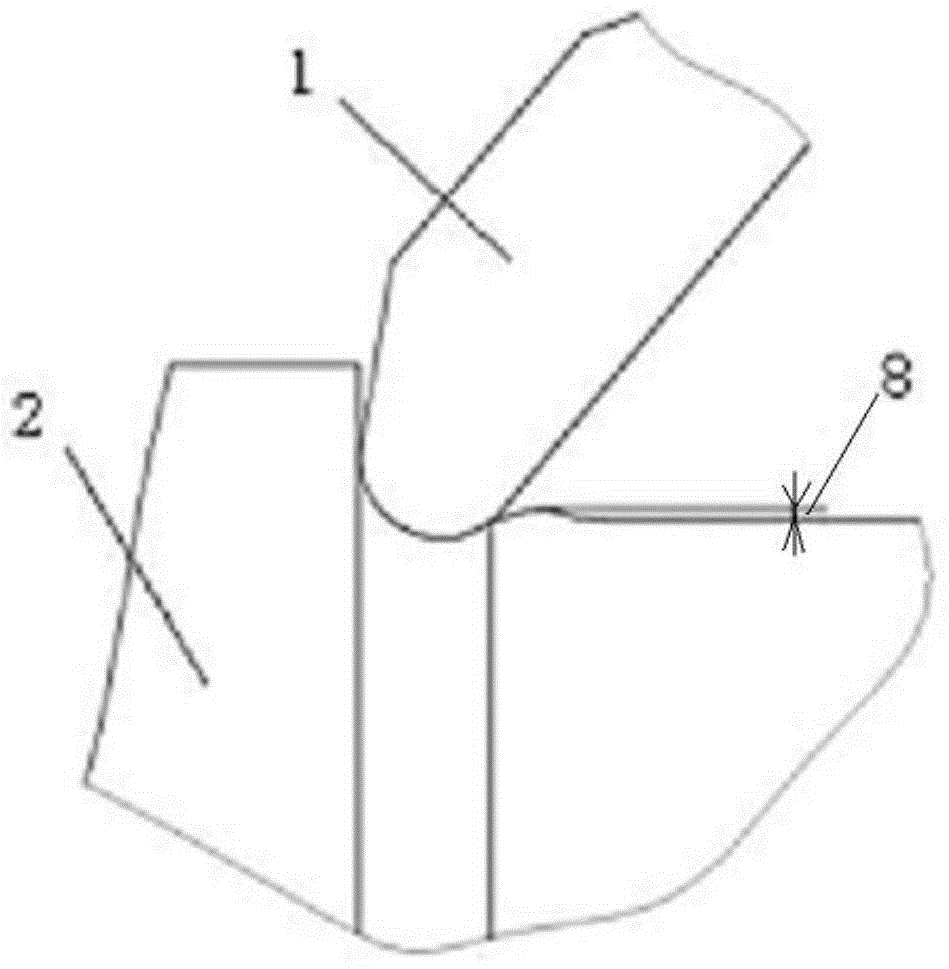

[0041] Such as figure 1 As shown, a support roller for correcting the cylindricity of a crankshaft journal according to the present invention includes a support roller 3, the support roller 3 includes a cylindrical part in the middle and a curved surface part in the end, during the rolling process The part of the curved surface at the end is in line contact with the rolling protrusion of the journal of the crankshaft 2, which can increase the contact area between the supporting roller 3 and the rolling protrusion, thereby increasing the force of the supporting roller 3 on the rolling protrusion, Under the action of high contact stress, the supporting rollers rotate continuously with the rolling process of the crankshaft journal, and gradually correct the rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com