Patents

Literature

141results about How to "Improve slice quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for cutting transparent material by using ultra-short pulse laser

ActiveCN102785031AAccelerateSmall kerfFine working devicesGlass severing apparatusMaterial consumptionTransfer procedure

The invention provides a method for cutting a transparent material by using ultra-short pulse laser. The ultra-short pulse laser output by an ultra-short pulse laser generating device is condensed by a condensation device so as to form a bunching laser beam; the bunching laser beam enters from the surface of the transparent material to be machined, so that the center refractive index at a laser application point is increased to form a waveguide structure along a laser emitting direction; the laser is transmitted to the inside of the transparent material along the waveguide structure, and continuously generates a waveguide structure along the laser emitting direction in a transmission process until the entire waveguide structure and the laser penetrate through the transparent material; and therefore, the laser moves in a direction which is vertical to the surface of the transparent material at uniform speed, so that a waveguide plane is formed in the transparent material. The invention further provides a device for cutting the transparent material by using the ultra-short pulse laser. The method and the device for cutting the transparent material by using the ultra-short pulse laser provided by the invention have the advantages of fast cutting speed, small cutting seam, no material consumption and no powder pollution. When the machined material bears a suitable external force, the material is cracked only along a stress fault surface; the broken surface nearly has no conical degree; and the roughness is good.

Owner:WUHAN JUNNO TECH

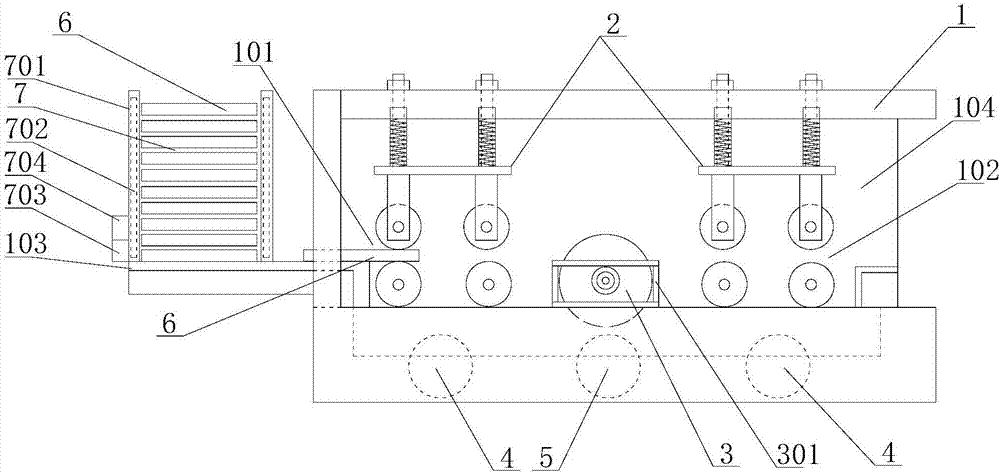

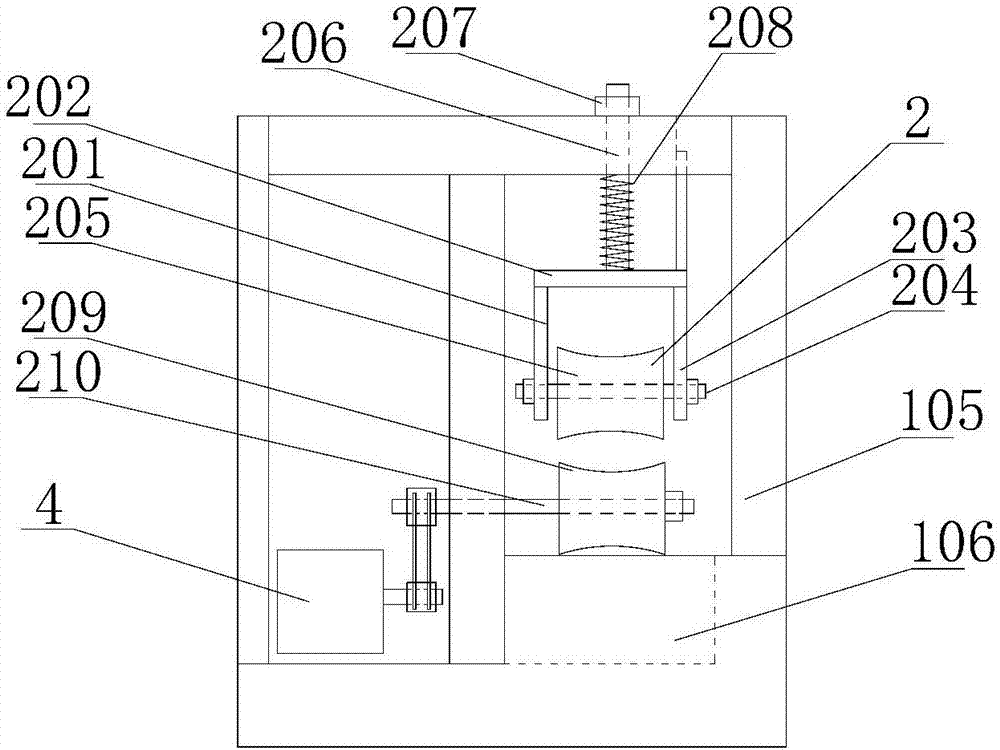

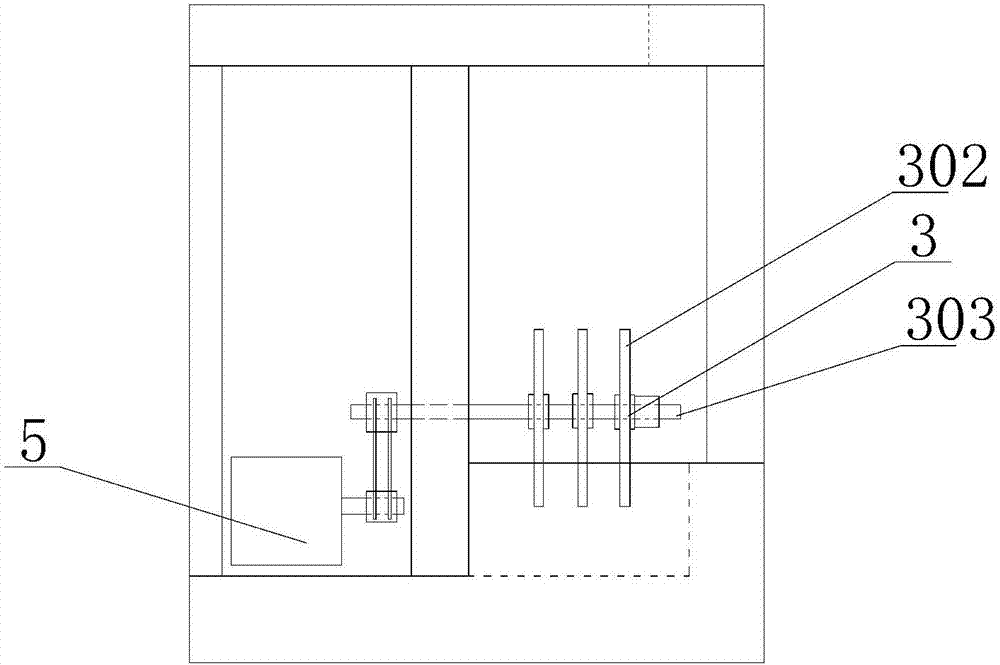

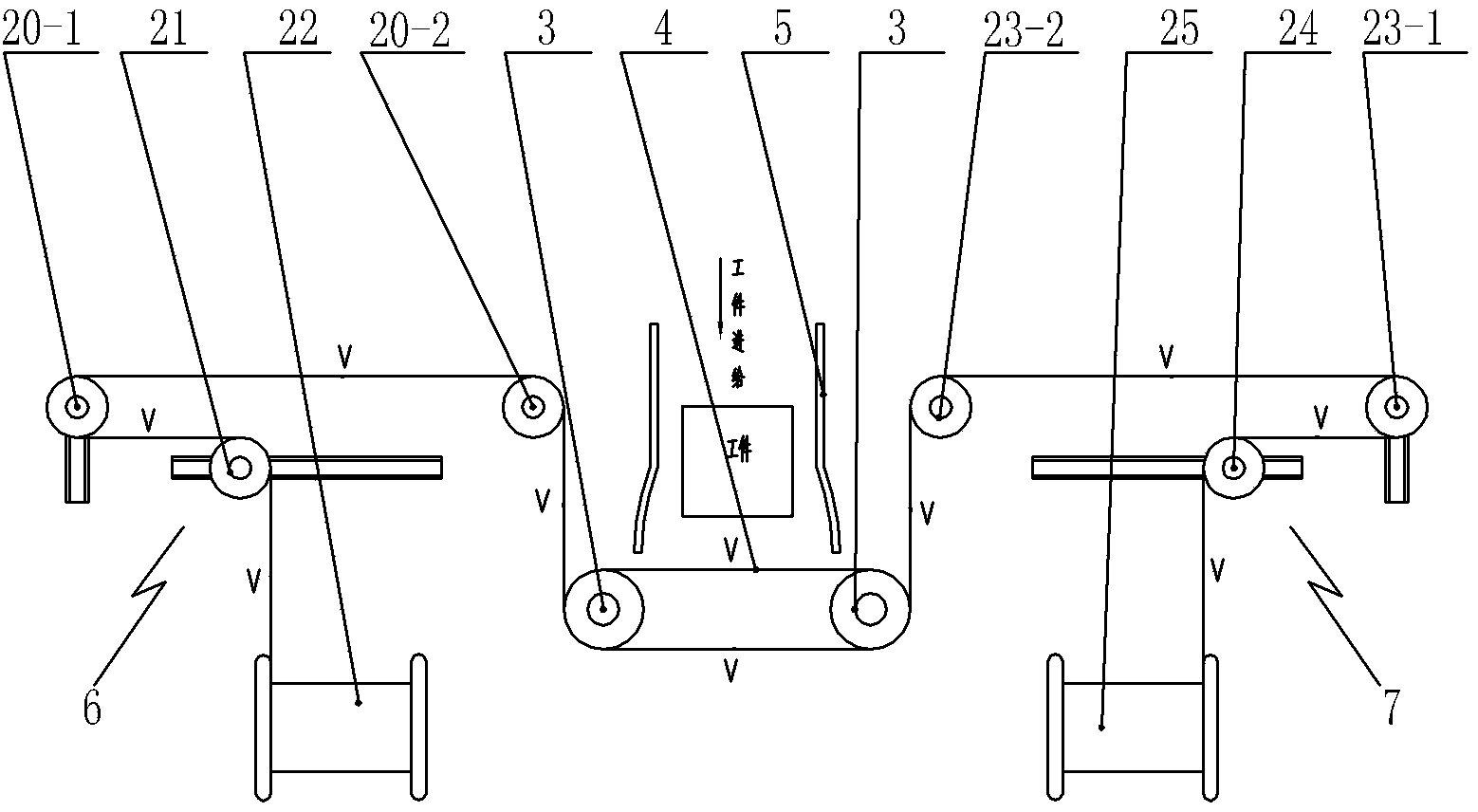

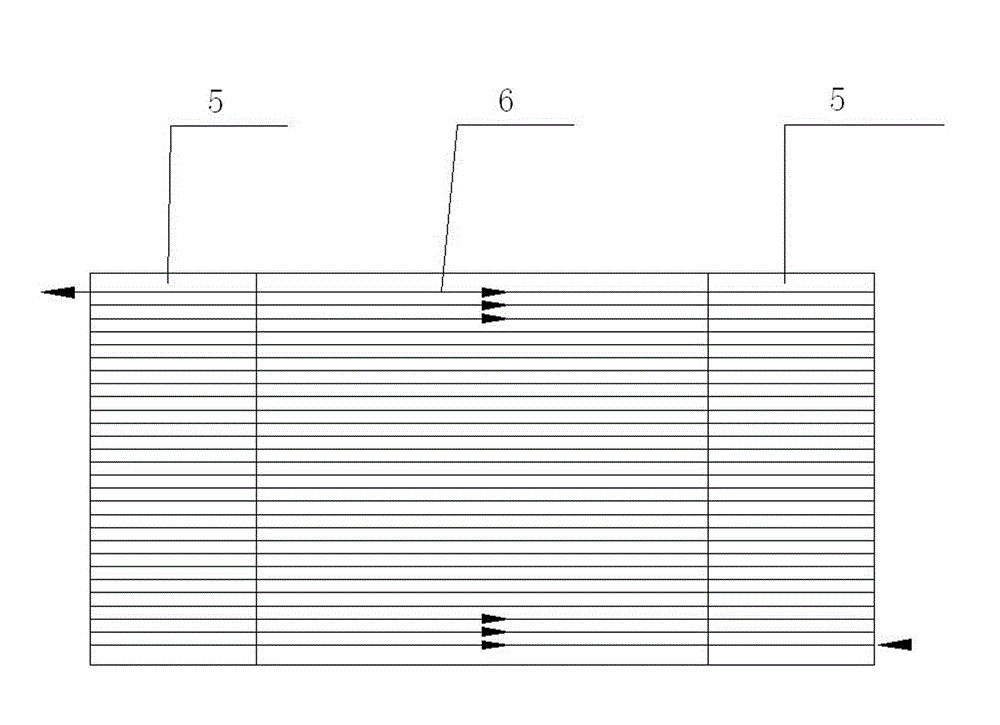

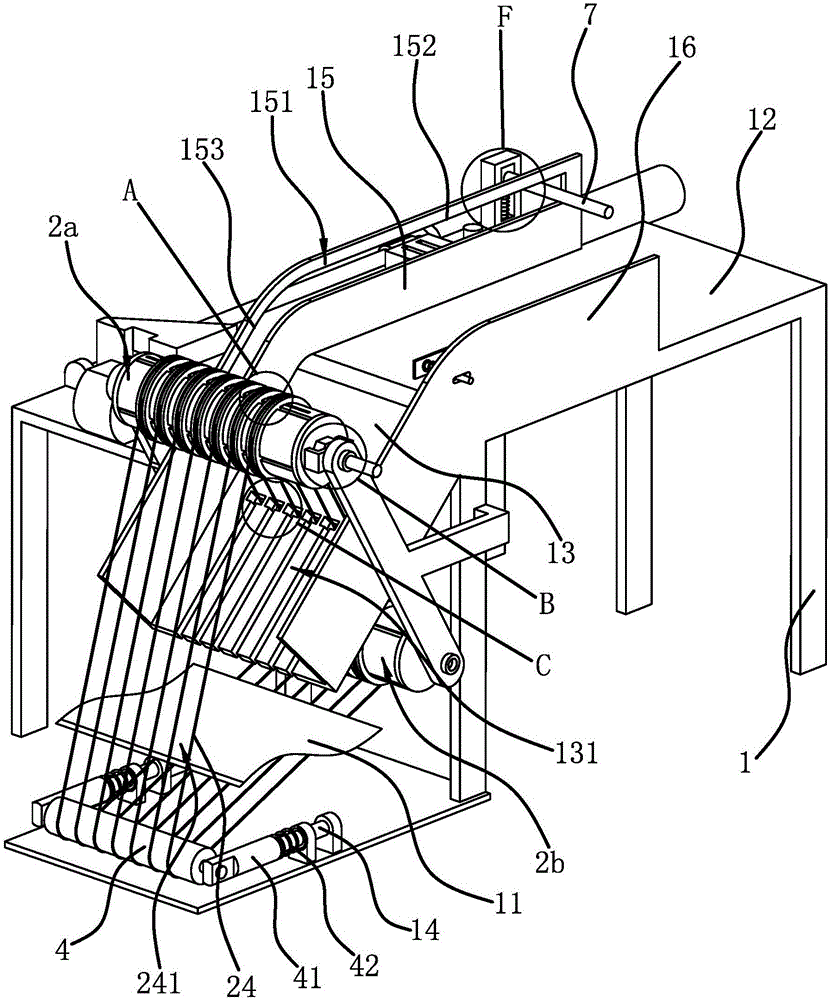

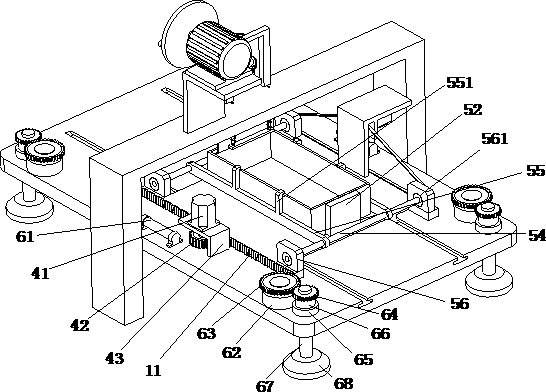

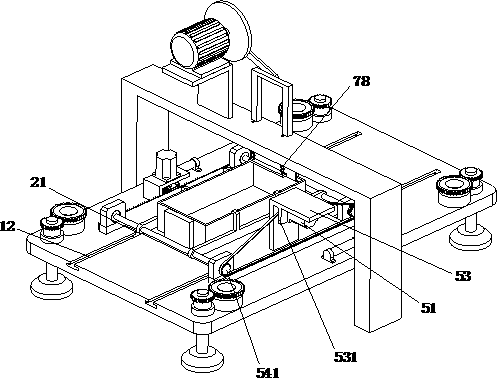

Stick slicing machine

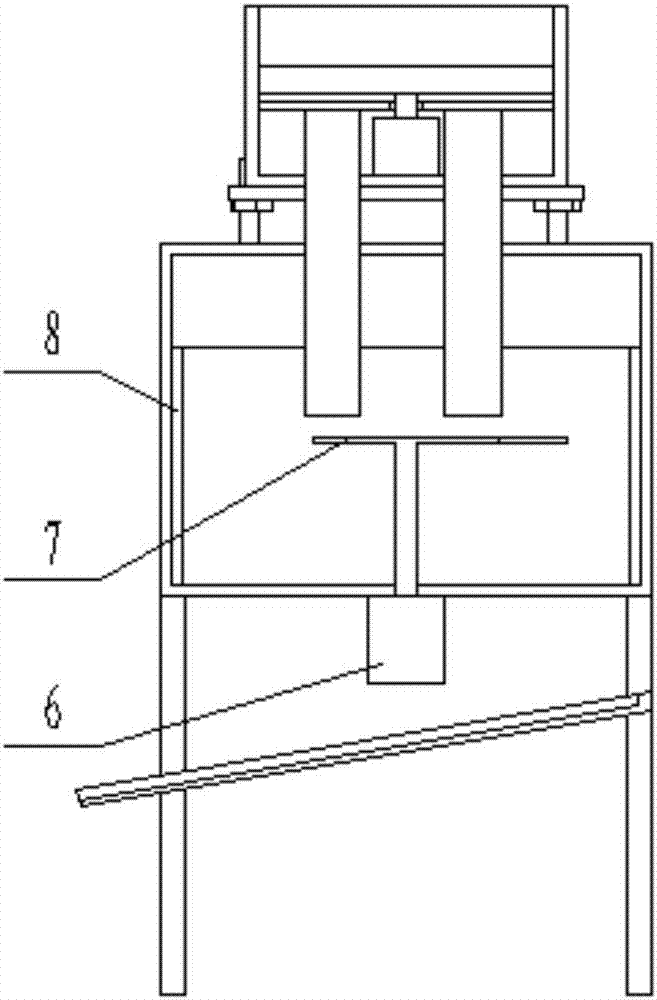

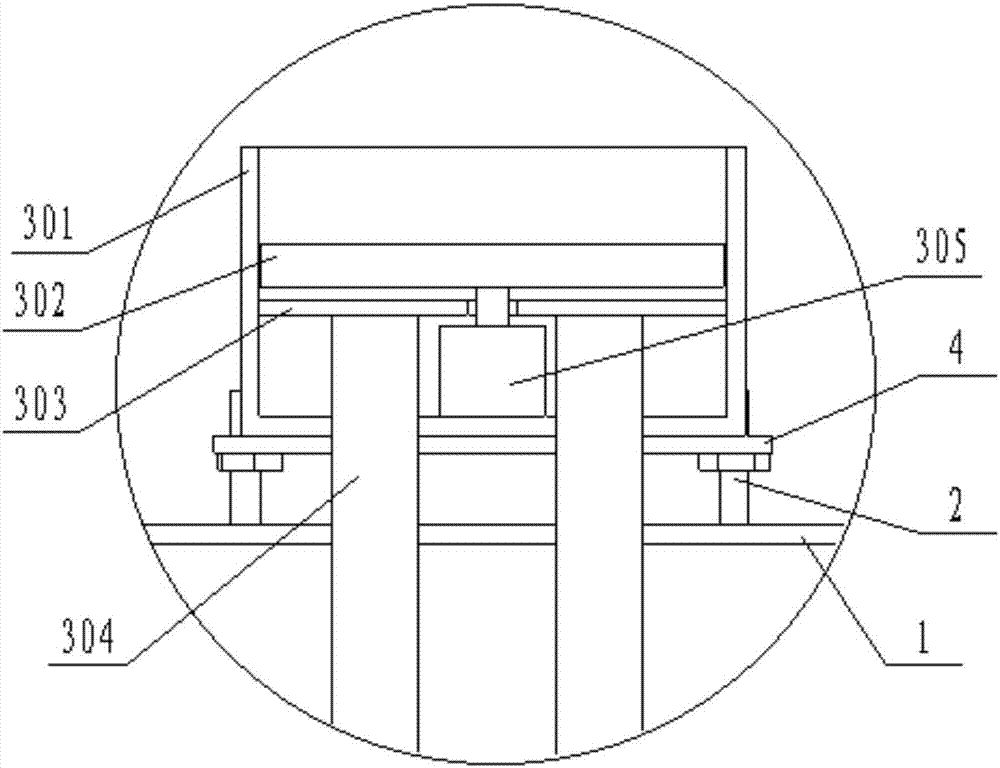

PendingCN107398955AImprove slicing efficiencyNo stuttering will occurFeeding devicesDrying gas arrangementsDrive shaftEngineering

The invention discloses a stick slicing machine and belongs to the technical field of wood processing. The stick slicing machine comprises a rack, a conveying mechanism, a cutting mechanism, a driving mechanism, a feeding frame and a storage frame. A conveying channel for sticks to pass is arranged in the rack. The conveying mechanism is arranged on the conveying channel and is used for conveying the sticks. The conveying mechanism comprises two conveying devices. Each conveying device comprises multiple upper guide wheels, multiple lower guide wheels and an upper guide wheel support. The cutting mechanism is arranged between the two conveying devices and comprises multiple disc saw blades, a cutting support and a second transmission shaft. The cutting support is arranged on the rack. The disc saw blades are rotationally arranged on the rack through the second transmission shaft. The drive mechanism is arranged on the rack and comprises a first drive motor and a second drive motor. The feeding frame is arranged on the rack and is provided with a conveying belt. The storage frame is arranged on the feeding frame and can contain the sticks and dry the sticks. The stick slicing machine solves the problem that an existing stick slicing machine is low in slicing efficiency.

Owner:广西河池市宜州梦若天蓝信息科技有限公司

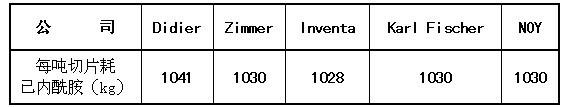

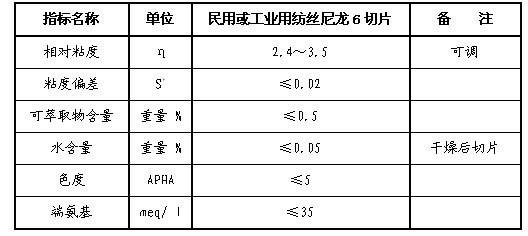

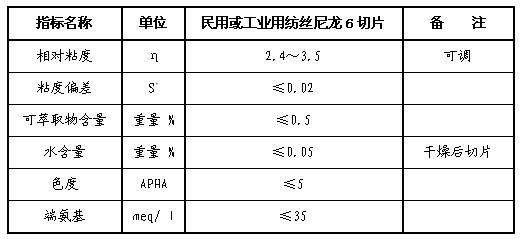

Production process for preparing fiber-grade nylon 6 chips with extracted aqueous concentrated solution and apparatus thereof

ActiveCN102382296AImprove slice qualityQuality improvementMonocomponent polyamides artificial filamentMaterial consumptionPolymerization reactor

The invention relates to a production process for preparing fiber-grade nylon 6 chips with extracted aqueous concentrated solution, which includes the following steps: filter pressing: the extracted aqueous concentrated solution is filter-pressed by a high-temperature filter press; preparation: the extracted aqueous concentrated solution is first added into a melting kettle, solid caprolactam andmolecular weight stabilizer are then added into a melting kettle, and after heating, caprolactam melt is obtained; prepolymerization: the caprolactam melt is heated by an energy saver, and then enters a prepolymerization reactor, and the prepolymerization reactor is heated and pressurized, so that prepolymerized material is obtained; postpolymerization: the prepolymerized material is sent into a postpolymerization reactor, and the postpolymerization reactor is depressurized to remove residual moisture, removes reaction heat, and keeps the temperature, so that the prepolymerized material carries out polycondensation reaction; dicing; chip extraction; chip drying; and packaging. The technical scheme of the invention can effectively reduce material consumption, energy consumption and pollution, the quality of the nylon 6 chips is high, and moreover, the invention can create high economic and social benefits.

Owner:浙江华建尼龙有限公司

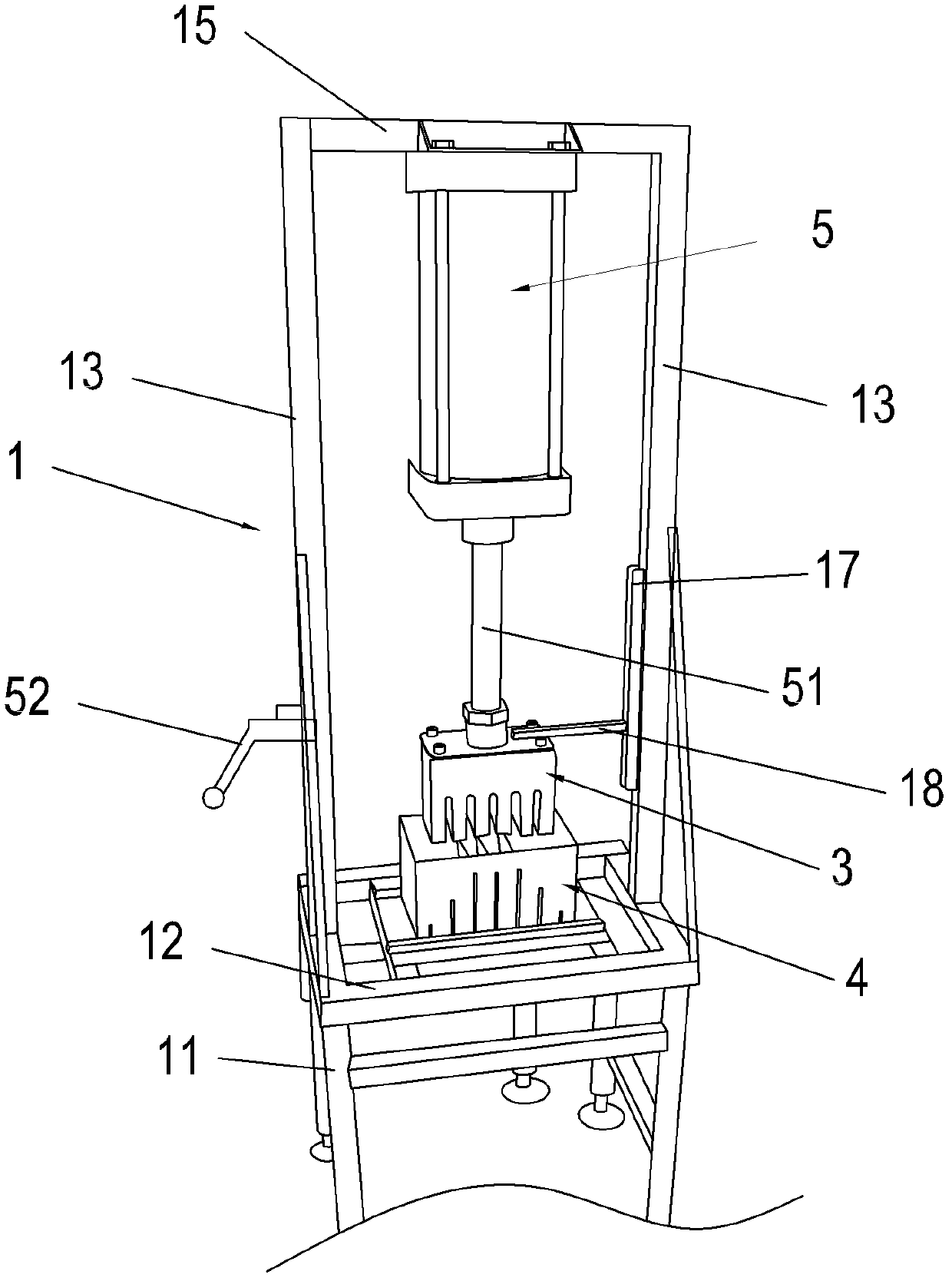

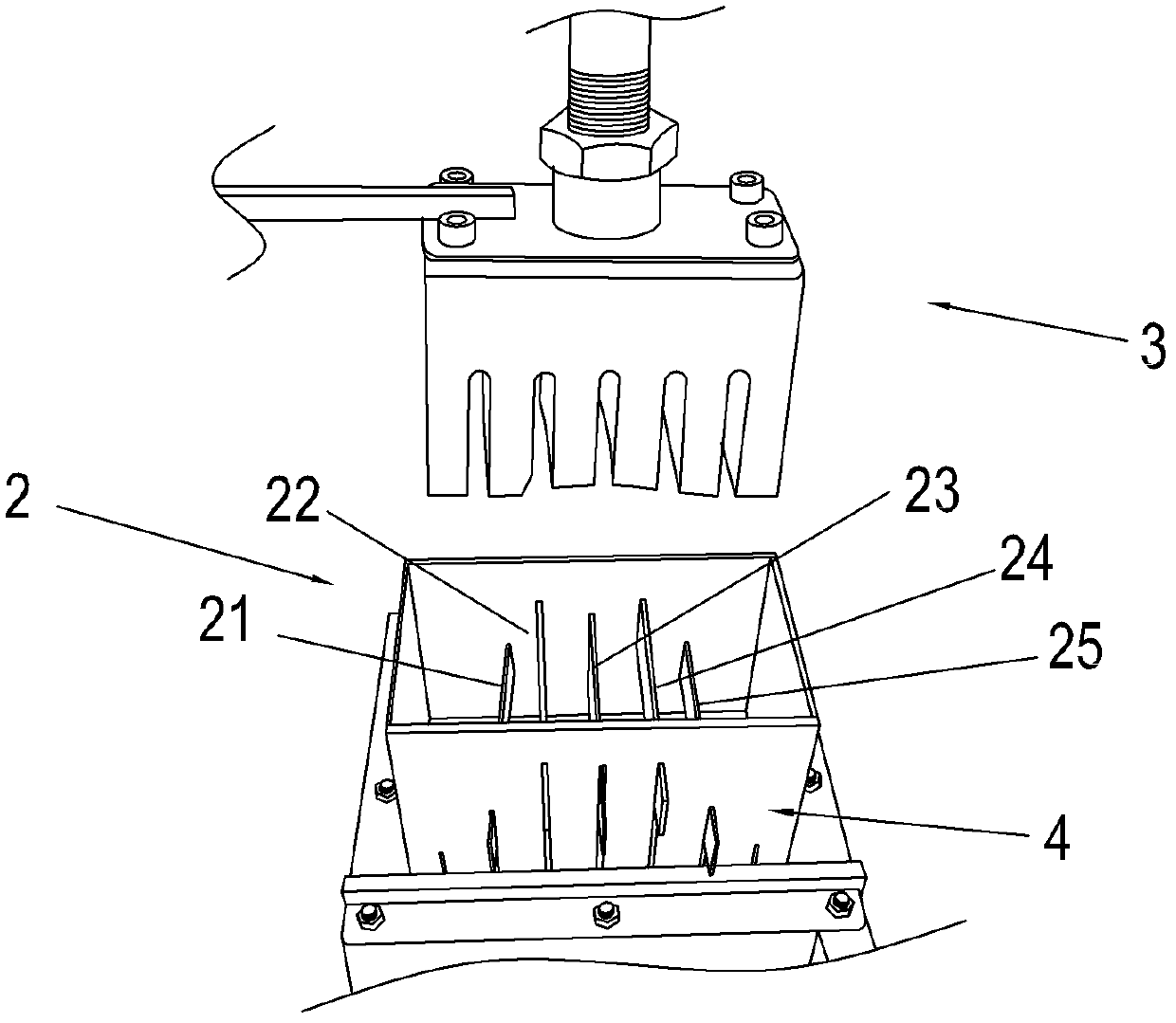

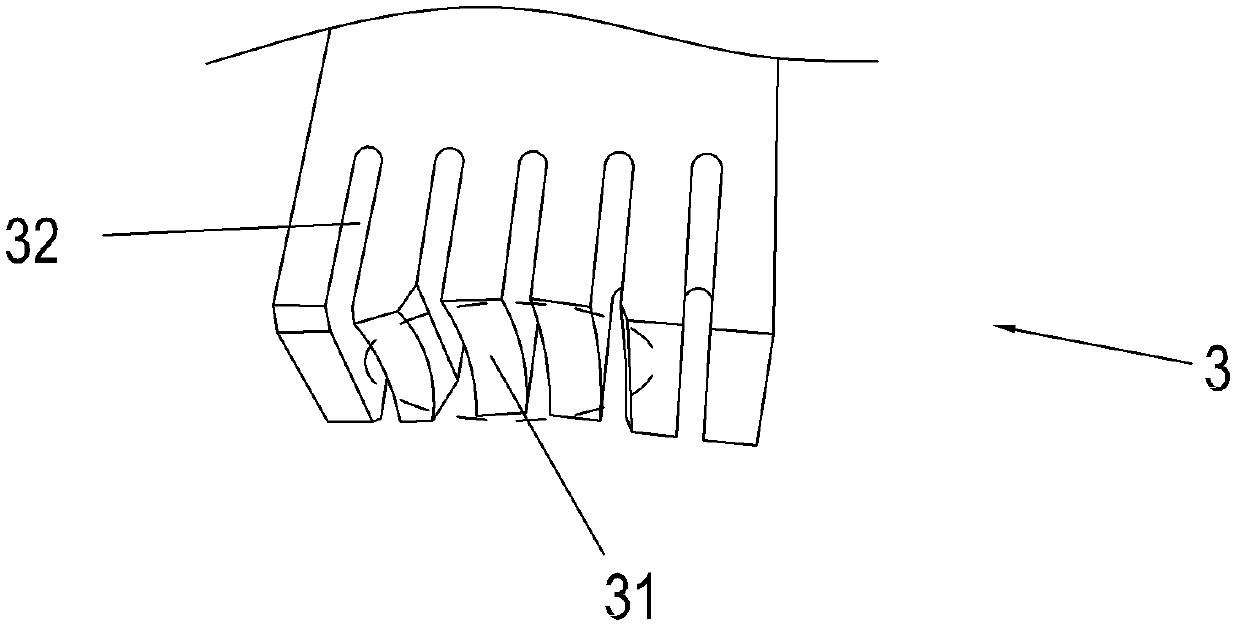

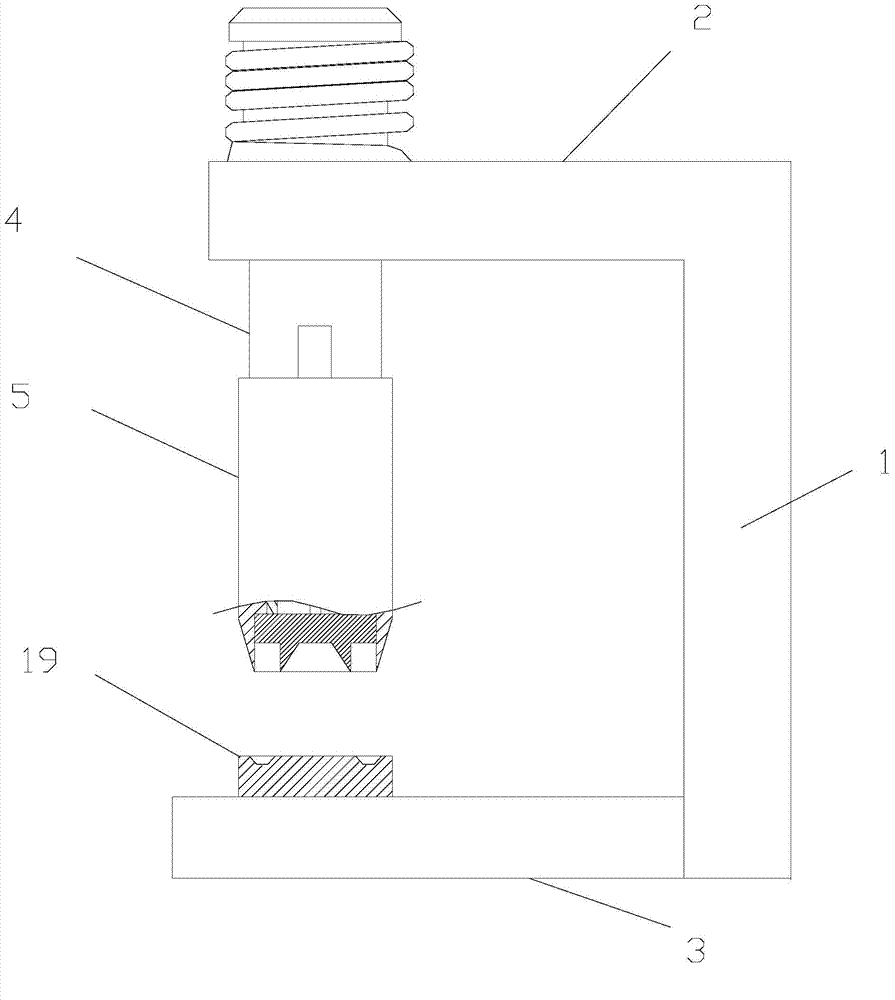

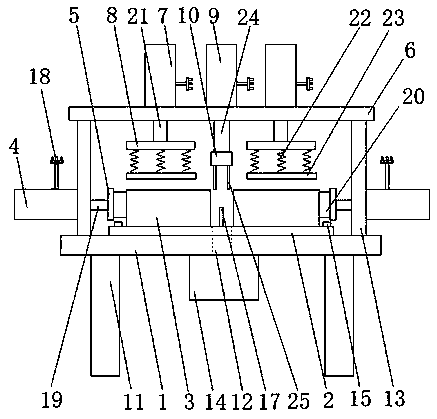

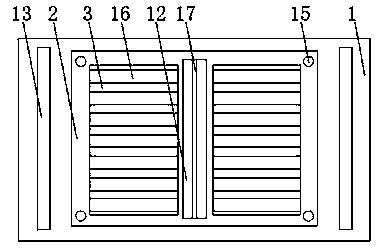

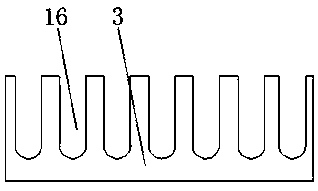

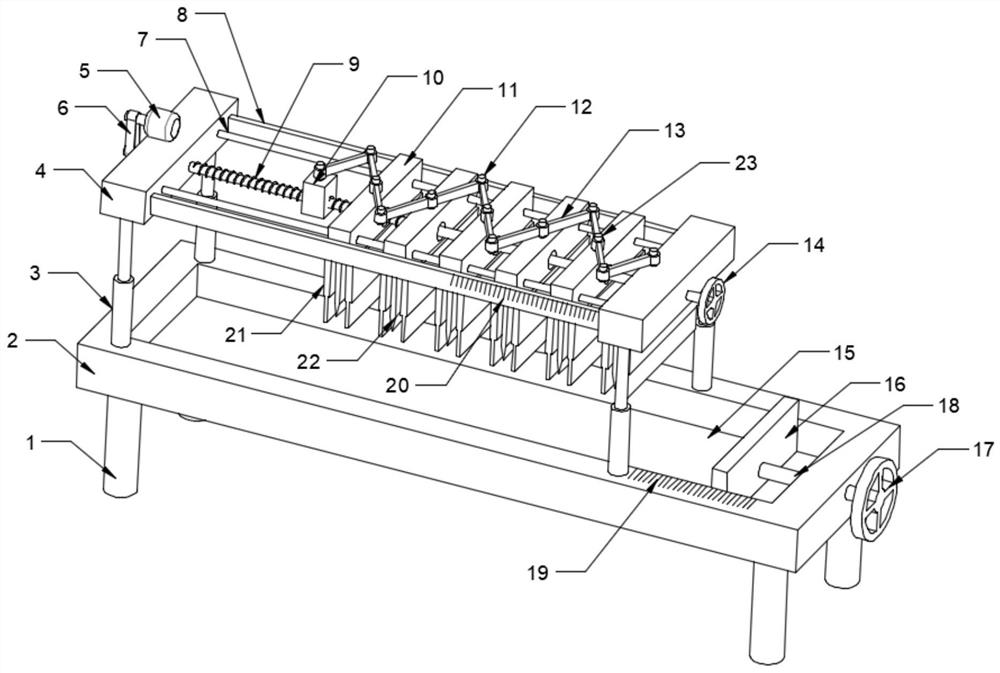

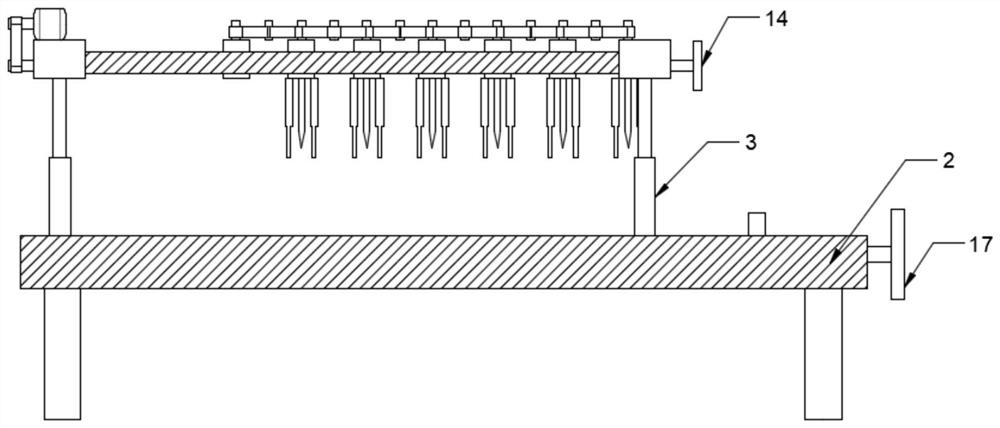

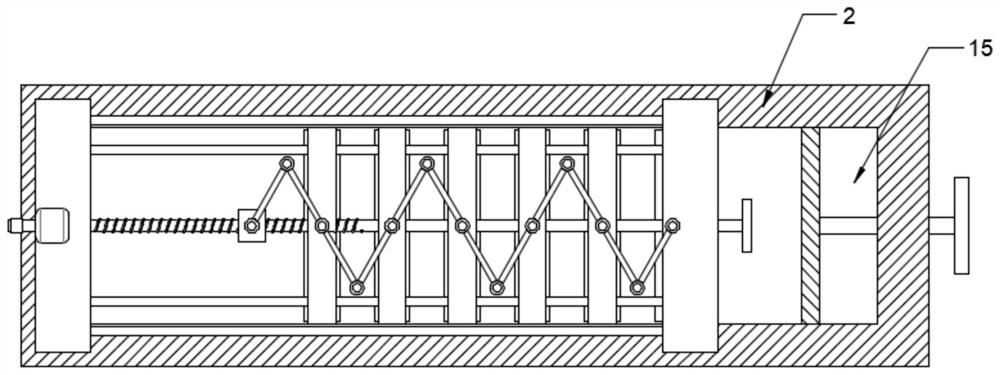

Taro cutting machine

InactiveCN103302686AEnough room for misalignmentAvoid squeezingMetal working apparatusEngineeringMechanical engineering

The invention discloses a taro cutting machine, which comprises a support and at least one slicing device which is arranged on the support, and the taro cutting machine is characterized in that the slicing device comprises a cutter group and a pressing block, wherein the cutter group comprises a plurality of cutters, and the cutters are transversely arranged in parallel and distributed on at least two horizontal planes; and the pressing block enables a taro to sequentially pass through the cutters of the cutter group on each horizontal plane to be sliced, the pressing block is connected with a driving device, and the pressing block is provided with a cutter groove corresponding to the cutter group. In the slicing process, the cutters are staggered on different horizontal planes, so that the taro has sufficient staggering space in the slicing process. The taro can be prevented from being squeezed into segments, and the slicing quality is improved.

Owner:福建省新润食品有限公司

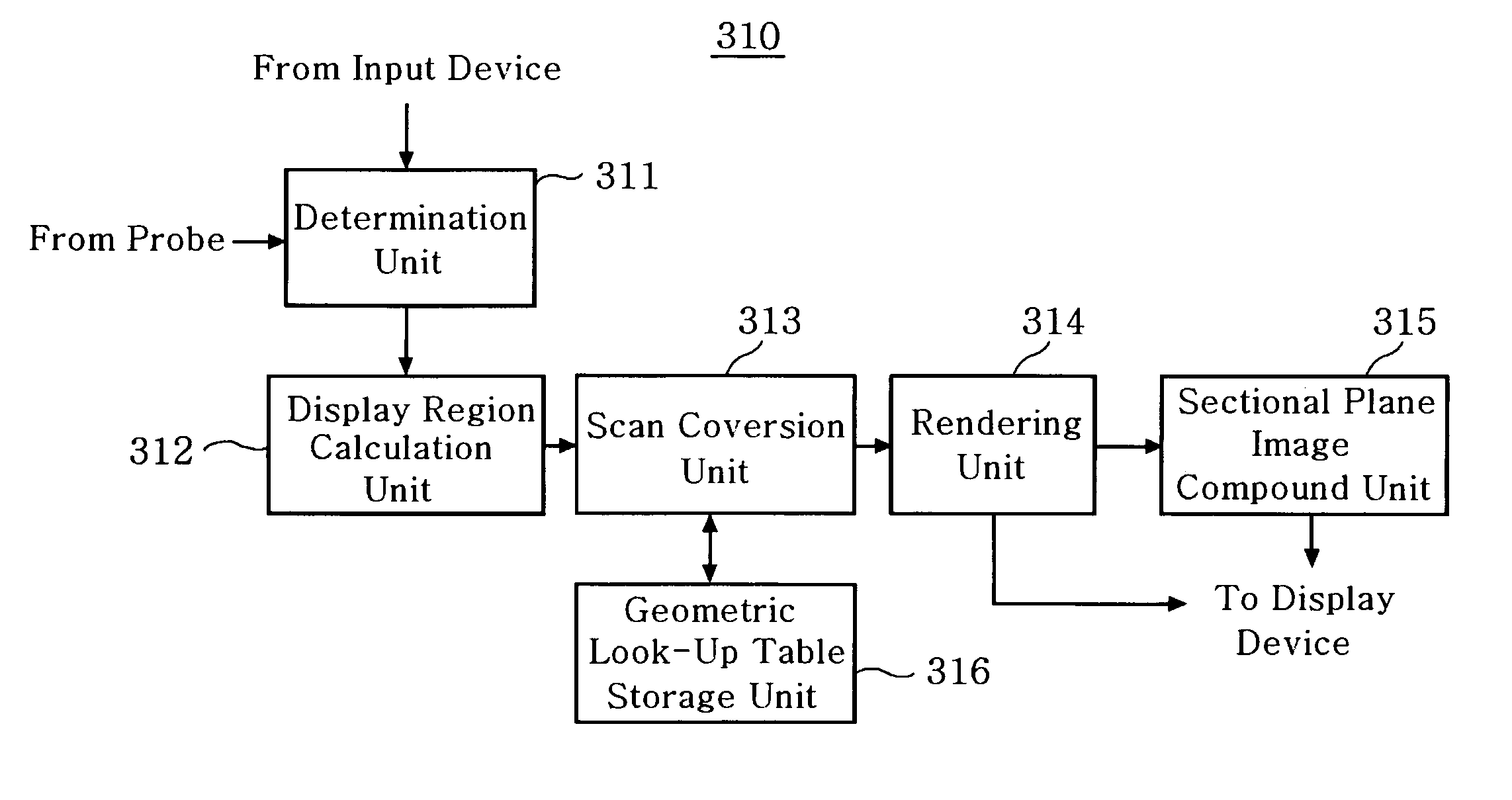

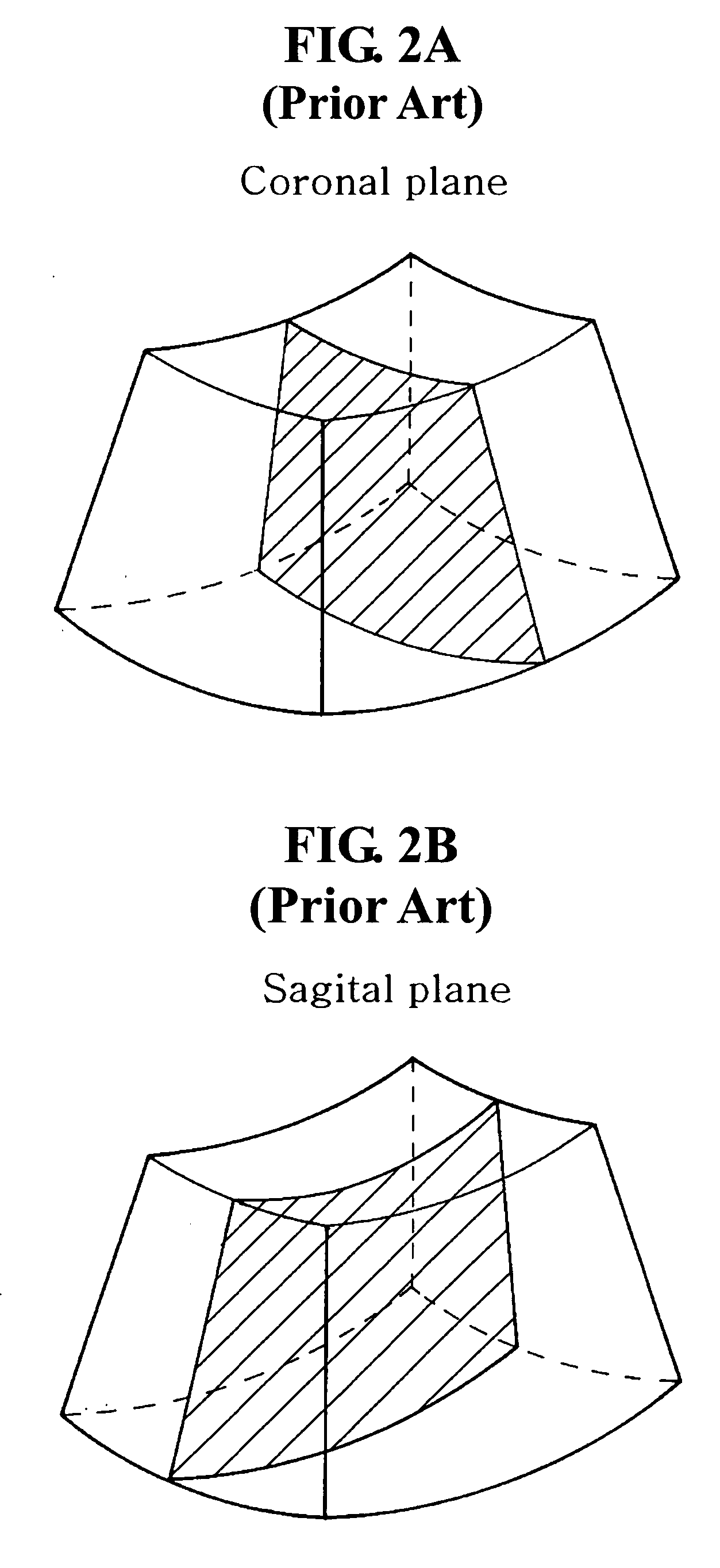

Apparatus and method for enhancing quality of sectional plane image in 3 dimensional ultrasound data

InactiveUS20060100512A1Improve slice qualityUltrasonic/sonic/infrasonic diagnosticsImage enhancementCompound aScan conversion

The present invention relates to an apparatus for enhancing the quality of a sectional plane image in a 3-dimensional ultrasound image. The apparatus for enhancing a sectional plane image in a 3-dimensional ultrasound image, includes: a display region calculation unit for selecting a reference sectional plane image in 3D ultrasound data of a target object received from a probe and calculating a display region to display the selected reference sectional plane image; a geometric look-up table storage unit for storing indices matched with 3-dimensional Cartesian coordinates of a screen displaying the target object and conical coordinates corresponding to the indices; a scan conversion unit for scan-converting conical coordinates of a plurality of sectional plane images with offsets between the sectional plane images adjusted to a predetermined value into Cartesian coordinates by referencing the geometric look-up table storage unit; a rendering unit for rendering the scan-converted sectional plane images including the reference sectional plane image; and a sectional plane image compound unit for compounding a predetermined number of sectional plane images in which the reference sectional plane image is positioned at a center thereof.

Owner:MEDISON CO LTD

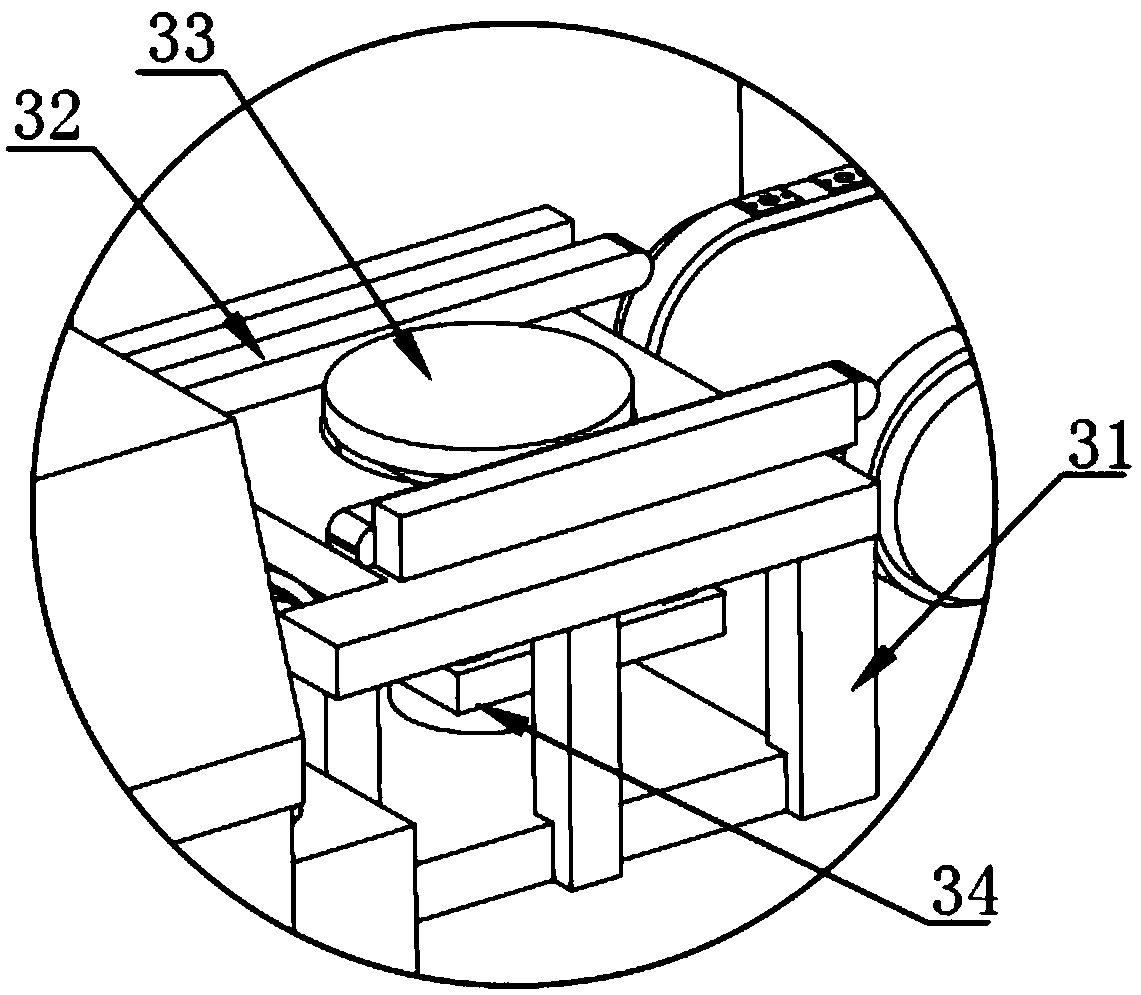

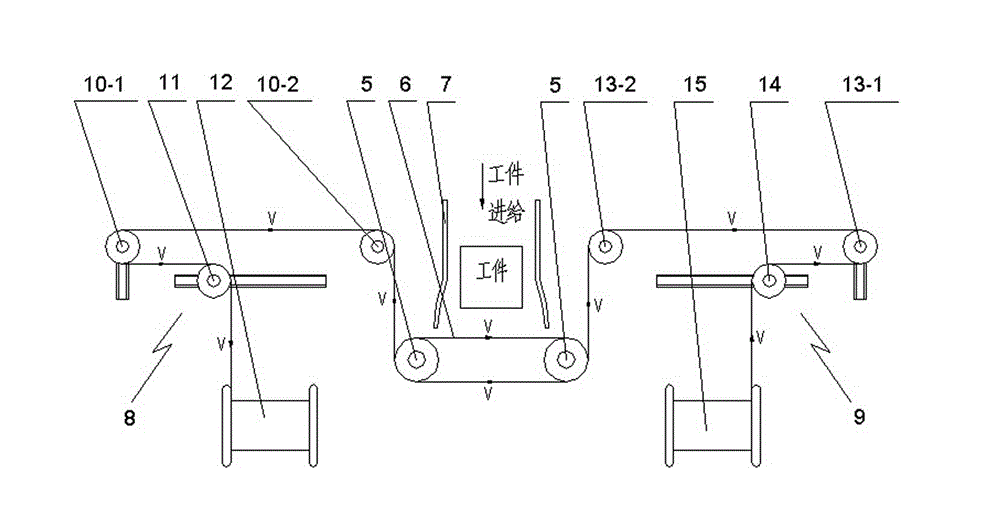

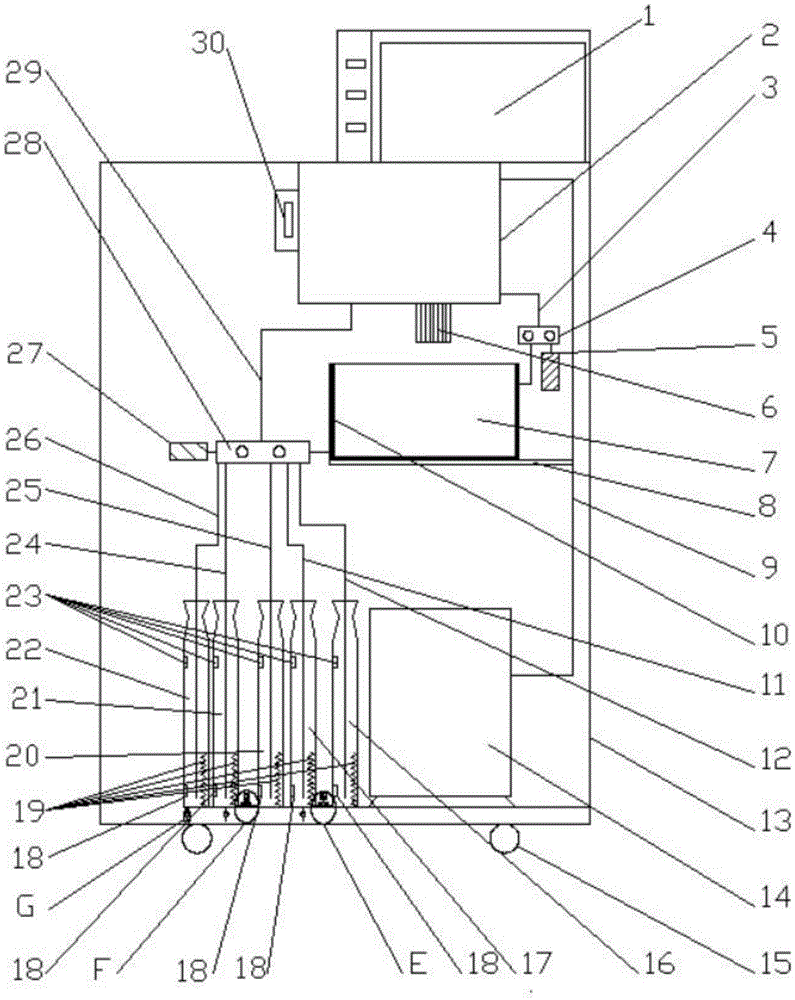

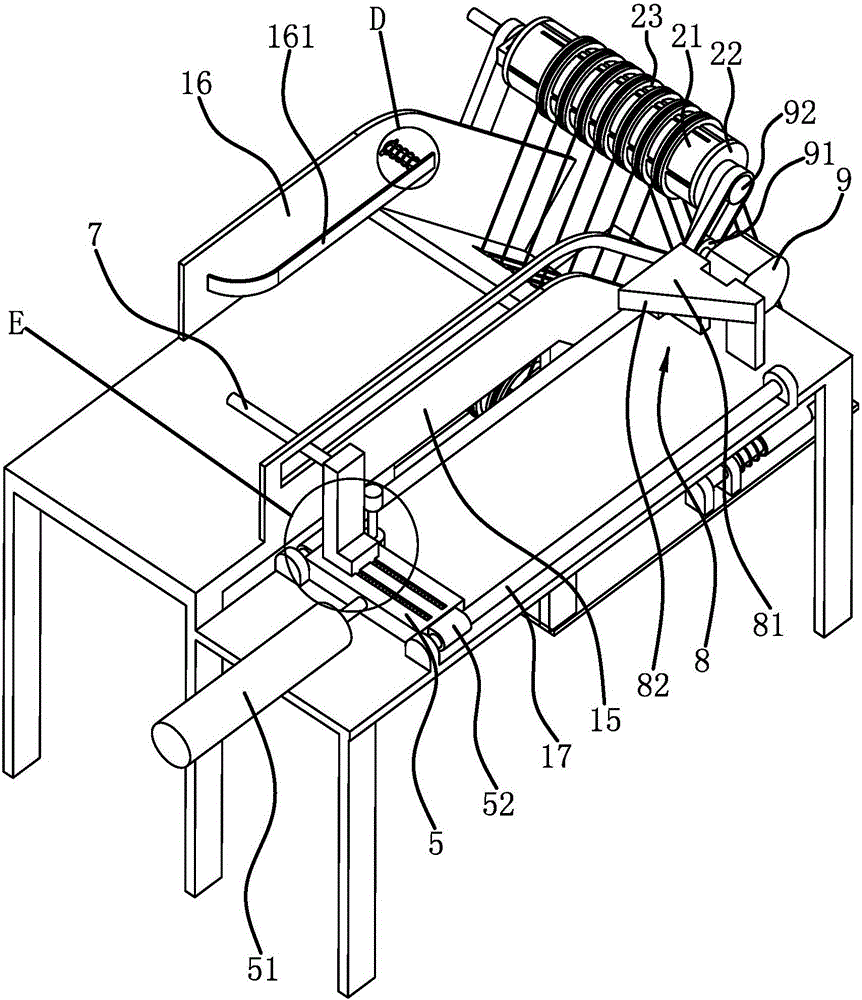

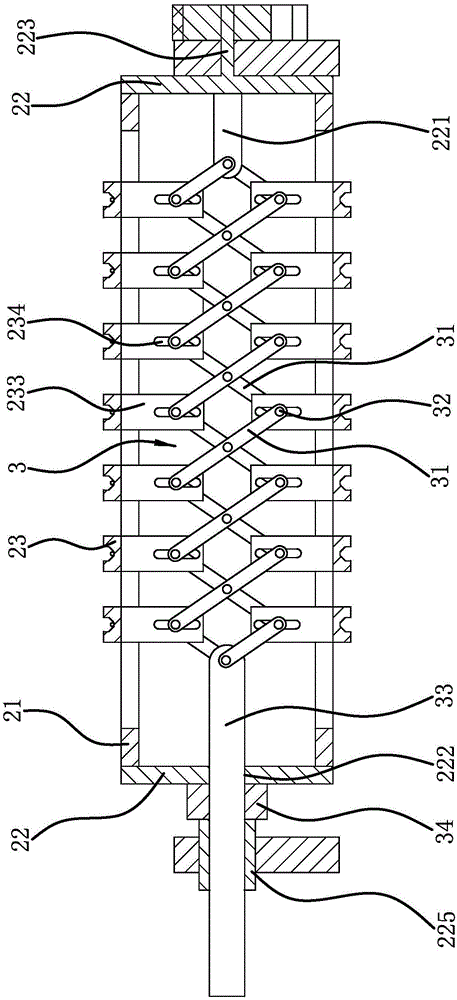

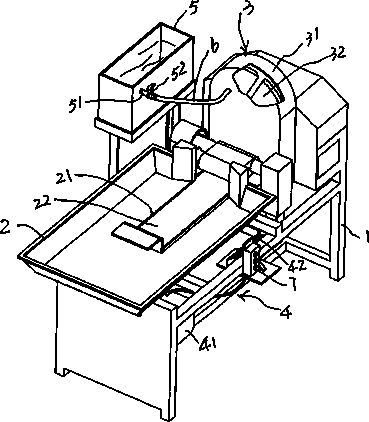

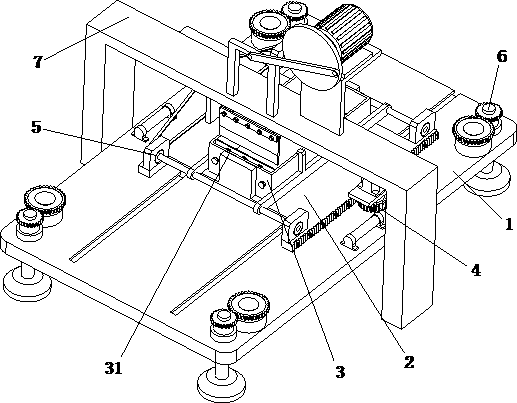

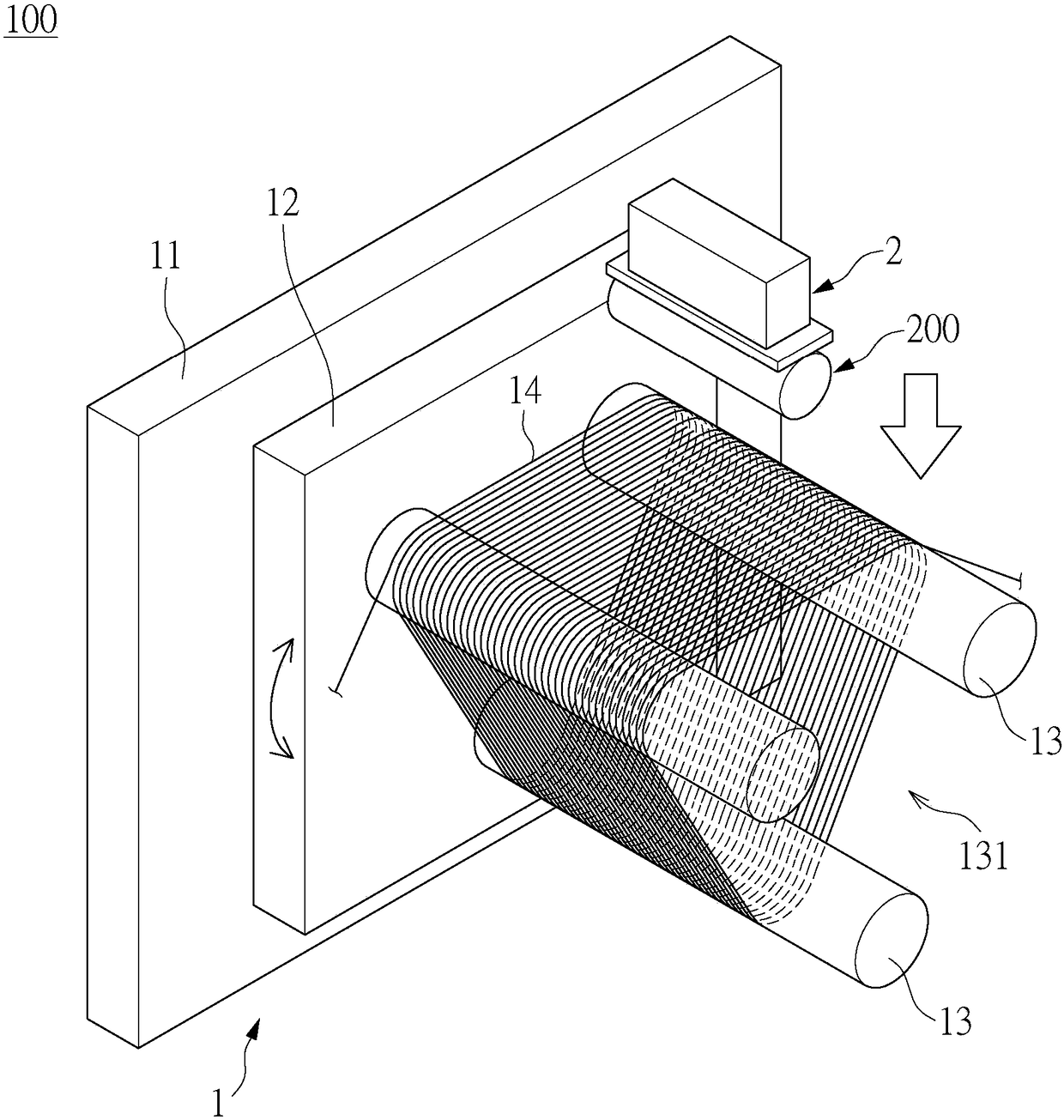

Numerical control diamond wire sapphire slicing machine

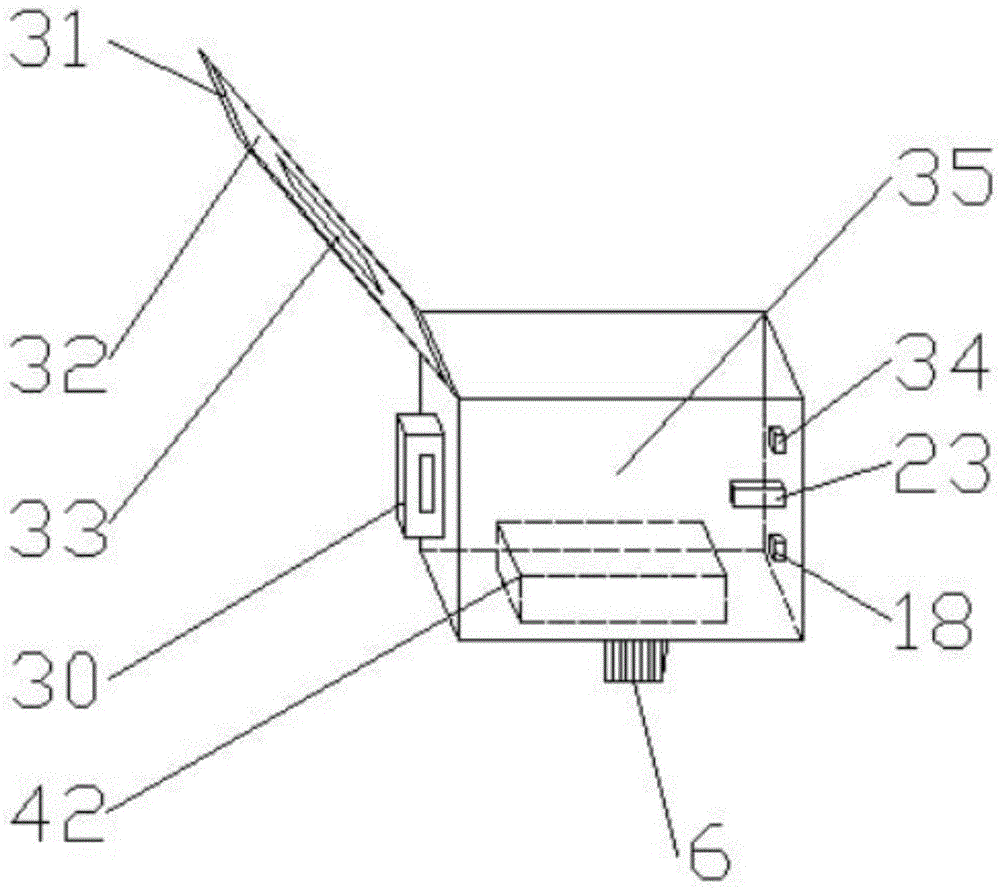

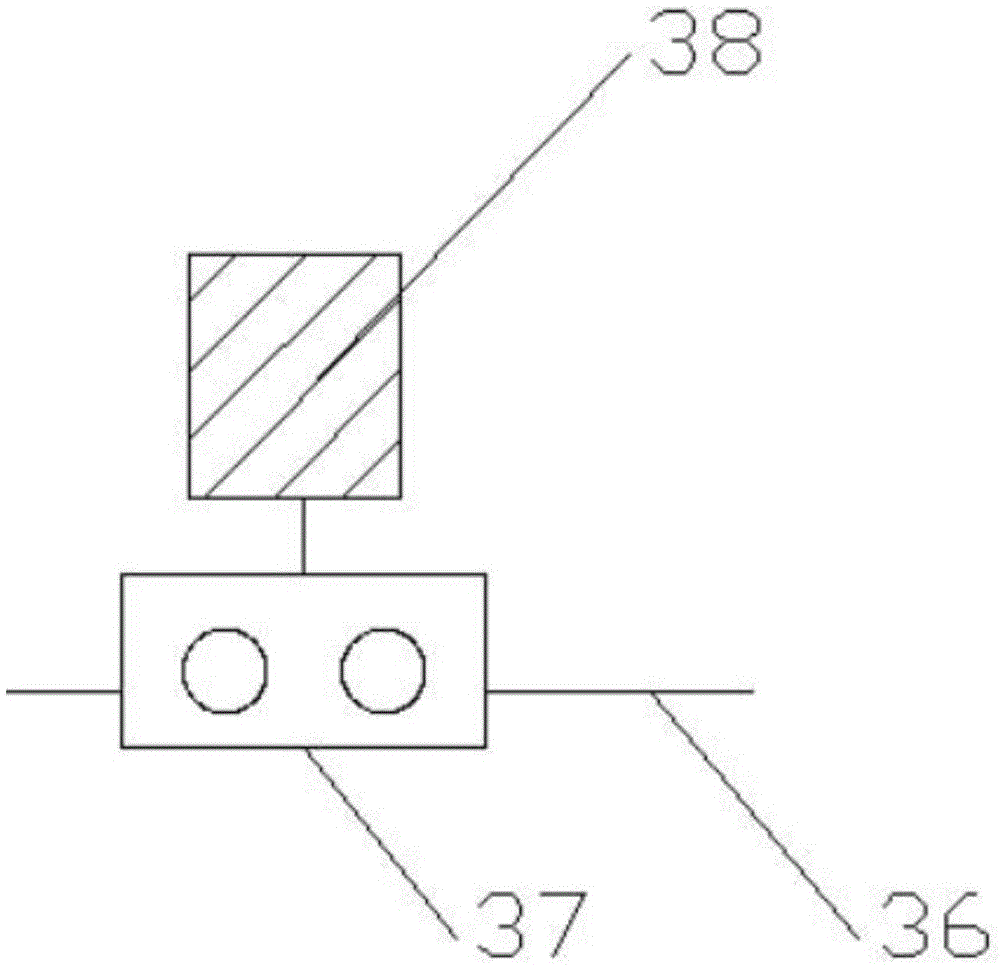

ActiveCN103950122ASimplified sawing processSmooth slicing processFine working devicesNumerical controlEconomic benefits

The invention provides a numerical control diamond wire sapphire slicing machine. According to the numerical control diamond wire sapphire slicing machine, the sawing process is simplified, the machining efficiency of the slicing machine is improved and the quality of a finished product is high, therefore, the aims of reducing production cost and improving economic benefits are fulfilled. The numerical control diamond wire sapphire slicing machine comprises a machine frame, wherein a feeding mechanism is arranged on the machine frame; two leading wire guide wheel structures are arranged on the machine frame and correspond to the feeding mechanism; diamond wires are wounded on the two leading wire guide wheel structures at intervals in sequence; cooling and lubricating spraying nozzles are correspondingly mounted above the leading wire guide wheel structures on the machine frame; a take-up winding device and a pay-off winding device are respectively arranged on the two sides of each leading wire guide wheel structure on the machine frame. The numerical control diamond wire sapphire slicing machine is characterized in that a swinging mechanism is arranged on the feeding mechanism.

Owner:WUXI SHANGJI AUTOMATION

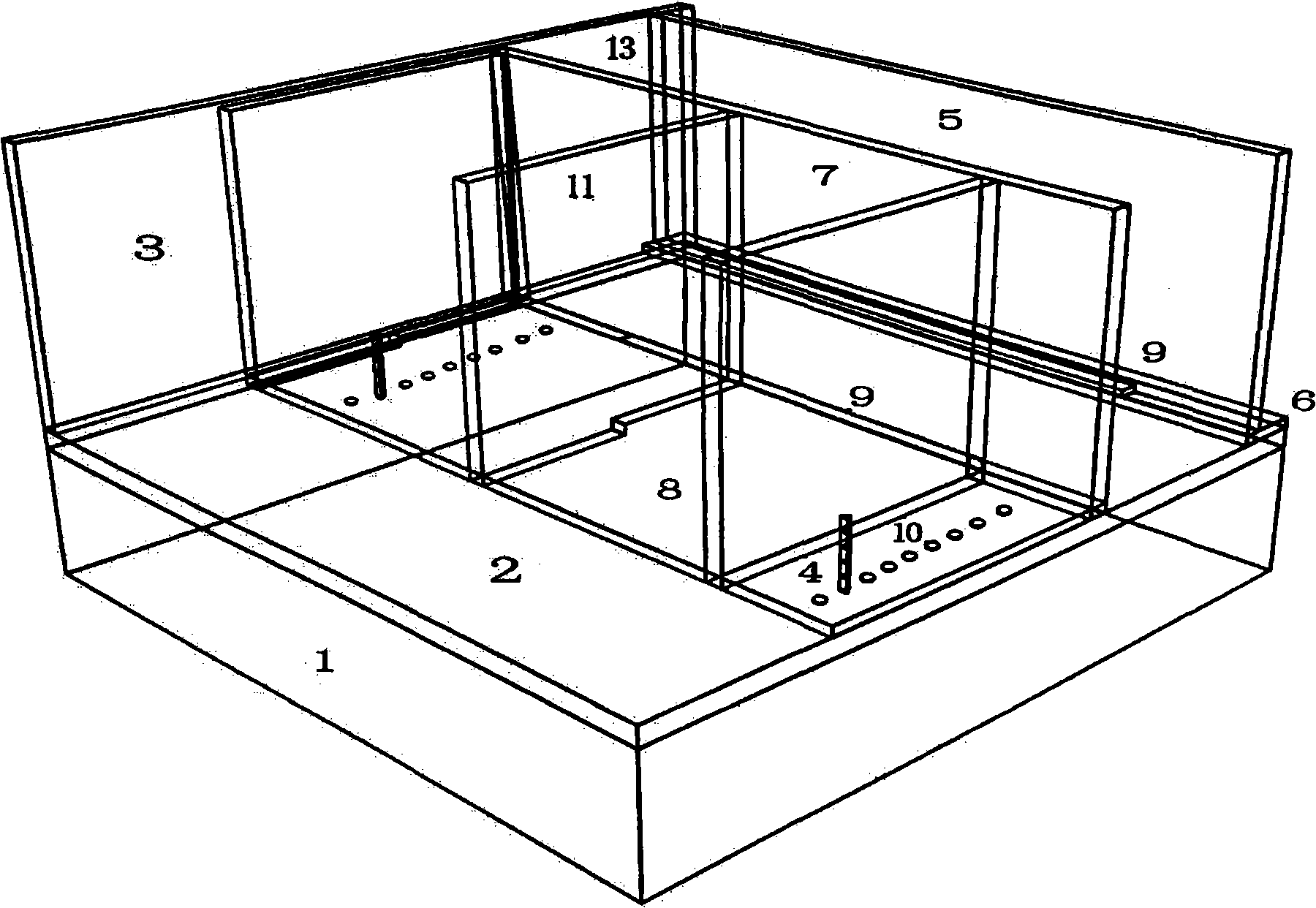

Silicon crystal cutting auxiliary tool

The invention discloses a silicon crystal cutting auxiliary tool. The silicon crystal cutting auxiliary tool has a bilaterally symmetric structure, wherein a straight tube, a tube hole, a plug, a circular tube and a hanging hook are arranged on one side of the tool; the straight tube is formed by sleeving an inner tube and an outer tube with hollow circular tube structures in a concentric circle form; the tube hole is formed on the inner tube; a tube seam is reverse to the direction of the tube hole and is relatively arranged on the outer tube; the tube hole can be closed or opened through a screw; the plug is connected with one end of the straight tube; the circular tube is arranged in the plug and is communicated with the inner tube; the hanging hook is fixed on the side face of the plug; a connection part of the plug and the inner tube is right-angled; and thus the bilaterally symmetric U-shaped silicon crystal cutting auxiliary tool is constructed. The flow and uniformity of mortar in the tube are adjusted and controlled in a silicon crystal cutting process by closing or opening the tube hole on the straight tube through the screw, so that the tool contributes to improving the surface quality of a silicon slice, solving the problem of influence on capability of driving mortar through a steel wire due to different mediums and fulfilling the aims of improving the quality of silicon crystal slices, reducing loss of silicon crystals and saving production cost.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

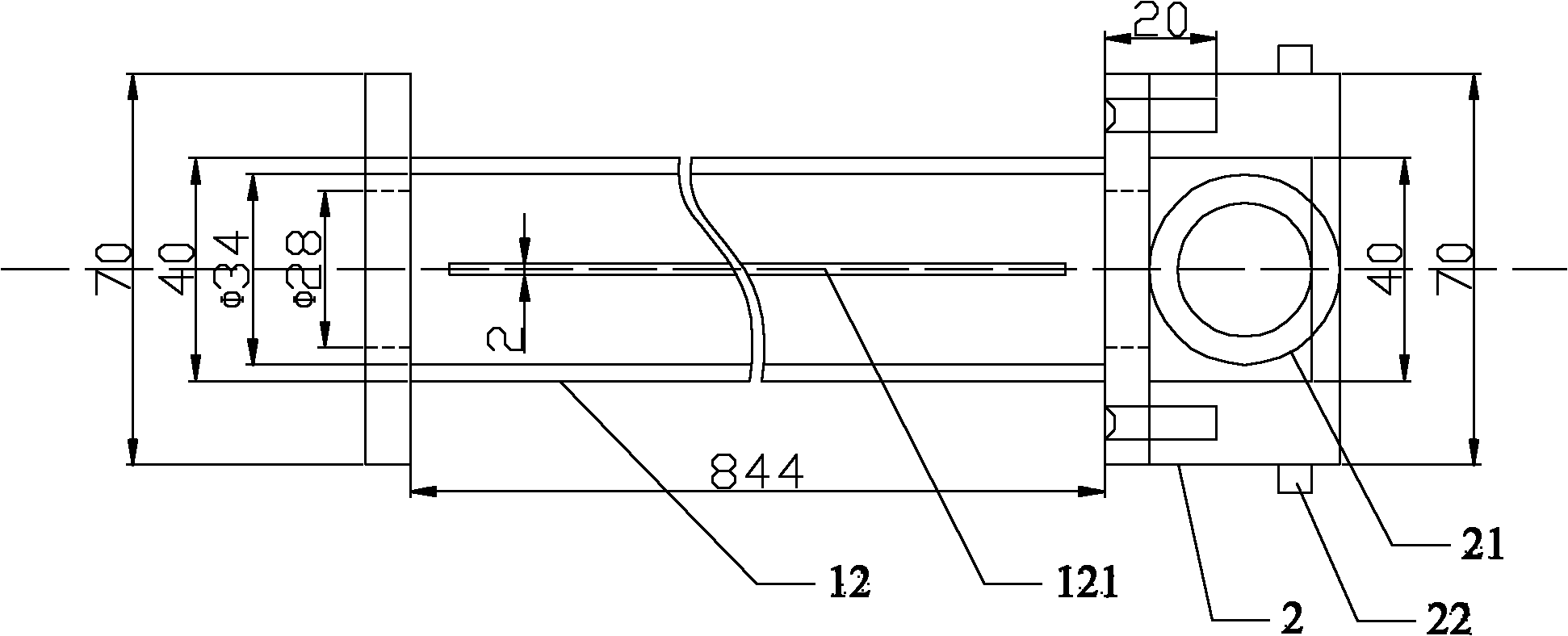

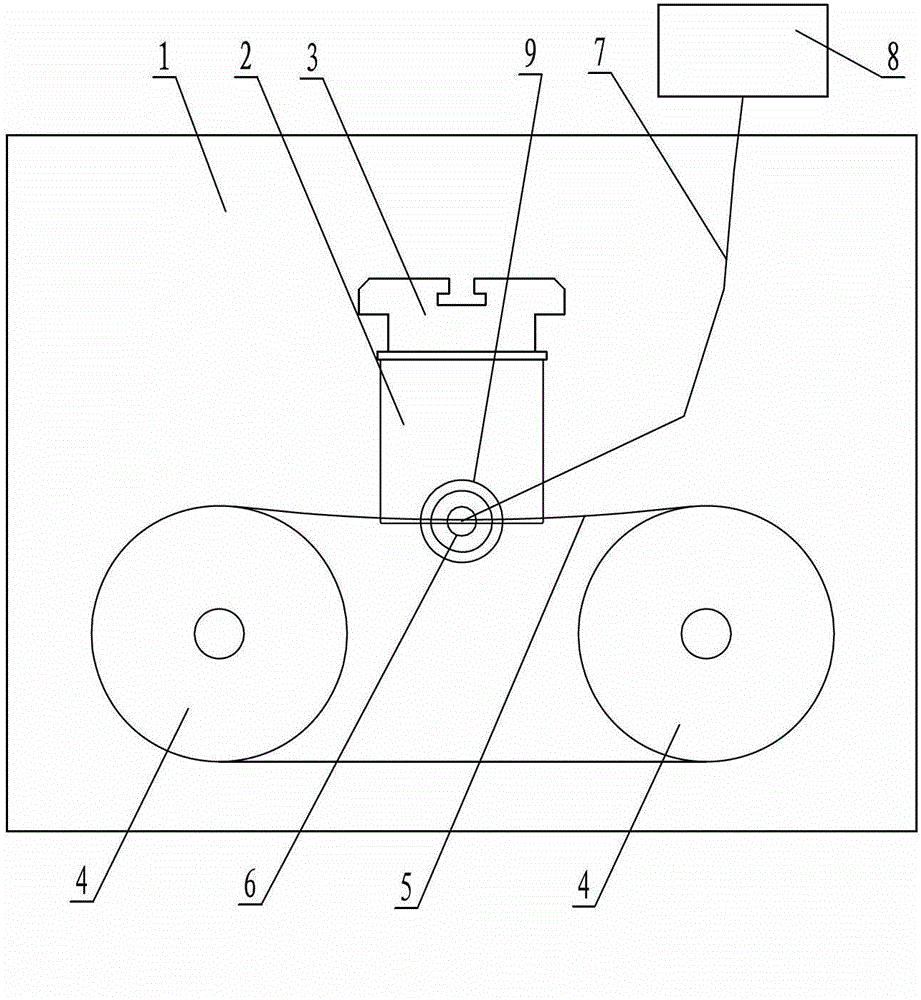

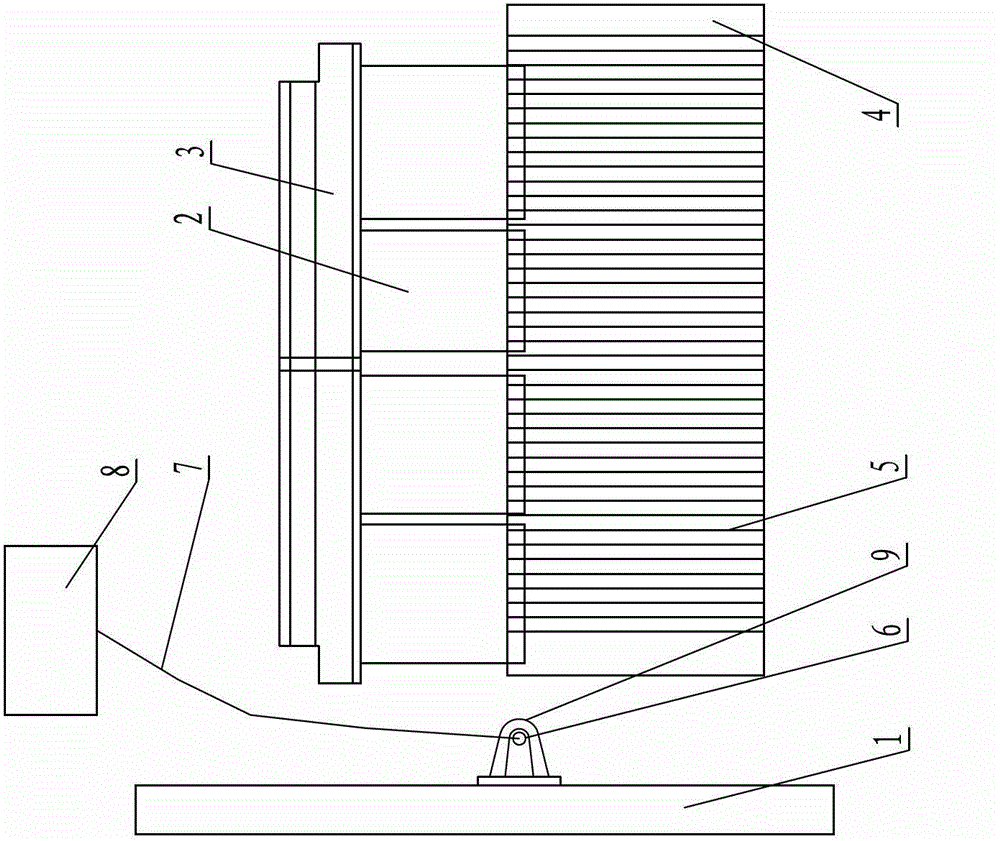

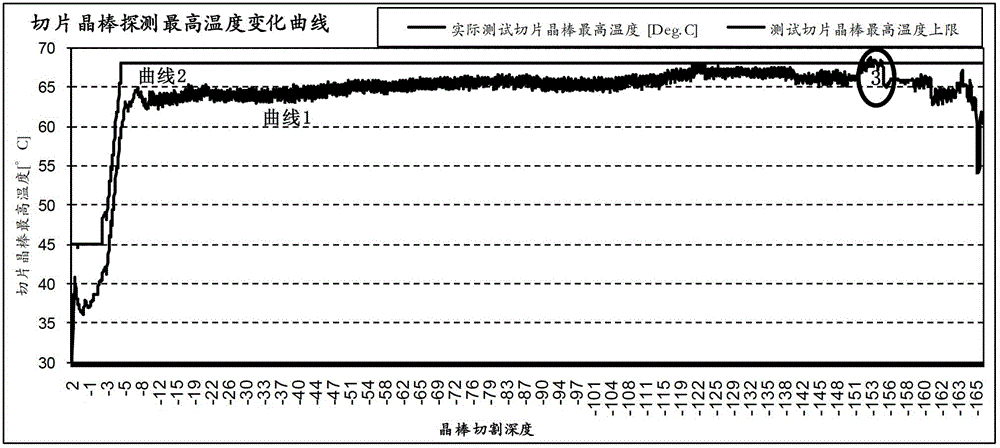

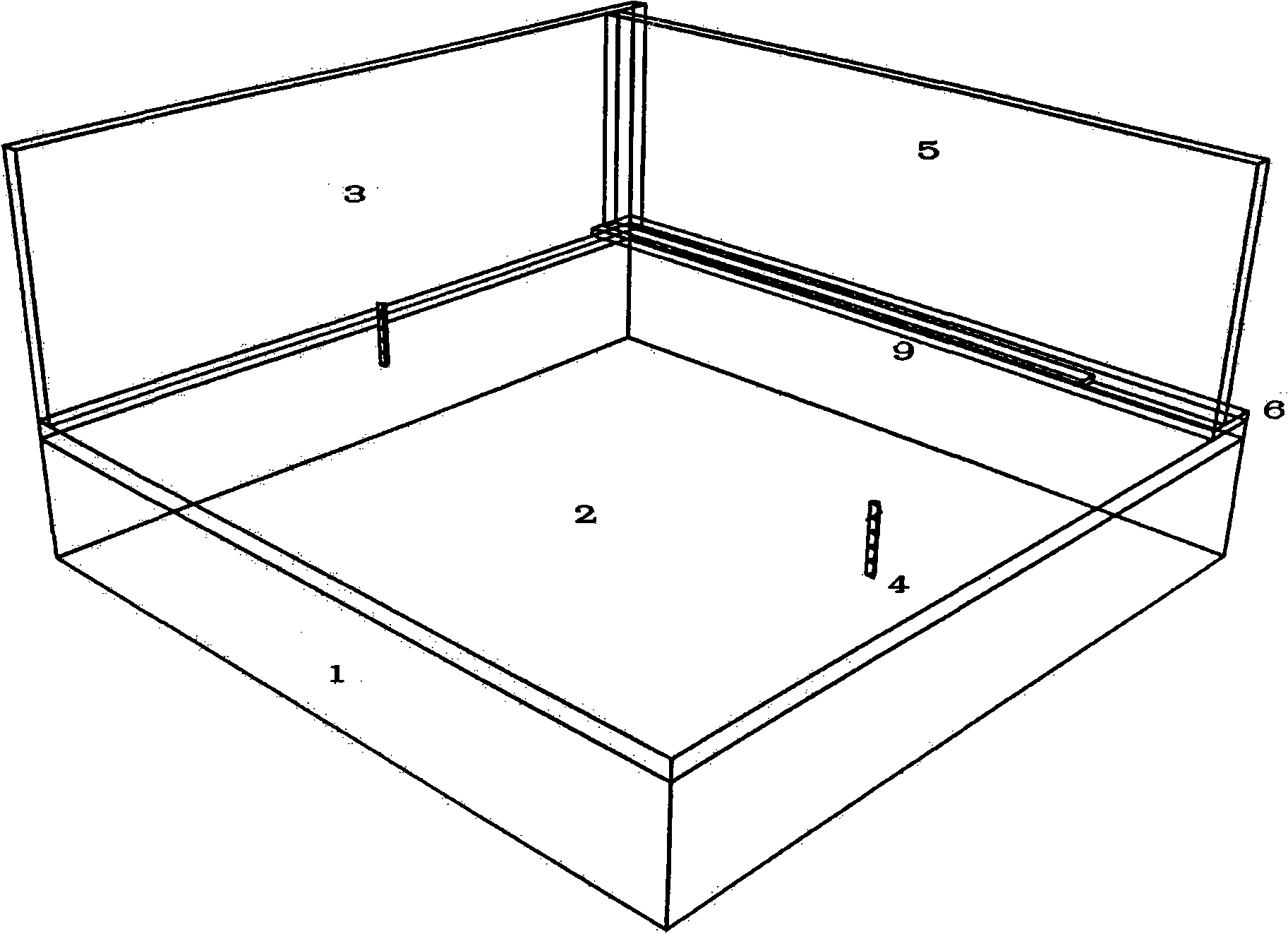

Silicon ingot slicing quality monitoring system and monitoring method

InactiveCN102744796AReduce the ratioReduce TTVRadiation pyrometryFine working devicesInfraredThrough transmission

The invention discloses a silicon ingot slicing quality monitoring system and a monitoring method. The silicon ingot slicing quality monitoring system comprises a slicing device, a detection device for detecting temperature at a crystal bar cutting part, and a control device with a central processing unit. The slicing device comprises an inner wall plate of a slicer. A crystal bar to be cut, a crystal tray for bonding the crystal bar, a pair of guide wheels below the crystal bar and a steel wire net for grinding the crystal bar winded between the guide wheels are arranged on one side of the inner wall plate. The detection device comprises an infrared sensor arranged on the inner wall plate. The infrared sensor is connected with a temperature inductive circuit through a transmission line. The extending direction of a central line of a probe of the infrared sensor is aligned with a middle position of the steel wire net which grinds the end surfaced of the crystal bar. The temperature inductive circuit transmits the collected data to the central processing unit after the data is processed. According to the silicon ingot slicing quality monitoring system and the monitoring method provided by the invention, the slicing process can be effectively controlled, and deficiencies such as crack edge, half piece, and rubber-faced broken piece with unfilled corner generated randomly in the slicing process are reduced, thereby realizing more stable slicing quality and higher slicing benefit.

Owner:TRINA SOLAR CO LTD

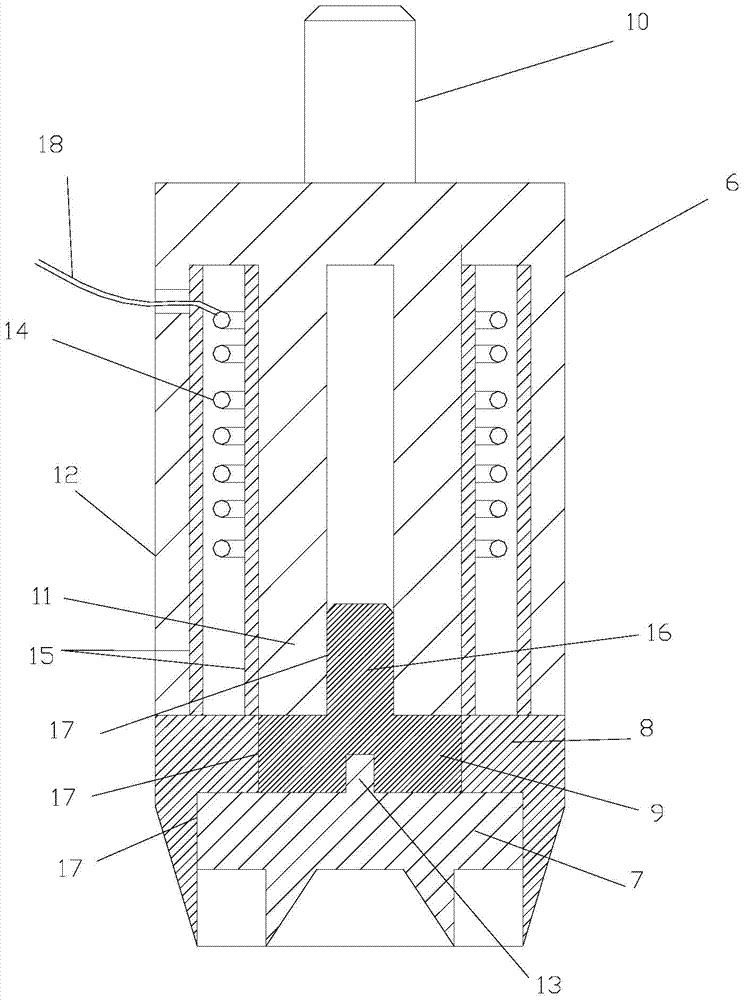

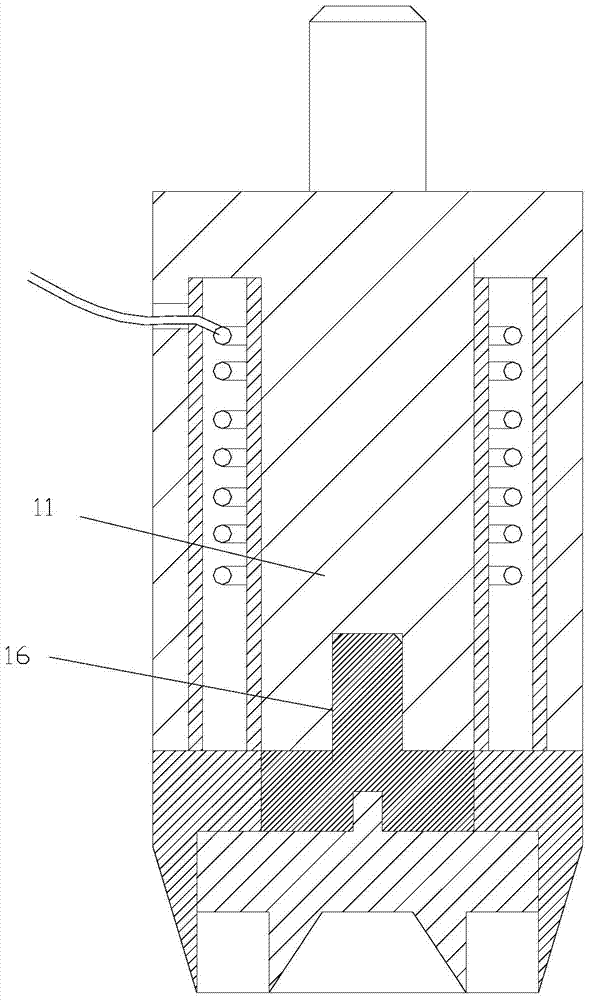

Edge cutting machine for rubber ring

InactiveCN103934860AEasy to installImprove slice qualityMetal working apparatusRubber ringInsulation layer

The invention discloses an edge cutting machine for a rubber ring. The edge cutting machine comprises a rack, the rack is provided with an upper arm and a base, a lifting mechanism is arranged on the upper arm, the lower portion of the lifting mechanism is connected with an upper punching head component, and a mould is arranged at the position, below the upper punching head component, on the base. The upper punching head component is composed of a barrel shell, an inner ring cutter, an outer ring cutter and a raised type plug, a connector is arranged at the top of the barrel shell, an inner pipe and an outer pipe which are distributed concentrically are arranged on the lower portion of the barrel shell, a top raised head of the raised type plug is placed in the inner pipe of the barrel shell, and the outer ring cutter is arranged on the lower portion of the raised type plug in a sleeved mode. The inner ring cutter is arranged in the outer ring cutter, the top face of the inner ring cutter abuts against the bottom face of the raised type plug, and the top face of the outer ring cutter abuts against the bottom of the outer pipe of the barrel shell. An electric heating ring is arranged between the inner pipe and the outer pipe, and insulation layers are arranged on the inner side and the outer side of the electric heating ring. The edge cutting machine has the advantages that mounting is convenient, the inner ring cutter and the outer ring cutter are more stable in the edge cutting process, and edge cutting quality is high.

Owner:杨帆

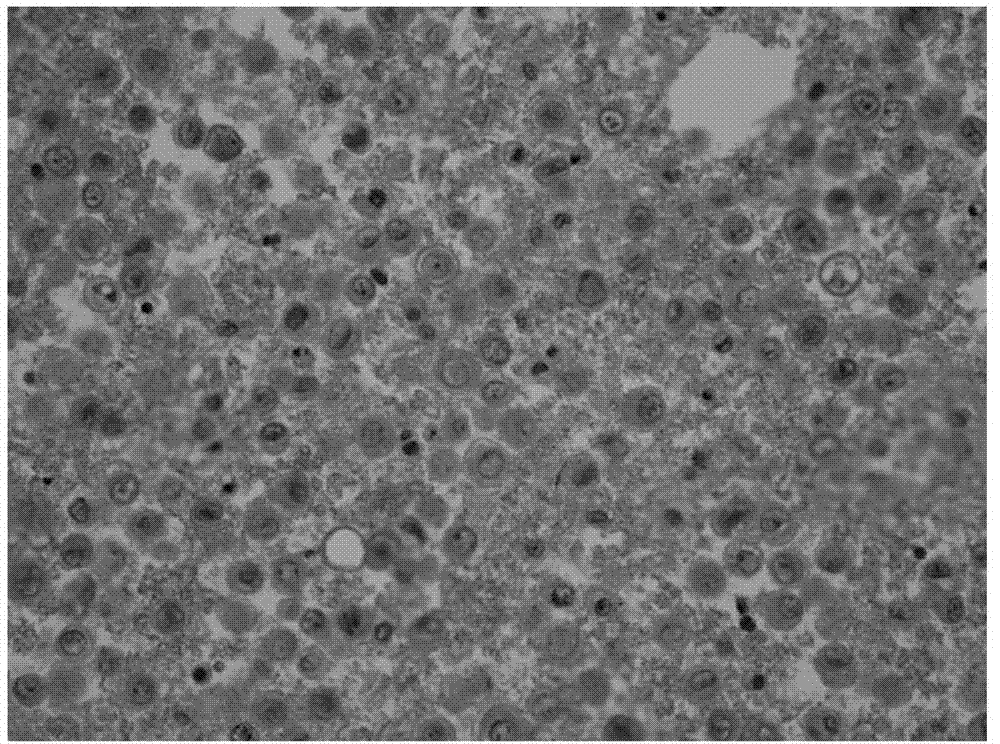

Method for quickly slicing fish tissues

InactiveCN102062709AResolve blurShorten the timePreparing sample for investigationStainingDistilled water

The invention belongs to the field of microscopic tissue slice, particularly relates to a method for quickly slicing and dyeing fish tissues. The method comprises the following steps: 1) solidifying the fish tissues for 4-6 hours by using stationary liquid, cutting the solidified fish tissues into slice tissue blocks being 2mm long, 2mm wide and 1-2mm high, soaking the slice tissue blocks for 10-20 seconds in egg white which is diluted by using distilled water at the volume ratio of 1:1, freezing the slices, and pasting slices, and 2) placing for 3-5 minutes at room temperature after being pasted, dyeing, airing, and sealing by using neutral gum and cover glass for observing with microscope. Through the method, the time is shortened and the problems of freezing slice tissues, cell dissolution and blurry image under microscope are solved.

Owner:SUZHOU UNIV

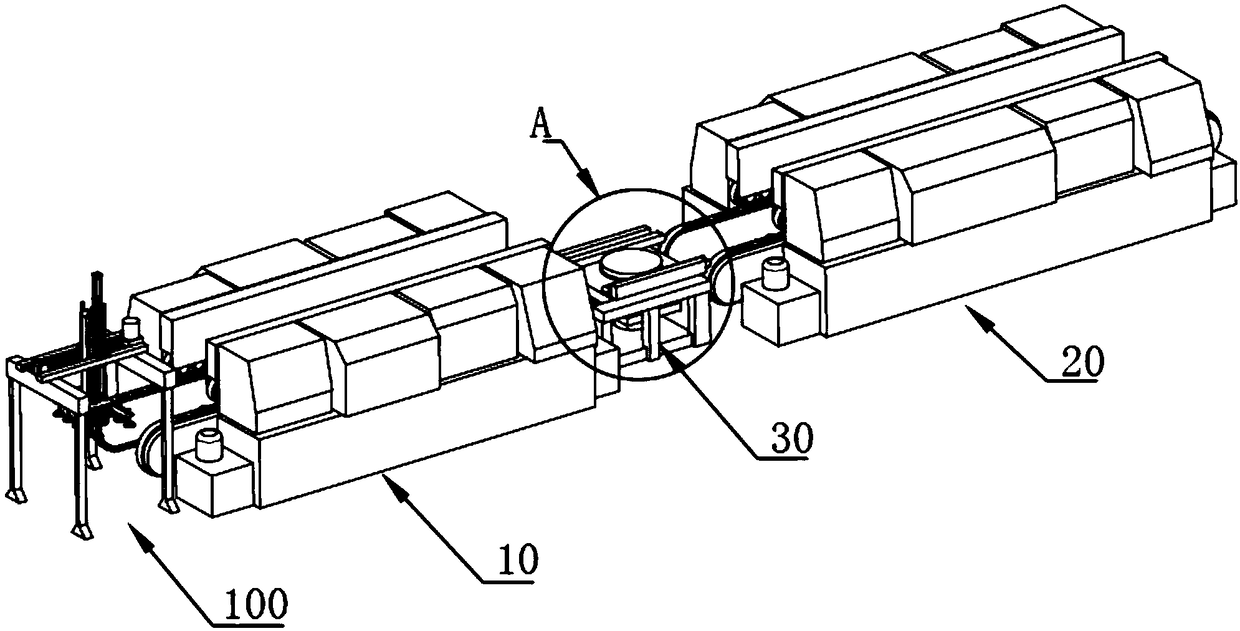

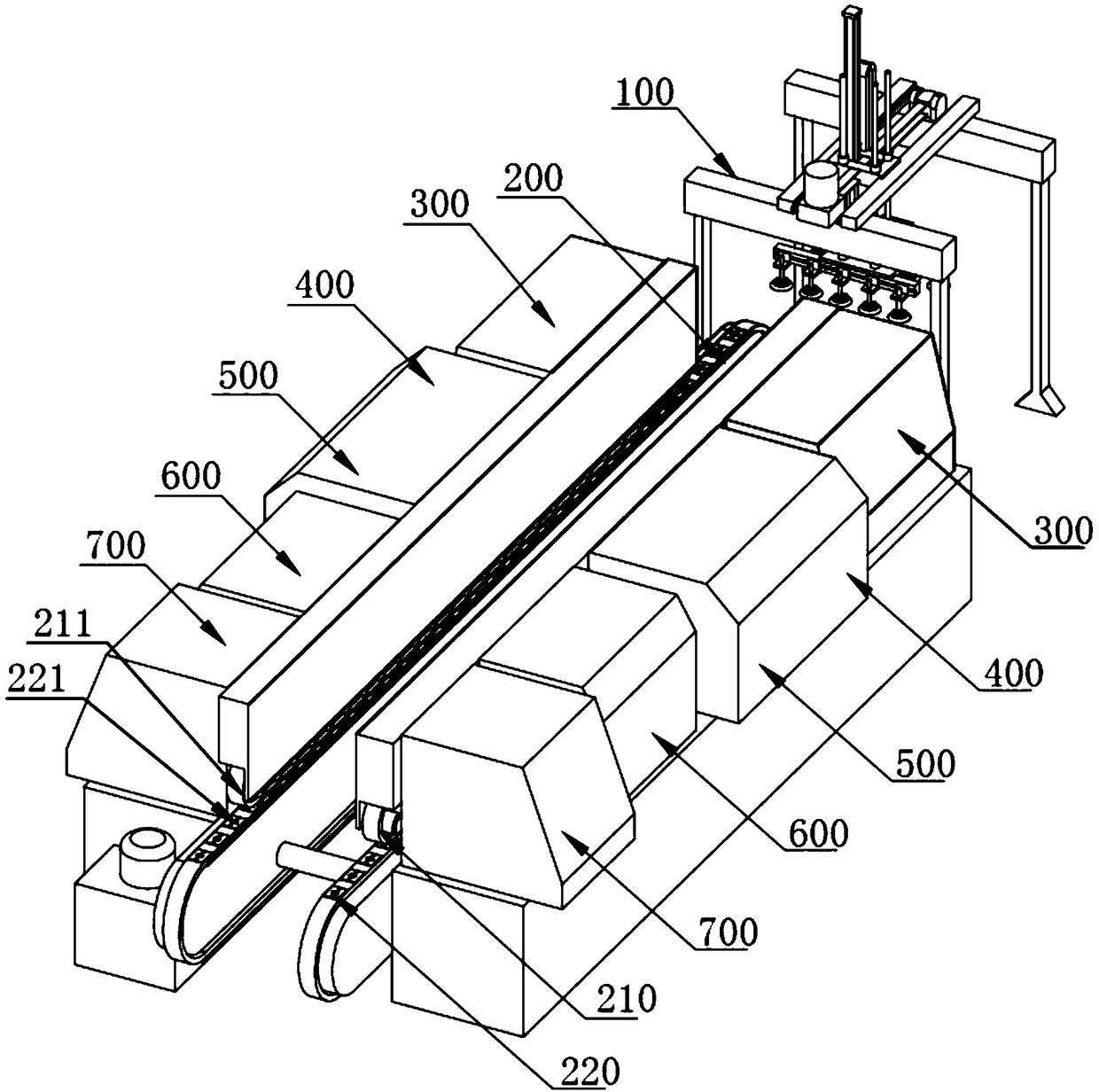

Full-automatic four-edge banding equipment and method for plate

PendingCN109227873AHigh degree of automationSave manpower and material resourcesPolishing machinesBelt grinding machinesMaterial resourcesEngineering

The invention relates to the technical field of plate processing equipment, in particular to full-automatic four-edge banding equipment and method for a plate. The equipment comprises a loading deviceused for taking and loading the plate, a first banding mechanism and a second banding mechanism, wherein a turntable mechanism is connected between the first banding mechanism and the second bandingmechanism, the first banding mechanism comprises a conveying device used for conveying the plate taken by the loading device, a cutting device used for cutting the plate during conveying, a banding device used for banding the cut plate, a trimming device used for trimming the banded plate, a polishing device used for polishing the trimmed plate and a sanding device used for sanding the polished plate. The full-automatic four-edge banding equipment and method for the plate have the advantages that the plate is full-automatically loaded, conveyed, cut, gummed, banded, compressed, cut off, trimmed, polished and sanded, and then repeatedly performs the above process on the plate to achieve four-edge banding, thereby solving the problem that the plate is cut and banded through manpower or half-automatic equipment in the prior art, the degree of automation is high, and the manpower and material resources are saved.

Owner:东莞市春旭机械科技有限公司

Medicine slicer

ActiveCN110614660AImprove slice qualityImprove efficiencyMetal working apparatusKnife bladesManipulator

The invention discloses a medicine slicer. The medicine slicer comprises a rack, a slicing component, a charging barrel and a material pressing manipulator, wherein the slicing component is horizontally arranged at the top of the rack and is provided with a material inlet; the charging barrel is arranged on one side of the slicing component and is communicated with the material inlet; the materialpressing manipulator is arranged at the top of the material inlet of the slicing component; the slicing component comprises two horizontal guide rails arranged on the rack in a parallel spacing manner, a medicine locating seat arranged between the two horizontal guide rails, a blade component which slides along the horizontal guide rails so as to penetrate through or be away from the medicine locating seat, as well as a driving component connected with the blade component; the medicine locating seat is a box body with an upper opening; two side walls, perpendicular to the horizontal guide rails, of the box body, can be opened or closed; if the blade component is close to the medicine locating seat, the two side walls of the box body are opened to form a horizontally-penetrating knife passing hole; and a pressing plate of the material pressing manipulator downward moves to be close to the bottom of the medicine locating seat for pressing to-be-sliced medicines into an inner cavity of the medicine locating seat. The blade component penetrates through the locating seat for automatically slicing and forming pressed medicines; and slices have good quality and high efficiency.

Owner:溆浦县龙盛农业科技发展有限公司

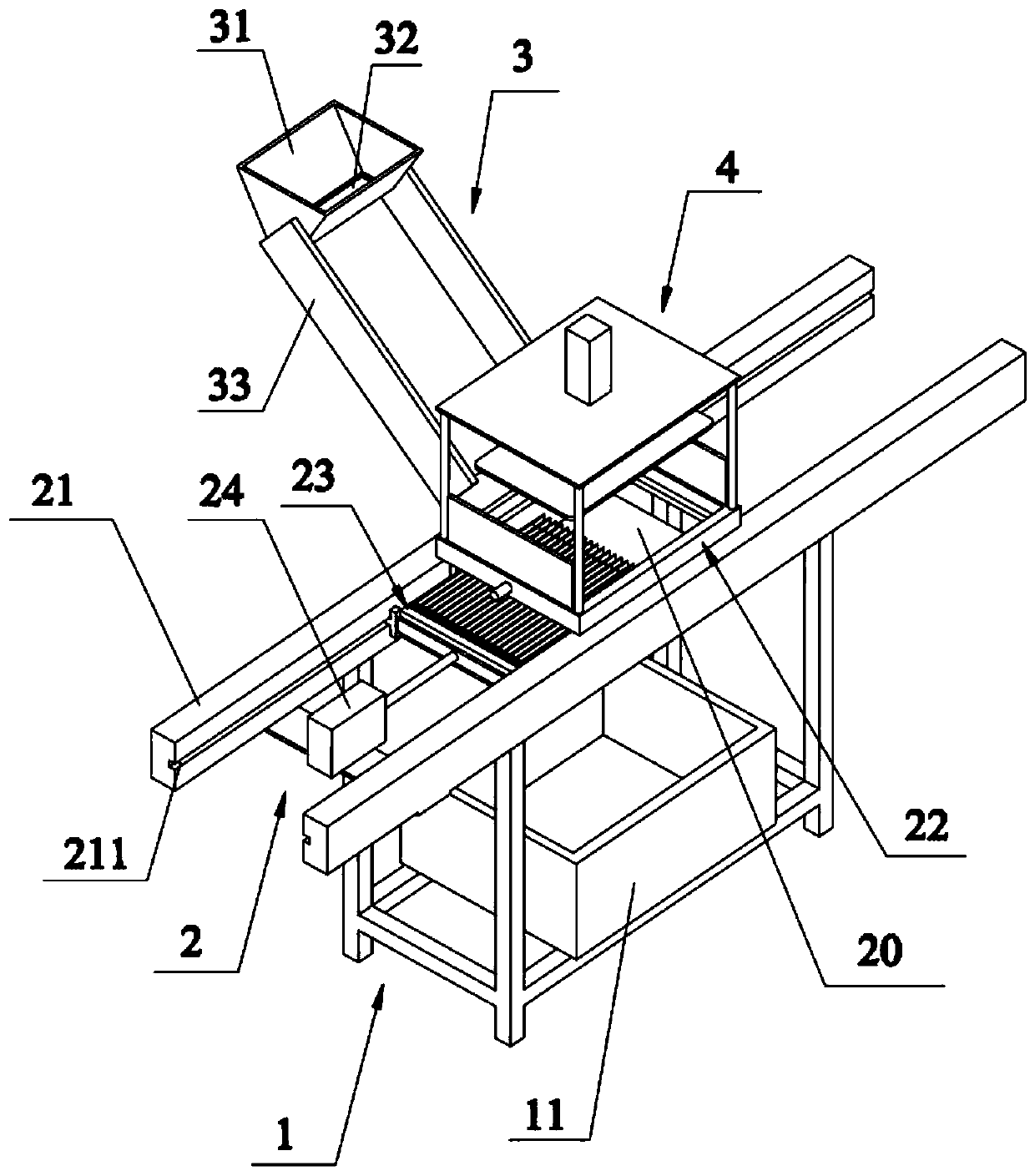

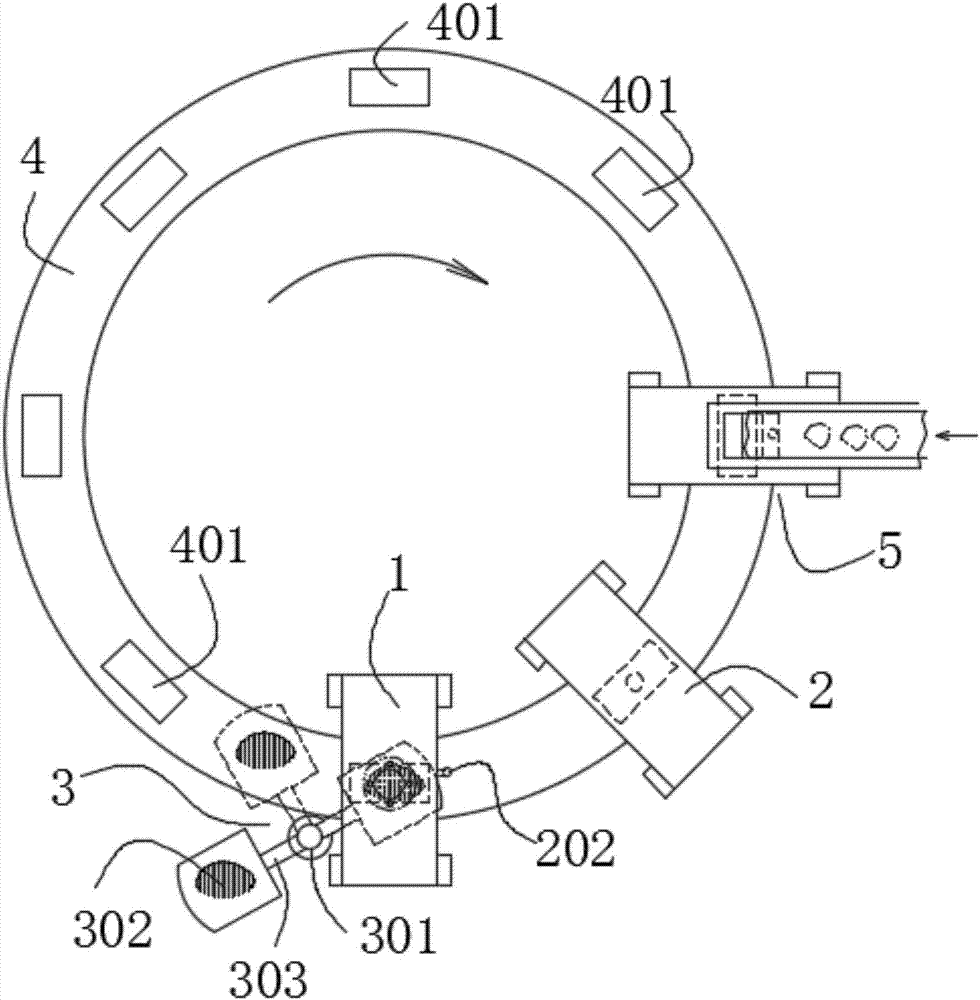

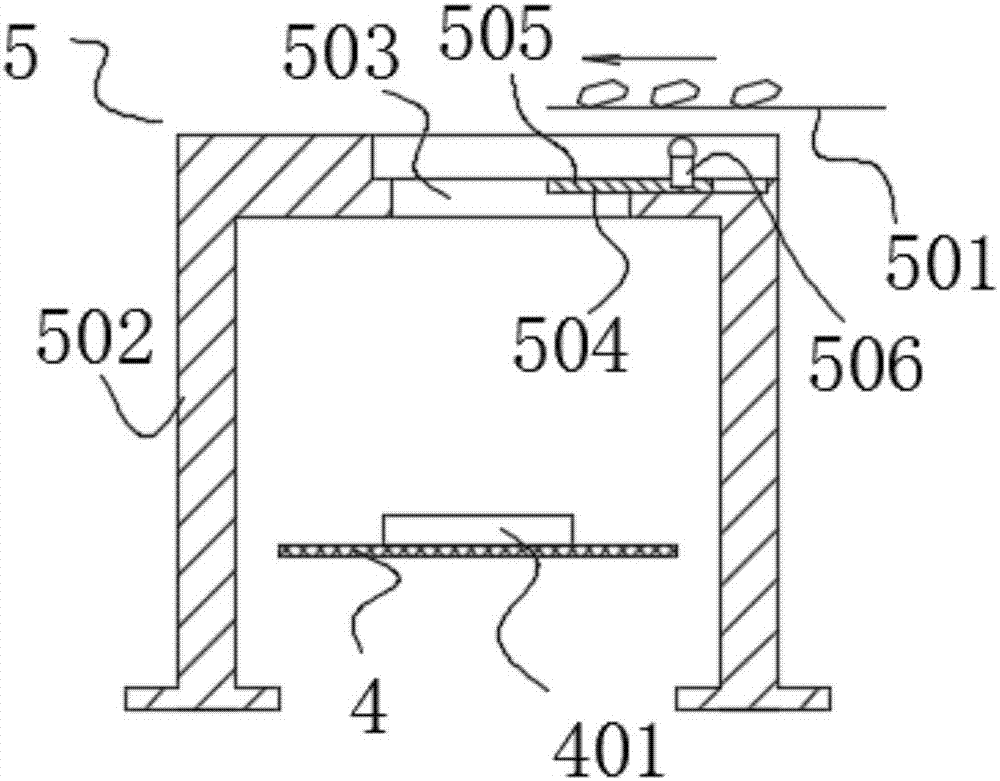

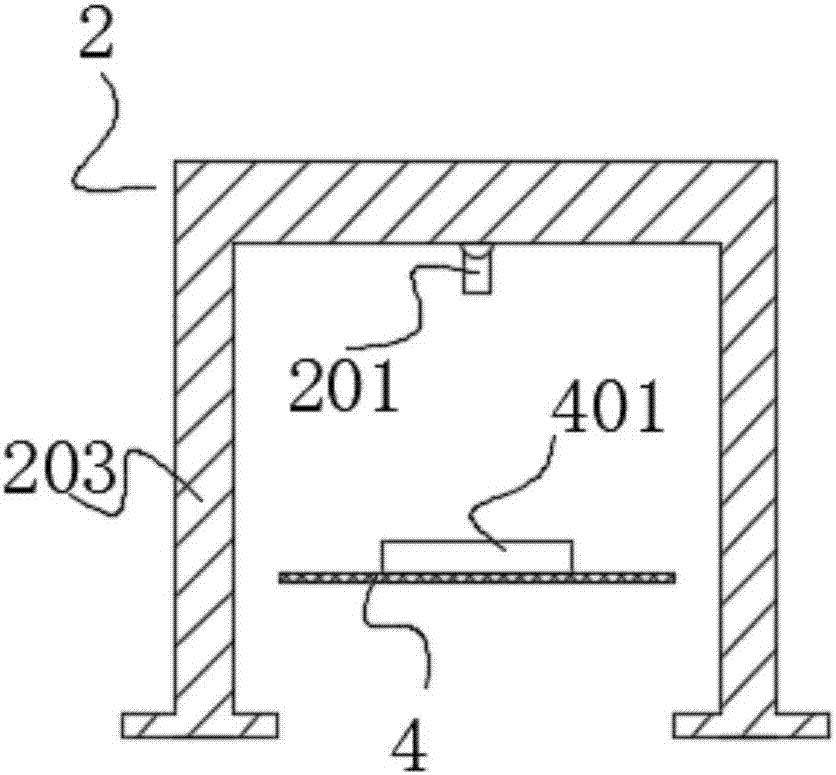

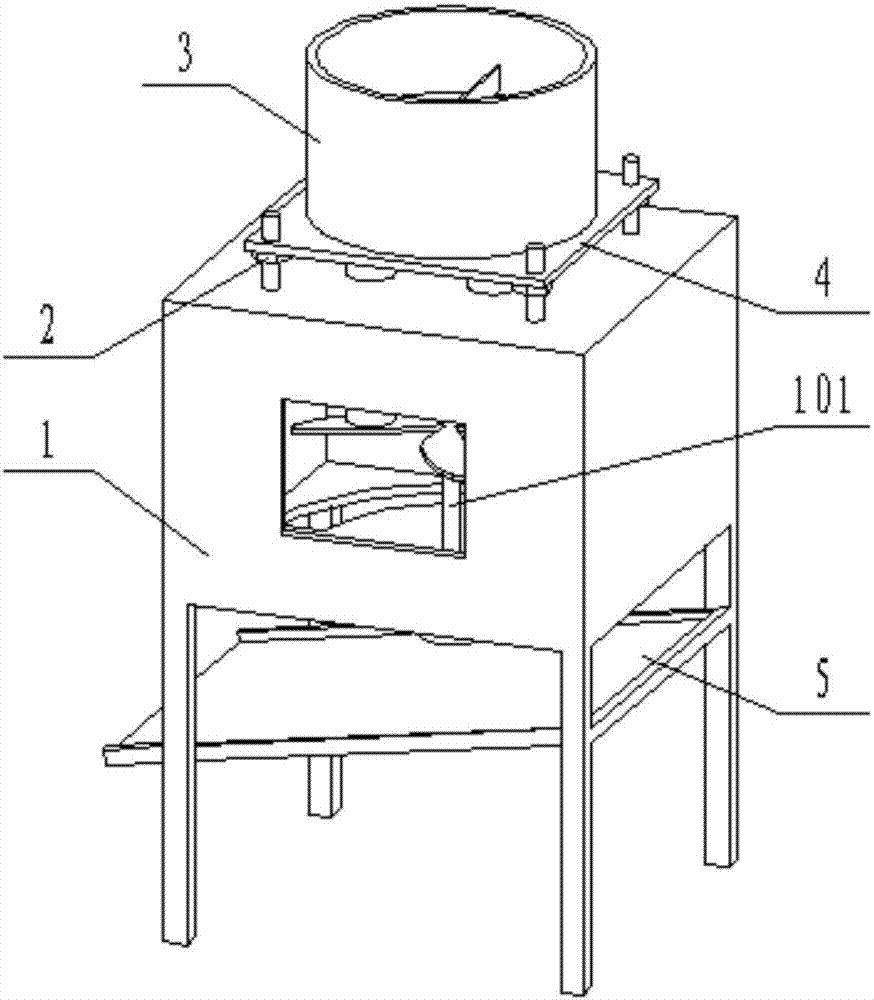

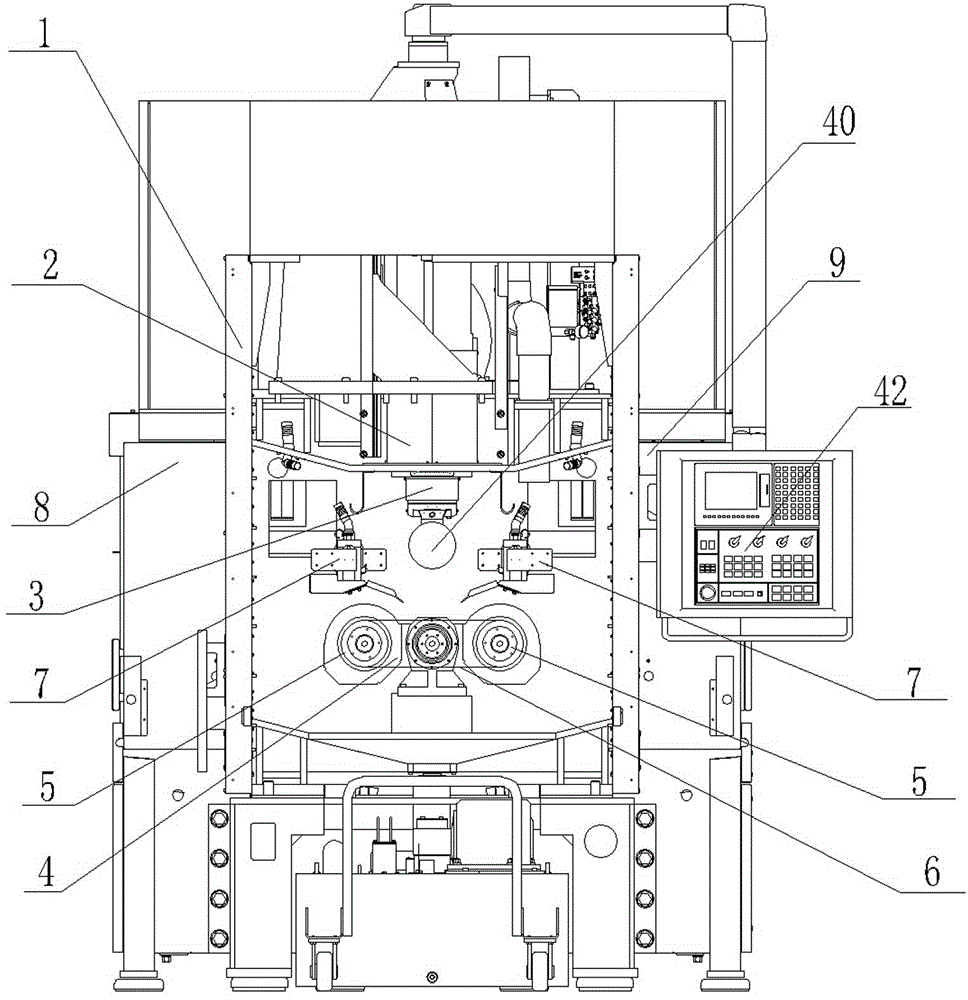

Food material slicing production line and slicing method thereof

ActiveCN107186764AEasy to fixImprove slice qualityMetal working apparatusProduction lineControl system

The invention discloses a food material slicing production line and a slicing method thereof. The food material slicing production line comprises a feeding mechanism, a data acquiring mechanism, a slicing mechanism, a discharging mechanism, an annular conveyor belt and a control system. A plurality of cutting boards are evenly arranged on the annular conveyor belt along a circle line, a plurality of stations are divided on the annular conveyor belt along the circle line according to the positions of the cutting boards, and the food material slicing production line rotates by one station every time. The slicing mechanism comprises a first n-shaped support, a cutter assembly and a pressing assembly. The cutter assembly comprises a blade fixing plate, a blade and a blade drive air cylinder. The blade drive air cylinder is fixed to the middle portion of a frame of the first n-shaped support, and the end portion of a piston of the blade drive air cylinder is detachably fixed to the blade fixing plate. The pressing assembly comprises a pressing plate and a pressing drive air cylinder. The slicing method comprises the steps of feeding, data acquiring, slicing, discharging and the like. The food material slicing production line can carry out uninterrupted slicing operation on any food material, production continuity and processing universality are achieved, the food processing efficiency and the quality can be greatly improved, and the production invest and the use cost can be greatly reduced.

Owner:HUANGGANG NORMAL UNIV

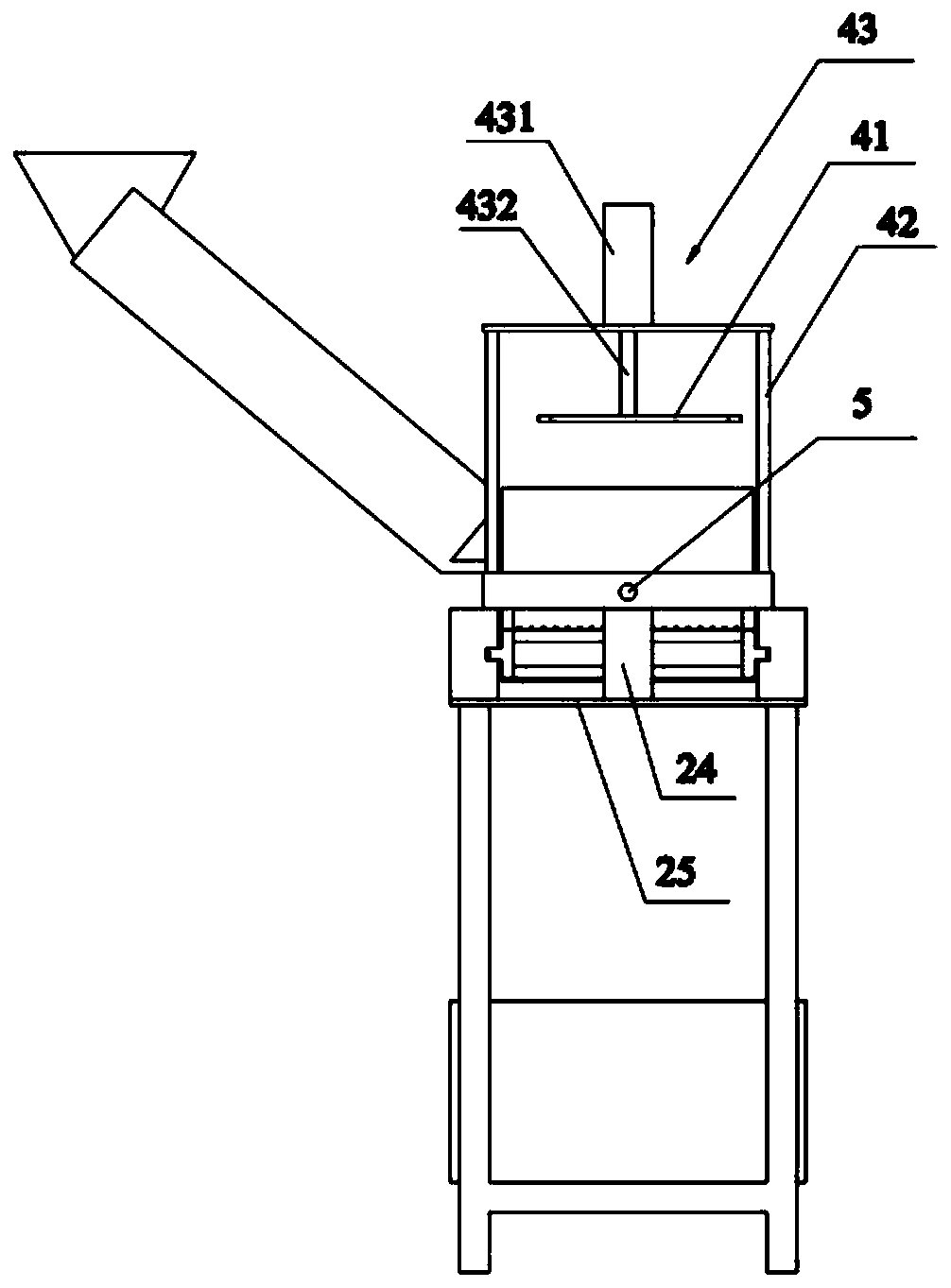

Dried sweet potato slicing and conveying integrated machine

PendingCN107457822APrevent blocking phenomenonImprove slice qualityMetal working apparatusMotor driveEngineering

The invention discloses an integrated machine for conveying dried sweet potato slices, which comprises a slicing box, a slicing motor is installed at the lower end of the slicing box, and a cutter disc is fixedly installed at the output end of the slicing box; a discharge port is arranged at the bottom of the slicing box , the outer side of the discharge port is provided with side guards; the upper end of the slicing box is fixed with a support plate through height-adjusting bolts, and a feeding device is installed at the upper end of the support plate. The beneficial effect is that: the feed motor drives the feed scraper to rotate to achieve stirring, and cooperates with the feed vibrating plate to realize the vibration, stirring and feeding of raw materials, which can prevent the phenomenon of material blocking; the raw materials enter the inside of the material guide tube under the action of vibration and stirring , to realize the adjustment of the feeding direction of the raw material, so as to ensure the consistent cutting direction and improve the cutting quality; the height of the support plate can be adjusted by adjusting the height of the bolt, so as to adjust the height of the feeding device and change the distance between the outlet of the guide tube and the cutter head. Adjust the slice thickness to meet different thickness requirements.

Owner:绍兴云疆网络科技服务有限公司

Novel numerically-controlled diamond wire sapphire slicer

PendingCN104552634ASmooth slicing processImprove efficiencyWorking accessoriesFine working devicesEngineeringMechanical engineering

The invention provides a novel numerically-controlled diamond wire sapphire slicer. Through the novel numerically-controlled diamond wire sapphire slicer, the sawing process is simplified, the machining efficiency of the slicer is increased, and the finished product quality is high, so that the aims of reducing the production cost and increasing the economical benefit are fulfilled. The novel numerically-controlled diamond wire sapphire slicer comprises a frame, wherein a feeding mechanism is arranged on the frame; a clamping fixture is arranged on the feeding mechanism. The novel numerically-controlled diamond wire sapphire slicer is characterized in that a swinging mechanism is arranged on the frame; the position of the swinging mechanism corresponds to the feeding mechanism; two lead guide wheel structures are arranged on the swinging mechanism; diamond wires are repeatedly wound on the two lead guide wheel structures in sequence at equal intervals.

Owner:WUXI SHANGJI AUTOMATION

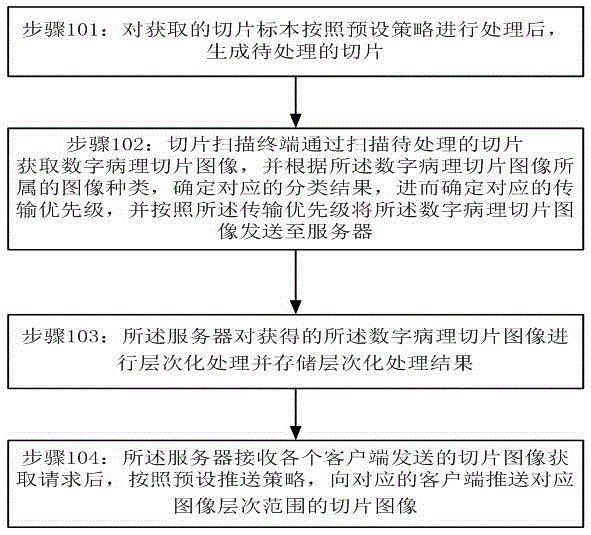

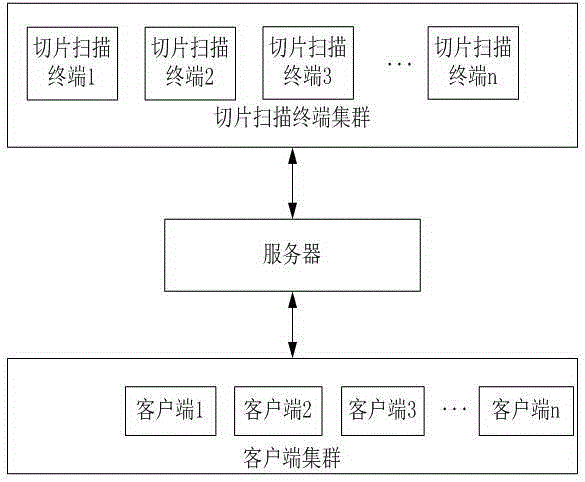

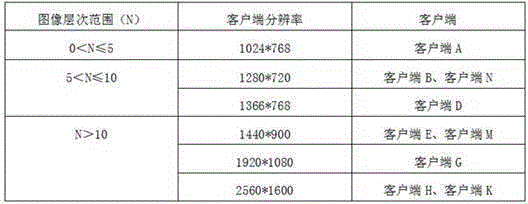

Remote pathologic diagnosis section digital image processing and transmitting technology

ActiveCN105357304AGood removal effectImprove clarityTransmissionPictoral communicationDigital signal processingImaging processing

The invention provides a remote pathologic diagnosis section digital image processing method, belonging to the technical field of medical image processing. The method comprises following steps that acquired section specimens are processed according to a preset strategy, and then to-be-processed sections are generated; a section scanning terminal scans the to-be-processed sections so as to acquire digital pathologic section images, determines corresponding transmission priorities, and sends the digital pathologic section images to a server according to the transmission priorities; the server performs hierarchical processing on the acquired digital pathologic section images and stores a hierarchical processing result; and the server receives section image acquisition requests from all client sides, and then pushes a section image corresponding to an image hierarchical range to a corresponding client side according to a preset push strategy. Through adoption of the method, important digital pathologic section images are guaranteed to have the priority to transmit, furthermore, a corresponding hierarchy of section image is pushed to a corresponding client side, so that the user experience is greatly improved.

Owner:广州华银医学检验中心有限公司

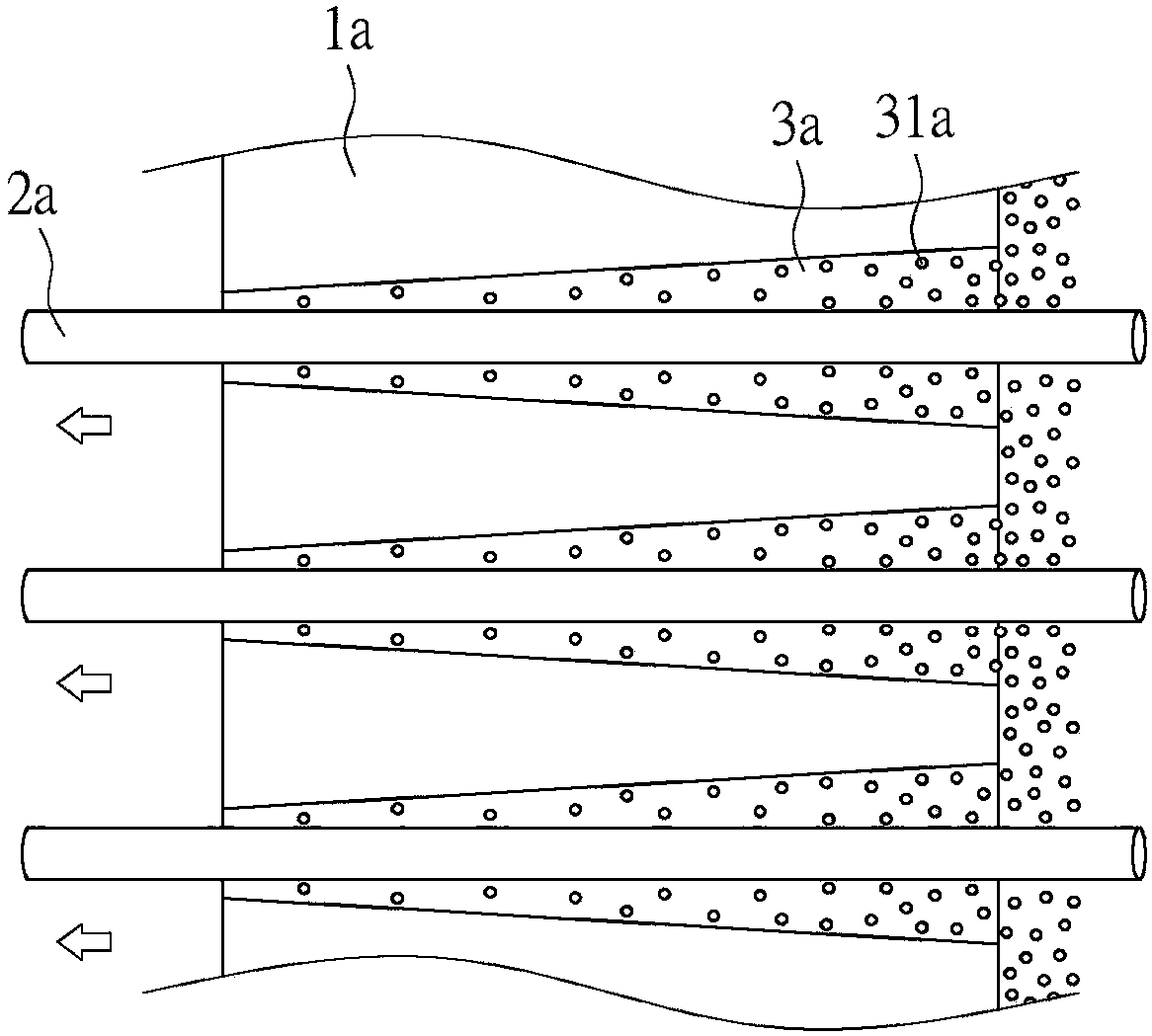

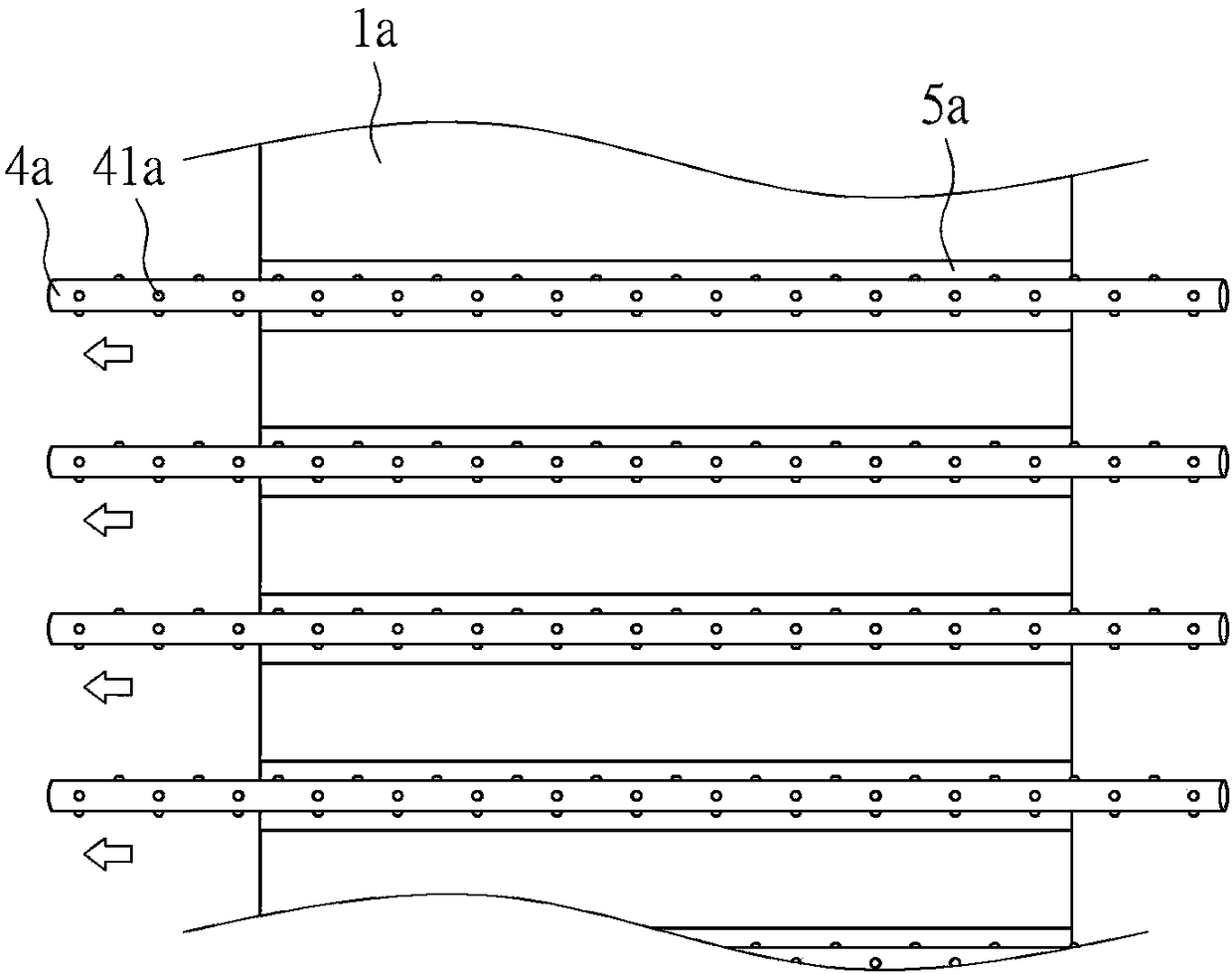

Method and device for cutting transparent material by using ultra-short pulse laser

ActiveCN102785031BNo pollution in the processNo generationFine working devicesGlass severing apparatusTransfer procedureRefractive index

The invention provides a method for cutting a transparent material by using ultra-short pulse laser. The ultra-short pulse laser output by an ultra-short pulse laser generating device is condensed by a condensation device so as to form a bunching laser beam; the bunching laser beam enters from the surface of the transparent material to be machined, so that the center refractive index at a laser application point is increased to form a waveguide structure along a laser emitting direction; the laser is transmitted to the inside of the transparent material along the waveguide structure, and continuously generates a waveguide structure along the laser emitting direction in a transmission process until the entire waveguide structure and the laser penetrate through the transparent material; and therefore, the laser moves in a direction which is vertical to the surface of the transparent material at uniform speed, so that a waveguide plane is formed in the transparent material. The invention further provides a device for cutting the transparent material by using the ultra-short pulse laser. The method and the device for cutting the transparent material by using the ultra-short pulse laser provided by the invention have the advantages of fast cutting speed, small cutting seam, no material consumption and no powder pollution. When the machined material bears a suitable external force, the material is cracked only along a stress fault surface; the broken surface nearly has no conical degree; and the roughness is good.

Owner:WUHAN JUNNO TECH

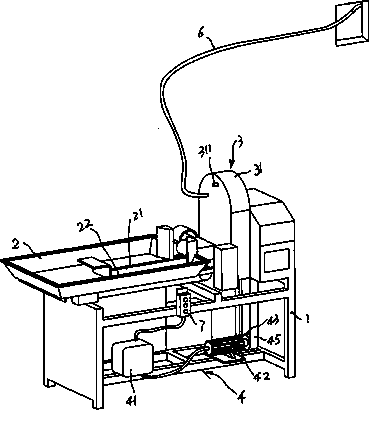

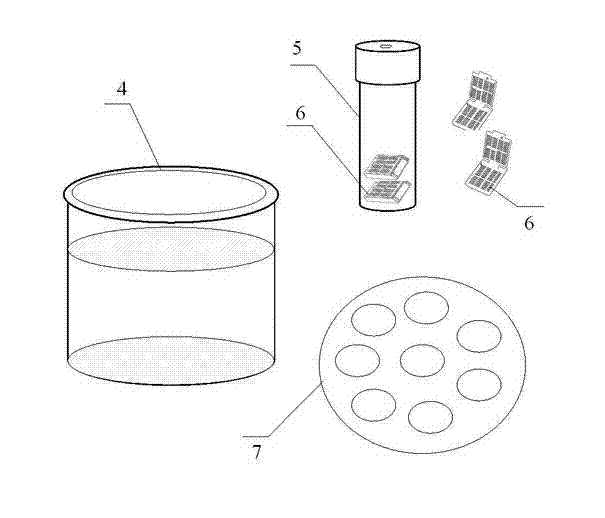

Rapid pathological tissue dehydrating machine

ActiveCN105606437AHigh speedDehydration fastPreparing sample for investigationPatient needSpecimen Handling

The invention relates to equipment for making biological tissue specimen paraffin sections, in particular to a rapid pathological tissue dehydrating machine. The rapid pathological tissue dehydrating machine comprises a machine box body and an intelligent operating table. A specimen treating box, a paraffin box, a vacuum pump, a plurality of reagent barrels and an ultrasonic generator are arranged in the machine box body, a microwave cavity is formed in the specimen treating box, a microwave source is connected to the microwave cavity, and the specimen treating box is connected with the paraffin box, the reagent barrels and the vacuum pump through pipeline assemblies. The rapid pathological tissue dehydrating machine integrates microwave treatment, ultrasonic treatment and vacuum treatment and cooperates with special reagents, traditional tissue treating time can be shortened to 20 min-3 h from 16 h-22 h, the procedures of immobilizing, dehydrating, transparentizing, wax impregnating, section making and diagnosing can be completed within 2 h after a small specimen is delivered, pathological diagnosis can be made within 32 h after a radical cure specimen is delivered, time of waiting for disease diagnosis is shortened for patients, anxiety is relieved, and especially time is saved for patients needing to receive special treatment such as surgery or targeted therapy; the length of stay is reduced for patients, and hospitalization expenses are reduced; meanwhile, the economic benefits of hospitals are increased.

Owner:济南宇鑫医疗器械有限公司

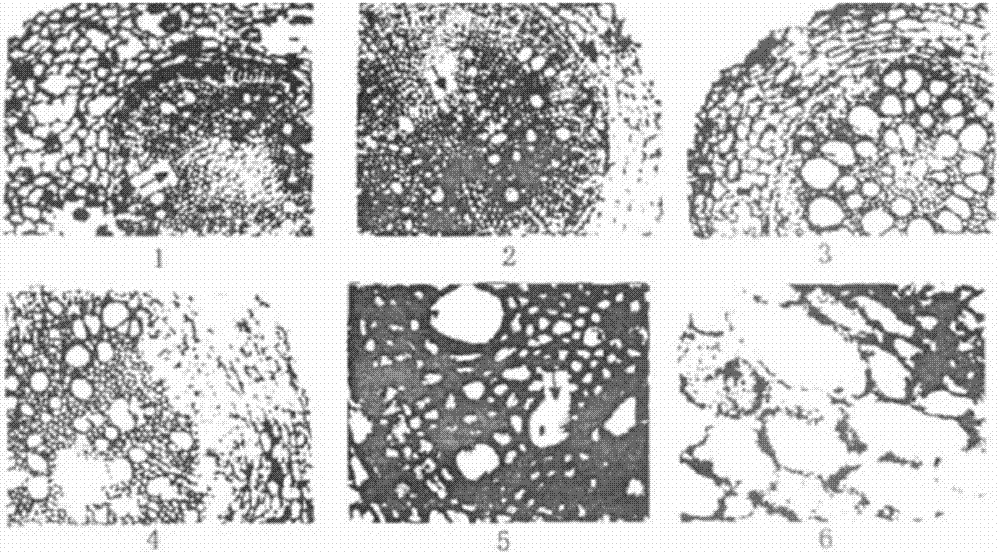

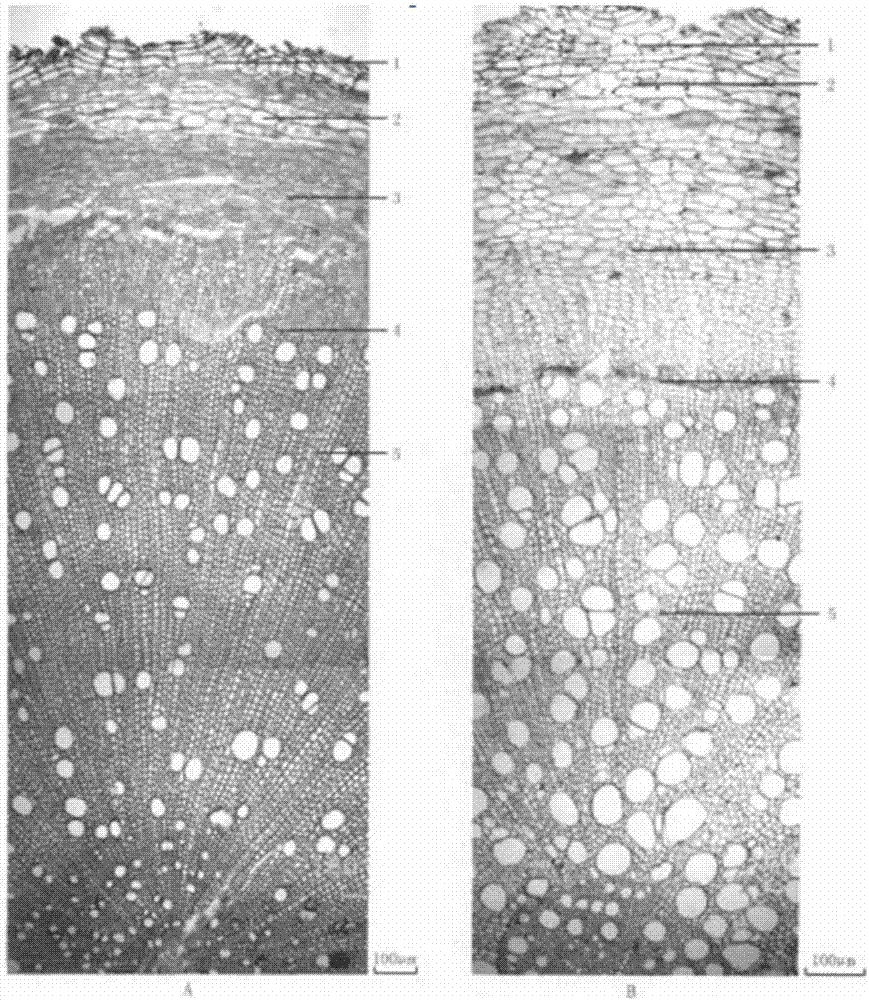

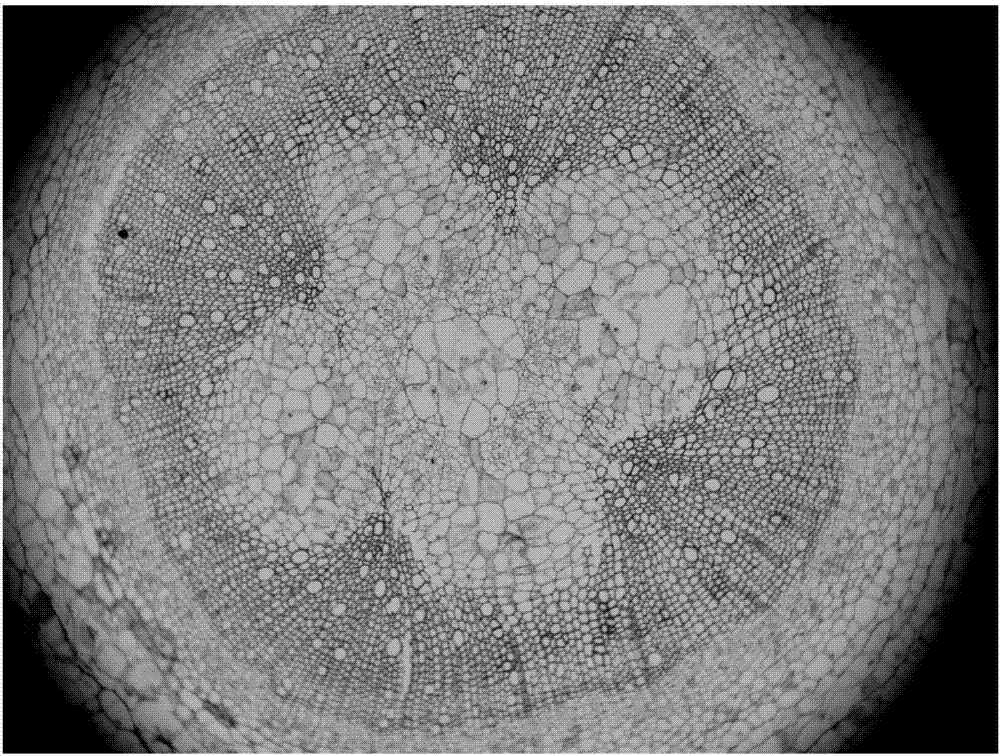

Preparation method of paraffin slices of eggplant root stalk part tissues

InactiveCN107167350AIntegrity guaranteedThe softening process is acceleratedPreparing sample for investigationWaxMicroscopic observation

The invention relates to a preparation method of paraffin slices of eggplant root stalk part tissues, and belongs to the technical field of biological histology. The method comprises the eleven steps of fixing, softening, dewatering, transparency treatment, wax soaking, coating and burying, wax trimming and slicing, slice unfolding and slice baking, wax removal, rehydration, dyeing, slice sealing and observation. The method belongs to a fast, convenient, safe and practical eggplant root stalk part tissue paraffin slice method. The result obtained by the method realizes high operability, high repeatability, high stability and high reliability. Through the microscopic observation, the slice quality is high; the effect is good; the tissue structure is clear. The method can be used for studying, observing and judging the form structure change of the eggplant root stalk part tissues, so that the physiological, pathological and morphological study can be performed on the eggplants. The method can also be widely applied to tissue slice experiments of eggplant fruits or even other plants; good scientific research application prospects are realized.

Owner:云南省农业科学院园艺作物研究所

Pineapple slicing device

ActiveCN106737986AAccurate locationImprove slice qualityMetal working apparatusDrive wheelEngineering

The invention provides a pineapple slicing device, and belongs to the technical field of pineapple slicing devices. The pineapple slicing device solves the problem that the existing pineapple slicing efficiency is low. The pineapple slicing device comprises a rack and a conveying belt. A feeding table plate is fixedly connected to the rack. The end portion of the feeding table plate is fixedly connected with a cutting support plate. The rack is further rotationally connected with a drive wheel and a driven wheel. The drive wheel and the driven wheel are sleeved with a plurality of annular frameworks. Every two corresponding frameworks are sleeved with a cutting rope. The cutting support plate is provided with a plurality of avoiding notches. The multiple cutting ropes penetrate the multiple avoiding notches correspondingly. The drive wheel and the driven wheel are internally provided with adjusting connecting rod assemblies. The part, on one side of the feeding table plate, of the rack is in sliding connection with a guiding base, the guiding base is in sliding connection with a positioning base, and the positioning base is connected with a positioning column. The pineapple slicing device can automatically slice pineapple and is good in slicing quality and high in adaptability.

Owner:广西诚杨食品有限公司

Traditional Chinese medicine raw material slicing device applicable to decoction piece processing

InactiveCN109093678AGood size uniformityImprove slice qualityMetal working apparatusBiochemical engineeringOperating table

The invention discloses a traditional Chinese medicine raw material slicing device applicable to decoction piece processing. The traditional Chinese medicine raw material slicing device comprises an operating table, a base plate, a bearing table, a first air cylinder, an adjusting plate, a top plate, a second air cylinder, a connecting plate, a third air cylinder and a connecting block; the deviceis characterized in that the operation table is arranged on a support; the bottom plate is arranged on the operation table through mounting bolts; the bearing table is arranged on the bottom plate; the first air cylinder is arranged on a vertical plate; the adjusting plate is arranged on a first piston rod; the top plate is arranged on the vertical plate; the second air cylinder is arranged on the top plate; and the connecting plate is arranged on a second piston rod. According to the device, a limiting plate is arranged in a material falling groove in the bottom plate; and after traditionalChinese medicine raw materials are sliced, the first air cylinder and the first piston rod are used for pushing the traditional Chinese medicine raw materials which need to be sliced to move in a bearing groove, and one ends of the traditional Chinese medicine raw materials needing to be sliced can be arranged in order under the action of the limiting plate, so that the size uniformity of the sliced traditional Chinese medicine materials is improved, and the slicing quality of the traditional Chinese medicine raw materials is enhanced.

Owner:张俊辉

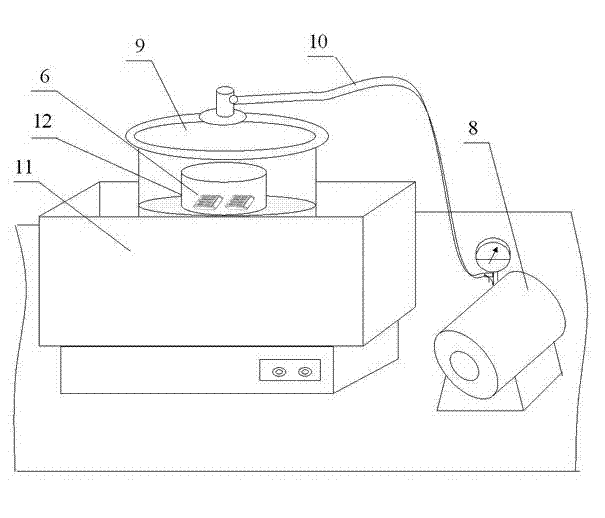

Hydrothorax and ascite malignant cell embedding method

InactiveCN104122132AEasy to get materialsEasy to obtainPreparing sample for investigationParaffin waxHydrothorax

The invention provides a hydrothorax and ascite malignant cell embedding method. The method comprises the following steps: putting hydrothorax and ascite in a plurality of 50-ml centrifugal tubes respectively, adding analytically pure ethyl alcohol into the centrifugal tubes respectively, and uniformly mixing and standing for 2-4h to obtain sediments; sucking up moisture in the sediment, wrapping a specimen by using a fixing mold and putting into a material drawing box; dehydrating the obtained specimen with the ethyl alcohol, and transparentizing the dehydrated specimen by adopting a transparent agent-xylene; putting the transparentized specimen in a 70-DEG C constant-temperature box for wax dipping, wherein an embedding agent is paraffin wax; and embedding the specimen after wax dipping with paraffin in an embedding workstation, pouring the specimen and the paraffin into an embedding box, putting the embedding box into cold water to rapidly solidify the paraffin after the paraffin on the surface of the embedding box is solidified, taking the paraffin block out of the embedding box and storing. The method can greatly increase the positive rate of cast-off cells, and can be used in further diagnosis of molecules, genes, immunohistochemistry and the like.

Owner:北京海思特医学检验实验室有限公司

Biological experiment slicing device

InactiveCN112248054ASame sizeSame distanceMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a biological experiment slicing device. The device comprises a column and a placing plate, a slicing assembly is arranged on the placing plate, the slicing assembly comprises cylinders, mounting plates, guide rods, a screw rod, a sliding block, adjusting blocks, limiting pins, connecting rods, cutters and rotating shafts, two ends of the two mounting plates are mounted on the placing plate through the cylinders, two ends of the two guide rods are fixedly arranged on the two mounting plates, the multiple adjusting blocks are movably arranged on the guide rods in a sleeved mode, through holes are formed in the upper middle portions of the adjusting blocks, the screw rod penetrates through the through holes, two ends of the screw rod are rotatably arranged in the two mounting plates, one end extends out of the mounting plate to be connected with a driving piece, the slide block is arranged on the screw rod, the rotating shafts are rotatably arranged on the slidingblock, the adjusting blocks and the ends, away from the sliding block, of the mounting plates, the multiple connecting rods are rotatably arranged on the rotating shafts, the outer ends of the adjacent connecting rods are hinged through the limiting pins, and the cutters are fixedly arranged on the lower surfaces of the adjusting blocks. The practicability and the slicing efficiency are improved by the arrangement of the slicing assembly.

Owner:李世军

Rotating disc type slicer

InactiveCN103419235AEasy to useImprove slice qualityMetal working apparatusDrive wheelReduction drive

The invention discloses a rotating disc type slicer, comprising a rack, a tray, a cutter box, a power drive mechanism and a material pushing mechanism, wherein the tray is fixed at the upper part of the rack; a discharge port is formed in the inner end of the tray; the cutter box comprises a box and a rotary blade; the box is adjacent to the tray; an air hole and a water inlet which is connected with a water inlet pipe are formed in the upper part of the box; a feed port is formed in the part, corresponding to the discharge port of the tray, under an outer side panel of the box; the center of the rotary blade is connected with an output shaft; the power drive mechanism is arranged in the rack, and comprises a motor which is electrically connected with a power switch, a speed reducer which is connected with an output shaft of the motor, a pair of drive wheel and driven wheel and a conveyor belt which is sleeved between the drive wheel and the driven wheel; the drive wheel is connected with an output shaft of the speed reducer; the driven wheel is fixedly connected with a connecting shaft in the center of the rotary blade. The rotating disc type slicer is characterized by also comprising a water tank which is fixedly arranged on the rack, and a water outlet is formed in the water tank, and is communicated with the water inlet pipe connected with the cutter box.

Owner:JIANGSU SIXIANG SILK

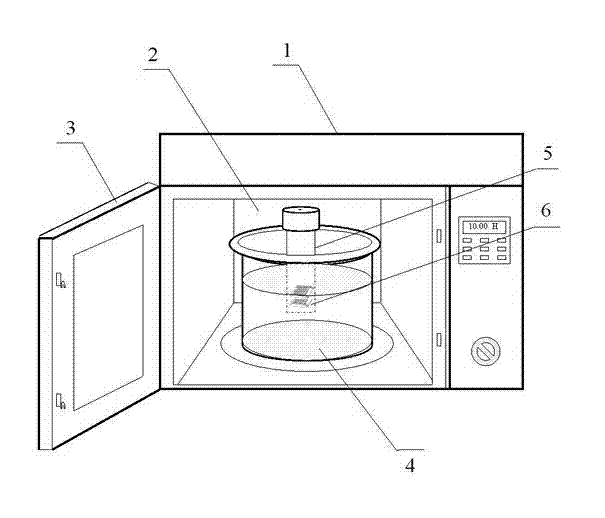

Method for fast flaking paraffin by microwave radiation water bath diathermy and device

InactiveCN102768145AAvoid spillingPrevent evaporationPreparing sample for investigationParaffin waxMedicine

The invention provides a method for fast flaking paraffin for a biological tissue sample and a device. A microwave radiation water bath diathermy is applied to help reagents which are weak in absorbing energy and paraffin be fast heated. The device for fast flaking paraffin is characterized by comprising a microwave radiation water bath diathermy part having the function of fast processing a tissue sample, and a vacuum negative pressure waxing part having the function of fast waxing the tissue sample. The procedure of flaking paraffin comprises the steps of fast tissue fixing, fast tissue dehydration and transparent handling once or twice and fast waxing. The reagents special for flaking paraffin comprises a fast fixing solution, a fast dehydration transparent reagent and a fast decalcification solution. The method and the device have the flexibility of processing tissue samples individually or in batch and the capability of processing different tissue samples simultaneously, and are stable and reliable in the flaking quality, and applied to the fast paraffin flaking and pathologic diagnosis for biological tissue samples for the pathology and inspection in the hospital, scientific research institutes and other organizations.

Owner:CHANGSHA COMBINE MEDICAL TECH

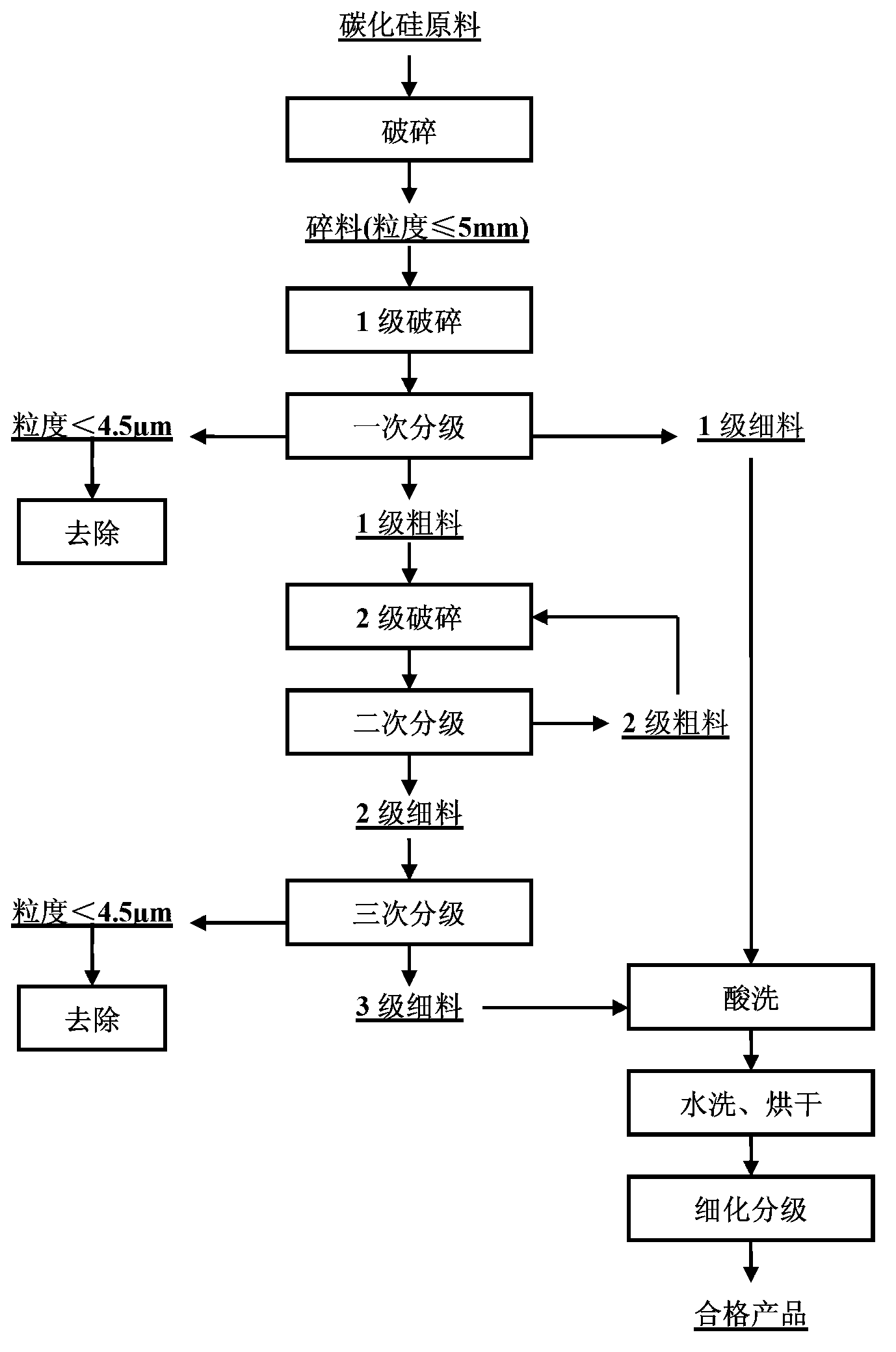

Preparation method of silicon carbide cutting edge materials for photovoltaic industry

InactiveCN102795626AReduced roundness valueThe roundness value increasesSilicon carbidePhotovoltaic industryCrystalline silicon

The invention discloses a preparation method of silicon carbide cutting edge materials for a photovoltaic industry and belongs to photovoltaic industries. The preparation method of silicon carbide cutting edge materials for a photovoltaic industry comprises the following steps of carrying out coarse crushing of a silicon carbide raw material, carrying out air classification after primary crushing, carrying out coarse screening and fine screening after secondary crushing, carrying out pickling classification to obtain a silicon carbide cutting edge material JIS1000, a silicon carbide cutting edge material JIS1200, a silicon carbide cutting edge material JIS1500 and a silicon carbide cutting edge material JIS2000. The preparation method provided by the invention has the advantages that compared with the traditional technology, the preparation method provided by the invention can realize production of a silicon carbide cutting edge material product having a low roundness value of 0.83 to 0.88 and a high yield of 70 to 75%; and the silicon carbide cutting edge material product obtained by the preparation method can effectively improve crystalline silicon cutting efficiency and slicing quality and obviously reduce the waste of a silicon carbide raw material.

Owner:NORTHEASTERN UNIV

Preparation method of jujube flower paraffin slices

InactiveCN108333013AFully dyedClear organizational structurePreparing sample for investigationParaffin waxMegaspore

The invention provides a preparation method of jujube flower paraffin slices, and belongs to the technical field of paraffin slices. The preparation method comprises the following steps that (1) jujube flower buds are fixed; the jujube flower buds have one stem segment with the length being 0.3 to 0.5cm; (2) dehydration; (3) first transparency treatment; (4) second transparency treatment; (5) waxing; (6) embedding; (7) wax trimming; (8) slicing; (9) slice unfolding; (10) dewaxing; (11) rehydration; (12) secondary rehydration; (13) dyeing; (14) slice covering and slice sealing. The preparationmethod of the jujube flower paraffin slices provided by the invention has the advantages that the complete longitudinal section of the megaspore can be obtained; further, the jujube flower cellular morphology and the development change of the megaspore inside cell and tissue structures can be conveniently observed; meanwhile, the basic rule in the megaspore development structure change and reproduction process can be obtained through observing the jujube flower paraffin slices.

Owner:BEIJING FORESTRY UNIVERSITY

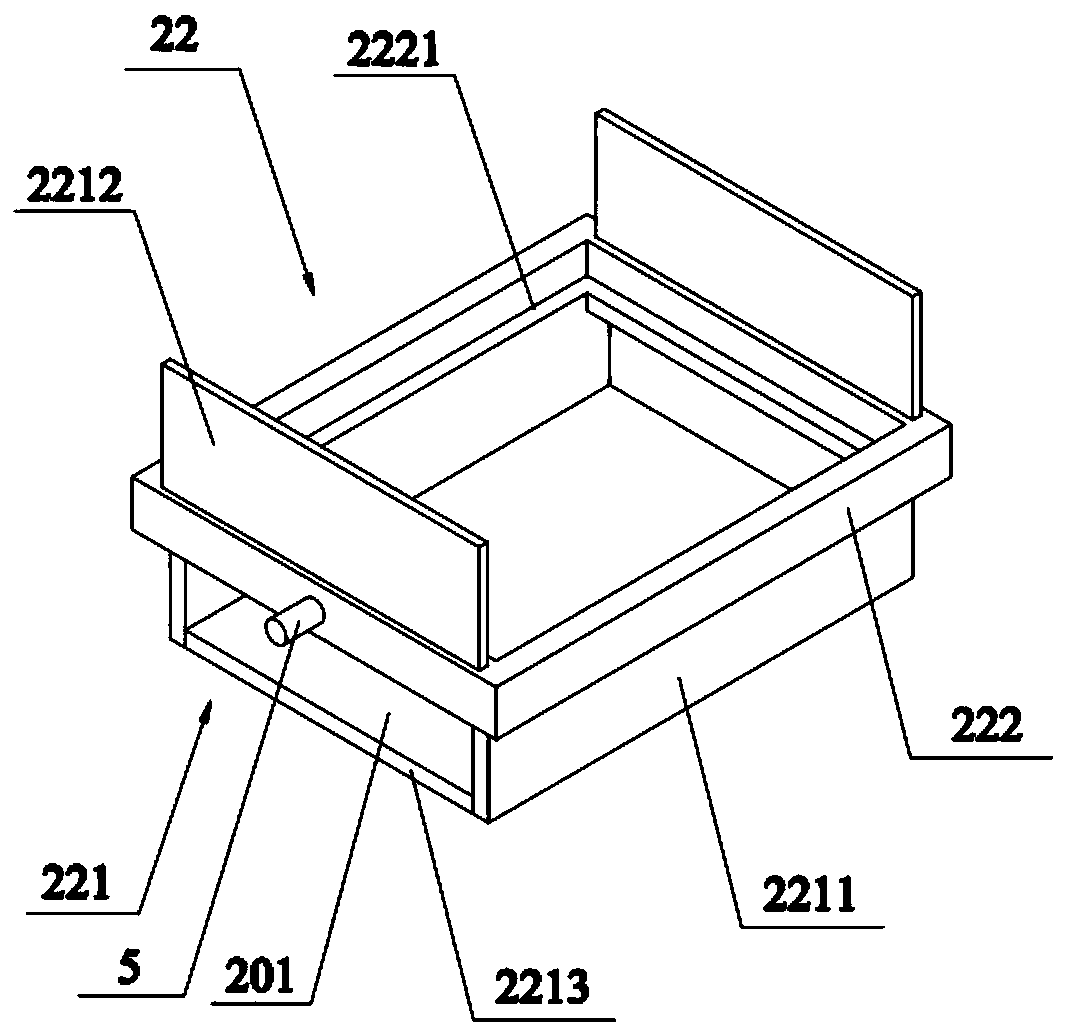

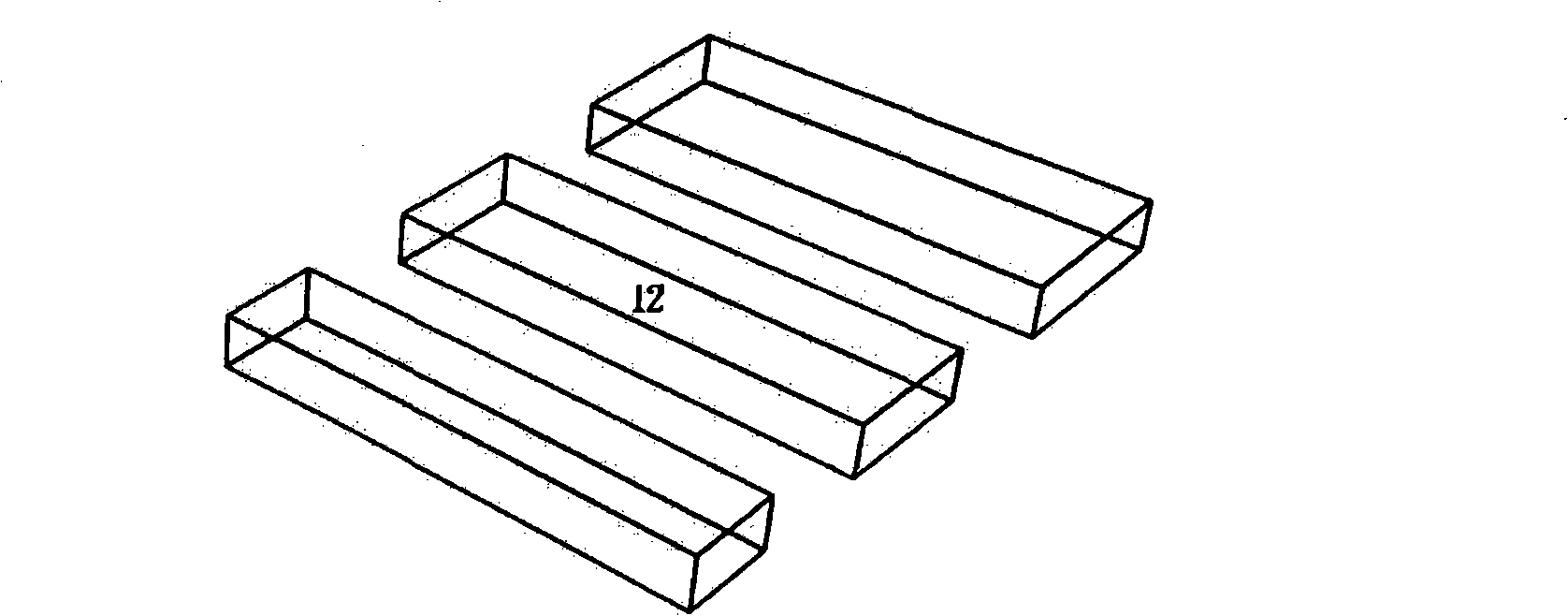

Large tissue section sampling platform

InactiveCN101261200AReduce volumeSimple structureWithdrawing sample devicesPreparing sample for investigationMedicineTissue sections

The invention discloses a pathological large tissue slice cutting-up bench, solves the problem of affecting slice quality owing to the lack of special devices during the material-drawing link of the present pathological large tissue slice and has the advantages of simple structure, convenient use and being effective to finish the material-drawing work of large tissue slice, etc. The pathological large tissue slice cutting-up bench has the structure that the pathological large tissue slice cutting-up bench comprises a pedestal, wherein, a chassis is arranged on the pedestal, the chassis is provided with a chassis side shield and a material-drawing groove fixed side plate, the lower part of the material-drawing groove fixed side plate is a fixed material-drawing rail, a movable material-drawing device is arranged on the chassis, the movable material-drawing device matches with the fixed bolt of a movable rail on the pedestal, meanwhile, the movable material-drawing device also forms a material-drawing groove with the material-drawing groove fixed side plate. The lower part of the movable material-drawing device is also provided with a material-drawing cutter groove which matches with the material-drawing cutter groove arranged on the lower part of the material-drawing groove fixed side plate, and a material-drawing cutter is arranged between the two material-drawing cutter grooves.

Owner:SHANDONG TUMOR HOSPITAL

Biomedical medicine slicing device

ActiveCN111086036AAvoid shakingEasy to moveWithdrawing sample devicesPreparing sample for investigationEngineeringMechanical engineering

The invention discloses a biological medicine slicing device, and relates to the technical field of biological medicine. The biological medicine slicing device comprises a support plate, an object carrying plate, a specimen box, a moving mechanism, a limiting mechanism, a height leveling mechanism and a slicing mechanism, wherein the height leveling mechanism is installed on the support plate, thebottom of the object carrying plate is provided with two symmetrically arranged guide blocks, the top of the support plate is provided with two guide sliding grooves which are in guide fit with the two guide blocks one by one, the moving mechanism is installed on the support plate, the moving mechanism is in transmission connection with the object carrying plate, the specimen box is installed onthe object carrying plate, a compensation assembly matched with the slicing mechanism is arranged in the specimen box, the limiting mechanism is installed on the object carrying plate, and the slicingmechanism is positioned above the support plate. According to the invention, shaking during slicing can be avoided, slicing quality is improved, and slicing efficiency is improved.

Owner:金丽素

Silicon carbide ingot slicing device and silicon carbide ingot slicing method

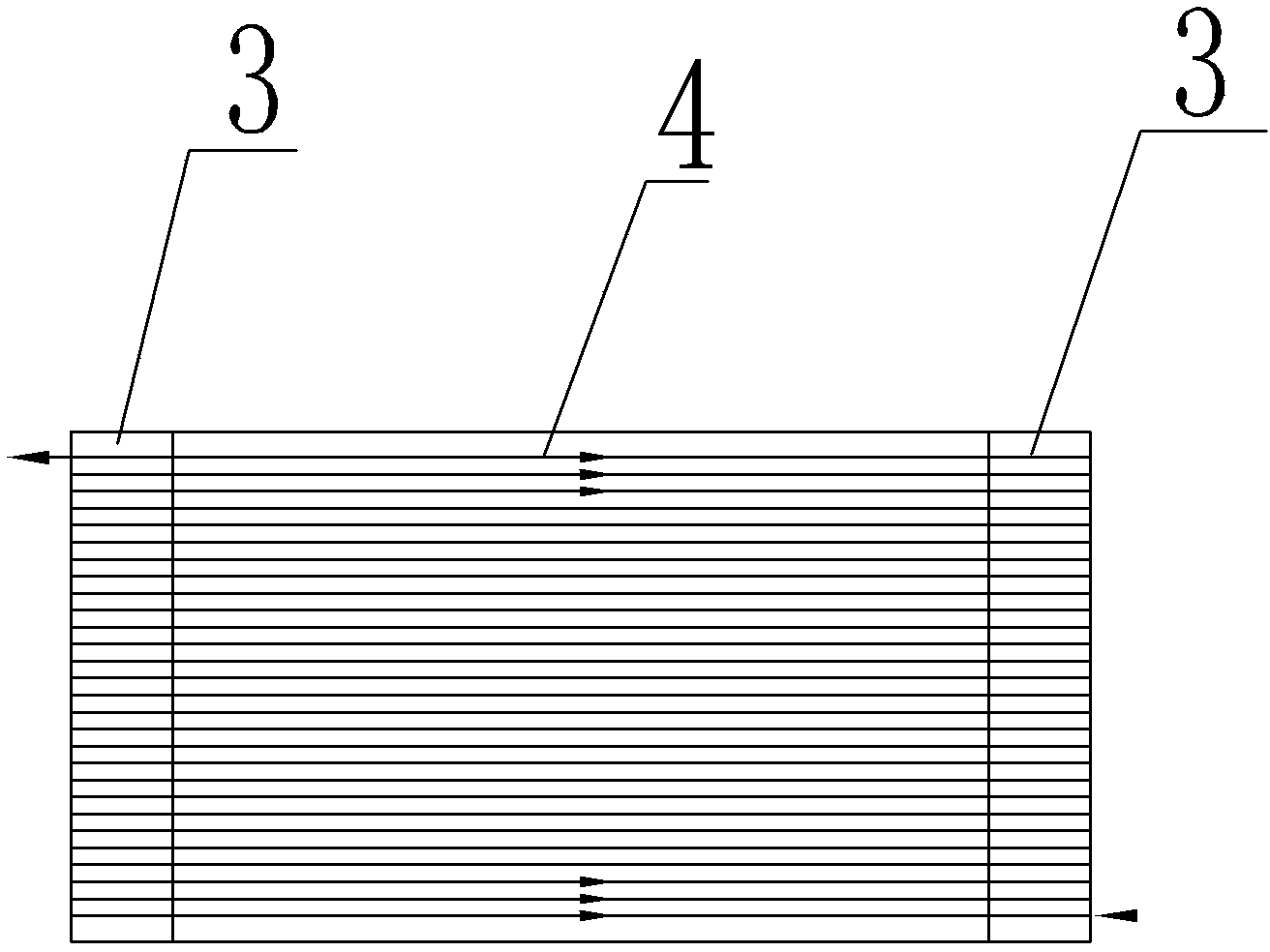

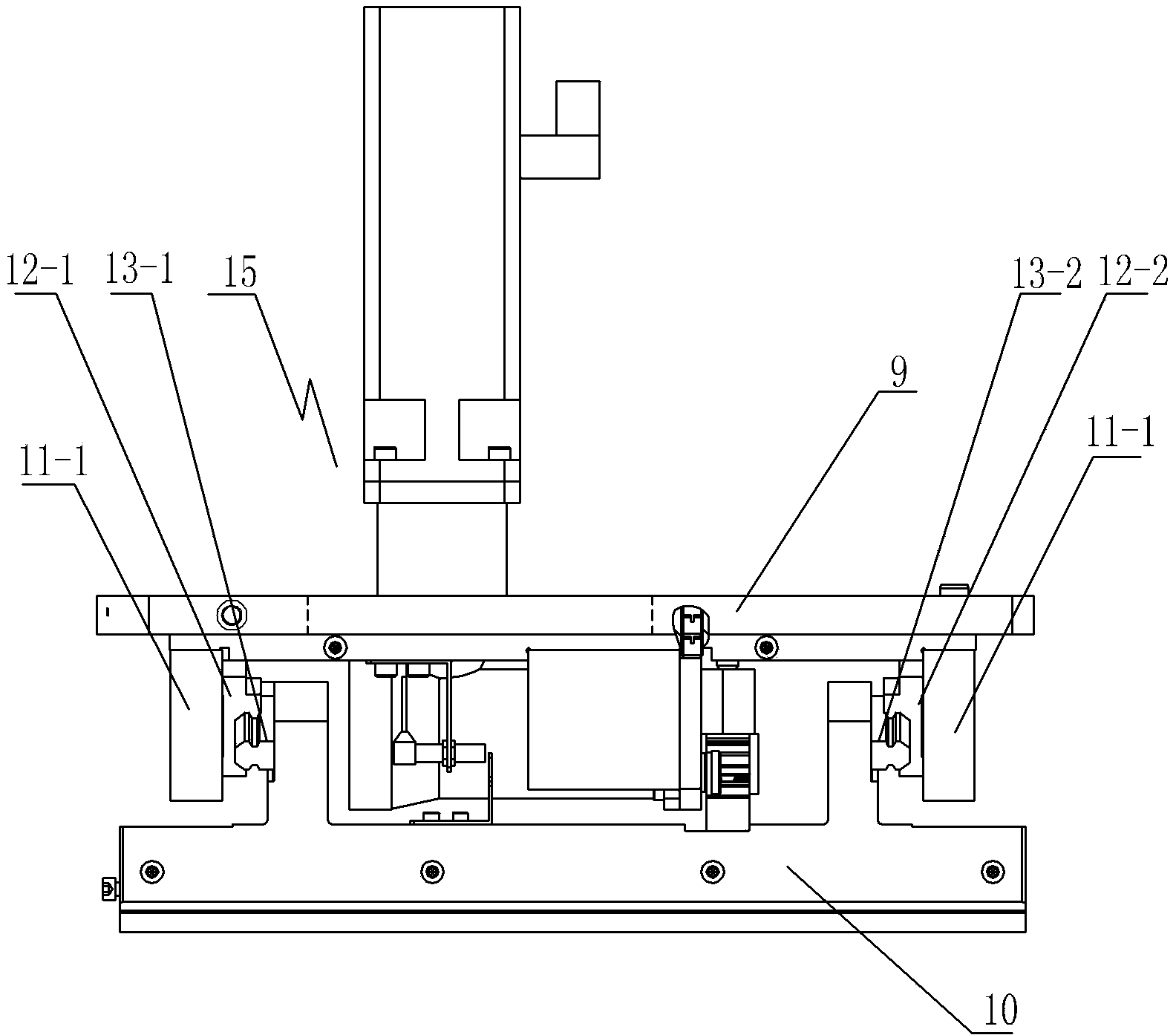

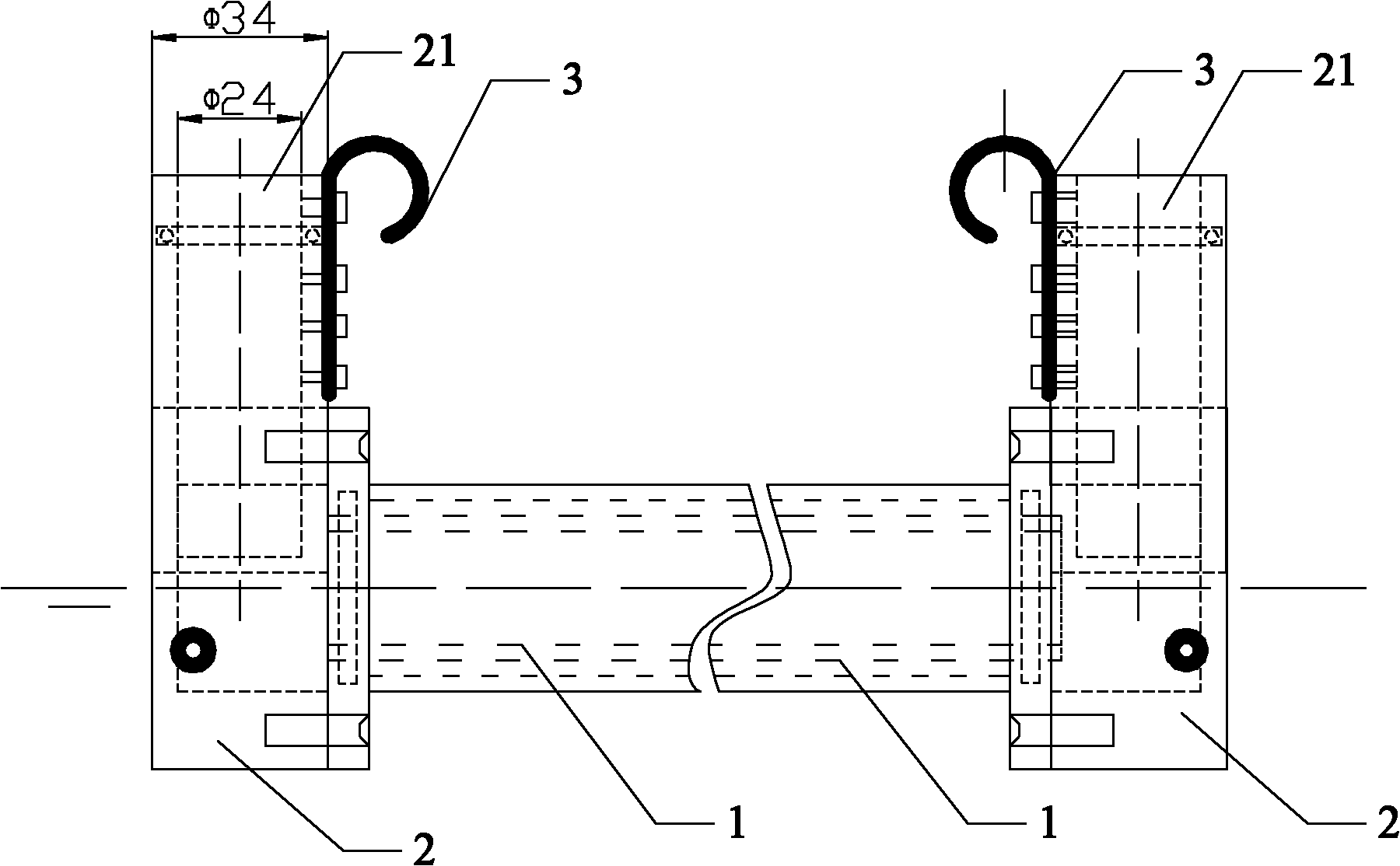

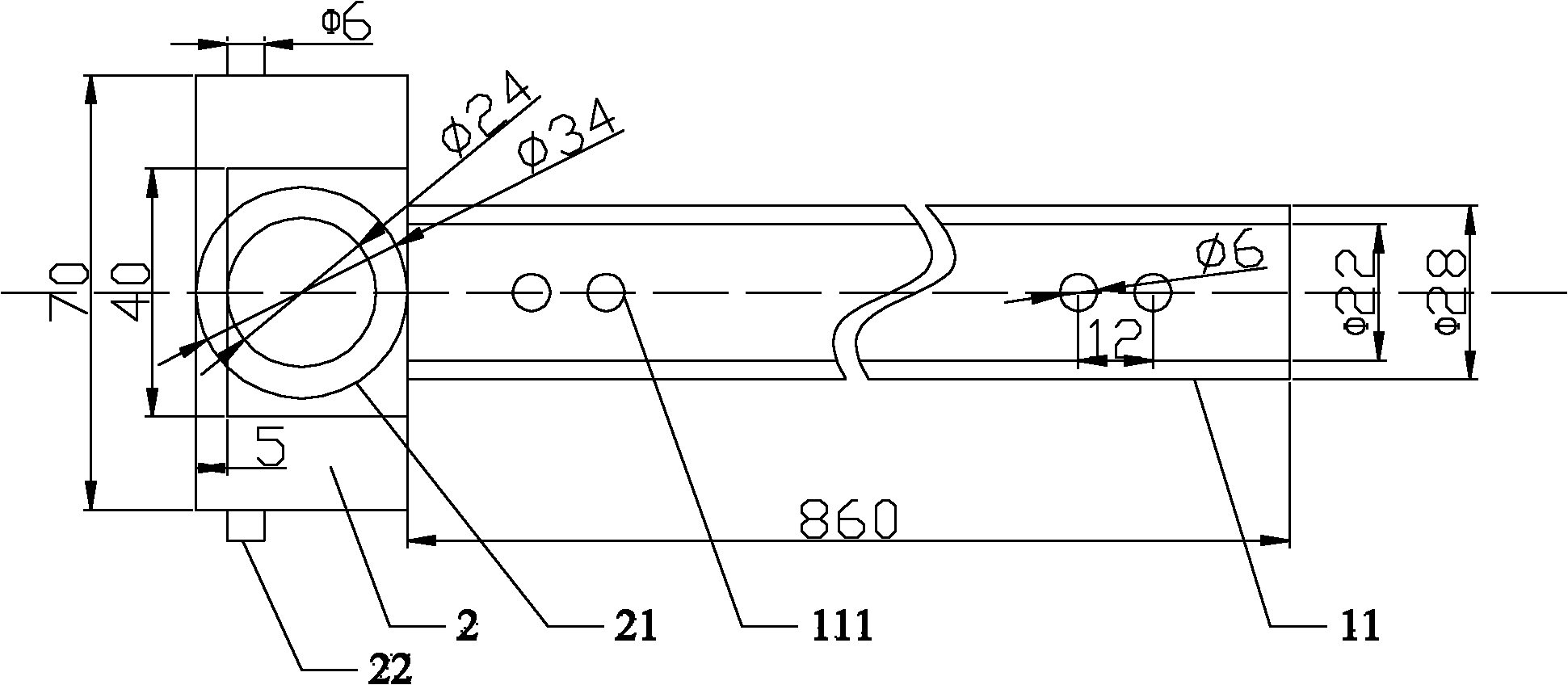

The invention discloses a silicon carbide ingot slicing device and a silicon carbide ingot slicing method. The silicon carbide ingot slicing device comprises a swinging wire cutting device and a worktable for fixing a silicon carbide ingot. The swinging wire cutting device includes a fixing base, a swinging table which is disposed on the fixing base and can swing relatively, a plurality of rollers, and a cutting line which is movably wound around the plurality of rollers at a linear velocity of at least 1510 m / min. The plurality of rollers collectively define a slicing channel through which the silicon carbide ingot passes. The portions of the cutting line on the slicing channel are arranged in parallel at intervals and are defined as a plurality of operation line segments. During the process that the silicon carbide ingot is cut by the plurality of operation line segments, the swinging table swings relative to the fixing base, and the worktable can be moved at an adjusted feed speed.The adjusted feed speed gradually decreases from an initial speed to the lowest speed and then gradually increases to the final speed, so that the cutting line is not liable to break and effectively improve the slicing quality of the silicon carbide ingot.

Owner:GLOBALWAFERS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com